Research on Heave Compensation Systems and Control Methods for Deep-Sea Mining

Abstract

1. Introduction

2. Overview of Heave Compensation in Ocean Engineering and Characteristics and Requirements of Heave Compensation for Deep-Sea Mining

2.1. Development of Heave Compensation Systems and Control Methods in Ocean Engineering

2.2. Characteristics and Requirements of Heave Compensation Control in Deep-Sea Mining Systems

2.3. Research and Development of Heave Compensation Systems in Deep-Sea Mining

3. Research and Proposal of Heave Compensation System for Deep-Sea Mining

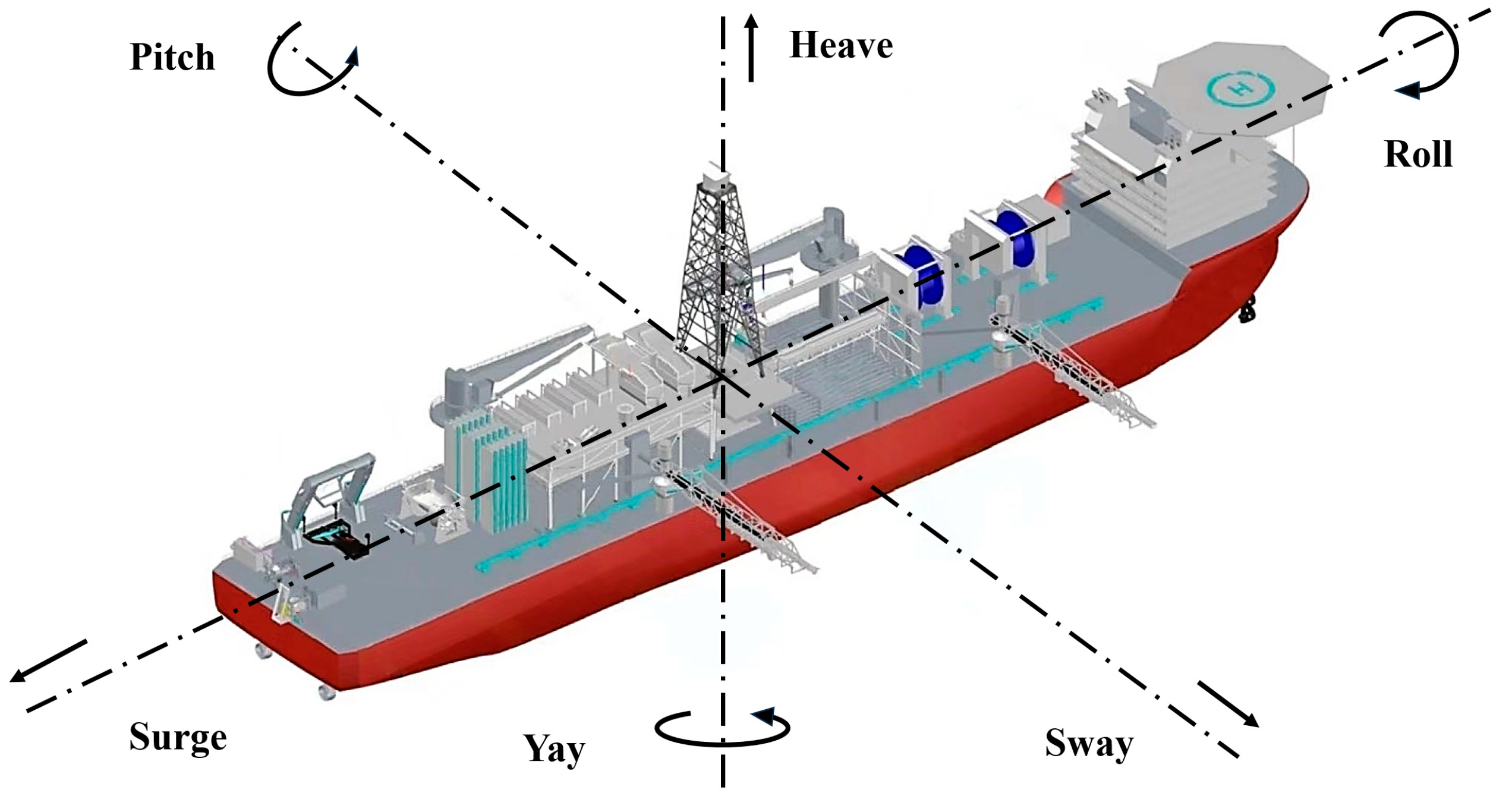

3.1. Proposal for Pitch and Roll Motion Compensation of the Lift Pipe System

3.2. Proposal for Heave Motion Compensation and Heave Compensation System Design

4. Research and Proposal of Heave Compensation Control Methods for Deep-Sea Mining

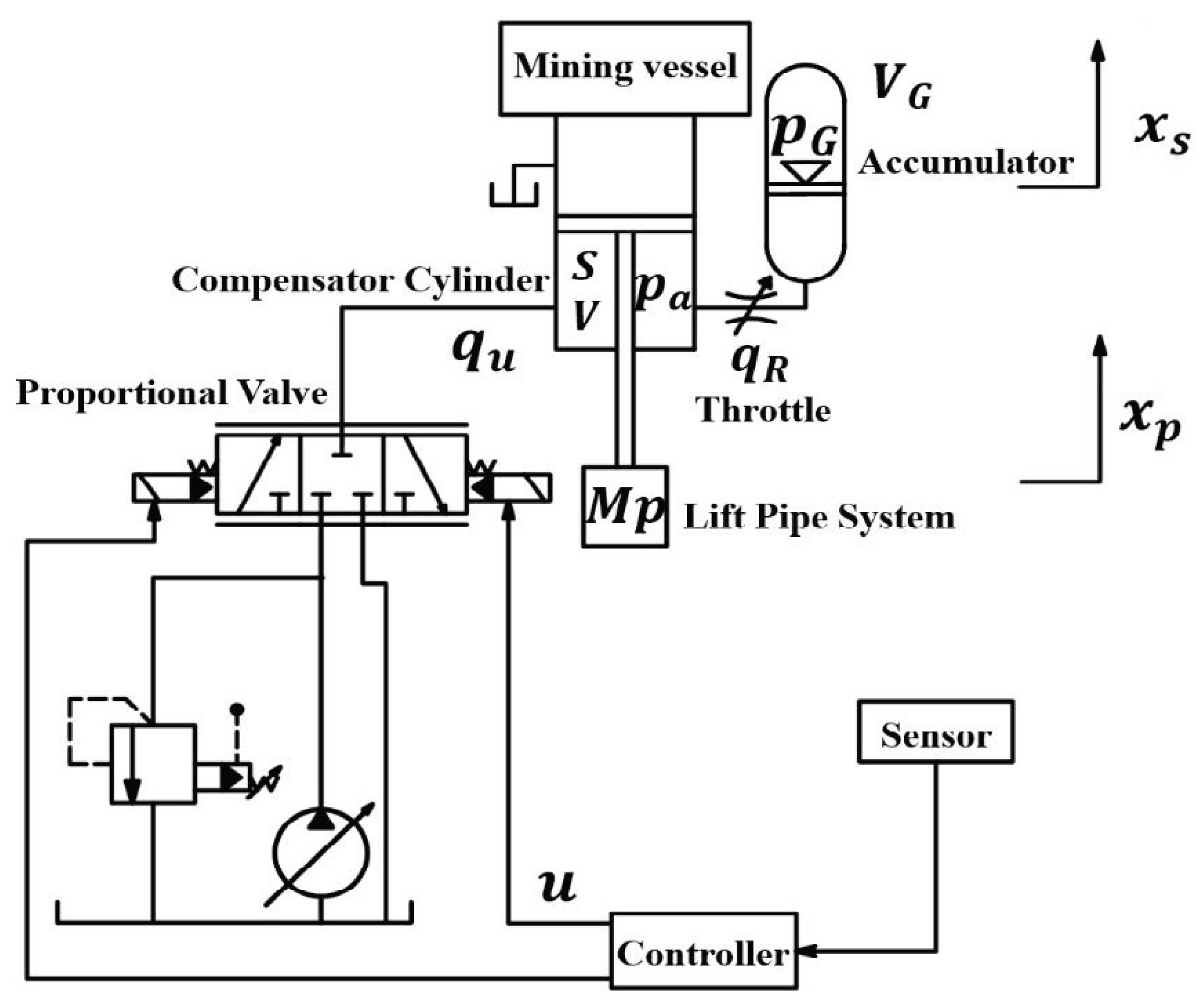

4.1. Construction of a Dynamic Model for the Proposed Heave Compensation System

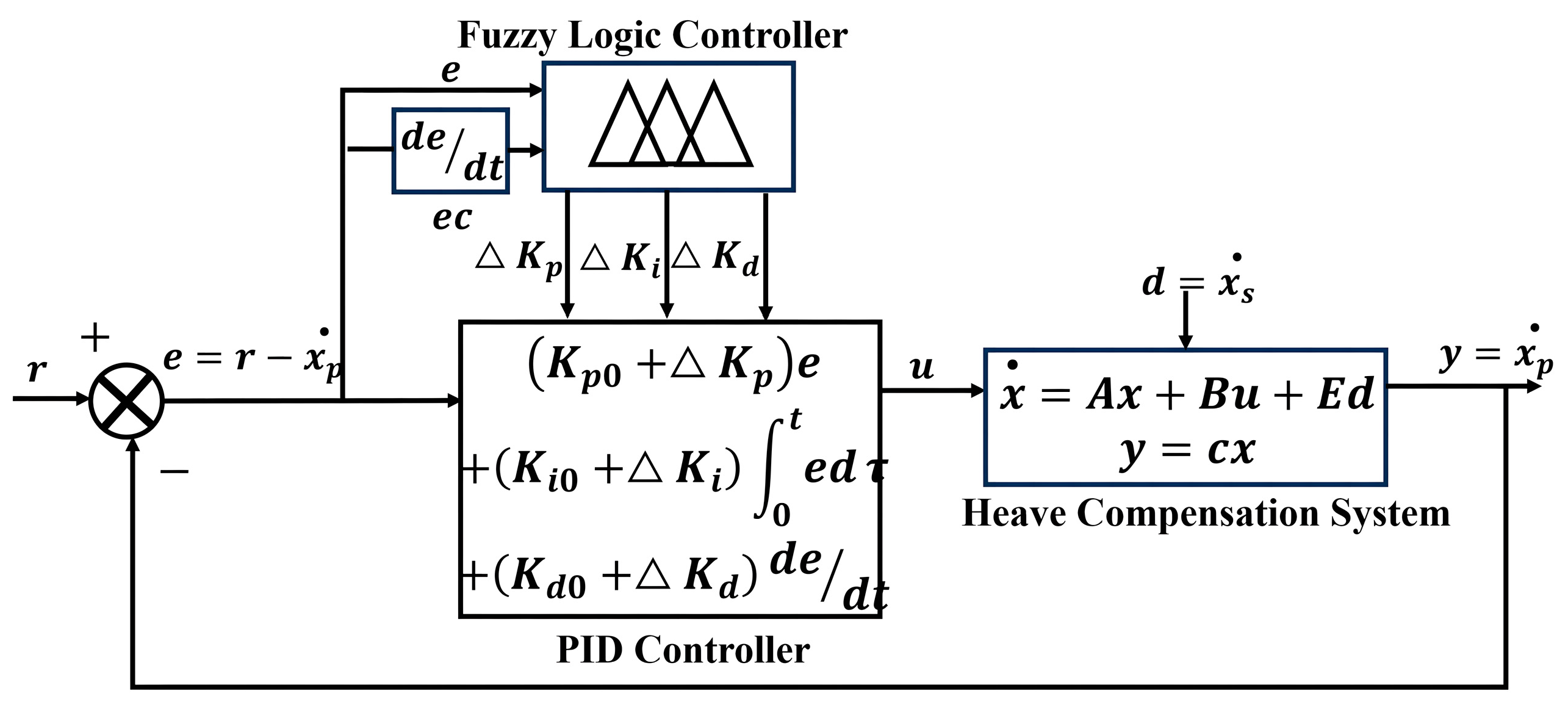

4.2. Design of the Fuzzy PID Control System for Heave Motion Compensation

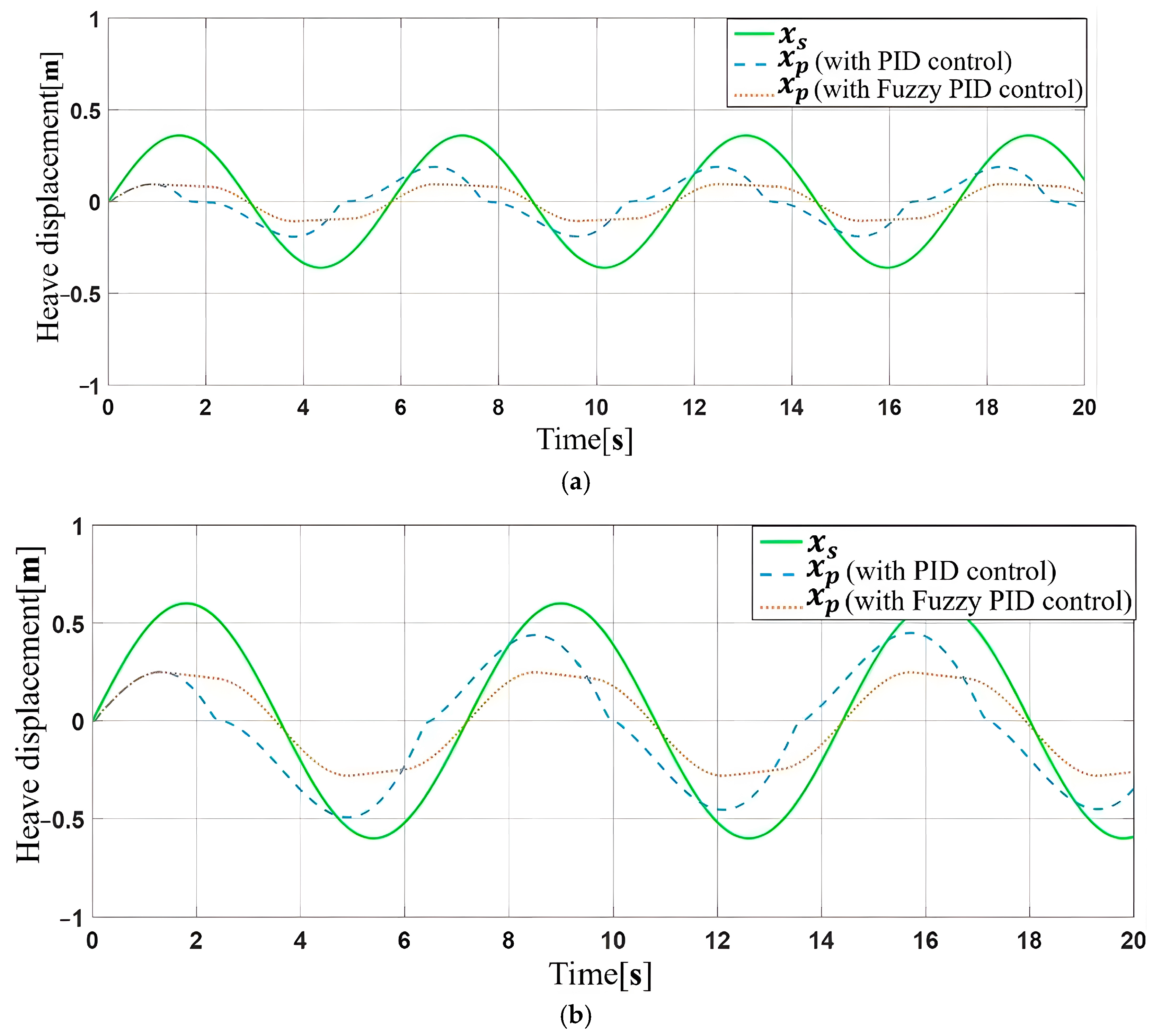

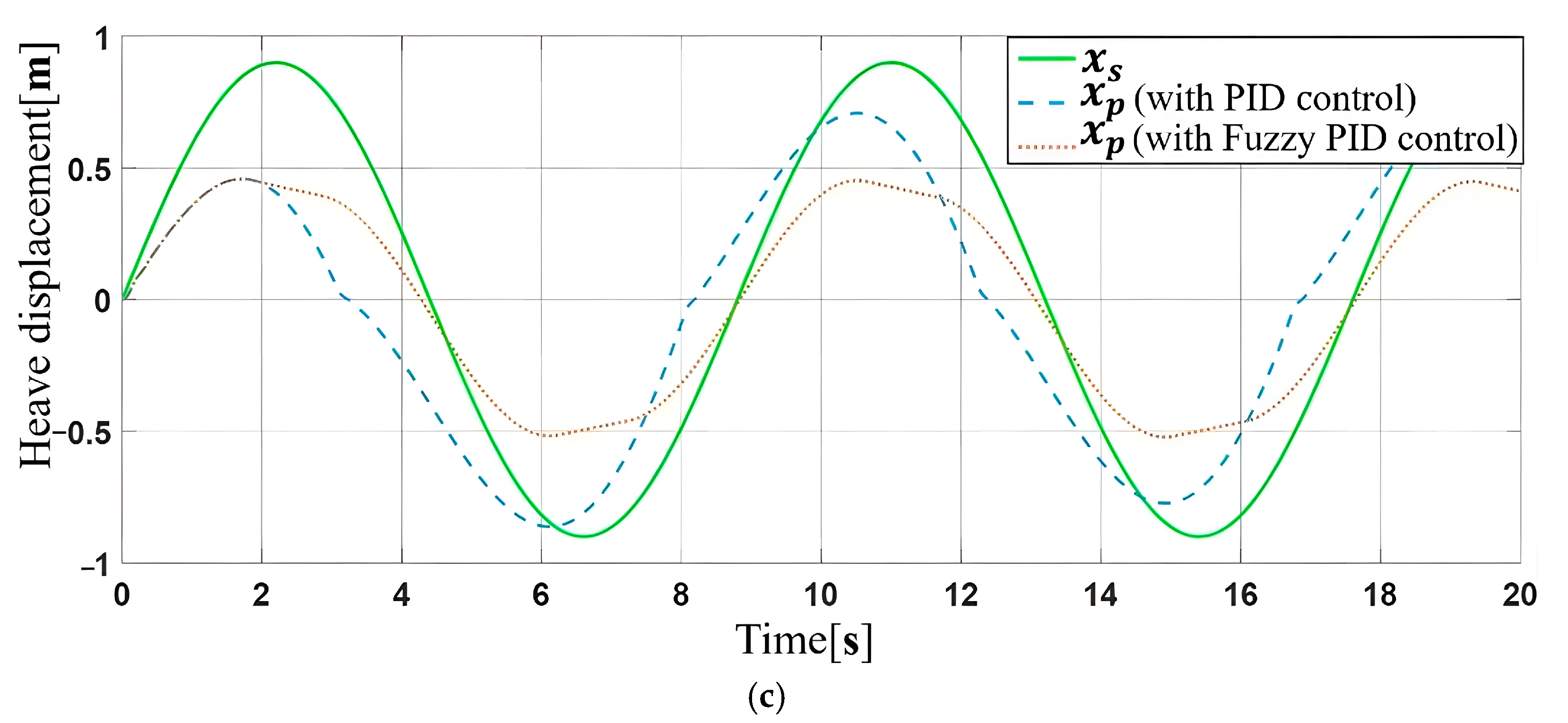

4.3. Analysis of Heave Motion Compensation Performance Based on Fuzzy PID Control

- The amplitude of changes in is much larger than that of and , indicating that the fuzzy PID controller primarily adjusts the proportional control parameter to alter the controller’s output signal;

- In the same sea state, increases linearly with the heave velocity of the lift pipe system, with a generally consistent trend, but, when the heave velocity approaches zero, it takes a smaller value within a certain range and remains relatively constant;

- Under different sea conditions, increases more significantly in higher sea states.

5. Conclusions

- (1)

- The characteristics of heave compensation for deep-sea mining were analyzed in this paper. Since the underwater load is a multi-kilometer-long lift pipe system suspended beneath the mining vessel, heave compensation for deep-sea mining is not typically performed by controlling cables. Instead, it is generally executed using long-stroke hydraulic (or pneumatic) cylinders, and a specialized mechanism is required for compensating pitch and roll motions.

- (2)

- A heave compensation system for deep-sea mining is proposed. This system replaces traditional gimbal mechanisms with flexible joints to compensate for pitch and roll motions, increasing the compensation angles from less than ±10° to ±15° without occupying the deck area of the mining vessel. A single-chamber, valve-controlled compensation cylinder with a high-pressure accumulator is employed for heave motion compensation. This configuration is compact and capable of generating a large compensation force. The flexible joint and high-pressure hydraulic control system have been successfully implemented in the offshore oil and gas industry, demonstrating strong economic viability and engineering feasibility. The proposed solutions have completed conceptual design and obtained Approval in Principle (AIP) certification from the China Classification Society.

- (3)

- The fuzzy PID control method for the heave compensation system in deep-sea mining and its application effects are studied. Using commercial deep-sea polymetallic nodule mining operations as the research background, a dynamic model is established for the proposed heave motion compensation system, and the control system is designed based on the fuzzy PID control method. Subsequently, an analysis of heave compensation performance under different sea conditions is conducted. The results indicate that the fuzzy PID control system dynamically adjusts the PID controller parameters, particularly the proportional control gain, according to the heave velocity and acceleration of the lifting pipeline: when the heave velocity and acceleration are high, a larger proportional gain is applied to enhance compensation; when they are low, a smaller gain is used to conserve compensatory energy. Therefore, compared to conventional PID control, fuzzy PID control achieves a superior heave compensation performance under disturbances of varying magnitudes and frequencies, improving the mining system’s capability to compensate for heave motion across diverse sea conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zinage, S.; Somayajula, A. A comparative study of different active heave compensation approaches. Ocean Syst. Eng. 2020, 10, 373–397. [Google Scholar] [CrossRef]

- Xie, T.C.; Huang, L.P.; Zou, D.S.; Chen, L.; Liu, D.S. Modelling and simulation analysis of active heave compensation control system for marine winch. Ocean Eng. 2021, 39, 1005–1009. [Google Scholar] [CrossRef]

- Yan, F.; Fan, K.; Yan, X.C.; Li, S.Z. Constant tension control of hybrid Active-Passive heave compensator based on adaptive integral sliding mode method. IEEE Access 2020, 8, 103782–103791. [Google Scholar] [CrossRef]

- Luo, M.Y. Research on Control System of ROV Active Heave Compensation Based on Prediction of Motion. Ph.D. Thesis, Shanghai Jiao Tong University, Shanghai, China, 2020. [Google Scholar]

- Ni, J.; Liu, S.; Wang, M.; Hu, X.; Dai, Y. The simulation research on passive heave compensation system for deep sea mining. In Proceedings of the International Conference on Mechatronics and Automation, Changchun, China, 9–12 August 2009; pp. 5111–5116. [Google Scholar] [CrossRef]

- Hatleskog, J.T.; Dunnigan, M.W. Heave compensation simulation for non-contact operations in deep water. In Proceedings of the OCEANS 2006, Boston, MA, USA, 18–21 September 2006; pp. 1–6. [Google Scholar] [CrossRef]

- Korde, U.A. Active heave compensation on drill-ships in irregular waves. Ocean Eng. 1998, 25, 541–561. [Google Scholar] [CrossRef]

- Woodacre, J.K.; Bauer, R.J.; Irani, R.A. A review of vertical motion heave compensation systems. Ocean Eng. 2015, 104, 140–154. [Google Scholar] [CrossRef]

- Hu, Z.W.; Song, Y. Experiment Research on the Power Characteristics of Heavy-Duty Semi-Active Heave Compensation Hydraulic System. Chin. Hydraul. Pneum. 2020, 5, 80–85. [Google Scholar]

- Teng, Y.Y.; Hu, Z.G.; Song, Y.; Chen, L.K. Energy Consumption Analysis of Mining Ship Heave Compensation System Based on AMESim. Mach. Tool Hydraul. 2023, 11, 170–174. [Google Scholar] [CrossRef]

- Kuchler, S.; Mahl, T.; Neupert, J.; Schneider, K.; Sawodny, O. Active control for an offshore crane using prediction of the vessels motion. IEEE/ASME Trans. Mechatron. 2011, 16, 297–309. [Google Scholar] [CrossRef]

- Hatleskog, J.T.; Dunnigan, M.W. Active heave crown compensation subsystem. In Proceedings of the OCEANS 2007—Europe, Aberdeen, UK, 18–21 June 2007; pp. 1–6. [Google Scholar] [CrossRef]

- Chen, H.; Wang, X.; Benbouzid, M.; Charpentier, J.-F.; Aϊt-Ahmed, N.; Han, J. Improved Fractional-Order PID Controller of a PMSM-Based Wave Compensation System for Offshore Ship Cranes. J. Mar. Sci. Eng. 2022, 10, 1238. [Google Scholar] [CrossRef]

- Kang, Y.J.; Liu, S.J. The development history and latest progress of Deep-Sea polymetallic nodule mining technology. Minerals 2021, 11, 1132. [Google Scholar] [CrossRef]

- Wang, M.H.; Jian, Q. Study on mining environment in China’s ocean mining area. China Min. Mag. 1996, 4, 22–25. [Google Scholar]

- Kang, D.; Kang, H.; Lee, K.; Ryu, M.; Lee, S.; Park, S. The preliminary front-end engineering and design of manganese nodules mining vessel. In Proceedings of the OCEANS—Yeosu, Yeosu, Republic of Korea, 21–24 May 2012; pp. 1–8. [Google Scholar] [CrossRef]

- Hu, Q. The Simulation Test Research on Mechanical Behavior of the Lifting Pipe System of Deep-Ocean Mining. Ph.D. Thesis, Central South University, Changsha, China, 2011. [Google Scholar]

- Li, L.J. Study on Design and Control of Active Heave Compensation System of Deep-Sea Mining Based on Dynamic Vibration Absorber. Ph.D. Thesis, Central South University, Changsha, China, 2012. [Google Scholar]

- Zheng, X.Z. Research on Kinematics of Hybrid Serial-Parallel Mechanisms for Compensating Platform in Deep-Ocean Mining. Ph.D. Thesis, Huazhong University of Science and Technology, Wuhan, China, 2004. [Google Scholar]

- Mcnary, J.F.; Person, A.; Ozudogru, Y.H. A 7500 ton capacity shipboard completely gimbaled and heave compensated platform. J. Pet. Technol. 1977, 29, 439–448. [Google Scholar] [CrossRef]

- Kaufman, R.; Latimer, J.P.; Tolefson, D.C.; Senni, S. The design and operation of a pacific ocean Deep-Ocean mining test ship: R/V Deepsea Minner 2. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 1985. OTC-4901-MS. [Google Scholar] [CrossRef]

- Brockett, F.H.; Huizingh, J.P.; McFarlane, J.A.R. Updated analysis of the capital and operating costs of a polymetallic nodule deep ocean mining system developed in the 1970s. In Proceedings of the ISA Workshop on Polymetallic Nodule Mining Technology, Chennai, India, 18–22 February 2008; pp. 54–80. [Google Scholar]

- Xiao, T.B.; Wu, B.H.; Luo, Z.H. Research on design and simulation of active heave compensation system of heavy lifting mine pipeline. Mach. Tool Hydraul. 2002, 6, 47–51. [Google Scholar]

- Tang, X.; Liu, S.; Huang, K. Design and simulation study on a virtual prototype of an active heave compensation system for Deep-ocean mining. In Proceedings of the Sixth ISOPE Ocean Mining Symposium, Changsha, China, 9–13 October 2005. [Google Scholar]

- Xiao, S.Y.; Xiao, T.B.; Liao, H.; Wu, B.H. Design and simulation of Heavy-load 3-Dimension motion compensation system for Deep-sea mining device. Mach. Tool Hydraul. 2009, 37, 202–204. [Google Scholar]

- Guo, Z.X. Study on Coupled Motion and Heave Compensation of Hydraulic Lifting System for Deep Sea Nodules. Ph.D. Thesis, Harbin Engineering University, Harbin, China, 2023. [Google Scholar]

- Zeng, F.Y. Design and Simulation Study of the Heave Compensation System Combined Action of Vibration Absorber and Accumulator. Ph.D. Thesis, Central South University, Changsha, China, 2010. [Google Scholar]

- Li, L.; Liu, S. Modeling and simulation of active-controlled heave compensation system of deep-sea mining based on dynamic vibration absorber. In Proceedings of the International Conference on Mechatronics and Automation, Changchun, China, 9–12 August 2009; pp. 1337–1341. [Google Scholar] [CrossRef]

- Lu, C. Research on Control Methods and Modeling and Simulation for the Wave Compensation System in the Deep-Sea Mining. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2009. [Google Scholar]

- Xiao, Q.J.; Wu, B.H.; Xiao, T.B.; Luo, Z.H. Fuzzy hybrid PID control applied in the deep sea mining heave compensate simulation system. Chin. Hydraul. Pneum. 2004, 10, 49–51. [Google Scholar]

- Li, W.H. Research on Neural Network Parameters Adaptive Control for Deep-Sea Mining Heave Motion Compensation. Ph.D. Thesis, Guangdong University of Technology, Guangzhou, China, 2011. [Google Scholar]

- Zhang, Y.; Sun, Y.G.; Hu, Z.G.; Fang, B.F.; Xie, Y.; Chen, L.K.; Teng, Y.Y. Control performance analysis of mining ship heave compensation system based on fuzzy logic algorithm. J. Eur. Syst. Autom. 2022, 55, 213–220. [Google Scholar] [CrossRef]

- Teng, Y.Y.; Hu, Z.G.; Sun, Y.G. Virtual prototype modeling and fuzzy control of the heave compensation system for a 500-ton deep-sea mining vessel. Trans. Inst. Meas. Control 2024, 1–13. [Google Scholar] [CrossRef]

- Butler, B. Heave compensation. In Proceedings of the Second Annual European Meeting of the Society of Petroleum Engineers, London, UK, 2–3 April 1973. [Google Scholar] [CrossRef]

- Southerland, A. Mechanical systems for ocean engineering. Naval Eng. J. 1970, 82, 63–74. [Google Scholar] [CrossRef]

- Groves, S.; Hogan, M.; Moses, S.A.; Dean, R.; Hartley, F.T. Flexible joint improvements may aid reliability. Offshore 2006, 66, 88–90. [Google Scholar]

- Oil States Industries, Inc. Technical Manual for Diverter II Flexible Joint Assembly; Oil States Industries: Arlington, TX, USA, 2015. [Google Scholar]

- Alex, R.; Li, J.; Liu, T.J. A riser and lifting system concept for deep sea polymetallic nodule mining. In Proceedings of the 50th Underwater Minerals Conference, St. Petersburg, FL, USA, 2–7 October 2022; pp. 1–12. [Google Scholar]

- Xiao, T.B. Research on Intelligent Heave Compensation System for Deep-Sea Mining Device. Ph.D. Thesis, Guangdong University of Technology, Guangzhou, China, 2004. [Google Scholar]

| Sea State | 4 | 5 | 6 |

|---|---|---|---|

| Heave Amplitude & Period | 0.36 m, 5.8 s | 0.6 m, 7.2 s | 0.9 m, 8.8 s |

| Pitch Amplitude | ±4° | ±8° | ±15° |

| Roll Amplitude | ±4° | ±15° | ±22° |

| Sea State | PID Control | Fuzzy PID Control | Compensation Improvement Rate |

|---|---|---|---|

| 4 | 47.72% | 74.12% | 26.4% |

| 5 | 25.75% | 58.93% | 33.18% |

| 6 | 17.16% | 50.78% | 33.62% |

| 36% | 69% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, Y.; Fang, H.; Wang, C.; Liu, S. Research on Heave Compensation Systems and Control Methods for Deep-Sea Mining. J. Mar. Sci. Eng. 2025, 13, 652. https://doi.org/10.3390/jmse13040652

Kang Y, Fang H, Wang C, Liu S. Research on Heave Compensation Systems and Control Methods for Deep-Sea Mining. Journal of Marine Science and Engineering. 2025; 13(4):652. https://doi.org/10.3390/jmse13040652

Chicago/Turabian StyleKang, Yajuan, Hongtao Fang, Changwei Wang, and Shaojun Liu. 2025. "Research on Heave Compensation Systems and Control Methods for Deep-Sea Mining" Journal of Marine Science and Engineering 13, no. 4: 652. https://doi.org/10.3390/jmse13040652

APA StyleKang, Y., Fang, H., Wang, C., & Liu, S. (2025). Research on Heave Compensation Systems and Control Methods for Deep-Sea Mining. Journal of Marine Science and Engineering, 13(4), 652. https://doi.org/10.3390/jmse13040652