Research on the Forming Detection Technology of Shell Plates Based on Laser Scanning

Abstract

1. Introduction

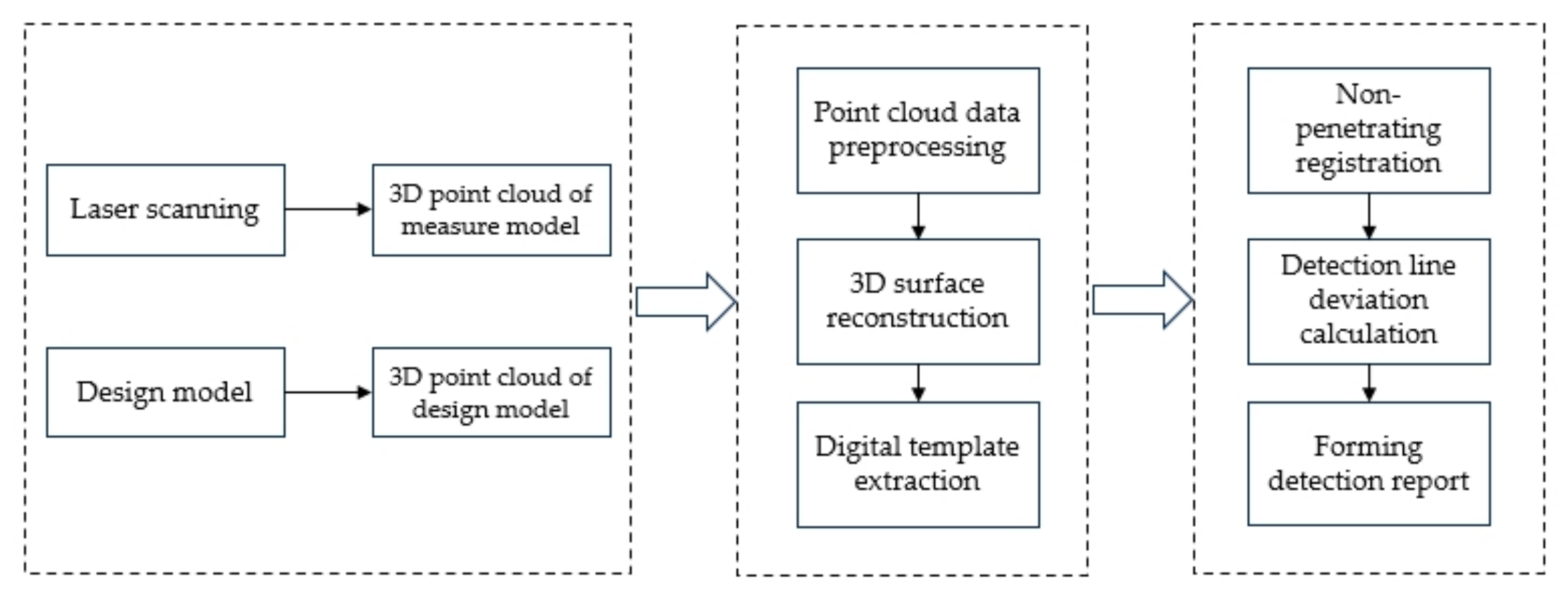

2. Methods

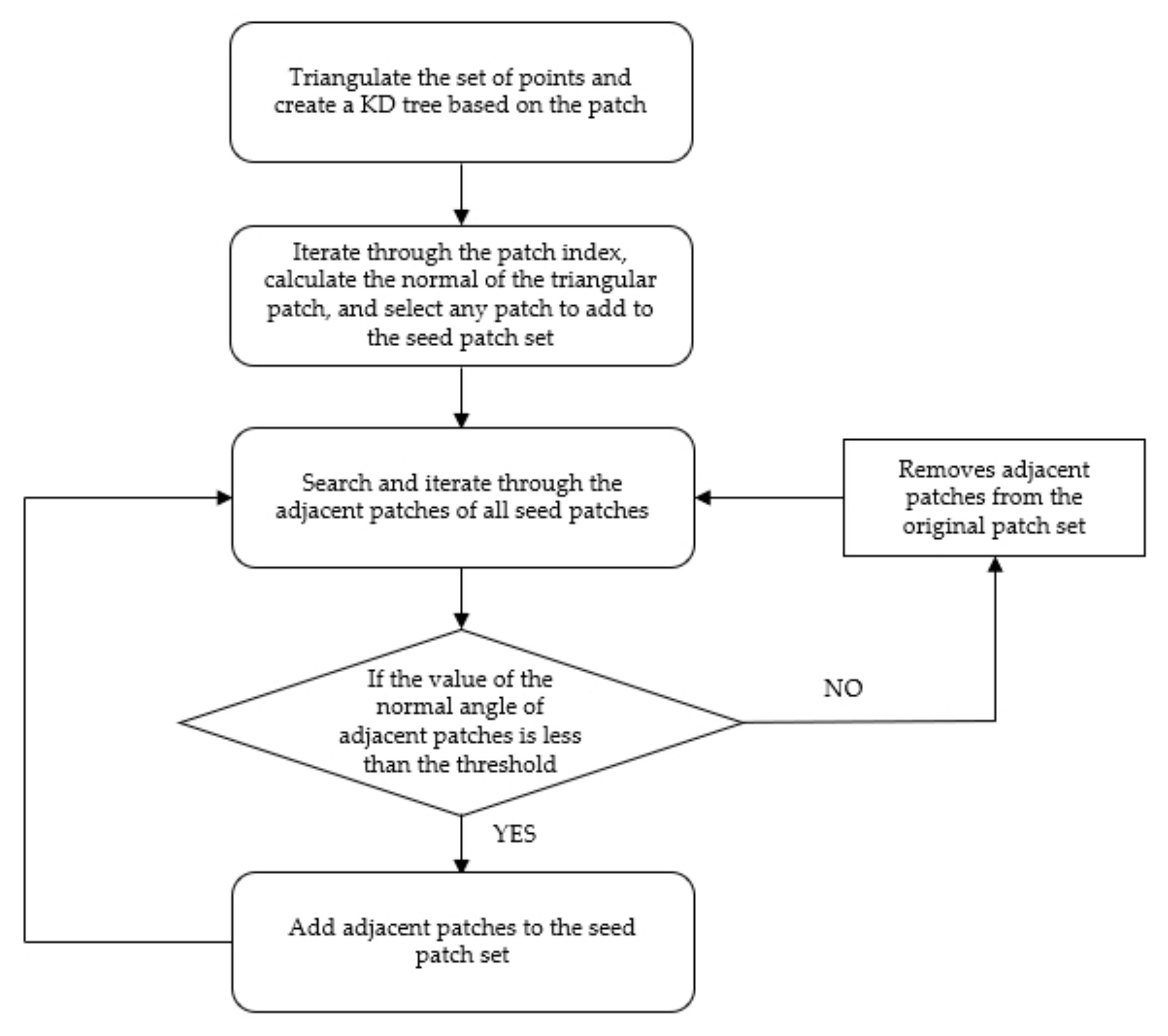

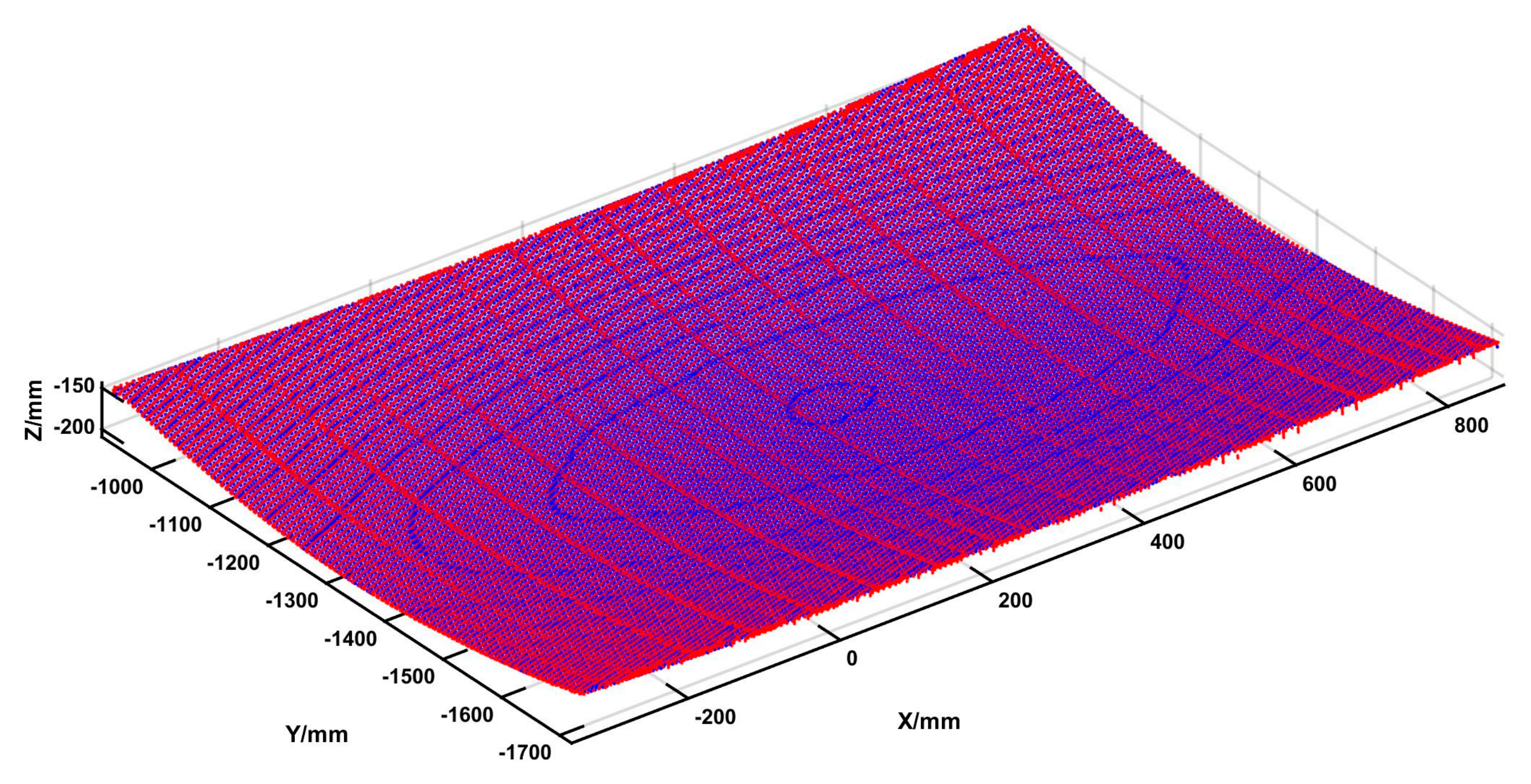

2.1. Research on the Point Cloud Data Preprocessing

2.1.1. Surface Point Cloud Data Preprocessing

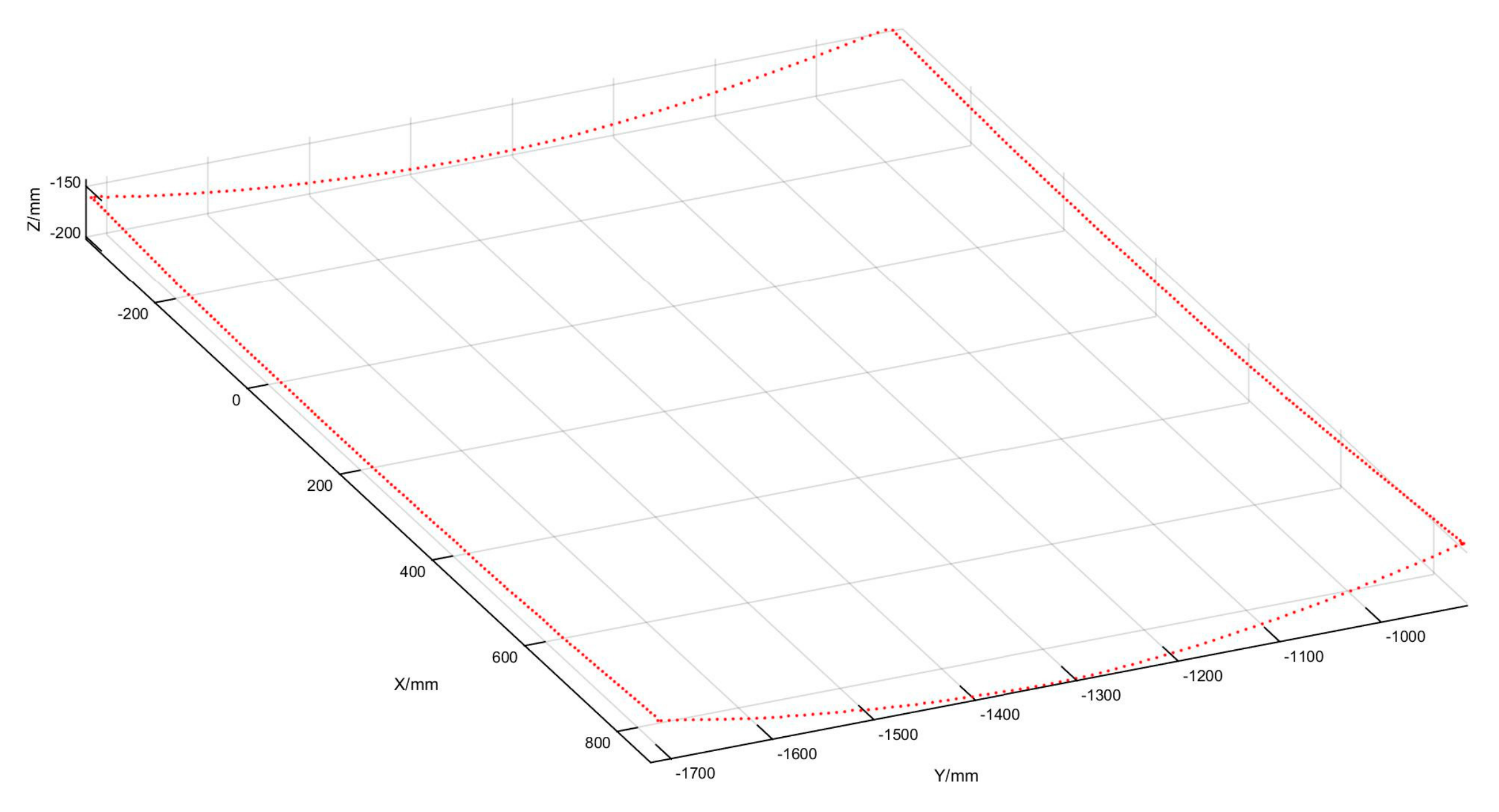

2.1.2. Boundary Point Cloud Data Preprocessing

- (1)

- External point reduction processing on the boundary point cloud dataset: for the external point that deviates from the original boundary, the external point is filtered based on the curvature value, and the point is removed at the location where the curvature changes greatly.

- (2)

- Spline interpolation: The boundary is expressed mathematically based on the cubic spline interpolation curve.

- (3)

- Base plane projection processing: The functional equations of the four boundaries are projected to the XY base plane, which is the plane where the outer plate is placed horizontally.

- (4)

- Finding the intersection point: The intersection point of each boundary projection is taken as the parameter of the input interpolation equation, and the average value of the function is used as the corner point.

2.2. Research on the Point Cloud Non-Penetrating Registration Method

2.2.1. Coarse Registration of Point Clouds Based on Boundary Information

- (1)

- Center of gravity registration: Based on the average value of the coordinates of each dimension of the point cloud data, the position of the center of gravity of the outer plate is obtained, and the translation makes the center of gravity of the point cloud of the design model coincide with the center of gravity of the point cloud of the measurement model.

- (2)

- Diagonal normal vector registration: According to the coordinates of the four corner points, find the cross product of the two diagonal vectors, that is, the normal vector of the geometric center of the surface, and rotate and align the two normal vectors.

- (3)

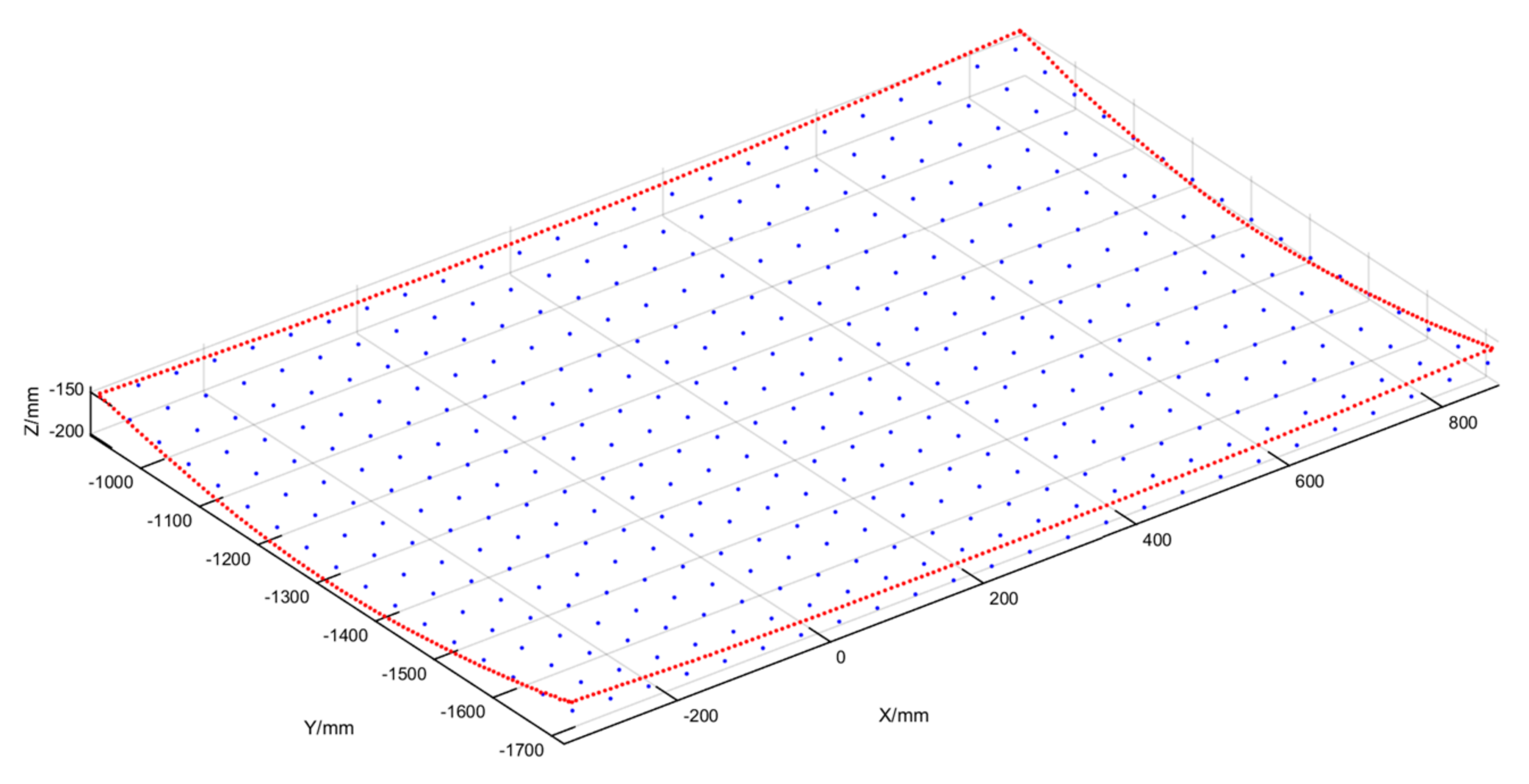

- Midpoint registration: Based on the calculated corner coordinates, calculate the theoretical midpoint position of the upper and lower left and right sides and find the actual midpoint position according to the minimum distance from the point cloud data to the theoretical midpoint. According to the midpoint set of the design model and the measurement model, the position of the centroid of the point set is calculated and the covariance matrix is established. The optimal rotation matrix from the design model to the measurement model is obtained by using the Singular Value Decomposition (SVD) method [13]. After rotation, the difference between the centroid of the design model point set and the centroid of the measurement model is calculated as the translation vector. Finally, the point set obtained in step 2 is rotated and translated. A set of point sets and outer plate boundary point cloud data is constructed for coarse registration, and the registration results are shown in Figure 5. The blue dots are the design values used for coarse registration algorithm experiments.

2.2.2. Precise Registration of Point Clouds Based on ICP

2.2.3. Non-Penetrating Registration Based on Nonlinear Constraint

Optimization Problems

2.3. Research on Digital Template Detection Technology

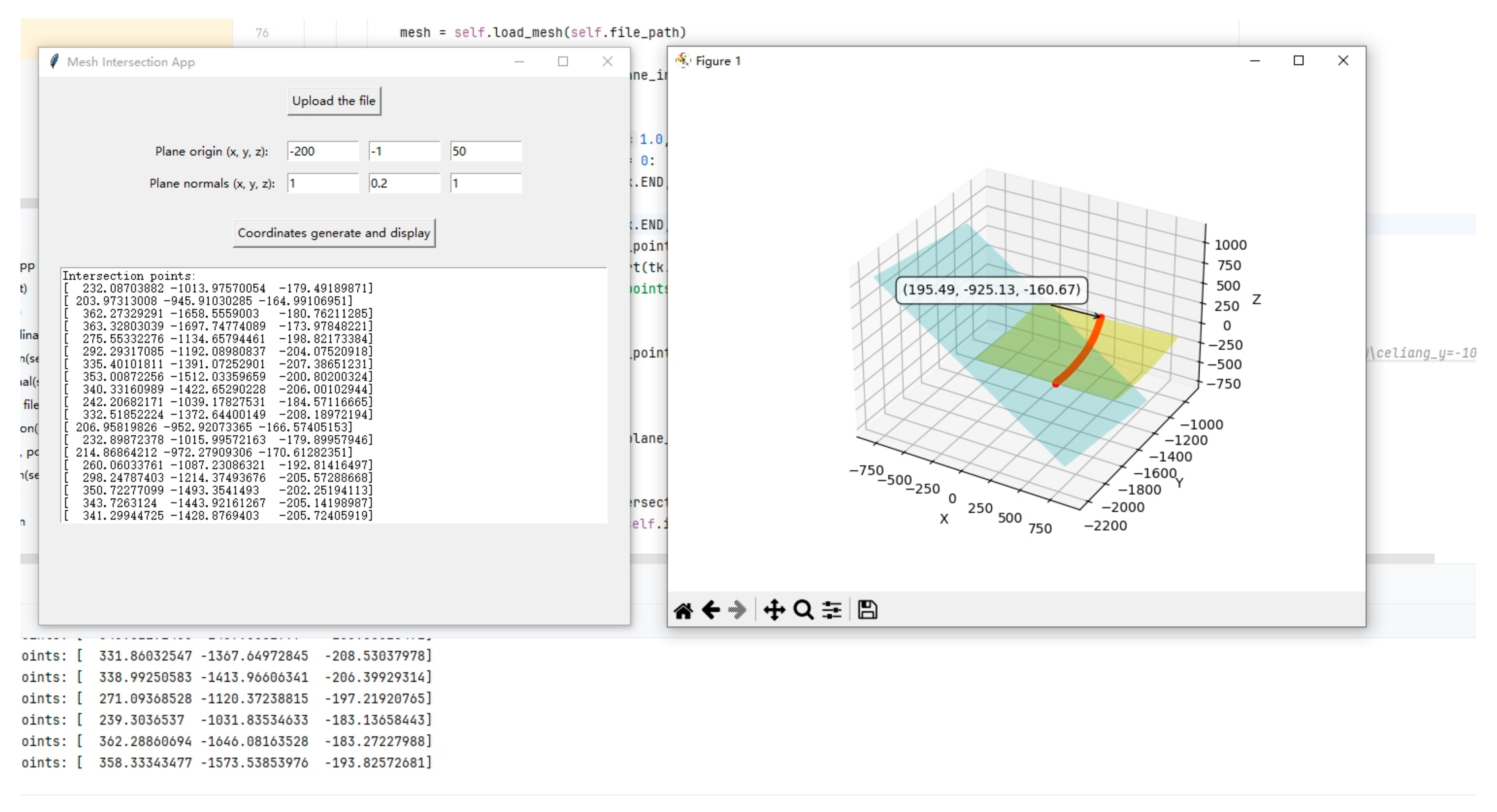

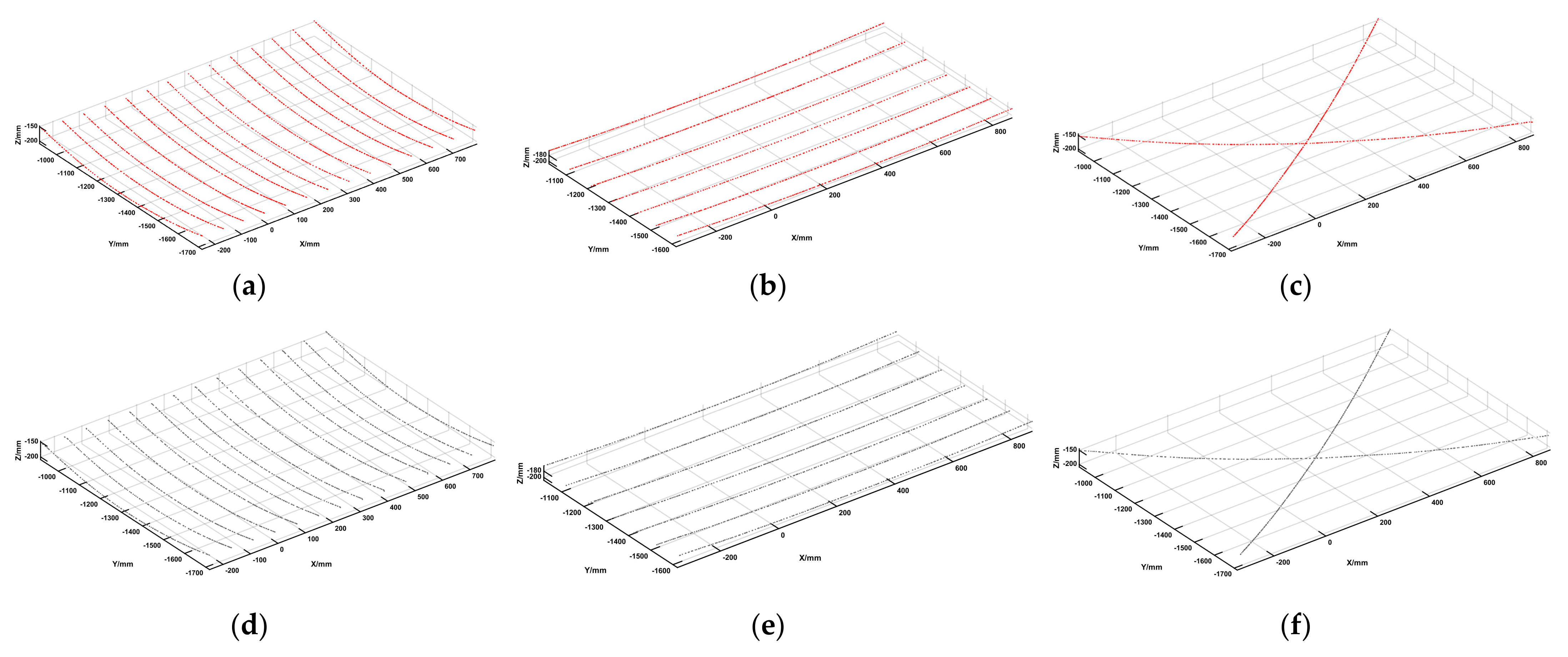

2.3.1. Digital Template and Detection Line Extraction

- (1)

- Enter the cross-section position information, including the three-dimensional coordinates of the cross-section origin and the normal vector of the cross-section.

- (2)

- Obtain the triangle patch and vertex index. Obtain the vertex index from the patch index, then obtain the vertex XYZ coordinate index.

- (3)

- Filter the triangular patch according to the cross-section information. First, the projection of each triangular patch perpendicular to the cross-sectional direction is obtained, according to the cross-sectional position such as X = X0. Then, the three coordinates X1, X2, X3 of each triangle patch in the X direction are sorted and the triangular patch through the cross-section is obtained according to the relationship X0 ≤ Max(Xi) & X0 ≥ Min(Xi). Then, the triangle patch is divided into a right triangle and non-right triangle, and the position relationship between the triangle patch and the cross-section is divided into three categories according to the sorting results, namely, the cross-section located between the left vertex and the middle vertex (XL < X0 < XM), the cross-section located at the middle vertex (XM = X0), and the cross-section located between the right vertex and the middle vertex (XM < X0 < XR).

- (4)

- Calculate the intersection point of the cross-section and the triangle patch. For the right-angled triangle, if the cross-section is tangent to the right-angled edge, the two vertex coordinates corresponding to the right-angled edge are output. Otherwise, the intersection is calculated according to the law of similar triangles. For non-right-angled triangles, the intersection coordinates are calculated according to the spatial coordinate calculation method according to the classification results. The classification of triangular patches is shown in Figure 8.

2.3.2. Standard of Detection

- (1)

- Deflection deviation integral

- (2)

- The average value of the deflection deviation

- (3)

- The maximum value of deflection deviation

- (4)

- Curvature deviation integral

- (5)

- The average value of curvature deviation

- (6)

- The maximum deviation of curvature

3. Results

4. Conclusions

- (1)

- The coarse registration method based on boundary information and the point cloud non-penetration registration method effectively solve the problems of low matching efficiency and point cloud penetration of complex surfaces, so that the detection results are in line with the actual engineering conditions.

- (2)

- Based on the digital template and detection line extraction technology of Delaunay triangulation, any number of detection point data can be quickly extracted with a detection accuracy better than 1 mm.

- (3)

- Based on the digital forming inspection standard, the visual inspection report can be quickly generated. The detection efficiency is increased by more than 75% compared with the traditional method, and the detection results can directly guide the prediction of secondary processing parameters, which provide a reliable technical solution for the digital inspection of the outer hull panel.

- (1)

- Aiming at the point cloud penetration problem that occurs after ICP registration of the design surface model and the measurement surface model, a point cloud non-penetration registration method based on the nonlinear constraint optimization problem is proposed. The registration algorithm is designed based on the SQP method, which effectively solves the point cloud penetration problem and makes the digital sample detection method in this paper conform to the actual situation of the project.

- (2)

- A digital forming detection method of a curved hull plate combined with deflection deviation and bending degree deviation was proposed, and the detection object was divided into transverse, longitudinal, and diagonal detection lines. The overall forming situation of the curved plate was effectively reflected through the indicators of deviation integral, average value, and maximum value, and the accuracy of the digital forming detection method was improved.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ICP | Iterative Closest Point |

| PCA | Principal Component Analysis |

| SVD | Singular Value Decomposition |

| SQP | Sequential Quadratic Programming |

References

- Shun, W.; Yibing, W.; Ji, W.; Rui, L. Development and Application of Line Heating Forming Difficulty Evaluation System for Curved Hull Plate. Ship Eng. 2023, 45, 143–147. [Google Scholar]

- Hiekata, K.; Mitsuyuki, T.; Okada, K.; Furukawa, Y. Development of Curvature Gap Estimation System for Deciding Thermal Forming Instructions of Ship Curved Shell Plates Using Laser Scanner. Int. J. Autom. Technol. 2018, 12, 339–347. [Google Scholar] [CrossRef]

- Guiyang, D. Research on Key Technologies of Robot Control and Forming in Line Heating; Guangdong University of Technology: Guangdong, China, 2019. [Google Scholar] [CrossRef]

- Yamauchi, T.; Tango, Y. 2018A-GS18-2 Practical Application of Measurement and Evaluation System for Curved Shell Plate. Conf. Proc. Jpn. Soc. Nav. Archit. Ocean Eng. 2018, 27, 463–465. [Google Scholar]

- Shin, J.G.; Ryu, C.H.; Nam, J.H. A comprehensive line-heating algorithm for automatic formation of curved shell plates. J. Ship Prod. 2004, 20, 69–78. [Google Scholar] [CrossRef]

- Xijin, Z.; Jing, Z.; Zhenqi, L.; Minzheng, H.; Rundang, Y. Introduction of Online Detection Technology and System Application for Hull Curved Plate Forming. Shipbuild. Technol. 2013, 04, 53–56. [Google Scholar]

- Ling, Z.; Yang, Y.; Feng, Y.; Yong, H. Binocular Vision Measurement Method of Curved Hull Plate. Shipbuild. Technol. 2021, 49, 50–55. [Google Scholar]

- Shi, D. Research on 3D Measurement Technology of Water and Heat Bending Based on Binocular Vision; Jiangsu University of Science and Technology: Zhenjiang, China, 2023. [Google Scholar]

- Chen, X.; Wei, C.; Xin, Z.; Zhao, J.; Xian, J. Ship Detection under Low-Visibility Weather Interference via an Ensemble Generative Adversarial Network. J. Mar. Sci. Eng. 2023, 11, 20–65. [Google Scholar] [CrossRef]

- Le-Dinh, T.; Tran, H. Aspects in Vessel System Offsets Survey Using 3-D Laser Scanning System; IOP Publishing Ltd.: Bristol, UK, 2025. [Google Scholar]

- Abbas, M.A.; Lichti, D.D.; Chong, A.K.; Setan, H.; Majid, Z.; Lau, C.L.; Idris, K.M.; Ariff, M.F.M. Improvements to the accuracy of prototype ship models measurement method using terrestrial laser scanner. Measurement 2017, 100, 301–310. [Google Scholar] [CrossRef]

- Mao, C.; Yu, R.; Song, A. A Depth Camera Hand-Eye Calibration Method Combined with TCP Calibration. J. Instrum. 2023, 44, 280–286. [Google Scholar]

- Jiajun, L.; Yi, A.; Pan, Q.; Hong, G. 3D Color Point Cloud Registration Based on Deep Learning Image Descriptors. J. Dalian Univ. Technol. 2021, 61, 316–323. [Google Scholar]

- Monji-Azad, S.; Kinz, M.; Männel, D.; Scherl, C.; Hesser, J. Robust-DefReg: A robust coarse to fine non-rigid point cloud registration method based on graph convolutional neural networks. Meas. Sci. Technol. 2025, 36, 015426. [Google Scholar] [CrossRef]

- Zhao, F.; Huang, H.; Hu, W. An optimized hierarchical point cloud registration algorithm. Multimed. Syst. 2025, 31, 14. [Google Scholar] [CrossRef]

- Shen, H.Q.; Son, S.H.; Kim, Y.M.; Ryu, C.H.; Shin, J.G. Forming Information Calculation Algorithm of 3-D Template for Evaluation of Curved Hull Plates. Procedia Cirp 2017, 62, 411–416. [Google Scholar] [CrossRef]

- Zhuoming, X.; Lianglun, C.; Zhouyan, Z.; Qiong, H.; Yikun, C. Quantitative Evaluation Method for Hull Outer Plate Forming Effect. China Test. 2016, 42, 20–24. [Google Scholar]

- GB/T34000–2016; China Shipbuilding Quality Standards. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Standardization Administration of China: Beijing, China, 2016.

| Coarse Registration Method | The Average Distance Between the Nearest Points (mm) | Average Run Time (s) |

|---|---|---|

| Boundary feature point registration | 21.3814 | 5.76 |

| SAC_IA | 111.4346 | 46.85 |

| RANSAC | 147.4253 | 55.87 |

| Evaluation Parameters | 3D Point Cloud | 2D Point Cloud | |

|---|---|---|---|

| SQP | Iteration duration (s) | 3.19 | 1.49 |

| The number of iterations (times) | 24 | 6 | |

| Optimum (mm2) | 1864.018 | 1868.359 | |

| Interior point method | Iteration duration (s) | 2.22 | 1.28 |

| The number of iterations (times) | 118 | 17 | |

| Optimum (mm2) | 2020.751 | 1893.478 |

| Detection Line Serial Number | SZ (mm2) | SZ-average (mm) | Zmax (mm) | CI | SC-average (mm−1) | Cmax (mm−1) |

|---|---|---|---|---|---|---|

| 1 | 375.8725 | 0.4764 | 0.8807 | 1.8057 | 0.0023 | 0.1582 |

| 2 | 356.7683 | 0.4551 | 0.8964 | 3.6764 | 0.0047 | 0.0155 |

| 3 | 422.3746 | 0.5385 | 0.8770 | 4.8851 | 0.0062 | 0.0649 |

| 4 | 340.2731 | 0.4327 | 0.7411 | 1.5328 | 0.0019 | 0.0523 |

| 5 | 411.7066 | 0.5235 | 0.8595 | 2.1162 | 0.0027 | 0.2678 |

| 6 | 411.9992 | 0.5239 | 0.8627 | 1.5823 | 0.0020 | 0.2822 |

| 7 | 448.9025 | 0.5691 | 0.9254 | 3.7085 | 0.0047 | 0.7123 |

| 8 | 408.2246 | 0.5155 | 2.2003 | 3.3758 | 0.0042 | 0.1708 |

| 9 | 448.0905 | 0.5657 | 1.0755 | 5.1318 | 0.0064 | 0.5579 |

| 10 | 557.3721 | 0.7092 | 1.2392 | 2.7188 | 0.0034 | 0.2987 |

| 11 | 512.2590 | 0.6523 | 1.2647 | 4.3445 | 0.0052 | 1.2255 |

| 12 | 548.2442 | 0.7024 | 1.2141 | 2.9446 | 0.0037 | 0.2882 |

| 13 | 358.0468 | 0.4527 | 0.7706 | 2.2842 | 0.0029 | 0.0409 |

| 14 | 443.7020 | 0.5620 | 1.0194 | 1.3883 | 0.0017 | 0.0395 |

| Detection Line Serial Number | SZ (mm2) | SZ-average (mm) | Zmax (mm) | CI | SC-average (mm−1) | Cmax (mm−1) |

|---|---|---|---|---|---|---|

| 1 | 788.9903 | 0.6564 | 1.1554 | 9.7685 | 0.0070 | 0.1417 |

| 2 | 764.9880 | 0.6380 | 1.4043 | 9.9301 | 0.0083 | 0.3391 |

| 3 | 770.4791 | 0.6399 | 1.2152 | 8.7202 | 0.0072 | 0.4177 |

| 4 | 637.4193 | 0.5324 | 1.1445 | 11.9461 | 0.0100 | 0.0669 |

| 5 | 656.6828 | 0.5470 | 1.0935 | 7.8518 | 0.0065 | 0.1204 |

| 6 | 1462.5702 | 1.2106 | 1.7366 | 18.7312 | 0.0143 | 0.1882 |

| 7 | 570.4808 | 0.4747 | 1.2329 | 13.5704 | 0.0113 | 0.1998 |

| Detection Line Serial Number | SZ (mm2) | SZ-average (mm) | Zmax (mm) | CI | SC-average (mm−1) | Cmax (mm−1) |

|---|---|---|---|---|---|---|

| 1 | 1571.0582 | 0.9338 | 1.8061 | 8.7122 | 0.0052 | 0.0194 |

| 2 | 1991.5769 | 1.1651 | 2.0169 | 8.6182 | 0.0050 | 0.0905 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Wang, B.; Liu, Y.; Li, R.; Huo, S.; Shi, J.; Pang, L. Research on the Forming Detection Technology of Shell Plates Based on Laser Scanning. J. Mar. Sci. Eng. 2025, 13, 1057. https://doi.org/10.3390/jmse13061057

Wang J, Wang B, Liu Y, Li R, Huo S, Shi J, Pang L. Research on the Forming Detection Technology of Shell Plates Based on Laser Scanning. Journal of Marine Science and Engineering. 2025; 13(6):1057. https://doi.org/10.3390/jmse13061057

Chicago/Turabian StyleWang, Ji, Baichen Wang, Yujun Liu, Rui Li, Shilin Huo, Jiawei Shi, and Lin Pang. 2025. "Research on the Forming Detection Technology of Shell Plates Based on Laser Scanning" Journal of Marine Science and Engineering 13, no. 6: 1057. https://doi.org/10.3390/jmse13061057

APA StyleWang, J., Wang, B., Liu, Y., Li, R., Huo, S., Shi, J., & Pang, L. (2025). Research on the Forming Detection Technology of Shell Plates Based on Laser Scanning. Journal of Marine Science and Engineering, 13(6), 1057. https://doi.org/10.3390/jmse13061057