Abstract

The electric potential gradient is a key factor in electroosmotically reinforcing soft clay. Its application history induces a series of physical and chemical reactions within the soil, influencing the selection of the gradient in the subsequent stage. To gain a deeper understanding of this complex process and its inherent mechanism, electroosmotic reinforcement tests on soft clay were conducted under varying electric voltage gradients. The changes in parameters, including current, drainage volume, shear strength, and water content within the soil, under different application histories of the voltage gradients, were measured. The experimental results demonstrate that the magnitude of the voltage adopted in previous historical stages had a significant impact on the current drainage situation as well as the enhancement of shear strength. During the studied historical period, a relatively high voltage gradient was applied until soil drainage stopped. However, at present, it has become extremely challenging to substantially increase the drainage volume regardless of whether the electrification voltage gradient remains stable, rises, or falls, even when the current does not drop too low. For soil with a high activity index, under an appropriate voltage, the input electrical energy can be more efficiently converted into various physical and chemical processes that enhance soil reinforcement. Regardless of the voltage gradient level adopted, the application of a low voltage gradient in the historical stage exerts a more beneficial influence on the current stage than a high voltage gradient. During the electroosmosis process, efforts should be made to maximize the drainage duration as it facilitates the promotion of the chemical reinforcement effect and reduces energy consumption.

1. Introduction

Electroosmosis has a long-standing application history in the treatment of soft clay foundations with low permeability [1]. This technology utilizes an electric field to make the moisture in soft clay migrate from the anode to the cathode together with hydrated cations, thus achieving the goals of rapid drainage consolidation and increasing the shear strength of the soil [2,3,4]. Furthermore, during the construction process, this method minimizes disturbance to the foundation soil and better preserves the original structural stability of the foundation. However, the electroosmosis method requires special electrodes, wires, and stable and reliable power supply equipment, and the long-term energization process consumes a substantial amount of electric energy. During the usage process, the electrodes may encounter corrosion and polarization phenomena, which can influence the treatment effect [5,6]. This not only raises the operating cost but also might be restricted by power supply conditions in large-scale applications [7]. The energy consumption of electroosmosis thus deserves continuous attention, and more new energy-saving and emission reduction schemes should be explored.

In the context of soft clay treatment via electroosmosis, multiple elements give rise to a plethora of unstable aspects and variable regulatory factors throughout the implementation stage [8]. For example, during the entire electroosmosis process, the accumulated conditions in the completed electrification stages, that is, the so-called electrification history, will influence the current ongoing electrification implementation stage as well as the subsequent yet-to-be-carried-out implementation stages from multiple different aspects. This kind of influence is reflected in aspects such as the distribution state of ions in the soil mass, the flow characteristics of pore water, and the arrangement pattern of soil particles, and further affects multiple links including the reinforcement effect, construction efficiency, and possible problems. The scope covered by the electrical energization history is quite extensive, which encompasses numerous key elements, such as the intermittent time during the electrical energization process, the situation of electrode switching, and the changes in the applied voltage gradient [4,9,10]. These elements are intertwined with each other and jointly form a complex and diverse electrical energization history. Any change in each of these elements may have a unique impact on the entire electrical energization process and further influence the results in relevant physical, chemical, or engineering aspects.

The voltage gradient is a crucial factor influencing the electroosmosis reinforcement effect of soft clay [11]. A higher voltage gradient can generate a stronger electric field force, which drives the hydrated cations in pore water to move directionally from the anode to the cathode, thus accelerating the speed of electro-osmotic drainage, reducing the water content in the soft clay more rapidly, and then effectively increasing the shear strength of the soil mass [12]. The duration of the voltage gradient is also of crucial importance. A continuously stable and appropriate voltage gradient can maintain the electroosmosis effect over a relatively long period of time, further optimizing the reinforcement effect. However, if the voltage gradient is too high and its duration is too long, it may lead to negative effects such as damage to the soil structure [13,14]. At present, for on-site applications, on-site tests, and laboratory tests, there are two ways to apply the electric voltage gradient, namely single-stage and multi-stage, as shown in Table 1. In on-site engineering applications or tests, due to the fact that the reinforcement scale is much larger and the number of electrodes is much higher compared to those in laboratory tests, low voltage is typically chosen. Moreover, taking into account aspects like safety requirements in open-air field settings, the necessity to cut down energy consumption for cost control, and the potential for interference with other on-site electrical devices, low voltage emerges as a more advantageous option [15,16].

When a single-stage voltage gradient was adopted, although anode corrosion resulted in voltage loss, high voltage was still conducive to reducing the soil water content and increasing the shear strength. It should also be noted that an increased voltage gradient only improves the proportion of effective voltage during the early stage of the electroosmotic process. In the long run, an excessively high voltage gradient is not beneficial for increasing the ratio of effective voltage to output voltage [17]. When it comes to a multi-stage electric voltage gradient, existing research has shown that a reasonable stepped-voltage scheme can reduce electrode corrosion and power consumption, help in effectively delaying the decrease in the current, and increase the volume of electroosmotic drainage and subsequent electroosmotic efficiency [18,19]. Stepped electroosmosis prevents the rapid increase in the interface resistance between the electrode and the soil and maintains the current intensity and electroosmotic efficiency at a high level during the later stage of electroosmosis [20]. However, whether a single-stage or a multi-stage voltage gradient is adopted, differences in the application history of the electric voltage gradient, such as its magnitude, duration, and intermittent time in the early stage, result in variations in ion migration, water migration, chemical cementation, and consolidation within the soil mass. These changes that occurred in the past will be preserved and accumulated, and they will undoubtedly affect the physical and chemical effects of electroosmosis in the soil during the middle and late stages, thereby influencing the efficiency of drainage consolidation.

Table 1.

Application methods of the voltage gradient and their action effects.

Table 1.

Application methods of the voltage gradient and their action effects.

| References | Type of Tests | Applied Voltage (V) or Voltage Gradient (V/cm) | Voltage Application Method | Method | Soil Improvement |

|---|---|---|---|---|---|

| Sun et al. [15] | On-site engineering application | Daytime: 20 V–40 V (increases by 5 V every 5 days); nighttime: 60 V–68 V (electrode conversion) | Multistage voltage | Vacuum preloading combined with electroosmosis | The stepped-up voltage during the day and electrode conversion during the night were helpful in maintaining the electric current in the soil during the day, and it did not decrease but instead slowly increased. |

| Burnotte et al. [16] | Field test | 0.33 → 0.23 → 0.50 V/cm | Multistage voltage | Electroosmosis | When temperatures at the anode reached values close to 100 °C, the resistivity of the system increased rapidly, resulting in a smaller effective voltage gradient in the soil and less efficient EO consolidation. |

| Chew et al. [21] | Field test | 5 V or 14 V | Single stage voltage | Electroosmosis | Shear strength improvement is clearly visible in the EO-treated clay, which is also indicated by the pore pressure response observed. |

| Rittirong et al. [11] | Field test | 7–10 V → 18–29 V | Multistage voltage | Stepped voltage electroosmosis | The average undrained shear strengths range from 22 kPa to 39 kPa after only five days of treatment. |

| Mahalleh et al. [22] | Laboratory model test | 0.5 V/cm or 1 V/cm or 2 V/cm or | Single stage voltage | Electroosmosis | Considering the voltage effect, it appears that soil strength increased with increasing voltage gradients, with the best improved result belonging to the voltage gradient of 2 V/cm. |

| Wen and Yan [23] | Laboratory model test | 6 V/cm or 4 V/cm or 2 V/cm | Single-stage voltage | Electroosmosis | A higher voltage gradient can improve electro-osmosis dewatering. |

| Xue et al. [24] | Laboratory model test | 6 V or 9 V or 12 V | Single-stage voltage | Electroosmosis combined with loading pressure | Although anode corrosion caused voltage loss, high voltage was still beneficial for reducing soil water content and increasing shear strength. |

| Shen et al. [17] | Laboratory model test | 1 V/cm or 1.5 V/cm or 1.75 V/cm or 2 V/cm or 2.25 V/cm | Single-stage voltage | Electroosmosis | An increased voltage gradient only improved the proportion of effective voltage in the early stage of the electro-osmotic process; in the long term, an overly high voltage gradient was not beneficial for increasing the ratio of effective voltage to output voltage. |

| Liu et al. [18] | Laboratory model test | 0.50 → 0.75 → 1.00 → 1.25 V/cm | Multistage voltage | Electroosmosis | A reasonable stepped voltage scheme can reduce power consumption and increase electroosmotic drainage volume and, later, electroosmotic efficiency. |

| Li et al. [19] | Laboratory model test | 10 V → 12.5 V → 15 V → 17.5 V (0.35 V/cm) | Multistage voltage | Vacuum preloading combined with electroosmosis | The appropriate stepped voltage method is better than the general combined methods, requires less power consumption, and causes less electrode corrosion. |

| Liu et al. [25] | Laboratory model test | 6.5 V → 8.0 V → 9.5 V | Multistage voltage | Stepped vacuum preloading combined with stepped voltage electroosmosis | Three vacuum preloading steps yielded better soil reinforcement effects. |

| Bian et al. [20] | Laboratory model test | 15 V → 22.5 V → 30 V | Multistage voltage | Vacuum preloading combined with stepped voltage electroosmosis | Stepped electroosmosis avoided the rapid increase in interface resistance between the electrode and the soil, and it maintained the current intensity and electroosmosis efficiency at a high level in the later stage of electroosmosis. |

| Huweg et al. [26] | Laboratory model test | 3 V/cm → 6 V/cm → 10 V/cm | Multistage voltage | Stepped voltage electroosmosis | The extracted water volumes were observed to increase with increased electric field intensity. |

In this research, by comparing the electroosmotic drainage volume, water content, shear strength, and other indicators of soft clay under single-stage voltage, two-stage voltage, three-stage voltage, and four-stage voltage, the effect of voltage gradient application history on the electroosmotic reinforcement of soft clay is studied. Furthermore, this research provides a theoretical basis and practical guidance for electroosmotic treatment of soft clay and explores new methods of electroosmotic technology that are more efficient and economical.

2. Materials and Methods

2.1. Soft Clay

The soil samples used in the experiment were prepared from clay powder and a certain amount of purified water. Due to the large quantity of test groups, the clay powder was sourced in four orders from a clay processing facility in Nantong, a coastal city in China. Initially, it was marine sedimentary soil. Considering that potential discrepancies might exist in the physical and chemical properties of these soil samples, only the particle size distribution test and the liquid–plastic limit test were conducted for differentiation purposes, as presented in Table 2. According to the Standard for Engineering Classification of Soil (GB/T 50145-2007) [27], clay particles are defined as soil particles with particle sizes less than 0.005 mm. It is evident that there are substantial differences in the clay content among the four batches of soil samples. Moreover, the higher the clay content, the greater the plasticity index. The operation steps were in accordance with the Standard for Geotechnical Testing Method (GB/T 50123-2019) [28]. Based on this, the activity index (A) of the four batches of soil samples was calculated.

where is plasticity index and is the percentage of the mass of particles with a particle size less than 0.002 mm in the total mass of the soil. All four batches of soil samples were normal clay, and the activity index of the second batch of soil samples was significantly higher than that of the other three batches.

Table 2.

Characteristics of clay powder used in this study.

The clay powder was first weighed precisely. Subsequently, the volume of distilled water required to achieve a water content of 50% was accurately gauged and then carefully poured into the weighed clay powder contained in a vessel. After thorough mixing to guarantee homogeneity, the container was tightly sealed with a plastic film and left to stand undisturbed overnight. Eventually, the water content of the actually prepared soil sample was tested using the oven-drying method, as shown in Table 3.

Table 3.

Experiment scenario for electrokinetic tests.

2.2. Electrokinetic Experiments Device

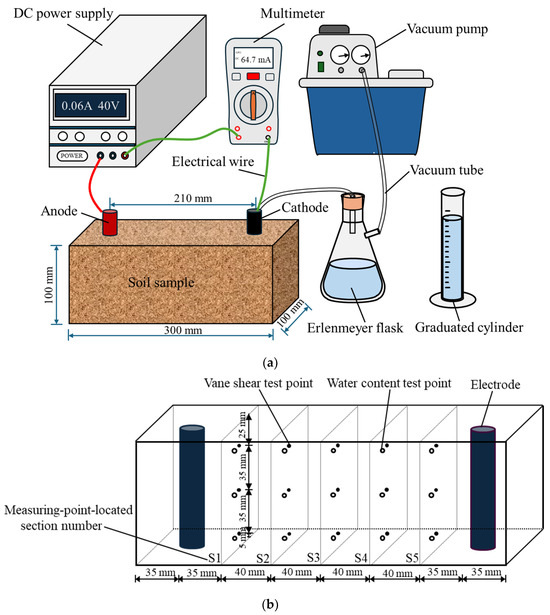

The experimental configuration depicted in Figure 1a is comprised of a model box, soil specimens, electrodes, a DC power supply, a digital multimeter, an Erlenmeyer flask, and a vacuum pump, among other components. The model box was made of polymethyl methacrylate with internal dimensions of 300 mm × 100 mm × 100 mm (length × width × height). Electrokinetic geosynthetics (EKGs) were selected as the electrodes. These EKG materials were fabricated from polyethylene, carbon black, and graphite, endowing them with excellent conductivity and corrosion resistance. The outer diameter and inner diameter of the EKGs measured 27 mm and 17 mm, respectively. Details on the EKG electrodes have been described by Sun et al. [29]. A Water Circulating Multi-Purpose Vacuum Pump (model SHB-IIIA) was utilized to extract the water that had accumulated around the cathode. This pump is characterized by a power of 180 W, a maximum vacuum degree reaching 0.098 MPa, and a single-tap air suction volume of 10 L/min. The DC power supply (model RXN-605D) is capable of providing a stable output voltage and is equipped with a digital display function. Its maximum output power amounts to 60 V × 5 A. Electric cables functioned as the connections linking the DC power supply to the EKGs.

Figure 1.

(a) Schematic diagram of the experimental device. (b) Distribution of detection points and sections for moisture content and vane shear strength.

2.3. Experimental Scheme

The experimental scheme is presented in Table 3. A total of four series of experiments with different voltage gradient levels were conducted, including the single-level voltage gradient series (T1-1~T1-4), the two-level voltage gradient series (T2-1~T2-10), the three-level voltage gradient series (T3-1~T3-3), and the four-level voltage gradient series (T4-1~RT4-1). The electric potential gradient is defined as the ratio of the voltage applied across the anode and cathode to the distance between the two electrodes, both of which are 21 cm. In the following text, descriptions will be made based on the applied voltage. In accordance with the provided experimental plan, the “Voltage Gradient Application History” is defined as the detailed record of the variations and sequential progressions of the voltage gradients applied to distinct experimental groups across a series of experiments. This record comprehensively encompasses essential elements such as the number of voltage gradient levels, the precise numerical values of each gradient level, and the order in which these gradients are applied. Furthermore, within this experimental framework, the “historical stage” pertains to, for a given time point within a specific experiment being investigated during the entire experimental course, the aggregate of all experimental procedures, data compilation, and experimental condition configurations that have transpired prior to that particular time point. This historical stage serves as a crucial backdrop, providing context and a basis for analyzing and interpreting the data and phenomena observed at the focal time point of the experiment.

Soil samples purchased in four batches were used in accordance with the sequence of the experiments. The batch information of the soil samples used in each experiment is shown in Table 3. The total duration of electroosmotic treatment for each experiment was 96 h, with an 8 h working period per day. During the first-stage voltage application, the continuous power-on time of this voltage was 96 h. For the second-stage voltage, the continuous power-on time of each voltage level was 48 h. When it comes to the third-stage voltage, the continuous power-on time of each voltage level was 32 h. And for the fourth-stage voltage, the continuous power-on time of each voltage level was 24 h.

During the test, the electric current, drainage volume, and energy consumption were recorded at regular intervals. The intermittent power-on time was not taken into account during the analysis of the test results. After each test, the water content and vane shear strength distributions were measured at five sections (S1–S5) at different distances from the anode. The distribution of measuring points is shown in Figure 1b. The shear strength tests were carried out using a dynamoelectric vane shear device (TT-LVS, manufactured by Zhejiang Geotechnical Instrument, Shaoxing, China). The vane shear apparatus features blades with a diameter of 25.4 mm, a height of 25.4 mm, and a thickness of 0.01 mm. The initial vane shear strength for each test is presented in Table 3.

3. Results and Discussion

3.1. Influence of Historical High Electric Voltage Gradients on the Electroosmosis Reinforcement Effect at the Present Stage

This series of tests encompassed both historical and current stages. In the historical stage (the first 48 h), a high voltage of either 40 V or 60 V was applied, with the corresponding electric potential gradients being 1.90 V/cm or 2.86 V/cm, respectively. During the current stage under investigation, voltages were higher than, lower than, or identical to those in the historical stage were used.

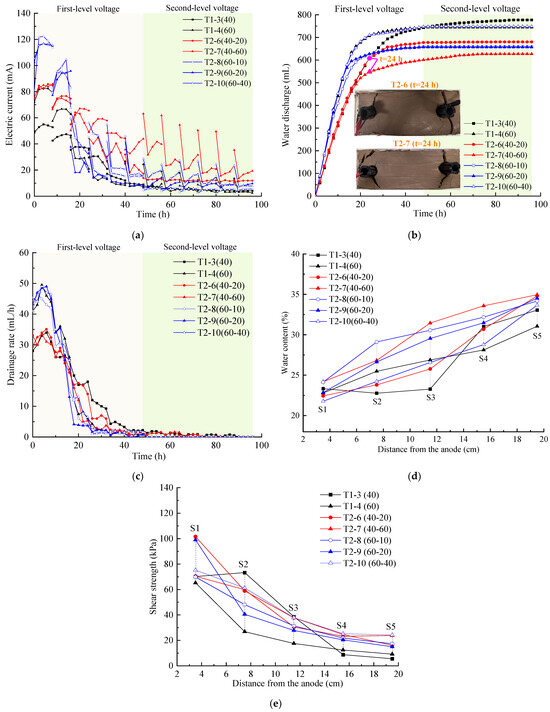

- (a)

- Electric current

Owing to variations in soil properties, in each historical test with applied voltages of 40 V and 60 V, as shown in Figure 2a, the initial current in tests using the second batch of soil samples was greater than that in tests with the first batch. For the same batch of soil, when high voltages of 40 V and 60 V were applied historically, the soil current was higher under 60 V than under 40 V during the initial stage. However, the current in the soil under 60 V then dropped rapidly and became lower than that under 40 V. At the present stage, if the voltage used in the historical stage or a voltage lower than that used in the historical stage was continued to be applied, the current basically remained at a relatively low level (less than 15 mA). If a voltage higher than that used in the historical stage was applied, the current slightly increased compared to the aforementioned situation. The intermittent power supply caused the current to experience short-term jumps.

Figure 2.

Influence of historical high electric voltage gradients on the electro-osmosis reinforcement effect at the present stage. (a) Electric current variation; (b) drainage volume varies with time; (c) drainage rate variation; (d) water content distribution; (e) shear strength distribution.

- (b)

- Water discharge and drainage rate

The differences in current at the initial moments of each test when the same high voltage was used in the historical stage did not cause significant differences in the drainage volume and drainage rate. In the historical stage, when high voltages of 40 V or 60 V were applied, the drainage volumes under the same voltage were close and almost increased linearly in the first approximately 16 h (Figure 2b). However, the drainage rate during this period showed a trend of first increasing and then decreasing (Figure 2c). The transient increase in the drainage rate corresponded to the transient rise in current. That is, the peaks in current intensity also corresponded to the enhancement of the electro-osmotic flow, as it facilitated the transportation of ions [14]. During this period, both the drainage volume and drainage rate under a voltage of 60 V at the same moment were higher than those under 40 V. After that, the drainage volume increased slowly and gradually leveled off, while the drainage rate continued to decrease. The influence of cracks on the drainage volume began to become prominent. The differences in crack development led to variations in the soil drainage volume under the same voltage. For example, judging from the crack development of T2-6 and T2-7 at t = 24 h in Figure 2b, after the cracks developed, the amount of soil between the anode and cathode of T2-6 was higher than that of T2-7. During the experimental process, the samples were subjected to specific stress conditions and environmental factors. The unique composition, microstructure, and material properties of the samples, which are their intrinsic characteristics, determined their response to the development of stress. For example, the distribution of internal pores and the strength of the bonding between particles in the samples affected the formation and propagation of cracks. Therefore, the drainage volume of T2-6 was higher than that of T2-7. At the present stage, whether the electrification voltage remained the same as that in the historical stage or increased or decreased, it was difficult to significantly increase the drainage volume even when the current did not drop too low (such as T2-7), and the drainage rate was close to zero.

The electroosmotic flow depends on fluid characteristics (dielectric constant and viscosity) and soil surface characteristics represented by the zeta potential and voltage gradient. Electroosmotic velocity, , is given by

where is electroosmotic permeability coefficient, is the voltage gradient, is the dynamic viscosity of the pore fluid, is the permittivity of the medium, is the zeta potential, and is soil porosity. Although in the later stage of the experiment the effective voltage gradient used for electroosmotic drainage was lower than the voltage gradient applied by the DC power supply due to reasons such as the increase in the interfacial resistance between the electrodes and the soil and the development of cracks in the soil, the key reason for the electroosmotic flow velocity to drop to zero was ke. This is probably due to the fact that when the drainage consolidation and physical and chemical reactions proceed, the parameters in Equation (3) change. The discharge of pore water causes the soil to consolidate under its own weight, resulting in a decrease in the void ratio. Extensive research has been carried out on the zeta potential variation, which is reported to decrease linearly with the logarithm of the pH of the soil medium [30]. The electroosmotic flow can almost be eliminated at of zero [31]. The depletion of ions into the soil is responsible for the rapid decrease in the electric current intensity and the subsequent inhibition of the electroosmotic flow [32]. The value of viscosity depends on the value of the water content. A decreased water content can increase the viscosity [33].

- (c)

- Water content and shear strength distribution

Each test basically followed the trend that the moisture content of the soil increased and the shear strength decreased from the anode to the cathode, as shown in Figure 2d,e. Applying a voltage of 40 V in both stages was more effective in promoting drainage in the S1–S3 sections, while applying a voltage of 60 V in both stages was more effective at promoting drainage in the S4 and S5 sections. As can be seen from Figure 2d, the moisture content distribution of each soil section with a 60 V voltage applied in both stages was lower than that of the three experiments with voltages of 60–10 V, 60–20 V, and 40–60 V applied in the two stages. This was consistent with the amount of drained water. However, the shear strength of each soil section with a 60 V voltage applied in both stages was lower than that of the above three experiments. Applying 40–20 V and 60–20 V in the two stages significantly increased the shear strength of the S1 cross-section.

3.2. Influence of Historical Low Electric Voltage Gradients on the Electro-Osmosis Reinforcement Effect at the Present Stage

This series of experiments included the historical stage and the present stage. In the historical stage (the first 48 h), a low voltage of either 10 V or 20 V was applied, with the corresponding electric potential gradients being 0.48 V/cm or 0.95 V/cm, respectively. In the present stage, voltages higher than or the same as those in the historical stage were used.

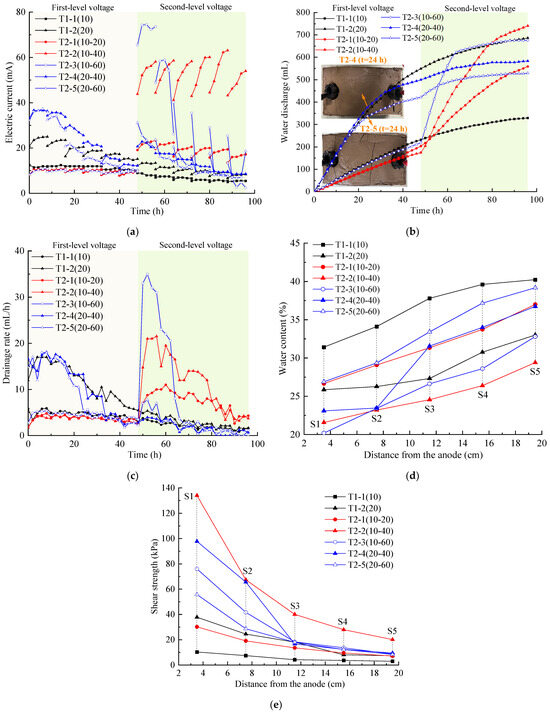

- (a)

- Electric current

As depicted in Figure 3a, owing to the disparities in soil properties, during the experiments in which a voltage of 20 V (0.95 V/cm) was imposed throughout the entire historical phase, the initial current in the experiments employing the second batch of soil samples was greater than that in the experiments utilizing the first batch of soil samples. However, in the experiments where a voltage of 10 V (0.48 V/cm) was applied throughout the historical stage, there was no significant difference between the two batches of soil samples. This means that various external and internal differences under a low voltage of 10 V will not be prominent. The current under a 10 V voltage was relatively stable, always remaining below 15 mA with a small variation range. This meant that the electrokinetic phenomenon in the soil was mainly electrophoresis accompanied by a weak electroosmotic flow [34]. The current under a 20 V voltage rose briefly and then gradually declined.

Figure 3.

Influence of historical low electric voltage gradients on the electro-osmosis reinforcement effect at the present stage. (a) Electric current variation; (b) drainage volume varies with time; (c) drainage rate variation; (d) water content distribution; (e) shear strength distribution.

At the present stage, if the voltage used in the historical stage was still adopted, the current would slightly decrease and maintain a relatively stable state. Regarding the experiment with the 10 V voltage used in the historical stage, when a 40 V voltage was adopted at that time, the magnitude and stability of the current were superior to those of 20 V and 60 V in sequence. When a 60 V voltage was adopted at the present stage, the current rose rapidly in a short period and then decreased significantly. Regarding the experiment with the 20 V voltage used in the historical stage, there was not much difference in the current when 40 V or 60 V was adopted at that time.

- (b)

- Water discharge and drainage rate

As shown in Figure 3b,c, during the historical stage, for various tests where the same low voltage was applied, the discrepancies in current at the initial moments did not result in substantial differences in the drainage volume and drainage rate. This might have been due to the relatively high moisture content of the soil at the initial moment and the limited migration ability of hydrated cations. During the historical stage, a voltage of 10 V was applied. In the current stage, voltages of 10 V, 20 V, 40 V, and 60 V, respectively, were used, showing different drainage capabilities. In the initial period, the higher the voltage, the greater the amount of drained water and the drainage rate. However, in the later stage, the higher the voltage, the faster the drainage rate decreased. The drainage rate under a 60 V voltage was the first to become unsustainable and dropped to a relatively low value. The drainage rates under 20 V and 40 V voltages finally dropped to the same level. After 96 h of power-on, the cumulative amounts of drained water for the two-stage voltages of 10–10 V, 10–20 V, 10–40 V, and 10–60 V were 328, 559, 740, and 675 mL, respectively. During the historical stage, a voltage of 20 V was applied. Owing to variations in crack development, exemplified by the crack development of T2-4 and T2-5 at t = 24 h in Figure 3b, the volume of drained water exhibited disparities even during the historical stage. However, in the current stage, whether the voltage used was the same as that in the historical stage or higher voltages of 40 V and 60 V were adopted, neither the amount of drained water nor the drainage rate could be significantly increased.

- (c)

- Water content and shear strength distribution

As shown in Figure 3d,e, when low voltages of 10–10 V, 10–20 V, and 20–20 V were adopted in both stages, the moisture content of each cross-section was higher than 25% and the shear strength was lower than 40 kPa. The effect of consolidation and drainage was poor. When comparing the application of 10–40 V with that of 10–60 V in the two stages, the moisture content of each cross-section in the former case was lower than that in the latter, while the shear strength was higher. A similar result was obtained when comparing 20–40 V with 20–60 V. The distribution of shear strength under different voltage gradient application histories is mainly attributed to several factors. Ion migration and water redistribution change the effective stress and soil density. Electrochemical reactions result in acidic anode-strengthening and alkaline cathode-weakening conditions. Chemical bonding and cementation are more prominent near the anode due to cation exchange and cementing agent precipitation. There are also soil fabric changes, with denser fabric near the anode and looser fabric near the cathode and non-uniform energy distribution driving more effective consolidation near the anode [35].

Among the four tests, the voltage differences in the two stages were 20, 30, 40, and 50 V, respectively, and the best drainage and consolidation effect was achieved when the voltage difference was 30 V. In all the tests employing secondary voltage, the shear strength of each cross-section in the 10–20 V test was the lowest. Nevertheless, the shear strength of each cross-section in the 20–60 V test, which had the lowest drainage volume and the highest average moisture content, was higher than that in the 10–20 V test, particularly in the S1 cross-section. This suggested that although the 20–60 V voltage was unfavorable for soil drainage, more vigorous physical and chemical reactions occurred in the soil under high voltage, and it was the cementation effect that further enhanced the shear strength at each cross-section position of the soil. In all the tests employing secondary voltage, the shear strength of each cross-section in the 10–20 V test was the lowest. Nevertheless, the shear strength of each cross-section in the 20–60 V test, which had the lowest drainage volume and the highest average moisture content, was higher than that in the 10–20 V test, particularly in the S1 cross-section. In the tests under secondary voltage, the shear strength of sections S1–S4 in the 10–40 V test was the highest. However, the shear strength of sections S1–S4 in the 60–40 V test, which had the highest drainage volume and the lowest average moisture content, was lower than that in the 10–40 V test, especially in section S1. This indicated that the effect of 40 V voltage on improving the shear strength of the soil was superior to that of 60 V.

3.3. Electroosmosis Reinforcement Effect Under Multi-Stage Electric Voltage Gradients

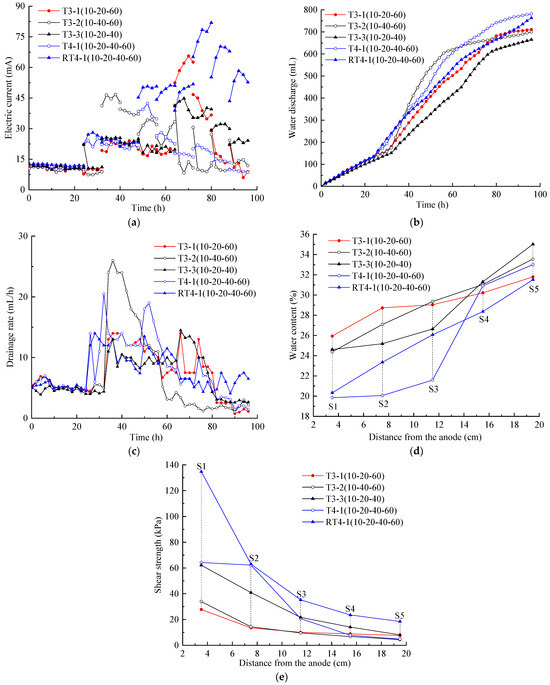

- (a)

- Electric current

As depicted in Figure 4a, when the 10–20–40 V experiment was compared with the 10–20–60 V experiment, the currents in the first two stages were close. This indicated that the differences in various soil changes were minimal under low voltages. In the third stage, the current under a voltage of 60 V dropped rapidly. Its magnitude and stability were both inferior to those under a voltage of 40 V. In the 10–40–60 V experiment, a relatively high current was obtained in the second stage. However, under the 60 V voltage in the third stage, it was consistently difficult to maintain a high current level. In the 10–20–40–60 V experiment using the soil of the third batch and its replicated experiment with the soil of the fourth batch, the currents in the first two stages were relatively consistent. But significant differences emerged in the currents of the last two stages, with the current in the fourth batch of soil maintaining a higher level. For all the experiments where the final stage voltage was 60 V, due to the different electrification histories in the earlier stages, the soil states varied, thus resulting in different current changes.

Figure 4.

Electroosmosis reinforcement effect under multi-stage electric voltage gradients. (a) Electric current variation; (b) drainage volume varies with time; (c) drainage rate variation; (d) water content distribution; (e) shear strength distribution.

- (b)

- Water discharge and drainage rate

As shown in Figure 4b,c, in the experiments with voltages of 10–20–40 V, 10–20–60 V, and 10–40–60 V in three stages, the drainage volumes and drainage rates under the 10 V voltage in the first stage were quite close. At the beginning of the second stage, the drainage rate with a voltage of 40 V was significantly higher than that with a voltage of 20 V. However, the drainage rate showed a continuous downward trend, and was significantly lower than the drainage rate under the 20 V voltage in the later period of this stage. Upon the instantaneous increase in voltage, the enhanced electric field intensity directly drove the migration of ions and water, leading to a significant rise in electroosmotic flow velocity. However, this effect was short-lived, as the subsequent phenomena of soil dehydration, reduced ion concentration, and soil structure densification and the influence of electrochemical reactions gradually became dominant, causing the electroosmotic flow velocity to continuously decrease [30]. As a result, a peak in flow velocity is observed.

In the third stage, under high voltages of 40 V or 60 V, the drainage rates of the tests with voltages of 10–20–40 V and 10–20–60 V increased. In the later period, the drainage rates decreased and became close to that of the test with voltages of 10–40–60 V. The cumulative drainage volumes of the three tests were 711, 700, and 665 mL, respectively. In the fourth stage, for the tests with voltages of 10–20–40–60 V and their replicated tests, as the voltages were replaced in a timely manner, the drainage rates could be maintained at a relatively high level for a longer period. Moreover, in the later stage of the tests, the drainage rates still remained at a certain level. The cumulative drainage volumes of the two tests were close, being 781 and 763 mL, respectively.

- (c)

- Water content and shear strength distribution

As shown in Figure 4d,e, although the drainage volumes of the tests with voltages of 10–20–40–60 V in the fourth stage and their replicated tests were very close, there were still certain differences in the moisture content and shear strength distributions. T4-1 (the soil of the third batch) significantly reduced the soil moisture content of the S2 and S3 sections, while T4-2 (the soil of the fourth batch) was more conducive to reducing the soil moisture content of the S4 and S5 sections. The moisture content of the soil in all sections of each test under the three-level voltage was higher than 24%. Under the four-level voltage, the moisture content of the S1 section could be reduced to approximately 20%, which was slightly lower than the plastic limit. The moisture content in the S4 and S5 sections in each test ranged from 28% to 35%, while the shear strength of both sections was lower than 25 kPa. The shear strength of the S1–S3 sections under the four-level voltage was significantly higher than that under the three-level voltage.

Under the condition of the same total treatment duration, a comparative analysis was carried out on the results from the three-stage voltage and four-stage voltage tests (Table 3). In the three-stage voltage test, the duration of each stage of voltage was maintained for 32 h. In the four-stage voltage test, the duration of each stage of voltage was maintained for 24 h. Compared with the three-stage voltage, the increase in the four-stage voltage in the time sequence was timelier, which could more effectively promote the drainage efficiency of the cross-section near the anode. Taking T3-3 and T4-1 as examples, as shown in Figure 4d, the moisture content of the S1–S3 cross-section in T4-1 is significantly lower than that in T3-3. However, the shear strength of the S1–S3 cross-section in T4-1 is not substantially different from that in T3-3. This is because the chemical reinforcement effect of T4-1 has not been significantly exerted. RT4-1 further demonstrates that the chemical reinforcement effect is influenced by the soil activity index. Specifically, the larger the activity index of the soil, the more obvious the chemical reinforcement effect; conversely, the smaller the activity index, the less obvious the chemical reinforcement effect.

3.4. Discussion

The test results of all the experiments are listed in Table 4. The total electroosmotic drainage volumes of three experiments, T1-2 (20), T2-3 (10–60), and T2-6 (40–20), were very close, being 686.1, 675.1, and 680.2 mL, respectively. The average moisture content of the reinforced soil and its coefficient of variation (COV) were also relatively similar. However, the average shear strengths differed significantly, being 19.168, 31.656, and 47.826 kPa, respectively. The soil samples used in T1-2 and T2-3 were from the first batch, while the soil sample of T2-6 was from the second batch. Based on the experimental data results listed in Table 3, it was concluded that high voltages (40 V or 60 V) could enhance the shear strength of the soil more effectively than low voltages (10 V or 20 V). Moreover, the 40 V voltage played a more remarkable role in increasing the soil drainage volume and shear strength and reducing the energy consumption per unit drainage volume.

Table 4.

Comparison of experimental results.

Under the effect of two-stage voltages, the magnitude of the voltage adopted in previous historical stages had a significant impact on the current drainage situation. Overall, the combination of low and high voltages in T2-2 (10–40) exhibited significant advantages in terms of increasing soil drainage volume and shear strength and reducing energy consumption per unit drainage volume. The combination of low voltages in T2-1 (10–20) was not conducive to the improvement of soil shear strength. The combination of 10 and 40 was successively superior to the combinations of 20 and 40 V as well as 10 and 60 V, and the combination of 20 and 40 V was better than that of 20 and 60 V. However, the combination of high and low voltages substantially increased the energy consumption per unit drainage volume, which was not beneficial to energy conservation and emission reduction.

The total electroosmotic drainage volumes of the three tests, T1-4 (60–60), T2-2 (10–40) and T2-10 (60–40), were very close, being 744.8, 740.2, and 748.3 mL, respectively. However, the drainage volumes during the initial 48 h historical stages of the three tests accounted for 100%, 23.6%, and 99.9% of their respective total drainage volumes. T1-4 and T2-10 were energized at voltages of 60 V and 40 V, respectively, for 48 h in the current stage, but the drainage volumes were almost zero. This led to the energy consumption per unit drainage volume of T1-4 and T2-10 being significantly higher than that of T2-2. The average shear strengths of T1-4, T2-2, and T2-10 differed significantly, being 26.266, 57.914, and 44.749 kPa, respectively. The main difference between T2-2 and T2-10 lay in the shear strength in the S1 cross-section near the anode. The shear strengths at other cross-sections were relatively close. This indicated that a voltage of 10–40 V was more conducive to improving the shear strength of the soil near the anode than a voltage of 60–40 V. The increase in the shear strength of the S1 and S2 cross-sections closer to the anode is not only related to drainage but also significantly influenced by chemical reinforcement [22]. The lower the moisture content at this location, the more obvious the improvement in shear strength.

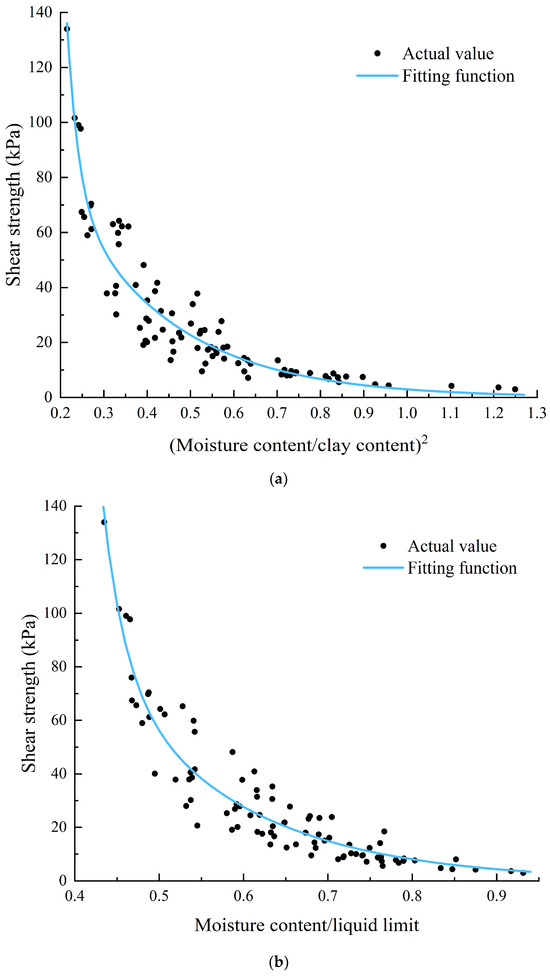

The shear strengths of all cross-sections of T1-4 were lower than those of T2-10. Since the historical voltages of the two tests were the same and the effects of applying high voltages in the current stage on the test results were almost identical, it could be determined that the main reason for the difference in shear strength between T1-4 and T2-10 was the clay particle content of the soil samples. The clay particle content of the first batch of soil samples used in T1-4 was 36.0%, while that of the second batch of soil samples used in T2-10 was 46.5%. Therefore, under the influence of the same voltage and for soil masses with similar drainage volumes, the soil samples with a higher clay particle content exhibited a greater increase in shear strength. T4-1 and RT4-1 also provided strong evidence for this view. The two tests adopted the same four-level voltage. The drainage volume of RT4-1 was 18.6 mL lower than that of T4-1, but its average shear strength was much higher than that of T4-1, being 54.984 kPa and 31.925 kPa, respectively. This was because the clay particle content of the fourth batch of soil samples used in RT4-1 was 41.2%, while that of the third batch of soil samples used in T4-1 was 34.3%. Since the strength, among other things, is related to the forces that bind the water to the clay particles, the strength for a given water content should likewise increase as the relative proportions of bound water increase [36]. According to the data obtained from 19 tests, including the average vane shear strength of each cross-section (Cu, kPa), the average moisture content (w) measured after the tests, as well as the initial liquid limit of the soil samples (wL) and the content of soil particles with a particle size smaller than 0.005 mm (P0.005) determined before the tests, the relationships of Cu~ and Cu~ are plotted as shown in Figure 5a,b. The equations of the fitted curves are obtained, respectively, as follows.

Figure 5.

(a) Relationships among vane shear strength, moisture content, and clay content. (b) Relationship between vane shear strength and moisture content/liquid limit.

The vane shear strength (Cu) is an exponential decay function with respect to and , respectively. After electroosmotic reinforcement, the shear strength of the soil is related not only to the soil moisture content but also to the initial clay particle content or liquid limit of the soil. This relationship can better reflect the influence of drainage consolidation and chemical reinforcement on the shear strength of the soil. The higher the clay content is, the larger the specific surface area of the soil will be, and the stronger its ability to interact with pore water will be. The liquid limit likewise increases regularly with increasing clay concentration and varies with clay type in the same way as strength does [36].

By comparing T3-1, T3-2, and T4-1 (all of which adopted the third batch of soil samples), as well as T3-3 and RT4-1 (both using the fourth batch of soil samples), it was found that under the four-level voltage with the step-by-step voltage-increasing energization method, the soil drainage volume, shear strength, and energy consumption per unit drainage volume were better than those under the three-level voltage. Although the drainage volume of T4-1 with a four-level voltage was merely no more than 85 mL higher than that of T3-1 and T3-2 with a three-level voltage, its average shear strength was 2.3 times higher. This implies that when the drainage volume reaches a certain value, a small amount of additional drainage will remarkably enhance the shear strength of the soil mass. Based on all the experimental data in Table 4, it can be observed that when it comes to single-level voltage, 40 V yields the best results; for two-level voltage, the combination of 10–40 V is optimal; and for three-level voltage, 10–20–40 V performs the best. Under the same experimental conditions, the four-level voltage configuration of 10–20–40–60 V demonstrates more pronounced advantages in terms of soil drainage volume, shear strength, and energy consumption per unit drainage volume. That is to say, during the historical energization process, the voltage should be increased step by step, and it is not advisable to drop from a high voltage to a low voltage.

Despite the fact that the soil samples, drainage volume, and energization time in the two experiments were the same, the drainage durations differed due to the distinct energization voltages in different historical stages. It is presumed that the chemical reinforcement effect depends on the electroosmotic drainage duration. Once the electroosmotic drainage ceases, the chemical reinforcement effects no longer function. The enhancement of the shear strength of the electro-osmosis-reinforced soil is related to physical and chemical reactions and processes such as electroosmosis, electrophoresis, electromigration, water electrolysis, and ion exchange. The moisture content (electroosmotic flow) near the S1 section at the anode in the two experiments was similar. The significant increase in shear strength at this section in T2-2 (10–40) might be associated with electrophoresis under the 10 V voltage (with a current less than 15 mA) in the historical stage, as well as other physical and chemical processes during the longer drainage duration. In contrast, the higher current and shorter drainage duration in T2-10 (60–40) were attributable, on the one hand, to drainage consolidation and, on the other hand, to the similar moisture content in the S1 section in the two experiments. However, this indicates that the voltage magnitude adopted in the historical stage can impact the current drainage volume, energy consumption per unit drainage volume, and growth of shear strength. Adopting a low voltage in the historical stage has a more favorable influence on the current stage compared to using a high voltage. The electroosmosis process should strive to extend the drainage duration as much as possible, which is conducive to promoting the chemical reinforcement effect.

The clay mineral constituents in soils exhibiting a high activity index demonstrate relatively elevated chemical reactivity. During the electro-osmosis process, the acidic milieu proximate to the anode (characterized by an augmented hydrogen ion concentration) and the alkaline environment adjacent to the cathode (marked by an increased hydroxide ion concentration) can instigate chemical reactions, including dissolution and precipitation, within the soil minerals. Soils with a high activity index are more predisposed to interact with these reaction byproducts, culminating in the formation of cementitious materials such as iron hydroxide and calcium carbonate. These cementitious compounds can occlude the interparticle voids, thereby securely bonding the soil particles together. This process enhances the soil’s structural integrity and mechanical strength, thereby rendering the electrochemical reinforcement effect more pronounced. For soil with a high activity index, under an appropriate voltage, the input electrical energy can be more efficiently converted into various physical and chemical processes that enhance soil reinforcement. Consequently, the reinforcement effect per unit of energy consumption is significantly more pronounced, which further underscores the advantages of its electrochemical reinforcement mechanism from a practical perspective (Table 4).

Increasing the voltage in a timely manner can provide sufficient energy to overcome the polarization resistance, facilitating continuous ion exchange and migration between the electrodes and the soil matrix. This ensures the uninterrupted progression of the electro-osmosis process and sustains or even enhances the electrochemical reinforcement effect. An appropriate increase in voltage elevates the electric field strength within the soil matrix. According to the fundamental principles of ion migration, enhanced electric field strength intensifies the electric field force acting on the ions, thereby accelerating their migration velocity within the soil. This promotes greater ion participation in electrochemical reactions, further advancing the aggregation and cementation of soil particles and ultimately improving the reinforcement efficacy. If the voltage increase is excessively large, it may induce overly severe localized dehydration within the soil mass, resulting in non-uniform shrinkage and differential settlement. This phenomenon not only compromises the uniformity of soil consolidation but also leads to inefficient energy utilization.

4. Conclusions

During the electroosmotic consolidation of soft clay, whether a single-stage or multi-stage electrical potential gradient is employed, the initial energizing process invariably impacts the subsequent strengthening performance and, consequently, the overall consolidation effectiveness. To investigate this phenomenon, a series of laboratory experiments were meticulously designed and carried out to scrutinize the influence of the application history of voltage gradients on the electroosmotic reinforcement of soft clay.

The experimental results demonstrate that the magnitude of the voltage adopted in previous historical stages had a significant impact on the current drainage situation as well as the enhancement of shear strength. In the studied historical period, a relatively high voltage gradient (>1.90 V/cm) was applied until soil drainage stopped; however, at present, it has become extremely challenging to substantially increase the drainage volume regardless of whether the electrification voltage remains stable, rises, or falls, even when the current does not drop too low. Moreover, high voltage gradients (>1.90 V/cm) can enhance soil shear strength more effectively than low voltage gradients (<0.95 V/cm). Irrespective of the voltage magnitude employed, the application of a low voltage gradient during the historical stage has a more favorable impact on the current stage than that of a high voltage gradient. The voltage applied at the current stage should not be lower than that applied during the historical stage. During the electroosmosis process, efforts should be made to maximize the drainage duration as it facilitates the promotion of the chemical reinforcement effect. For soil with a high activity index, under an appropriate voltage, the input electrical energy can be more efficiently converted into various physical and chemical processes that enhance soil reinforcement. The vane shear strength (Cu) is an exponential decay function with respect to and , respectively. After electroosmotic reinforcement, the shear strength of the soil is related not only to the soil moisture content but also to the initial clay particle content or liquid limit of the soil.

Variations in interfacial resistance, zeta potential, and ion depletion under different electric potential gradients are crucial for a comprehensive comprehension understanding of electroosmotic flow in soil drainage. In the future, in-depth research on these aspects will be carried out to further elucidate their roles and underlying mechanisms the electroosmotic-based soil drainage processes.

Author Contributions

Z.S.: writing—review and editing, writing—original draft, visualization, validation, investigation, formal analysis, project administration, funding acquisition, conceptualization. Y.Q.: writing—original draft, visualization, validation, investigation, formal analysis, data curation. J.Z.: resources, investigation, methodology, data curation. B.M.M.: investigation, data curation. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (42207189), Postgraduate Research & Practice Innovation Program of Jiangsu Province (SJCX24_2072), and Scientific Research Project of Jiangsu Provincial Construction System in 2024 (second batch, serial number 128).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

Authors Zhaohua Sun and Jianming Zhang were employed by the company Zhongru Construction Group Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Casagrande, I.L. Electro-osmosis in soils. Geotechnique 1949, 1, 159–177. [Google Scholar] [CrossRef]

- Mitchell, J.K. Conduction phenomena: From theory to geotechnical practice. Geotechnique 1991, 41, 299–340. [Google Scholar] [CrossRef]

- Estabragh, A.R.; Naseh, M.; Javadi, A.A. Improvement of clay soil by electro-osmosis technique. Appl. Clay Sci. 2014, 95, 32–36. [Google Scholar] [CrossRef]

- Martin, L.; Alizadeh, V.; Meegoda, J. Electro-osmosis treatment techniques and their effect on dewatering of soils, sediments, and sludge: A review. Soils Found. 2019, 59, 407–418. [Google Scholar] [CrossRef]

- Mohamedelhassan, E.; Shang, J.Q. Effects of electrode materials and current intermittence in electro-osmosis. Proc. Inst. Civ. Eng.-Ground Improv. 2001, 5, 3–11. [Google Scholar] [CrossRef]

- Kherad, M.K.; Vakili, A.H.; bin Selamat, M.R.; Salimi, M.; Farhadi, M.S.; Dezh, M. An experimental evaluation of electroosmosis treatment effect on the mechanical and chemical behavior of expansive soils. Arab. J. Geosci. 2020, 13, 260. [Google Scholar] [CrossRef]

- Iwata, M.; Tanaka, T.; Jami, M.S. Application of electroosmosis for sludge dewatering—A review. Dry. Techn. 2013, 31, 170–184. [Google Scholar] [CrossRef]

- Shang, J.Q.; Lo, K.Y.; Huang, K.M. On factors influencing electro-osmotic consolidation. Geotech. Eng. 1996, 27, 23–36. [Google Scholar]

- Fu, H.; Fang, Z.; Wang, J.; Chai, J.; Cai, Y.; Geng, X.; Jin, J.; Jin, F. Experimental comparison of electroosmotic consolidation of Wenzhou dredged clay sediment using intermittent current and polarity reversal. Mar. Georesources Geotechnol. 2018, 36, 131–138. [Google Scholar] [CrossRef]

- Jayasekera, S. Electrokinetics to modify strength characteristics of soft clayey soils: A laboratory based investigation. Electrochim. Acta 2015, 181, 39–47. [Google Scholar] [CrossRef]

- Rittirong, A.; Douglas, R.S.; Shang, J.Q.; Lee, E.C. Electrokinetic improvement of soft clay using electrical vertical drains. Geosynth. Int. 2008, 15, 369–381. [Google Scholar] [CrossRef]

- Pandey, B.K.; Rajesh, S. Enhanced engineering characteristics of soils by electro-osmotic treatment: An overview. Geotech. Geol. Eng. 2019, 37, 4649–4673. [Google Scholar] [CrossRef]

- Akram, S.; Imran, M.; Ashraf, S.; Akram, A.; Kamran, K.; Ishaq, M.; Hussain, A.A.; Abbas, J.K.; Ajaj, Y.; Habila, M.A. Effect of electroosmotic and hydraulic flow on the desalination of soils. J. Appl. Electrochem. 2024, 54, 1685–1698. [Google Scholar] [CrossRef]

- Pandey, B.K.; Rajesh, S.; Chandra, S. Engineering and physicochemical response of soft clay with electrokinetic consolidation process. Acta Geotech. 2024, 19, 5125–5141. [Google Scholar] [CrossRef]

- Sun, Z.; Geng, J.; Wei, G.; Li, W. Engineering application of vacuum preloading combined with electroosmosis technique in excavation of soft soil on complex terrain. PLoS ONE 2023, 18, e0288026. [Google Scholar] [CrossRef] [PubMed]

- Burnotte, F.; Lefebvre, G.; Grondin, G. A case record of electroosmotic consolidation of soft clay with improved soil electrode contact. Can. Geot. J. 2004, 41, 1038–1053. [Google Scholar] [CrossRef]

- Shen, Y.; Feng, J.; Shi, W.; Qiu, C. Effects of voltage gradients on electro-osmotic characteristics of Taizhou soft clay. Int. J. Electrochem. Sci. 2019, 14, 2136–2159. [Google Scholar] [CrossRef]

- Liu, H.; Cui, Y.; Shen, Y.; Ding, X. A new method of combination of electroosmosis, vacuum and surcharge preloading for soft ground improvement. China Ocean Eng. 2014, 28, 511–528. [Google Scholar] [CrossRef]

- Li, X.; Zhao, R.; Fu, H.; Wang, J.; Cai, Y.; Hu, X.; Zhou, J.; Hai, J. Slurry improvement by vacuum preloading and electro-osmosis. Proc. Inst. Civ. Eng.-Geotech. Eng. 2019, 172, 145–154. [Google Scholar] [CrossRef]

- Bian, X.; Yang, H.; Liu, H.; Xu, Z.; Zhang, R. Experimental study on the improvement of sludge by vacuum preloading-stepped electroosmosis method with prefabricated horizontal drain. Geotext. Geomembr. 2024, 52, 753–761. [Google Scholar] [CrossRef]

- Chew, S.H.; Karunaratne, G.P.; Kuma, V.M.; Lim, L.H.; Toh, M.L.; Hee, A.M. A field trial for soft clay consolidation using electric vertical drains. Geotext. Geomembr. 2004, 22, 17–35. [Google Scholar] [CrossRef]

- Mahalleh, H.A.M.; Siavoshnia, M.; Yazdi, M. Effects of electro-osmosis on the properties of high plasticity clay soil: Chemical and geotechnical investigations. J. Electroanal. Chem. 2021, 880, 114890. [Google Scholar] [CrossRef]

- Wen, L.; Yan, C. Influence of the electric voltage gradient, electrode spacing and electrode radius on slurry dewatering by vertical electro-osmosis. Int. J. Electrochem. Sci. 2020, 15, 11326–11339. [Google Scholar] [CrossRef]

- Xue, Z.; Tang, X.; Yang, Q. Influence of voltage and temperature on electro-osmosis experiments applied on marine clay. Appl. Clay Sci. 2017, 141, 13–22. [Google Scholar] [CrossRef]

- Liu, F.; Li, Z.; Yuan, G.; Hu, X.; Zhang, D.; Du, Y.; Gou, C. Improvement of dredger fill by stepped vacuum preloading combined with stepped voltage electro-osmosis. Mar. Georesources Geotechnol. 2021, 39, 822–831. [Google Scholar] [CrossRef]

- Huweg, A.F.S.; Kamel, F.; Raine, S. Investigating the effect of electro-osmosis on sandy soil near saturated conditions. In Proceedings of the 2010 Southern Region Engineering Conference (SREC 2010), Toowoomba, Australia, 10–12 November 2010. [Google Scholar]

- GB/T 50145-2007; Standardization Administration of the People’s Republic of China. Standard for Engineering Classification of Soils. China Planning Press: Beijing, China, 2007. (In Chinese)

- GB/T 50123-2019; Standardization Administration of the People’s Republic of China. Standard for Geotechnical Testing Method. China Planning Press: Beijing, China, 2019. (In Chinese)

- Sun, Z.; Wu, T.; Yao, K.; Kasu, C.M.; Zhao, X.; Li, Z.; Gong, J. Consolidation of soft clay by cyclic and progressive electroosmosis using electrokinetic geosynthetics. Arab. J. Geosci. 2022, 15, 1193. [Google Scholar] [CrossRef]

- Acar, Y.B.; Alshawabkeh, A.N. Principles of electrokinetic remediation. Environ. Sci. Technol. 1993, 27, 2638–2647. [Google Scholar] [CrossRef]

- Asadi, A.; Huat, B.B.K.; Nahazanan, H.; Keykhah, H.A. Theory of electroosmosis in soil. Int. J. Electrochem. Sci. 2013, 8, 1016–1025. [Google Scholar] [CrossRef]

- Cameselle, C. Enhancement of electro-osmotic flow during the electrokinetic treatment of a contaminated soil. Electrochimica Acta 2015, 181, 31–38. [Google Scholar] [CrossRef]

- Lee, S.H.H.; Widjaja, B. Phase concept for mudflow based on the influence of viscosity. Soils Found. 2013, 53, 77–90. [Google Scholar] [CrossRef]

- Sun, Z.; Qing, Y.; Zhang, C.; Eugene, B.D. Electroosmosis and electrophoresis in soft clay under direct current electric field. Heliyon 2024, 10, e28718. [Google Scholar] [CrossRef] [PubMed]

- Jeyakanthan, V.; Gnanendran, C.T.; Lo, S. Laboratory assessment of electro-osmotic stabilization of soft clay. Can. Geotech. J. 2011, 48, 1788–1802. [Google Scholar] [CrossRef]

- Trask, P.D.; Close, J.E.H. Effect of clay content on strength of soils. Coast. Eng. Proc. 1957, 1, 50. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).