The Role of Integrated Multi-Energy Systems Toward Carbon-Neutral Ports: A Data-Driven Approach Using Empirical Data

Abstract

1. Introduction

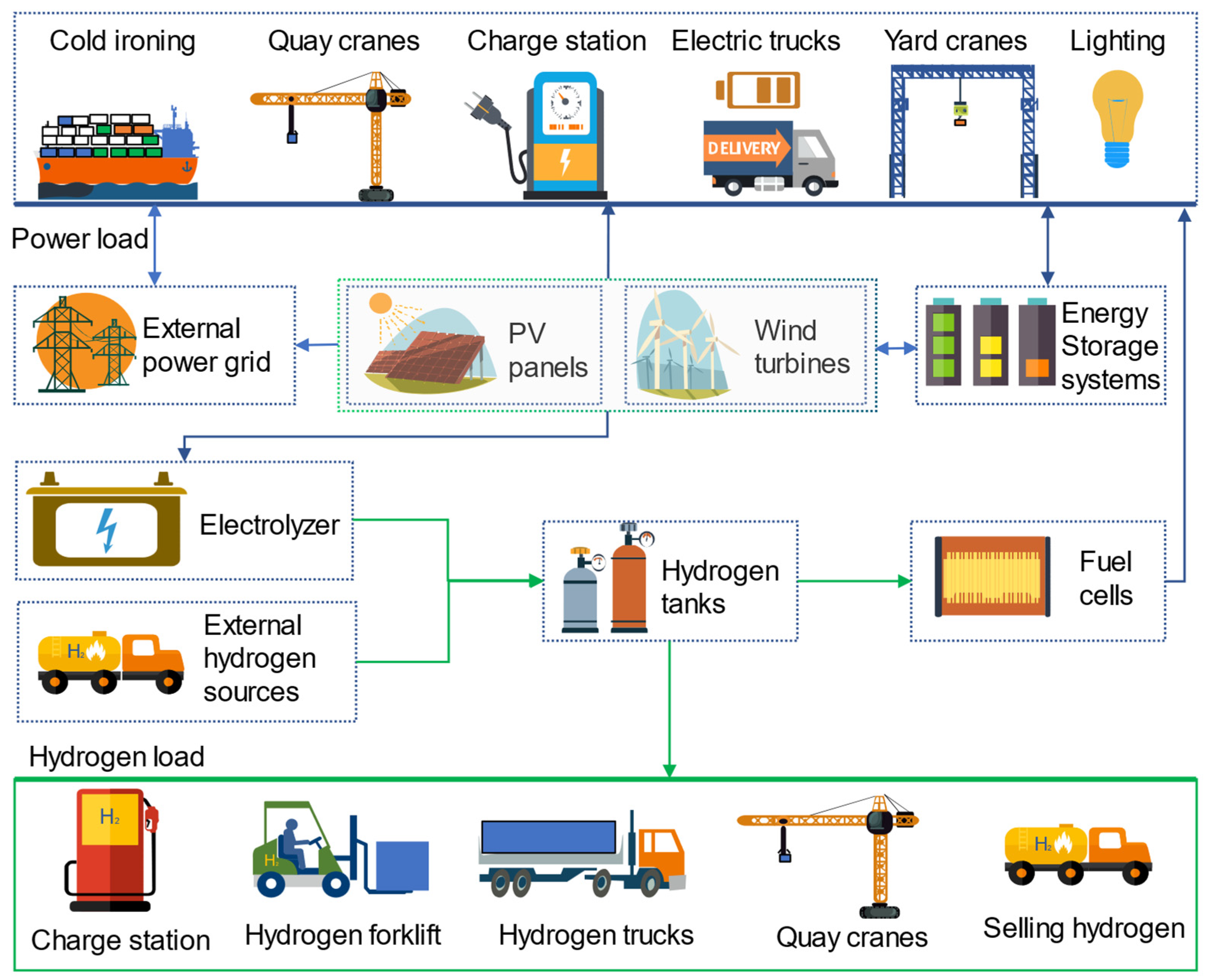

2. Multi-Energy Fusion System Architecture

2.1. System Architecture

2.2. Subsystem Composition

2.2.1. Wind Power System

2.2.2. Photovoltaic System

- Module selection: 540 Wp PERC high-efficiency monocrystalline modules (conversion efficiency > 20%) and 330 Wp TopCon monocrystalline modules were chosen for the steel rooftop, balancing aesthetics and performance.

- Power generation efficiency: A distributed PV configuration combines data collection and performance optimization for steady, high-efficiency operation.

2.2.3. Energy Storage System

- 3.8 MW/0.8 MWh system: This employs lithium titanate batteries and is comprised of one storage unit with one battery cabin and one step-up converter cabin.

- 2.5 MW/3 MWh system: Similarly, lithium titanate batteries comprise one storage unit with two battery cabins and one step-up converter cabin.

2.2.4. Hydrogen Energy System

- Hydrogen production: A 500 Nm3/h water-electrolysis hydrogen plant, including a hydrogen purification device, is installed. The electrolyzer uses electricity to split water and yield hydrogen with 99.8% purity, further purified to 99.999% for practical applications.

- Hydrogen storage: The system includes high and medium-pressure hydrogen tanks (20 MPa and 45 MPa), each with capacities of 49.35 m3 and 9 m3, respectively. Compressors (one at 20 MPa and one at 45 MPa) feed hydrogen into the storage tanks for subsequent dispensing.

- Hydrogen fuel cell systems: A 280 kW fuel cell system offers backup power for the port, featuring three 120 kW fuel cell modules that yield 94 kW. The hydrogen-powered equipment includes heavy-duty hydrogen trucks, hydrogen forklifts, and hybrid fuel cell yard cranes.

3. Methodology

3.1. System-Level Evaluation Methods

3.1.1. Energy and Emission Calculation Methods

- Determine electricity consumption: Calculate the port’s total electricity consumption over a specific period, covering all relevant equipment.

- Convert to standard coal consumption: Convert the electricity consumption into standard coal based on the coefficient (0.4 kg of standard coal per kWh [28]).

- Calculate emissions: Determine the standard coal-to-CO2 and pollutant emission factors (Table 1). Multiply these factors by the amount of standard coal to determine the emissions of CO2, SO2, NOX, etc.

- is carbon emissions,

- is standard coal,

- is CO2 emissions,

- is SO2 emissions,

- is NOX emissions.

3.1.2. Collaborative Emission Reduction Calculation

- is total standard coal consumption (t),

- is the physical amount of fuel used (t),

- is the conversion factor (tce/t or tce/kWh),

- is the energy type.

- is the contribution rate (%) of clean energy x for pollutant y,

- is the pollution reduction achieved using clean energy x (t),

- is the total pollutant y reduction achieved by employing all clean energies (t).

3.2. Subsystem Evaluation Method

3.2.1. Wind Energy System Performance Evaluation

- ✧

- Availability Evaluation

- Cut-in wind speed is the minimum wind speed required for the wind turbine to start generating power.

- Cut-out wind speed is the critical wind speed beyond which the turbine shuts down to prevent damage, either through emergency braking or by adjusting the blade pitch to the maximum.

- is the availability of the wind turbine,

- is wind speed,

- is cut-in wind speed,

- is cut-out wind speed,

- is power output,

- is the number of valid data points.

- ✧

- Utilization Rate Evaluation

- is the wind turbine utilization rate,

- is available hours,

- is unavailable hours.

3.2.2. PV System Performance Evaluation

- System efficiency: Measures the ability of the PV system to convert solar energy into electricity.

- Conversion efficiency: Reflects the energy conversion efficiency of the PV cells.

- Electrical efficiency: Assesses the energy losses during the electrical output process.

- ✧

- System Efficiency

- is the performance ratio,

- is the total energy output of the PV system during the τ period, in kilowatt-hours (kWh),

- is the installed capacity of the PV system in kilowatts (kW),

- is total irradiance received by the PV array during the τ period, in kWh/m2,

- is standard irradiance condition, set to 1 kW/m2.

- ✧

- Conversion Efficiency

- is the conversion efficiency (%),

- is the maximum output power under standard test conditions (kW),

- A is the area of the photovoltaic cells (m2),

- is the solar irradiance incident on the PV cells during the υ period (kWh/m2).

- ✧

- Electrical Efficiency

- is electrical efficiency (%),

- is the total output power of the PV system (kW),

- is the installed capacity of the PV system (kW).

3.2.3. Energy Storage System Performance Evaluation

- ✧

- Energy Efficiency Evaluation

- Energy efficiency (charge/discharge efficiency): Measures energy conversion efficiency during charging and discharging.

- Power factor: Reflects the quality of the power output.

- Response time: Assesses the system’s ability to respond to load changes quickly.

- is energy efficiency (%),

- is energy input to the battery module (charging energy),

- is energy output from the battery module (discharging energy).

- ✧

- Energy Density Evaluation

- Mass energy density

- is the charging mass–energy density (Wh/kg),

- is the initial charging energy,

- is the mass of the battery (kg).

- is the discharging mass–energy density (Wh/kg),

- is the initial discharging energy,

- is the mass of the battery (kg).

- Volume energy density

- is the charging volume energy density (Wh/L),

- is the initial charging energy,

- is the volume of the battery (L).

- is the discharging volume energy density (Wh/L),

- is the initial discharging energy,

- is the volume of the battery (L).

3.2.4. Hydrogen Energy System Performance Evaluation

- ✧

- Hydrogen Production Rate

- ✧

- Hydrogen Production Efficiency

- is hydrogen production efficiency (%),

- LHV is a lower heating value of hydrogen (MJ/Nm3),

- is total hydrogen produced (m3),

- is the system’s input voltage (V),

- is the system’s input current (A),

- is hydrogen production time (hours).

- The numerator represents the total chemical energy stored in the hydrogen.

- The denominator represents the total electrical energy consumed by the system during hydrogen production.

- Using this formula, the system’s efficiency in converting electrical energy into the chemical energy stored in hydrogen can be intuitively assessed.

4. Results Analysis

4.1. System Performance Analysis

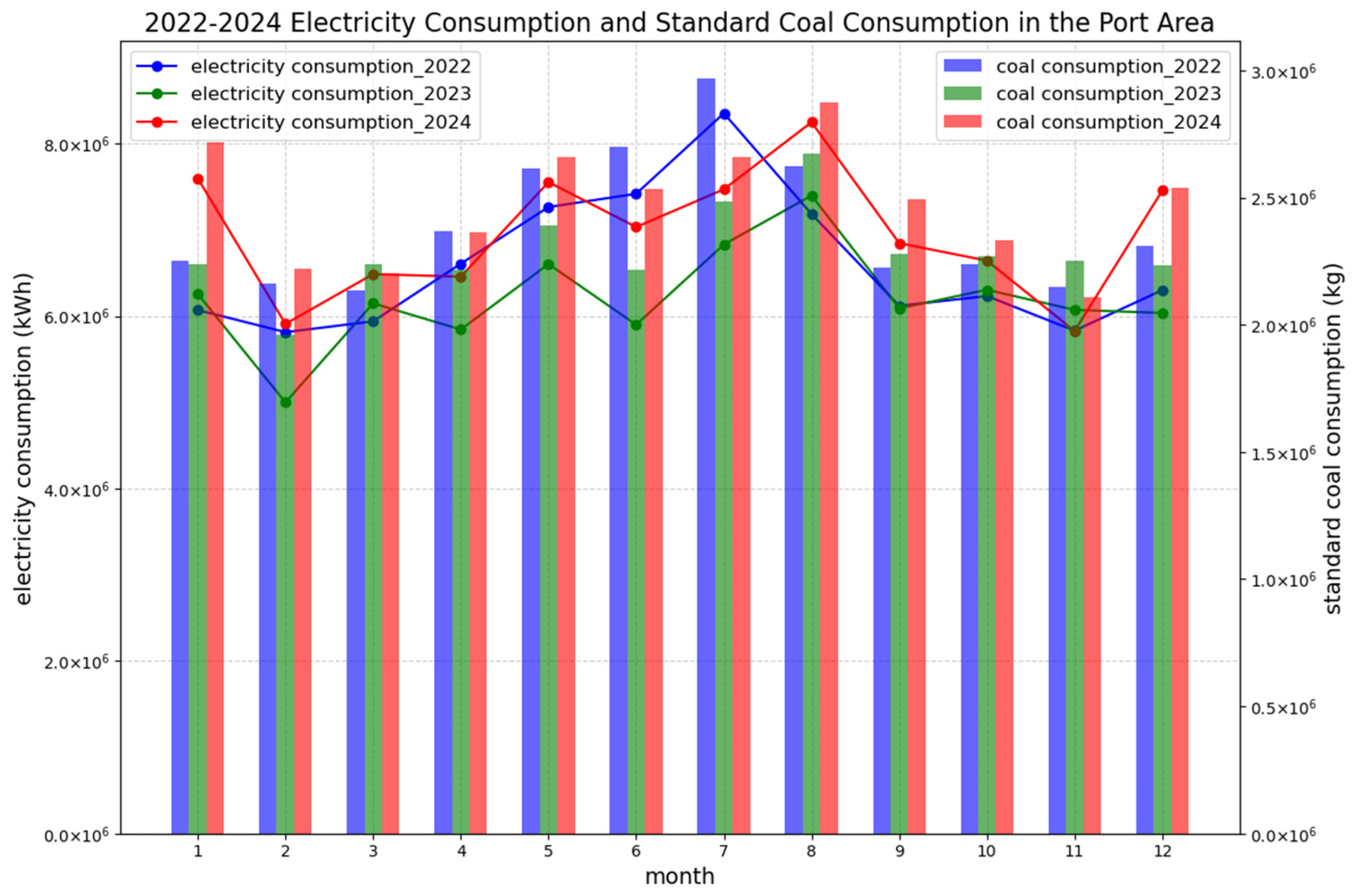

4.1.1. Energy Consumption and Emission Characteristics Analysis

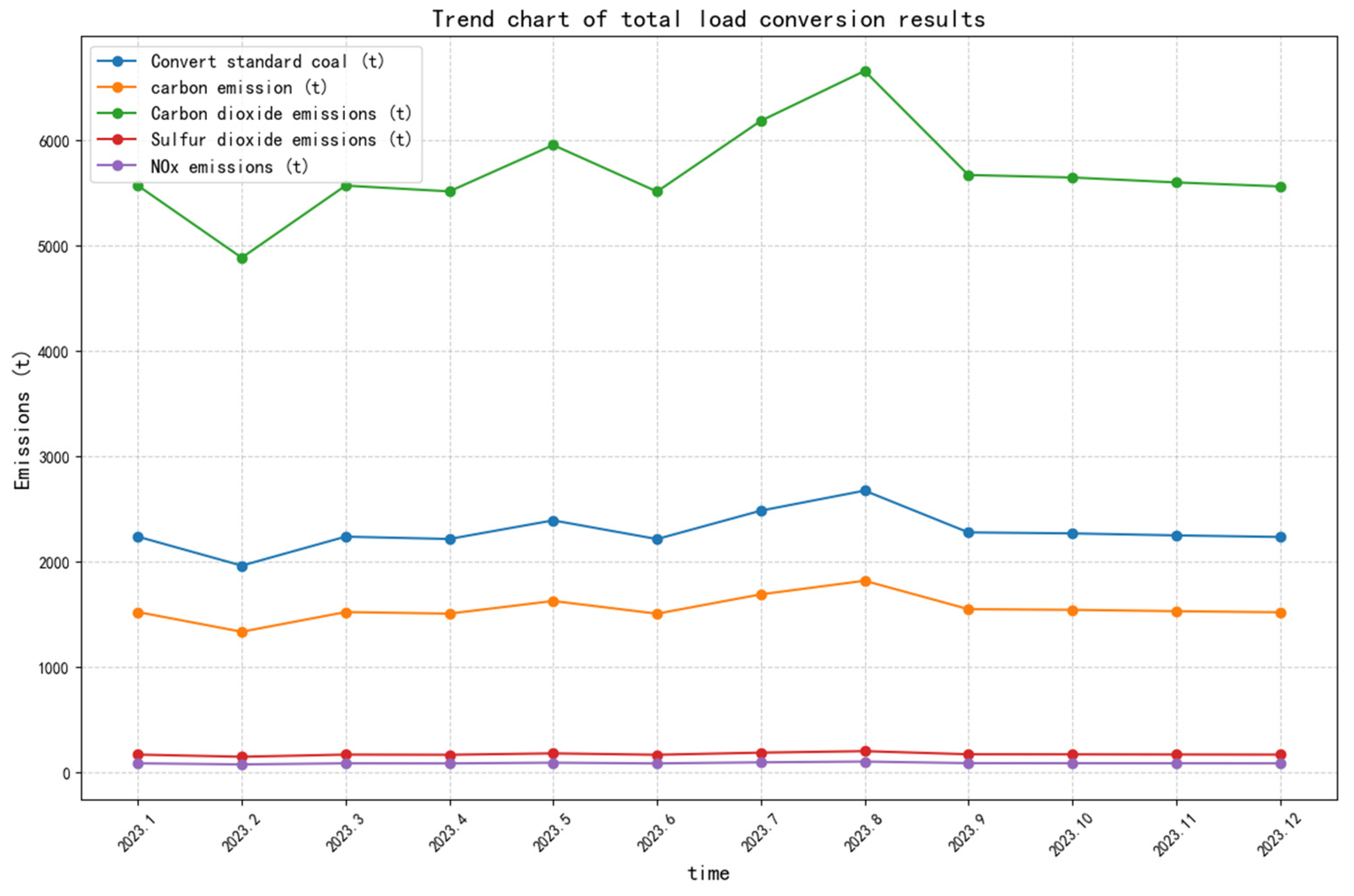

4.1.2. Emission Reduction Effects Analysis

- ✧

- Energy Savings, CO2, and SO2 Emission Reductions

- ✧

- Contribution Analysis of Clean Energy to Collaborative Emission Reductions

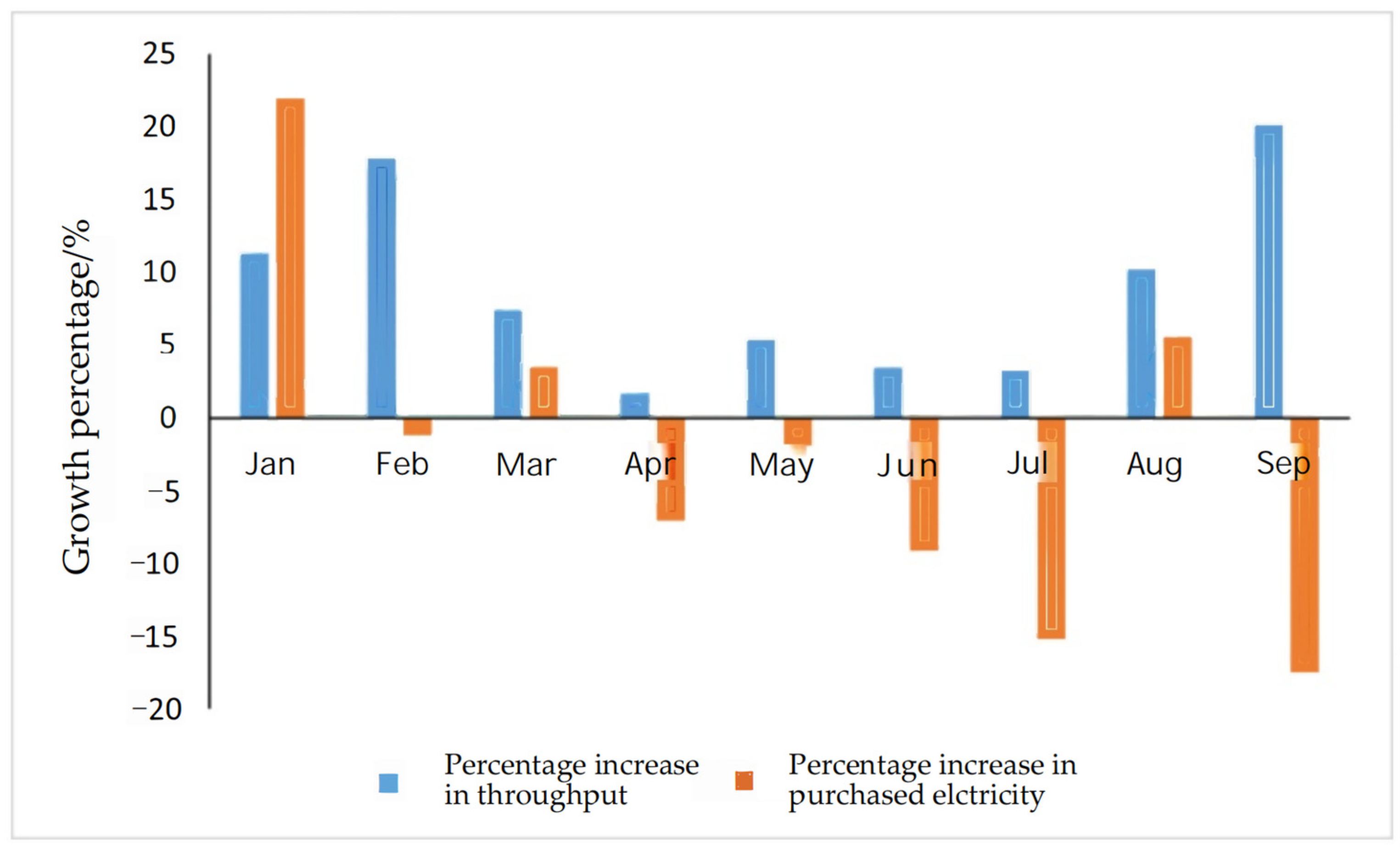

4.1.3. Comparison Analysis Before and After the Implementation of the Multi-Energy Integration System

- ✧

- Impact of the Multi-Energy Integration System on Purchased Electricity

- ✧

- Performance of the Multi-Energy Integration System in 2024

4.2. Subsystem Performance Analysis

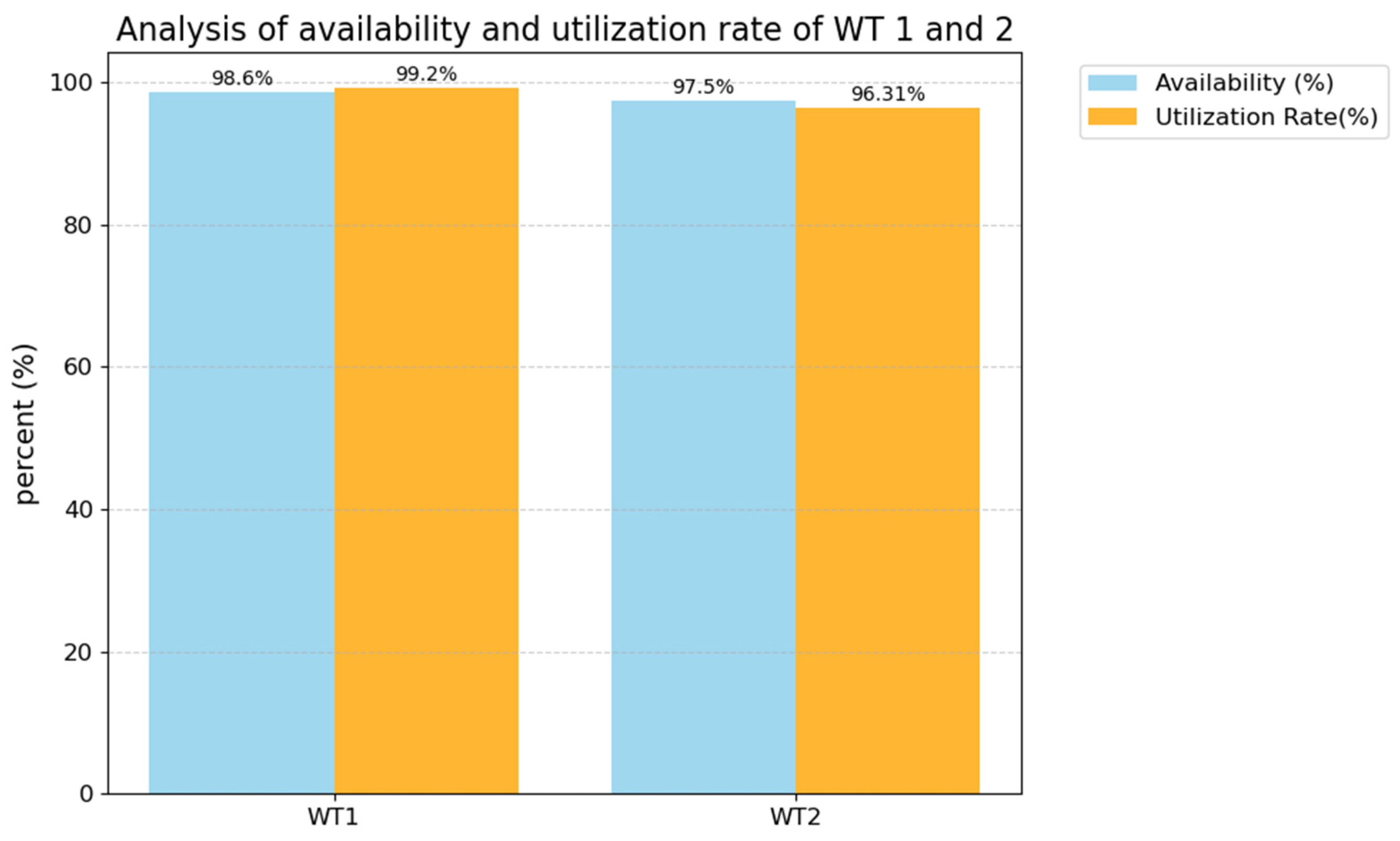

4.2.1. Performance Analysis on Wind Power System

- ✧

- Availability Analysis

- ✧

- Utilization Rate Analysis

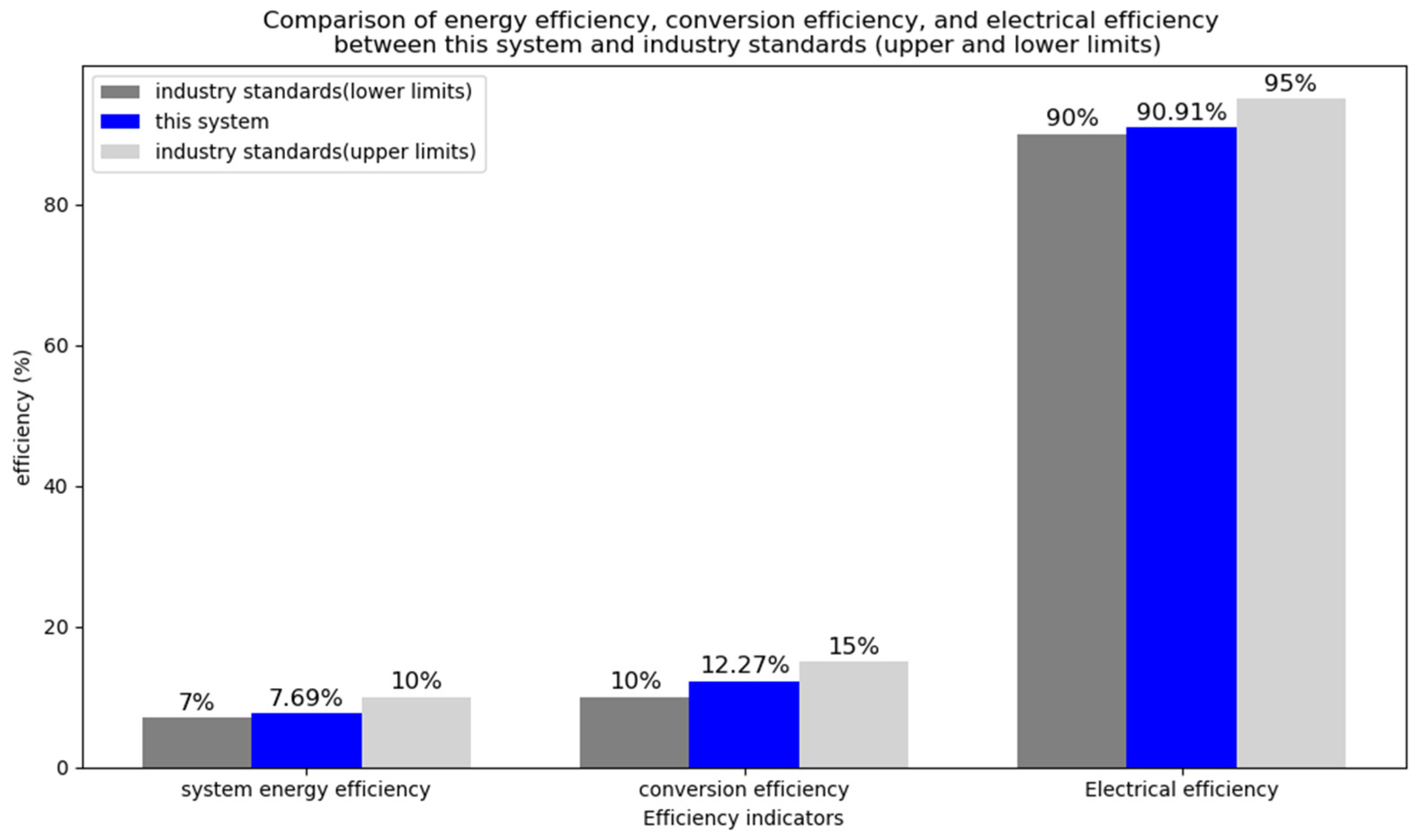

4.2.2. Performance Analysis on PV System

- ✧

- System Efficiency Analysis

- ✧

- Conversion Efficiency Analysis

- ✧

- Electrical Efficiency Analysis

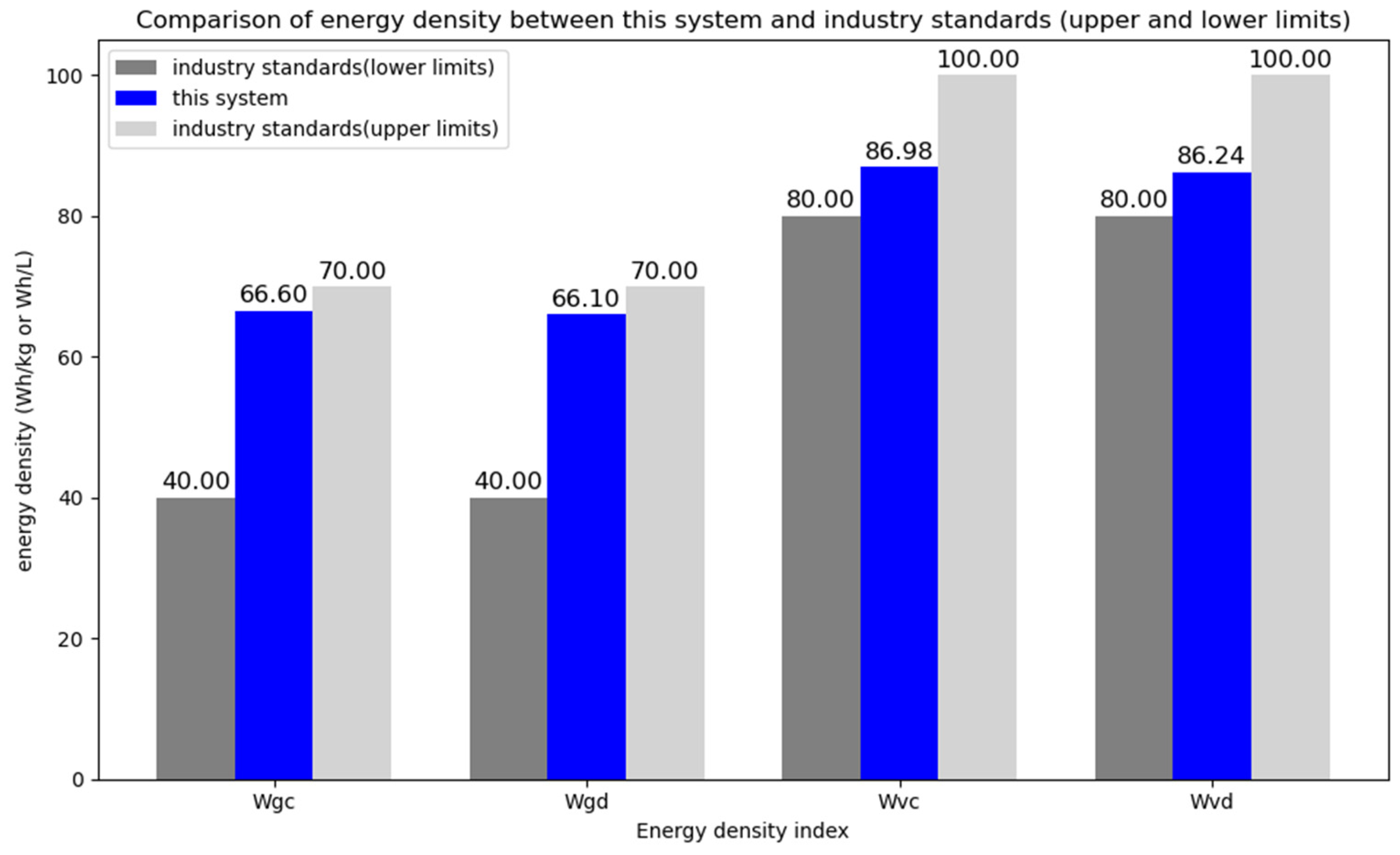

4.2.3. Performance Analysis on Energy Storage System

- ✧

- Energy Efficiency Analysis

- ✧

- Specific Energy Density Analysis

- ✧

- Volumetric Energy Density Analysis

4.2.4. Performance Analysis on Hydrogen Energy System

- ✧

- Hydrogen Production Analysis

- ✧

- Hydrogen Production Efficiency Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tang, D.; Chen, Z.; Zhao, W.; Yuan, Y.; Yuan, C.; Guerrero, J.M.; Zio, E. Sustainable mega-seaports with integrated multi-energy systems: Life-cycle environmental and economic evaluation. J. Clean. Prod. 2024, 478, 143905. [Google Scholar] [CrossRef]

- Zhang, Z.; Song, C.; Zhang, J.; Chen, Z.; Liu, M.; Aziz, F.; Yap, P.S. Digitalization and innovation in green ports: A review of current issues, contributions and the way forward in promoting sustainable ports and maritime logistics. Sci. Total Environ. 2024, 912, 169075. [Google Scholar] [CrossRef]

- Abas, N.; Kalair, A.; Khan, N. Review of fossil fuels and future energy technologies. Futures 2015, 69, 31–49. [Google Scholar] [CrossRef]

- Zhang, Q.; Qi, J.; Zhen, L. Optimization of integrated energy system considering multi-energy collaboration in carbon-free hydrogen port. Transp. Res. Part E Logist. Transp. Rev. 2023, 180, 103351. [Google Scholar] [CrossRef]

- Chang, C.C.; Wang, C.M. Evaluating the effects of green port policy: Case study of Kaohsiung harbor in Taiwan. Transp. Res. Part D Transp. Environ. 2012, 17, 185–189. [Google Scholar] [CrossRef]

- Sachs, J.D.; Schmidt-Traub, G.; Williams, J. Pathways to zero emissions. Nat. Geosci. 2016, 9, 799–801. [Google Scholar] [CrossRef]

- Yang, Y.C.; Chang, W.M. Impacts of electric rubber-tired gantries on green port performance. Res. Transp. Bus. Manag. 2013, 8, 67–76. [Google Scholar] [CrossRef]

- Herrero, A.; Ortega Piris, A.; Diaz-Ruiz-Navamuel, E.; Gutierrez, M.A.; Lopez-Diaz, A.I. Influence of the implantation of the onshore power supply (OPS) system in Spanish medium-sized ports on the reduction in CO2 emissions: The case of the Port of Santander (Spain). J. Marine Sci. Eng. 2022, 10, 1446. [Google Scholar] [CrossRef]

- Colarossi, D.; Lelow, G.; Principi, P. Local energy production scenarios for emissions reduction of pollutants in small-medium ports. Transp. Res. Interdiscip. Perspect. 2022, 13, 100554. [Google Scholar] [CrossRef]

- Colarossi, D.; Principi, P. Optimal sizing of a photovoltaic/energy storage/cold ironing system: Life Cycle cost approach and environmental analysis. Energy Convers. Manag. 2023, 291, 117255. [Google Scholar] [CrossRef]

- Gong, X.; Li, X.; Zhong, Z. Strategic bidding of hydrogen-wind-photovoltaic energy system in integrated energy and flexible ramping markets with renewable energy uncertainty. Int. J. Hydrogen Energy 2024, 80, 1406–1423. [Google Scholar] [CrossRef]

- Pivetta, D.; Dall’Armi, C.; Sandrin, P.; Bogar, M.; Taccani, R. The role of hydrogen as enabler of industrial port area decarbonization. Renew. Sustain. Energy Rev. 2024, 189, 113912. [Google Scholar] [CrossRef]

- Donelly, J. Qingdao Port Becomes the World’s First Hydrogen-Powered and 5G Intelligent Port; Port Technology: London, UK, 2022. [Google Scholar]

- Gutierrez-Romero, J.E.; Esteve-Pérez, J.; Zamora, B. Implementing Onshore Power Supply from renewable energy sources for requirements of ships at berth. Appl. Energy 2019, 255, 113883. [Google Scholar] [CrossRef]

- Sifakis, N.; Konidakis, S.; Tsoutsos, T. Hybrid renewable energy system optimum design and smart dispatch for nearly Zero Energy Ports. J. Clean. Prod. 2021, 310, 127397. [Google Scholar] [CrossRef]

- Vichos, E.; Sifakis, N.; Tsoutsos, T. Challenges of integrating hydrogen energy storage systems into nearly zero-energy ports. Energy 2022, 241, 122878. [Google Scholar] [CrossRef]

- Seddiek, I.S. Application of renewable energy technologies for eco-friendly sea ports. Ships Offshore Struct. 2020, 15, 953–962. [Google Scholar] [CrossRef]

- Tang, D.; Zheng, Z.; Guerrero, J.M. A hybrid multi-criteria dynamic sustainability assessment framework for integrated multi-energy systems incorporating hydrogen at ports. Int. J. Hydrogen Energy 2025, 99, 540–552. [Google Scholar] [CrossRef]

- Song, T.; Li, Y.; Zhang, X.P.; Wu, C.; Li, J.; Guo, Y.; Gu, H. Integrated port energy system considering integrated demand response and energy interconnection. Int. J. Electr. Power Energy Syst. 2020, 117, 105654. [Google Scholar] [CrossRef]

- Pu, Y.; Chen, W.; Zhang, R.; Liu, H. Optimal operation strategy of port integrated energy system considering demand response. In Proceedings of the 2020 IEEE 4th Conference on Energy Internet and Energy System Integration (EI2), Wuhan, China, 30 October–1 November 2020; pp. 518–523. [Google Scholar] [CrossRef]

- Li, Y.; Tang, D.; Yuan, C.; Diaz-Londono, C.; Agundis-Tinajero, G.D.; Guerrero, J.M. The roles of hydrogen energy in ports: Comparative life-cycle analysis based on hydrogen utilization strategies. Int. J. Hydrogen Energy 2025, 106, 1356–1372. [Google Scholar] [CrossRef]

- Georgilakis, P.S. Technical challenges associated with the integration of wind power into power systems. Renew. Sustain. Energy Rev. 2008, 12, 852–863. [Google Scholar] [CrossRef]

- Rosen, M.A.; Koohi-Fayegh, S. The prospects for hydrogen as an energy carrier: An overview of hydrogen energy and hydrogen energy systems. Energy Ecol. Environ. 2016, 1, 10–29. [Google Scholar] [CrossRef]

- Ramakumar, R.; Bigger, J.E. Photovoltaic systems. Proc. IEEE 1993, 81, 365–377. [Google Scholar] [CrossRef]

- Rajesh, R.; Mabel, M.C. A comprehensive review of photovoltaic systems. Renew. Sustain. Energy Rev. 2015, 51, 231–248. [Google Scholar] [CrossRef]

- Nikolaidis, P.; Poullikkas, A. A comparative overview of hydrogen production processes. Renew. Sustain. Energy Rev. 2017, 67, 597–611. [Google Scholar] [CrossRef]

- Ge, P.; Tang, D.; Yuan, Y.; Guerrero, J.M.; Zio, E. A hierarchical multi-objective co-optimization framework for sizing and energy management of coupled hydrogen-electricity energy storage systems at ports. Appl. Energy 2025, 384, 125451. [Google Scholar] [CrossRef]

- Zhang, F.; Bai, F. Medium- and long-term prediction of carbon emissions from coal consumption and carbon dioxide emissions. China Coal 2022, 48, 36–40. [Google Scholar] [CrossRef]

- Zhao, M.; Chen, Z.; Blaabjerg, F. Generation ratio availability assessment of electrical systems for offshore wind farms. IEEE Trans. Energy Convers. 2007, 22, 755–763. [Google Scholar] [CrossRef]

- Mabel, M.C.; Raj, R.E.; Fernandez, E. Adequacy evaluation of wind power generation systems. Energy 2010, 35, 5217–5222. [Google Scholar] [CrossRef]

- Castro Sayas, F.; Allan, R.N. Generation availability assessment of wind farms. IEE Proc. Gen. Trans. Distr. 1996, 143, 507–518. [Google Scholar] [CrossRef]

- Meral, M.E.; Dincer, F. A review of the factors affecting operation and efficiency of photovoltaic based electricity generation systems. Renew. Sustain. Energy Rev. 2011, 15, 2176–2184. [Google Scholar] [CrossRef]

- Lukutin, B.V.; Shandarova, E.B.; Fuks, I.L. Energy efficiency of photovoltaic power plants in stand-alone power supply systems. In Proceedings of the 2016 2nd International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Chelyabinsk, Russia, 19–20 May 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Green, M.A.; Bremner, S.P. Energy conversion approaches and materials for high-efficiency photovoltaics. Nat. Mater. 2017, 16, 23–34. [Google Scholar] [CrossRef] [PubMed]

- Abdi, H.; Mohammadi-ivatloo, B.; Javadi, S.; Khodaei, A.R.; Dehnavi, E. Energy storage systems. Distrib. Gener. Syst. 2017, 7, 333–368. [Google Scholar] [CrossRef]

- Wang, D.; Han, C.; Mo, F.; Yang, Q.; Zhao, Y.; Li, Q.; Han, C.; Liang, G.; Dong, B.; Zhi, C. Energy density issues of flexible energy storage devices. Energy Storage Mater. 2020, 28, 264–292. [Google Scholar] [CrossRef]

- Liu, Y.T.; Liu, S.; Li, G.R.; Gao, X.P. Strategy of enhancing the volumetric energy density for lithium–sulfur batteries. Adv. Mater. 2021, 33, 2003955. [Google Scholar] [CrossRef]

- Younas, M.; Shafique, S.; Hafeez, A.; Javed, F.; Rehman, F. An overview of hydrogen production: Current status, potential, and challenges. Fuel 2022, 316, 123317. [Google Scholar] [CrossRef]

- Ozbilen, A.; Dincer, I.; Rosen, M.A. Comparative environmental impact and efficiency assessment of selected hydrogen production methods. Environ. Impact Assess. Rev. 2013, 42, 1–9. [Google Scholar] [CrossRef]

| Year | Total Electricity Consumption (Billion kWh) | Total Energy Consumption (10,000 Tons) | Carbon (Tons) | CO2 (Tons) | SO2 (Tons) | NOx (Tons) |

|---|---|---|---|---|---|---|

| 2019 | 0.75 | 2.956 | 20,102 | 73,608 | 2217 | 1123 |

| 2020 | 0.78 | 3.013 | 20,489 | 75,025 | 2260 | 1145 |

| 2021 | 0.804 | 2.899 | 19,710 | 72,174 | 2174 | 1101 |

| 2022 | 0.79 | 2.874 | 19,543 | 71,563 | 2156 | 1092 |

| 2023 | 0.745 | 2.745 | 18,666 | 68,351 | 2059 | 1043 |

| Clean Energy Type | Solar PV | Wind Power | Hydrogen Energy | Shore Power |

|---|---|---|---|---|

| Electricity (10,000 kWh) | 28.22 | 151.33 | / | 1.1 |

| Standard coal saved (tons) | 112.88 | 605.32 | / | 4.4 |

| Carbon saved (tons) | 76.76 | 411.62 | / | 2.99 |

| CO2 reduction (tons) | 281.35 | 1508.76 | / | 10.97 |

| SO2 reduction (tons) | 8.47 | 45.4 | / | 0.33 |

| NOx reduction (tons) | 4.23 | 22.7 | / | 0.17 |

| Clean Energy Type | Solar PV | Wind Power | Hydrogen Energy | Shore Power |

|---|---|---|---|---|

| Contribution rate | 0.16 | 0.84 | / | 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, S.; Huang, Z.; Tang, D.; Ma, W.; Guerrero, J.M. The Role of Integrated Multi-Energy Systems Toward Carbon-Neutral Ports: A Data-Driven Approach Using Empirical Data. J. Mar. Sci. Eng. 2025, 13, 477. https://doi.org/10.3390/jmse13030477

Yu S, Huang Z, Tang D, Ma W, Guerrero JM. The Role of Integrated Multi-Energy Systems Toward Carbon-Neutral Ports: A Data-Driven Approach Using Empirical Data. Journal of Marine Science and Engineering. 2025; 13(3):477. https://doi.org/10.3390/jmse13030477

Chicago/Turabian StyleYu, Shaohua, Zhaoliang Huang, Daogui Tang, Weiming Ma, and Josep M. Guerrero. 2025. "The Role of Integrated Multi-Energy Systems Toward Carbon-Neutral Ports: A Data-Driven Approach Using Empirical Data" Journal of Marine Science and Engineering 13, no. 3: 477. https://doi.org/10.3390/jmse13030477

APA StyleYu, S., Huang, Z., Tang, D., Ma, W., & Guerrero, J. M. (2025). The Role of Integrated Multi-Energy Systems Toward Carbon-Neutral Ports: A Data-Driven Approach Using Empirical Data. Journal of Marine Science and Engineering, 13(3), 477. https://doi.org/10.3390/jmse13030477