From the perspective of naval architecture, design methods are generally divided into two approaches: (1) conventional and (2) unconventional vessels. Due to its peculiarities and a very sparse database of similar vessels, the latter is more suitable for a multi-purpose autonomous surface vessel design. In this case, based on Lamb [

12] and Cross [

13,

14], the strategy adopted was to organize all requirements imposed to the vessel and relate them to the functional parts that compose the idealized vessel, always ensuring design cycles (Evans Spiral [

15]) focus on the integration of all systems to allow for its operation in the most efficient and safe way. Dividing the multi-purpose vessel similarly to other authors in the specialized literature, such as [

1], the main requirements and functional parts are presented in

Figure 1.

3.1. Hull, Compartmentation and Deck Arrangement

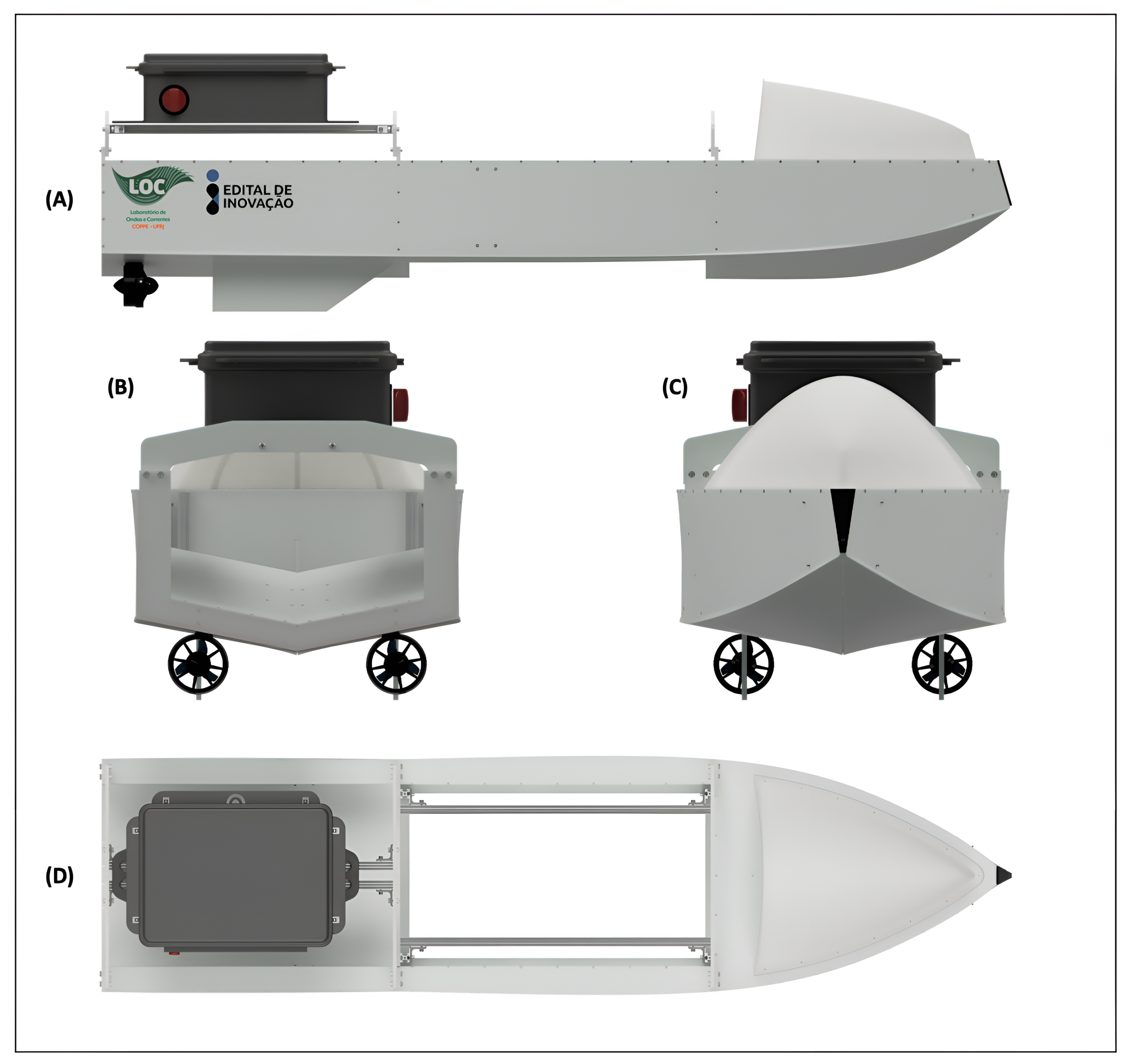

The hull concept is based on V-shaped hulls that use flat plates, facilitating construction. Due to the multi-purpose requirement, 4 operational profiles were defined to cover the most comprehensive applications, considering the current scenario of unmanned surface vehicles. By adopting a modular concept, each profile has a hull configuration that fits a respective profile application, as presented in

Figure 3. Each of these profiles is described below:

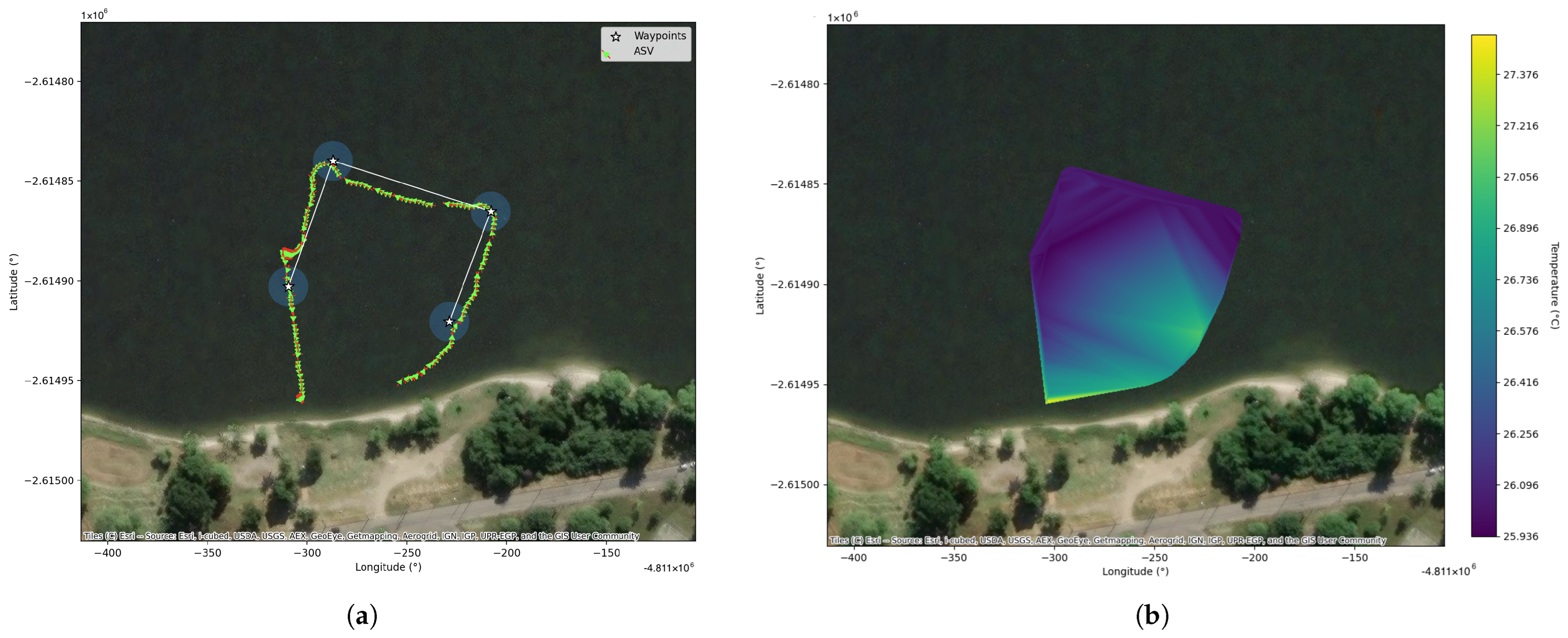

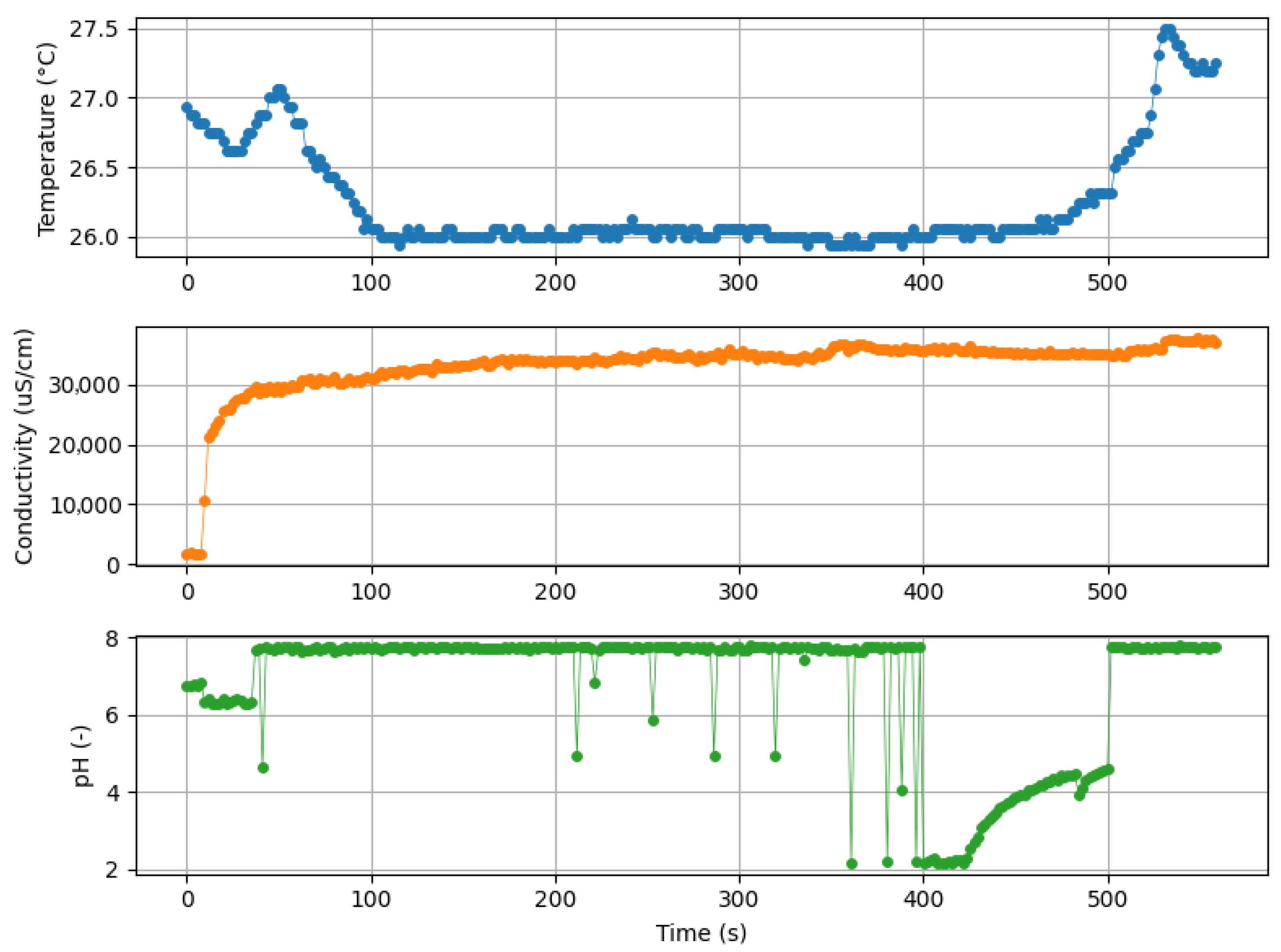

The fully-opened mode is the main assembly, which can be transformed into other configurations by adding pre-fabricated modules. Although the fully-opened mode does not have a specific purpose, it can be used for task executions. The field tests described in

Section 5 were made with this mode.

The moonpool mode can carry out tasks such as water quality assessment, ROV (Remotely Operated Vehicle) launch and recovery, and bathymetric surveying. The moonpool is 0.68 m long and 0.40 m wide.

For the wetbay mode, externally fixed rails can provide a flexible layout for a launch and recovery system through the stern. This system can be used with AUVs (Autonomous Underwater Vehicles), ROVs, and any other system equipped with sensors.

Using the cargo mode, the ASV is capable of transporting other platforms or additional equipment on deck. For cargoes with a low center of gravity, a maximum payload of 50 kg is possible to be reached.

The hull can be manufactured with many methods and materials. The construction method adopted is called “one-off”, where a temporary frame is first built to assemble the primary structure elements, and then the bottom, side, and deck plates are incorporated. The hull was built using commercial PVC sheets that were CNC-machined and finally attached to the main structure with stainless steel bolts and polymeric sealant. With this method, no surface treatment is required, becoming time- and cost-effective.

Table 2.

Items used to build the ASV.

Table 2.

Items used to build the ASV.

| Description | Quantity | Unit Price (USD) * | Total Price (USD) |

|---|

| Flat Allen Screw MA 3 × 20 Stainless Steel 304/A2 | 216 | $0.09 | $19.87 |

| Flat Allen Screw MA 4 × 20 Stainless Steel 304/A2 | 12 | $0.09 | $1.04 |

| Cylindrical Allen Screw MA 6 × 16 Stainless Steel 304/A2 | 28 | $0.20 | $5.60 |

| Hex Nut MA 6 – 1.00 Wrench 10 Stainless Steel 304/A2 | 16 | $0.09 | $1.36 |

| Rectangular Nut for Aluminum Profile M6 Base 20 | 12 | $0.38 | $4.56 |

| Aluminum Bracket 38 × 38 × 15 mm | 8 | $0.50 | $4.00 |

| Structural Aluminum Profile 20 × 20 V-Slot (1 m) | 5 | $7.24 | $36.20 |

| Gray Waterproof Box Master 43.6 × 32.6 × 14 cm | 1 | $22.44 | $22.44 |

| Rigid PVC Sheet White 1000 × 1000 × 5 mm | 6 | $76.41 | $458.46 |

| Rigid PVC Sheet White 1000 × 1000 × 8 mm | 2 | $121.08 | $242.16 |

| LiPo Battery 14.8 V 5200 mAh 30C 4S | 2 | $257.00 | $514.00 |

| GPS GY-NEO6MV2 | 1 | $36.00 | $36.00 |

| XBEE PRO S1 | 2 | $95.92 | $191.84 |

| USB to Serial Adapter for XBEE | 2 | $7.48 | $14.96 |

| Raspberry Pi 4B/5 | 1 | $149.32 | $149.32 |

| Arduino Mega 2560 R3 | 1 | $30.00 | $30.00 |

| Motor 2212 1400 kv + ESC 40A | 2 | $36.00 | $72.00 |

| 3D printing PLA filament | 1 | $18.00 | $18.00 |

| Electrical Wires (1 m each) | 10 | $0.36 | $3.60 |

| Battery Switch | 1 | $31.60 | $31.60 |

| GPS Antenna WT1997 SMA – 5 m | 1 | $9.95 | $9.95 |

| SMA Antenna 3 dBi Wi-Fi 433 MHz | 1 | $5.03 | $5.03 |

| Compass | 1 | $5.50 | $5.50 |

| WiFi Router | 1 | $14.80 | $14.80 |

| High-Strength PVC Adhesive 400 g | 2 | $4.33 | $8.66 |

| - | - | Total | $1900.96 |

The PVC sheets are more suitable for open threads through the sheet plane with a minimum thickness of 5 mm, which was the minimum thickness adopted for the hull plating. The frame structure was built with 8 mm plates, giving more robustness to the hull, especially to the lift and anchoring points.

With these premises, the main hull section can be assessed to evaluate the integrity of the vessel structure in response to the design loads. The hull beam method is widely used in naval architecture applications, where the hull is represented by a beam with the same sectional area, material, and moment of inertia of the midship section. Through the Euler–Bernoulli formulation, the maximum bending stress is analytically assessed considering the design bend moment (sagging moment). However, this approach must be undertaken carefully, as the Euler–Bernoulli theory does not account for deflections in the transverse beam section, which means it can only be applied when the transverse section is sufficiently stiff.

For such a small vessel, the critical loads arise from transport and handling, particularly when the vessel is subjected to a simply supported condition at both ends or at the midship section, when a single lift can be applied.

Table 3 shows the main parameters for the structural assessment, demonstrating how robust the multi-purpose vessel is, due to the construction method and materials chosen. It is worth noting that the fully-open mode has the smallest midship section among all profiles, and it was considered to obtain the results shown in

Table 3.

Although the structure appears to be overpredicted when the tensile strength is compared with , it is crucial to monitor the structural integrity even for small vessels to ensure the robustness and safety of the vessel design.

The vessel was divided into four compartments. The first one is placed forward of the moonpool to ensure that any damage at the bow cannot lead to a stability issue. Similarly, the double hull along the moonpool section and the aft portion are watertight compartments and were filled with EPS foam to ensure that the insubmersible requirement is fulfilled. The fourth compartment is the electronic box. It is attached to two beams above the deck, allowing the box to adjust the longitudinal position of the CoG depending on the operational mode.

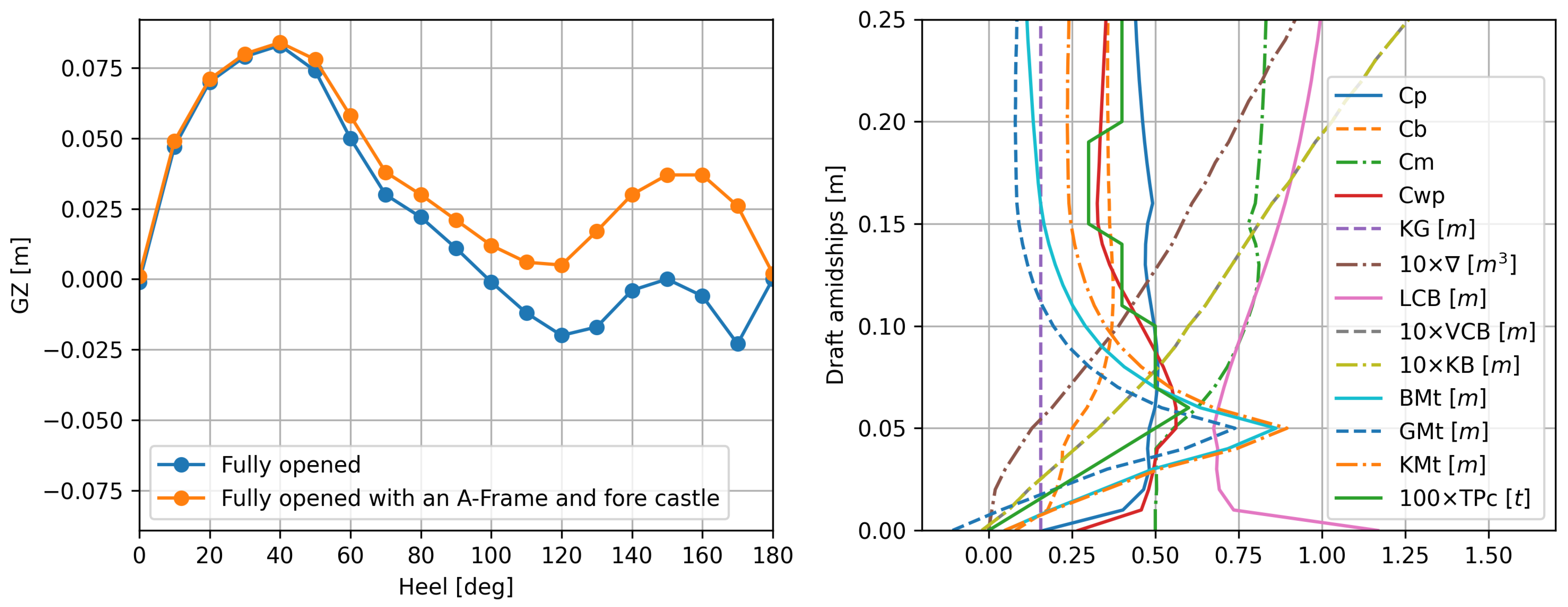

The fundamental aspects regarding hydrostatics and stability are generally expressed with the GZ curve and hydrostatic curves. For details, see Lewis [

16]. The GZ curve is a graphic representation of the righting lever (GZ) versus the heel angle. The positive area below the curve can be understood as the work necessary to capsize the vessel, and the negative area as the work to get back upright. So, the self-righting capability is observed when there is no negative area below the GZ curve.

Figure 4 shows the GZ curve in blue only for the vessel in the fully opened mode. An A-Frame in the aft and a closed fore castle in the bow can easily turn the vessel into a self-righting boat, represented by the orange curve in

Figure 4, which enables it to get back upright after a strong environmental load, like a wave or a boat collision.

The hydrostatic curves express parameters related to geometric aspects (

) and boat capacity along the draft (displaced volume ∇, position of center of buoyancy

B and metacenter

M), which is very useful to assess different payload scenarios in terms of equilibrium. A comprehensive discussion on this topic is presented by Lewis [

16]. The hydrostatic curves shown on the right side of

Figure 4 were obtained for the fully-opened mode. The geometric coefficients are generally used for design purposes, to compare expected values for each application with the current designed vessel, and will not be extensively discussed in this paper.

The hull resistance at a specific navigating speed is a crucial parameter for the propulsion and power system design. For V-shaped hulls, the Savitsky method [

17] offers a simple and easy-to-compute procedure for estimating hull resistance in the planning regime. When a boat is floating with no speed, the buoyancy force is responsible for withstanding the weight. In the planning regime, the hydrodynamic force takes place to support the vessel’s weight in a dynamic equilibrium.

Thus, the method proposed by Savitsky is based on geometric characteristics of prismatic planing surfaces and empirical relations to predict the horsepower required, also assessing the trim angle, final draft, and porpoising stability.

Among the operational modes, the cargo mode is the most critical scenario in terms of drag resistance. Hence, this scenario was chosen to estimate the propulsion power needed. The moonpool geometry contributes significantly to the resistance, due to the high vorticity region created by the geometric discontinuity. In this case, for such a peculiar hull, only numerical approaches are capable of predicting the total hull resistance, which was not considered in this work.

Table 4 shows the main parameters for hull resistance assessment.

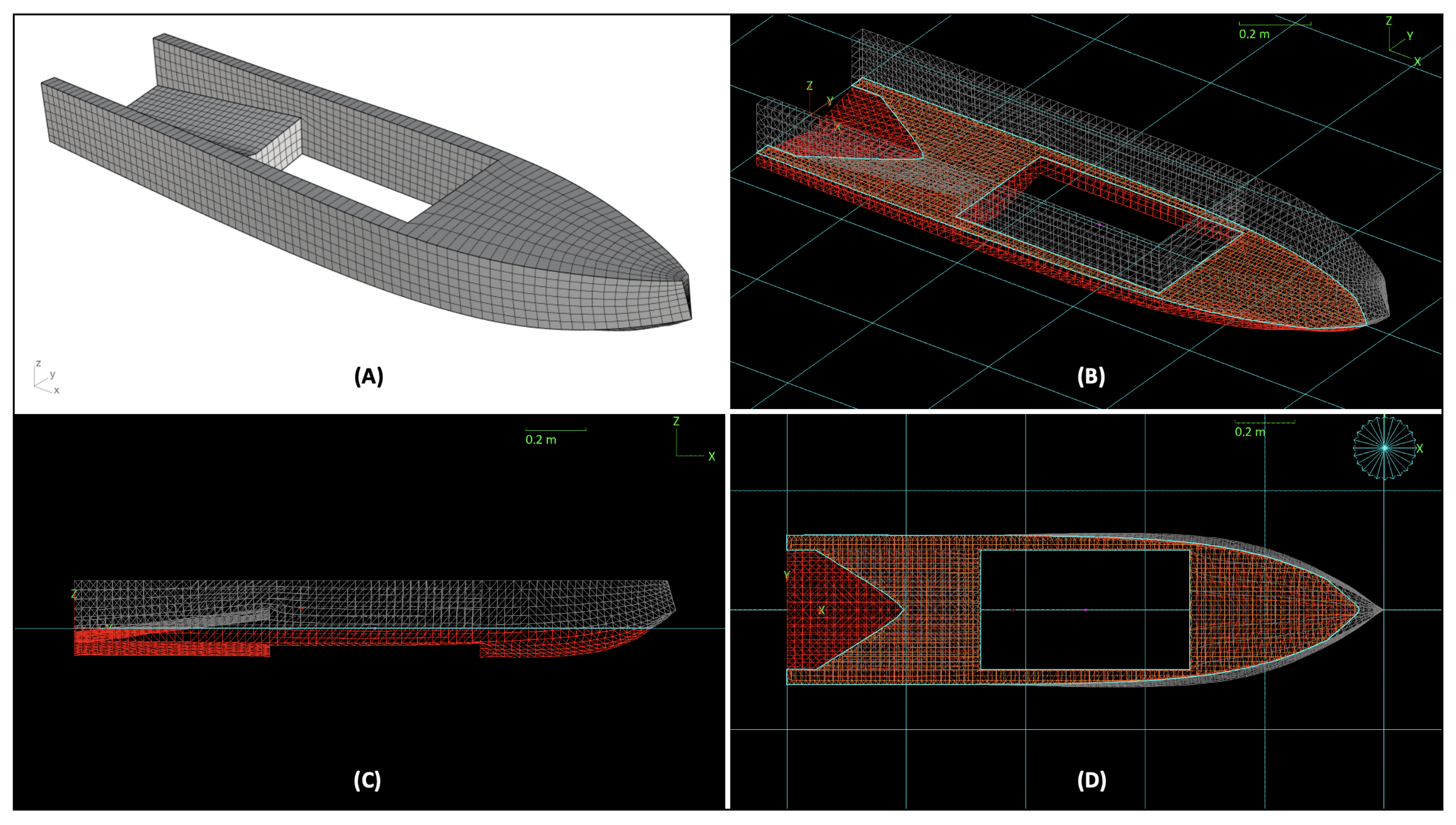

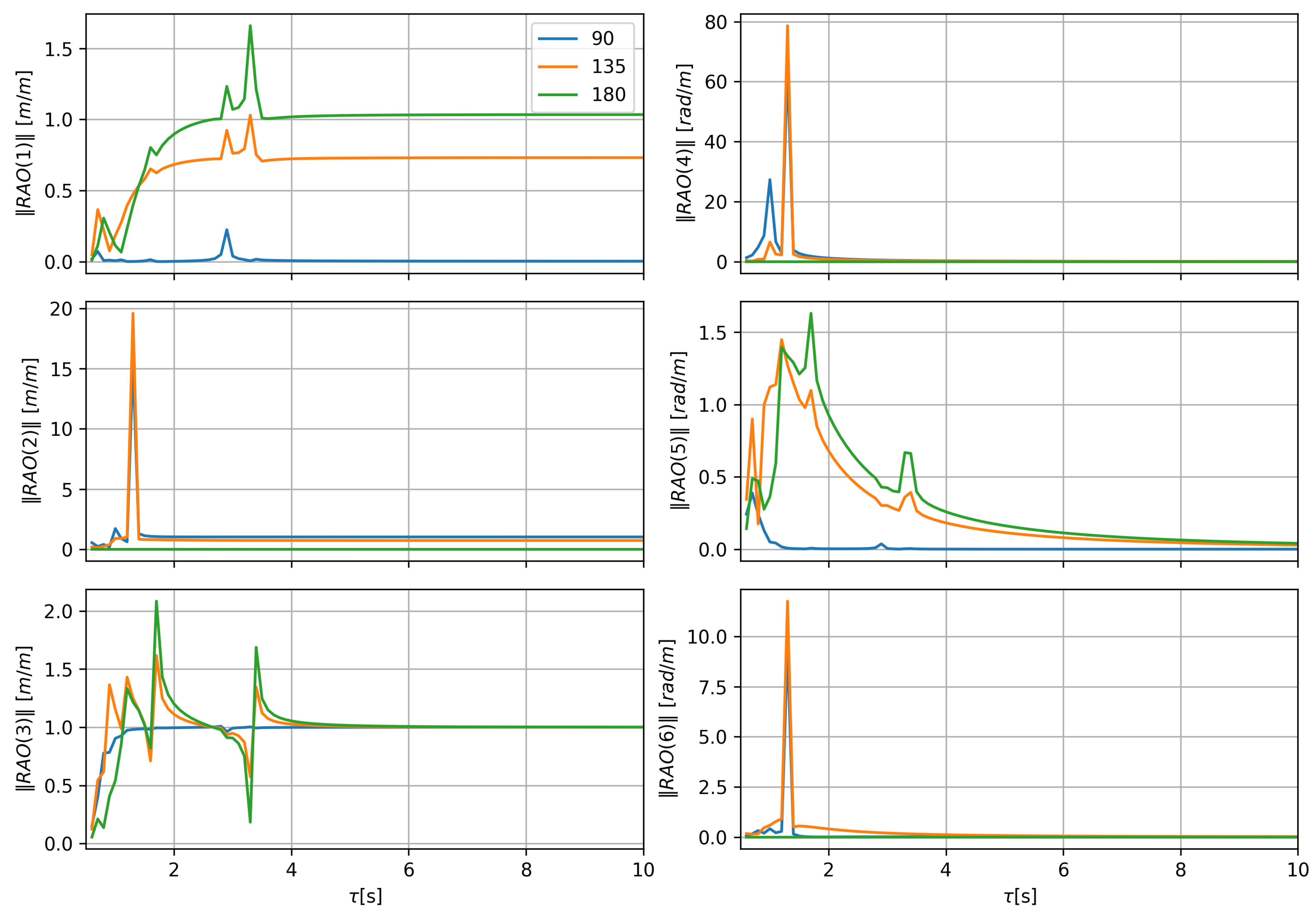

To quantify certain hydrodynamic properties of the hull, we computed the loading and responses for the vessel due to surface water waves using potential flow theory under the OrcaWave software [

18] (

Figure 5). The input parameters we considered are given in

Table 5. The output results include the added mass and damping matrices, load RAOs (Response Amplitude Operators), and displacement RAOs. Some examples of these results are shown in

Figure 6 and

Figure 7, and the full output is given in the

orcawave_results.xlsx file in the repository of the project.

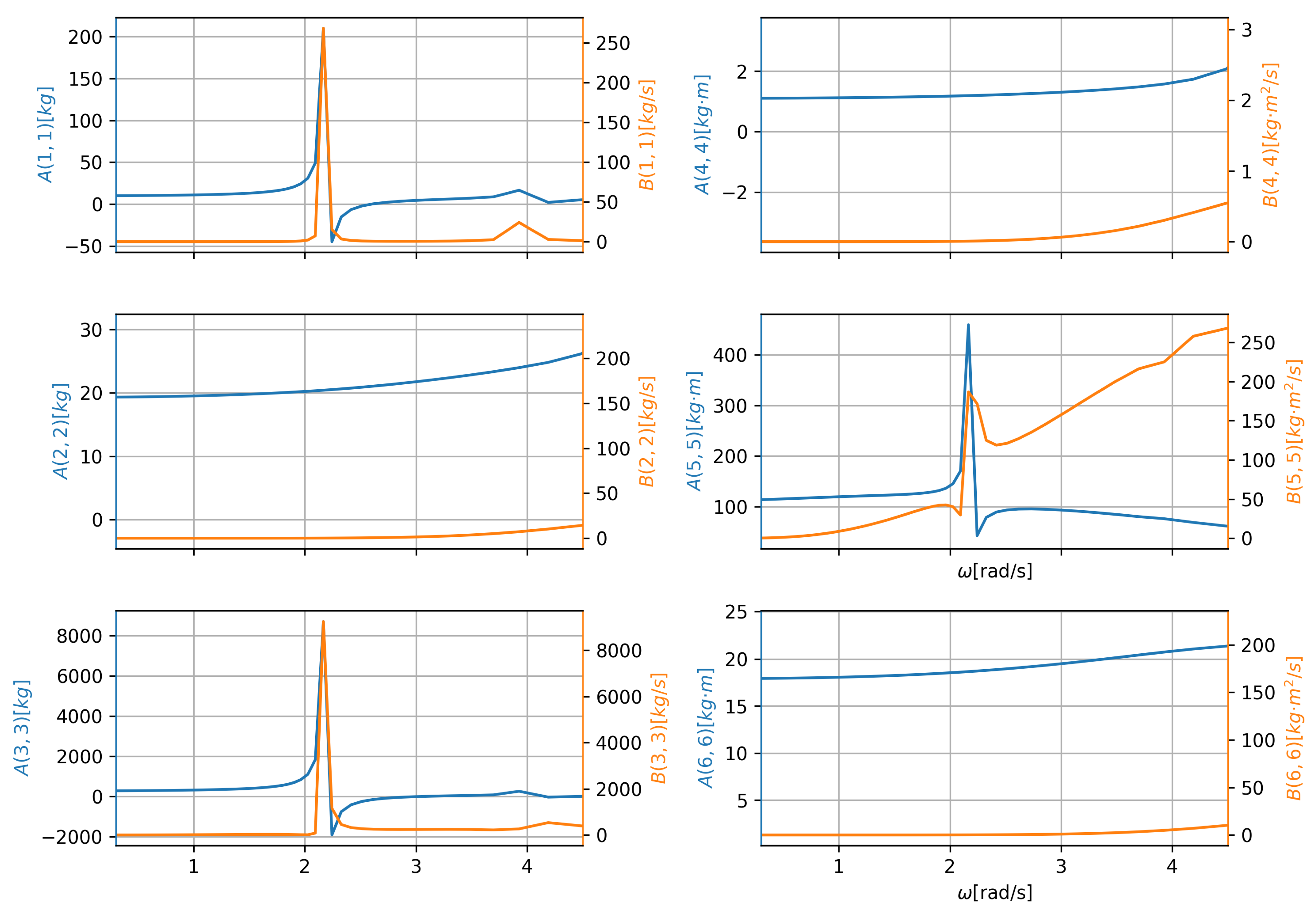

Concerning the obtained added mass (

) and damping (

) coefficients, as well as the RAOs, a prominent spike near 2 rad/s can be observed in both the added mass and damping curves. This feature corresponds to the resonance mode of the waves inside the moonpool and is also visible in the RAOs. The resonance frequency depends on the moonpool dimensions, as these determine the wavelength responsible for the resonance effect. Besides size, other factors, such as shape, draft, and vessel speed, also influence the moonpool resonance [

19]. It is worth noting that the heave motion coefficients are strongly affected at the resonance frequency due to the excitation of the corresponding mode. Depending on the application of the ASV, these observations are crucial for those interested in placing instruments within the moonpool, since the behavior of the water elevation in that region will depend on the wave frequency. In addition, the RAOs will indicate the regions where the ASV is expected to have amplified responses, which can be important for some instruments and/or for the safety of some operation.

These results can be used to carry out analysis using simulation software such as DynaSOS [

20] and Orcaflex [

21]. Furthermore, other approaches that allow for studying the maneuvering aspects can be applied based on these frequency-dependent coefficients [

22].

3.2. Propulsion, Electronics and Power System

Propulsion systems are generally complex systems that involve many aspects, such as propeller–hull interaction, mechanical efficiency in the transmission system, engine–propeller matching, and the propeller design itself. However, considering the budget limitation, commercial models were considered to compose the propulsion system.

To simplify the propulsion system design, a configuration with two thrusters in parallel and no rudder was chosen. Thus, there are fewer mechanisms to control, and the hull assembly is simpler. The drawback of this choice is the potential loss of control in the event of an engine failure, which implies greater robustness to avoid such a situation.

Due to the lack of specific information about commercial thrusters, a power approach to define the propulsion system is more efficient. Then, based on the hull resistance presented in

Section 3.1, the thrust horsepower can be predicted. Considering an open-water efficiency of 50% for ducted propellers as stated in [

23], the delivered horsepower can be defined as follows:

In Equation (

1), the thrust (

T) is assumed to be equal to the hull resistance, and the speed of advance (

) is the vessel speed, both presented in

Table 4. So, a maximum power of 108 W is needed to operate the cargo mode with the designed displacement. Thus, the commercial thruster model T100 by Blue Robotics is considered. It already has an electric engine, propeller, and nozzle, and it is directly attached to the hull bottom. The maximum power of each engine is 130 W, which exceeds the minimum delivered horsepower required. Using this simple power approach, it is possible to make a more reliable power prediction without highly specialized software.

It is important to mention that two skegs were placed aligned with the propellers to protect them in case of any collision with the bottom in shallow water or any floating object.

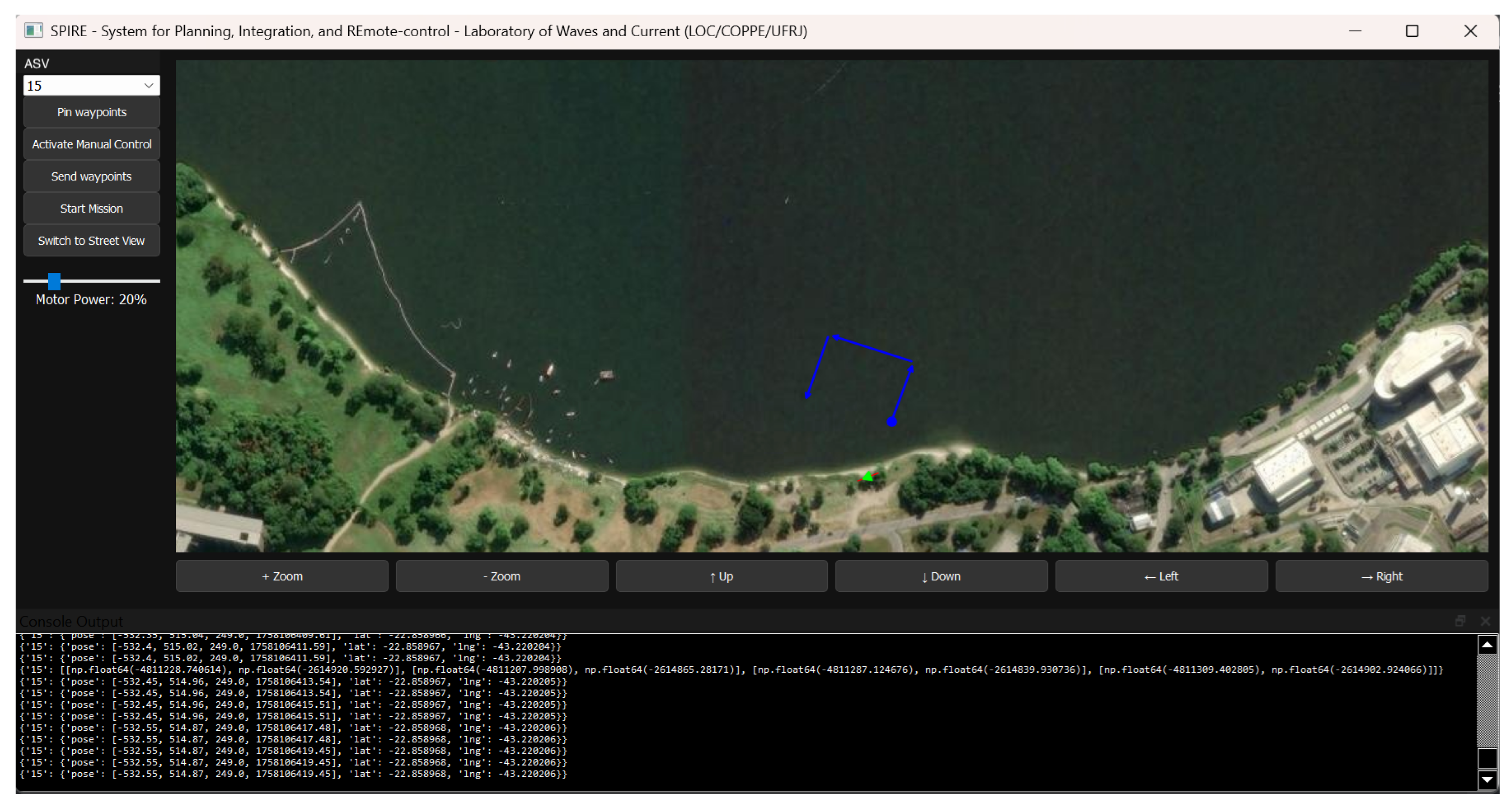

To provide a starting point for multiple uses, we focused the electrical/electronic system on the essential parts to have a minimal level of remote control and automation.

The idea was to place a Master Switch to turn on/off the system. The power source is composed of two LiPo batteries (Leão, Maringá, Paraná, Brazil) with 14.8 V, each having 5200 mAh of capacity. The software runs on the Raspberry Pi 4B (Raspberry Pi, Pencoed, Wales), which is connected to an Arduino MEGA 2560 (Arduino, Monza, MB, Italy) to allow for the use of analog ports and other sensors that are more integrated into this environment. To remotely control the graphical desktop of the Raspberry Pi OS (version 2025-05-06), the boat has its own WiFi router. The Raspberry connects to the main parts of the system (

Figure 8), each one with specific roles:

Compass: shows the orientation of the vessel;

GPS: shows the position of the vessel;

XBee: allows for short-range communication;

ESC: allows for control of the motor;

Arduino (version 2.3.6): to be used with sensors.

As the main batteries are 14.8 V, a buck converter is necessary for the Raspberry and the WiFi router, which are 5 V. The motors are powered directly from the batteries (through the switch and the ESCs). Thus, other sensors can be added using the Arduino (which is connected to the Raspberry through the USB) or the Raspberry.