Improving Green Shipping by Using Alternative Fuels in Ship Diesel Engines

Abstract

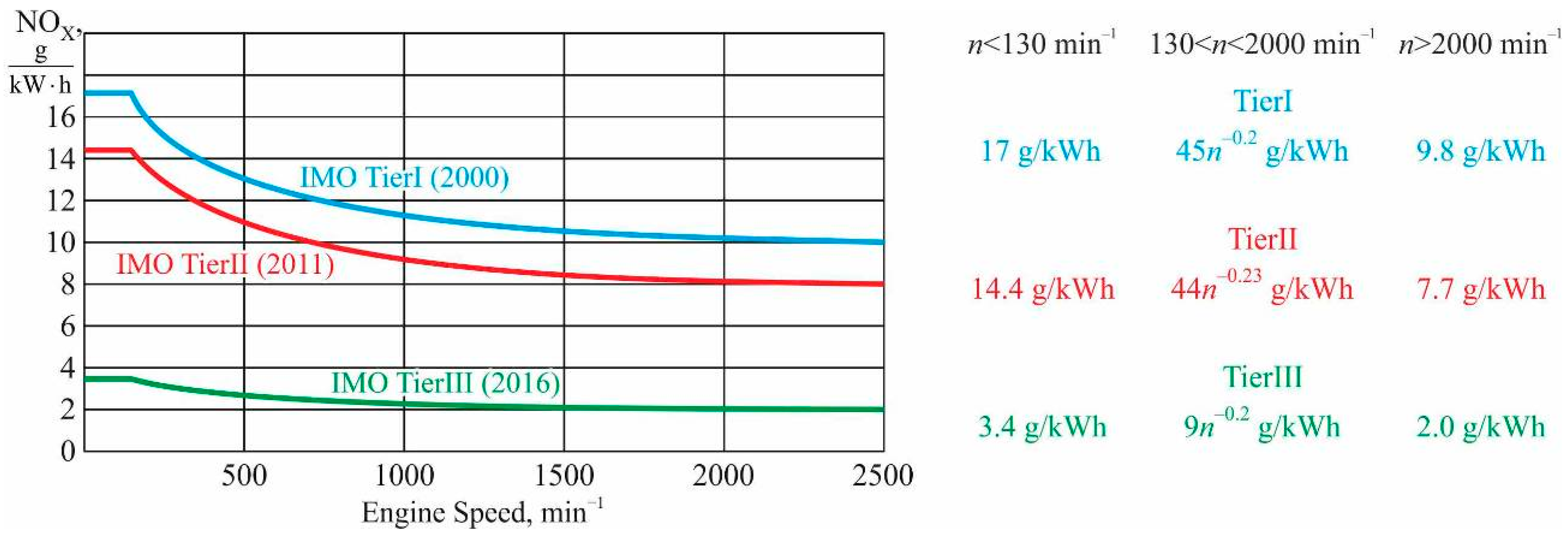

1. Introduction

- No more than 0.1% when the vessel is in special environmental areas (Sulfur Emission Control Areas—SECAs);

- No more than 0.5% when the vessel is outside SECAs.

2. Literature Review

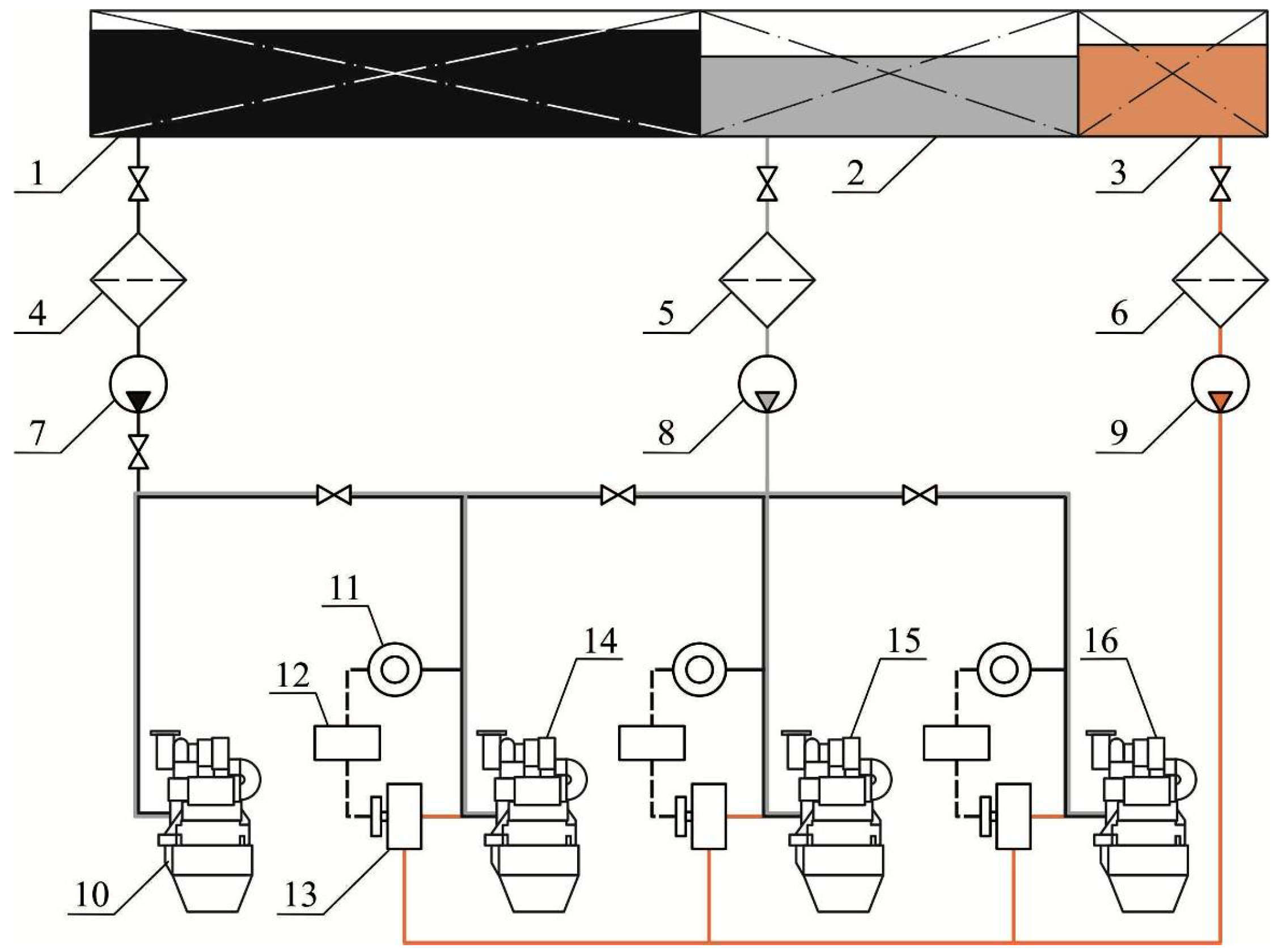

3. Materials and Methods

- Type—four-stroke, trunk;

- Diameter of cylinder unit—0.32 m;

- Stroke—0.40 m;

- Rotation speed—750 min−1;

- Number of cylinders—6;

- Power—3480 kW.

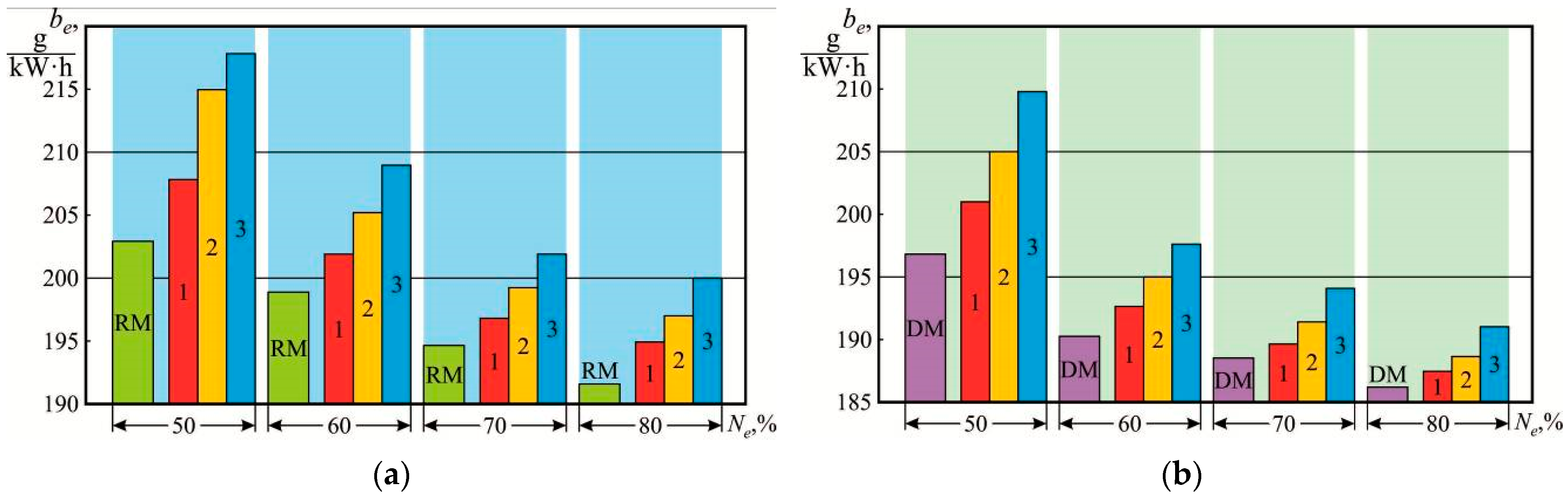

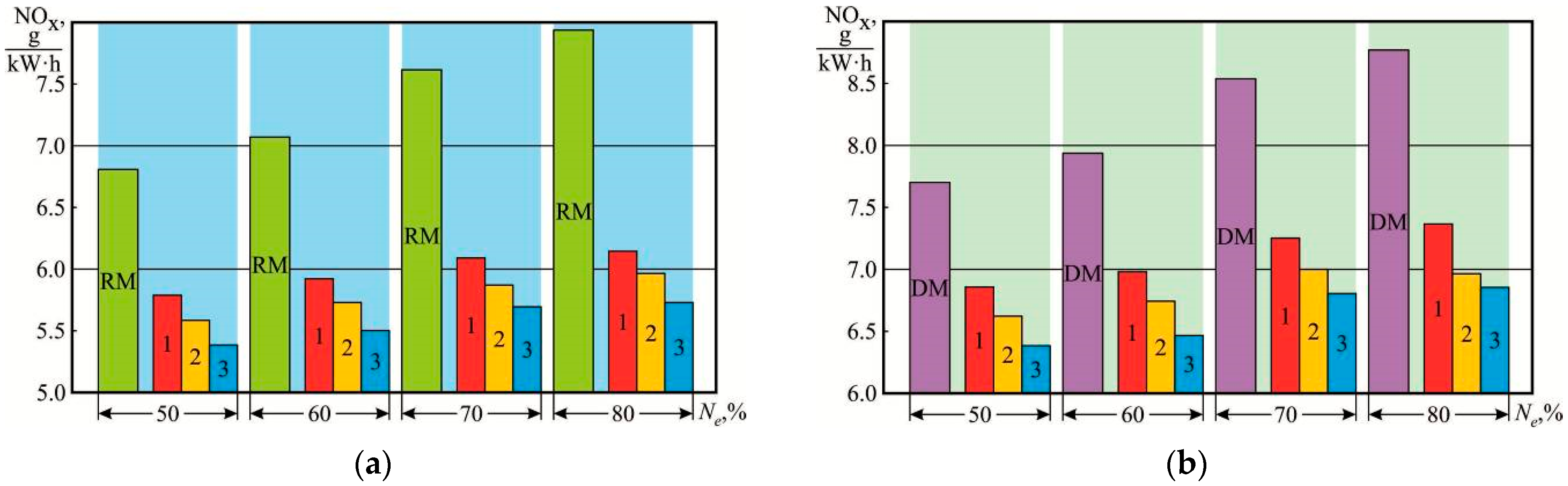

4. Results

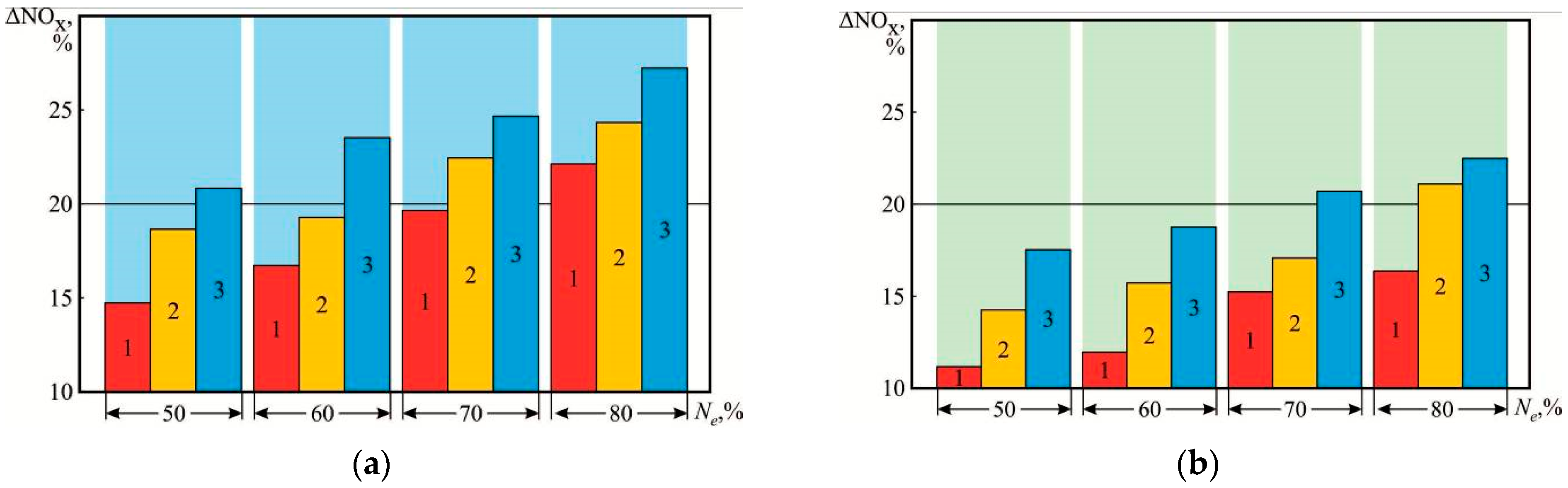

- For a 50% load from a value of 6.82 g/(kW·h), which corresponds to operations on fuel of oil origin RMG500 to values of 5.43 g/(kW·h), 5.63 g/(kW·h), and 5.81 g/(kW·h), which correspond to fuel mixtures containing 10%, 20%, and 30% FAME biodiesel, respectively; in relative values, this is 14.81%, 17.45%, and 20.38%;

- For a 60% load from a value of 7.12 g/(kW·h), which corresponds to operations on oil-based fuel RMG500 to values of 5.93 g/(kW·h), 5.75 g/(kW·h), and 5.53 g/(kW·h), which correspond to fuel mixtures containing 10%, 20%, and 30% FAME biodiesel, respectively; in relative values, this is 16.71%, 19.24%, and 22.33%;

- For a 70% load from a value of 7.62 g/(kW·h), which corresponds to operations on RMG500 petroleum fuel to values of 6.12 g/(kW·h), 5.93 g/(kW·h), and 5.73 g/(kW·h), which correspond to fuel mixtures containing 10%, 20% and 30% FAME biodiesel, respectively; in relative values, this is 19.69%, 22.18% and 24.80%;

- For an 80% load from the value of 7.97 g/(kW·h), which corresponds to operations on oil-based fuel RMG500 to the values of 6.18 g/(kW·h), 6.01 g/(kW·h), and 5.81 g/(kW·h), which correspond to fuel mixtures containing 10%, 20%, and 30% FAME biodiesel, respectively; in relative values, this is 22.46%, 24.59% and 27.10%.

- For a 50% load—11.20%, 14.71%, and 17.71%, which correspond to 10%, 20%, and 30% of the FAME biodiesel content in the fuel mixture;

- For a 60% load—11.93%, 15.58%, and 18.47%, which correspond to 10%, 20%, and 30% of the FAME biodiesel content in the fuel mixture;

- For a 70% load—15.36%, 17.70%, and 20.52%, which correspond to 10%, 20%, and 30% of the FAME biodiesel content in the fuel mixture;

- For an 80% load—16.42%, 20.64%, and 22.01%, which correspond to 10%, 20%, and 30% of the FAME biodiesel content in the fuel mixture.

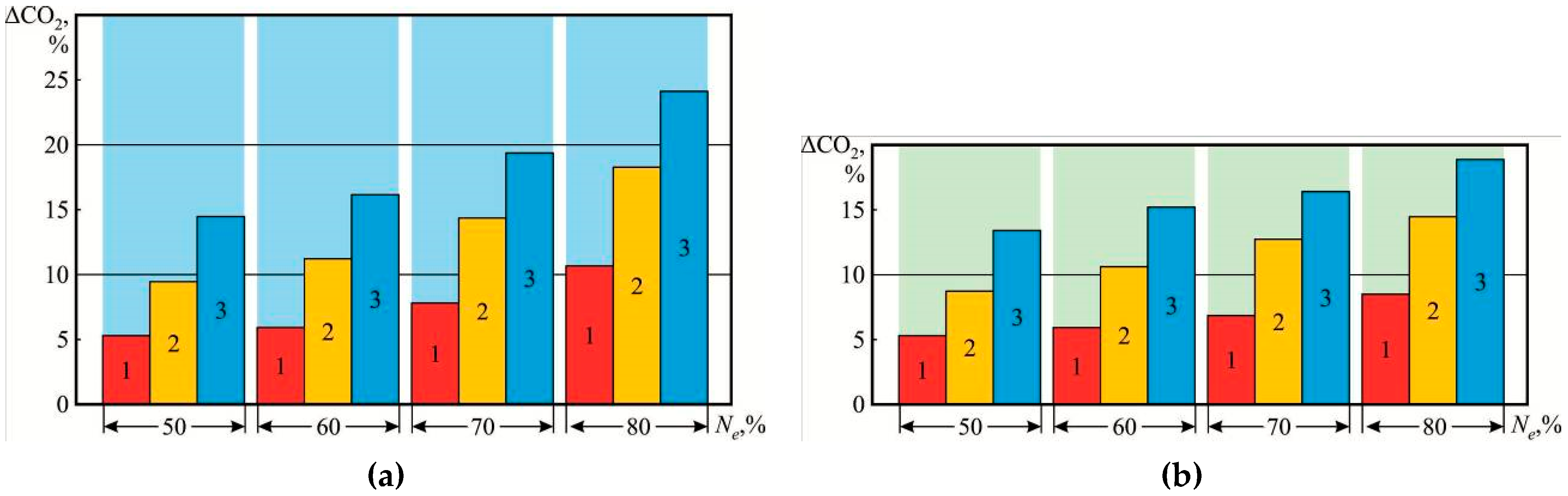

- The use of biodiesel also leads to CO2 emission reductions, namely

- Fora 50% load from a value of 6.22%, which corresponds to operations on RMG500 petroleum-based fuel to values of 5.88%, 5.62%, and 5.40%, which correspond to fuel mixtures containing 10%, 20%, and 30% FAME biodiesel, respectively; in relative values, this is 5.47%, 9.65%, and 14.63%;

- For a 60% load from a value of 6.43%, which corresponds to operations on RMG500 petroleum-based fuel to values of 6.03%, 5.72%, and 5.31%, which correspond to fuel mixtures containing 10%, 20%, and 30% FAME biodiesel, respectively; in relative values, this is 6.22%, 11.04% and 16.02%;

- For a 70% load from 6.78%, which corresponds to operations on RMG500 petroleum fuel to 6.25%, 5.80%, and 5.46%, which correspond to fuel blends containing 10%, 20%, and 30% FAME biodiesel, respectively; in relative values, this is 7.82%, 14.45% and 19.47%;

- For an 80% load from 7.22%, which corresponds to operations on RMG500 petroleum fuel to 6.42%, 5.86%, and 5.52%, which correspond to fuel blends containing 10%, 20%, and 30% FAME biodiesel, respectively; in relative values, this is 11.08%, 18.84%, and 23.55%.

- For a 50% load—5.31%, 8.85%, and 13.27%, which corresponds to 10%, 20%, and 30% of the content of FAME biodiesel fuel in the fuel mixture;

- For a 60% load—5.97%, 10.81%, and 14.22%, which corresponds to 10%, 20%, and 30% of the content of FAME biodiesel fuel in the fuel mixture;

- For a 70% load—6.69%, 12.99%, and 16.06%, which corresponds to 10%, 20%, and 30% of the content of FAME biodiesel in the fuel mixture;

- For an 80% load—8.18%, 14.58%, and 18.80%, which corresponds to 10%, 20%, and 30% of the content of FAME biodiesel in the fuel mixture.

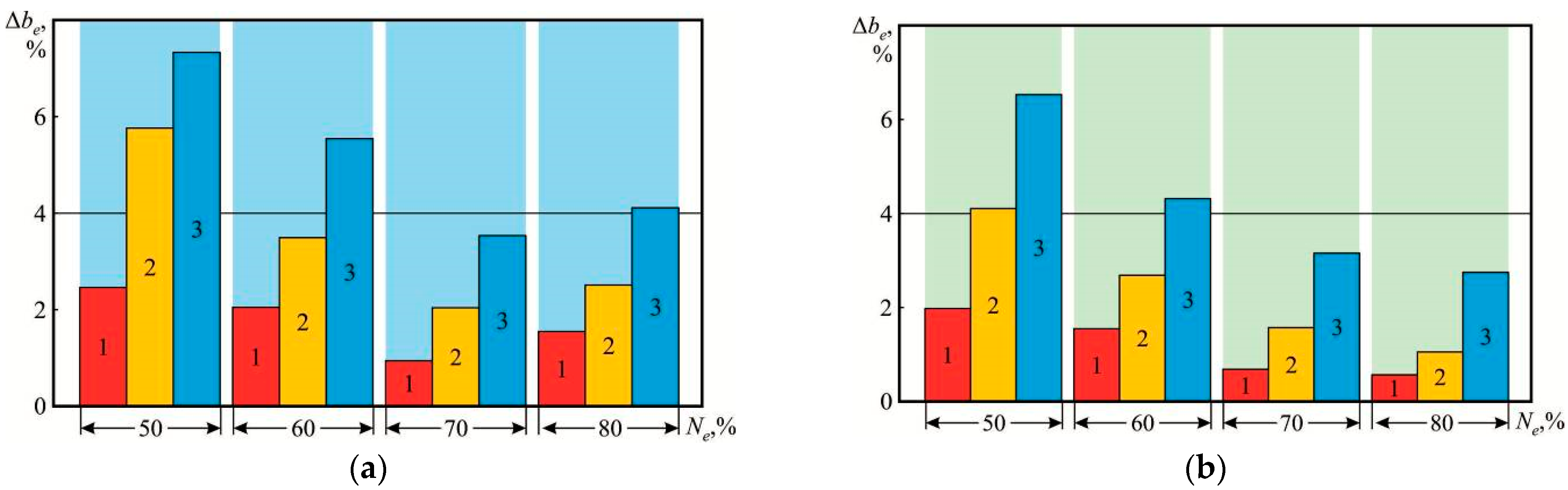

- For a 50% load—2.46%, 5.91%, and 7.39%, corresponding to 10%, 20%, and 30% FAME biodiesel content in the fuel blend;

- For a 60% load—2.02%, 3.54%, and 5.56%, corresponding to 10%, 20%, and 30% FAME biodiesel content in the fuel blend;

- For a 70% load—1.03%, 2.05%, and 3.59%, corresponding to 10%, 20%, and 30% FAME biodiesel content in the fuel blend;

- For an 80% load—1.56%, 2.60%, and 4.17%, which corresponds to 10%, 20%, and 30% of the FAME biodiesel content in the fuel mixture.

- For a 50% load—2.03%, 4.06%, and 6.60%, corresponding to 10%, 20%, and 30% FAME biodiesel content in the fuel mixture;

- For a 60% load—1.58%, 2.63%, and 4.21%, corresponding to 10%, 20%, and 30% FAME biodiesel content in the fuel mixture;

- For a 70% load—0.53%, 1.60%, and 3.19%, corresponding to 10%, 20%, and 30% FAME biodiesel content in the fuel mixture;

- For an 80% load—0.546%, 1.08%, and 2.69%, which corresponds to 10%, 20%, and 30% of the FAME biodiesel content in the fuel mixture.

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sagin, S.; Madey, V.; Sagin, A.; Stoliaryk, T.; Fomin, O.; Kučera, P. Ensuring Reliable and Safe Operation of Trunk Diesel Engines of Marine Transport Vessels. J. Mar. Sci. Eng. 2022, 10, 1373. [Google Scholar] [CrossRef]

- Budashko, V.; Shevchenko, V. The Synthesis Of Control System To Synchronize Ship Generator Assemblies. East.-Eur. J. Enterp. Technol. 2021, 1, 45–63. [Google Scholar] [CrossRef]

- Magkouris, A.; Belibassakis, K. A Novel BEM for the Hydrodynamic Analysis of Twin-Hull Vessels with Application to Solar Ships. J. Mar. Sci. Eng. 2024, 12, 1776. [Google Scholar] [CrossRef]

- Huang, G.; Tang, Y.; Chen, X.; Chen, M.; Jiang, Y. A Comprehensive Review of Floating Solar Plants and Potentials for Offshore Applications. J. Mar. Sci. Eng. 2023, 11, 2064. [Google Scholar] [CrossRef]

- Yasuda, A.; Taniguchi, T.; Katayama, T. Numerical Investigation of Aerodynamic Interactions between Rigid Sails Attached to Ship. J. Mar. Sci. Eng. 2024, 12, 1425. [Google Scholar] [CrossRef]

- Aumtab, C.; Wanichanon, T. Stability and Tracking Control of Nonlinear Rigid-Body Ship Motions. J. Mar. Sci. Eng. 2022, 10, 153. [Google Scholar] [CrossRef]

- Zhang, K.; Xiong, R.; Li, Q.; Chen, C.; Tian, J.; Shen, W. A novel pseudo-open-circuit voltage modeling method for accurate state-of-charge estimation of LiFePO4 batteries. Appl. Energy. 2023, 347, 121406. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Duan, Z.; Wang, C. State of Charge Estimation for Lithium Battery in Shipboard DC Power Grid Based on Differential Evolutionary Algorithm. J. Mar. Sci. Eng. 2025, 13, 126. [Google Scholar] [CrossRef]

- Yan, Y.; Chen, Z.; Gao, D. Nonlinear Model Predictive Control Energy Management Strategy for Hybrid Power Ships Based on Working Condition Identification. J. Mar. Sci. Eng. 2025, 13, 269. [Google Scholar] [CrossRef]

- Sagin, S.V.; Kuropyatnyk, O.A.; Zablotskyi, Y.V.; Gaichenia, O.V. Supplying of Marine Diesel Engine Ecological Parameters. Naše More Int. J. Marit. Sci. Technol. 2022, 69, 53–61. [Google Scholar] [CrossRef]

- Sagin, S.; Kuropyatnyk, O.; Matieiko, O.; Razinkin, R.; Stoliaryk, T.; Volkov, O. Ensuring Operational Performance and Environmental Sustainability of Marine Diesel Engines through the Use of Biodiesel Fuel. J. Mar. Sci. Eng. 2024, 12, 1440. [Google Scholar] [CrossRef]

- Wen, M.; Li, Y.; Zhu, W.; Cao, R.; Sun, K. Experimental Study on Effects of RCSL and RCTL Combustion Chamber for Combustion Process of Highly Intensified Diesel Engine. Energies. 2022, 15, 6368. [Google Scholar] [CrossRef]

- Varbanets, R.; Fomin, O.; Píštěk, V.; Klymenko, V.; Minchev, D.; Khrulev, A.; Zalozh, V.; Kučera, P. Acoustic Method for Estimation of Marine Low-Speed Engine Turbocharger Parameters. J. Mar. Sci. Eng. 2021, 9, 321. [Google Scholar] [CrossRef]

- Sagin, S.V.; Solodovnikov, V.G. Cavitation Treatment of High-Viscosity Marine Fuels for Medium-Speed Diesel Engines. Mod. Appl. Sci. 2015, 9, 269–278. [Google Scholar] [CrossRef]

- Sagin, S.V.; Semenov, O.V. Motor Oil Viscosity Stratification in Friction Units of Marine Diesel Motors. Am. J. Appl. Sci. 2016, 13, 200–208. [Google Scholar] [CrossRef]

- Vladov, S.; Shmelov, Y.; Yakovliev, R. Optimization of Helicopters Aircraft Engine Working Process Using Neural Networks Technologies. In Proceedings of the COLINS-2022: 6th International Conference on Computational Linguistics and Intelligent Systems, Gliwice, Poland, 12–13 May 2022; Volume 3171, pp. 1639–1656. Available online: https://ceur-ws.org/Vol-3171/paper117.pdf (accessed on 23 January 2025).

- Sagin, S.; Kuropyatnyk, O.; Sagin, A.; Tkachenko, I.; Fomin, O.; Píštěk, V.; Kučera, P. Ensuring the Environmental Friendliness of Drillships during Their Operation in Special Ecological Regions of Northern Europe. J. Mar. Sci. Eng. 2022, 10, 1331. [Google Scholar] [CrossRef]

- Myrhorod, V.; Hvozdeva, I.; Budashko, V. Multiparameter Approximation Model of Temperature Conditions of Marine Diesel Generator Sets, Based on Markov Chain Monte Carlo. TransNav J. 2022, 16, 779–784. [Google Scholar] [CrossRef]

- Sagin, S.V.; Sagin, S.S.; Fomin, O.; Gaichenia, O.; Zablotskyi, Y.; Píštěk, V.; Kučera, P. Use of biofuels in marine diesel engines for sustainable and safe maritime transport. Renew. Energy. 2024, 224, 120221. [Google Scholar] [CrossRef]

- Nelyubov, D.V.; Fakhrutdinov, M.I.; Sarkisyan, A.A.; Sharin, E.A.; Ershov, M.A.; Makhova, U.A.; Makhmudova, A.E.; Klimov, N.A.; Rogova, M.Y.; Savelenko, V.D.; et al. New Prospects of Waste Involvement in Marine Fuel Oil: Evolution of Composition and Requirements for Fuel with Sulfur Content up to 0.5%. J. Mar. Sci. Eng. 2023, 11, 1460. [Google Scholar] [CrossRef]

- Sagin, S.V.; Kuropyatnyk, O.A. The Use of Exhaust Gas Recirculation for Ensuring the Environmental Performance of Marine Diesel Engines. Naše More Int. J. Marit. Sci. Technol. 2018, 65, 78–86. [Google Scholar] [CrossRef]

- Likhanov, V.A.; Lopatin, O.P. Dynamics of soot formation and burnout in a gas diesel cylinder. IOP Conf. Ser. Mater. Sci. Eng. 2020, 862, 062033. [Google Scholar] [CrossRef]

- Kuropyatnyk, O.A.; Sagin, S.V. The Exhaust Gas Recirculation as a Major Technique Designed to Reduce NOx Emissions from Marine Diesel Engines. Naše More Int. J. Marit. Sci. Technol. 2019, 66, 1–9. [Google Scholar] [CrossRef]

- Van, T.G.; Ramirez, J.; Ristovskim, Z.; Brown, R.J. Global impact of recent IMO regulation on marine fuel oil refining processes and ship emissions. Transp. Res. Part D Transp. Environ. 2019, 70, 123–134. [Google Scholar] [CrossRef]

- Van Roy, W.; Merveille, J.-B.; Scheldeman, K.; Van Nieuwenhove, A.; Schallier, R.; Van Roozendael, B.; Maes, F. Assessment of the Effect of International Maritime Regulations on Air Quality in the Southern North Sea. Atmosphere 2023, 14, 969. [Google Scholar] [CrossRef]

- Melnyk, O.; Onyshchenko, S.; Onishchenko, O. Development measures to enhance the ecological safety of ships and reduce operational pollution to the environment. Sci. J. Silesian Univ. Technol. Ser. Transp. 2023, 118, 195–206. [Google Scholar] [CrossRef]

- Xing, H.; Spence, S.; Chen, H. A comprehensive review on countermeasures for CO2 emissions from ships. Renew. Sustain. Energy Rev. 2020, 134, 110222. [Google Scholar] [CrossRef]

- Grzelakowski, A.S.; Herdzik, J.; Skiba, S. Maritime Shipping Decarbonization: Roadmap to Meet Zero-Emission Target in Shipping as a Link in the Global Supply Chains. Energies 2022, 15, 6150. [Google Scholar] [CrossRef]

- Sagin, S.V.; Karianskyi, S.; Sagin, S.S.; Volkov, O.; Zablotskyi, Y.; Fomin, O.; Píštěk, V.; Kučera, P. Ensuring the safety of maritime transportation of drilling fluids by platform supply-class vessel. Appl. Ocean Res. 2023, 140, 103745. [Google Scholar] [CrossRef]

- Kneba, Z.; Stepanenko, D.; RudnickiI, J. Numerical methodology for evaluation the combustion and emissions characteristics on WLTP in the light duty dual-fuel diesel vehicle. Combust. Engines 2022, 189, 94–102. [Google Scholar] [CrossRef]

- International Convention for the Prevention of Pollution from Ships (MARPOL); International Maritime Organization. Available online: https://www.imo.org/en/about/Conventions/Pages/International-Convention-for-the-Prevention-of-Pollution-from-Ships-(MARPOL).aspx (accessed on 14 February 2025).

- Ershov, M.A.; Savelenko, V.D.; Makhmudova, A.E.; Rekhletskaya, E.S.; Makhova, U.A.; Kapustin, V.M.; Mukhina, D.Y.; Abdellatief, T.M.M. Technological Potential Analysis and Vacant Technology Forecasting in Properties and Composition of Low-Sulfur Marine Fuel Oil (VLSFO and ULSFO) Bunkered in Key World Ports. J. Mar. Sci. Eng. 2022, 10, 1828. [Google Scholar] [CrossRef]

- Shen, F.; Li, X. Effects of fuel types and fuel sulfur content on the characteristics of particulate emissions in marine low-speed diesel engine. Environ. Sci. Pollut. Res. 2020, 27, 37229–37236. [Google Scholar] [CrossRef] [PubMed]

- Zablotsky, Y.V.; Sagin, S.V. Enhancing Fuel Efficiency and Environmental Specifications of a Marine Diesel When using Fuel Additives. Indian J. Sci. Technol. 2016, 9, 353–362. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Xie, G.; Li, J.; Xu, W.; Jiang, F.; Huang, Y.; Tan, D. Investigation on the combustion and emission characteristics of diesel engine fueled with diesel/methanol/n-butanol blends. Fuel 2022, 314, 123088. [Google Scholar] [CrossRef]

- Sahar, M.; Kassem, H.; Driss, Z.; Abid, M. Effects of hydrogen enrichment and injection location on in-cylinder flow characteristics, performance and emissions of gaseous LPG engine. Energy 2021, 150, 92–108. [Google Scholar] [CrossRef]

- Chen, C.; Yao, A.; Yao, C.; Wang, H.; Liu, M.; Li, Z. Selective catalytic reduction of nitrogen oxides with methanol over the (Cobalt-Molybdenum)/Alumina dual catalysts under the diesel methanol dual fuel conditions. Chem. Eng. Sci. 2020, 211, 115320. [Google Scholar] [CrossRef]

- Chen, C.; Yao, A.; Yao, C.; Wang, D.; Lu, H.; Fen, J. Study of the characteristics of PM and the correlation of soot and smoke opacity on the diesel methanol dual fuel engine. Appl. Therm. Eng. 2019, 148, 391–403. [Google Scholar] [CrossRef]

- Karthic, S.; Kumar, M. Experimental investigations on hydrogen biofueled reactivity controlled compression ignition engine using open ECU. Energy 2021, 229, 120787. [Google Scholar] [CrossRef]

- Melnyk, O.; Onishchenko, O.; Onyshchenko, S.; Voloshyn, A.; Kalinichenko, Y.; Rossomakha, O.; Naleva, G.; Rossomakha, O. Autonomous Ships Concept and Mathematical Models Application in their Steering Process Control. TransNav J. 2022, 16, 553–559. [Google Scholar] [CrossRef]

- Moon, C.; Jeong, S.; Roh, G.; Park, K. Development of Representative Sailing Mode Construction Methodology Using Markov Chain. J. Mar. Sci. Eng. 2024, 12, 329. [Google Scholar] [CrossRef]

- Lu, Y.; Gu, Z.; Liu, S.; Wu, C.; Shao, W.; Li, C. Research on Main Engine Power of Transport Ship with Different Bows in Ice Area According to EEDI Regulation. J. Mar. Sci. Eng. 2021, 9, 1241. [Google Scholar] [CrossRef]

- Öztürk, E.; Can, Ö. Effects of EGR, injection retardation and ethanol addition on combustion, performance and emissions of a DI diesel engine fueled with canola biodiesel/diesel fuel blend. Energy 2020, 244, 123129. [Google Scholar] [CrossRef]

- Feng, C.; Deng, Y.; Chen, L.; Han, W.; Jiaqiang, E.; Wei, K.; Han, D.; Zhang, B. Hydrocarbon emission control of a hydrocarbon adsorber and converter under cold start of the gasoline engine. Energy 2022, 239, 122138. [Google Scholar] [CrossRef]

- Mei, D.; Yu, Q.; Zhang, Z.; Yue, S.; Tu, L. Effects of Two Pilot Injection on Combustion and Emissions in a PCCI Diesel Engine. Energies 2021, 14, 1651. [Google Scholar] [CrossRef]

- Melnyk, O.; Onyshchenko, S.; Onishchenko, O.; Koskina, Y.; Lohinov, O.; Veretennik, O.; Stukalenko, O. Fundamental Concepts of Deck Cargo Handling and Transportation Safety. Eur. Transp. 2024, 98, 1. [Google Scholar] [CrossRef]

- Salova, T.; Lekomtsev, P.; Likhanov, V.; Lopatin, O.; Belov, E. Development of calculation methods and optimization of working processes of heat engines. AIP Conf. Proc. 2023, 2700, 050015. [Google Scholar] [CrossRef]

- Wang, Y.; Wright, L.A. A Comparative Review of Alternative Fuels for the Maritime Sector: Economic, Technology, and Policy Challenges for Clean Energy Implementation. World 2020, 2, 456–481. [Google Scholar] [CrossRef]

- Labeckas, G.; Slavinskas, S.; Mickevicius, T. Experimental investigation of biodiesel-n-butanol fuels blends on performance and emissions in a diesel engine. Combust. Engines 2022, 188, 90–95. [Google Scholar] [CrossRef]

- Melnyk, O.M.; Onishchenko, O.A.; Shyshkin, O.V.; Volkov, O.M.; Volyanskyy, S.M.; Maulevych, V.O.; Kreitser, K.O. Enhancing shipboard technical facility performance through the utilization of low-sulfur marine fuel grades. J. Chemistry and Technol. 2024, 32, 233–245. [Google Scholar] [CrossRef]

- Sultanbekov, R.; Denisov, K.; Zhurkevich, A.; Islamov, S. Reduction of Sulphur in Marine Residual Fuels by Deasphalting to Produce VLSFO. J. Mar. Sci. Eng. 2022, 10, 1765. [Google Scholar] [CrossRef]

- Melnyk, O.; Onishchenko, O.; Onyshchenko, S.; Golikov, V.; Sapiha, V.; Shcherbina, O.; Andrievska, V. Study of Environmental Efficiency of Ship Operation in Terms of Freight Transportation Effectiveness Provision. TransNav 2022, 16, 723–729. [Google Scholar] [CrossRef]

- Rony, Z.I.; Mofijur, M.; Hasan, M.M.; Rasul, M.G.; Jahirul, M.I.; Ahmed, S.F.; Kalam, M.A.; Badruddin, I.A.; Khan, T.Y.; Show, P.L. Alternative fuels to reduce greenhouse gas emissions from marine transport and promote UN sustainable development goals. Fuel 2023, 338, 127220. [Google Scholar] [CrossRef]

- Wang, Z.; Dong, B.; Li, M.; Ji, L.; Han, E. Configuration of Low-Carbon fuels green marine power systems in diverse ship types and Applications. Energy Convers. Manag. 2024, 302, 118139. [Google Scholar] [CrossRef]

- Gautam, K.R.; Andresen, G.B.; Victoria, M. Review and Techno-Economic Analysis of Emerging Thermo-Mechanical Energy Storage Technologies. Energies 2022, 15, 6328. [Google Scholar] [CrossRef]

- Kotulla, M.; Gŏno, M.; Gŏno, R.; Vrzala, M.; Leonowicz, Z.; Kłosok-Bazan, I.; Boguniewicz-Zabłocka, J. Renewable Energy Sources as Backup for a Water Treatment Plant. Energies 2022, 15, 6288. [Google Scholar] [CrossRef]

- Vrzala, M.; Gŏno, M.; Gŏno, R.; Kotulla, M.; Wzorek, M.; Leonowicz, Z. Distributed Generation Power Systems in Wastewater Management. Energies 2022, 15, 6283. [Google Scholar] [CrossRef]

- Mi, J.J.; Wang, Y.; Zhang, N.; Zhang, C.; Ge, J. A Bibliometric Analysis of Green Shipping: Research Progress and Challenges for Sustainable Maritime Transport. J. Mar. Sci. Eng. 2024, 12, 1787. [Google Scholar] [CrossRef]

- Moon, S.; Park, S.; Son, J.; Oh, K.; Jang, S. Simplified Modeling and Analysis of Surface Temperature Distribution in Electrically Heated Catalyst for Diesel Urea-SCR Systems. Energies 2022, 15, 6406. [Google Scholar] [CrossRef]

- Vladov, S.; Scislo, L.; Sokurenko, V.; Muzychuk, O.; Vysotska, V.; Sachenko, A.; Yurko, A. Helicopter Turboshaft Engines’ Gas Generator Rotor R.P.M. Neuro-Fuzzy Onboard Controller Development. Energies 2024, 17, 4033. [Google Scholar] [CrossRef]

- Ershov, M.A.; Savelenko, V.D.; Makhova, U.A.; Kapustin, V.M.; Abdellatief, T.M.M.; Karpov, N.V.; Dutlov, E.V.; Borisanov, D.V. Perspective towards a gasoline-property-first approach exhibiting octane hyperboosting based on isoolefinic hydrocarbons. Fuel 2022, 321, 124016. [Google Scholar] [CrossRef]

- Ershov, M.A.; Savelenko, V.D.; Shvedova, N.S.; Kapustin, V.M.; Abdellatief, T.M.M.; Karpov, N.V.; Dutlov, E.V.; Borisanov, D.V. An evolving research agenda of merit function calculations for new gasoline compositions. Fuel 2022, 322, 124209. [Google Scholar] [CrossRef]

- Lopez, J.A.; Alvarez, P.; Onur, B.; Kiliciris, A.; Vis, F.A. An inventory control policy for liquefied natural gas as a transportation fuel. Omega 2020, 90, 101985. [Google Scholar] [CrossRef]

- Balci, G.; Phan, T.T.N.; Surucu-Balci, E.; Iris, Ç. A roadmap to alternative fuels for decarbonising shipping: The case of green ammonia. Res. Transp. Bus. Manag. 2024, 53, 101100. [Google Scholar] [CrossRef]

- Matieiko, O. Monitoring of the inertization of cargo tanks of LNG class vessels. Technol. Audit. Prod. Reserves 2024, 5, 30–37. [Google Scholar] [CrossRef]

- Ershov, M.A.; Grigorieva, E.V.; Abdellatief, T.M.M.; Kapustin, V.M.; Abdelkareem, M.A.; Kamil, M.; Olabi, A.G. Hybrid low-carbon high-octane oxygenated gasoline based on low-octane hydrocarbon fractions. Sci. Total Environ. 2021, 756, 142715. [Google Scholar] [CrossRef] [PubMed]

- Aydın, S. Detailed evaluation of combustion, performance and emissions of ethyl proxitol and methyl proxitol-safflower biodiesel blends in a power generator diesel engine. Fuel 2020, 270, 117492. [Google Scholar] [CrossRef]

- Temizer, I.; Cihan, O.; Eskici, B. Numerical and experimental investigation of the effect of biodiesel/diesel fuel on combustion characteristics in CI engine. Fuel 2020, 270, 117523. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Tian, J.; Dong, R.; Zou, Z.; Gao, S.; Tan, D. Performance, combustion and emission characteristics investigations on a diesel engine fueled with diesel/ethanol/n-butanol blends. Energy 2022, 249, 123733. [Google Scholar] [CrossRef]

- Mozakka, M.; Salimi, M.; Hosseinpour, M.; Borhani, T.N. Why LNG Can Be a First Step in East Asia’s Energy Transition to a Low Carbon Economy: Evaluation of Challenges Using Game Theory. Energies 2022, 15, 6476. [Google Scholar] [CrossRef]

- Hyeon, S.; Lee, J.; Choi, J. Evaluation of Fuel Gas Supply System for Marine Dual-Fuel Propulsion Engines Using LNG and Ammonia Fuel. Energies 2022, 15, 6303. [Google Scholar] [CrossRef]

- Yu, P.; Yin, Y.; Yue, Q.; Wu, S. Experimental Study of Ship Motion Effect on Pressurization and Holding Time of Tank Containers during Marine Transportation. Sustainability 2022, 14, 3595. [Google Scholar] [CrossRef]

- Zablotsky, Y.V.; Sagin, S.V. Maintaining Boundary and Hydrodynamic Lubrication Modes in Operating High-pressure Fuel Injection Pumps of Marine Diesel Engines. Indian J. Sci. Technol. 2016, 9, 208–216. [Google Scholar] [CrossRef]

- Guët, A.T.; Monios, J.; Cariou, P. Successful adoption of maritime environmental policy: The Mediterranean emission control area. Mar. Policy 2024, 166, 106228. [Google Scholar] [CrossRef]

- Khan, A.A.; Minai, A.F.; Pachauri, R.K.; Malik, H. Optimal Sizing, Control, and Management Strategies for Hybrid Renewable Energy Systems: A Comprehensive Review. Energies 2022, 15, 6249. [Google Scholar] [CrossRef]

- Lopatin, O.P. Modeling of physico-chemical processes in the combustion chamber of gas diesel. AIP Conf. Proc. 2024, 2969, 050008. [Google Scholar] [CrossRef]

- Likhanov, V.A.; Lopatin, O.P.; Vylegzhanin, P.N. Calculation of geometric parameters of diesel fuel ignition flares. IOP Conf. Ser. Mater. Sci. Eng. 2020, 862, 062074. [Google Scholar] [CrossRef]

- Ershov, M.A.; Grigorieva, E.V.; Abdellatief, T.M.M.; Chernysheva, E.A.; Makhin, D.Y.; Kapustin, V.M. A New Approach for Producing Mid-Ethanol Fuels E30 Based on Low-Octane Hydrocarbon Surrogate Blends. Fuel Process. Technol. 2021, 213, 106688. [Google Scholar] [CrossRef]

- Vladov, S.; Shmelov, Y.; Yakovliev, R.; Stushchankyi, Y.; Havryliuk, Y. Neural Network Method for Controlling the Helicopters Turboshaft Engines Free Turbine Speed at Flight Modes. In Proceedings of the MoMLeT+DS 2023: 5th International Workshop on Modern Machine Learning Technologies and Data Science, Lviv, Ukraine, 3 June 2023; Volume 3426, pp. 89–108. Available online: https://ceur-ws.org/Vol-3426/paper8.pdf (accessed on 23 January 2025).

- Yilmaz, N.; Vigil, F.M.; Atmanli, A.; Donaldson, B. Detailed Analysis of PAH Formation, Toxicity and Regulated Pollutants in a Diesel Engine Running on Diesel Blends with n-Propanol, n-Butanol and n-Pentanol. Energies 2022, 15, 6487. [Google Scholar] [CrossRef]

- Jha, S.; Nanda, S.; Acharya, B.; Dalai, A.K. A Review of Thermochemical Conversion of Waste Biomass to Biofuels. Energies 2022, 15, 6352. [Google Scholar] [CrossRef]

- Mustayen, A.G.M.B.; Rasul, M.G.; Wang, X.; Bhuiya, M.M.K.; Negnevitsky, M.; Hamilton, J. Theoretical and Experimental Analysis of Engine Performance and Emissions Fuelled with Jojoba Biodiesel. Energies 2022, 15, 6282. [Google Scholar] [CrossRef]

- Kuzmin, K.A.; Sultanbekov, R.R.; Khromova, S.M.; Vovk, M.A.; Rudko, V.A. Establishing the influence of recycled used oil on the sedimentation stability of residual marine fuel. Fuel 2025, 389, 134625. [Google Scholar] [CrossRef]

- Cruz-Peragón, F.; Torres-Jiménez, E.; Lešnik, L.; Arma, O. Methodology improvements to simulate performance and emissions of engine transient cycles from stationary operating modes. A case study applied to biofuels. Fuel 2022, 312, 122977. [Google Scholar] [CrossRef]

- Legue, D.R.K.; Ayissi, Z.M.; Babikir, M.H.; Obounou, M.; Ekobena Fouda, H.P. Experimental and Simulation of Diesel Engine Fueled with Biodiesel with Variations in Heat Loss Model. Energies 2021, 14, 1622. [Google Scholar] [CrossRef]

- Figaj, R.; Żoładek, M.; Homa, M.; Pałac, A. A Novel Hybrid Polygeneration System Based on Biomass, Wind and Solar Energy for Micro-Scale Isolated Communities. Energies 2022, 15, 6331. [Google Scholar] [CrossRef]

- Millo, F.; Vlachos, T.; Piano, A. Physicochemical and mutagenic analysis of particulate matter emissions from an automotive diesel engine fuelled with fossil and biofuel blends. Fuel 2021, 285, 119092. [Google Scholar] [CrossRef]

- Sultanbekov, R.; Islamov, S.; Mardashov, D.; Beloglazov, I.; Hemmingsen, T. Research of the Influence of Marine Residual Fuel Composition on Sedimentation Due to Incompatibility. J. Mar. Sci. Eng. 2021, 9, 1067. [Google Scholar] [CrossRef]

- Chena, Z.; Chena, H.; Wang, L.; Geng, L.; Zen, K. Parametric study on effects of excess air/fuel ratio, spark timing, and methanol injection timing on combustion characteristics and performance of natural gas/methanol dual-fuel engine at low loads. Energy Convers. Manag. 2020, 210, 112742. [Google Scholar] [CrossRef]

- Yadav, P.; Athanassiadis, D.; Yacout, D.; Tysklind, M.; Upadhyayula, V. Environmental Impact and Environmental Cost Assessment of Methanol Production from wood biomass. Environ. Pollut. 2020, 265, 114990. [Google Scholar] [CrossRef]

- Sagin, S.; Karianskyi, S.; Madey, V.; Sagin, A.; Stoliaryk, T.; Tkachenko, I. Impact of Biofuel on the Environmental and Economic Performance of Marine Diesel Engines. J. Mar. Sci. Eng. 2023, 11, 120. [Google Scholar] [CrossRef]

- Gharehghani, A.; Kakoee, A.; Andwari, A.M.; Megaritis, T.; Pesyridis, A. Numerical Investigation of an RCCI Engine Fueled with Natural Gas/Dimethyl-Ether in Various Injection Strategies. Energies 2021, 14, 1638. [Google Scholar] [CrossRef]

- Andrade Torres, F.; Doustdar, O.; Herreros, J.M.; Li, R.; Poku, R.; Tsolakis, A.; Martins, J.; Vieira de Melo, S.A.B. A Comparative Study of Biofuels and Fischer–Tropsch Diesel Blends on the Engine Combustion Performance for Reducing Exhaust Gaseous and Particulate Emissions. Energies 2021, 14, 1538. [Google Scholar] [CrossRef]

- Jiaqi, H.; Helin, X.; Xiaolong, Y.; Fengyun, G.; Xiuqing, H. Effects of methanol blending on combustion characteristics and various emissions of a diesel engine fueled with soybean biodiesel. Fuel 2020, 15, 118734. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Li, J.; Wang, S.; Zhong, Y.; Dong, R.; Gao, S.; Cao, C.; Tan, D. Investigation on combustion, performance and emission characteristics of a diesel engine fueled with diesel/alcohol/n-butanol blended fuels. Fuel 2022, 320, 123975. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Tian, J.; Xie, G.; Tan, D.; Qin, B.; Huang, Y.; Cui, S. Effects of Different Diesel-Ethanol Dual Fuel Ratio on Performance and Emission Characteristics of Diesel Engine. Processes 2021, 9, 1135. [Google Scholar] [CrossRef]

- Madey, V.V. Usage of biodiesel in marine diesel engines. Austrian J. Tech. Nat. Sciences. Sci. J. 2021, 7–8, 18–21. [Google Scholar] [CrossRef]

- Strus, M.; Poprawski, W. Efficiency of the Diesel engine fuelled with the advanced biofuel Bioxdiesel. Combust. Engines 2021, 186, 89–95. [Google Scholar] [CrossRef]

- Shadidi, B.; Najafi, G.; Zolfigol, M.A. A Review of the Existing Potentials in Biodiesel Production in Iran. Sustainability 2022, 14, 3284. [Google Scholar] [CrossRef]

- Popovskii, Y.M.; Sagin, S.V.; Khanmamedov, S.A.; Grebenyuk, M.N.; Teregerya, V.V. Designing, calculation, testing and reliability of machines: Influence of anisotropic fluids on the operation of frictional components. Russ. Eng. Res. 1996, 16, 1–7. [Google Scholar]

- Likhanov, V.A.; Lopatin, O.P.; Yurlov, A.S.; Anfilatova, N.S. Investigation of the effective performance of diesel engines running on methanol and rapeseed oil methyl ether. J. Phys. Conf. Ser. 2021, 1889, 042067. [Google Scholar] [CrossRef]

- Melnyk, O.; Onyshchenko, S.; Onishchenko, O.; Shumylo, O.; Voloshyn, A.; Koskina, Y.; Volianska, Y. Review of Ship Information Security Risks and Safety of Maritime Transportation Issues. Trans. Nav 2022, 16, 717–722. [Google Scholar] [CrossRef]

- Yang, Z.; Tan, Z.; Tan, Q.; Tu, S. Analysis of Carbon Particulate Matter Removal Performance of Dual-Fuel Marine Engine with DOC + CDPF. Atmosphere. 2023, 14, 1041. [Google Scholar] [CrossRef]

- Sagin, S.V.; Solodovnikov, V.G. Estimation of Operational Properties of Lubricant Coolant Liquids by Optical Methods. Int. J. Appl. Eng. Res. 2017, 12, 8380–8391. [Google Scholar]

- Sagin, S.V.; Semenov, O.V. Marine Slow-Speed Diesel Engine Diagnosis with View to Cylinder Oil Specification. Am. J. Appl. Sci. 2016, 13, 618–627. [Google Scholar] [CrossRef]

- Kaminski, P. Experimental Investigation into the Effects of Fuel Dilution on the Change in Chemical Properties of Lubricating Oil Used in Fuel Injection Pump of Pielstick PA4V185 Marine Diesel Engine. Lubricants 2022, 10, 162. [Google Scholar] [CrossRef]

- Varbanets, R.; Shumylo, O.; Marchenko, A.; Minchev, D.; Kyrnats, V.; Zalozh, V.; Aleksandrovska, N.; Brusnyk, R.; Volovyk, K. Concept of vibroacoustic diagnostics of the fuel injection and electronic cylinder lubrication systems of marine diesel engines. Pol. Marit. Res. 2022, 29, 88–96. [Google Scholar] [CrossRef]

- Minchev, D.S.; Gogorenko, O.A.; Kyrnats, V.I.; Varbanets, R.A.; Moshentsev, Y.L.; Píštěk, V.; Kučera, P.; Shumylo, O.M. Prediction of centrifugal compressor instabilities for internal combustion engines operating cycle simulation. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023, 237, 572–584. [Google Scholar] [CrossRef]

- Neumann, S.; Varbanets, R.; Minchev, D.; Malchevsky, V.; Zalozh, V. Vibrodiagnostics of marine diesel engines in IMES GmbH systems. Ships Offshore Struct. 2022, 18, 1535–1546. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, Y.; Wang, J.; Tan, D.; Zhang, Z.; Yang, D. Effects of Different Biodiesel-Diesel Blend Fuel on Combustion and Emission Characteristics of a Diesel Engine. Processes 2021, 9, 1984. [Google Scholar] [CrossRef]

- Varbanets, R.; Minchev, D.; Savelieva, I.; Rodionov, A.; Mazur, T.; Psariuk, S.; Bondarenko, V. Advanced marine diesel engines diagnostics for IMO decarbonization compliance. AIP Conf. Proc. 2024, 3104, 020004. [Google Scholar] [CrossRef]

- Varbanets, R.; Zalozh, V.; Shakhov, A.; Savelieva, I.; Piterska, V. Determination of top dead centre location based on the marine diesel engine indicator diagram analysis. Diagnostyka 2020, 21, 51–60. [Google Scholar] [CrossRef]

- Gorb, S.; Popovskii, A.; Budurov, M. Adjustment of speed governor for marine diesel generator engine. Int. J. GEOMATE 2023, 25, 125–132. [Google Scholar] [CrossRef]

- Lopatin, O.P. Investigation of the combustion process in a dual-fuel engine. J. Phys. Conf. Ser. 2024, 2697, 012079. [Google Scholar] [CrossRef]

- Bortuzzo, V.; Bertagna, S.; ·Braidotti, L.; Bucci, V. Towards CO2 emissions reduction of shipping: Ca(OH)2 based carbon capture system for safeguarding the marine environment. Front. Mar. Sci. 2025, 12, 1434342. [Google Scholar] [CrossRef]

- Liang, C.; Sun, W.; Shi, J.; Wang, K.; Zhang, Y.; Lim, G. Decarbonizing Maritime Transport through Green Fuel-Powered Vessel Retrofitting: A Game-Theoretic Approach. J. Mar. Sci. Eng. 2024, 12, 1174. [Google Scholar] [CrossRef]

- Skoko, I.; Stanivuk, T.; Franic, B.; Bozic, D. Comparative Analysis of CO2 Emissions, Fuel Consumption, and Fuel Costs of Diesel and Hybrid Dredger Ship Engines. J. Mar. Sci. Eng. 2024, 12, 999. [Google Scholar] [CrossRef]

- Madey, V. Assessment of the efficiency of biofuel use in the operation of marine diesel engines. Technol. Audit. Prod. Reserves 2022, 2, 34–41. [Google Scholar] [CrossRef]

- Mahi, R.; Joubert, A.; Villot, A.; Sagot, B.; Le Coq, L. Methodological Development for Studying the Chemical Composition of Exhaust Particle Emissions: Application to a Passenger Vessel Operating on Marine Gas Oil. Atmosphere 2025, 16, 126. [Google Scholar] [CrossRef]

- Gu, Y.; Wang, Y.; Iris, Ç. Integrated green technology adoption, ship speed optimization and slot management for shipping alliance under emission limits and uncertain fuel prices. J. Clean. Prod. 2025, 494, 144939. [Google Scholar] [CrossRef]

| Vessel Operating Area | Operation Without Additional Exhaust Gas Cleaning System for Sulfur Oxides | Use of an Additional Exhaust Gas Cleaning System for Sulfur Oxides |

|---|---|---|

| Fuel Oil Sulfur Content, % | Ratio Emission SO2 (ppm)/CO2 (v %) | |

| Outside SECAs | 0.5 | 21.7 |

| Inside SECAs | 0.1 | 4.3 |

| Characteristic | Fuel Type | ||

|---|---|---|---|

| DMA10 | RMG500 | FAME | |

| Density at 20 °C, kg/m3 | 884 | 962 | 926 |

| Viscosity 40 °C, sSt | 9.4 | 496 | 314 |

| Sulfur content, % | 0.057 | 0.48 | 0.022 |

| Lower calorific, kJ/kg | 43,280 | 39,070 | 37,720 |

| General Load, kW | Load on Individual Diesel Engines, kW (%) | |||

|---|---|---|---|---|

| Auxilary Engine No. 1 | Auxilary Engine No. 2 | Auxilary Engine No. 3 | Auxilary Engine No. 4 | |

| 5630 | 1750 (50) | 1750 (50) | 1750 (50) | 380 |

| 4220 | 1750 (50) | ––– | 720 | 1750 (50) |

| 6720 | 2100 (60) | 2100 (60) | 420 | 2100 (60) |

| 5050 | 2100 (60) | 2100 (60) | ––– | 850 |

| 7880 | 2450 (70) | 530 | 2450 (70) | 2450 (70) |

| 5510 | 2450 (70) | 610 | ––– | 2450 (70) |

| 8880 | 2800 (80) | 2800 (80) | 2800 (80) | 480 |

| 6310 | 2800 (80) | 710 | 2800 (80) | ––– |

| Load, % | Type of Fuel | |||

|---|---|---|---|---|

| RMG500 (100%) | RMG500 (90%) + FAME (10%) | RMG500 (80%) + FAME (20%) | RMG500 (70%) + FAME (30%) | |

| 50 | 203 | 208 | 215 | 218 |

| 60 | 198 | 202 | 205 | 209 |

| 70 | 195 | 197 | 199 | 202 |

| 80 | 192 | 195 | 197 | 200 |

| Load, % | Type of Fuel | |||

|---|---|---|---|---|

| RMG500 (100%) | RMG500 (90%) + FAME (10%) | RMG500 (80%) + FAME (20%) | RMG500 (70%) + FAME (30%) | |

| 50 | 6.82 | 5.81 | 5.63 | 5.43 |

| 60 | 7.12 | 5.93 | 5.75 | 5.53 |

| 70 | 7.62 | 6.12 | 5.93 | 5.73 |

| 80 | 7.97 | 6.18 | 6.01 | 5.81 |

| Load, % | Type of Fuel | |||

|---|---|---|---|---|

| RMG500 (100%) | RMG500 (90%) + FAME (10%) | RMG500 (80%) + FAME (20%) | RMG500 (70%) + FAME (30%) | |

| 50 | 6.22 | 5.88 | 5.62 | 5.31 |

| 60 | 6.43 | 6.03 | 5.72 | 5.40 |

| 70 | 6.78 | 6.25 | 5.80 | 5.46 |

| 80 | 7.22 | 6.42 | 5.86 | 5.52 |

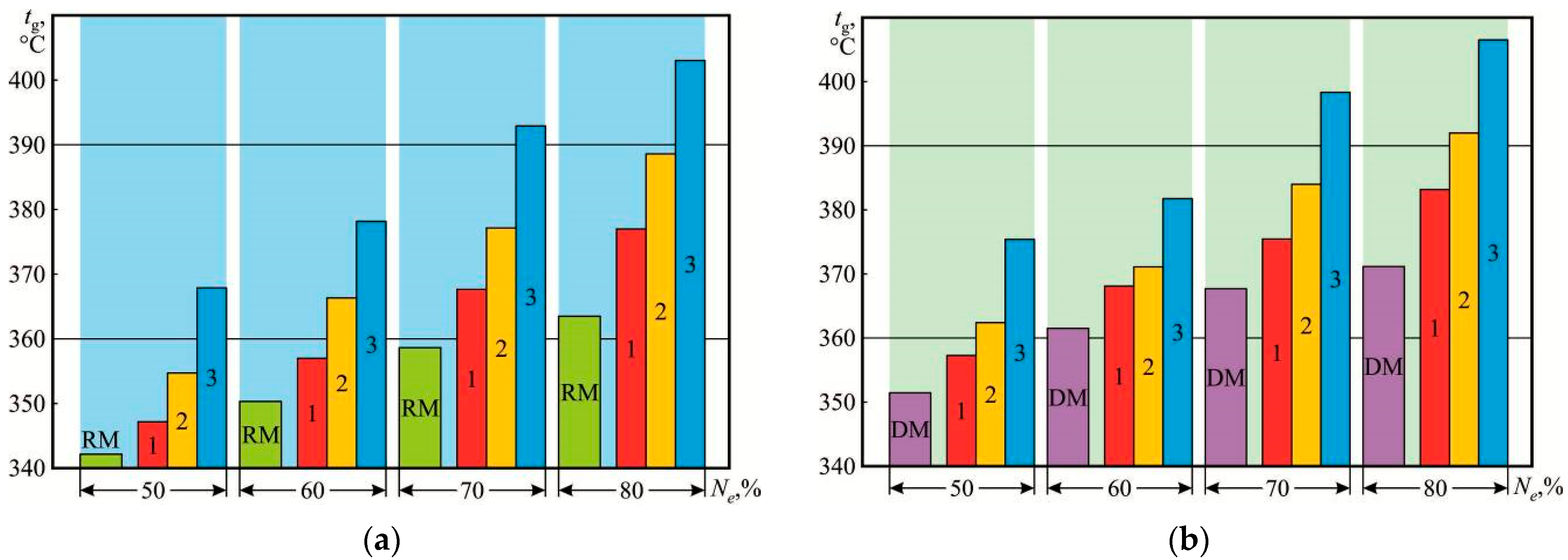

| Load, % | Type of Fuel | |||

|---|---|---|---|---|

| RMG500 (100%) | RMG500 (90%) + FAME (10%) | RMG500 (80%) + FAME (20%) | RMG500 (70%) + FAME (30%) | |

| 50 | 343 | 348 | 356 | 368 |

| 60 | 352 | 358 | 367 | 379 |

| 70 | 359 | 368 | 378 | 392 |

| 80 | 363 | 376 | 388 | 403 |

| Load, % | Type of Fuel | |||

|---|---|---|---|---|

| DMA10 (100%) | DMA10 (90%) + FAME (10%) | DMA10 (80%) + FAME (20%) | DMA10 (70%) + FAME (30%) | |

| 50 | 197 | 201 | 205 | 210 |

| 60 | 190 | 193 | 195 | 198 |

| 70 | 188 | 189 | 191 | 194 |

| 80 | 186 | 187 | 188 | 191 |

| Load, % | Type of Fuel | |||

|---|---|---|---|---|

| DMA10 (100%) | DMA10 (90%) + FAME (10%) | DMA10 (80%) + FAME (20%) | DMA10 (70%) + FAME (30%) | |

| 50 | 7.68 | 6.82 | 6.55 | 6.32 |

| 60 | 7.96 | 7.01 | 6.72 | 6.49 |

| 70 | 8.53 | 7.22 | 7.02 | 6.78 |

| 80 | 8.77 | 7.33 | 6.96 | 6.84 |

| Load, % | Type of Fuel | |||

|---|---|---|---|---|

| DMA10 (100%) | DMA10 (90%) + FAME (10%) | DMA10 (80%) + FAME (20%) | DMA10 (70%) + FAME (30%) | |

| 50 | 6.78 | 6.42 | 6.18 | 5.88 |

| 60 | 7.03 | 6.61 | 6.27 | 6.03 |

| 70 | 7.47 | 6.97 | 6.5 | 6.27 |

| 80 | 7.82 | 7.18 | 6.68 | 6.35 |

| Load, % | Type of Fuel | |||

|---|---|---|---|---|

| DMA10 (100%) | DMA10 (90%) + FAME (10%) | DMA10 (80%) + FAME (20%) | DMA10 (70%) + FAME (30%) | |

| 50 | 351 | 356 | 362 | 373 |

| 60 | 361 | 367 | 371 | 382 |

| 70 | 367 | 376 | 385 | 399 |

| 80 | 371 | 383 | 392 | 407 |

| Load, % | Type of Fuel | ||

|---|---|---|---|

| RMG500 (90%) + FAME (10%) | RMG500 (80%) + FAME (20%) | RMG500 (70%) + FAME (30%) | |

| 50 | 2.46 | 5.91 | 7.39 |

| 60 | 2.02 | 3.54 | 5.56 |

| 70 | 1.03 | 2.05 | 3.59 |

| 80 | 1.56 | 2.60 | 4.17 |

| Load, % | Type of Fuel | ||

|---|---|---|---|

| RMG500 (90%) + FAME (10%) | RMG500 (80%) + FAME (20%) | RMG500 (70%) + FAME (30%) | |

| 50 | 14.81 | 17.45 | 20.38 |

| 60 | 16.71 | 19.24 | 22.33 |

| 70 | 19.69 | 22.18 | 24.80 |

| 80 | 22.46 | 24.59 | 27.10 |

| Load, % | Type of Fuel | ||

|---|---|---|---|

| RMG500 (90%) + FAME (10%) | RMG500 (80%) + FAME (20%) | RMG500 (70%) + FAME (30%) | |

| 50 | 5.47 | 9.65 | 14.63 |

| 60 | 6.22 | 11.04 | 16.02 |

| 70 | 7.82 | 14.45 | 19.47 |

| 80 | 11.08 | 18.84 | 23.55 |

| Load, % | Type of Fuel | ||

|---|---|---|---|

| RMG500 (90%) + FAME (10%) | RMG500 (80%) + FAME (20%) | RMG500 (70%) + FAME (30%) | |

| 50 | 5/1.46 | 13/3.79 | 25/7.29 |

| 60 | 6/1.70 | 15/4.26 | 27/7.67 |

| 70 | 7/2.51 | 19/5.29 | 33/9.19 |

| 80 | 13/3.58 | 25/6.89 | 40/11.00 |

| Load, % | Type of Fuel | ||

|---|---|---|---|

| DMA10 (90%) + FAME (10%) | DMA10 (80%) + FAME (20%) | DMA10 (70%) + FAME (30%) | |

| 50 | 2.03 | 4.06 | 6.60 |

| 60 | 1.58 | 2.63 | 4.21 |

| 70 | 0.53 | 1.60 | 3.19 |

| 80 | 0.54 | 1.08 | 2.69 |

| Load, % | Type of Fuel | ||

|---|---|---|---|

| DMA10 (90%) + FAME (10%) | DMA10 (80%) + FAME (20%) | DMA10 (70%) + FAME (30%) | |

| 50 | 11.20 | 14.71 | 17.71 |

| 60 | 11.93 | 15.58 | 18.47 |

| 70 | 15.36 | 17.70 | 20.52 |

| 80 | 16.42 | 20.64 | 22.01 |

| Load, % | Type of Fuel | ||

|---|---|---|---|

| DMA10 (90%) + FAME (10%) | DMA10 (80%) + FAME (20%) | DMA10 (70%) + FAME (30%) | |

| 50 | 5.31 | 8.85 | 13.27 |

| 60 | 5.97 | 10.81 | 14.22 |

| 70 | 6.69 | 12.99 | 16.06 |

| 80 | 8.18 | 14.58 | 18.80 |

| Load, % | Type of Fuel | ||

|---|---|---|---|

| DMA10 (90%) + FAME (10%) | DMA10 (80%) + FAME (20%) | DMA10 (70%) + FAME (30%) | |

| 50 | 4/1.42 | 11/3.13 | 22/6.27 |

| 60 | 6/1.66 | 10/2.77 | 21/5.82 |

| 70 | 9/2.45 | 18/4.90 | 23/8.72 |

| 80 | 12/3.23 | 21/5.66 | 36/9.70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sagin, S.; Haichenia, O.; Karianskyi, S.; Kuropyatnyk, O.; Razinkin, R.; Sagin, A.; Volkov, O. Improving Green Shipping by Using Alternative Fuels in Ship Diesel Engines. J. Mar. Sci. Eng. 2025, 13, 589. https://doi.org/10.3390/jmse13030589

Sagin S, Haichenia O, Karianskyi S, Kuropyatnyk O, Razinkin R, Sagin A, Volkov O. Improving Green Shipping by Using Alternative Fuels in Ship Diesel Engines. Journal of Marine Science and Engineering. 2025; 13(3):589. https://doi.org/10.3390/jmse13030589

Chicago/Turabian StyleSagin, Sergii, Oleksandr Haichenia, Sergey Karianskyi, Oleksiy Kuropyatnyk, Roman Razinkin, Arsenii Sagin, and Oleksandr Volkov. 2025. "Improving Green Shipping by Using Alternative Fuels in Ship Diesel Engines" Journal of Marine Science and Engineering 13, no. 3: 589. https://doi.org/10.3390/jmse13030589

APA StyleSagin, S., Haichenia, O., Karianskyi, S., Kuropyatnyk, O., Razinkin, R., Sagin, A., & Volkov, O. (2025). Improving Green Shipping by Using Alternative Fuels in Ship Diesel Engines. Journal of Marine Science and Engineering, 13(3), 589. https://doi.org/10.3390/jmse13030589