Abstract

This study investigated the status of anchors for small fishing vessels that correspond with the risk factors of submarine cables, which are essential elements for offshore wind farms. As for target vessels, small coastal fishing vessels of less than ten tons were divided into four categories by tonnage, and 71 locations were compared from a total of 59 fishing vessels. In the results, the shank showed a difference of approximately 18.2% from 119.3 to 145.8 cm on average, while the stock exhibited a difference of approximately 18.9% from 130.3 to 160.6 cm. The size of the anchor, however, was not proportional to the increase in the tonnage of the fishing vessel, and the anchors were produced in their own forms, based on the experience of the crew in many cases. In the statistical processing results, significant differences occurred in all areas except for the fluke. The stock and shank, which affect the dragging anchor, showed significant differences at a level of p < 0.05 while the bill, bill to bill, and bill to shank exhibited differences at a level of p < 0.01. This indicates that standardized criteria are required for the anchors of small coastal fishing vessels of less than ten tons, and that design standards for materials and reinforcements also need to be prepared as thin rebars or wooden columns are used, in addition to steel pipes, as the materials of the stock in many cases.

1. Introduction

Vessels usually remain berthed or anchored except when they sail at sea. An effective way to stay in one place at sea without docking is to berth the vessel using the anchor [1]. The anchor of a vessel dropped at sea is buried under the seabed, and it generates a holding force to make it possible to stay in a place over an extended period of time against external forces, such as wind and tidal currents [1].

In general, anchoring stability can be ensured by adjusting the length of the installed anchor and chain during the design of the vessel, but it is difficult to ensure anchoring stability using the length of the chain alone in harsh environments, such as stormy weather [2]. In addition, if the anchor exceeds the holding force, dragging the anchor occurs, raising concerns over a shipwreck on the coast or a collision [2].

As described, the role of the anchor is very important, and it has a long history. Before the development of the shipbuilding industry in the past, it is known that heavy stone was used for the role of the shank so that the anchor could be buried well under the seabed [3]. The processed stone was tied to a rope for the role of the anchor before the application of the mechanical method, but the form of the anchor was gradually improved from the form of simple stone for fast and easy anchoring in the seabed [4].

In the modern shipbuilding industry, most anchors are made of heavy steel and they are classified into stock and stockless anchors, based on their shape [5]. In the case of fishing vessels, they frequently leave designated anchorage sites as they cast anchor near fisheries [6], and the accidents caused by dragging anchors occur for anchored vessels. Some of the lost fishing-vessel anchors cause significant problems with submarine cables that are installed under the seabed [7]. According to related research, 70% of the problems with submarine cables are caused by fishing-vessel anchors, and such problems frequently occur at a low water depth of less than 200 m. Therefore, the need to prepare relevant protective regulations or standards has been consistently emphasized [7]. As dragging-anchor accidents for ships have consistently occurred, research into and development of dragging-anchor risk-detection programs have been conducted to detect the risk of dragging anchors in advance and to make it possible to take appropriate measures [8].

Owing to the global trend of renewable energy development, the dissemination of offshore wind power has also been expanded in South Korea [9]. Consequently, offshore wind farms that occupy marine space overlap with the existing fishing-activity space [10]. In particular, damage to submarine cables, which are essential for offshore wind farms in the country, is frequently caused by fishing activities and anchors.

Anchoring has been reported to be a cause of mechanical damage to marine habitats and ecosystems [11,12], with damage and wear occurring when anchors are deployed and retrieved [13,14].

Thus, a response to this is necessary, but design standards for the burial depth according to the anchor size or cable protection are insufficient [15]. As protection against these problems is required, some studies on coexistent fishing equipment have been conducted to allow fishing in offshore wind farms or to promote co-prosperity with fisheries [16]. Nevertheless, there are few studies on the impact of the anchors used by small fishing vessels of less than ten tons, which represent the majority of fishing activities in coastal waters, on submarine cables.

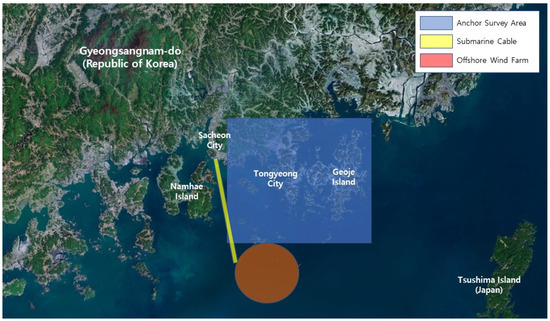

Therefore, this study aimed to investigate, compare, and analyze the types and usage status of the anchors used in small coastal fishing vessels of less than ten tons so as to identify risk factors according to the offshore wind farm and cable installation plan near Yokjido Island, Tongyeong-si, Gyeongsangnam-do, Korea.

2. Materials and Methods

2.1. Investigation of the Shapes of Anchors for Small Fishing Vessels

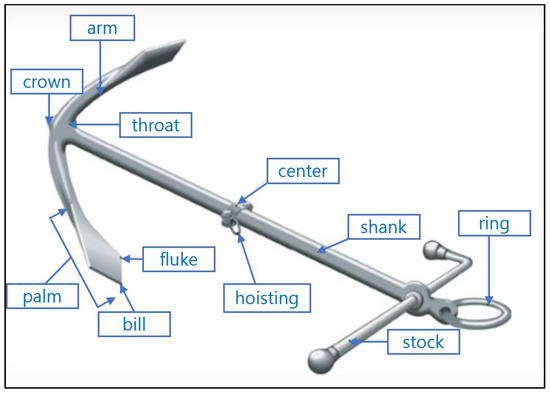

Typical methods of casting anchors from vessels include single anchoring and two anchoring. For fishing vessels, single anchoring is usually performed to prevent entangled anchors and for fast sailing [17]. Figure 1 shows an anchor referred to as the stock anchor with the stock. It is commonly used in small vessels, such as fishing vessels, due to inconvenient containment despite a high holding force.

Figure 1.

Anchor shape of a fishing vessel.

The anchors used in small coastal fishing vessels of less than ten tons have long been developed in various ways and shapes based on the experience of local fishermen. Although there are some differences in structural names, the names according to the typical stock anchor type can be classified as follows.

The long and straight bar that forms the body of the anchor is referred to as the shank. The arm is the part that begins to bend from the bottom of the main anchor shank to both sides and leads to the palm, and the throat is the point where both anchor arms meet the anchor shank.

The protruding part at the tip of the anchor shank is referred to as the crown. The bill is the tip of the anchor hook, and the fluke is the large area of the anchor hook on both sides. The stock is the column perpendicular to the anchor shank installed at the end of the anchor shank facing the anchor arms. It plays a crucial role in determining the position of the anchor so that the two anchor arms can hold the seabed. The ring is installed at the end of the anchor shank where the anchor stock is installed. The chain or rope connected to the anchor is fastened here. A small hoisting ring is installed at the center of the anchor shank. It is used to lift the anchor from the seabed by tying a rope.

Table 1 summarizes the names and functions of each part of a typical stock anchor commonly used in small vessels.

Table 1.

Setting of survey item codes of the anchor according to G/T.

2.2. Analysis of Submarine-Cable Risk Factors of Anchors

The submarine cables installed under the seabed can be damaged by natural and artificial risk factors [18].

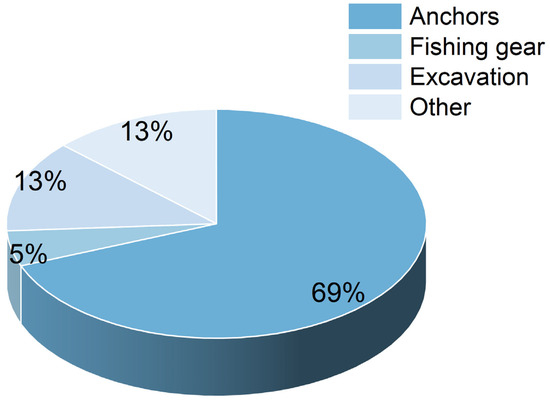

In particular, the artificial risk factors caused by anchors and fishing gear are dominant in coastal areas with frequent ship travel and fishing activities. In the oceans, on the other hand, natural risk factors with relatively lower frequencies (e.g., waves and flows) are dominant. In the past, when submarine cables were installed under the seabed without protective measures, the use of fishing gear was recognized as a risk factor. After the installation of submarine cables, however, it is known that most risk factors are caused by dragging anchors from vessels [18]. According to an overseas report on submarine-cable risk factors, approximately 69% of all accidents are the damage caused by dragging anchors and fishing gear, representing approximately 5% of the damage [19].

Figure 2 summarizes the risk factors of submarine cables. The method of digging furrows on the seabed and laying cables has been mainly used to reduce the damage to submarine cables caused by dragging anchor [20].

Figure 2.

Causes of marine-cable damage (CiGRE-398, 2009) [20].

The seabed penetration of dragging anchor may vary depending on the chain mass and geometry, as well as soil conditions, but it is necessary first to examine the characteristics of anchors prior to soil conditions [18]. The anchors used in actual vessels are various types, and they have different penetration characteristics of dragging anchor depending on their shape [21].

Since it is difficult to accommodate all the characteristics of many types of anchors, considering the installation design of submarine cables, it is necessary to set the geometry and specifications of standard anchors and prepare specific installation-related design standards [18].

This indicates that it is necessary to prepare for the damage to submarine cables caused by various dragging anchor characteristics of the anchors used in vessels and that field research is required to prepare basic design standards in the future for small fishing vessels engaged in fishing activities in domestic coastal areas.

2.3. Research Method

In this study, small coastal fishing vessels that operated mainly in Tongyeong-si, Gyeongsangnam-do were classified by tonnage in accordance with the offshore wind power and cable-dissemination plan, and each anchor type and their specifications were investigated and analyzed to present standardized anchor settings and measures for small coastal fishing vessels of less than ten tons with insufficient anchor-related specifications, despite the high frequency of ship operation when offshore wind farms and cables are installed in the sea near Yokjido Island, Tongyeong-si.

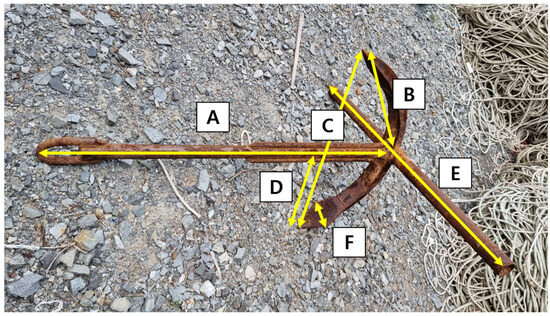

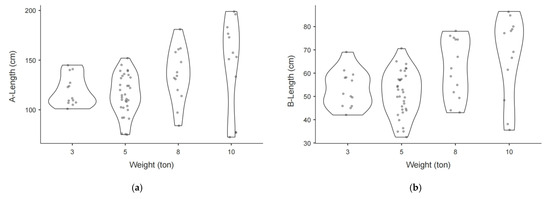

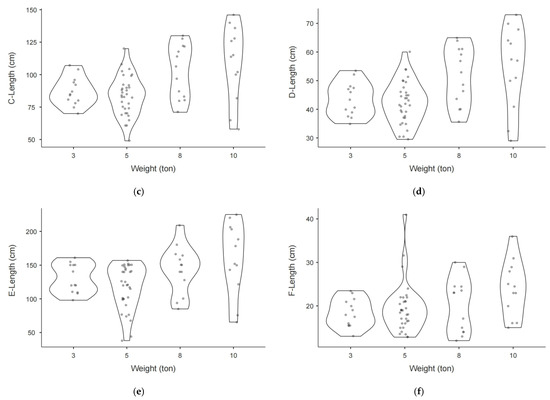

Figure 3 shows an example of the setting of the specifications required for field research of the anchors used in the small coastal fishing vessels registered in Tongyeong-si, Gyeongsangnam-do. Six sections from A to F were set, and the tonnage of target vessels was classified into four categories based on gross tonnage (G/T): less than three tons (W3), less than five tons (W5), less than eight tons (W8), and less than ten tons (W10). The total field research period was approximately six months, and results were derived from a total of 71 vessels, for which quantitative assessment was possible except for those that could not perform long-term fishing activities or had damaged or lost anchors. Table 1 summarizes the categories by tonnage and survey items as codes for the target vessels, while Figure 3 shows the measured locations of the anchor.

Figure 3.

Setting of measurement item locations of anchors for small fishing vessels.

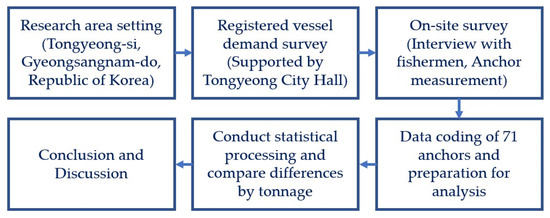

Table 2 shows the research target. In the field research, inaccurate or partially damaged or special materials and improved anchors that did not match ordinary stock anchors were excluded among the 135 vessels that visited the area. As for the anchors used for quantitative analysis, 71 anchors were finally selected from 58 fishing vessels. The field research was conducted for approximately six months with the support of the research team and field research supporters, as well as fishermen. Figure 4 shows the flow chart of the research procedure, and Figure 5 shows the actual area where the anchor survey was conducted.

Table 2.

Research target summary.

Figure 4.

Summary of flow chart for research analysis.

Figure 5.

Location of anchor survey area.

3. Results

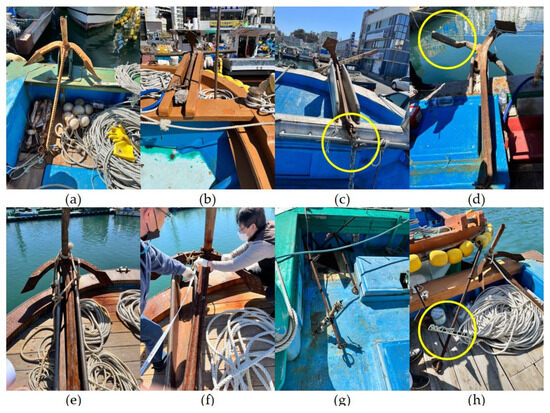

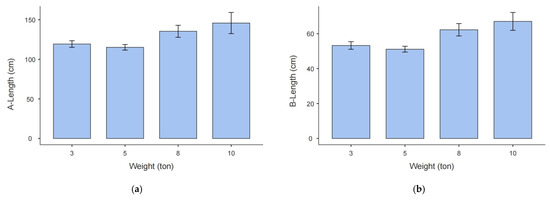

The cumulative data on the actual size of the anchors used in small coastal fishing vessels by tonnage were visualized by conducting long-term field research, and the results are presented in Figure 6. Figure 7 shows the images of the examples of the anchors in various shapes secured by conducting field research in the survey area.

Figure 6.

Comparison of the actual size of the anchors used in small coastal fishing vessels by tonnage: (a) shank, (b) bill, (c) bill to bill, (d) bill to shank, (e) stock, (f) fluke.

Figure 7.

Photo of various uses and problems of stock anchors; (a) small-sized, (b) medium-sized, (c) chain type, (d) damage to stock, (e) large-sized, (f) measurement, (g) rebar, (h) rope used.

The shank showed a difference of approximately 18.2% from 119.3 cm for three-ton vessels to 145.8 cm for ten-ton vessels on average. However, it did not increase uniformly by tonnage category, and it seems that there were slight differences depending on the manufacturing characteristics. The bill showed a difference of approximately 20.6% from 51.1 to 67.1 cm. The bill-to-bill distance also showed a difference of approximately 20.2% from 87.2 to 109.3 cm, and the bill-to-shank distance exhibited a difference of 20.3% as well. This shows that the balance was almost similar for each size as the bill for all of the anchors used at the site was close to a typical symmetrical shape. The size of the stock, which has the largest impact on holding force (the main function of anchors) and dragging anchors, increased by approximately 18.9% from 130.3 cm for three-ton vessels to 160.6 cm for ten-ton vessels, but it decreased to 117.3 cm for five-ton vessels. This appears to be due to the difference in the types of fishing in the absence of standardization and the difference in the practice of making and using the stock based on the long-term experience of the crew. There were also many differences in the material of the stock. Steel pipes or rebars were typically used, but wooden columns were processed and used in the form of a wedge in some vessels. This indicates that it is necessary to prepare standards considering the sizes and materials of standard anchors used in small fishing vessels in the future. The fluke showed a difference of approximately 23.0% from 18.4 to 23.9 cm. Table 3 summarizes the measurement results of the anchors used in small coastal fishing vessels by tonnage, while Figure 8 shows them by section.

Table 3.

Average sizes of the anchors used in small coastal fishing vessels.

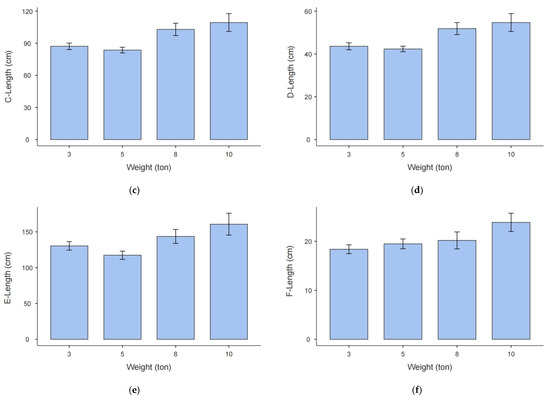

Figure 8.

Comparison of the average sizes of the anchors used in small coastal fishing vessels by tonnage: (a) shank, (b) bill, (c) bill to bill, (d) bill to shank, (e) stock, (f) fluke.

One-Way Analysis of Variance (ANOVA) for Anchor Size

To examine whether there were significant differences in the anchors used in small coastal fishing vessels depending on tonnage, one-way ANOVA was conducted based on the measured data. One-way ANOVA is a method of verifying the average difference under conditions with three or more dependent variables when there is one independent variable. The independent variable is the length of the anchor by section, while the dependent variables are the tons of the vessels. Statistical processing was performed using Jamovi 1.6v, an open-source software program [22,23]. Since the number of samples was not the same for each group, post-validation was performed using the Games–Howell method [24]. df2 is the within-group degrees of freedom, F is the statistic, and p is the significance level. Table 4 shows the statistical processing results.

Table 4.

Computerized statistical and analytical results of noise for each area.

F = 3.09 and p = 0.044 were obtained for the shank (A), and F = 3.41 and p = 0.032 for the stock (E). Both the shank and stock sections showed significant differences at a level of p < 0.05. There were significant differences for bill (B), bill to bill (D), and bill to shank (E) at a level of p < 0.01. In the case of the fluke (F), there was no statistically significant difference. Thus, the sizes of the anchors used in small coastal fishing vessels of less than ten tons were different by tonnage. This makes it very difficult to predict the degree of damage to submarine cables caused by the anchors of fishing vessels and the risk factors for pre-design. Therefore, if the sizes to be applied to the design of standardized anchors, clear standards on materials, and improved anchor design are applied in the future, it will be possible to respond to some risk factors.

4. Conclusions

In this study, the characteristics of the anchors used in small coastal fishing vessels of less than ten tons were investigated, and the status of 71 locations from 59 vessels, which were classified by tonnage, was examined to respond to the risk factors of damage to submarine cables, which frequently occurs due to dragging anchors from vessels.

The field-research results revealed that the stock of the anchors used in small fishing vessels was mostly made of steel pipes, but some anchors used thin rebars or wooden columns, regardless of their size. Since this causes problems with the holding force and durability and has a significant impact on the occurrence of dragging anchor, it is necessary to apply common design standards for materials and reinforcements during the design of anchors in the future.

As for the measured values, the shank showed a difference of approximately 18.2% from 119.3 to 145.8 cm on average, while the bill exhibited a difference of approximately 20.6% from 51.1 to 67.1 cm. The bill-to-bill length and the bill-to-shank length also showed a similar difference of approximately 20.2%, indicating that the bill of the anchors used at the site had similar geometry as it was close to a typical symmetrical shape. The sizes of the anchors, however, were not consistently proportional to the increase in tonnage.

When statistical processing was performed using one-way analysis of variance (ANOVA), all of the sections, except for the fluke, showed significant differences. The shank and stock showed differences at a significance level of p < 0.05, while the bill, bill to bill, and bill to shank exhibited statistical differences at a significance level of p < 0.01.

Therefore, it is difficult to predict risk factors during the pre-design of submarine cable construction because most small fishing vessels have various differences and sizes, regardless of tonnage. In addition, anchor installation standards, such as DNV-RP-E302, do not provide standards for vessels under 10 tons, suggesting limitations [25]. This indicates that it is necessary to establish common design standards for anchors through various studies in the future. Our research team plans to conduct a comparative study with other regions of our country using the same method.

Author Contributions

Conceptualization, T.-H.L. and B.-K.J.; methodology, B.-K.J.; software, T.-H.L.; validation, T.-H.L. and B.-K.J.; formal analysis, T.-H.L.; investigation, B.-K.J.; resources, B.-K.J.; data curation, B.-K.J.; writing—original draft preparation, T.-H.L.; writing—review and editing, T.-H.L.; visualization, T.-H.L.; supervision, B.-K.J.; project administration, B.-K.J.; funding acquisition, B.-K.J. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by a Research Grant of Pukyong National University (2025).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Park, Y.S. A Study on the Amendment to the Guidelines on the Contributing Proportion to the Cause in Collision Cases between Ships Underway and Ships at Anchor. Marit. Law Rev. 2016, 28, 173–204. [Google Scholar]

- Min, S.S.; Noh, I.J.; Lee, Y.C. A Study on the Stability of Anchoring Vessels Based on the Analysis of the Holding Forces and External Forces. J. Korea Soc. Nav. Sci. Technol. 2024, 7, 24–30. [Google Scholar]

- Park, S.M. An analysis of anchor stones on the west and south coasts. J. Cult. Herit. Stud. 2022, 55, 6–22. [Google Scholar]

- Kim, T.J. Current status and preservation management of anchor stones of Underwater excavated from waters of Incheon and Chungcheong area. Korean J. Marit. Herit. Stud. 2018, 11, 153–173. [Google Scholar]

- Hong, K.H. Analysis on Typology and Usage of Traditional Datdol (Anchor Stones) from the Mado Underwater Site, Taean County in Korea; Graduated School of Chosun University: Gwangju, Republic of Korea, 2012. [Google Scholar]

- Lee, T.H. Analysis of Ancient Ship Anchor Stone Shapes Through Research on the Relics from the Ocean in the Korea West Coast-Focusing on the Relics Found Near the Yeongheung-do Shipwreck in Ongjin-gun, Incheon. J. Fish. Mar. Sci. Educ. 2020, 32, 1639–1646. [Google Scholar]

- Kim, B.Y.; Kim, K.I.; Kim, M.S.; Kimura, N.; Lee, C.H. Characteristic of holding power due to nature of seabed at anchor. J. Korean Soc. Fish. Ocean Technol. 2022, 58, 230–240. [Google Scholar] [CrossRef]

- Jung, J.J.; Lee, Y.S.; Shin, H.S. A study for construction of Shore-end Submarine cable. J. Korea Inst. Electron. Commun. Sci. 2007, 2, 203–209. [Google Scholar]

- Kim, J.S.; Park, J.M.; Jung, C.H. The Development of the Anchor Dragging Risk Assessment Program. J. Korean Soc. Mar. Environ. Saf. 2018, 24, 646–653. [Google Scholar] [CrossRef]

- Ok, S.Y.; Kim, K.W.; Kim, C.J.; Won, J.H.; Lee, H.Y. Drag Anchor Performance Experiment and Numerical Analysis for Coexistence Fishery Facility in Offshore Wind Farm. J. Wind Energy 2023, 14, 21–28. [Google Scholar]

- Davis, A.R.; Broad, A.; Gullett, W.; Reveley, J.; Steele, C.; Schofield, C. Anchors away? The impacts of anchor scour by ocean-going vessels and potential response options. Mar. Policy 2016, 73, 1–7. [Google Scholar] [CrossRef]

- Deter, J.; Lozupone, X.; Inacio, A.; Boissery, P.; Holon, F. Boat anchoring pressure on coastal seabed: Quantification and bias estimation using AIS data. Mar. Pollut. Bull. 2017, 123, 175–181. [Google Scholar] [CrossRef] [PubMed]

- Francour, P.; Ganteaume, A.; Poulain, M. Effects of boat anchoring in Posidonia Oceanica seagrass beds in the Port-Cros National Park (north-western Mediterranean Sea). Aquat. Conserv. Mar. Freshw. Ecosyst. 1999, 9, 391–400. [Google Scholar] [CrossRef]

- Milazzo, M.; Badalamenti, F.; Ceccherelli, G.; Chemello, R. Boat anchoring on Posidonia oceanica beds in a marine protected area (Italy, western Mediterranean): Effect of anchor types in different anchoring stages. J. Exp. Mar. Biol. Ecol. 2004, 299, 51–62. [Google Scholar] [CrossRef]

- Kim, J.Y.; Lee, H.Y.; Han, K.W.; Kang, K.S. Selection and Layout Design of Suitable Areas for Coexistence with Fisheries within a Southwest Offshore Wind Farm. J. Wind. Energy 2024, 15, 13–23. [Google Scholar]

- Lee, Y.S.; Kim, S.Y.; Yu, Y.U.; Yun, G.H. A Study on the Selection of Target Ship for the Protection of Submarine Power Cable. J. Korean Soc. Mar. Environ. Saf. 2018, 24, 662–669. [Google Scholar] [CrossRef]

- Choi, E.J.; Kim, H.W.; Kim, J.W. An Economical Feasibility Analysis of Sea Farm Project Using Co-Location in Offshore Wind Farms. J. Prod. Res. 2015, 33, 73–80. [Google Scholar]

- Lee, C.H. Characteristic of hull motion due to external forces at anchor. J. Korean Soc. Fish. Ocean Technol. 2023, 59, 135–144. [Google Scholar] [CrossRef]

- Kim, J.H.; Chun, I.S.; Kang, H.N. Formulation of Anchor and Chain Specifications for Establishing Subsea Cable Burial Depth. J. Coast. Disaster Prev. 2023, 10, 85–93. [Google Scholar] [CrossRef]

- CIGRE-398. Third-Party Damage to Underground and Submarine Cables; CIGRE: Paris, France, 2009. [Google Scholar]

- DNV. DNV-RP-0360 Subsea Power Cables in Shallow Water, Recommended Practice (RP); DNV: Greater Oslo, Norway, 2016. [Google Scholar]

- Taylor, R.; Valent, P. Design Guide for Drag Embedment Anchors; Naval Civil Engineering Laboratory: Port Hueneme, CA, USA, 1984. [Google Scholar]

- Lee, T.H.; Lee, N.U.; Lee, D.J.; Jung, B.K. Analysis of ship noise characteristics generated according to sailing conditions of the G/T 1000-ton stern fishing trawler. J. Mar. Sci. Eng. 2021, 9, 914. [Google Scholar] [CrossRef]

- The Jamovi Project. Jamovi Software, version 1.6; Amsterdam, The Netherlands, 2021. Available online: https://www.jamovi.org (accessed on 21 April 2025).

- DNV. DNV-RP-E302 Design and Installation of Plate Anchors in Clay (2000); DNV: Greater Oslo, Norway, 2000. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).