1. Introduction

With the advancement of economic globalization, oceanic domains have become critical to national energy security and economic sustainability [

1,

2]. Maritime Autonomous Surface Ship (MASS), characterized by their high autonomy and intelligence, are emerging as transformative technologies for maritime exploration and industry development [

3,

4]. Gas turbines, known for their excellent dynamic performance [

5,

6], quiet operation [

7], compact structure, and high power density [

8], hold considerable potential for application in the MASS field.

For the MASS, superior maneuverability and operational stability are key performance indicators. High-mobility conditions such as automatic obstacle avoidance and accelerated pursuit can impose significant impacts on the MASS’s electrical system, which manifest as frequent variations in the load power at the engine end. Speed control is a critical component of the gas turbine control system, directly influencing the turbine’s dynamic performance, reliability, lifespan, and power quality [

9]. The speed controller must maintain minimal speed fluctuations under steady-state conditions, minimize overshoot during external disturbances or sudden load changes, and enable the system to quickly return to a stable state. Therefore, the optimization of gas turbine speed control is essentially a multi-objective optimization and trade-off problem between fast response and stability.

The proportional-integral-derivative (PID) control method is widely used in gas turbines due to its simplicity, clear physical significance, ease of implementation, and robustness. As a linear controller, the PID typically linearizes the controlled system under the design operating conditions and tunes the control parameters based on classical control theory [

10]. However, the controller gain parameters that are tuned for specific operating conditions may not provide optimal control performance across the full operating range. Furthermore, under varying external conditions, large-scale load fluctuations, or the degradation of gas turbine components, pre-tuned parameters may result in degraded control performance or even engine instability. The unique characteristics of MASS prevent the on-site tuning of the gas turbine control system, thereby reducing the reliability of unmanned gas turbine units during long-range operations.

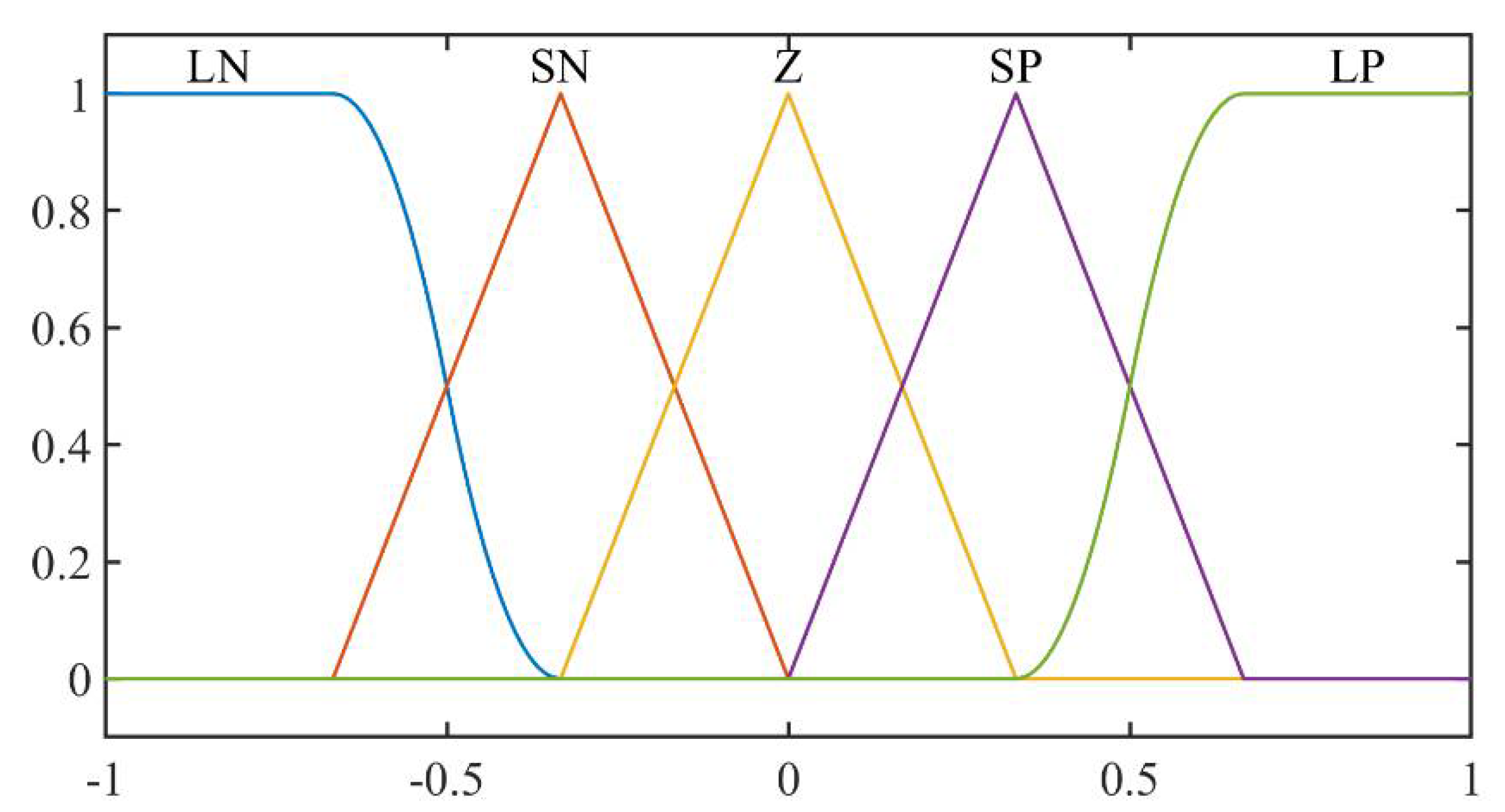

With the advancement of modern intelligent control theories, sophisticated algorithms including neural networks, model predictive control (MPC), and sliding mode control have been increasingly implemented to enhance gas turbine speed control systems. Iqbal et al. [

11] developed a fuzzy rule-based PID parameter adaptation strategy to mitigate instability in grid-connected gas turbines under load fluctuations. Similarly, Li et al. [

12] utilized fuzzy adaptive PID control to suppress overspeed phenomena during load shedding in turbine-generator systems. Nevertheless, the design of effective fuzzy adjustment mechanisms presents significant challenges, requiring the meticulous selection of membership functions and rule formulation that heavily depends on engineering expertise. While neural network-enhanced PID methods [

13,

14,

15] demonstrate adaptive parameter tuning capabilities, their practical implementation is constrained by computational complexity and slow convergence rates, rendering them unsuitable for real-time parameter adaptation.

In the realm of model-based approaches, Jurado et al. [

16] employed linearized MPC to improve generator set stability, though its effectiveness remains restricted to linear operating regimes. Subsequent innovations by Saez et al. [

17] introduced genetic algorithm-optimized fuzzy predictive control to address nonlinear system challenges, while Haji et al. [

18] proposed adaptive MPC with online parameter estimation. However, the intricate model structures and substantial computational demands that are inherent to nonlinear MPC implementations hinder their widespread engineering adoption.

Robust control strategies have emerged as alternative solutions, with Ariffin et al. [

19] employing an

control method to counteract manufacturing tolerance impacts, and Gomma et al. [

20] designing state-space robust controllers with anti-windup compensation. Najimi et al. [

21] further advanced this domain through linear autoregressive robust control design. These methods, however, typically exhibit conservatism in control performance, where robustness improvements necessitate trade-offs in dynamic responsiveness.

The active disturbance rejection control (ADRC) algorithm integrates classical control theory with modern control methods. Unlike traditional control approaches, ADRC does not rely on an accurate system model but treats unmodeled dynamics and uncertainties as disturbances, effectively addressing the limitations of model-dependent modern control methods. This makes ADRC particularly suitable for gas turbine speed control in MASS. In reference [

22], an ADRC algorithm was designed for a micro gas turbine generator system, which demonstrated a faster dynamic response compared to PID control.

Wang et al. [

23] employed deep reinforcement learning to optimize the ADRC algorithm, achieving the self-adaptive tuning of its gain parameters. Chen et al. [

24] integrated fractional-order theory into the ADRC framework, demonstrating enhanced transient response characteristics. Furthermore, Yue et al. [

25] proposed an improved ADRC algorithm based on an adaptive unscented Kalman filter (AUKF). The results demonstrated that this algorithm can improve both the system’s response speed and its robustness against unknown disturbances.

Despite these advancements, conventional ADRC implementations face industrial adoption barriers due to their reliance on multiple nonlinear functions that complicate parameter tuning and theoretical analysis. To address this, Gao [

26] pioneered linear ADRC (LADRC) through bandwidth-based simplification, significantly advancing industrial applications. However, LADRC exhibits inherent limitations when applied to highly nonlinear systems like gas turbines, manifesting as inadequate disturbance estimation accuracy and poor adaptability to operational uncertainties, ultimately compromising control performance.

Motivated by the foregoing discussions, this paper proposes a novel nonsmooth fuzzy ADRC method for gas turbines, based on an adaptive disturbance rejection mechanism. Compared to existing studies, the novelty and contributions of this paper can be summarized in the following three aspects:

(1) A new control technique is proposed that combines nonsmooth theory, fuzzy adaptive control theory, and LADRC theory. This method organically integrates the advantages of all three methodologies, is model-independent, and allows for easy parameter tuning. It also demonstrates superior dynamic response and robustness, overcoming the limitations of traditional PID control, the heavy reliance on models in modern control methods, and the inadequate disturbance estimation and adaptability of conventional ADRC methods.

(2) Unlike conventional ESO [

20,

22], a novel nonsmooth ESO (NS_ESO) is designed for disturbance estimation, which effectively improves estimation accuracy and speed by replacing the linear function with a nonsmooth function, ensuring the finite-time convergence of the ESO.

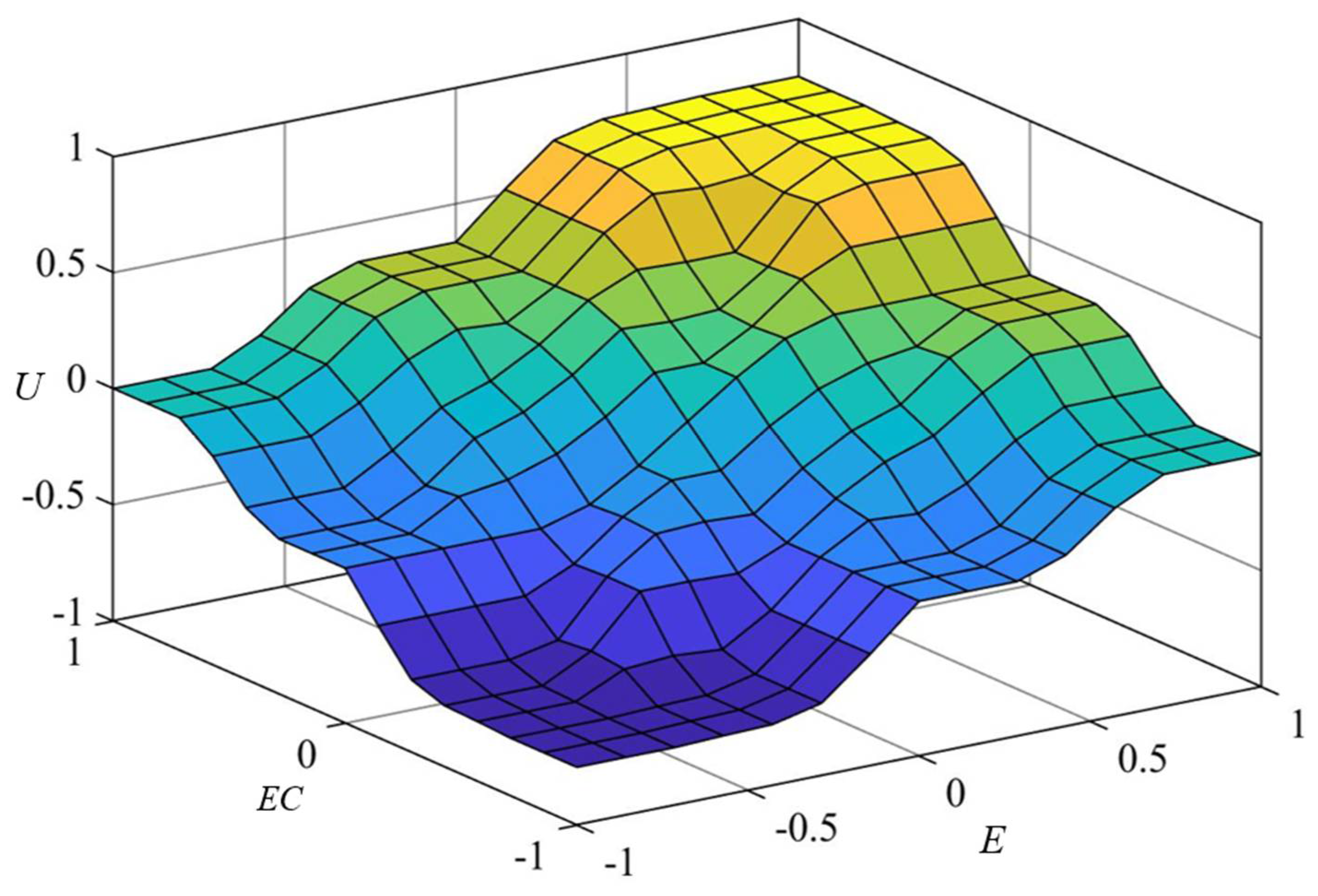

(3) Fuzzy adaptive control is incorporated as an optimization mechanism into the control strategy. The optimization focuses on designing a new adaptive control law based on a fuzzy logic controller, enabling the real-time adjustment of PD controller parameters based on error and error-derivative signals, thereby further enhancing the robustness and response speed of the controller.

The rest of this article is organized as follows.

Section 2 introduces the design process of the NS_FADRC method.

Section 3 details the stability analysis process of NS_FADRC.

Section 4 presents the corresponding experimental results. Finally,

Section 5 concludes this article.

3. System Stability Analysis

The main objective of this Section is to prove the stability of the designed controller. Before proceeding with the proof, it is necessary to introduce the definition of finite-time stability and the related lemmas. Additionally, some essential assumptions that were overlooked during the controller design in previous Sections are also provided in this Section.

Definition 1. ([

25,

26])

. Consider the following nonlinear system:where

is the state vector, and the function

:

is a continuous function defined on an open region

. It is assumed that system (21) has a unique solution for positive time when starting from the initial state. Let system (21) satisfy the following conditions:The equilibrium point of system (21) satisfies the Lyapunov stability condition.

For any initial condition , there exists a continuous function: such that the solution of system (21) satisfies the following: when , the solution satisfies , , and for , the solution .

Then, system (21) exhibits finite-time convergence. If is globally bounded, system (21) achieves global finite-time stability.

To facilitate the analysis of the system’s finite-time convergence characteristics, we present another lemma on finite-time stability based on the Lyapunov function.

Lemma 1. ([

25,

27])

. Consider system (21). Suppose that there exists a continuous function that satisfies the following conditions:- (1)

is positive definite;

- (2)

There exist real numbers , and an open neighborhood containing the origin such that:

Then, the equilibrium point

of system (21) is finite-time convergent. Moreover, the convergence time satisfies:

where

is the initial value of function

.

Lemma 2. ([

28])

. For any m × n-dimensional matrix , the singular values of are the arithmetic square roots of the eigenvalues of , and the smallest singular value is non-negative. Furthermore, for an -dimensional square matrix , its eigenvalues can be negative. Assumption 1. For gas turbine system (2), represents a generalized disturbance that includes the unknown nonlinearities and external perturbations of the system.

Assumption 2. is a continuous, differentiable, and bounded function, with its derivative satisfying , where is a positive constant.

Based on the separation principle, the stability of the closed-loop system can be proven by separately analyzing the stability of the ESO and SEF.

3.1. The Stability Analysis of the NS_ESO

Theorem 1. For system (2), there exist appropriate constants , , and () such that the observation values of the NS_ESO converge to the true state parameters within a finite time.

Proof. To prove this, we construct a Lyapunov function, which is given by the following expression:

where

,

.

By taking the derivative of the matrix

, we can obtain:

By substituting observation error matrix (11) into Equation (25), the result can be computed as follows:

where

,

,

, and

.

The stability of error matrix (26) depends on matrix

, and the characteristic polynomial of matrix

can be expressed as:

Since the coefficients of the characteristic polynomial are all positive, it follows that the matrix

is a Hurwitz matrix, and thus the error matrix

is stable. Next, we differentiate the Lyapunov function

:

where

. We define parameter

.

Since the matrix

is a Hurwitz matrix, there exists a symmetric positive definite matrix

such that the following equation holds.

From Equation (24), the following inequality can be derived:

where

denotes the smallest eigenvalue of matrix

, and

denotes the largest eigenvalue of matrix

.

By combining Equation (30) and Equation (28), the following can be obtained:

where

.

By manipulating Equation (29), the following can be obtained:

Note that both matrices

and

are nonsingular, so the following inequality holds:

By decomposing the nonsingular matrix

, the following can be obtained:

Therefore, the smallest singular value of the matrix

satisfies the following inequality:

Since

is a diagonal matrix and

, we have:

Next, we will discuss two cases. □

Case 1: If , then we can further derive the following relation: Substituting Equations (37) and (38) into Equation (31), we obtain:

where

,

.

There exist appropriate parameters

,

,

and

such that

, and the following relation holds:

By combining Equations (30) and (31), the following can be obtained:

where

is the minimum value of the parameter

. Clearly, based on Lemma 1, it can be concluded that observation error system (12) is finite-time stable.

Case 2: If , the proof process is similar to Case 1. The following relation is obtained: Further, the following relationship can be obtained:

Therefore, there exists

, which, similar to Equation (41),

satisfies the following relation:

where

is the minimum value of the parameter

. According to Lemma 1, it can be concluded that observation error system (12) is finite-time stable.

3.2. The Stability Analysis of FSEF

Since we only adjust the gain parameters of the SEF adaptively through fuzzy logic, the stability analysis process is relatively simple, and further details can be found in reference [

29].

4. Verification of the Control System

4.1. Experiment Environment Setup

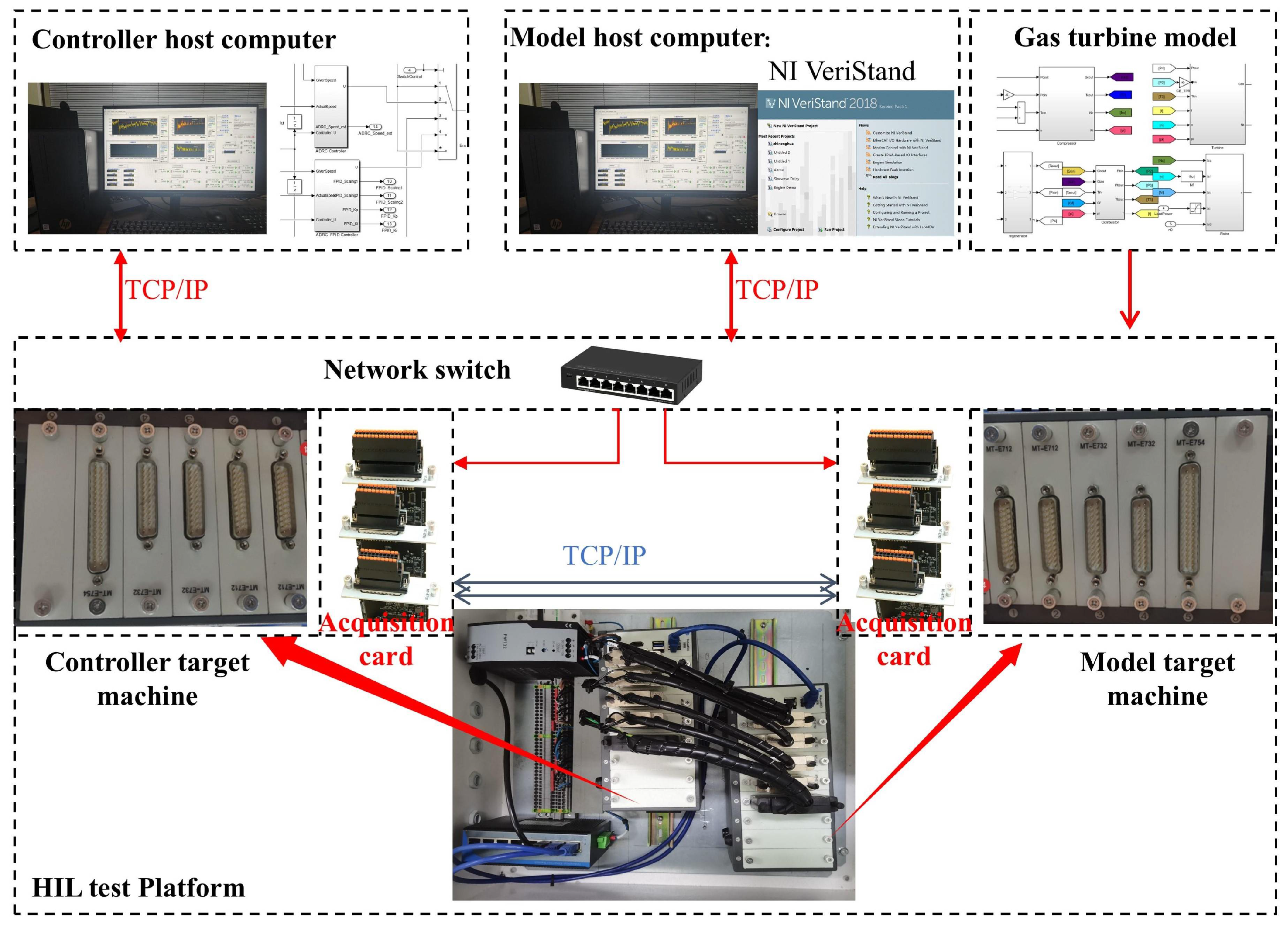

HIL refers to a technique that integrates physical hardware components such as controllers, communication buses, and processor nodes into a simulation loop. The HIL simulation platform avoids the high risks and costs associated with the full-scale physical testing of gas turbine control systems. Moreover, since the HIL simulation platform uses real controller hardware and actual input-output signals, it is closer to the real engineering control environment, making it an important validation tool for the fast prototyping of control systems.

To validate the control performance of the NS_FADRC algorithm proposed in this paper, an HIL experimental platform was built, as shown in

Figure 7. The platform mainly consists of four parts: the model host computer, the controller host computer, the model target machine, and the controller target machine. The hardware configuration is shown in

Table 2. Among these, the model host computer and the controller host computer are primarily used for simulation modeling and analysis, software-in-the-loop simulation, target machine code generation, compilation, linking, and downloading. During the HIL semi-physical testing process, the host computers are used to implement rich human–machine interaction functions. To meet the real-time requirements of the HIL semi-physical test environment, a real-time device based on the PharLap system is used as the target machine. The PharLap system is an industrial-grade real-time operating system with an interrupt response time of less than 1 microsecond, which meets the real-time requirements of the control system for HIL semi-physical testing. Additionally, the real-time device uses an 8-slot RobustRIO U808 chassis, which allows for easy expansion with its E-series and NI C-series boards. By adding A/D and D/A data acquisition cards, it is capable of signal conversion functionality.

To verify the advanced nature of the NS_FADRC algorithm, comparisons are made with the PID control algorithm, the fuzzy PID control algorithm (FPID), and the LADRC algorithm. The control object selected for this study is the micro gas turbine component-level simulation model developed by the author in reference [

30]. Both the control system and the micro gas turbine simulation model are built on the Matlab 2021b platform, and Simulink Coder in MATLAB is used to automatically generate industrial control machine code that can run on the PharLap real-time operating system. All four control algorithms are based on the trial-and-error method for parameter tuning, with the tuned gain parameters shown in

Table 3. The trial-and-error method is an approach that relies on engineering experience to select the optimal control parameter combination by trying multiple parameter combinations. Based on engineering experience with gas turbine speed control, it is known that the differential term in the PID control introduces high-frequency oscillations, amplifying the effects of sensor measurement noise and disturbances on the control system, thus reducing system stability. Therefore, in this paper, the differential terms in the PID and FPID control algorithms are set to zero.

4.2. Speed Tracking Performance Test

The step response test is an important method for evaluating the dynamic response capability of the control system. At the same time, the variable-speed operation of the gas turbine is essentially a speed tracking process [

31]. To verify the dynamic response capability of the proposed NS_FADRC algorithm and its control performance, the step-up acceleration tests from 50,800 r/min to 51,000 r/min and the step-down deceleration tests from 51,000 r/min to 50,800 r/min are conducted. The simulation environment for the model is based on ISO standard environmental conditions, and the load power is set to no load. The gain parameters for the PID, FPID, LADRC, and NS_FADRC algorithms are set according to those shown in

Table 3. To more intuitively demonstrate the dynamic response capability of the proposed control algorithm, we use overshoot

, rise time

, and settling time

as evaluation criteria.

Figure 8 presents the speed step response results for the four controllers, with each controller’s response shown in different colored curves. The results indicate that, whether during the speed step-up acceleration or step-down deceleration process, all four control algorithms can effectively track the speed setpoint signal. Among them, the traditional PID control algorithm exhibits the largest overshoot and the longest settling time, while the NS_FADRC control algorithm demonstrates the smallest overshoot and no significant speed fluctuations. The dynamic performance indicators of the step response for all four control algorithms are detailed in

Table 4.

Based on the analysis of the dynamic speed response performance of four control algorithms presented in

Table 4, the findings are as follows:

(1) Overshoot: Overshoot intuitively reflects the degree of overshooting in the output characteristics of the system during a step response. The larger the overshoot is, the more intense the fluctuations in the system’s response are, indicating poorer stability. For micro gas turbine generator sets, excessive overshoot can deteriorate the combustion process, reduce structural strength, and degrade power quality. In both step-up and step-down processes, the overshoot of the PID control algorithm is the largest, at 0.233% and 0.186%, respectively. The overshoot of the LADRC algorithm is smaller than that of the FPID and PID algorithms. The NS_FADRC algorithm exhibits the smallest overshoot, with a value of 0.01% during acceleration, which is 95.7% lower than the PID control algorithm, and 0.0341% during deceleration, which is 81.7% lower than the PID control algorithm. Therefore, compared to the PID, FPID, and LADRC algorithms, NS_FADRC not only ensures the rapid tracking of speed targets but also maintains the smallest overshoot, making it more advantageous for the stable operation of the generator set.

(2) Rise time: The differences in rise time among the four control algorithms are relatively small. In the step-up acceleration process, the rise time for the PID control algorithm is 0.88 s, that for the FPID control algorithm it is 0.98 s, that for the LADRC algorithm it is 1.1 s, and that for the NS_FADRC algorithm it is 1.66 s. The rise time of NS_FADRC is longer than that of LADRC, the rise time of LADRC is longer than that of FPID, and the PID control algorithm has the shortest rise time. In the step-down deceleration process, the relationship between the rise times of the four algorithms follows the same trend as in the step-up acceleration process. Rise time characterizes the dynamic response speed of the control system: the shorter the time, the faster the response. However, for micro gas turbine generator sets, both too short and too long a rise time can have adverse effects on the system. A rise time that is too short may cause overshoot in the turbine speed and lead to excessive variations in fuel flow, affecting the quality of combustion. On the other hand, a rise time that is too long indicates a weaker dynamic response capability, potentially causing the control system to fail under large-scale transient changes. As shown in

Figure 8, all four control algorithms achieve relatively short rise times, but the PID and FPID algorithms, due to their shorter rise times, result in larger overshoots in speed.

(3) Settling time: In the step acceleration phase, the PID control algorithm exhibits the longest settling time of 13.08 s, while the settling times of the FPID, NS_FADRC, and LADRC algorithms progressively decrease to 11.74 s, 3.38 s, and 3.36 s, respectively. In the step deceleration phase, the PID control algorithm again has the longest settling time of 14.1 s, followed by FPID with a settling time of 12.61 s. The LADRC algorithm achieves a settling time of 4.75 s, outperforming FPID, while NS_FADRC has the shortest settling time of 4.08 s. Notably, the settling times of the NS_FADRC and LADRC algorithms are significantly shorter than those of PID and FPID.

Based on the above analysis, it can be concluded that, in terms of speed tracking performance, the NS_FADRC algorithm outperforms the LADRC, FPID, and PID control algorithms. Both the NS_FADRC and LADRC algorithms adopt a design approach that integrates observer-based feedforward compensation with error feedback, resulting in significantly superior control performance compared to the PID-based architecture, which relies solely on passive feedback for error elimination.

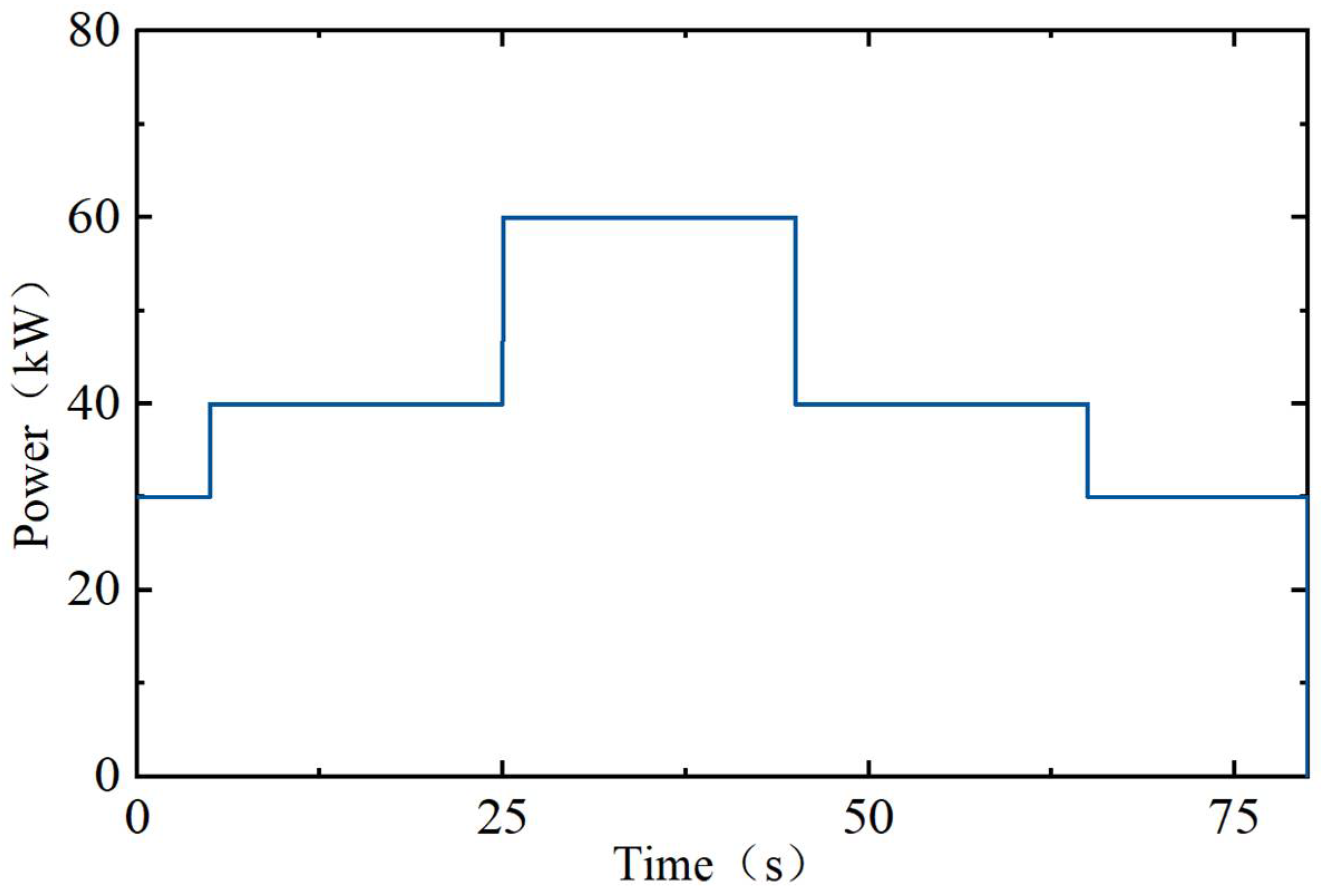

4.3. Performance Testing Under Load Disturbance

In the gas turbine generator sets used in the MASS, external load disturbances are the most common source of disturbance. These are typically caused by factors such as the acceleration or deceleration of the vessel, or the connection or disconnection of high-power electrical equipment. These load disturbances directly impact the operating state of the gas turbine and represent a class of external disturbances that the control system must pay particular attention to. When an external load change occurs, the gas turbine’s most immediate response is speed fluctuations. To ensure power quality and the safety of the unit, the speed controller must be able to respond quickly and effectively to these load disturbances. Specifically, the controller adjusts the fuel flow to the gas turbine to rapidly eliminate speed fluctuations. Given that the characteristic parameters of the gas turbine vary with operating conditions, the designed control algorithm must exhibit excellent dynamic performance and robustness to effectively counteract the adverse effects of load disturbances under various operating conditions.

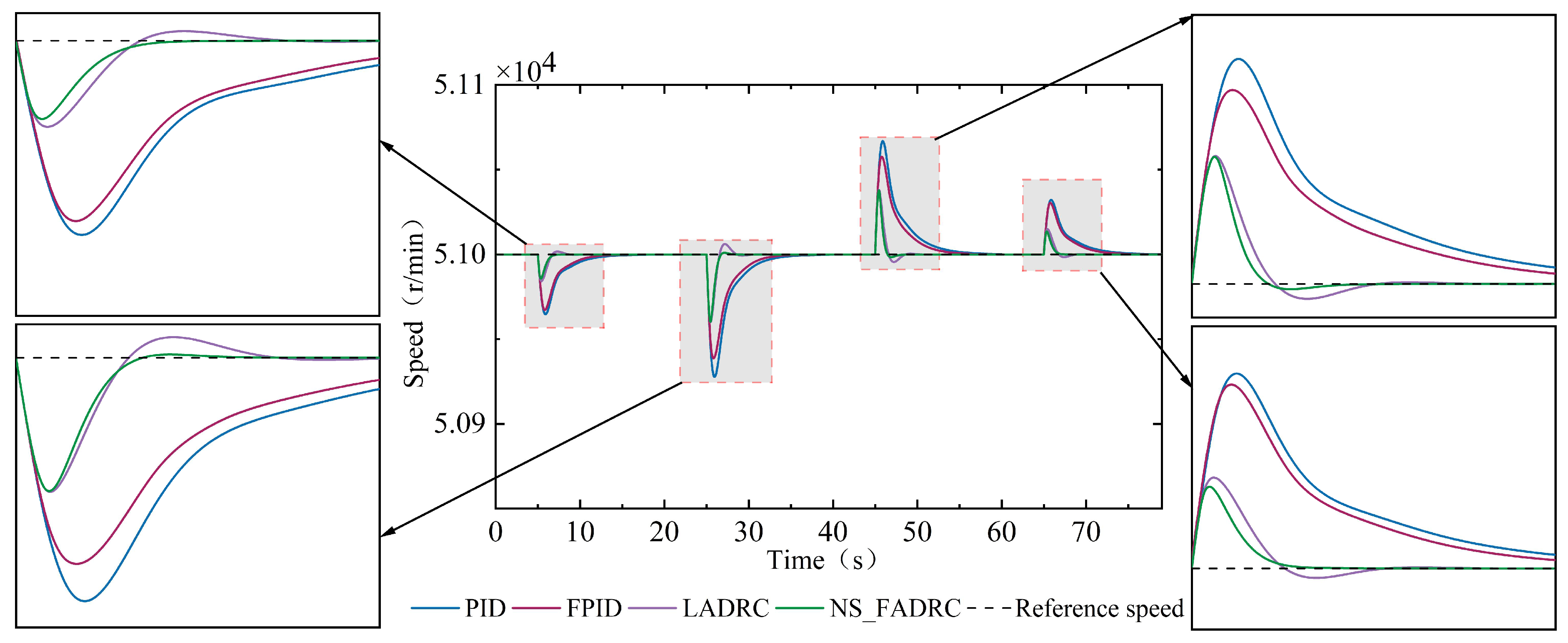

As shown in

Figure 9, this study tests the control performance of the proposed speed control algorithms under four different operating conditions. For convenience, the four test operating conditions are labeled as A1, A2, A3, and A4, with their corresponding details shown in

Table 5. The speed response results of the four control algorithms under operating conditions A1, A2, A3, and A4 are presented in

Figure 10. More detailed performance comparison results are provided in

Table 6.

From

Figure 10, it can be seen that under the four test conditions (A1, A2, A3, and A4), all four control algorithms can effectively achieve stable speed control of the gas turbine. Furthermore, the speed deviation of the gas turbine is positively correlated with the magnitude of the load disturbance. However, among these four control algorithms, the conventional PID control algorithm exhibits the largest speed deviation, the longest settling time, and the poorest dynamic performance. Compared to the other three algorithms, the NS_FADRC algorithm has the smallest settling time and speed fluctuation amplitude under all four test conditions, indicating that this algorithm can effectively address the trade-off between the transient regulation rate and settling time, thereby achieving optimal dynamic performance. Similarly to the speed step tracking process, the performance of the NS_FADRC and LADRC algorithms significantly outperforms that of the FPID and PID control algorithms.

From

Table 6, it can clearly be seen that under the A1 test condition, the transient regulation rate of the NS_FADRC algorithm is 0.0279%, which is only 0.41 times that of the PID control algorithm, 0.43 times that of the FPID control algorithm, and 0.91 times that of the LADRC algorithm. Meanwhile, the settling time of the NS_FADRC algorithm is 1.85 s, which is 7.96 s shorter than that of the PID control algorithm, 6.2 s shorter than that of the FPID control algorithm, and 1.41 s shorter than that of the LADRC algorithm. Under the A2, A3, and A4 conditions, the NS_FADRC algorithm performs better than the other three control algorithms in terms of both the transient regulation rate and settling time, with the improvement in settling time being especially significant for NS_FADRC.

4.4. Performance Testing Under Parameter Uncertainty

The application scenario of MASS is characterized by complex and variable working environments, extreme operating conditions, and unmanned operation. According to the external characteristics of gas turbines, the model parameters of the gas turbine can vary significantly with changes in load and environmental temperature. Model mismatch has become a challenging issue that is difficult to avoid in gas turbines. Therefore, a high-performance speed controller should exhibit robust performance to ensure that it can maintain excellent control effectiveness even when the gas turbine model parameters change. The previous Section has verified the performance of the NS_FADRC algorithm under varying load conditions. This Section will verify the speed control effect of this algorithm under different environmental temperatures.

To evaluate the performance of the speed control algorithm under different environmental temperatures, simulation tests were conducted at ambient temperatures of 5 °C and 20 °C. The test loads still used four typical non-design operating conditions, A1, A2, A3, and A4, with the control algorithm gain parameters taken from the data in

Table 3.

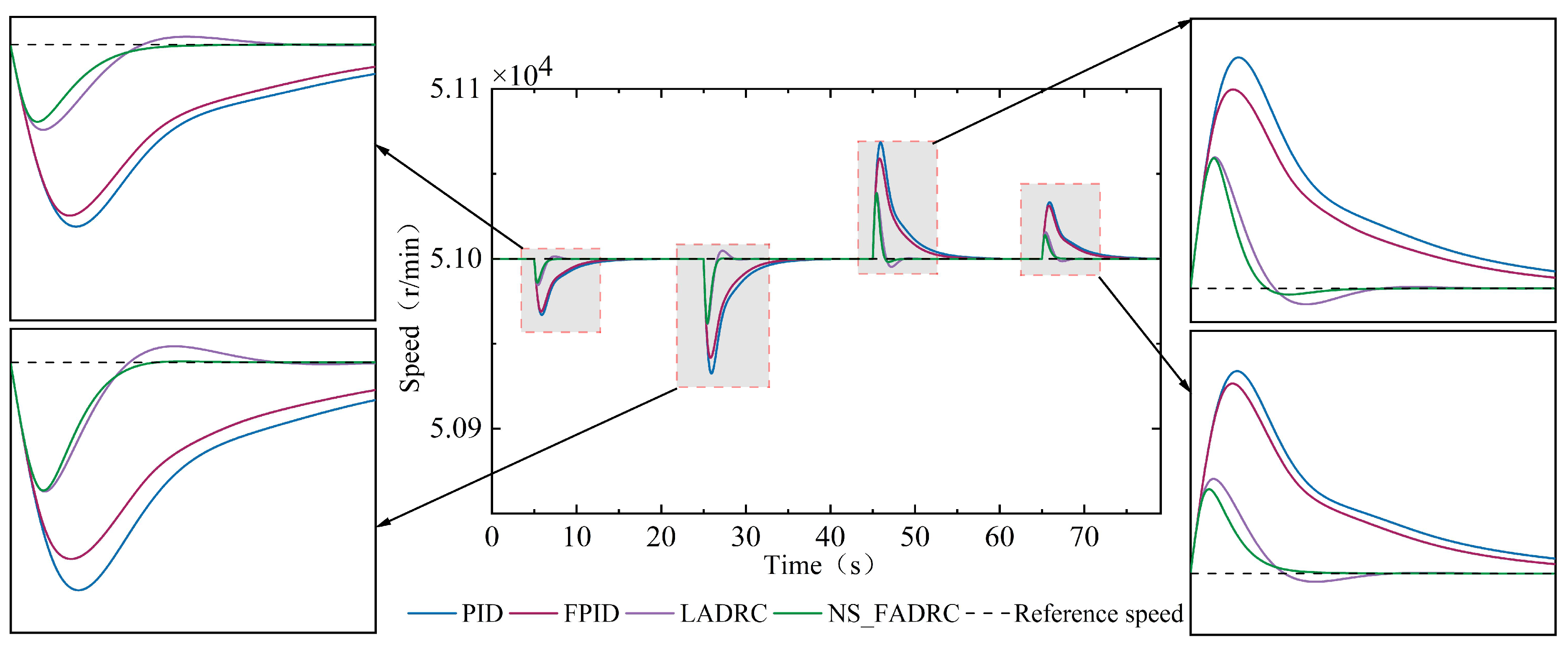

First, with an ambient temperature

T0 = 5 °C, the speed response curves of the gas turbine under A1, A2, A3, and A4 conditions are shown in

Figure 11. From

Figure 11, it is clearly visible that compared to the traditional PID control algorithm, the FPID, LADRC, and NS_FADRC algorithms exhibit smaller speed deviations. In particular, the NS_FADRC algorithm stabilizes the speed at the rated value with the least speed deviation and the shortest time across all operating conditions. From

Table 7, it can be directly observed that at

T0 = 5 °C, among the four control algorithms, the NS_FADRC algorithm achieves the smallest transient regulation rate and the shortest settling time under A1, A2, A3, and A4 conditions, indicating that it can still maintain the best dynamic response performance in low-temperature environments.

Next, we set the ambient temperature

T0 = 20 °C and conducted simulation tests on the four control algorithms under identical load conditions to evaluate their control performance at temperatures higher than the ISO standard environment. As shown in

Figure 12, the PID control algorithm exhibits the largest speed deviation and significant fluctuations when the operating conditions change. In contrast, the FPID control algorithm shows smaller speed deviations than the PID algorithm, and the LADRC algorithm further reduces the speed deviation compared to the FPID. According to

Table 8, the NS_FADRC algorithm demonstrates the smallest speed deviation and the shortest stabilization time compared to the other three algorithms. In conclusion, the NS_FADRC algorithm proposed in this paper maintains the best control performance even at temperatures above those of the ISO standard environment.

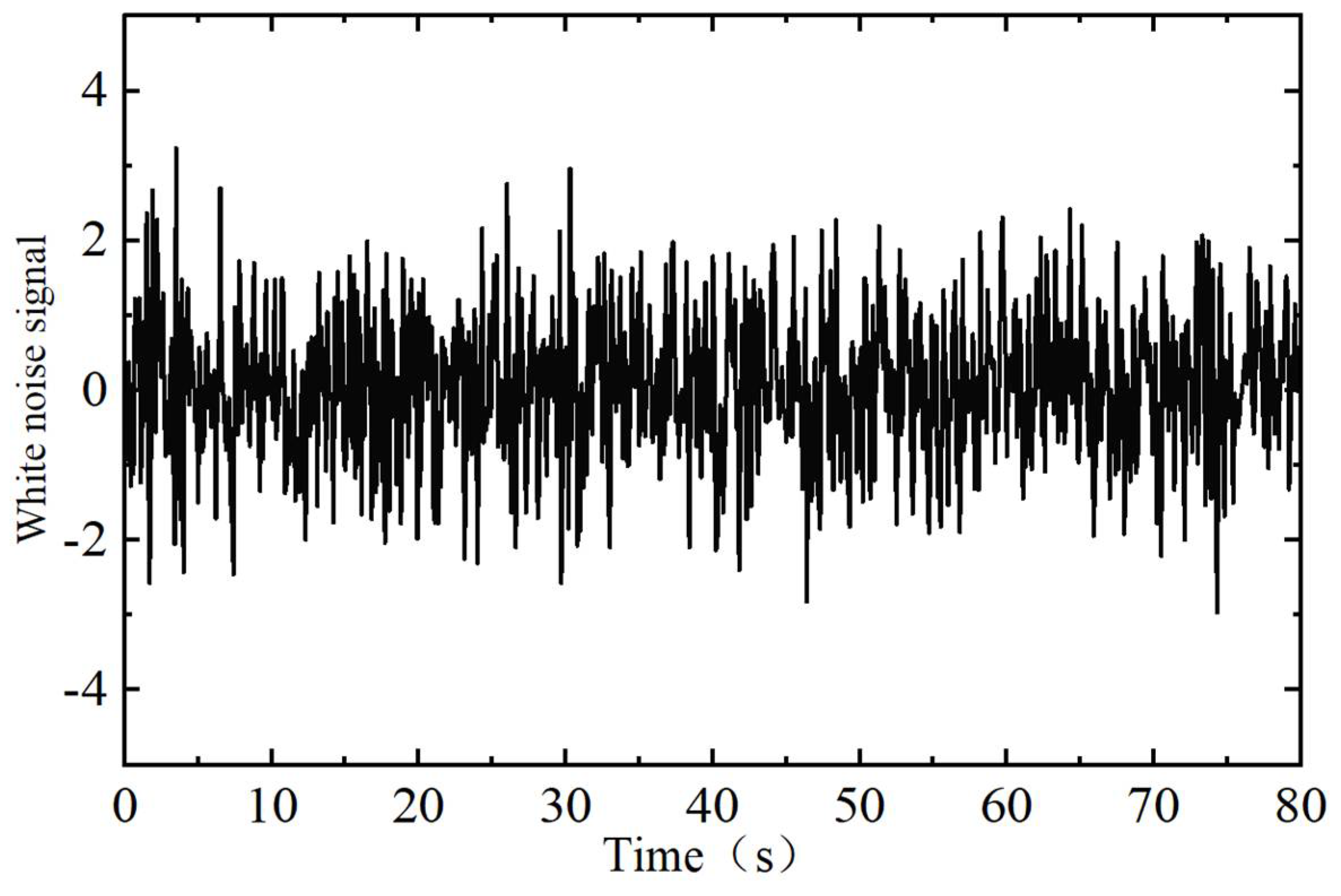

4.5. Performance Testing Under Measurement Noise Interference

In the actual operation of a gas turbine, the speed measurement signal is often affected by sensor measurement noise. To better simulate real-world scenarios, Gaussian white noise with a zero mean was added to the speed signal, as shown in

Figure 13. The mathematical expression of the Gaussian white noise signal is

, where

is a random variable that follows a Gaussian distribution with a mean of 0 and a variance of 1, and

is a constant, which is taken as 2 in this paper. The test load conditions retain the labels of A1, A2, A3, and A4, with the gain parameters of the four control algorithms continuing to use the values from

Table 3.

The gas turbine speed response results are shown in

Figure 14. It can be observed that after the operating conditions change, the NS_FADRC algorithm achieves the smallest speed deviation and the shortest time to stabilize the speed at the rated value. In comparison, the speed deviation of the LADRC algorithm is similar to that of NS_FADRC, but it exhibits overshoot during the speed recovery phase, resulting in a longer stabilization time. The FPID control algorithm adjusts the parameters of the control algorithm using fuzzy logic, and its speed deviation and stabilization time are smaller than those of the PID control algorithm in all test conditions. Both LADRC and NS_FADRC utilize observers to estimate disturbances, significantly improving the disturbance rejection capability of the control algorithm, and their control performance in all four load disturbance conditions is far superior to that of the FPID and PID control algorithms.

Even in the presence of measurement noise in the speed signal, the NS_FADRC algorithm still demonstrates excellent dynamic response performance, indicating its strong robustness and adaptability to noise. This result further verifies the effectiveness and reliability of the NS_FADRC algorithm for practical gas turbine control.

5. Conclusions

This paper proposes a novel NS_FADRC speed control method for gas turbines, based on nonsmooth control theory and fuzzy control principles. Unlike conventional approaches, the proposed method does not require an accurate mathematical model of the gas turbine. Instead, it treats the unknown nonlinear dynamics and external disturbances of the system as perturbations, which are estimated and compensated for using the ESO. Furthermore, the traditional ESO is enhanced through nonsmooth control theory, enabling finite-time convergence and thereby improving its disturbance estimation capability. To overcome the limitations of traditional LSEF and NSEF, including poor adaptability to dynamic system changes, difficulty in tracking complex disturbances, and challenges in parameter tuning, the paper introduces fuzzy logic control. This leads to the design of a novel fuzzy adaptive control law that dynamically adjusts the parameters of the PD controller. The stability of the proposed control scheme is rigorously validated through Lyapunov-based stability analysis.

To demonstrate the effectiveness and superiority of the proposed control algorithm, an HIL semi-physical experimental platform is developed using automatic code generation technology. The NS_FADRC controller is compared against PID, FPID, and LADRC methods. Experimental results reveal that, under conditions such as speed step tracking, load disturbances, and the presence of parameter uncertainties and measurement noise, the NS_FADRC algorithm consistently outperforms the other methods in terms of control performance. In contrast to passive disturbance rejection approaches like PID and FPID, NS_FADRC actively estimates and compensates for disturbances, significantly enhancing the dynamic response and robustness of the gas turbine generator set on the MASS, thereby enhancing the maneuverability and reliability of the MASS. In addition, the research findings presented in this paper are also applicable to the control fields of industrial gas turbines and aircraft engines, demonstrating strong generalization ability and versatility.