Acoustic Measurements and Simulations on Yachts: An Evaluation of Airborne Sound Insulation

Abstract

1. Introduction

2. Materials and Methods

2.1. Comfort Classes for Yachts

- Class annotations, which serve to certify that the vessel complies with noise and vibration criteria and are subject to a periodic inspection regime.

- Compliance certificates, which serve to certify that the vessel complies with the noise and vibration criteria.

2.2. Procedure

- 1.

- Selection of a boat to be used as a case study. It was necessary to have a boat already set up, for which the distribution diagrams and technical specifications of the internal structures were available and on which it was possible to carry out measurements on board.

- 2.

- Analysis of the layout of the decks, identification of the most important (from the acoustic comfort point of view) spaces and, consequently, the stratigraphy of the related bulkheads and the properties of the used materials.

- 3.

- Calculation of the weighted sound reduction index with the use of simulation software by modeling the stratigraphy provided by the manufacturer and the related materials.

- 4.

- On-board measurements of the weighted sound reduction index of the boat’s internal bulkheads using the measurement procedures typically used in construction.

- 5.

- Analysis and comparison of the results obtained using the simulations and measurements on board.

- 6.

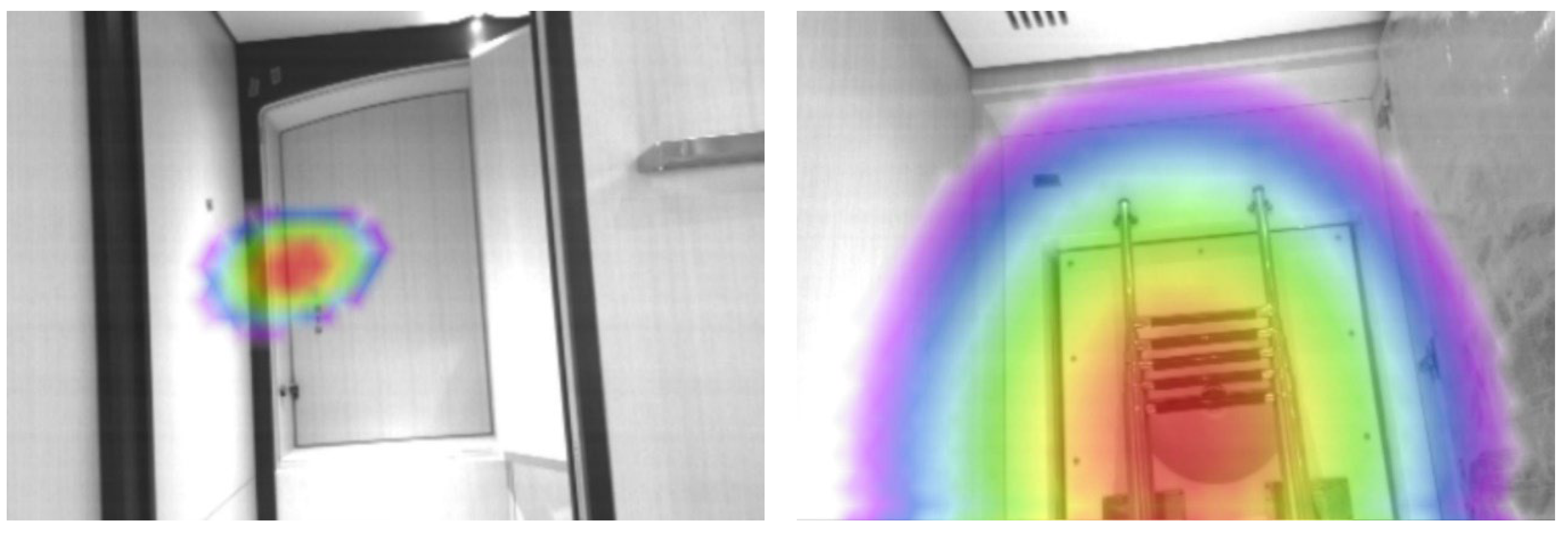

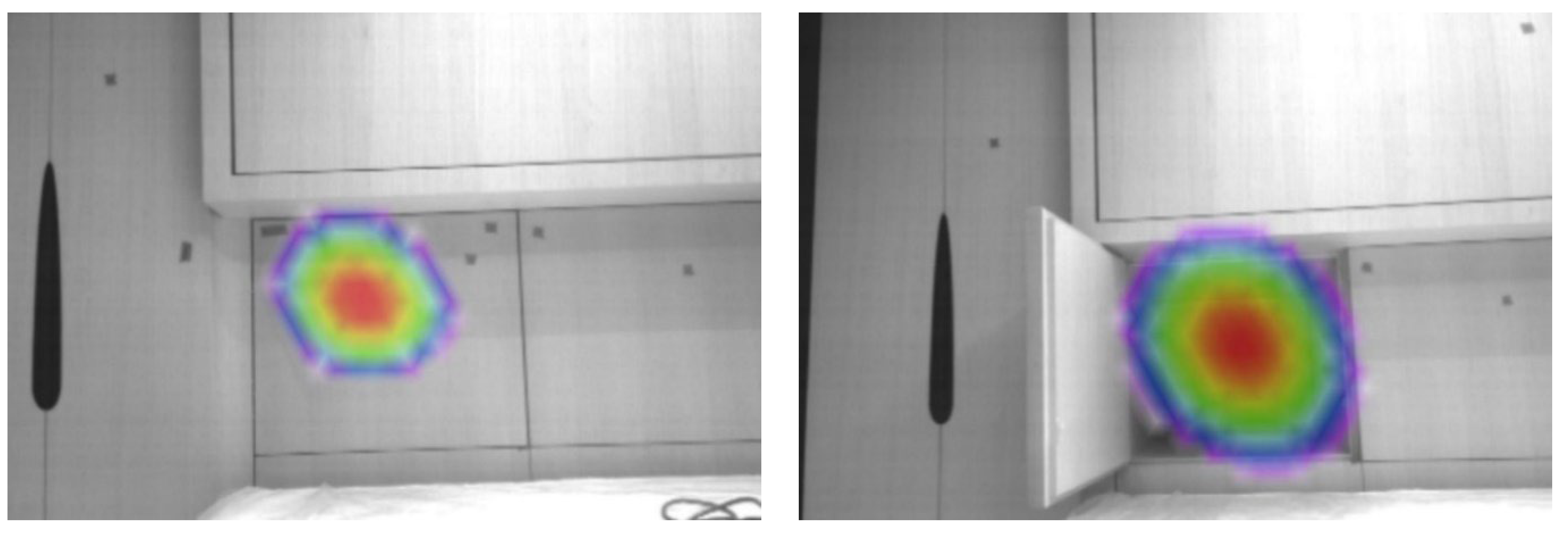

- Identification of any critical and problematic aspects encountered in the comparison between the simulations and measurements on board and the performance of the acoustic measurements obtained using an acoustic camera.

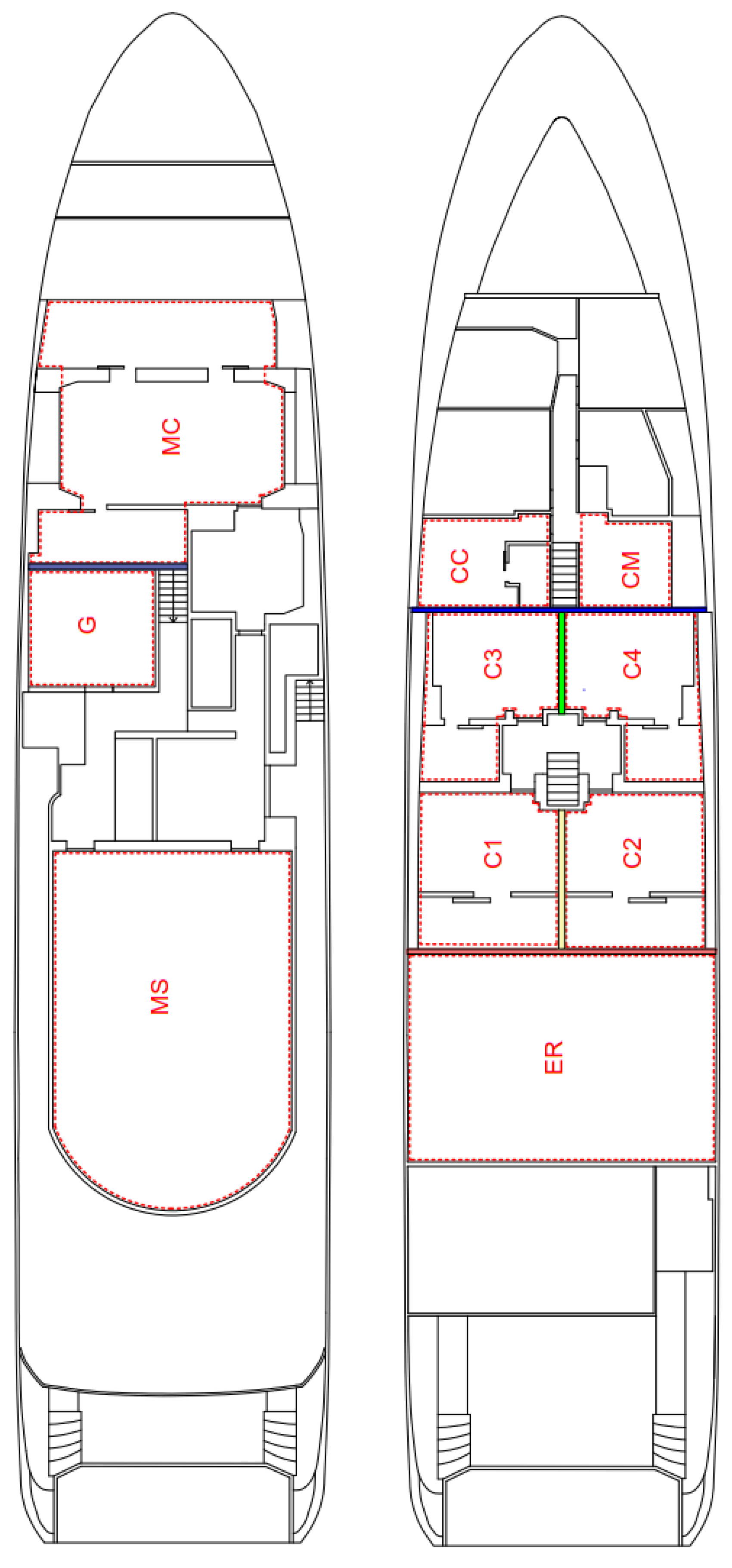

3. Case Study

4. Application of the Proposed Procedure to the Case Study

4.1. Determination of Apparent Weighted Sound Reduction Index (R′w)

4.2. Measurement of Apparent Weighted Sound Reduction Index (R′w)

- D is the difference in the sound pressure level (dB).

- L1 and L2 are sound pressure levels (dB) in the emitting room and in the receiving room, respectively.

- T is the reverberation time in the receiving room (s).

- T0 is the reference reverberation time (s) which, for the lived enclosed environment, is equal to 0.5 s.

Measurement Instruments

- A sound meter 01dB Fusion, model 11021 (Acoem, Limonest, France), and certificate of calibration LAT 068 47704-A, with microphone preamp 01dB Pre22, model 1605118, and microphone 01dB, model 226229.

- An omnidirectional sound source with Norsonic power amplifier 260 (23364) and speaker 229 (Norsonic, Tramby, Norway).

5. Results

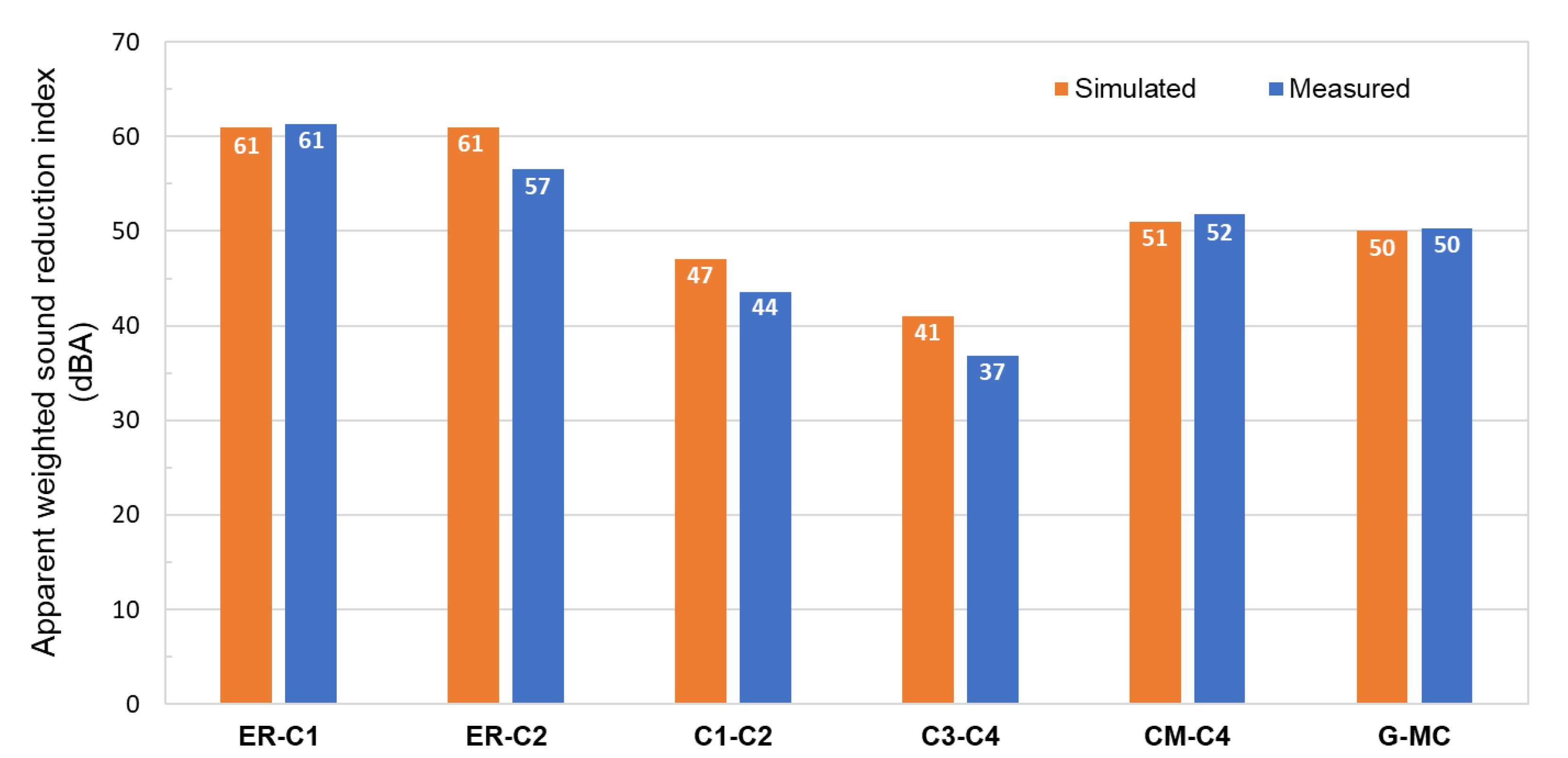

5.1. Results of Acoustic Simulations

5.2. Results of On-Board Measurements

6. Discussion

7. Conclusive Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| C | Spectrum adaptation term for pink noise |

| Ctr | Spectrum adaptation term for low and medium frequencies noise |

| D | Difference in the sound pressure level (dB) |

| DnT | Standardized difference in the sound pressure level (dB) |

| L1 | Sound pressure levels (dB) in the emitting room |

| L2 | Sound pressure levels (dB) in the receiving room |

| K | Flanking contribution factor |

| M′ | Surface mass |

| Rw | Airborne sound insulation (dBA) |

| R′w | Apparent weighted airborne sound insulation index (dBA) |

| S | Surface (m2) |

| T | Reverberation time in the receiving room (s) |

| T0 | Reference reverberation time (s) for the lived enclosed environment (0.5 s) |

| V | Volume (m3) |

Abbreviations

| ABS | American Bureau of Shipping |

| BV | Bureau Veritas |

| CAC | Crew Accommodation Comfort |

| CC | Crew cabin |

| CM | Crew mess |

| C1, C2 | VIP cabins |

| C3, C4 | Guest cabins |

| DNV-GL | Det Norske Veritas and Germanischer Lloyd |

| ER | Engine Room |

| EVOB | Eigen Value-Optimized Beamforming algorithm |

| G | Galley |

| LR | Lloyd’s Register |

| MS | Main saloon |

| MC | Master cabin |

| PAC | Passenger Accommodation Comfort |

| PCAC | Passenger and Crew Accommodation Comfort |

| RINA | Registro Italiano Navale |

References

- Duman, I.I. Human Comfort in Yacht Spaces. Br. J. Arts Soc. Sci. 2015, 19, 68–75. [Google Scholar]

- Pais, T.; Moro, L.; Boote, D.; Biot, M. Vibration Analysis for the Comfort Assessment of Superyachts. J. Mar. Sci. Appl. 2017, 16, 323–333. [Google Scholar] [CrossRef]

- Cakici, F.; Sukas, O.F.; Alkan, A.D. An Investigation of Comfort on Board Calculations for a Passenger Catamaran and a Yacht. In Proceedings of the INT-NAM Conference at Yildiz Technical University, Istanbul, Turkey, 23–24 October 2014. [Google Scholar]

- Fantozzi, F.; Rocca, M. An extensive collection of evaluation indicators to assess occupants’ health and comfort in indoor environment. Atmosphere 2020, 11, 90. [Google Scholar] [CrossRef]

- Leccese, F.; Rocca, M.; Salvadori, G.; Belloni, E.; Buratti, C. A multicriteria method to identify and rank IEQ criticalities: Measurements and applications for existing school buildings. Energy Built Environ. 2025, 6, 387–401. [Google Scholar] [CrossRef]

- Duman, I.I.; Zengel, R. Effects of Physical Design features to human comfort on floating spaces. Open House Int. 2016, 41, 93–100. [Google Scholar] [CrossRef]

- Liu, H.; Zhan, L.; Lin, X.; Gong, Z. Study of comprehensive comfort evaluation based on fuzzy method in the ship’s cabins. Therm. Sci. Eng. Prog. 2024, 53, 102738. [Google Scholar] [CrossRef]

- Goujard, B.; Sakout, A.; Valeau, V. Acoustic comfort on board ships: An evaluation based on a questionnaire. Appl. Acoust. 2005, 66, 1063–1073. [Google Scholar] [CrossRef]

- Aydin, M.; Yilmaz Aydin, T.; Guntekin, E. Noise and Vibration damping for yacht interior. Mugla J. Sci. Technol. 2016, 2, 166–170. [Google Scholar] [CrossRef][Green Version]

- Borelli, D.; Gaggero, T.; Rizzuto, E.; Schenone, C. Onboard ship noise: Acoustic comfort in cabins. Appl. Acoust. 2021, 177, 107912. [Google Scholar] [CrossRef]

- Prato, A.; Silvestri, P.; Pais, T.; Gaggero, F.; Schiavi, A. Airborne sound transmission loss of ship bulkheads: A new methodological approach for in-laboratory assessment by including low frequencies. Ocean Eng. 2023, 285, 115428. [Google Scholar] [CrossRef]

- Bocanegra, J.A.; Borelli, D.; Gaggero, T.; Rizzuto, E.; Schenone, C. Characterizing onboard noise in ships: Insights from statistical, machine learning and advanced noise index analyses. Ocean Eng. 2023, 285, 115273. [Google Scholar] [CrossRef]

- Borelli, D.; Gaggero, T.; Rizzuto, E.; Schenone, C. Analysis of noise on board a ship during navigation and manoeuvres. Ocean Eng. 2015, 105, 256–269. [Google Scholar] [CrossRef]

- Liu, H.; Lin, X.; Gong, Z.; Shi, J. Combined Annoyance Assessment of Ship Structural Vibration and Ambient Noise. Buildings 2023, 13, 363. [Google Scholar] [CrossRef]

- Boote, D.; Pais, T.; Dellepiane, S. Vibrations of Superyacht Structures: Comfort Rules and Predictive Calculations. In Analysis and Design of Marine Structure 2013, 1st ed.; CRC Press: Boca Raton, FL, USA, 2013; ISBN 9780429212550. [Google Scholar]

- Seiler, R.D.; Holdbach, G. Acoustic quality on board ships. Proceeding Meet. Acoust. 2013, 19, 040132. [Google Scholar] [CrossRef]

- Rocca, M.; Di Puccio, F.; Forte, P.; Leccese, F. Acoustic comfort requirements and classifications: Buildings vs. yachts. Ocean Eng. 2022, 255, 111374. [Google Scholar] [CrossRef]

- Silvestri, P.; Pais, T.; Vergassola, G. The role of structural and insulating material in the structure-borne noise propagation of superyachts. Mech. Based Des. Struct. Mach. 2024, 53, 3349–3368. [Google Scholar] [CrossRef]

- American Bureau of Shipping (ABS). Guide for Comfort on Yacht; American Bureau of Shipping: Spring, TX, USA, 2019. [Google Scholar]

- Bureau Veritas (BV). Rules for the Classification of Steel Ships—Part F: Additional Class Notations; NR 467.F1 DT R18 E; Marine & Offshore: Paris, France, 2025. [Google Scholar]

- Det Norske Veritas and Germanischer Lloyd (DNV GL). Rules for Classification—Ships; Det Norske Veritas and Germanischer Lloyd (DNV GL): Oslo, Norway, 2021. [Google Scholar]

- Lloyd’s Register of Shipping (LR). Rules and Regulations for the Classification of Special Service Crafts; Lloyd’s Register of Shipping (LR): London, UK, 2020. [Google Scholar]

- Registro Italiano Navale (RINA). Rules for the Classification of Yacht—Part E: Additional Class Notations; Registro Italiano Navale (RINA): Genova, Italy, 2025. [Google Scholar]

- Sharp, B. Prediction Methods for the Sound Transmission of Building Elements. Noise Control Eng. 1978, 11, 53–63. [Google Scholar] [CrossRef]

- Cremer, L.; Heckl, M.; Petersson, B.A.T. Structure-Borne Sound. In Structural Vibrations and Sound Radiation at Audio Frequencies, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar] [CrossRef]

- Fahy, F.; Gardonio, P. Sound and Structural Vibration. In Radiation, Transmission and Response, 2nd ed.; Academic Press: Cambridge, MA, USA, 2007. [Google Scholar] [CrossRef]

- Rindel, J.H. Sound Radiation form Building Structures and Acoustical Properties of Thick Plates. In Proceedings of the COMETT-SAVOIR Course, Noise Control in Buildings—Up-to-Date Practice CSTB, Grenoble, France, 16–18 March 1995. [Google Scholar]

- UNI/TR 11175-1:2024; Acustica in Edilizia—Linee Guida Per la Previsione Delle Prestazioni Acustiche Degli Edifici—Applicazione Delle Norme Tecniche Alla Tipologia Costruttiva Nazionale—Parte 1: Metodo di Calcolo Semplificato Basato su Grandezze a Numero Unico. Ente Nazionale Italiano di Unificazione: Milano, Italy, 2024.

- UNI/TR 11175-2:2024; Acustica in Edilizia—Linee Guida Per la Previsione Delle Prestazioni Acustiche Degli Edifici—Applicazione Delle Norme Tecniche Alla Tipologia Costruttiva Nazionale—Parte 2: Dati di Ingresso per il Modello di Calcolo. Ente Nazionale Italiano di Unificazione: Milano, Italy, 2024.

- Marinò, A. Costruzioni Navali in Composito. Università Degli Studi di Trieste. 2016. Available online: https://moodle2.units.it/pluginfile.php/187366/mod_resource/content/0/Alberto%20Marin%C3%B2%20-%20Costruzioni%20Navali%20in%20Composito%20%282016%29.pdf (accessed on 29 April 2025).

- Tang, X.; Yan, X. Airflow resistance of acoustical fibrous materials: Measurements, calculations and applications. J. Ind. Text. 2020, 49, 981–1010. [Google Scholar] [CrossRef]

- ISO 16283; Acoustics—Field Measurement of Sound Insulation in Buildings and of Building Elements. Part 1: Airborne Sound Insulation. International Organization for Standardization: Geneva, Switzerland, 2014.

- Kanka, S.; Fredianelli, L.; Artuso, F.; Fidecaro, F.; Licitra, G. Evaluation of Acoustic Comfort and Sound Energy Transmission in a Yacht. Energies 2023, 16, 808. [Google Scholar] [CrossRef]

- ISO 3382-2; Acoustics—Acoustics. Measurement of Room Acoustic Parameters. Part 2: Reverberation Time in Ordinary Rooms. International Organization for Standardization: Geneva, Switzerland, 2008.

- Sijtsma, P. Experimental Techniques for Identification and Characterization of Noise Sources; Technical Report NLR-TP-2004-165; National Aerospace Laboratory NLR: Amsterdam, The Netherlands, 2004; pp. 1–47. [Google Scholar]

- Hald, J. Basic theory and properties of statistically optimized near-field acoustical holography. J. Acoust. Soc. Am. 2009, 125, 2105–2120. [Google Scholar] [CrossRef]

- Sijtsma, P. CLEAN Based on Spatial Source Coherence. Int. J. Aeroacoust. 2007, 6, 357–374. [Google Scholar] [CrossRef]

- Schmidt, R.O. Multiple Emitter Location and signal Parameter Estimation. IEEE Trans. Antennas Propag. 1986, 34, 276–280. [Google Scholar] [CrossRef]

- Capon, J. High-resolution frequency-wavenumber spectrum analysis. Proc. IEEE 1969, 57, 1408–1418. [Google Scholar] [CrossRef]

- Brooks, T.F.; Humphreys, W.M. A Deconvolution Approach for the Mapping of Acoustic Sources (DAMAS) Determined from Phased Microphone Arrays. J. Sound Vib. 2006, 294, 856–879. [Google Scholar] [CrossRef]

- Licitra, G.; Artuso, F.; Bernardini, M.; Moro, A.; Fidecaro, F.; Fredianelli, L. Acoustic Beamforming Algorithms and Their Applications in Environmental Noise. Curr. Pollut. Rep. 2023, 9, 486–509. [Google Scholar] [CrossRef]

- Vergassola, G. The prediction of noise propagation onboard pleasure crafts in the early design stage. J. Ocean Eng. Mar. Energy 2020, 6, 15–30. [Google Scholar] [CrossRef]

| Airborne Sound Insulation | Rw (dBA) |

|---|---|

| Cabin to cabin | 38 |

| Messrooms, recreation rooms, public spaces and entertainment areas, to cabins and hospitals | 48 |

| Corridor to cabin | 33 |

| Cabin to cabin with a communicating door | 33 |

| Apparent Weighted Airborne Sound Insulation Index R′w (dBA) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Class Society | BV | DNV GL | LR | RINA | |||||||

| Comfort Class | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | A | B |

| Passengers areas | |||||||||||

| Top grade Cabin—Top grade cabin Cabin | 45 | 42 | 40 | 46 | 43 | 40 | 45 | 42 | 40 | 43 | 35 |

| Standard Cabin—Standard Cabin | 41 | 38 | 36 | 41 | 38 | 35 | 41 | 39 | 38 | 40 | 35 |

| Top grade Cabin—Corridor or communicating cabin | 42 | 40 | 37 | 41 | 39 | 37 | 42 | 40 | 37 | 40 | 35 |

| Standard Cabin—Corridor or communicating cabin | 42 | 40 | 37 | 38 | 35 | 33 | 38 | 36 | 35 | 40 | 35 |

| Top grade Cabin—Stairs | 48 | 45 | 45 | - | - | - | 50 | 47 | 45 | 48 | 45 |

| Standard Cabin—Stairs | 48 | 45 | 45 | - | - | - | 47 | 45 | 43 | 48 | 45 |

| Top grade Cabin—Mess rooms, recreation rooms, public spaces | 55 | 53 | 50 | 56 | 53 | 50 | 55 | 50 | 50 | 53 | 48 |

| Standard Cabin—Mess rooms, recreation rooms, public spaces | 55 | 53 | 50 | 51 | 48 | 45 | 52 | 48 | 48 | 53 | 48 |

| Cabin—Public spaces designed for loud music | 64 | 62 | 60 | - | - | - | 60 | 60 | 60 | 65 | 55 |

| Crew areas | |||||||||||

| Cabin—Cabin | 37 | 35 | 32 | 38 | 35 | 32 | - | - | - | 35 | 35 |

| Cabin—Corridor or communicating cabin | 35 | 32 | 30 | 37 | 32 | 28 | - | - | - | 33 | 27 |

| Top grade Cabin—Stairs | 35 | 32 | 30 | - | - | - | - | - | - | - | - |

| Cabin—Mess rooms, recreation rooms, public spaces | 45 | 45 | 45 | 50 | 47 | 42 | 35 | 30 | |||

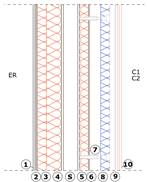

| Partition | Layer | Materials | Density (kg/m3) | Thickness (mm) |

|---|---|---|---|---|

| Bulkhead between Engine room and VIP cabins | ||||

| 1 | Sheet in aluminum and polyethylene | 2900 | 2 |

| 2 | Plastic polymer and mineral filler sound insulation | 2000 | 2 × 2.5 | |

| 3 | Mineral wool | 130 | 30 | |

| 4 | Mineral wool | 150 | 50 | |

| S | Glass-reinforced plastic (GRP) with PVC core | 600 | 44 | |

| 5 | Mineral Wool | 130 | 30 | |

| 6 | Plastic polymers and mineral fillers sound insulation | 2000 | 2 × 2.5 | |

| 7 | Dampign system | - | 100 | |

| 8 | Fiberglass | 66 | 30 | |

| 9 | Aluminum frame | - | - | |

| 10 | Composite panel wood–rubber cork–wood (8/6/8) | 615 | 22 | |

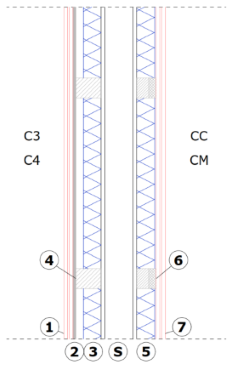

| Bulkhead between VIP cabins | ||||

| 1 | Fiberglass | 66 | 30 |

| 2 | Elastic sandwich spacer | - | 15 | |

| 3 | Composite panel wood–rubber cork–wood (8/6/8) | 615 | 15 | |

| S | Glass-reinforced plastic (GRP) with PVC core | 600 | 44 | |

| Bulkhead between VIP cabins and Standard cabins | ||||

| 1 | Composite panel wood–rubber cork–wood (8/6/8) | 615 | 15 |

| 2 | Plastic polymers and mineral fillers sound insulation | 2000 | 2.5 | |

| 3 | Fiberglass | 66 | 30 | |

| 4 | Rigid spacer | - | 40 | |

| S | Glass-reinforced plastic (GRP) with PVC core | 600 | 44 | |

| 5 | Fiberglass | 66 | 30 | |

| 6 | Elastic sandwich spacer | - | 15 | |

| 7 | Composite panel wood–rubber cork–wood (8/6/8) | 615 | 15 | |

| Materials | Layer | Density (kg/m3) | Thickness (mm) | Flow Resistivity (Rayl/m) | Young Modulus (Gpa) | Damping |

|---|---|---|---|---|---|---|

| Fiberglass | 66 | 30 | 29,200 | - | - | |

| Mineral wool | 130 | 30/50 | 77,500 | - | - | |

| Plastic polymers and mineral fillers sound insulation | 2000 | 2.5 | - | 6.00 | 0.010 | |

| Composite panel wood–rubber cork–wood (8/6/8) | Okumè wood | 530 | 6.0 | - | 1.82 | 0.020 |

| Rubber Cork | 950 | 8.0 | - | 7.0 | 0.100 | |

| Okumè wood | 530 | 6 | - | 1.82 | 0.020 | |

| Glass-reinforced plastic (GRP) with PVC core | GRP | 1600 | 1.6 | - | 4.7 | 0.010 |

| PVC core | 500 | 40 | - | 0.26 | 0.100 | |

| GRP | 1600 | 1.6 | - | 4.7 | 0.010 |

| Room | Nr. of Microphone Positions | Nr. of Sound Source Positions |

|---|---|---|

| C1 | 9 | 1 |

| C2 | ||

| C3 | 6 | 1 |

| C4 | ||

| MC | 5 | 2 |

| Room 1 | Room 2 | Nr. of Microphone Positions | Nr. of Sound Source Positions | Nr. of Background Positions |

|---|---|---|---|---|

| ER | C1 | 6 | - | 5 |

| ER | C2 | 6 | - | 5 |

| C2 | C1 | 5 | 5 | 5 |

| C3 | C4 | 5 | 5 | 5 |

| CM | C4 | 5 | 5 | 5 |

| G | MC | 5 | 5 | 5 |

| Room 1 | Room 2 | Thickness (mm) | Bulkhead Surface (m2) | M′ (kg/m2) | Rw (dB) | C (dB) | Ctr (dB) | K′ (dB) | R′w (dB) |

|---|---|---|---|---|---|---|---|---|---|

| ER | C1 | 220 | 9.4 | 80 | 64 | −2 | −7 | 3 | 61 |

| ER | C2 | 220 | 9.4 | 80 | 64 | −2 | −7 | 3 | 61 |

| C2 | C1 | 155 | 6.8 | 50 | 50 | −5 | −13 | 3 | 47 |

| C3 | C4 | 45 | 7.0 | 26 | 44 | −3 | −5 | 3 | 41 |

| CM | C4 | 185 | 7.0 | 53 | 54 | −6 | −14 | 3 | 51 |

| G | MC | 200 | 8.7 | 57 | 53 | −6 | −14 | 3 | 50 |

| Room 1 | Room 2 | DnT (dB) | R′w (dB) |

|---|---|---|---|

| ER | C1 | 61.5 | 61.3 |

| ER | C2 | 56.7 | 56.5 |

| C2 | C1 | 43.7 | 43.5 |

| C3 | C4 | 38.9 | 36.8 |

| CM | C4 | 53.8 | 51.8 |

| G | MC | 53.0 | 50.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rocca, M.; Di Puccio, F.; Forte, P.; Fidecaro, F.; Artuso, F.; Kanka, S.; Leccese, F. Acoustic Measurements and Simulations on Yachts: An Evaluation of Airborne Sound Insulation. J. Mar. Sci. Eng. 2025, 13, 988. https://doi.org/10.3390/jmse13050988

Rocca M, Di Puccio F, Forte P, Fidecaro F, Artuso F, Kanka S, Leccese F. Acoustic Measurements and Simulations on Yachts: An Evaluation of Airborne Sound Insulation. Journal of Marine Science and Engineering. 2025; 13(5):988. https://doi.org/10.3390/jmse13050988

Chicago/Turabian StyleRocca, Michele, Francesca Di Puccio, Paola Forte, Francesco Fidecaro, Francesco Artuso, Simon Kanka, and Francesco Leccese. 2025. "Acoustic Measurements and Simulations on Yachts: An Evaluation of Airborne Sound Insulation" Journal of Marine Science and Engineering 13, no. 5: 988. https://doi.org/10.3390/jmse13050988

APA StyleRocca, M., Di Puccio, F., Forte, P., Fidecaro, F., Artuso, F., Kanka, S., & Leccese, F. (2025). Acoustic Measurements and Simulations on Yachts: An Evaluation of Airborne Sound Insulation. Journal of Marine Science and Engineering, 13(5), 988. https://doi.org/10.3390/jmse13050988