The Effect of In-Pipe Fluid States and Types on Axial Stiffness Characteristics of Fiber-Reinforced Flexible Pipes

Abstract

1. Introduction

2. Numerical Modeling of the Fiber-Reinforced Flexible Pipe

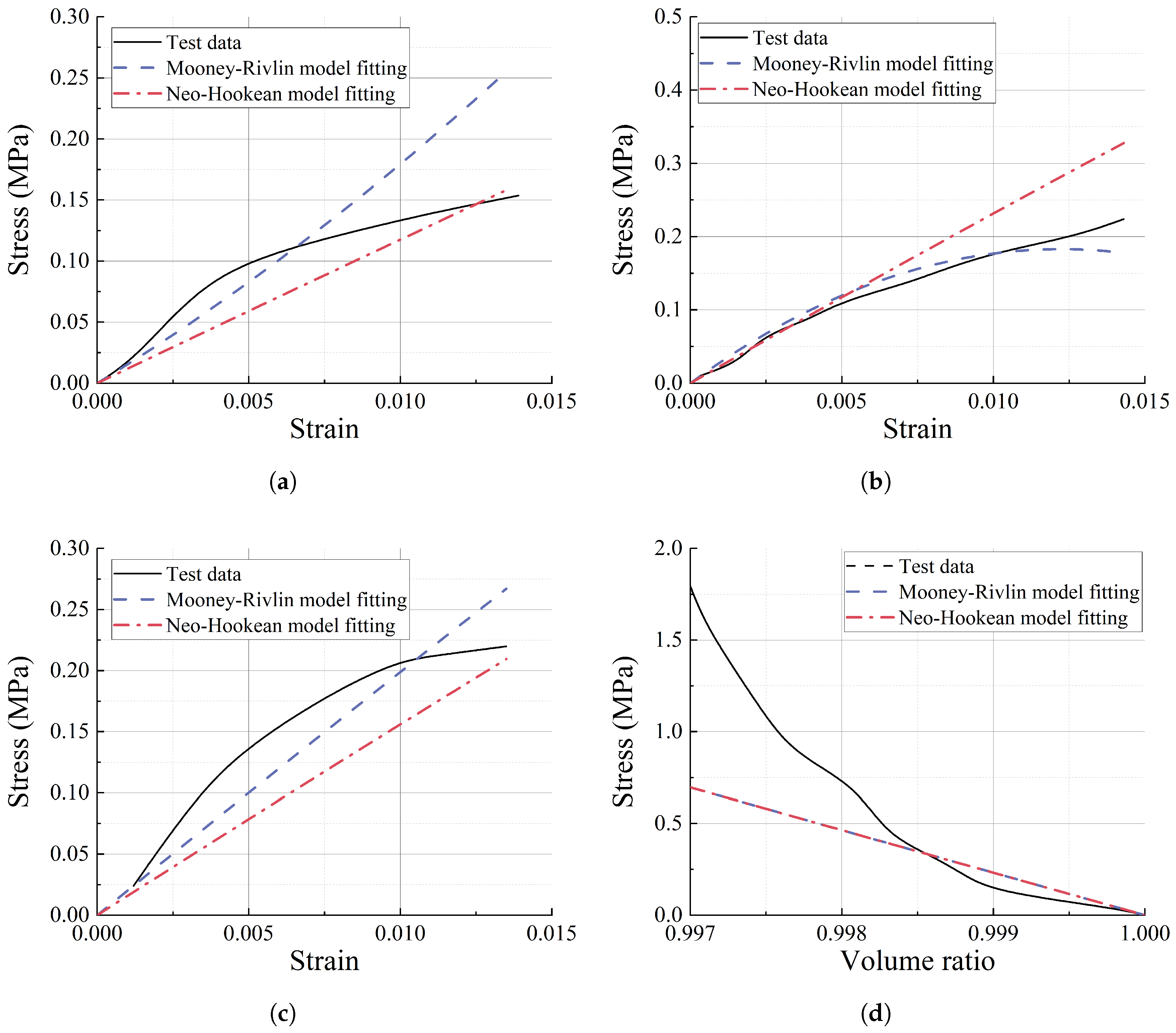

2.1. Material Characterization and Hyperelastic Constitutive Modeling

2.2. Development of the Numerical Model

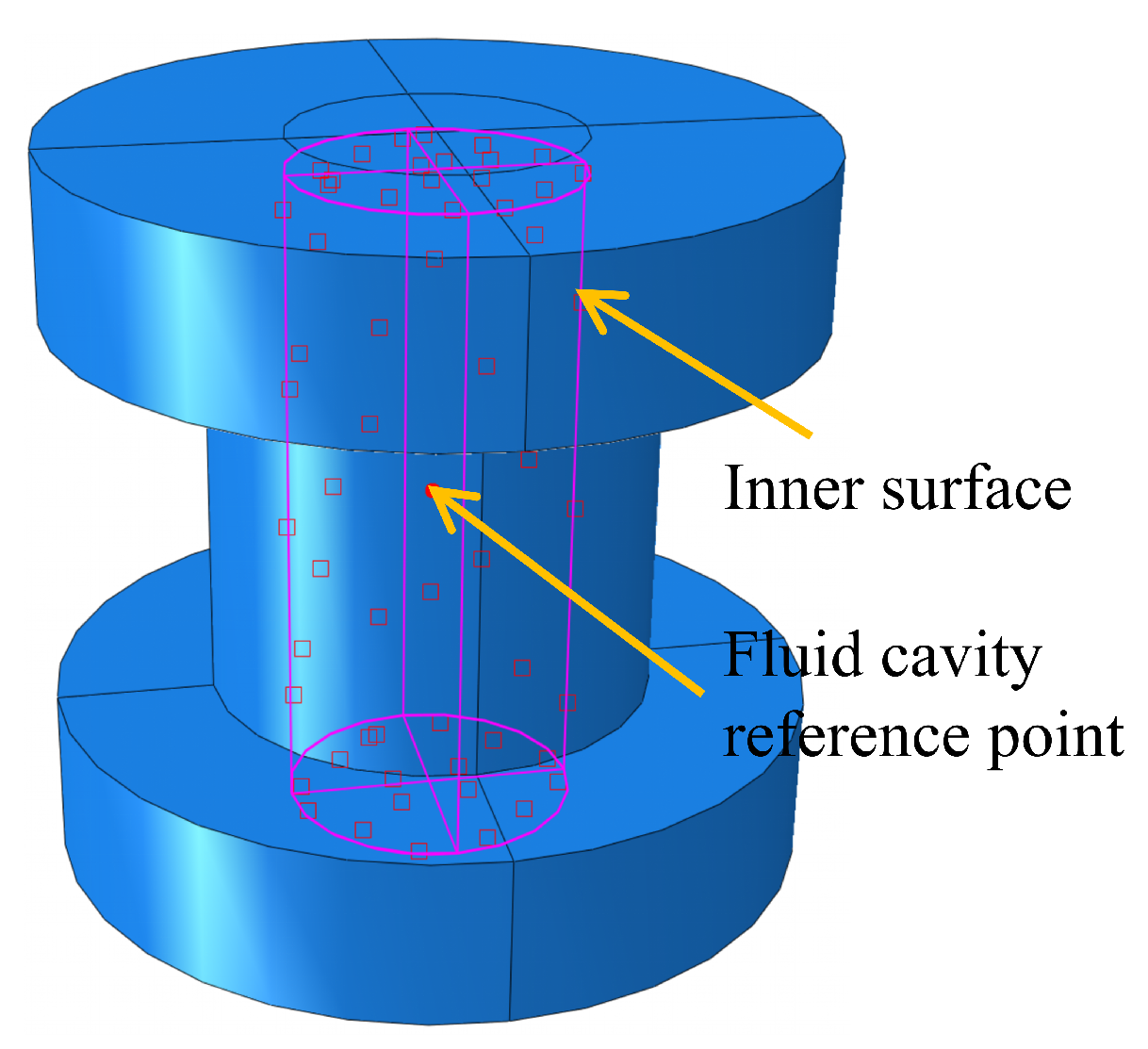

2.2.1. Fluid–Structure Coupling Model Based on the Fluid Cavity Method

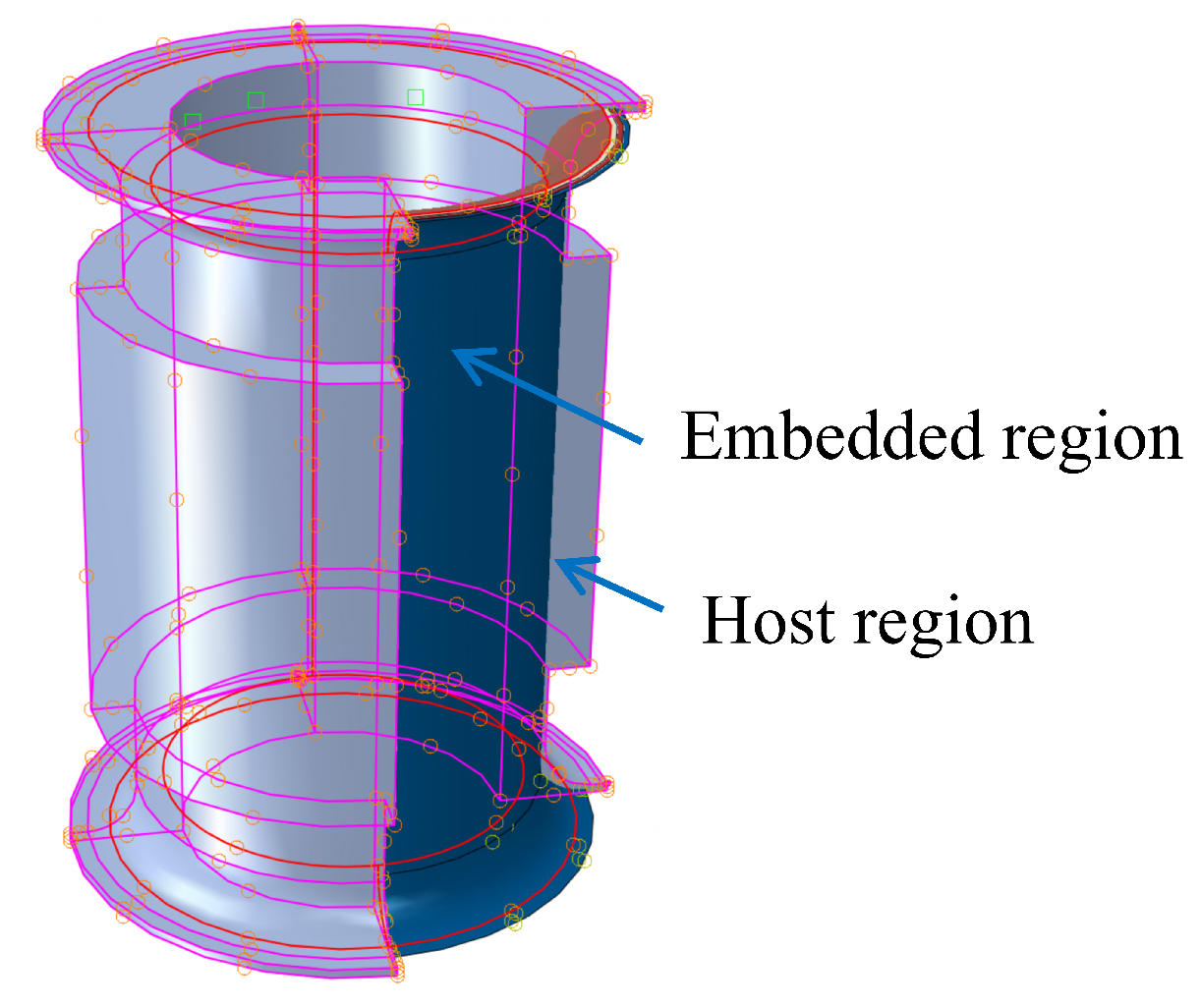

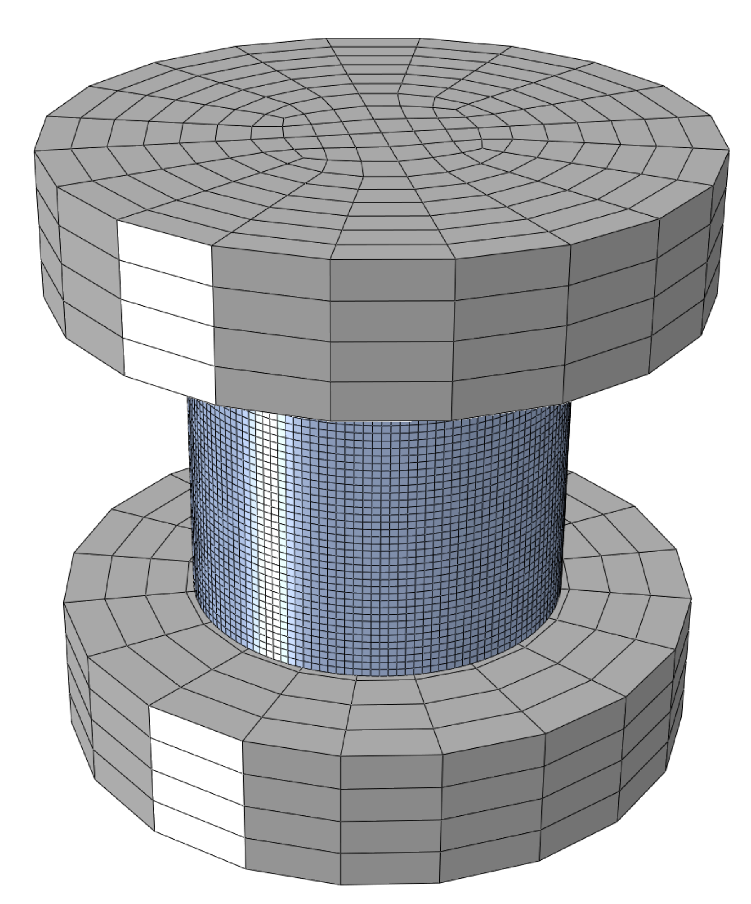

2.2.2. Interaction, Meshing, and Boundary Conditions

- Closed state simulation: The fluid cavity pressure control is deactivated after the first analysis step, effectively trapping initially pressurized fluid within the pipe;

- Constant pressure state simulation: The fluid pressure applied in the first analysis step is maintained throughout the second analysis step, ensuring invariant internal pressure during axial loading.

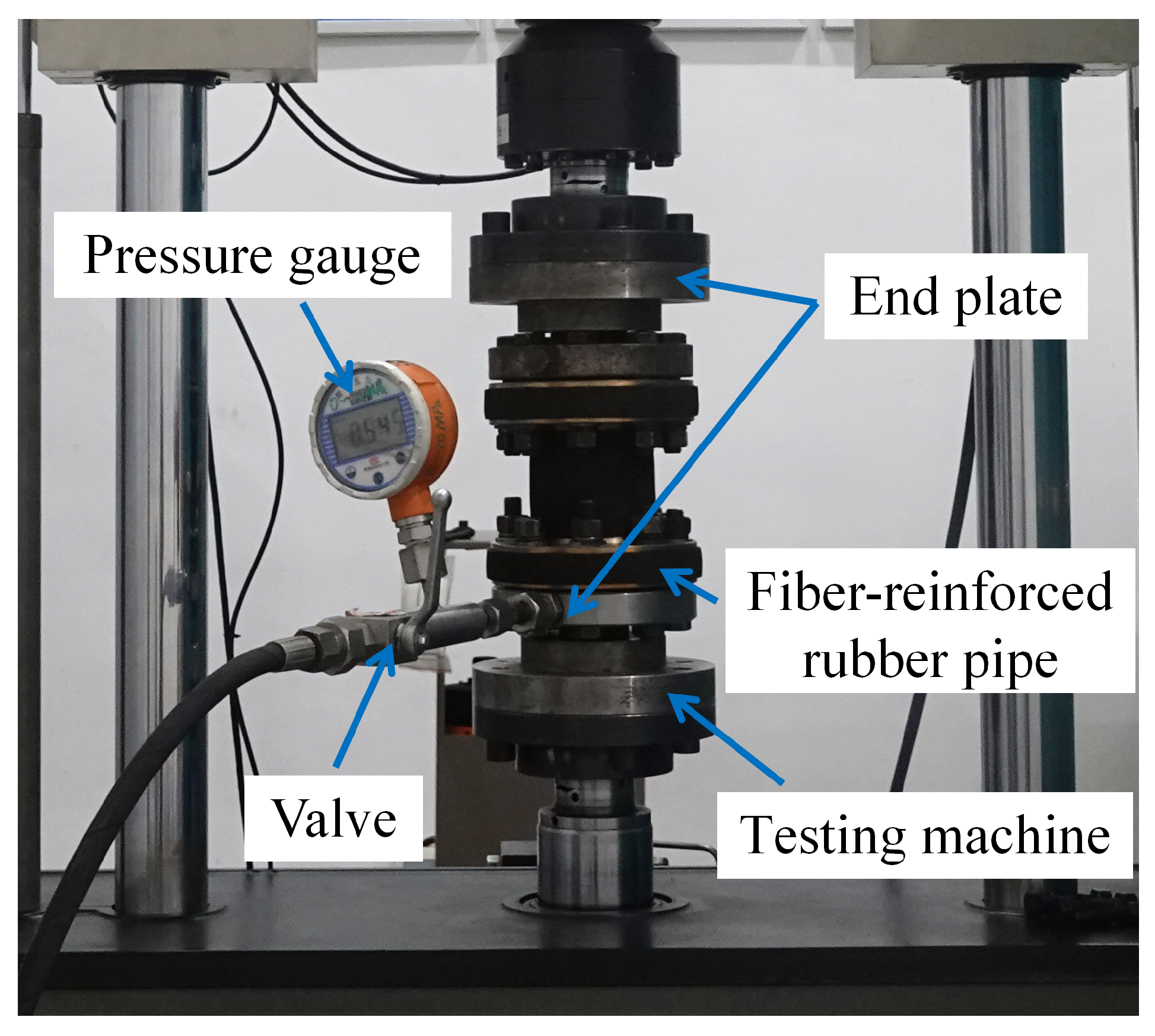

3. Axial Stiffness Testing of Fiber-Reinforced Flexible Pipes

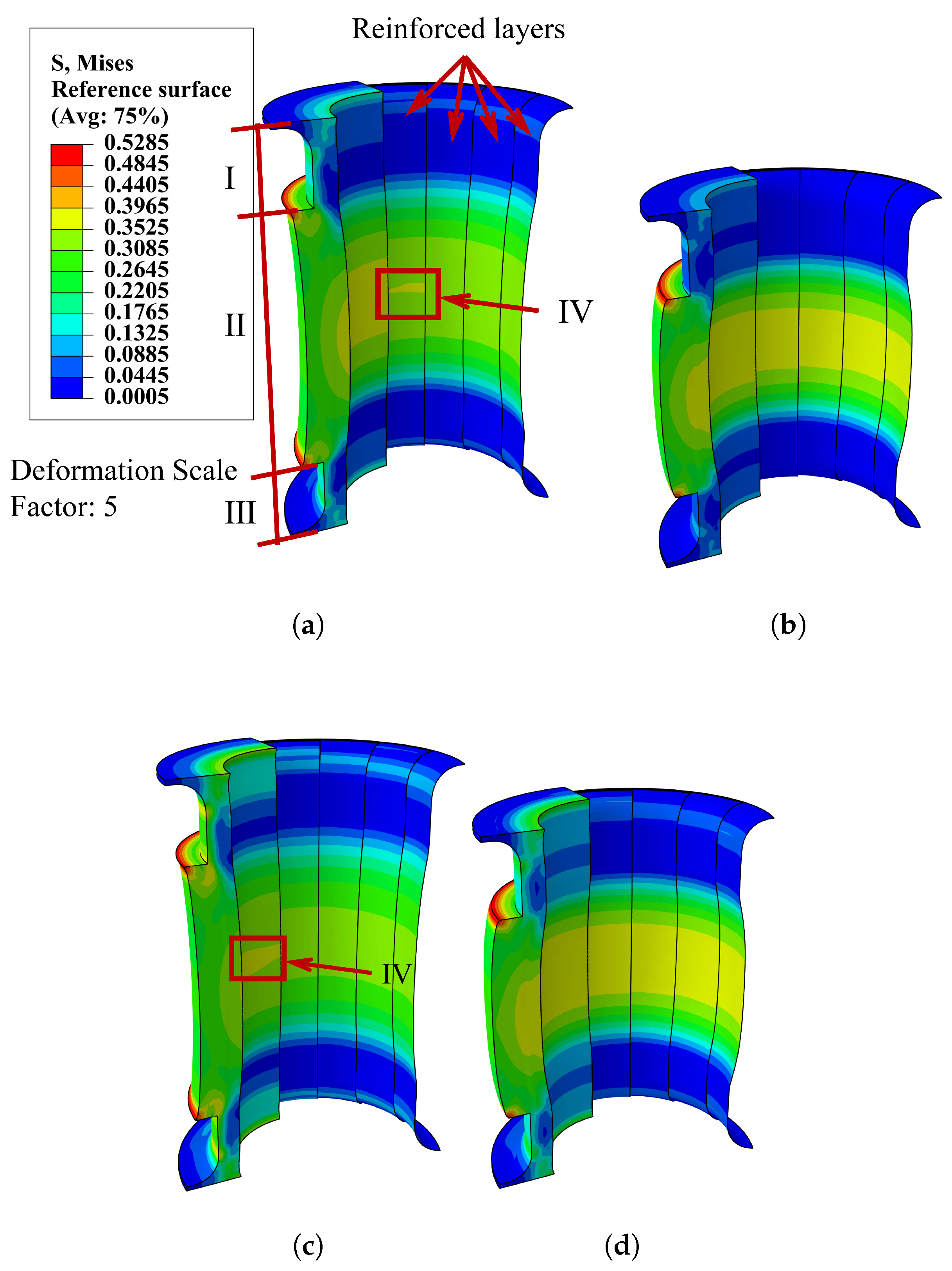

4. Results and Discussion

4.1. Numerical Results and Experimental Validation of FRF Pipe Axial Stiffness

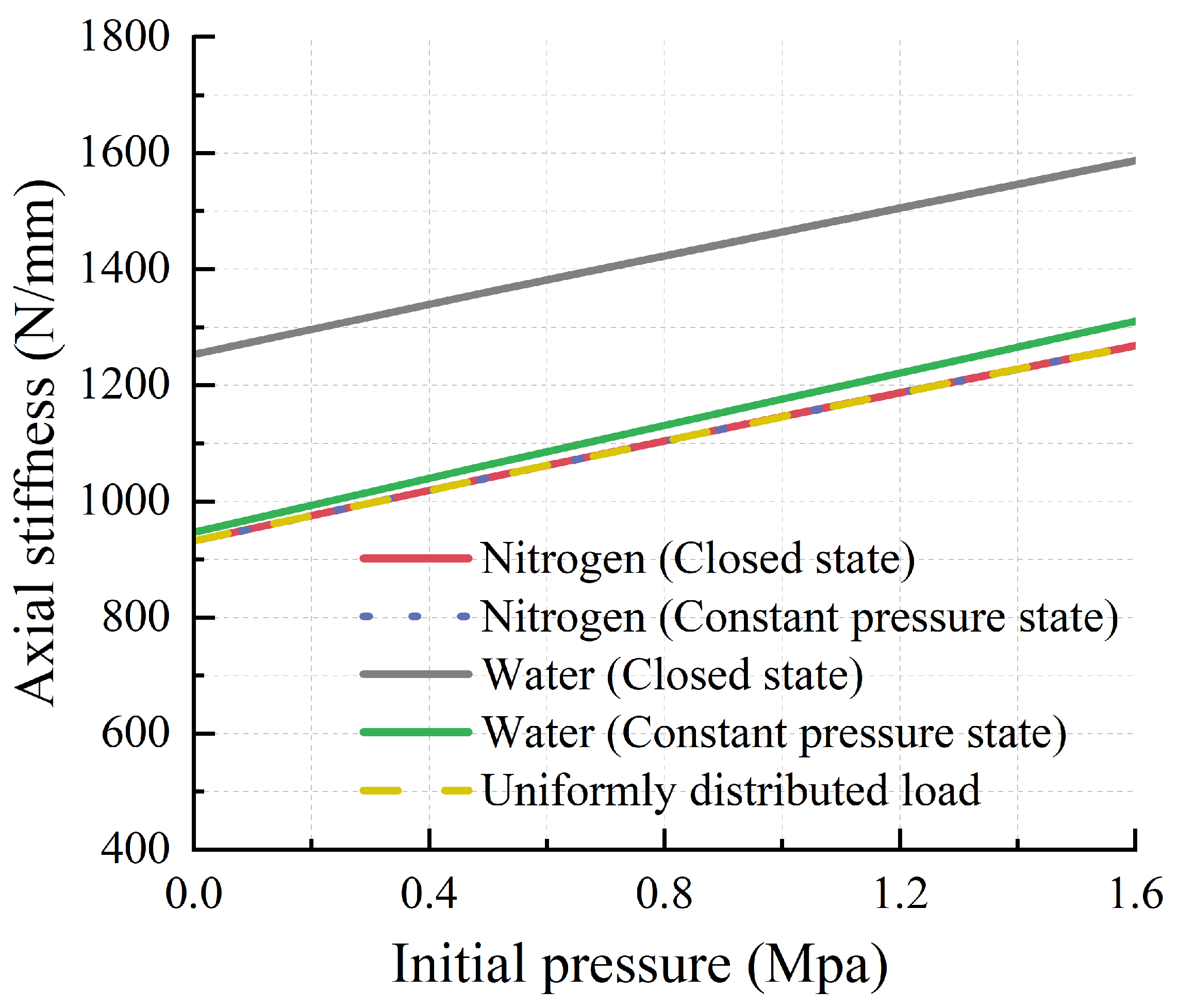

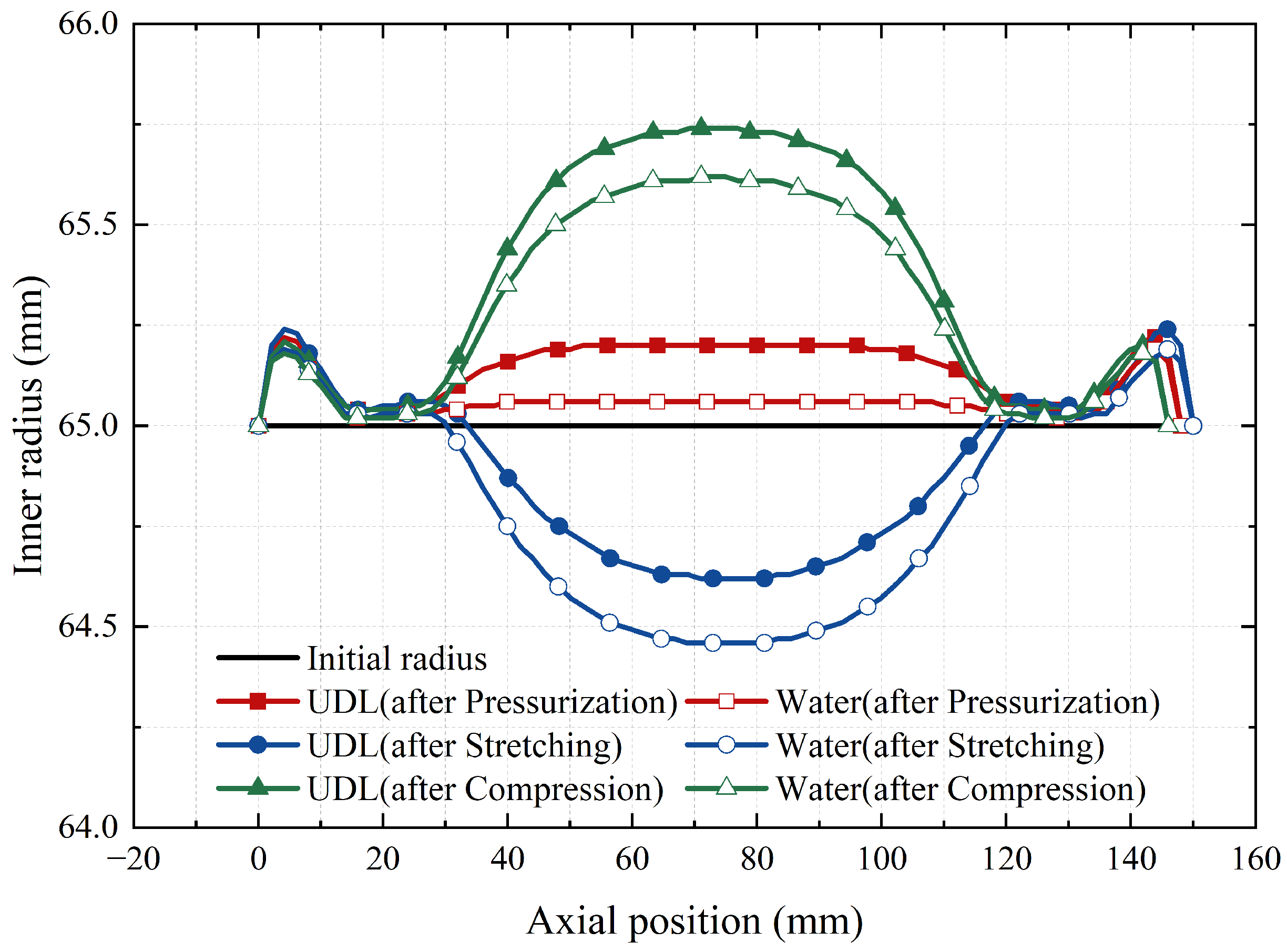

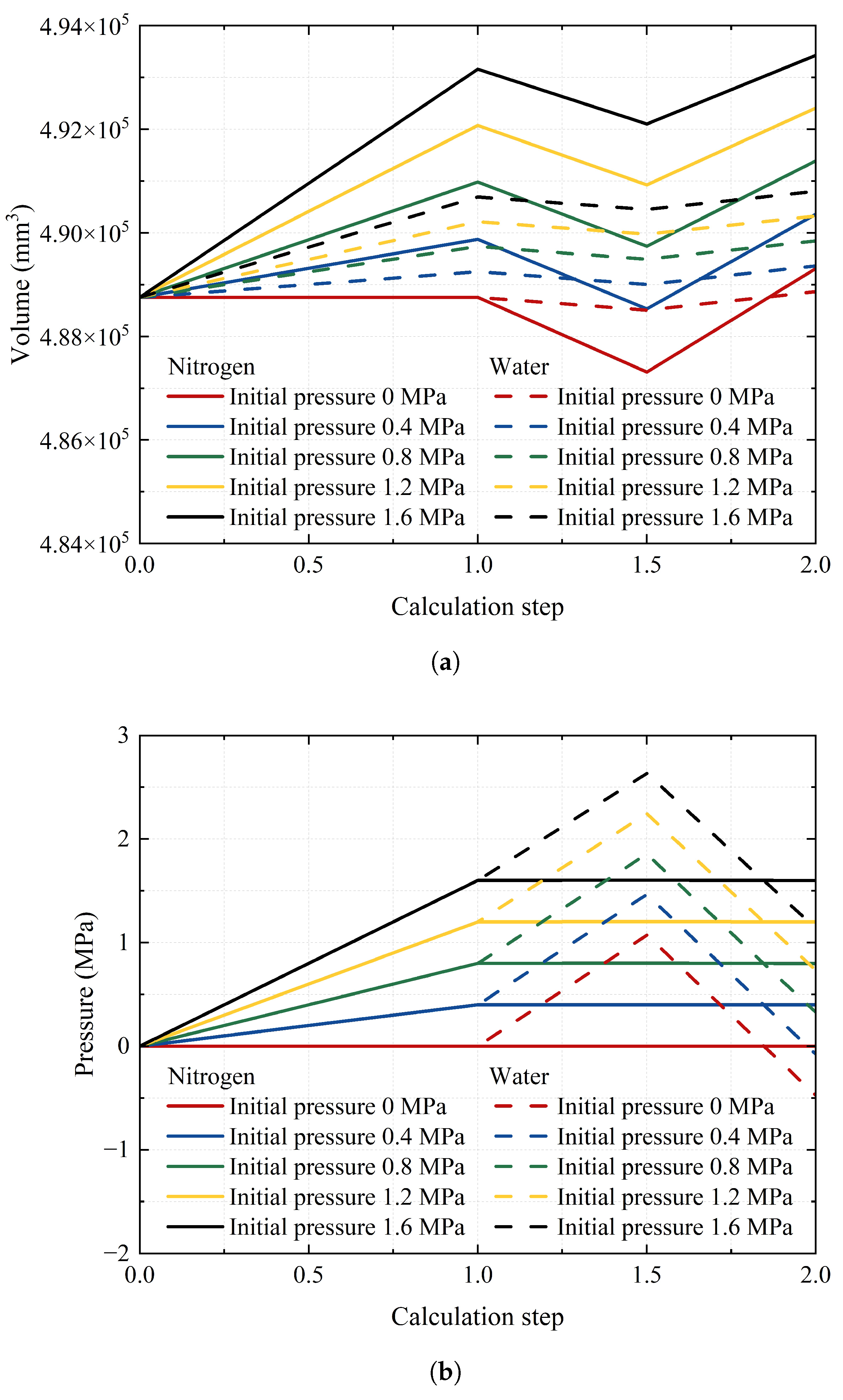

4.2. Effects of Fluid States and Types on Axial Stiffness

4.3. Effects of Fluid Parameters on the Axial Stiffness of the FRF Pipe in the Closed State

5. Conclusions

- Weak fluid–structure coupling allows gas-induced loads to be simplified as UDL in both the closed and constant pressure states. This simplification remains valid for the water-filled constant pressure state as well;

- In the closed state, when water serves as the internal fluid of the pipe, the strong coupling effect between water’s incompressibility and the pipe structure precludes the simplification of the force exerted by water on the pipe as UDL. Additionally, during axial loading, significant fluctuations in water pressure may result in the internal pipe pressure exceeding or falling below the allowable pressure range specified for the pipe design. Furthermore, particular attention should be given to the fact that end effects induced by water pressure no longer manifest as a constant force;

- In the closed state, there is a positive correlation between the bulk modulus of the liquid and the axial stiffness of the FRF pipe. By establishing an asymptotic saturation model, the quantitative relationship between the structural stiffness of the pipe and the stiffness contribution from the liquid is elucidated. This formula decouples structural stiffness from liquid effects, ensuring that it degrades to the gas-condition result at low bulk modulus values and asymptotically approaches the upper limit of the combined structural–fluid stiffness at high bulk modulus values.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| FRF | Fiber-reinforced flexible |

| UDL | Uniformly distributed load |

| MPa | Megapascal |

| C3D8R | Three-dimensional 8-node linear brick element with reduced integration |

| M3D4R | Three-dimensional 4-node membrane element with reduced integration |

| WDW | Microcomputer-controlled Electronic Universal Testing Machine |

| MTS | Material Testing System |

| ASTM | American Society for Testing and Materials |

| SSE | Sum of squared errors |

References

- Alabtah, F.G.; Mahdi, E.; Eliyan, F.F. The use of fiber reinforced polymeric composites in pipelines: A review. Compos. Struct. 2021, 276, 114595. [Google Scholar] [CrossRef]

- Diniță, A.; Ripeanu, R.G.; Ilincă, C.N.; Cursaru, D.; Matei, D.; Naim, R.I.; Tănase, M.; Portoacă, A.I. Advancements in Fiber-Reinforced Polymer Composites: A Comprehensive Analysis. Polymers 2023, 16, 2. [Google Scholar] [CrossRef] [PubMed]

- Wei, D.; An, C.; Wu, C.; Duan, M.; Estefen, S.F. Torsional structural behavior of composite rubber hose for offshore applications. Appl. Ocean. Res. 2022, 128, 103333. [Google Scholar] [CrossRef]

- Gao, Q.; Zhang, P.; Duan, M.; Yang, X.; Shi, W.; An, C.; Li, Z. Investigation on structural behavior of ring-stiffened composite offshore rubber hose under internal pressure. Appl. Ocean. Res. 2018, 79, 7–19. [Google Scholar] [CrossRef]

- Fang, P.; Xu, Y.; Gao, Y.; Ali, L.; Bai, Y. Mechanical responses of a fiberglass flexible pipe subject to tension & internal pressure. Thin-Walled Struct. 2022, 181, 110107. [Google Scholar]

- Liu, Q.; Xue, H.; Tang, W.; Yuan, Y. Theoretical and numerical methods to predict the behaviour of unbonded flexible riser with composite armour layers subjected to axial tension. Ocean. Eng. 2020, 199, 107038. [Google Scholar] [CrossRef]

- De Oliveira, J.; Goto, Y.; Okamoto, T. Theoretical and methodological approaches to flexible pipe design and application. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 6–9 May 1985; Volume 17, pp. 517–526. [Google Scholar]

- Wang, Y.; Lou, M.; Liang, W.; Zhang, C. Numerical and experimental investigation on tensile fatigue performance of reinforced thermoplastic pipes. Ocean. Eng. 2023, 287, 115814. [Google Scholar] [CrossRef]

- Jaszak, P.; Skrzypacz, J.; Adamek, K. The design method of rubber-metallic expansion joint. Open Eng. 2018, 8, 532–538. [Google Scholar] [CrossRef]

- Xu, G.m.; Shuai, C.g. Axial and lateral stiffness of spherical self-balancing fiber reinforced rubber pipes under internal pressure. Sci. Eng. Compos. Mater. 2021, 28, 96–106. [Google Scholar] [CrossRef]

- Kruijer, M.; Warnet, L.; Akkerman, R. Analysis of the mechanical properties of a reinforced thermoplastic pipe (RTP). Compos. Part A Appl. Sci. Manuf. 2005, 36, 291–300. [Google Scholar] [CrossRef]

- Xia, M.; Takayanagi, H.; Kemmochi, K. Analysis of multi-layered filament-wound composite pipes under internal pressure. Compos. Struct. 2001, 53, 483–491. [Google Scholar] [CrossRef]

- Xing, J.; Geng, P.; Yang, T. Stress and deformation of multiple winding angle hybrid filament-wound thick cylinder under axial loading and internal and external pressure. Compos. Struct. 2015, 131, 868–877. [Google Scholar] [CrossRef]

- Gao, P.; Gao, Q.; An, C.; Zeng, J. Analytical modeling for offshore composite rubber hose with spiral stiffeners under internal pressure. J. Reinf. Plast. Compos. 2020, 40, 352–364. [Google Scholar] [CrossRef]

- Rogers, T. Problems for helically wound cylinders. In Continuum Theory of the Mechanics of Fibre-Reinforced Composites; Springer: Berlin/Heidelberg, Germany, 1984; pp. 147–178. [Google Scholar]

- Evans, J.; Gibson, A. Composite angle ply laminates and netting analysis. Proc. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 2002, 458, 3079–3088. [Google Scholar] [CrossRef]

- Gu, F.; Huang, C.k.; Zhou, J.; Li, L.p. Mechanical response of steel wire wound reinforced rubber flexible pipe under internal pressure. J. Shanghai Jiaotong Univ. Sci. 2009, 14, 747–756. [Google Scholar] [CrossRef]

- Wang, Y.; Lou, M.; Yang, L.; Wu, L. Study on the tensile properties of reinforced thermoplastic pipes under different internal pressures and temperatures. Int. J. Press. Vessel. Pip. 2022, 200, 104820. [Google Scholar] [CrossRef]

- Khaniki, H.B.; Ghayesh, M.H.; Chin, R.; Amabili, M. A review on the nonlinear dynamics of hyperelastic structures. Nonlinear Dyn. 2022, 110, 963–994. [Google Scholar] [CrossRef]

- Tonatto, M.L.; Tita, V.; Araujo, R.T.; Forte, M.M.; Amico, S.C. Parametric analysis of an offloading hose under internal pressure via computational modeling. Mar. Struct. 2017, 51, 174–187. [Google Scholar] [CrossRef]

- Tong, F.; Lan, F.; Chen, J.; Li, D.; Li, X. Numerical study on the injury mechanism of blunt aortic rupture of the occupant in frontal and side-impact. Int. J. Crashworthiness 2022, 28, 270–279. [Google Scholar] [CrossRef]

- Ye, Y.; Gan, J.; Liu, H.; Guan, Q.; Zheng, Z.; Ran, X.; Gao, Z. Experimental and numerical studies on bending and failure behaviour of inflated composite fabric membranes for marine applications. J. Mar. Sci. Eng. 2023, 11, 800. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, T.; Meng, C.; Jiao, Z.; Meng, F.; Guo, S. Numerical simulation modeling and kinematic analysis onto double wedge-shaped airbag of nursing appliance. Sci. Rep. 2023, 13, 14261. [Google Scholar] [CrossRef] [PubMed]

- Sosa, E.M.; Wong, J.C.S.; Adumitroaie, A.; Barbero, E.J.; Thompson, G.J. Finite element simulation of deployment of large-scale confined inflatable structures. Thin-Walled Struct. 2016, 104, 152–167. [Google Scholar] [CrossRef]

- Cao, Z.; Wan, Z.; Yan, J.; Fan, F. Static behaviour and simplified design method of a Tensairity truss with a spindle-shaped airbeam. J. Constr. Steel Res. 2018, 145, 244–253. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers–Tension, d412-16 ed.; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Mullins, L. Softening of rubber by deformation. Rubber Chem. Technol. 1969, 42, 339–362. [Google Scholar] [CrossRef]

- Shahzad, M.; Kamran, A.; Siddiqui, M.Z.; Farhan, M. Mechanical Characterization and FE Modelling of a Hyperelastic Material. Mater. Res. 2015, 18, 918–924. [Google Scholar] [CrossRef]

- Ali, A.; Hosseini, M.; Sahari, B.B. A review of constitutive models for rubber-like materials. Am. J. Eng. Appl. Sci. 2010, 3, 232–239. [Google Scholar] [CrossRef]

- Zhang, B.; Zhao, Y.; You, J.; Zhang, Z. Experimental and numerical analysis of rubber isolator dynamic stiffness under hydrostatic pressure. Ocean. Eng. 2024, 314, 119650. [Google Scholar] [CrossRef]

- Dassault Systèmes. About Surface-Based Fluid Cavities. Online Documentation. Available online: https://help.3ds.com/2022x/simplified_chinese/dsdoc/sima3dxanlrefmap/simaanl-c-surfacebasedcavityover.htm?contextscope=onpremise (accessed on 7 April 2025).

- Mohapatra, S.C.; Guedes Soares, C. Impact of the compressive force on wave diffraction by a circular elastic floater for offshore aquaculture system. In Innovations in the Analysis and Design of Marine Structures; CRC Press: Boca Raton, FL, USA, 2025; pp. 13–19. [Google Scholar]

| Parameter | Value |

|---|---|

| Density (t/mm3) | |

| Young’s modulus (MPa) | |

| Poisson’s ratio | 0.36 |

| Parameter | Value | |

|---|---|---|

| Water | Density (t) | |

| Bulk modulus (MPa) | 2100 | |

| Nitrogen | The molecular weight of the ideal gas (t/mol) | |

| Grid Size (mm) | Total Number of Elements | Axial Stiffness (N/mm) | Relative Error (vs. Grid Size 1.5 mm) | Calculation Time (s) |

|---|---|---|---|---|

| 3 | 49,233 | 1389.65 | −6.31% | 91 |

| 2.5 | 83,081 | 1437.74 | −3.07% | 171 |

| 2 | 131,616 | 1465.04 | −1.23% | 284 |

| 1.5 | 306,649 | 1483.29 | - | 2466 |

| State | Fluid | Axial Stiffness (N/mm) | Error | |

|---|---|---|---|---|

| Numerical | Experimental | |||

| Closed | Water | % | ||

| Nitrogen | % | |||

| Constant pressure | Water | 1288.23 | 1271.47 | % |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, J.; Zhao, Y.; Zhang, B. The Effect of In-Pipe Fluid States and Types on Axial Stiffness Characteristics of Fiber-Reinforced Flexible Pipes. J. Mar. Sci. Eng. 2025, 13, 1069. https://doi.org/10.3390/jmse13061069

You J, Zhao Y, Zhang B. The Effect of In-Pipe Fluid States and Types on Axial Stiffness Characteristics of Fiber-Reinforced Flexible Pipes. Journal of Marine Science and Engineering. 2025; 13(6):1069. https://doi.org/10.3390/jmse13061069

Chicago/Turabian StyleYou, Jingyue, Yinglong Zhao, and Ben Zhang. 2025. "The Effect of In-Pipe Fluid States and Types on Axial Stiffness Characteristics of Fiber-Reinforced Flexible Pipes" Journal of Marine Science and Engineering 13, no. 6: 1069. https://doi.org/10.3390/jmse13061069

APA StyleYou, J., Zhao, Y., & Zhang, B. (2025). The Effect of In-Pipe Fluid States and Types on Axial Stiffness Characteristics of Fiber-Reinforced Flexible Pipes. Journal of Marine Science and Engineering, 13(6), 1069. https://doi.org/10.3390/jmse13061069