1. Introduction

Offshore platforms have found extensive applications in the realms of oil and gas extraction, marine research and exploration, wind power generation, et al. Within the realm of offshore platforms, there exist two primary classifications: fixed and floating structures, with the jacket offshore platform comprising approximately 95% of total offshore platforms, owing to its exceptional mechanical performance, superior structural safety, and reliability [

1]. However, the transition to deepwater deployments intensifies structural vibration in harsh marine environments, such as wind, waves, and currents [

2,

3,

4]. Such vibrations may excite higher-order structural modes, generating localized stress concentrations and fatigue crack propagation to threaten structural security. The structural vibration persists until complete energy dissipation occurs through damping pathways, highly relying on the friction in joints and microcrack friction in reinforced concrete, where the energy dissipation rate remains low under elastic strain ranges [

5,

6,

7]. Conventional vibration mitigation strategies usually prioritize structural stiffening, which is inherently dependent on substantial material consumption to achieve natural frequency modulation. However, such mass-intensive approaches incur prohibitive economic penalties, particularly in deepwater applications [

8,

9,

10]. Consequently, dynamic control methodologies, such as vibration suppression technologies and energy dissipation systems, have been demonstrated to be efficient in vibration control [

11,

12,

13], serving as a pivotal strategy for enhancing the resilience of offshore platforms.

Vibration control strategies bifurcate into active, semi-active, and passive paradigms; the active and semi-active control systems [

14,

15] are reliant on real-time sensor–actuator networks and external energy supply [

16,

17]. However, their complexity, energy dependence, and maintenance sensitivity prove prohibitive for offshore infrastructure exposed to harsh marine environments [

18,

19]. On the other hand, passive control systems do not need external energy and rely on structural motion-generating control forces to enhance structural stability and reliability. Passive control can be divided into the following two categories based on the energy consumption mechanism: (1) dynamic vibration absorbers, such as tuned mass dampers (TMDs) [

20], tuned liquid dampers (TLDs) [

21], tuned liquid column dampers (TLCDs) [

22], et al., and (2) hysteretic or viscoelastic mechanism-based absorbers, such as the friction damper (FD) [

23], shape memory alloy (SMA) dampers [

24], hydrodynamic buoyant mass damper (HBMD), et al. The TMD is composed of a mass block, springs, and viscous dampers, designed to counteract structural vibrations through resonant energy dissipation. Wu et al. [

25] utilized TMDs in offshore platforms under earthquake loads—the maximum displacement and acceleration were reduced by 27% and 32%, respectively. Gavgani et al. [

26] utilized the genetic algorithm to obtain the optimal parameters for TMDs and adopted the Latin Hypercube Sampling method to yield the probabilistic distribution of TMDs. While conventional TMDs demonstrate significant vibration mitigation potential, recent advancements have focused on developing enhanced TMD variants to address challenges in multi-hazard environments and structural adaptability. Lin et al. [

20] proposed a pounding TMD (PTMD) for the Canton Tower under earthquake loads, and the results showed that the non-uniformly distributed PTMD exhibits better performance than the uniformly distributed one. Pourzangbar et al. [

27] analyzed the influence of the frequency ratio, damping ratio, and mass ratio of the pendulum PTMD on jacket dynamic responses. Moreover, owing to the cost efficiency and superior damping performance, the TLD and its variants are utilized to reduce structural vibration by leveraging the resonant sloshing motion of liquid in a container. Jin et al. [

28] utilized the TLD to control the earthquake response of the jacket platform, resulting in a larger mass ratio that can provide a more significant earthquake response. Sardar et al. [

29] analyzed the effects of the TLD in reducing wave-induced structural vibration; the results demonstrated that the optimal TLD location is the top deck, and the controlling performance was more effective with the mass ratio increasing. Dou et al. [

21] developed a coupling numerical model to analyze the effects of the TLD in reducing the nonlinear vibration of supporting structural platforms, finding that the mass ratio of 2% and the frequency ratio of 1% were optimal. Building upon TLD foundations, hybrid and optimized liquid damping systems have emerged to tackle challenges under combined environmental hazards. Colwell et al. [

22] used the TLCD to reduce fatigue damage to a jacket platform. Mousavi et al. [

30] evaluated the effectiveness of a tuned liquid column–gas damper (TLCGD) in decreasing the vibrations of jacket platforms under earthquake, demonstrating that the optimal frequency of the TLCGD was uncoupled with the area ratio and the head loss coefficient. Moharrami et al. [

31] used the HBMD to reduce the wave-induced displacement response of offshore platforms.

Hysteretic mechanism-based absorbers dissipate energy through irreversible material deformation or sliding friction, and their performance does not rely on rate. Golafshani et al. [

23] presented a mathematical formulation to evaluate the structural response of the jacket platform, obtaining the optimal parameters of the FD to reduce the wave-induced vibration. Owing to their exceptional energy dissipation capacity and superior fatigue resistance under cyclic loading, SMAs have been increasingly employed in offshore platform vibration control. Enferadi et al. [

24] developed an idealized multilinear constitutive model to simulate the hysteretic force–displacement behavior of SMA elements. Numerical implementation of this model demonstrated a reduction in deck displacement, acceleration, and base shear. Ghasemi et al. [

32] used the Ideal Gas Molecules Movements algorithm to improve the efficiency of SMAs in a jacket platform—the results indicated that the optimal SMA reduced deck deformation by 47.5%, deck acceleration by 56.5%, and base shear by 28%.

Compared with the above control devices, VDs achieve broadband energy dissipation through fluid shear deformation, which indicates that VDs have advantages in enabling the mitigation of complex dynamic load scenarios, and the velocity-dependent energy dissipation mechanism ensures more stable hysteretic responses [

33,

34,

35]. Moreover, the hermetically sealed hydraulic systems require significantly less maintenance while maintaining corrosion resistance. These attributes position VDs as a superior and economically viable solution for harsh marine environments. Janbazi Rokni et al. [

36] applied the VD in a jacket platform and analyzed the effects of the VD configuration on jacket fatigue life, with results demonstrating that fatigue damage with VDs is approximately 0.01 times that without VDs. Emami et al. [

37] utilized vertically oriented fluid VDs in a jacket structure to enhance fatigue performance, and the fatigue life of the structural joint was increased by three times. Beyond fatigue life extension, the optimal configuration of VDs has garnered significant attention. Tabeshpour et al. [

38] investigated the effects of VDs in enhancing the long-term performance of jacket platforms and proposed the optimal VD arrangement. Vaezi et al. [

5] investigated the effects of the brace-viscous damper with different distributions, configurations, and brace stiffness in an offshore platform; the results indicated that the toggle configuration significantly reduced the base shear. However, existing analyses predominantly consider wave loads in isolation, neglecting the coupled dynamics of simultaneous wind, wave, and earthquake multi-hazard excitations, and overlooking the soil–structure interaction, which may amplify drift accumulation through nonlinear superposition and degrade viscous damper functionality.

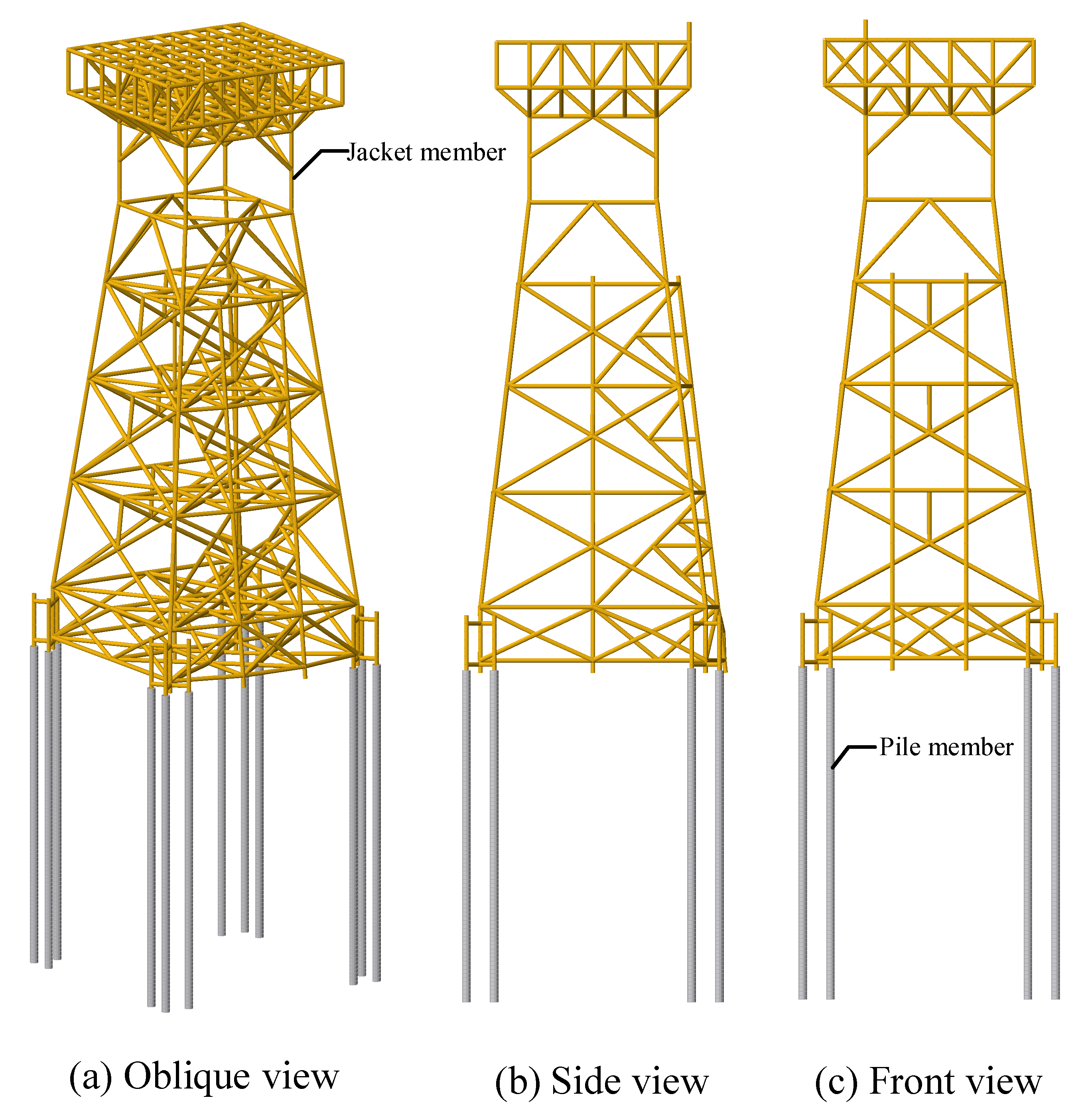

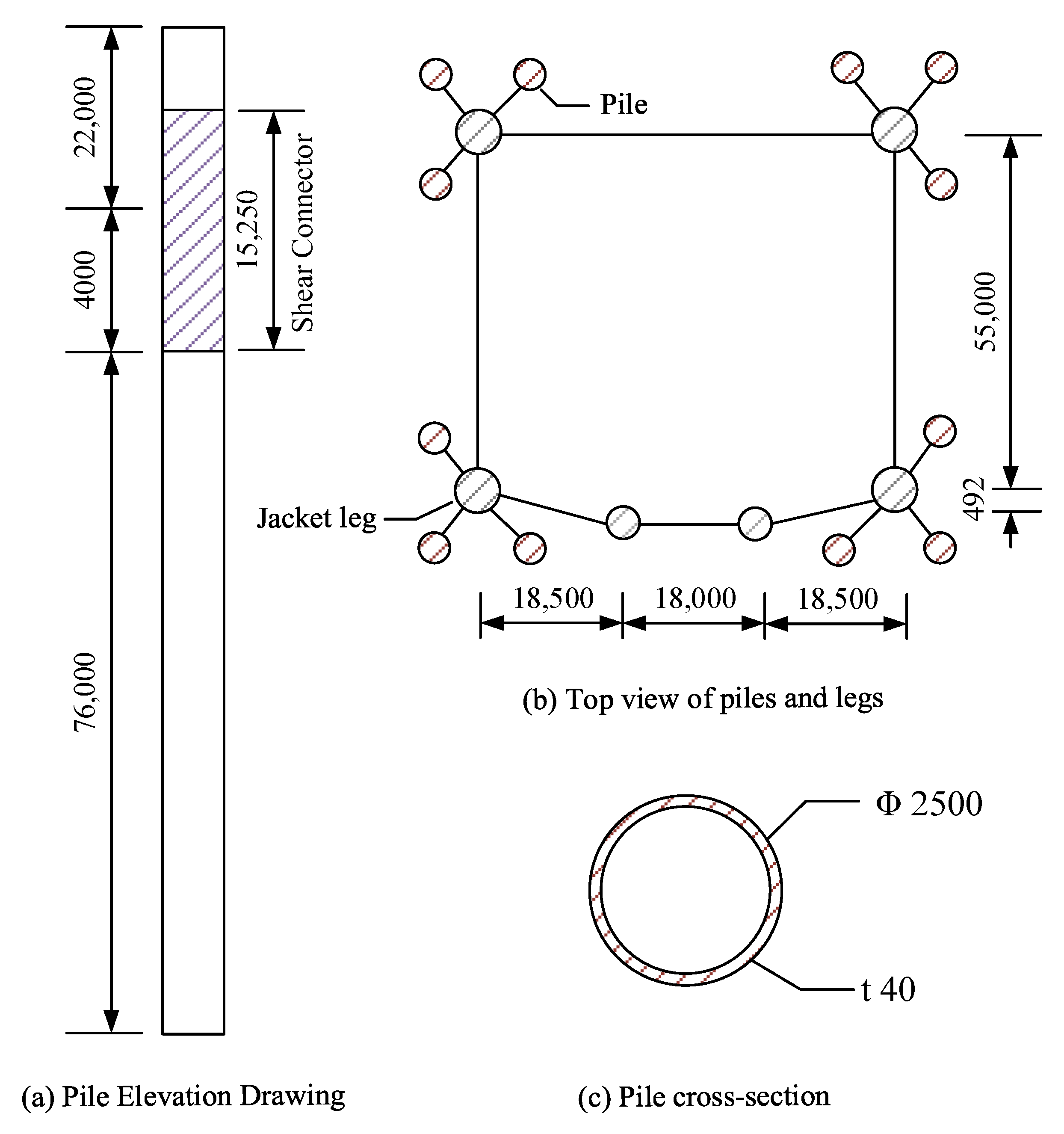

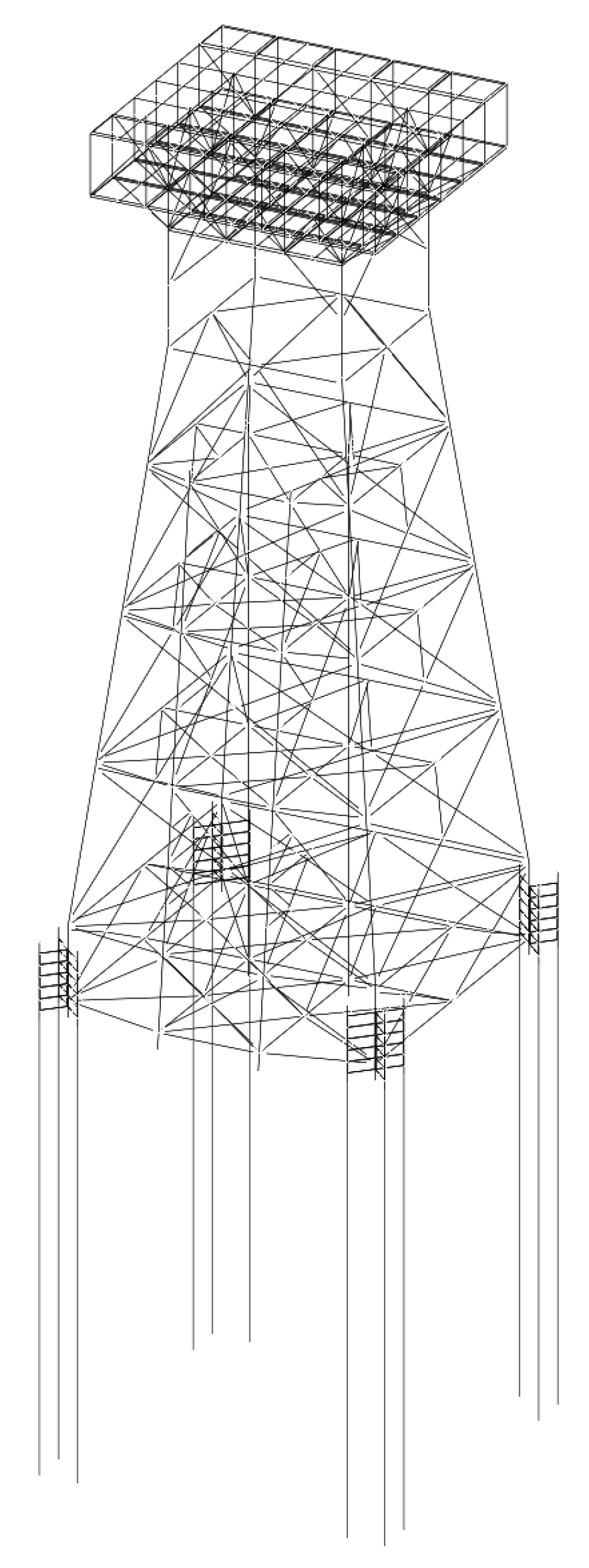

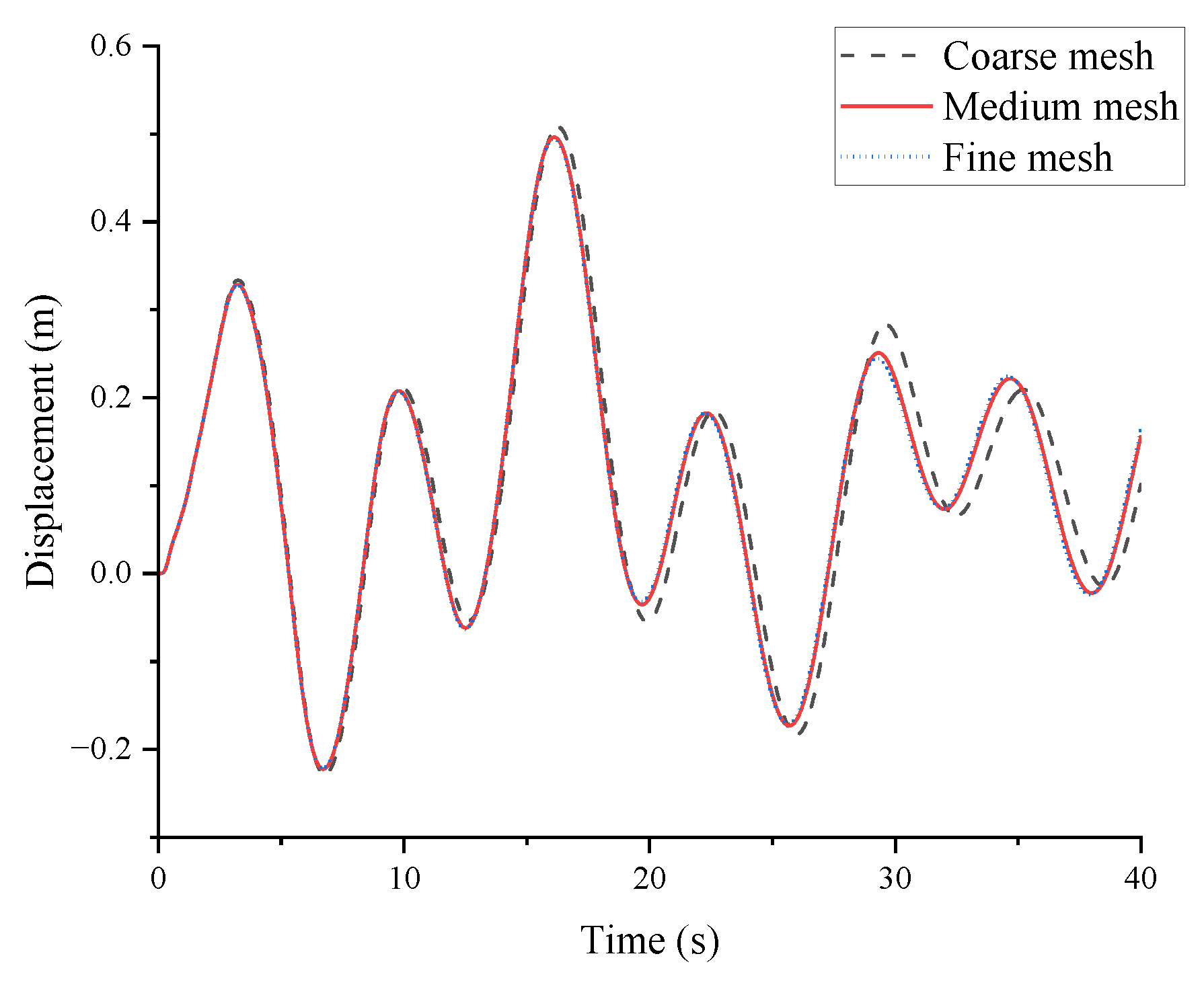

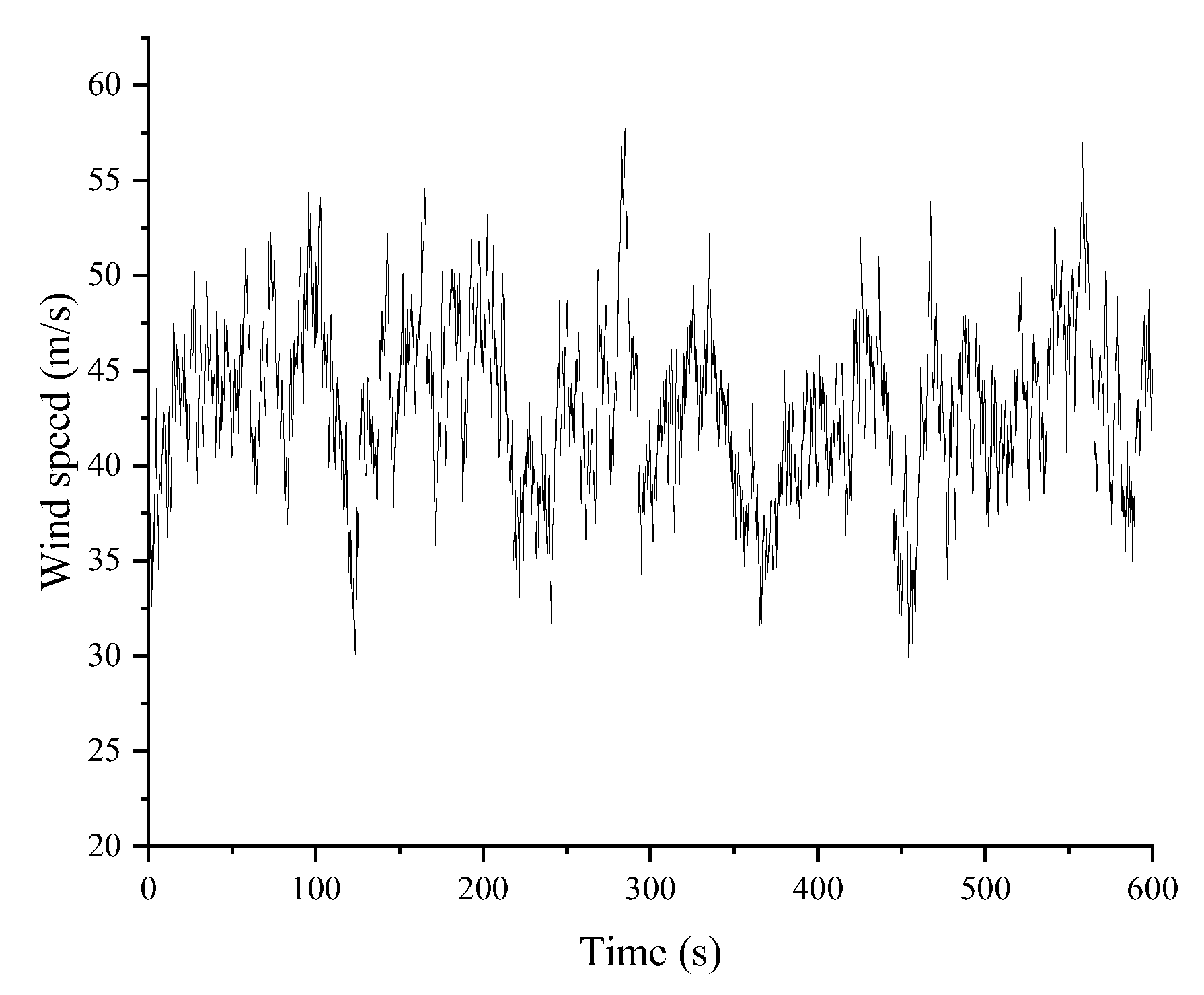

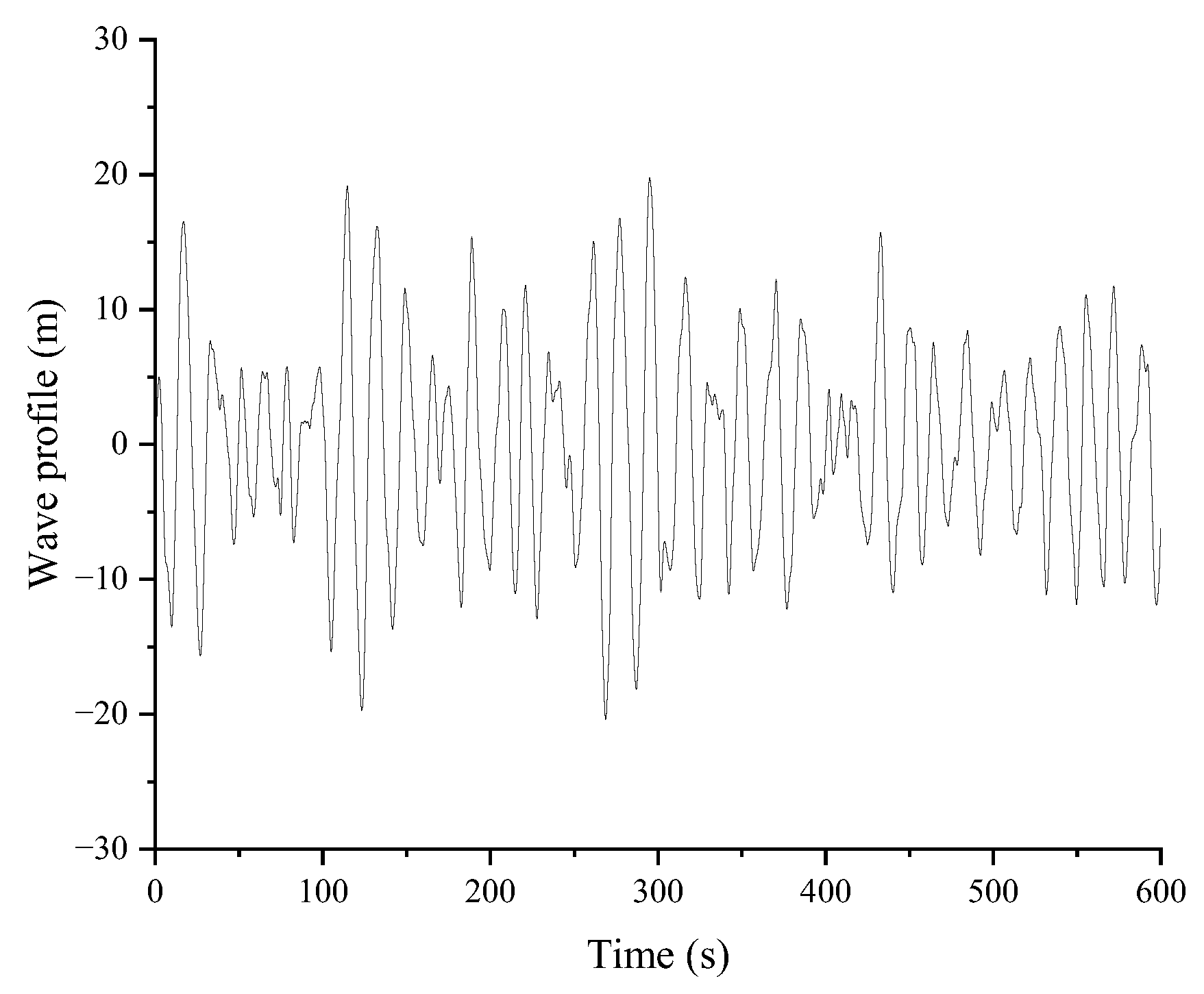

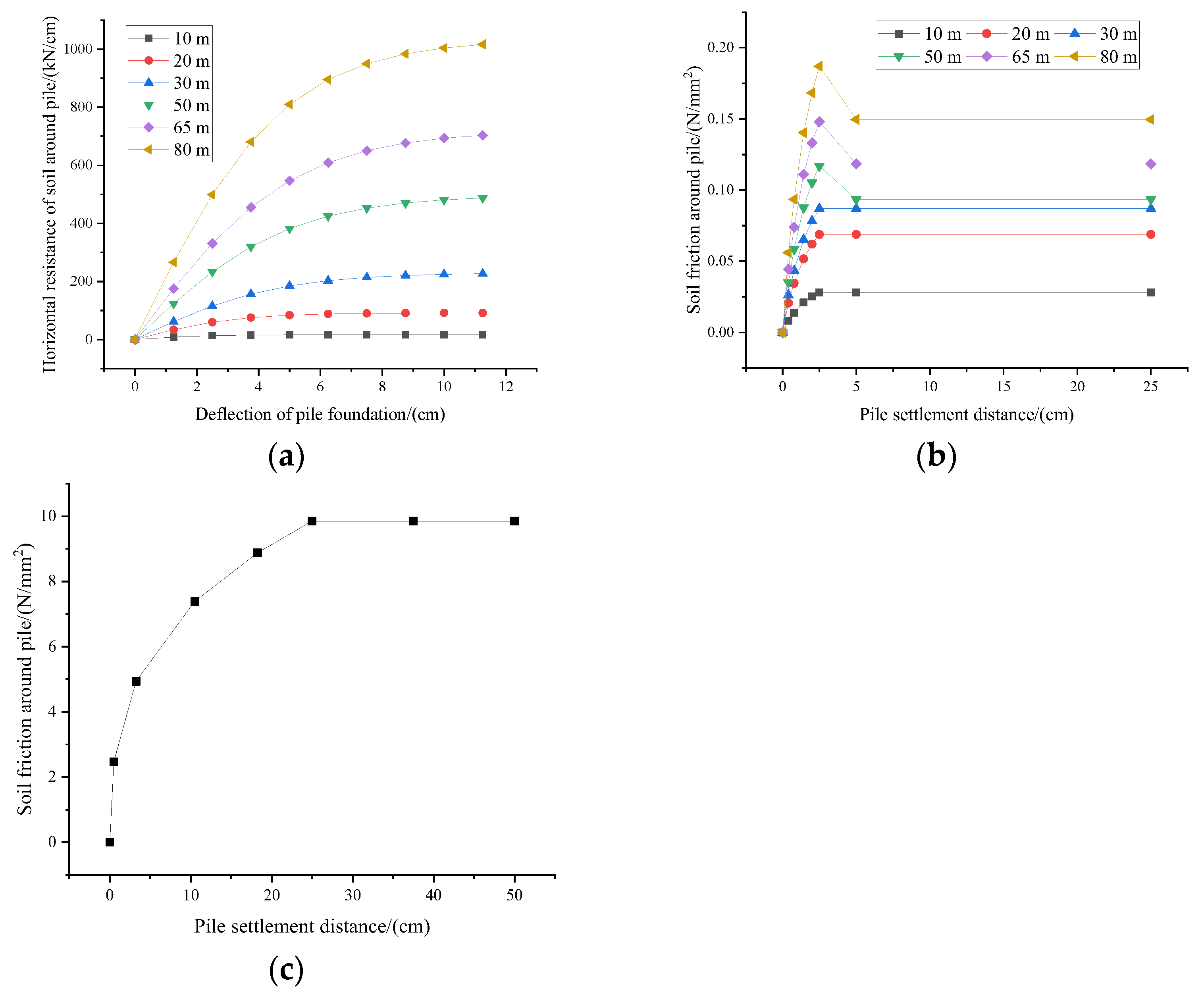

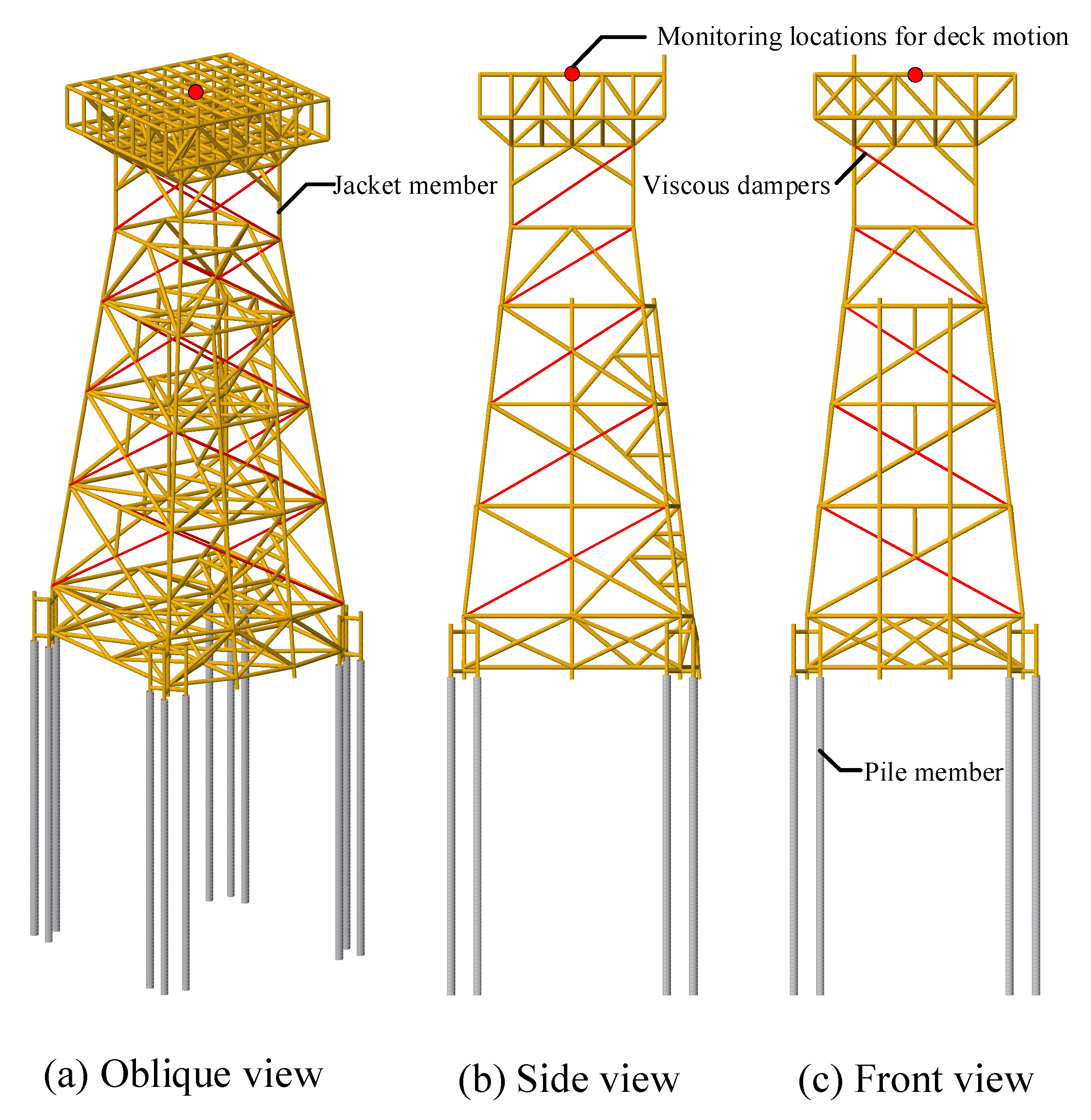

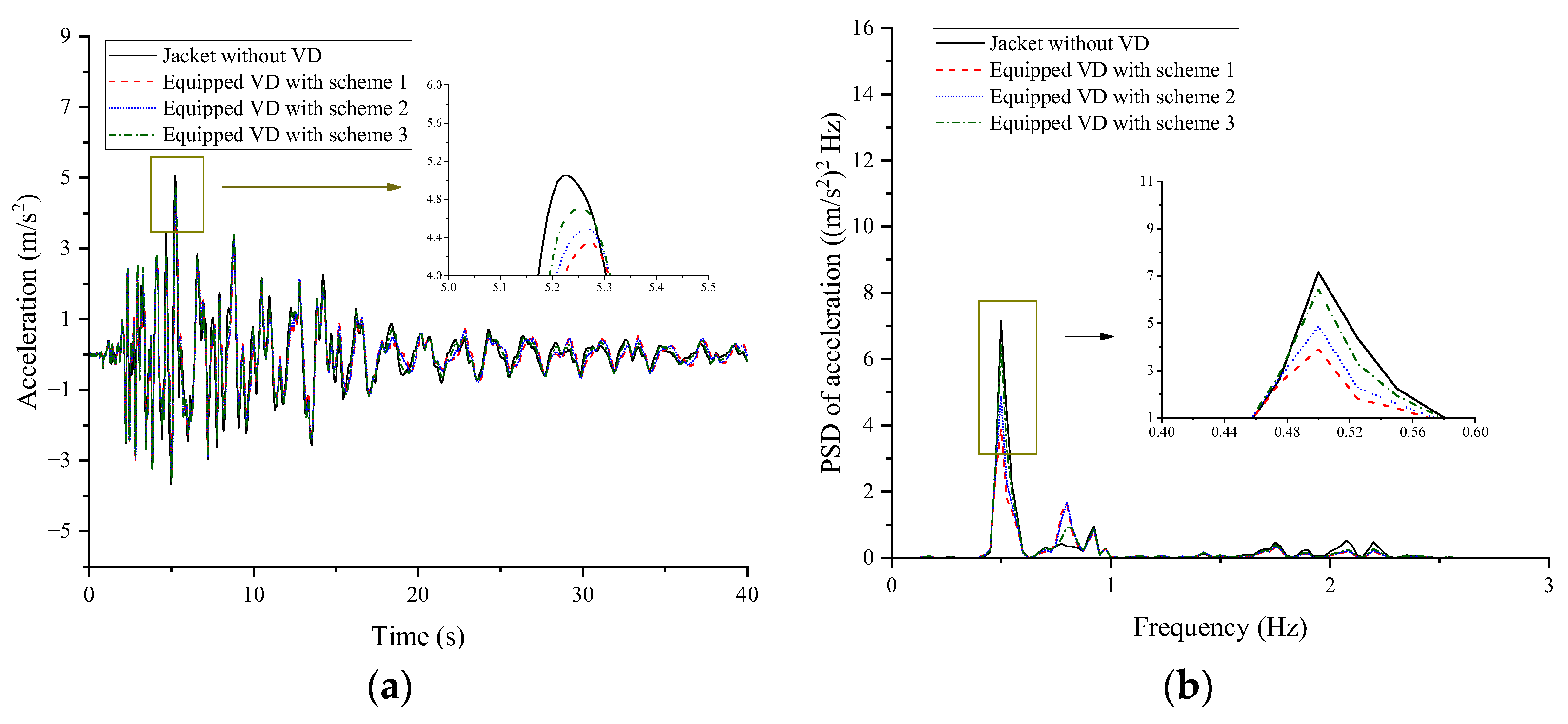

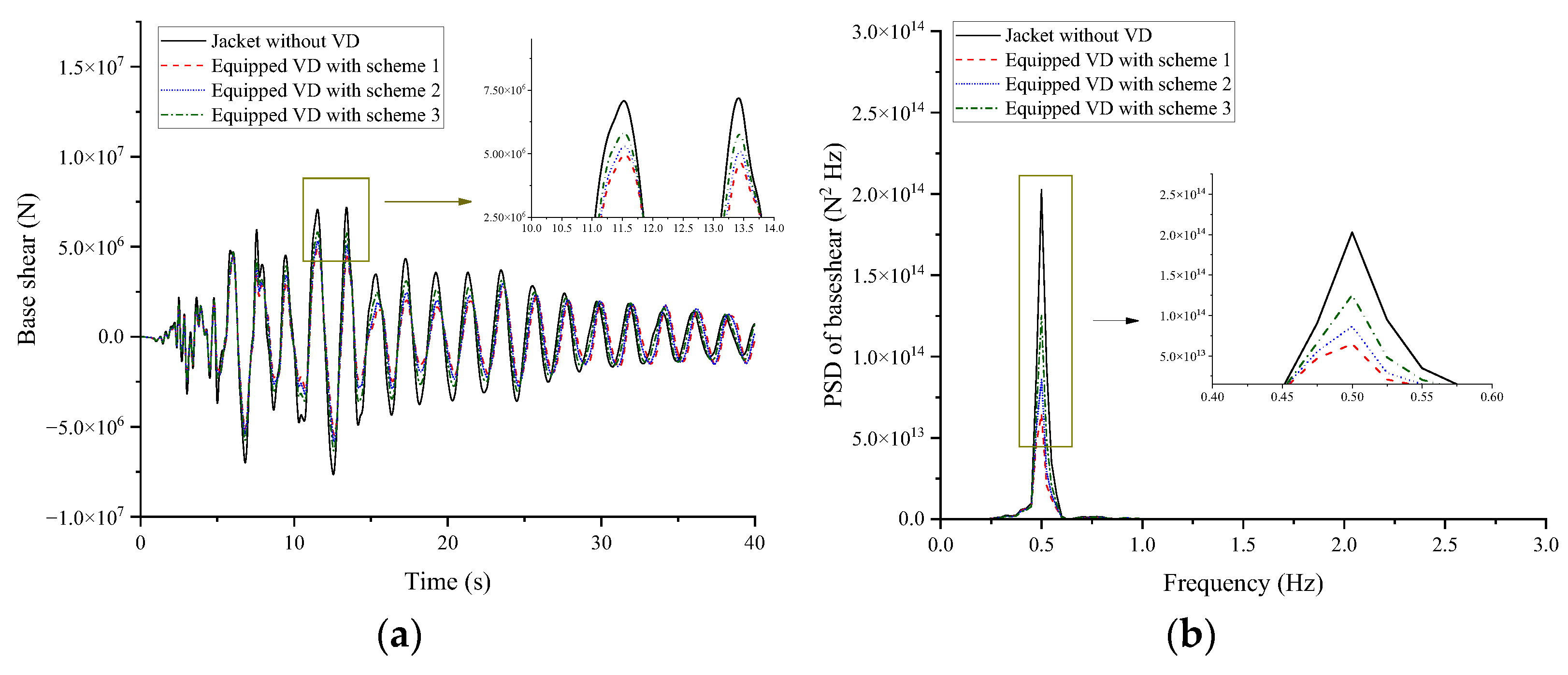

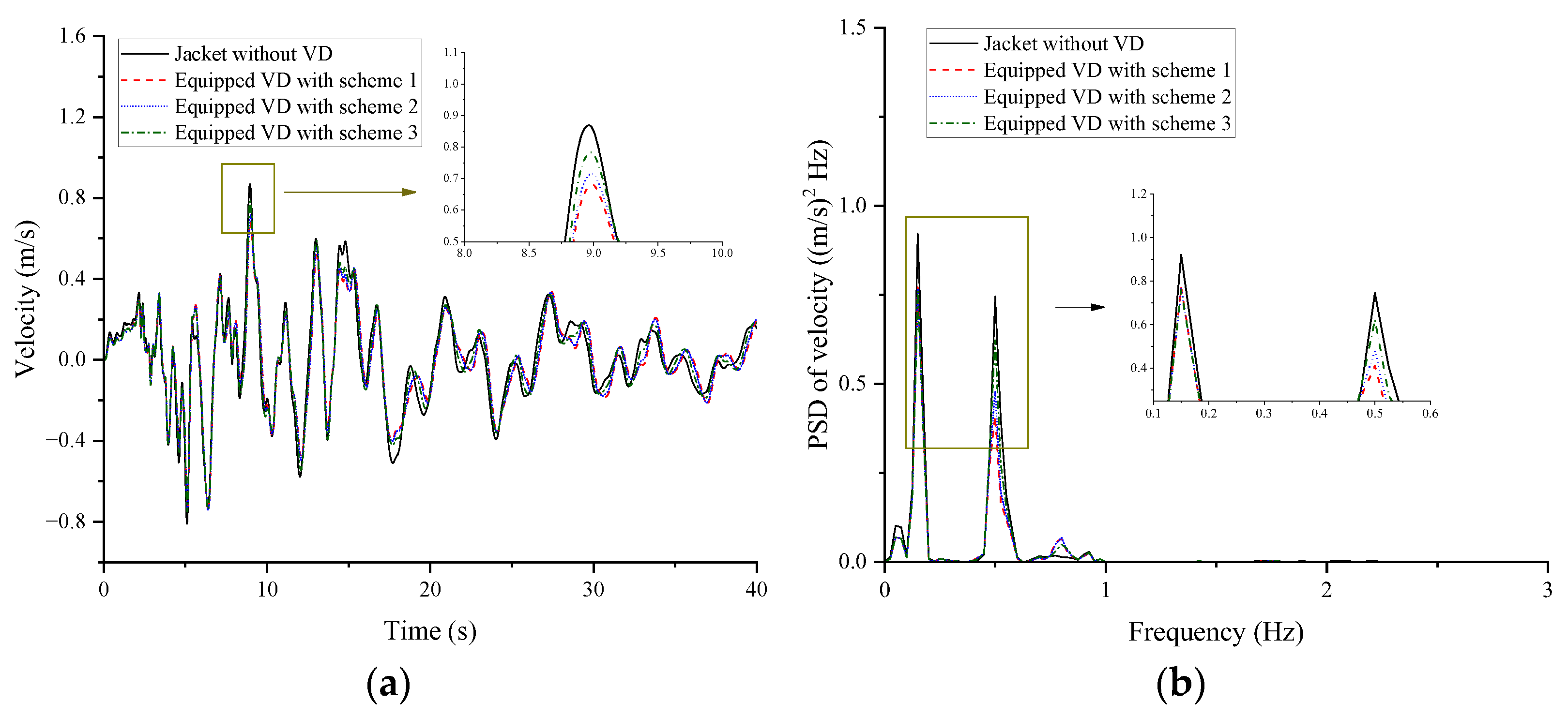

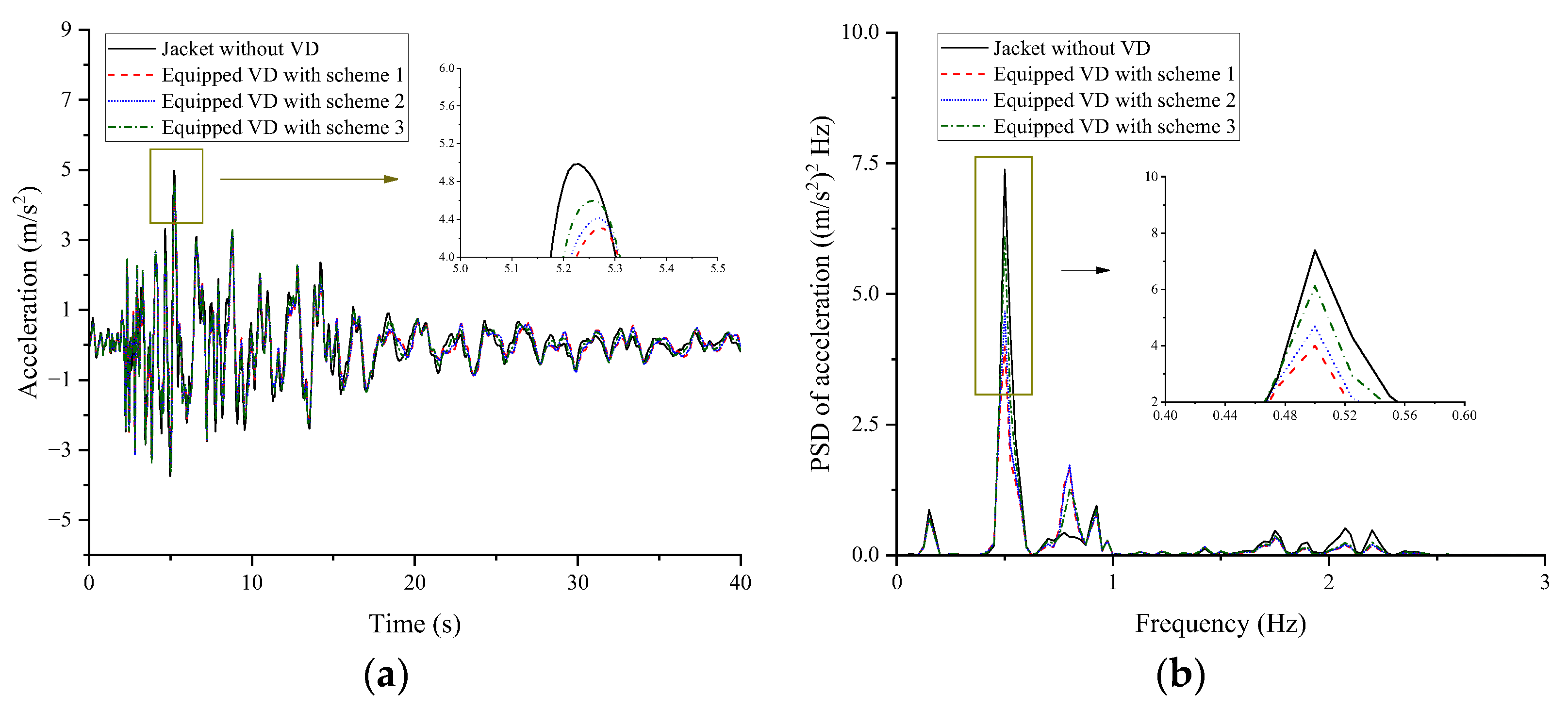

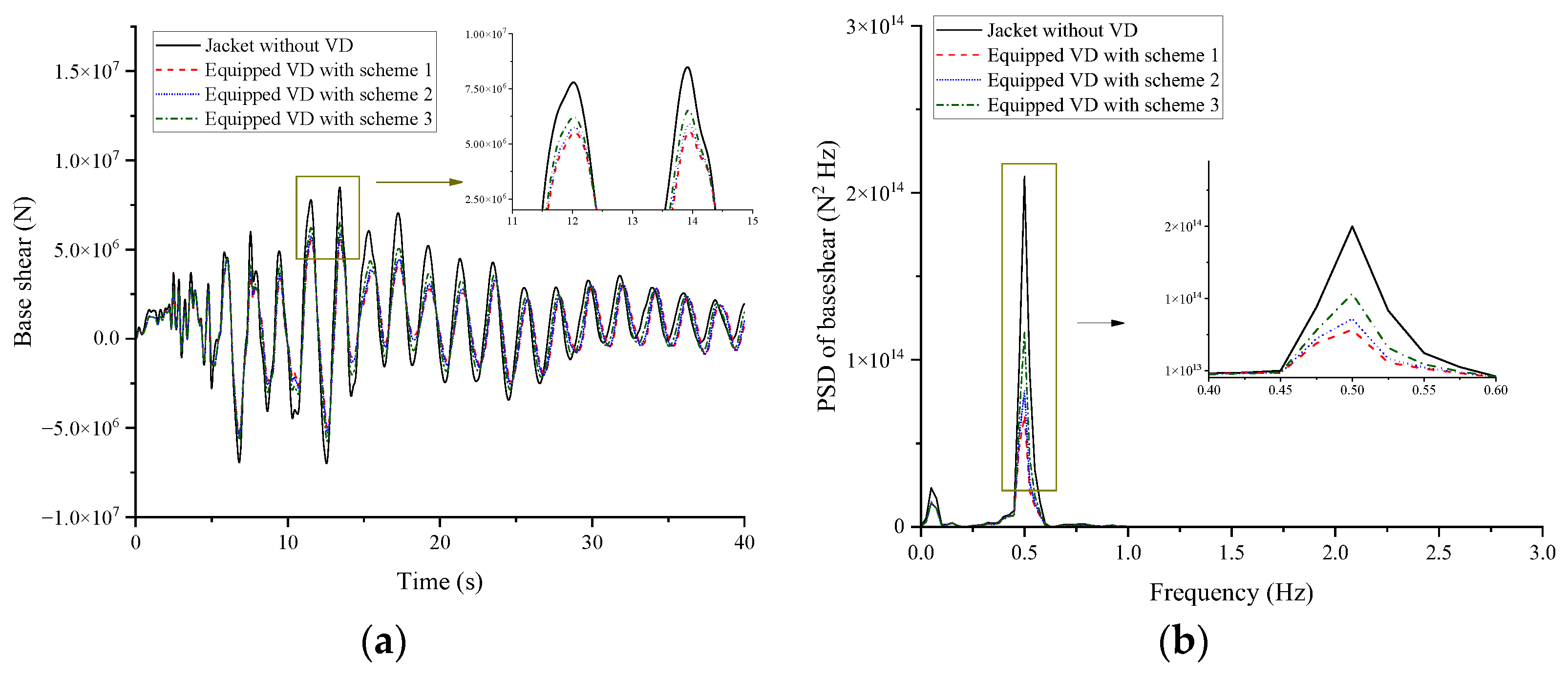

This study investigated the vibration control performance of viscous dampers on a deepwater offshore platform under wind, wave, and earthquake loads. A fine finite element model of the jacket platform was established in the Opensees software, and the soil–structure interaction was considered based on the p-y, t-z, and q-z springs. The wind speed and wave profile were evaluated by the von Kármán and JONSWAP spectrums, respectively, and the corresponding forces were calculated by Morison’s equation. The Kobe 1995 earthquake in Japan was selected as the earthquake excitation. The dynamic responses of the offshore platform equipped with VDs under seismic action only and the joint action of wind, wave, and earthquake excitation were analyzed. The VD-integrated offshore platform demonstrates superior vibration control under both seismic and multi-hazard excitations, achieving significant response reductions in deck displacement, velocity, acceleration, and base shear under earthquake loads, at 9.95%, 22.33%, 14.00%, and 31.08%, respectively, as well as 15.87% in displacement, 21.48% in velocity, 13.51% in acceleration, and 34.31% in base shear for combined wind–wave–earthquake loads. Furthermore, parametric analysis reveals that increasing damping coefficients substantially enhances this control effectiveness.

2. Viscous Dampers

The dynamic behavior of offshore jacket structures under environmental loads such as waves, wind, et al., necessitates a rigorous analysis of structural vibrations. To characterize the time-dependent response of offshore platforms, the governing equations of motion under external excitation have the following expression:

where

represents the structural mass matrix.

indicates the damping matrix.

K refers to the structural stiffness matrix.

,

, and

define the deformation, velocity, and acceleration of the structure, respectively.

F denotes the external forces, including wind load

, wave and current load

, and earthquake loads

,

Structural damping refers to the inherent energy dissipation mechanisms within a material or system, arising from internal friction, microstructural hysteresis, and localized deformations, et al.

can be evaluated by the following equation:

where

represents the damping matrix of the structure.

indicates the added damping matrix due to the damper. The determination of the damping coefficient

is based on the target damping ratio, and can be yielded by the following formula [

33]:

where

is the target damping ratio.

represents the natural period of the offshore platform.

refers to the total stiffness. This study considered the target damping ratio of 10% [

37].

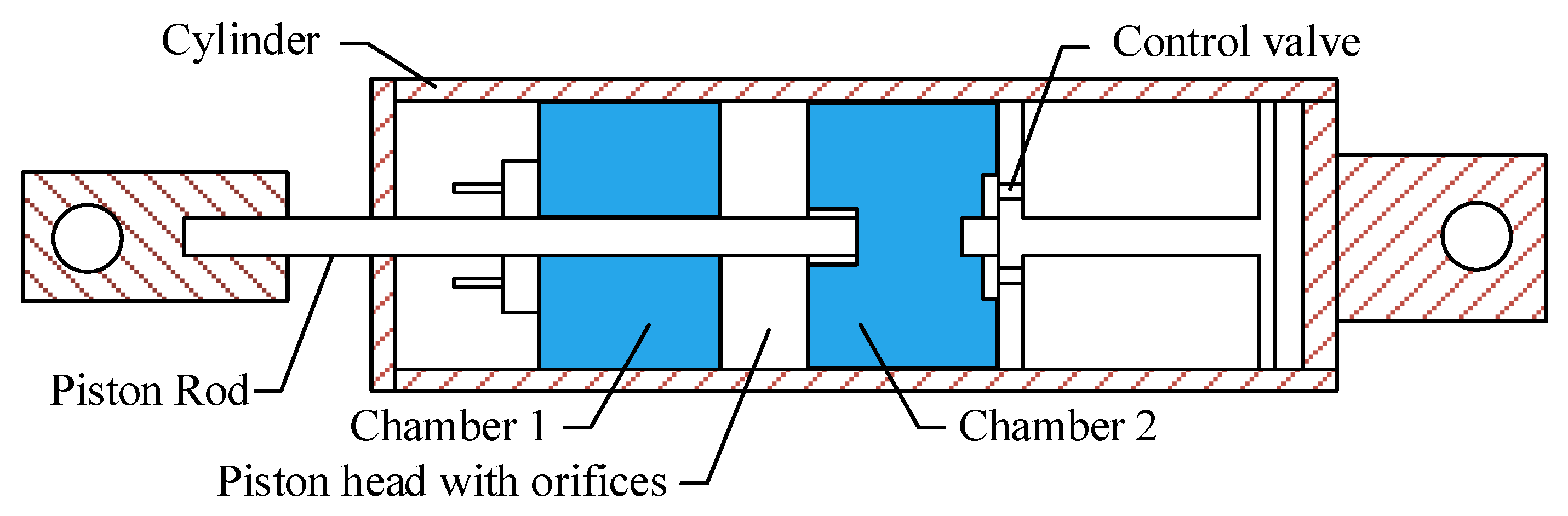

Viscous dampers, as shown in

Figure 1, provide supplemental energy dissipation without altering the fundamental frequency characteristics, thereby avoiding resonance risks under operational conditions. Furthermore, the damper’s passive operation eliminates the need for external power or complex control systems, significantly reducing lifecycle costs. The integration of viscous dampers offers a critical balance between dynamic performance and cost efficiency.