Experimental Research on Petrophysical, Geomechanical Features, and Fracture Behaviors of Organic-Rich Marine Shale

Abstract

1. Introduction

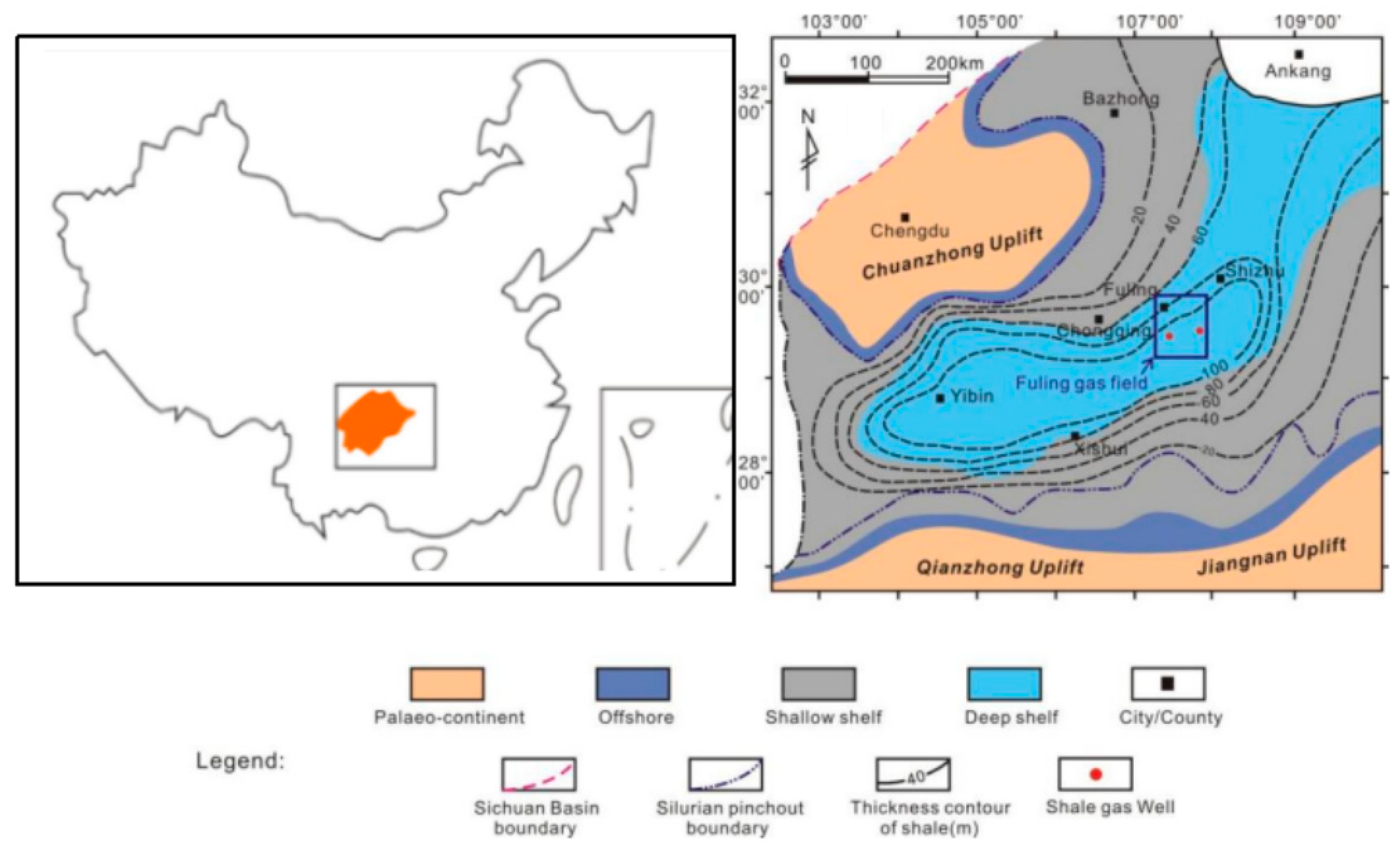

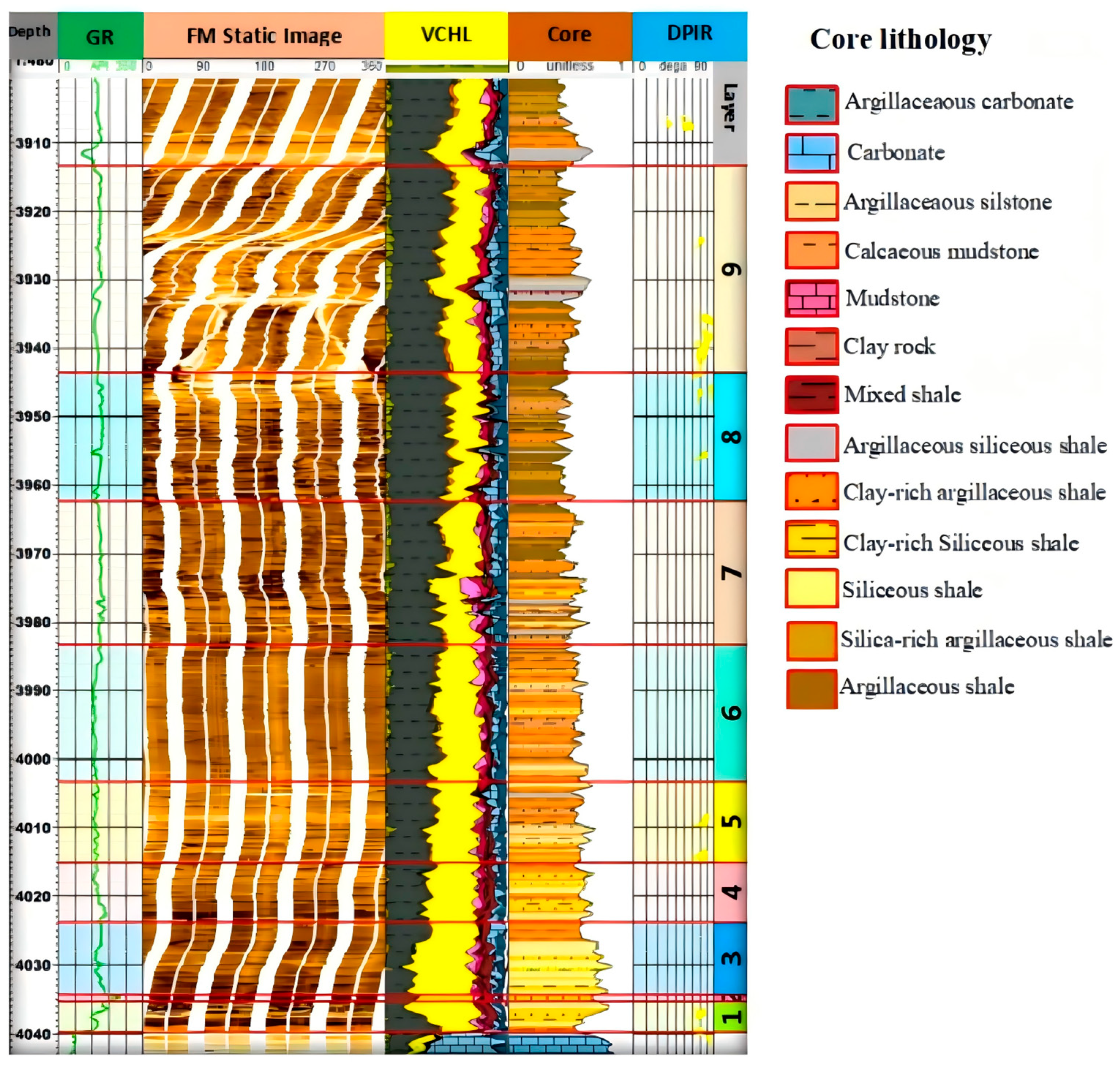

2. Geological Background

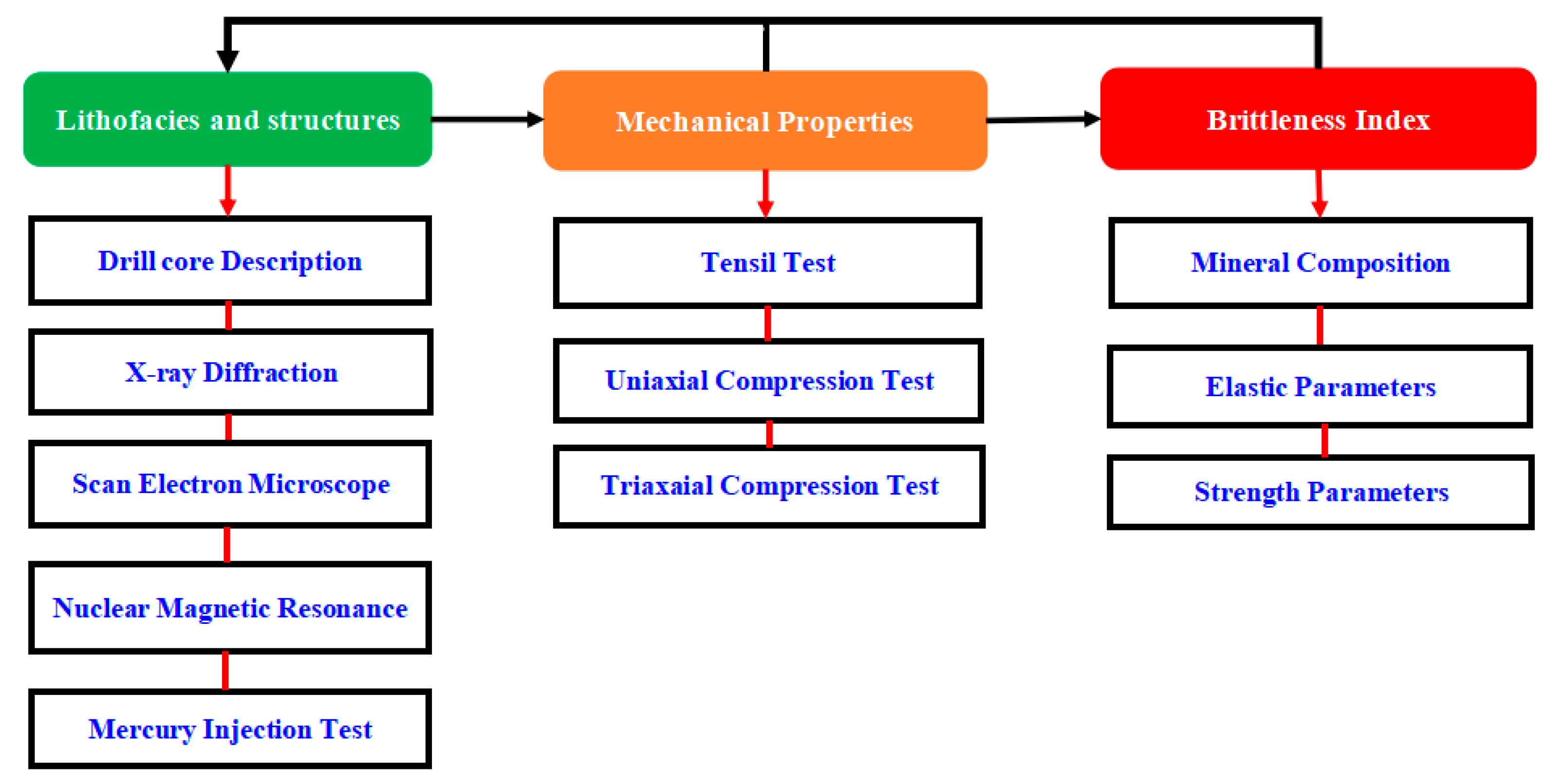

3. Materials and Methods

3.1. Sample Selection and Preparation

3.2. Experimental Principle and Instruments

3.2.1. Mineral, Geochemical, and Petrophysical Tests

- (1)

- X-ray diffraction (XRD) analysis: The powder samples were treated with a 10.0% hydrogen peroxide solution for one hour to eliminate any impurities that may have been introduced during the sample preparation process. Finally, the mineral particles underwent filtration and were rinsed with deionized water, followed by drying in an electronic oven at 100 °C for 12 h prior to testing. XRD measurements were conducted using a Bruker D8 Advance XRD apparatus (Bruker AXS GmbH, Karlsruhe, Germany) with Cu-Kα radiation operating at 40 mA.

- (2)

- Scanning electron microscopy (SEM) analysis: The small block specimen surface was smoothed to achieve a uniform finish using dry emery paper, and was coated with carbon, which serves as a conductive layer for scanning electron microscopy (SEM). The SEM scanning tests were conducted using a FEI Nova400 Scanning Electron Microscope (FEI Company, Hillsboro, OR, USA).

- (3)

- Nuclear Magnetic Resonance (NMR) analysis: Nuclear magnetic resonance experimental instrument model, Neumed MesoMR12-060H-I (Suzhou Niumag Analytical Instrument Co., Ltd., Suzhou, China), was used to analyze the pore structure by collecting the internal nuclear magnetic signals of the sample. The fluid used in this experiment was deionized water. The samples used in the test and the mercury injection experiment were taken from the same core. Before the test, the samples were prepared into 1 cm3.

- (4)

- Mercury Injection Test: this test used an Autopore IV mercury porosimeter (Micromeritics Instrument Corporation, Norcross, GA, USA), which is a 60,000 psi porosimeter that can measure the pore diameter range from 360 μm to 3 nm. All samples undergo a vacuum stage to ensure that all in situ fluids are evacuated before mercury is introduced into the testing cell. During the mercury injection process, the volume of mercury introduced is quantified by measuring the capacitance change in the penetrometer stem.

- (5)

- Geochemical analysis: The vitrinite reflectance was measured using a microphotometer MSP200 (J&M Analytik AG, Essen, Germany). Multiple measurement points were collected to compute the average thermal maturity. The TOC content was determined with a LECO CS230 carbon/sulfur analyzer (LECO Corporation, St. Joseph, MI, USA). Inorganic carbon was removed from shale powders finer than 100 mesh using hydrochloric acid, prior to pyrolysis at 540 °C. The microphotometer (MSP200) was employed again to assess the vitrinite reflectance. In order to determine the average thermal maturity, multiple measurement points were collected. Before assessing vitrinite reflectance, kerogen samples were extracted from the shale specimens through Soxhlet extraction and acid treatments. Following the Chinese industry standard (SY/T6940-2013), gas content testing was performed using FCG006 and FCG009 (BESD Technology, Beijing, China). The experiment was conducted at a formation temperature of 60°. The analytical gas, residual gas, and lost gas contents were combined to calculate the total gas content of the shale.

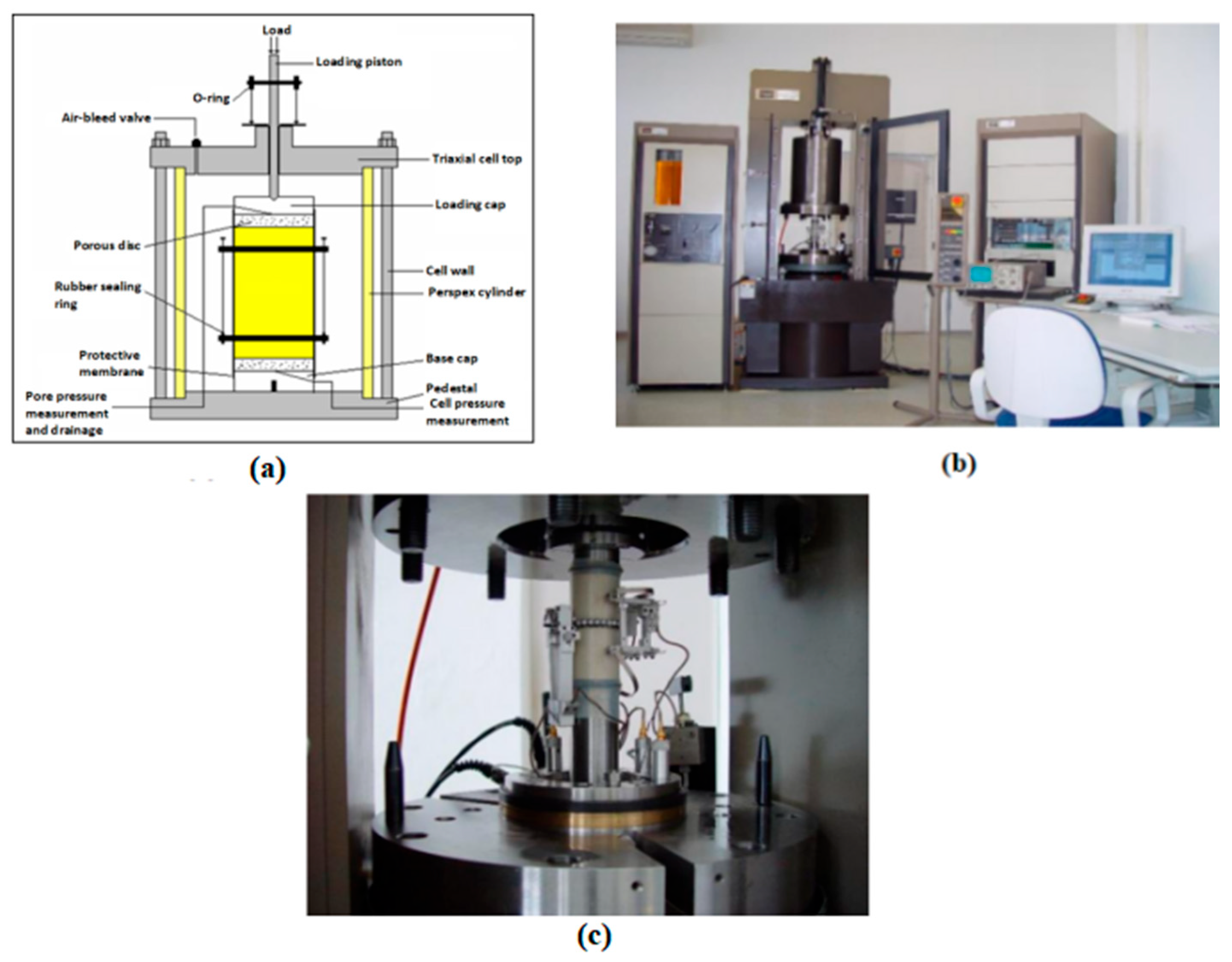

3.2.2. Triaxial–Unixial Compression Test Experiment

4. Results

4.1. Microstructure Characteristics of Organic-Rich Marine Shale Reservoir with Different Lithofacies

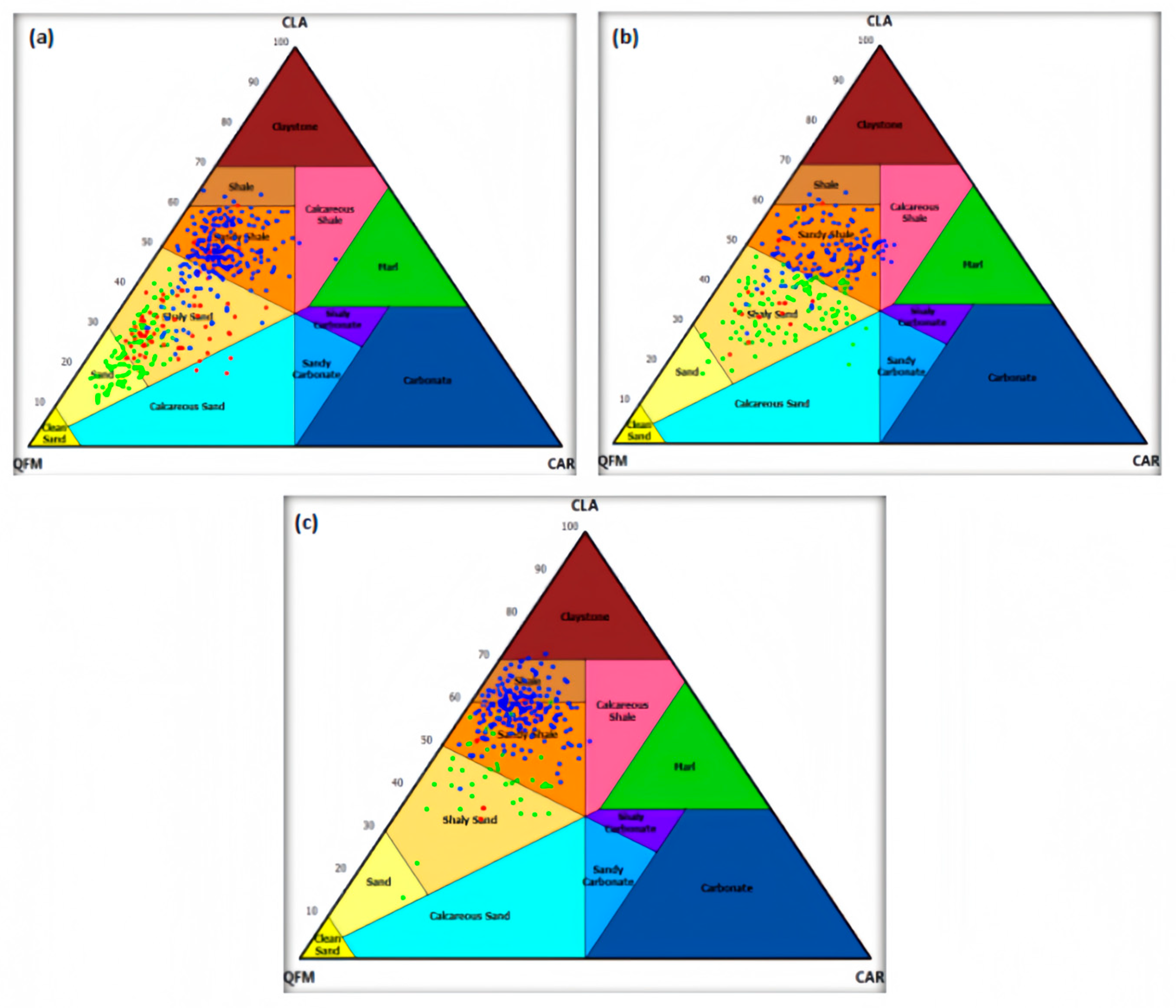

4.1.1. Shale Mineral Components and Geochemical Characteristics

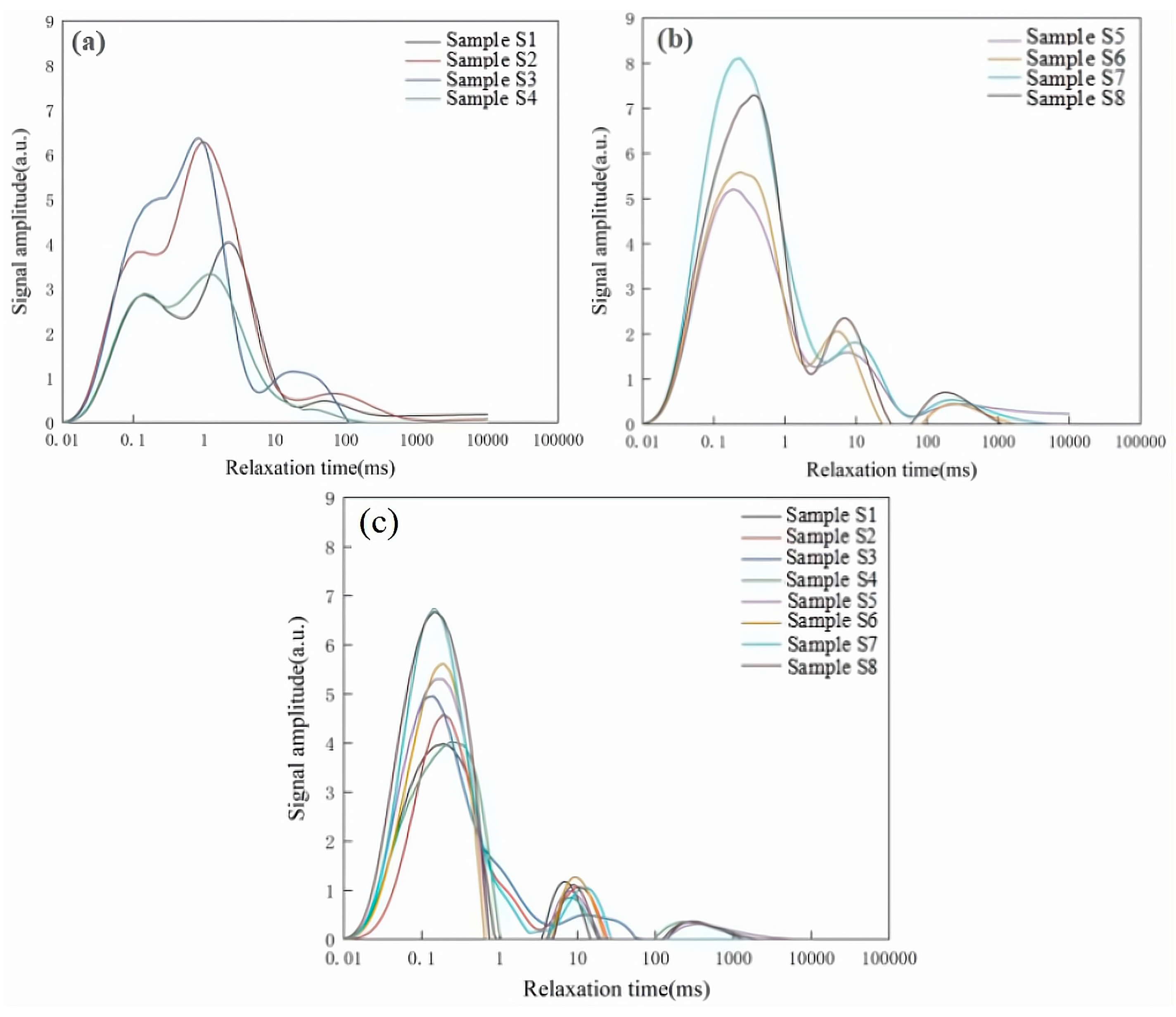

4.1.2. Shale Pore Structure Characteristics

- (1)

- Scanning Electron Microscopy (SEM) Results

- (2)

- Nuclear Magnetic Resonance (NMR) Results

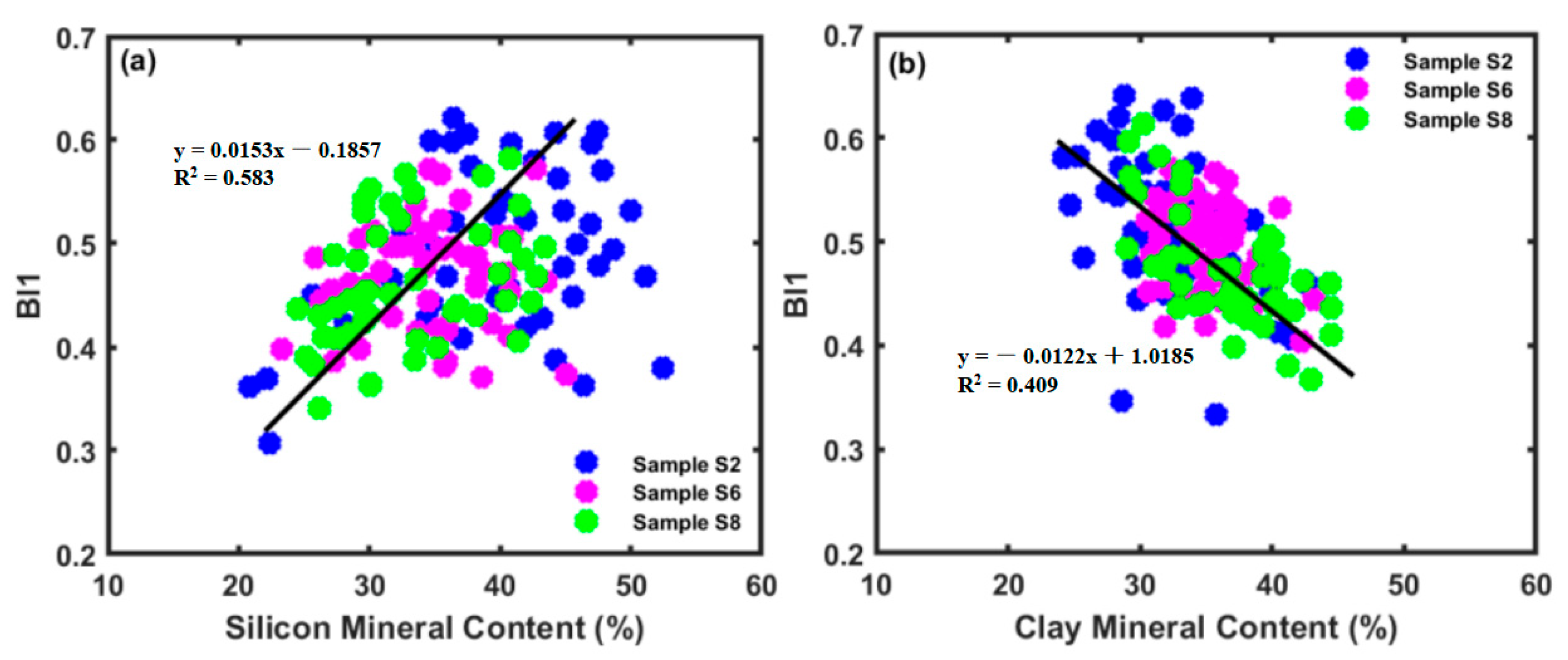

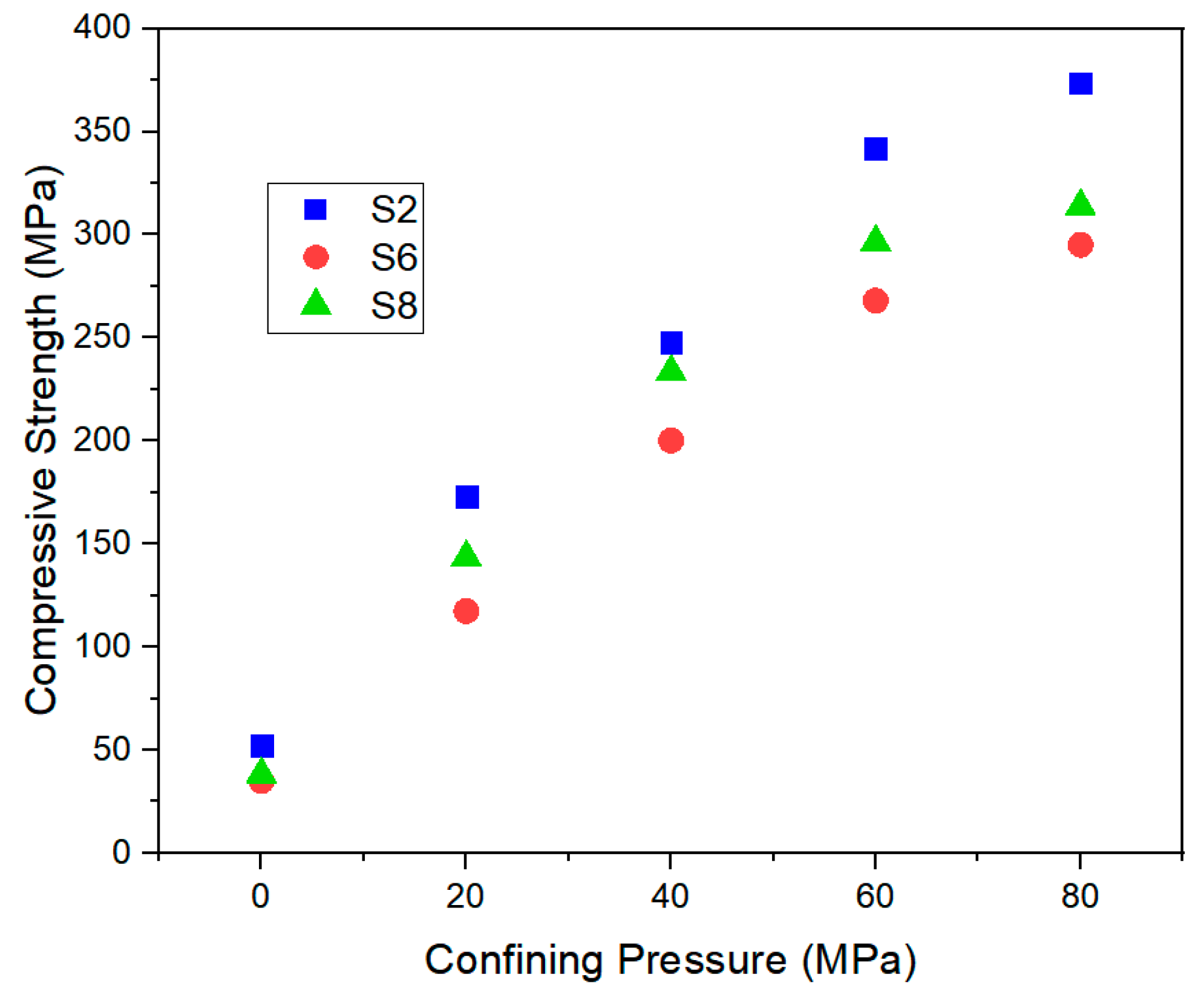

4.2. Influence of Mineral Component on Elastic Parameter Characteristics and Brittleness Index

4.3. Geomechanical Features Results

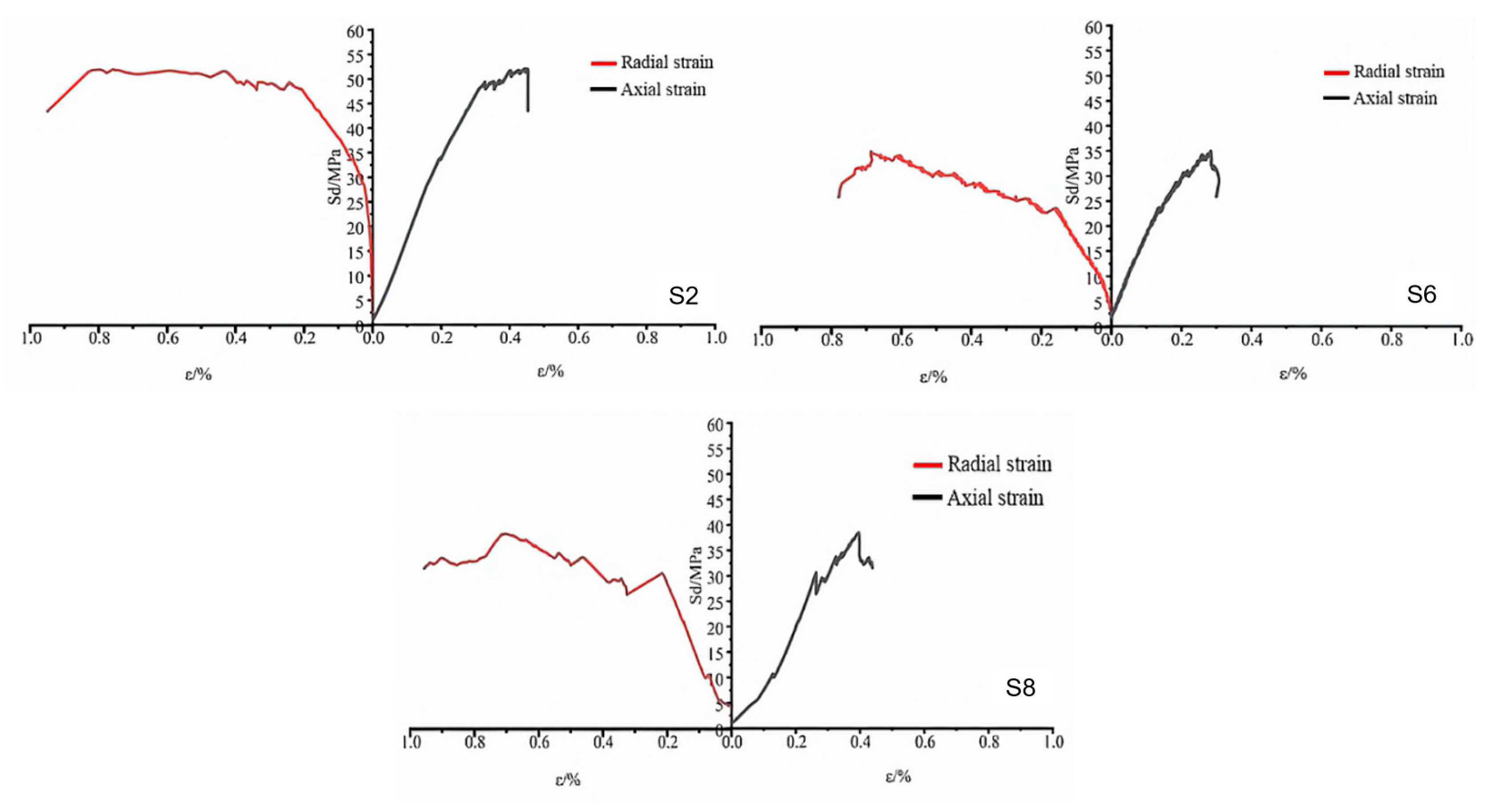

4.3.1. Uniaxial Compressive Strength Characteristics of Organic-Rich Shale

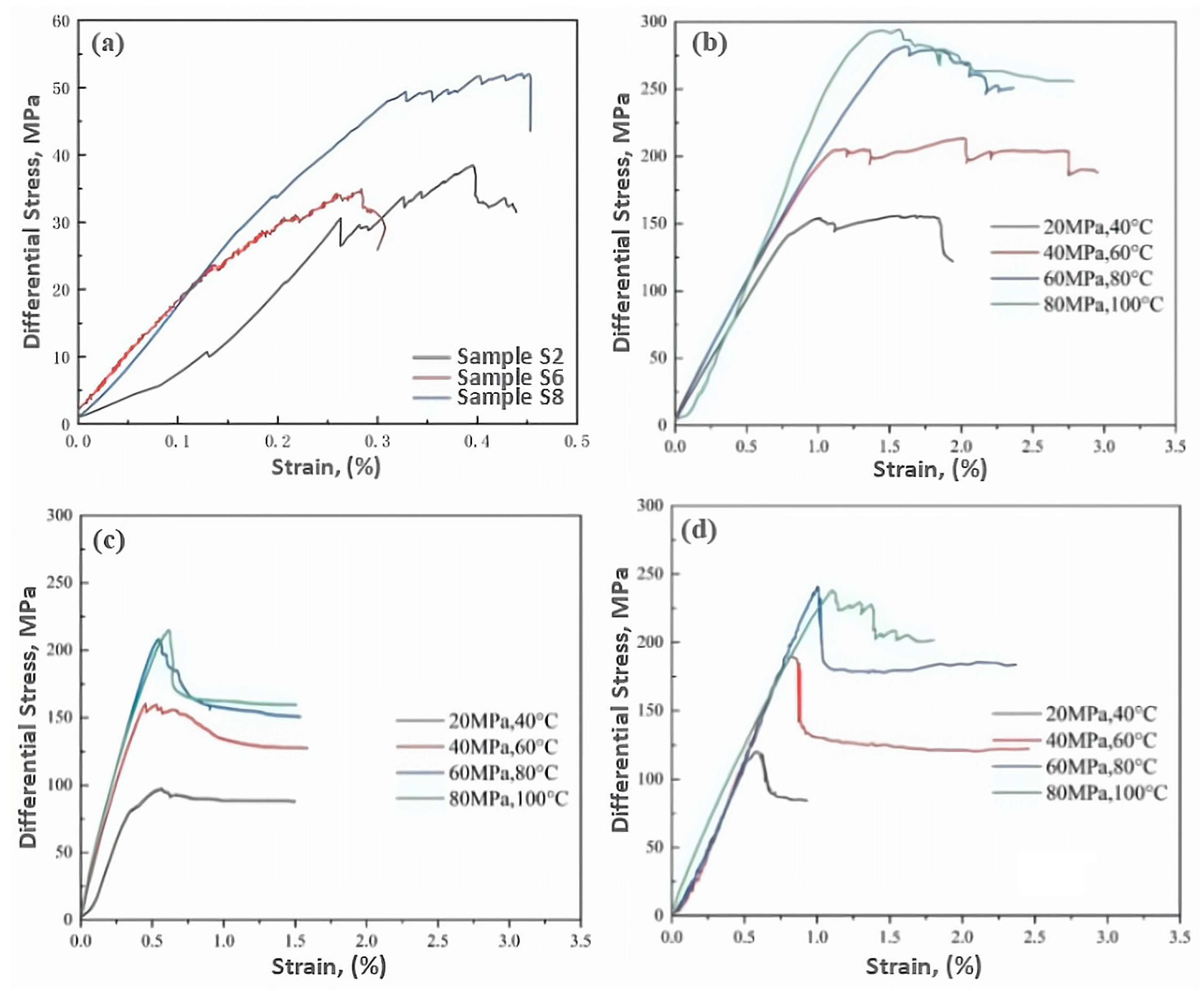

4.3.2. Triaxial Compression Characteristics of Organic-Rich Shale Under the Coupling Effect of Temperature and Pressure

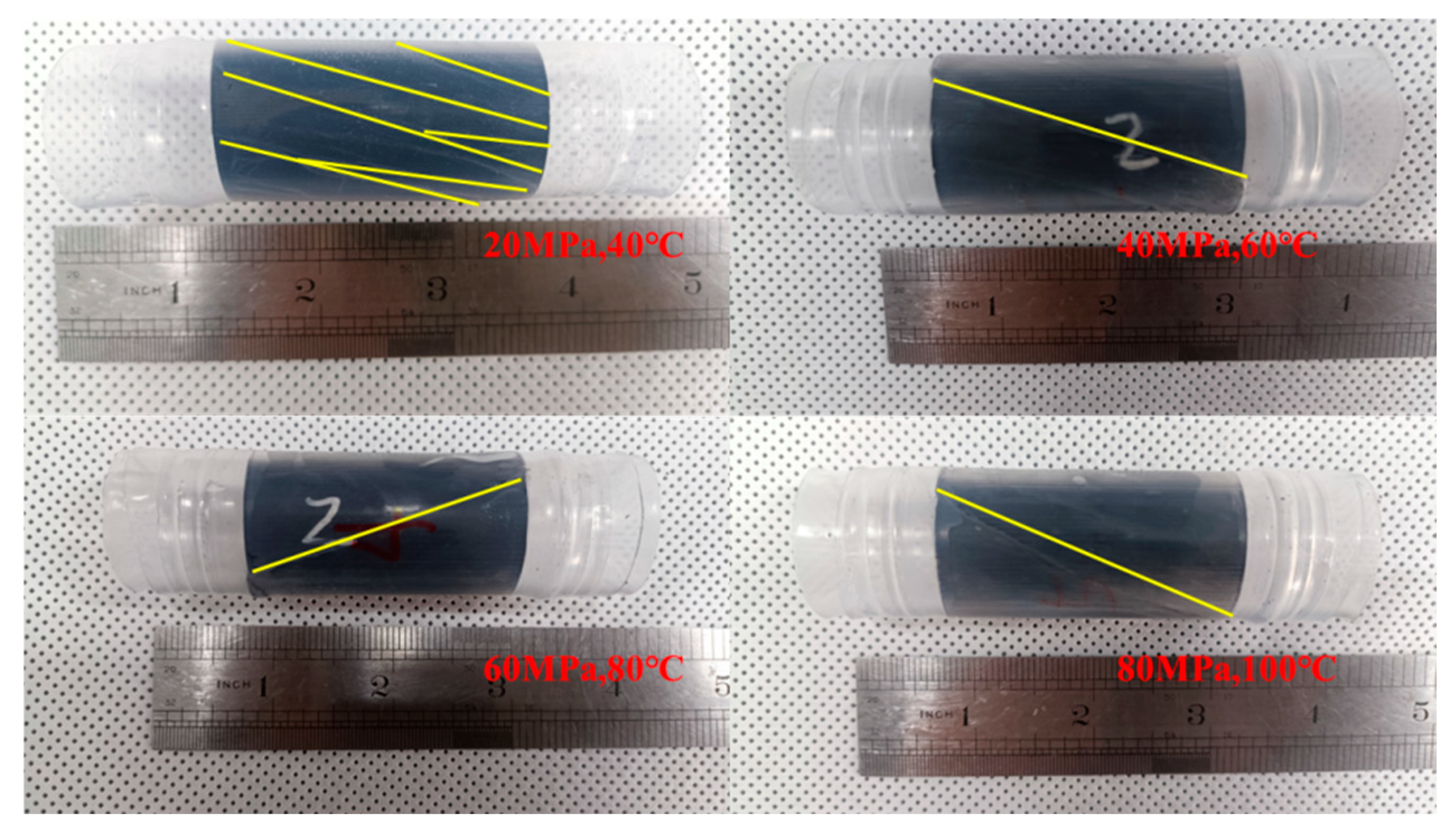

4.4. Failure Mode of Different Organic-Rich Shale Samples Under the Coupling Effect of Temperature and Pressure

4.4.1. Triaxial Failure Mode Analysis

4.4.2. Uniaxial Failure Mode Analysis

4.4.3. Failure Mode of Deep Shale Under the Coupling Effect of Temperature and Pressure

5. Conclusions

- Generally, the study on Well A demonstrated that based on variations in rock properties such as lithology, graptolite distribution, and rock resistivity, the Longmaxi shale is divided into three members. The results of the X-ray diffraction analysis indicated that the upper member is much more dominated by clay minerals while the lower member is dominated by the concentration of siliceous minerals. The silicon mineral concentration shows a steady rise from the upper layers to the lower layers, whereas the clay mineral concentration reveals a consistent decline in the same direction. Nanopores are prevalent, and elevated thermal maturities contribute to substantial gas storage capacity. A notable rise in total organic carbon, porosity, and the percentage of natural gas content was observed from the upper to the lower sections of the reservoir. Particularly promising results were noted in the lower member (Layers ①–⑤) of the reservoir.

- The study of the geomechanical features confirmed that the elastic modulus, triaxial strength, brittleness index, the uniaxial compressive strength, and tensile strength of the Longmaxi shale exhibit significant variation as a result of differing mineralogical compositions. The elevated proportion of clay minerals reduce the triaxial strength, uniaxial compressive strength, brittleness index, and elastic modulus.

- These characteristics increase the likelihood of forming fracture networks during hydraulic fracturing process. The presence of well-defined bedding planes will have a considerable impact on the propagation of hydraulic fractures, ultimately altering the distribution of the fracture network. The breakdown of the rock sample during triaxial–uniaxial compression loading primarily took place after the peak stress was attained, leading to the failure and rupture of the sample.

- Nevertheless, we determined that triaxial–uniaxial compression loading represents a fracturing process in which gradual damage initiates upon reaching a specific stress threshold. The damage accumulates, ultimately leading to the failure of the samples at their maximum stress point. We recognized that this stress threshold varies for each group of samples, according to their mineral compositions. Also, the failure mechanisms observed in various shale specimens predominantly manifest as shear and extensional fractures.

- Currently, more advanced simulation approaches to track the multi-field coupling effect throughout fracture initiation and growth is crucial to further understand and uncover the mechanism of crack initiation and growth. However, we believe that experimental study must be conducted in addition to these simulation approaches, to validate the outcomes of modeling.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| XRD | X-ray Diffraction |

| TOC | Total Organic Carbon |

| ISRM | International Society for Rock Mechanics |

| MTS | Materials Triaxial Test Standard |

| MIP | Mercury Injection Porosimetry |

| SEM | Scanning Electron Microscopy |

| NMR | Nuclear Magnetic Resonance |

| BI | Brittleness Index |

| UCS | Unconfined Compressive Strength |

| UCT | Uniaxial Compression Test |

| TCT | Triaxial Compression Test |

References

- Chang, C.; Zoback, M.D.; Khaksar, A. Empirical relations between rock strength and physical properties in sedimentary rocks. J. Petrol. Sci. Eng. 2006, 51, 223–237. [Google Scholar] [CrossRef]

- Benson, S.M.; Cole, D.R. CO2 sequestration in deep sedimentary formations. Elements 2008, 4, 325–331. [Google Scholar] [CrossRef]

- Tuzingila, R.M.; Kong, L.; Koy Kasongo, R. Experimental Techniques and Rock Physics Modeling to Study the Effects of Mineral Content and Thermal Maturation on Elastic Properties of the Organic-Rich Shale: Case Study of the Longmaxi Formation. SPE J. 2025, 30, 1884–1905. [Google Scholar] [CrossRef]

- Tuzingila, R.M.; Kong, L.; Koy Kasongo, R. A review on experimental techniques and their applications in the effects of mineral content on geomechanical properties of reservoir shale rock. Rock Mech. Bull. 2024, 3, 100110. [Google Scholar] [CrossRef]

- Ma, Y.; Pan, Z.; Zhong, N.; Connell, L.D.; Down, D.I.; Lin, W.; Zhang, Y. Experimental study of anisotropic gas permeability and its relationship with fracture structure of Longmaxi Shales, Sichuan Basin, China. Fuel 2016, 180, 106–115. [Google Scholar] [CrossRef]

- Wang, X.; Shi, F.; Liu, H.; Wu, H.A. Numerical simulation of hydraulic fracturing in orthotropic formation based on the extended finite element method. J. Nat. Gas Sci. Eng. 2016, 33, 56–69. [Google Scholar] [CrossRef]

- Douma, L.A.N.R.; Regelink, J.A.; Bertotti, G.; Boersma, Q.D.; Barnhoorn, A. The mechanical contrast between layers controls fracture containment in layered rocks. J. Struct. Geol. 2019, 127, 103856. [Google Scholar] [CrossRef]

- Liu, J.X.; Liu, W.; Yang, C.H.; Huo, L. Experimental study on mechanical properties of mud shale under different strain rates. Rock Soil Mech. 2014, 35, 3093–3100. (In Chinese) [Google Scholar]

- Li, Q.; Chen, M.; Jin, Y.; Wang, F.P. Experimental research on failure modes and mechanical behaviors of gas-bearing shale. Chin. J. Rock Mech. Eng. 2012, 31 (Suppl. S2), 3763–3771. [Google Scholar]

- Diao, H. Rock mechanical properties and brittleness evaluation of shale reservoir. Acta Petrol. Sin. 2013, 29, 3300–3306. [Google Scholar]

- Chen, T.; Feng, X.; Zhang, X.; Cao, W.D.; Fu, C.J. Experimental study on mechanical and anisotropic properties of black shale. Chin. J. Rock Mech. Eng. 2014, 33, 1772–1779. [Google Scholar]

- Jia, Y.; Tang, J.; Lu, Y.; Lu, Z. Laboratory Geomechanical and Petrophysical Characterization of Longmaxi Shale Properties in Lower Silurian Formation, China. Mar. Pet. Geol. 2021, 124, 104800. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J.; Mao, H.; Huo, L.; Hou, Z.K. Anisotropic experimental study on mechanical properties of shale under uniaxial compression. Met. Mine 2015, 44, 33–37. [Google Scholar]

- Jia, C.; Chen, J.; Guo, Y.; Yang, C.H.; Xu, J.B.; Wang, L. Research on mechanical behaviors and failure modes of layer shale. Rock Soil Mech. 2013, 34 (Suppl. S2), 57–61. [Google Scholar]

- Chen, Y.; Watanabe, K.; Kusuda, H.; Kusaka, E.; Mabuchi, M. Crack growth in Westerly granite during a cyclic loading test. Eng. Geol. 2011, 117, 189–197. [Google Scholar] [CrossRef]

- Xiao, J.; Ding, D.; Jiang, F.; Xu, G. Fatigue damage variable and evolution of rock subjected to cyclic loading. Int. J. Rock Mech. Min. Sci. 2010, 47, 461–468. [Google Scholar] [CrossRef]

- Dubey, R.K.; Gairola, V.K. Influence of structural anisotropy on the uniaxial compressive strength of pre-fatigued rocksalt from Himachal Pradesh, India. Int. J. Rock Mech. Min. Sci. 2000, 37, 993–999. [Google Scholar] [CrossRef]

- Qiu, S.; Feng, X.; Xiao, J.; Zhang, C. An experimental study on the pre-peak unloading damage evolution of marble. Rock Mech. Rock Eng. 2014, 47, 401–419. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, S.; Xu, X.; Fang, L. Evolution of the elastic properties of a bedded argillite damaged in cyclic triaxial tests. Int. J. Rock Mech. Min. Sci. 2013, 58, 103–110. [Google Scholar] [CrossRef]

- Gatelier, N.; Pellet, F.; Loret, B. Mechanical damage of an anisotropic porous rock in cyclic triaxial tests. Int. J. Rock Mech. Min. Sci. 2002, 39, 335–354. [Google Scholar] [CrossRef]

- Xie, R.; Zhou, W.; Liu, C.; Yin, S.; Radwan, A.E.; Lei, W.; Cai, W. Experimental investigation on dynamic and static rock mechanical behavior, failure modes, and sequences of frequent interbedded sand and shale reservoirs. Interpretation 2022, 10, SF23–SF36. [Google Scholar] [CrossRef]

- Mustafa, A.; Tariq, Z.; Mahmoud, M.; Radwan, A.E.; Abdulraheem, A.; Abouelresh, M.O. Data-driven machine learning approach to predict mineralogy of organic-rich shales: An example from Qusaiba Shale, Rub’ al Khali Basin, Saudi Arabia. Mar. Pet. Geol. 2022, 137, 105495. [Google Scholar] [CrossRef]

- Sohail, G.M.; Radwan, A.E.; Mahmoud, M. A review of Pakistani shales for shale gas exploration and comparison to North American shale plays. Energy Rep. 2022, 8, 6423–6442. [Google Scholar] [CrossRef]

- Niandou, H.; Shao, J.F.; Henry, J.P.; Fourmaintraux, D. Laboratory investigation of the mechanical behaviour of Tournemire shale. Int. J. Rock Mech. Min. Sci. 1997, 34, 3–16. [Google Scholar] [CrossRef]

- Wang, M.; Tan, C.; Meng, J.; Yang, B.; Li, Y. Crack classification and evolution in anisotropic shale during cyclic loading tests by acoustic emission. J. Geophys. Eng. 2017, 14, 930–938. [Google Scholar] [CrossRef]

- Wang, M.; Xiao, L. The b-value analysis of bedded shale under cyclic loading tests. J. Geophys. Eng. 2018, 15, 1291–1299. [Google Scholar] [CrossRef]

- Yang, B.; Xue, L.; Wang, M.; Li, Y. Study on damage-fracture of shale based on the energy principle. J. Basic Sci. Eng. 2018, 26, 997–1004. [Google Scholar]

- Xu, D.; Yuan, X.; Wu, J.; Fan, L.; Yang, X.; Tang, Y.; Zhang, J. Optimal design of cumulative shale gas hydraulic fracturing process based on rock fatigue damage theory. Integr. Ferroelectr. Int. J. 2019, 200, 99–107. [Google Scholar] [CrossRef]

- Guo, Y.; Yang, C.; Wang, L.; Xu, F. Effects of cyclic loading on the mechanical properties of mature bedding shale. Adv. Civ. Eng. 2018, 2018, 8985973. [Google Scholar] [CrossRef]

- Sone, H.; Zoback, M. Mechanical properties of shale-gas reservoir rocks—Part 1: Static and dynamic elastic properties and anisotropy. Geophysics 2013, 78, D381–D392. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Hammes, U. Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix-related mudrock pores. AAPG Bull. 2012, 96, 1071–1098. [Google Scholar] [CrossRef]

- Tuzingila, R.M.; Kong, L.; Koy Kasongo, R. Contribution of Anisotropic Features of an Organic-Rich Shale Gas Reservoir on Hydraulic Fracturing. J. Energy Eng. 2025, 151, 04025042. [Google Scholar] [CrossRef]

- Tuzingila, R.M.; Kong, L.; Koy Kasongo, R. Investigation of the Mineral Content and Geomechanical Behaviors of Shale Gas Reservoirs after CO2 Injection Using Rock Physics Modeling. Int. J. Geomech. 2025, 25, 04025217. [Google Scholar] [CrossRef]

- Revil, A.; Grauls, D.; Brevart, O. Mechanical compaction of sand/clay mixtures. J. Geophys. Res. 2002, 107, 2293. [Google Scholar] [CrossRef]

- Crawford, B.R.; Faulkner, D.R.; Rutter, E.H. Strength, porosity, and permeability development during hydrostatic and shear loading of synthetic quartz-clay fault gouge. J. Geophys. Res. Solid Earth 2008, 113, 1–14. [Google Scholar] [CrossRef]

- Kohli, A.H.; Zoback, M.D. Frictional properties of shale reservoir rocks. J. Geophys. Res. Solid Earth 2013, 118, 5109–5125. [Google Scholar] [CrossRef]

- Yang, R.; Hao, F.; He, S.; He, C.; Guo, X.; Yi, J.; Hu, H.; Zhang, S.; Hu, Q. Experimental investigations on the geometry and connectivity of pore space in organic-rich Wufeng and Longmaxi shales. Mar. Pet. Geol. 2017, 84, 225–242. [Google Scholar] [CrossRef]

- Chen, L.; Lu, Y.; Jiang, S.; Li, J.; Guo, T.; Luo, C. Heterogeneity of the lower Silurian Longmaxi marine shale in the southeast Sichuan Basin of China. Mar. Pet. Geol. 2015, 65, 232–246. [Google Scholar] [CrossRef]

- Ling, K.; He, J.; Pei, P.; Wang, S.; Ni, X. Comparisons of Biot’s Coefficients of Bakken Core Samples Measured by Three Methods. In Proceedings of the 50th US Rock Mechanics/Geomechanics Symposium, Houston, TX, USA, 26–29 June 2016; American Rock Mechanics Association: Westminster, CO, USA, 2016. [Google Scholar]

- Zhou, H.; Wei, L.; Wang, T.; Wang, Y.; Pang, H.; Zhang, T. Evaluation method of Weirong deep shale gas reservoir and its application. Pet. Reserv. Eval. Dev. 2021, 11, 42–49. [Google Scholar]

- Chen, Y.; Jin, Y.; Chen, M.; Yi, Z.; Zheng, X. Quantitative evaluation of rock brittleness based on the energy dissipation principle, an application to type II mode crack. J. Nat. Gas Sci. Eng. 2017, 45, 527–536. [Google Scholar] [CrossRef]

- Liu, H.; Lai, B.; Chen, J. Unconventional spontaneous imbibition into shale matrix: Theory and a methodology to determine relevant parameters. Transp. Porous Media 2016, 111, 41–57. [Google Scholar] [CrossRef]

- Slatt, R.M.; Abousleiman, Y. Merging Sequence Stratigraphy and Geomechanics for Unconventional Gas Shales. Lead. Edge 2011, 30, 274–282. [Google Scholar] [CrossRef]

- Jarvie, D.M.; Hill, R.J.; Ruble, T.E.; Pollastro, R.M. Unconventional shale-gas systems: The Mississippian Barnett Shale of north-central Texas as one model for thermogenic shale-gas assessment. Am. Assoc. Petrol. Geol. Bull. 2007, 91, 475–499. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Jarvie, D.M. Morphology, genesis, and distribution of nanometer-scale pores in siliceous Mudstones of the Mississippian Barnett shale. J. Sediment. Res. 2009, 79, 848–861. [Google Scholar] [CrossRef]

- Shao, X.-H.; Pang, X.-Q.; Li, M.-W.; Li, Z.-M.; Zhao, Y. Hydrocarbon Generation from Lacustrine Shales with Retained Oil during Thermal Maturation. Pet. Sci. 2020, 17, 1478–1490. [Google Scholar] [CrossRef]

- Qin, Z.; Liu, Z.; Liu, C.; Zhu, X.; Steel, R.J.; Tian, H.; Wang, K.; Song, Z. Experimental Study on the Development Characteristics and Controlling Factors of Microscopic Organic Matter Pore and Fracture System in Shale. Front. Earth Sci. 2021, 9, 773960. [Google Scholar] [CrossRef]

- Tuzingila, R.M.; Kong, L.; Li, C.; Wang, Z.; Landu, C.Z. Impact of Rock−ScCO2 Interaction on Shale Features and Its Implication in CO2 Geological Storage and Fracturing: Review and Perspectives. Energy Fuels 2025, 39, 18311–18349. [Google Scholar] [CrossRef]

- Song, C.; Elsworth, D.; Zhi, S.; Wang, C. The influence of particle morphology on microbially induced CaCO3 clogging in granular media. Mar. Georesources Geotechnol. 2019, 39, 74–81. [Google Scholar] [CrossRef]

- Song, C.; Elsworth, D. Strengthening mylonitized soft-coal reservoirs by microbial mineralization. Int. J. Coal Geol. 2018, 200, 166–172. [Google Scholar] [CrossRef]

- Zhang, D.; Ranjith, P.G.; Perera, M.S.A. The brittleness indices used in rock mechanics and their application in shale hydraulic fracturing: A review. J. Petrol. Sci. Eng. 2016, 143, 158–170. [Google Scholar] [CrossRef]

- Abousleiman, Y.; Tran, M.; Hoang, S. Geomechanics field and laboratory characterization of Woodford shale: The next gas play. In Proceedings of the SPE Annual Technical Conference and Exhibition, Anaheim, CA, USA, 11–14 November 2007. [Google Scholar]

- Rozhko, A.Y.; Kim, S.; Mews, K.S.; Lozovyi, S.; Holt, R.M. Manifestation of Negative Microfracture Compressibility Due to Capillarity in Tight Rocks at Partial Saturation with Free Gas’. Rock Mech. Rock Eng. 2024, 57, 9121–9143. [Google Scholar] [CrossRef]

- Aoudia, K.; Miskimins, J.L.; Harris, N.B.; Mnich, C.A. Statistical analysis of the effects of mineralogy on rock mechanical properties of the Woodford shale and the associated impacts for hydraulic fracture treatment design. In Proceedings of the 44th US Rock Mechanics Symposium and 5th US–Canada Rock Mechanics Symposium, Salt Lake City, UT, USA, 27–30 June 2010; p. 11. [Google Scholar]

- Labani, M.M.; Rezaee, R. The importance of geochemical parameters and shale composition on rock mechanical properties of gas shale reservoirs: A case study from the Kockatea Shale and Carynginia Formation from the Perth Basin, Western Australia. Rock Mech. Rock Eng. 2015, 48, 1249–1257. [Google Scholar] [CrossRef]

- Singh, M.; Raj, A.; Singh, B. Modified Mohr-Coulomb criterion for non-linear triaxial and polyaxial strength of intact rocks. Int. J. Rock Mech. Min. Sci. 2011, 48, 546–555. [Google Scholar] [CrossRef]

- Bowker, K.A. Barnett shale gas production, Fort Worth basin: Issues and discussion. AAPG Bull. 2007, 91, 523–533. [Google Scholar] [CrossRef]

- Buller, D.; Hughes, S.; Market, J.; Petre, E.; Spain, D.; Odumosu, T. Petrophysical evaluation for enhancing hydraulic stimulation in horizontal shale gas wells. In Proceedings of the SPE Annual Technical Conference and Exhibition Florence, Florence, Italy, 19–22 September 2010. [Google Scholar]

- Mullen, J. Petrophysical characterization of the eagle ford shale in south Texas. In Proceedings of the Canadian Unconventional Resources and International Petroleum Conference, Calgary, AB, Canada, 19–21 October 2010. [Google Scholar]

- Valter, C.; Alda, M.; Maurizio, M.; Elio, R.; Roberto, G.; Andrea, O. Gas shale reservoir characterization: A North Africa case. In Proceedings of the SPE Annual Technical Conference and Exhibition, Florence, Italy, 19–22 September 2010. [Google Scholar]

| Depth (m) | Layer Number | Sample | Mineral Content (wt.%) | TOC (%) | Phi (%) | Total Gas Content, m3/t | ||

|---|---|---|---|---|---|---|---|---|

| Carbonate | Quartz-Feldp | Clay | ||||||

| 3956 | ⑨ | S9 | 9.27 | 43.15 | 47.84 | 2.32 | 3.39 | 2.1 |

| 3981 | ⑧ | S8 | 9.52 | 45.52 | 44.02 | 2.73 | 3.28 | 2.5 |

| 3994 | ⑦ | S7 | 10.68 | 49.44 | 42.60 | 2.23 | 2.82 | 3.0 |

| 4002 | ⑥ | S6 | 10.44 | 49.07 | 41.8 | 2.47 | 3.68 | 3.1 |

| 4012 | ⑤ | S5 | 10.80 | 51.76 | 43.6 | 2.77 | 4.01 | 3.8 |

| 4022 | ④ | S4 | 10.70 | 53.38 | 38.43 | 3.35 | 4.57 | 4.9 |

| 4030 | ③ | S3 | 11.52 | 59.52 | 29.40 | 3.84 | 4.53 | 5.7 |

| 4036 | ② | S2 | 10.92 | 59.26 | 26.33 | 4.50 | 5.41 | 7.6 |

| 4041 | ① | S1 | 14.37 | 48.92 | 29.14 | 4.35 | 5.39 | 4.9 |

| Sample | Confining Pressure (MPa) | Temperature (°C) | Σma (MPa) | Σmin (MPa) | ε1 (%) | Εmin (%) | Εmax (%) | BI2 |

|---|---|---|---|---|---|---|---|---|

| S2 | 0 | 20 | 52.03 | 45.11 | 0.3 | 0.43 | 0.54 | 3.50 |

| 20 | 40 | 153.1 | 125.4 | 0.67 | 1.01 | 1.87 | 3.02 | |

| 40 | 60 | 208.1 | 186.5 | 0.77 | 1.35 | 2.07 | 2.37 | |

| 60 | 80 | 281.8 | 247.3 | 0.89 | 1.68 | 2.55 | 2.19 | |

| 80 | 100 | 293.7 | 255.6 | 0.93 | 1.56 | 2.66 | 2.51 | |

| S6 | 0 | 20 | 34.95 | 25.89 | 0.15 | 0.29 | 0.32 | 2.46 |

| 20 | 40 | 97.4 | 90.36 | 0.25 | 0.6 | 0.68 | 1.91 | |

| 40 | 60 | 160.2 | 137.06 | 0.32 | 0.68 | 1.05 | 1.96 | |

| 60 | 80 | 208.1 | 162.10 | 0.25 | 0.56 | 1.38 | 1.83 | |

| 80 | 100 | 215.2 | 170.11 | 0.29 | 0.6 | 1.51 | 1.95 | |

| S8 | 0 | 20 | 38.43 | 32.06 | 0.23 | 0.39 | 0.44 | 2.97 |

| 20 | 40 | 123.73 | 90.40 | 0.24 | 0.54 | 0.71 | 2.14 | |

| 40 | 60 | 192.51 | 143.4 | 0.35 | 0.72 | 0.88 | 2.42 | |

| 60 | 80 | 236.60 | 191.6 | 0.41 | 0.87 | 1.12 | 2.14 | |

| 80 | 100 | 234.11 | 201.3 | 0.5 | 1.13 | 1.43 | 1.99 |

| Sample Number | Θ (°) | Peak Load (kN) | Damage Displacement (mm) | Diameter (mm) | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| 1 | 0 | 6.08 | 0.46 | 25 | 6.19 |

| 2 | 30 | 13.41 | 0.67 | 25 | 13.67 |

| 3 | 45 | 11.29 | 0.59 | 25 | 11.50 |

| 4 | 60 | 8.84 | 0.53 | 25 | 9.01 |

| 5 | 90 | 6.99 | 0.53 | 25 | 7.13 |

| Parameters | Sample | ||

|---|---|---|---|

| S2 | S6 | S8 | |

| Mass/g | 65.91 | 62.89 | 65.93 |

| Diameter/mm | 24.61 | 24.62 | 24.80 |

| Length/mm | 51.65 | 48.79 | 51.32 |

| Density | 2.68 | 2.71 | 2.66 |

| Longitudinal wave speed m/s | 4340 | 4435 | 4138 |

| Shear wave speed m/s | 2821 | 3015 | 3015 |

| Confining pressure/MPa | 20 | 20 | 20 |

| Compressive strength/MPa | 153.1 | 97.4 | 123.73 |

| Elastic modulus/GPa | 18.97 | 22.63 | 20.05 |

| Poisson’s ratio | 0.141 | 0.184 | 0.119 |

| Uniaxial compressive strength (MPa) | 52.03 | 34.95 | 38.43 |

| Sample | Confining Pressure (MPa) | Temperature (°C) | Axial Deviatoric Stress (MPa) | Resistant to Stress Strength (MPa) | Yang’s Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|---|---|---|

| S2 | 0 | 20 | 52.03 | 52.03 | 17.92 | 0.125 |

| 20 | 40 | 153.1 | 173.1 | 18.97 | 0.141 | |

| 40 | 60 | 208.1 | 248.1 | 21.47 | 0.126 | |

| 60 | 80 | 281.8 | 341.8 | 21.03 | 0.161 | |

| 80 | 100 | 293.7 | 373.7 | 21.91 | 0.135 | |

| S6 | 0 | 20 | 34.95 | 34.95 | 18.97 | 0.112 |

| 20 | 40 | 97.4 | 117.4 | 22.63 | 0.184 | |

| 40 | 60 | 160.2 | 200.2 | 42.78 | 0.282 | |

| 60 | 80 | 208.1 | 268.1 | 46.11 | 0.263 | |

| 80 | 100 | 215.2 | 295.2 | 45.79 | 0.249 | |

| S8 | 0 | 20 | 38.43 | 38.43 | 14.58 | 0.105 |

| 20 | 40 | 123.73 | 143.73 | 20.05 | 0.119 | |

| 40 | 60 | 192.51 | 233.73 | 22.68 | 0.109 | |

| 60 | 80 | 236.60 | 296.60 | 22.96 | 0.107 | |

| 80 | 100 | 234.11 | 314.11 | 25.12 | 0.143 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kong, L.; Tuzingila, R.M.; Wang, Z.; Jiang, S.; Lenzo, R.S. Experimental Research on Petrophysical, Geomechanical Features, and Fracture Behaviors of Organic-Rich Marine Shale. J. Mar. Sci. Eng. 2025, 13, 2245. https://doi.org/10.3390/jmse13122245

Kong L, Tuzingila RM, Wang Z, Jiang S, Lenzo RS. Experimental Research on Petrophysical, Geomechanical Features, and Fracture Behaviors of Organic-Rich Marine Shale. Journal of Marine Science and Engineering. 2025; 13(12):2245. https://doi.org/10.3390/jmse13122245

Chicago/Turabian StyleKong, Lingyun, Romulus Mawa Tuzingila, Zihang Wang, Shu Jiang, and Rais Seki Lenzo. 2025. "Experimental Research on Petrophysical, Geomechanical Features, and Fracture Behaviors of Organic-Rich Marine Shale" Journal of Marine Science and Engineering 13, no. 12: 2245. https://doi.org/10.3390/jmse13122245

APA StyleKong, L., Tuzingila, R. M., Wang, Z., Jiang, S., & Lenzo, R. S. (2025). Experimental Research on Petrophysical, Geomechanical Features, and Fracture Behaviors of Organic-Rich Marine Shale. Journal of Marine Science and Engineering, 13(12), 2245. https://doi.org/10.3390/jmse13122245