A Comparative Study of Combustion Characteristics for the Evaluation of the Feasibility of Crude Bioethanol as a Substitute for Marine Fuel Oil

Abstract

1. Introduction

2. Materials and Methods

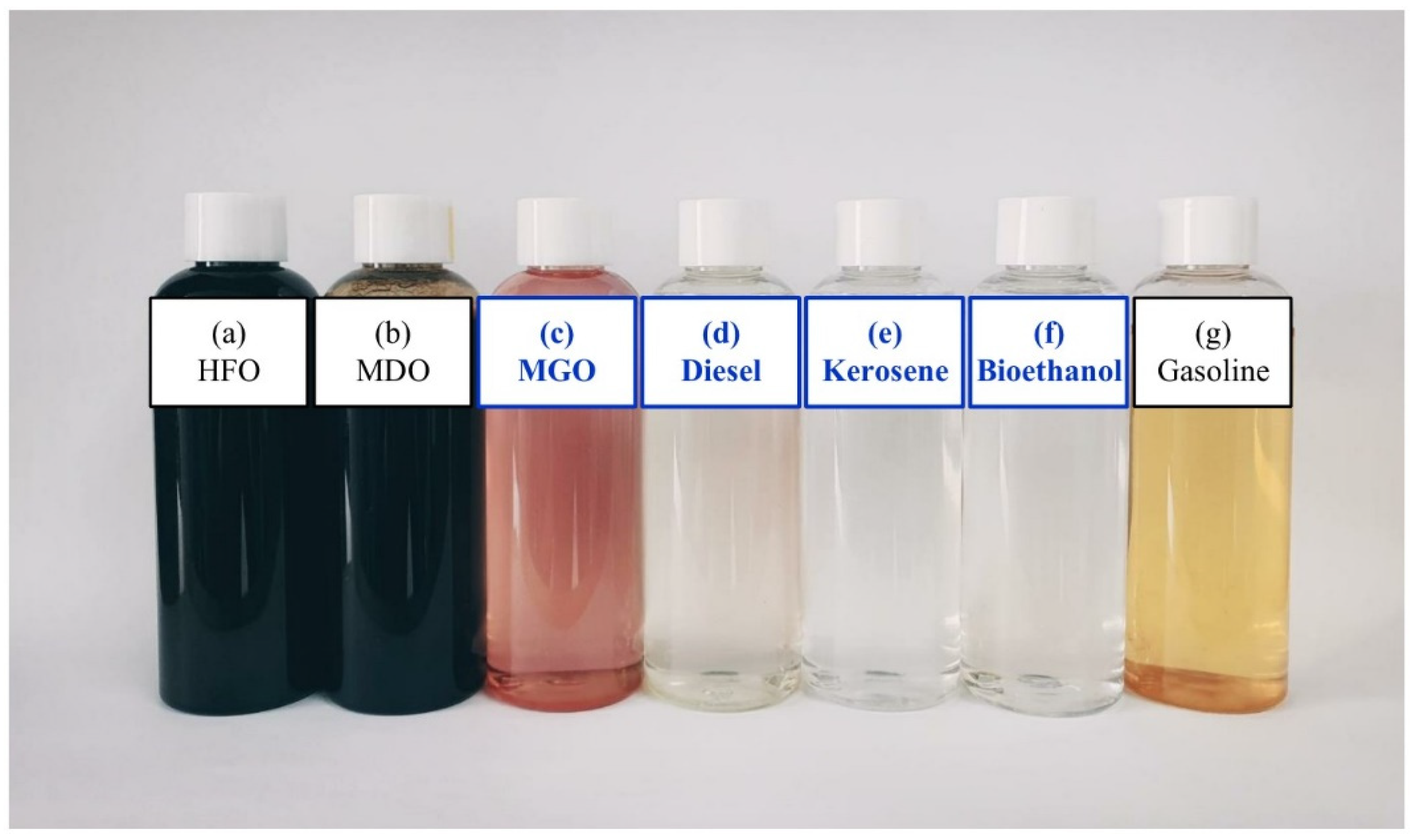

2.1. Marine Gas Oil (MGO) and Bioethanol (BE100)

2.2. Analysis of Fuel Composition and Physical Properties

2.3. Design and Fabrication of a 1-Ton Combustion Chamber

2.4. Experimental Conditions and Methods

3. Results

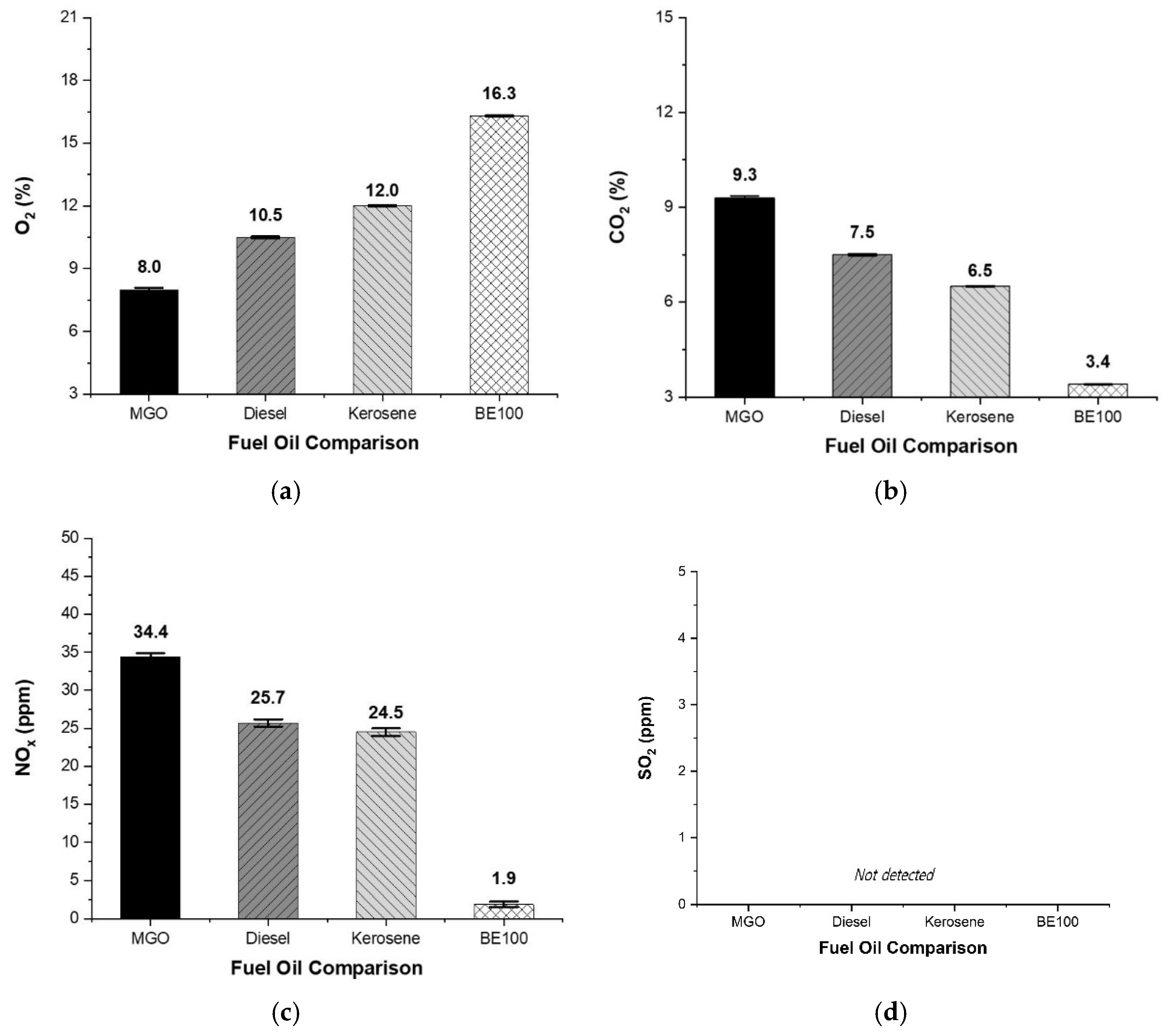

3.1. Exhaust Gas Emissions

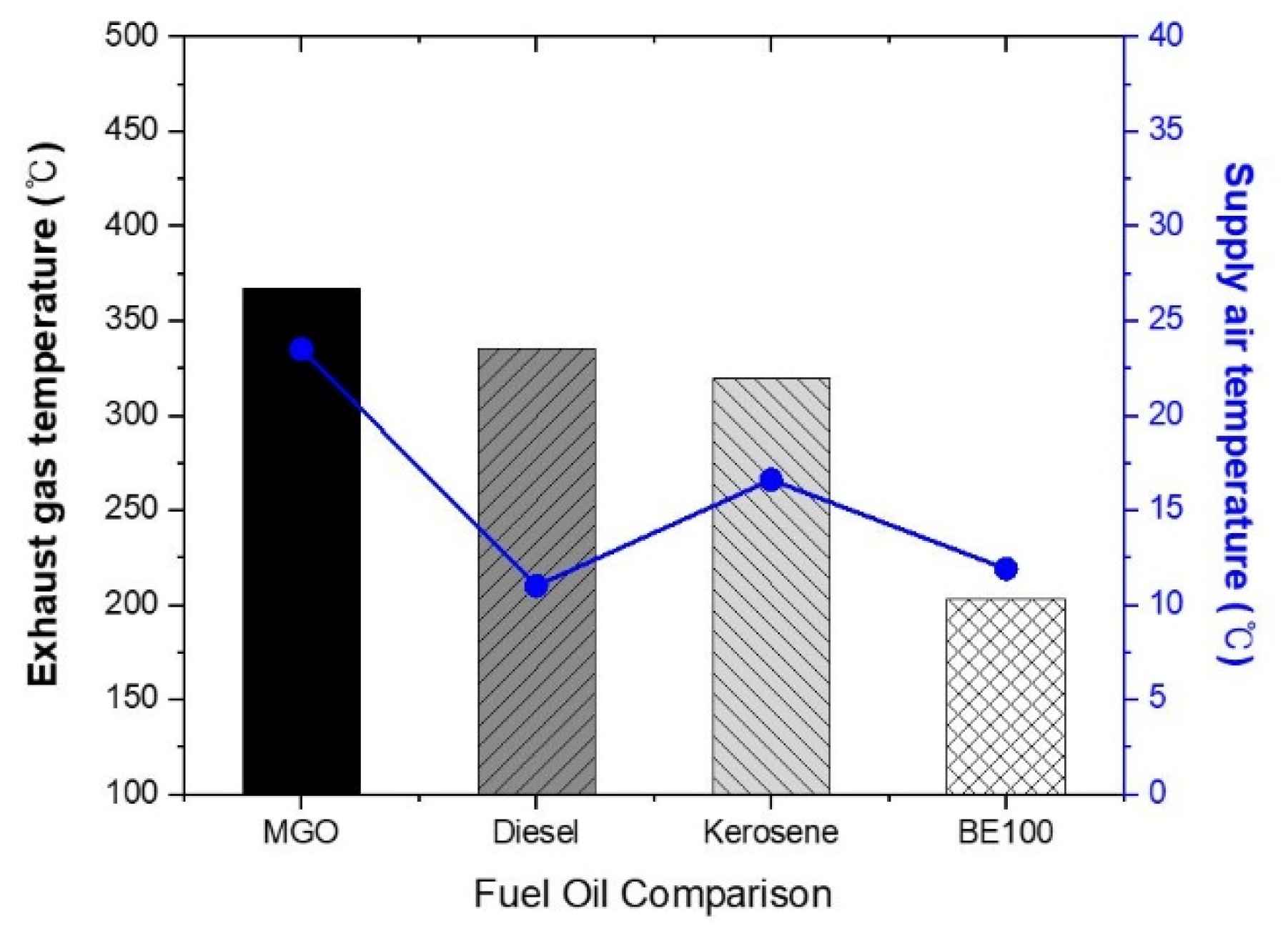

3.2. Exhaust Gas Temperature

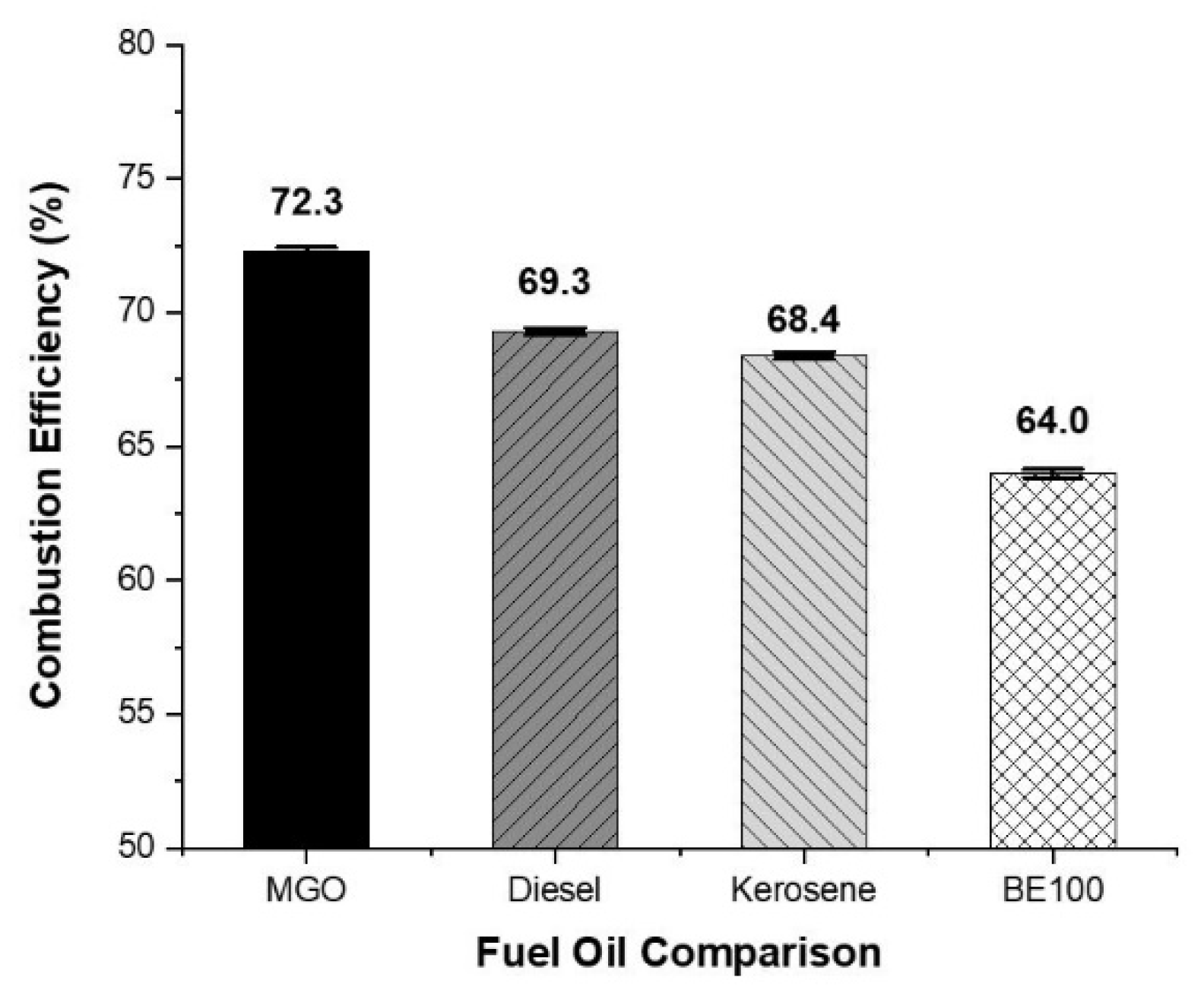

3.3. Combustion Efficiency

4. Statistical Analysis

One-Way Analysis of Variance (ANOVA)

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, J.W.; Lee, T.H.; Ryu, Y.H. Thermo-Gravimetric Analysis of MGO-Bioethanol Blended Fuel Oil. J. Korean Soc. Mech. Technol. 2024, 26, 1187–1192. [Google Scholar]

- Kim, J.W. The Effects of MGO-Bioethanol Blended Oil Using Standard Combustion Chamber on Exhaust Emissions Characteristics; Pukyoung National University: Busan, Republic of Korea, 2024. [Google Scholar]

- Lee, T.H.; Lee, S.H.; Lee, J.K. Exhaust gas emission improvements of water/bunker C oil-emulsified fuel applied to marine boiler. J. Mar. Sci. Eng. 2021, 9, 477. [Google Scholar] [CrossRef]

- Demirbas, A. Biodiesel: A Realistic Fuel Alternative for Diesel Engines; Springer: London, UK, 2008. [Google Scholar]

- Force, C.A.T. Prevention of Air Pollution from Ships: Reducing Shipping Emissions of Air Pollution-Feasible and Cost-Effective Options Submitted by Friends of the Earth International to the Marine Environment Protection Committee; IMO: London, UK, 2005. [Google Scholar]

- Gritsenko, D. Regulating GHG Emissions from shipping: Local, global or polycentric approach? Mar. Policy 2017, 84, 130–133. [Google Scholar] [CrossRef]

- Lee, S.B.; Cho, M.I.; Kang, S.G.; Huh, C. Necessity and Research Challenges of Onboard Carbon Capture Technology in Achieving the IMO’s Goal of Reducing GHG. J. Korean Soc. Mar. Environ. Energy 2023, 26, 336–348. [Google Scholar] [CrossRef]

- Choi, J.S.; Han, S.G.; Choi, J.H.; Park, S.K.; Park, R.S.; Kim, D.H. A Study on Characteristics of Exhaust Gas Emissions of Water-Bunker Oil Mixed by Homogenizer. J. Korean Soc. Mar. Environ. Saf. 2013, 19, 518–524. [Google Scholar] [CrossRef]

- Lee, T.H.; Ryu, Y.H. A Study on mixing properties of coffee ground-fuel for improvement of air pollution from ships. J. Korean Soc. Mech. Technol. 2021, 23, 181–186. [Google Scholar]

- Ryu, Y.H.; Dan, T. Investigation on the Effects of Dimethyl Ether Blending to Bunker Oil for Marine Diesel Engine Use; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- IMO. Alternative Fuels-Scalability and Sustainability, Future Fuels and Technology for Lowand Zero-Carbon Shipping Project in Website; IMO: London, UK, 2024. [Google Scholar]

- Kim, J.W.; Lee, T.H.; Park, J.U. Manufacturing Method for MGO-Bioethanol Mixed Fuel Oil. J. Korean Soc. Mech. Technol. 2024, 26, 293–298. [Google Scholar]

- Lee, T.H.; Kang, I.S. Small Combustion Chamber for Marine Fuel Oil and Analysis of Exhaust Gas Characteristics of Marine Gas Oil. J. Mar. Sci. Eng. 2023, 11, 609. [Google Scholar] [CrossRef]

- Kim, J.W.; Park, J.U.; Lee, T.H.; Kang, I.S. Characteristics of exhaust emissions from MGO–bioethanol fuel blend using a combustion chamber. Adv. Mech. Eng. 2024, 16, 16878132241298338. [Google Scholar] [CrossRef]

- Bae, S.J. Combustion and emission characteristics of a diesel engine fueled with diesel-bioethanol blends according to engine speed. J. Korean. Soc. Mech. Technol. 2022, 24, 572–577. [Google Scholar]

- Bae, S.J. A study on the combustion and emission characteristics of diesel-bioethanol blends in compressionignition engines according to idle operating conditions. J. Korean. Soc. Mech. Technol. 2022, 24, 706–711. [Google Scholar]

- Ha, S.Y. A Study on Combustion and Exhaust Emissions Characteristics in a Spark Ignition (SI) Engine with Bioethanol Fuel; Hanyang University: Busan, Republic of Korea, 2010. [Google Scholar]

- Poulopoulos, S.G.; Philippopoulos, C.J. The effect of adding oxygenated compounds to gasoline on automotive exhaust emissions. J. Eng. Gas Turbines Power 2003, 125, 344–350. [Google Scholar] [CrossRef]

- Jeuland, N.; Montagne, X.; Gautrot, X. Potentiality of ethanol as a fuel for dedicated engine. Oil Gas Sci. Technol. 2004, 59, 559–570. [Google Scholar] [CrossRef]

- ISO 8217:2017; ISO 8217—Petroleum Products—Fuels (Class F)—Specifications of Marine Fuels. ISO: Geneva, Switzerland, 2017.

- Legislative Bureau. Oil and Alternative Fuel Business Act; National Legal Information Center: Sejong, Republic of Korea, 2019.

- Kim, J.W.; Lee, T.H.; Park, J.U. Development of a Lap scale 1-ton Standard Combustion Chamber. J. Korean Soc. Mech. Technol. 2024, 26, 371–376. [Google Scholar]

- Kang, M.K. A Study on the Exhaust Characteristics of Diesel Engine Emissions and the Feasibility of Using Waste Vinyl Pyrolysis Oil as Marine Fuel; National Korea Maritime & Ocean University: Busan, Republic of Korea, 2024. [Google Scholar]

- Lee, J.H.; Lee, S.Y. Current status and prospects of bioalcohol. News Inf. Chem. Eng. 2018, 36, 673–679. [Google Scholar]

- Ra, C.H.; Sunwoo, I.S.; Kim, S.K. Bioethanol Production from Macroalgal Biomass. J. Life. Sci. 2016, 26, 976–982. [Google Scholar] [CrossRef]

- Lee, S.M.; Choi, I.S.; Kim, S.K.; Lee, J.H. Production for bio-ethanol from brown algae by enzymic hydrolysis. J. KSBB 2009, 24, 483–488. [Google Scholar]

- Badal, C.S.; Michael, C.A. Enzymatic saccharification and fermentation of alkaline peroxide pretreated rice hulls to ethanol. Enzym. Microb. Technol. 2007, 41, 528–532. [Google Scholar]

- Hwang, I.H.; Doe, J.W.; Kang, H.K.; Sung, S.R.; Ha, J.H.; Na, B.K. Study on the Density and Volume Change Property of Petroleum Products according to Temperature Variation. J. Oil Appl. Sci. 2017, 34, 1112–1120. [Google Scholar]

- Sattarin, M.; Modarresi, H.; Bayat, M.; Teymori, M. New Viscosity Correlations for Dead Crude Oils. Pet. Coal 2007, 49, 33–39. [Google Scholar]

- K-petro. Composion Analysis Test Report of TSC2024-0118E; K-petro Co., Ltd.: Sungnam, Republic of Korea, 2024. [Google Scholar]

- K-petro. Composion Analysis Test Report of TSC2025-0024E; K-petro Co., Ltd.: Sungnam, Republic of Korea, 2025. [Google Scholar]

- Lee, T.H.; Kim, J.W.; Ryu, Y.H. Exhaust Emission Characterisitics of MGO-Biodiesel Mixed Oil. J. Korean Soc. Mech. Technol. 2024, 26, 660–667. [Google Scholar]

- Lee, T.H.; Kang, I.S. Development of 30 liter small boiler for testing marine fuel oil. J. Korean Soc. Mech. Technol. 2023, 25, 223–228. [Google Scholar]

- TESTO. Flue Gas Analyzer Instruction Manual on Testo-340; Testo Co., Ltd.: West Chester, PA, USA, 2016. [Google Scholar]

- No, K.S. The Proper Methods of Statistical Analysis for Dissertation; Hanbit Academy Inc.: Seoul, Repubic of Korea, 2019. [Google Scholar]

| List | Standard Method [20] | MGO | Diesel | Kerosene | BE100 | Unit |

|---|---|---|---|---|---|---|

| Lower calorific value (LHV) | ASTM D240-19 | 43,030 | 42,700 | 43,250 | 24,190 | J/g |

| High calorific value (HHV) | ASTM D240-19 | 46.065 | 45.780 | 46.335 | 27.010 | MJ/kg |

| Density @ 15 °C | KS M ISO 12185:1996 | 840.8 | 821.2 | 786.7 | 811.5 | Kg/m3 |

| Flash point | ASTM D93-20 | 67.5 | 47.5 | 44.0 | Less than 40.0 | °C |

| Kinematic viscosity @ 40 °C | KS M ISO 3104:2020 | 3.011 | 2.557 | 1.097 | 1.210 | mm2/s |

| Item | List | Specification | Unit |

|---|---|---|---|

| Combustion Chamber | Type | Square cylinder | - |

| Volume | 900 | liter | |

| Size | 750 × 750 × 1600 | mm | |

| Thickness | 3.2 | t | |

| Sight glass | H125 × W250 | mm | |

| Funnel | 5K 200A | mm | |

| Weight | About 265 | kg | |

| Burner Assembly | Model | SGH-10 | - |

| Fuel | Diesel, etc. | - | |

| Consumption | 4–10 | kg/h | |

| Calorific value | Max. 99,000 | kcal/h | |

| Weight | 40 | kg | |

| Nozzle | Model | 030H6920 | - |

| Flow rate | 3.72 | kg/h | |

| Angle | 60 | ° | |

| Definition point | Max. 10.0 | bar |

| Experiment Condition | Values | Unit | |||

|---|---|---|---|---|---|

| Test Oil | MGO M | Diesel D | Kerosene K | BE100 BE | % |

| Chamber Pressure | −0.000002 | −0.000008 | −0.000047 | 0.00021 | bar |

| Chamber Temperature | 434.73 | 418.16 | 404.37 | 252.41 | °C |

| Fuel Injection Pressure | 9.27 | 9.19 | 9.02 | 9.13 | bar |

| Fuel Oil Temperature | 14.18 | 13.98 | 15.33 | 12.03 | °C |

| Supply Air Temperature | 23.5 | 11.1 | 16.6 | 11.9 | °C |

| Parameter | Range | Accuracy (%) | Resolution | Unit |

|---|---|---|---|---|

| O2 | 0–25 | ±0.20 | 0.01 | % |

| CO2 | 0–CO2max | ±0.20 | 0.10 | % |

| NOx | 0–4000 | ±5–10 | 1.00 | ppm |

| SO2 | 0–5000 | ±10 | 1.00 | ppm |

| Temperature | −40–1200 | ±0.50 | 0.10 | °C |

| Item | Fuel Oil | One-Way ANOVA Analysis Results | |||||

|---|---|---|---|---|---|---|---|

| N | M | SD | F | p | Tukey | ||

| Exhaust Gas Temperature | MGO M | 300 | 367.113 | 1.434 | 2,342,163.674 | 0.000 *** | M > D > K > BE |

| Diesel D | 300 | 335.366 | 1.008 | ||||

| Kerosene K | 300 | 319.703 | 1.223 | ||||

| BE100 BE | 300 | 203.239 | 0.570 | ||||

| O2 | MGO M | 300 | 8.034 | 0.081 | 3,026,252.487 | 0.000 *** | M < D < K < BE |

| Diesel D | 300 | 10.538 | 0.045 | ||||

| Kerosene K | 300 | 11.976 | 0.030 | ||||

| BE100 BE | 300 | 16.251 | 0.019 | ||||

| CO2 | MGO M | 300 | 9.322 | 0.062 | 2,939,641.218 | 0.000 *** | M > D > K > BE |

| Diesel D | 300 | 7.524 | 0.032 | ||||

| Kerosene K | 300 | 6.531 | 0.021 | ||||

| BE100 BE | 300 | 3.420 | 0.013 | ||||

| NOx | MGO M | 300 | 34.353 | 0.486 | 359,719.804 | 0.000 *** | M > D > K > BE |

| Diesel D | 300 | 25.670 | 0.471 | ||||

| Kerosene K | 300 | 24.477 | 0.500 | ||||

| BE100 BE | 300 | 1.850 | 0.358 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-W.; Lee, T.-H. A Comparative Study of Combustion Characteristics for the Evaluation of the Feasibility of Crude Bioethanol as a Substitute for Marine Fuel Oil. J. Mar. Sci. Eng. 2025, 13, 433. https://doi.org/10.3390/jmse13030433

Kim J-W, Lee T-H. A Comparative Study of Combustion Characteristics for the Evaluation of the Feasibility of Crude Bioethanol as a Substitute for Marine Fuel Oil. Journal of Marine Science and Engineering. 2025; 13(3):433. https://doi.org/10.3390/jmse13030433

Chicago/Turabian StyleKim, Ju-Wan, and Tae-Ho Lee. 2025. "A Comparative Study of Combustion Characteristics for the Evaluation of the Feasibility of Crude Bioethanol as a Substitute for Marine Fuel Oil" Journal of Marine Science and Engineering 13, no. 3: 433. https://doi.org/10.3390/jmse13030433

APA StyleKim, J.-W., & Lee, T.-H. (2025). A Comparative Study of Combustion Characteristics for the Evaluation of the Feasibility of Crude Bioethanol as a Substitute for Marine Fuel Oil. Journal of Marine Science and Engineering, 13(3), 433. https://doi.org/10.3390/jmse13030433