Upgrade and Application of the Dynamic Positioning System for a Small Waterplane Area Twin Hull Vessel

Abstract

1. Introduction

2. Materials and Methods

2.1. Mathematical Model of Ship Manoeuvring

2.2. Environmental Load Calculation

2.2.1. Wind Load

2.2.2. Wave Load

2.2.3. Current Load

3. Results

3.1. Upgrade of the Dynamic Positioning System

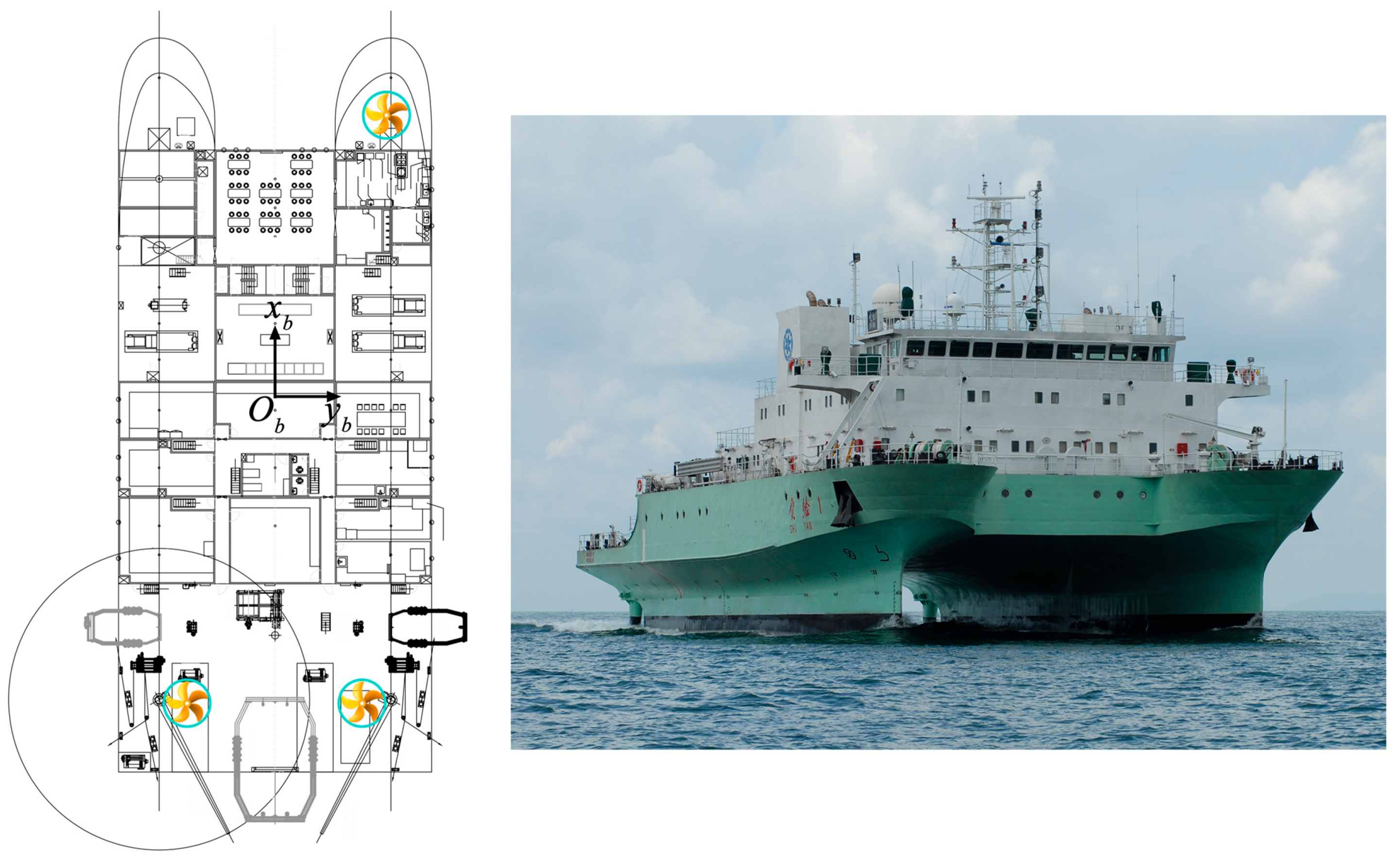

3.1.1. R/V SHIYAN 1

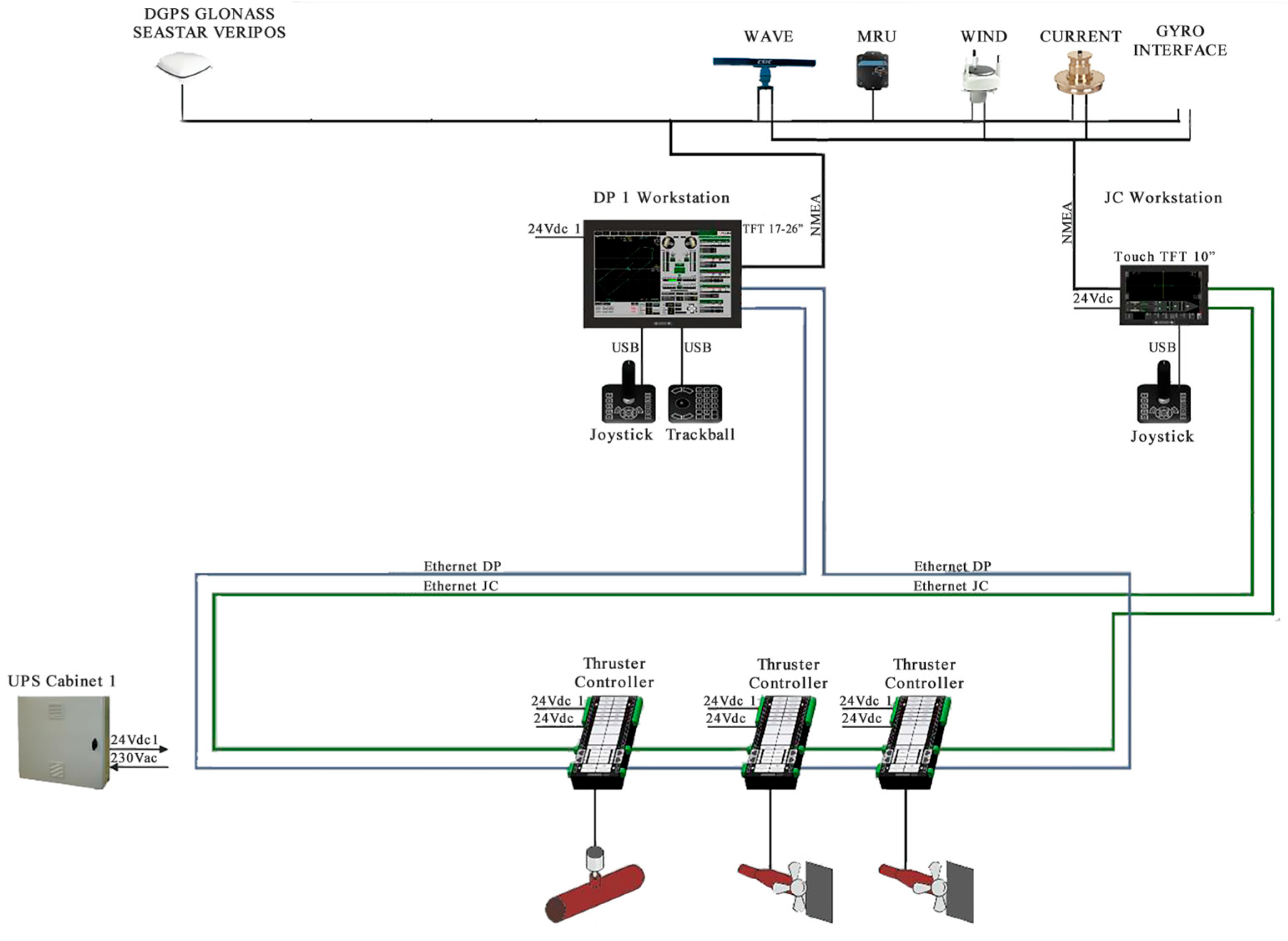

3.1.2. The MEGA-GUARD System

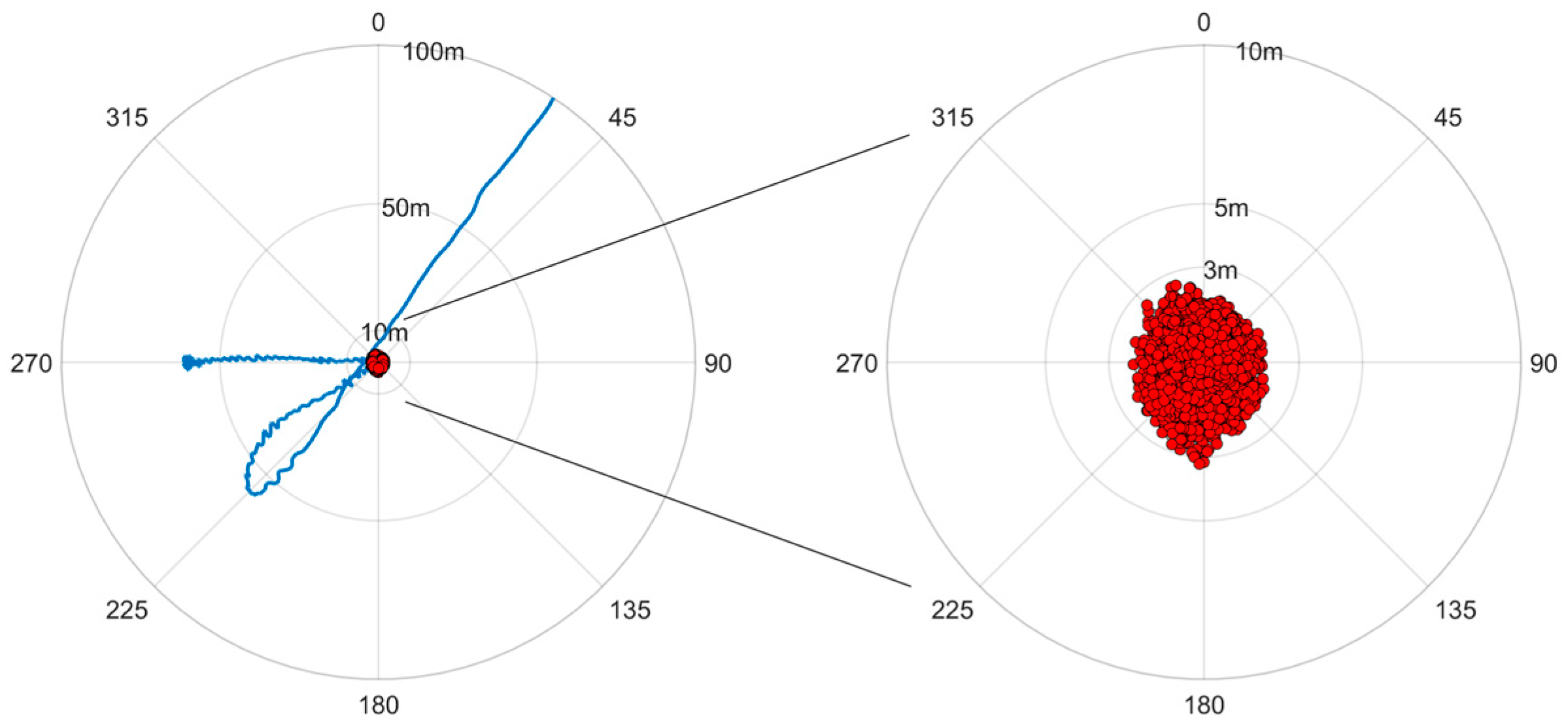

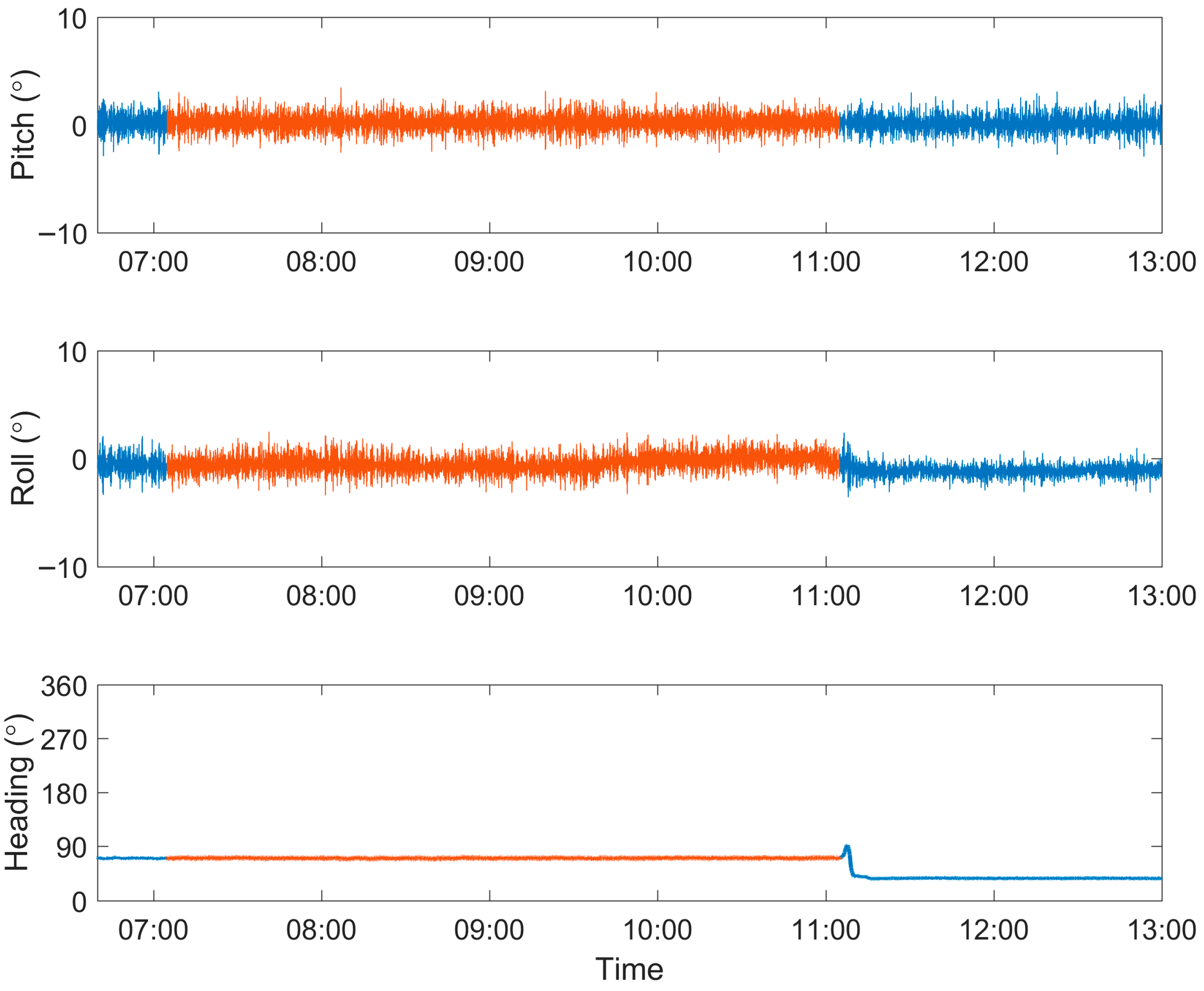

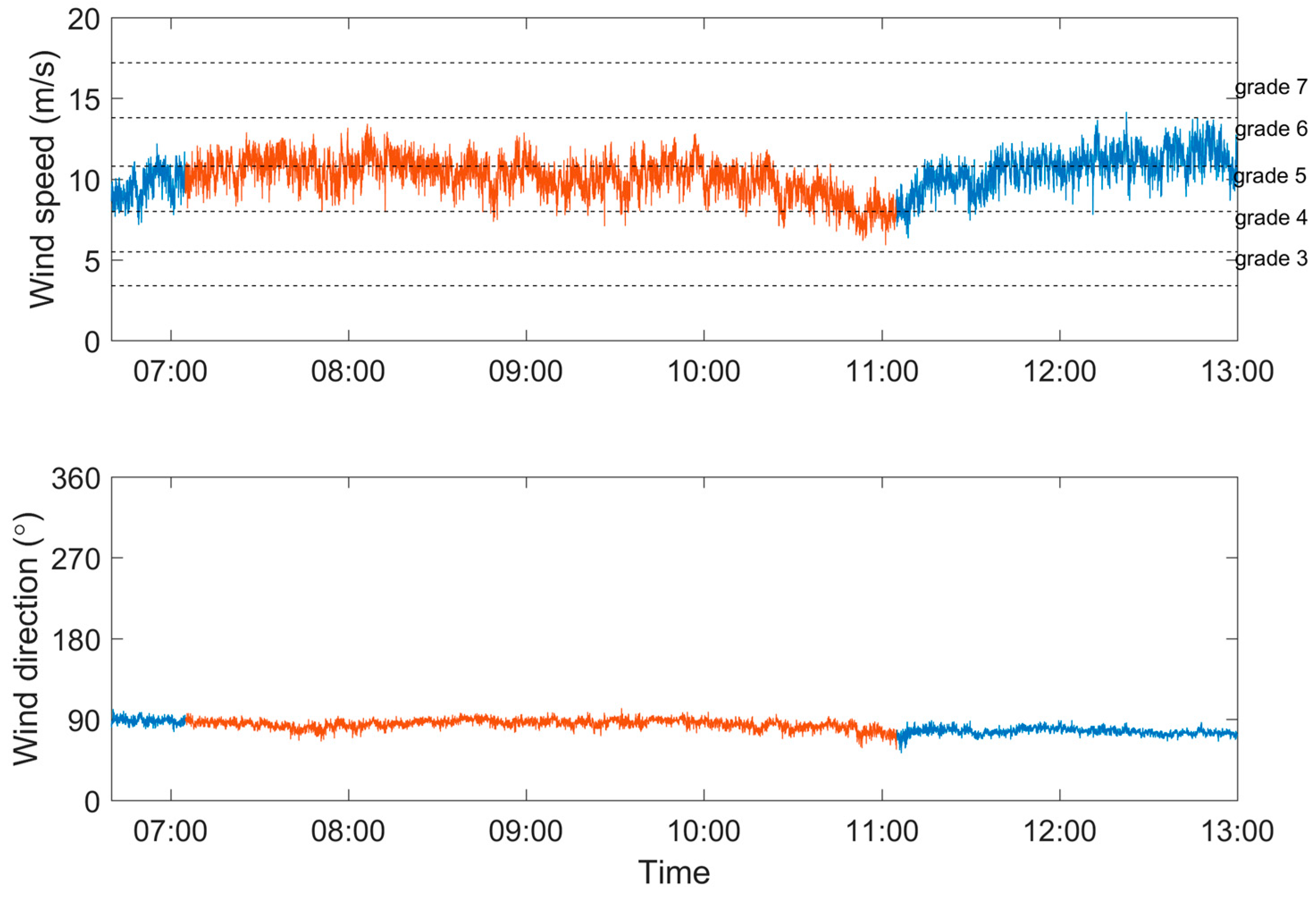

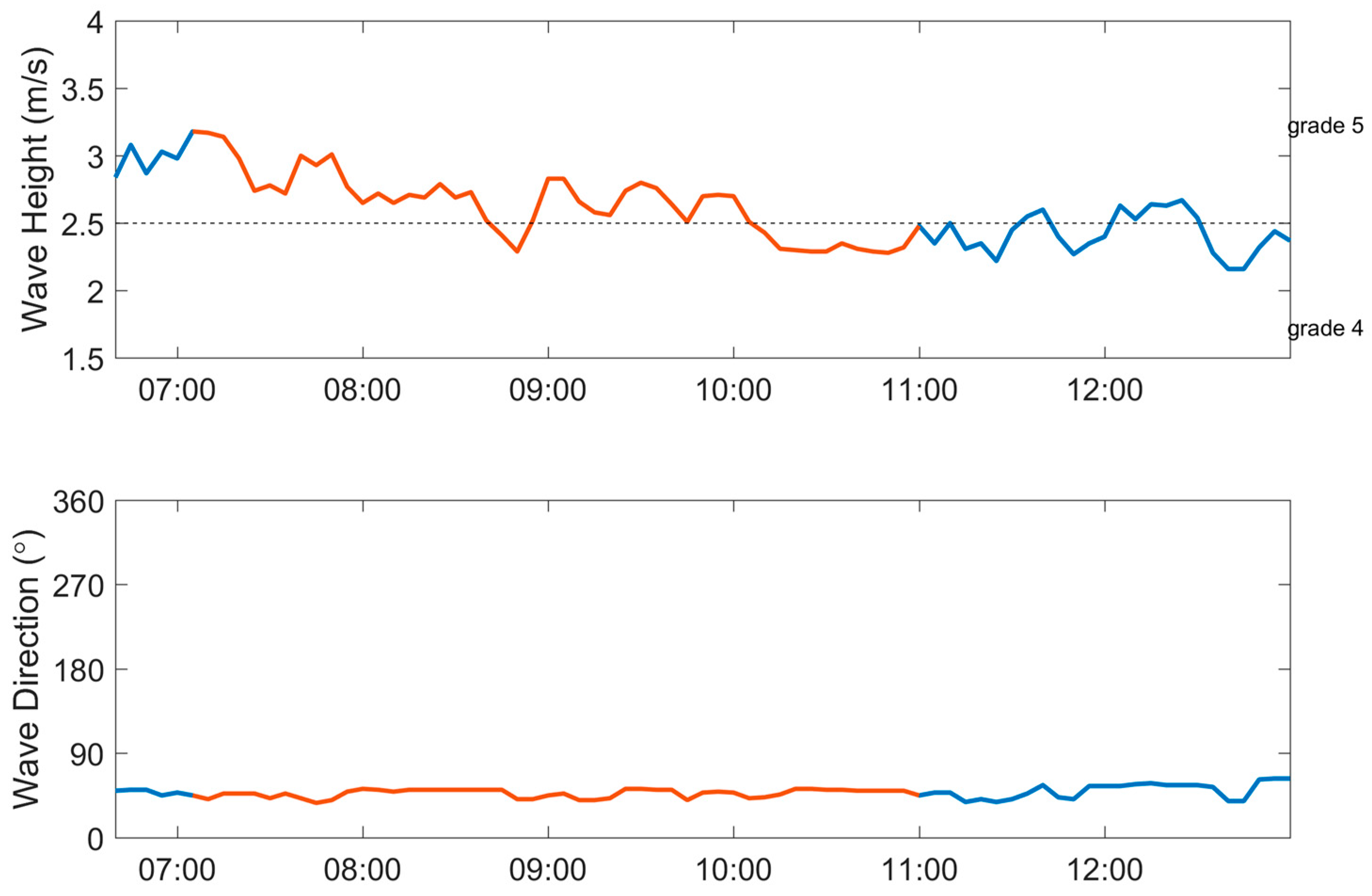

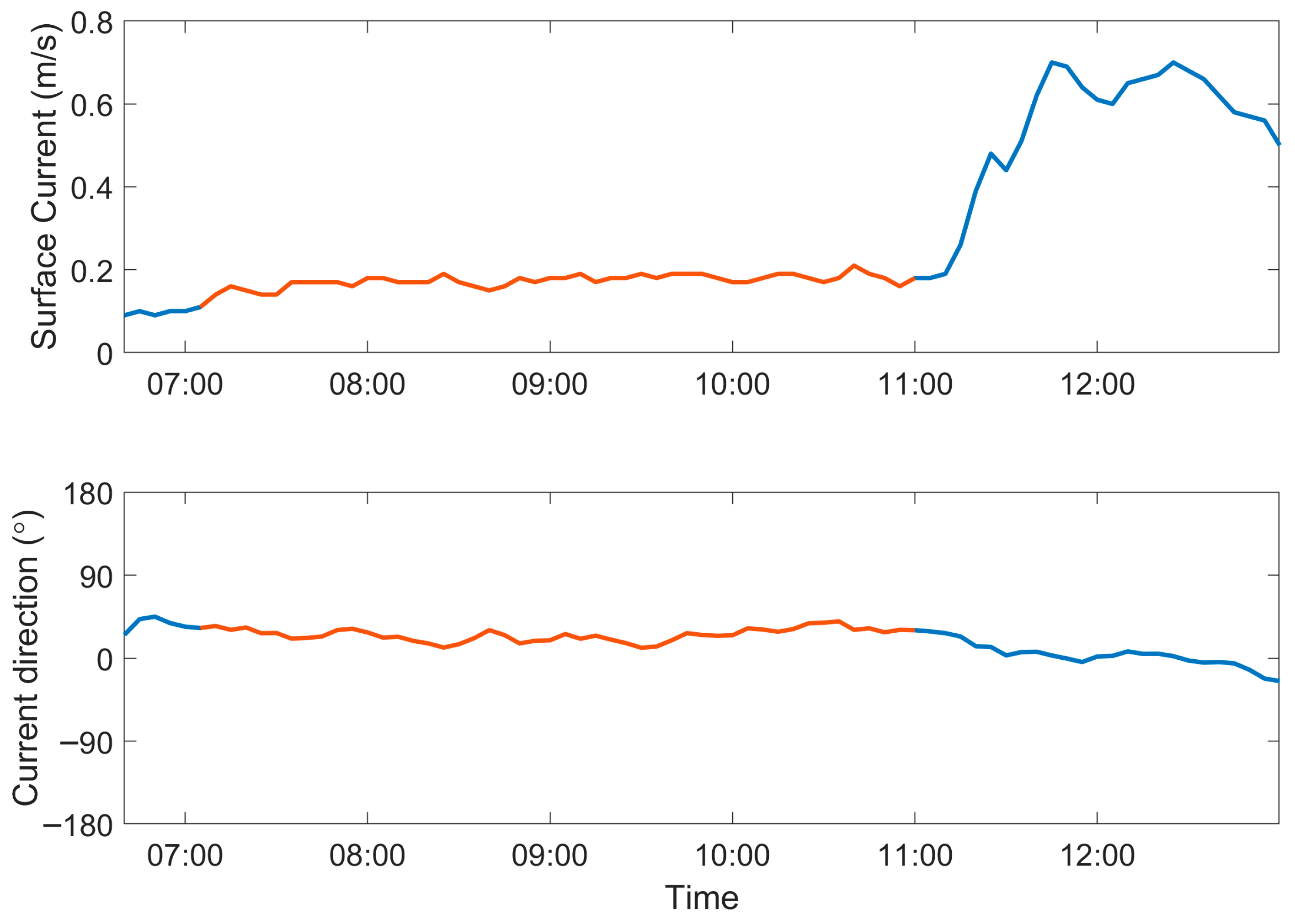

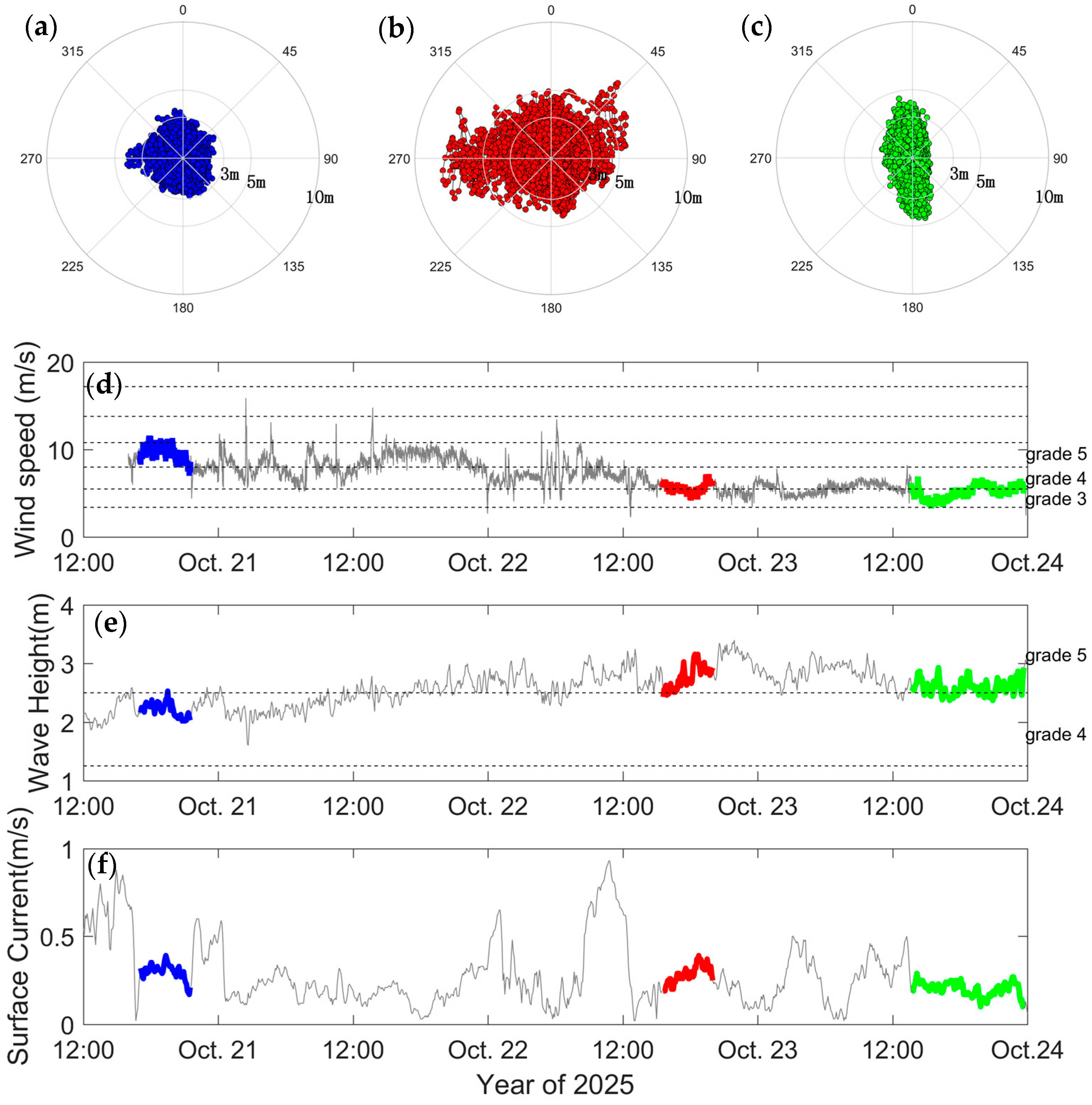

3.2. Application of Offshore Experiments

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Warren, N.F. What Future for Semi-Submersible Twin-Hull Ship. Nav. Archit. 1977, 2, 53–55. [Google Scholar]

- Campana, E.F.; DiMascio, A.; Esposito, P.G. Domain decomposition technique for the design of twin hull ship. Hydrodyn. Theory Appl. 1996, 1–2, 59–64. [Google Scholar]

- Kamil, M.S.; Muslim, M.; Ali, I. Solving Wave Flow Energy Propagated by Twin-Hull Ships (Catamarans). J. Phys. Conf. Ser. 2017, 822, 012057. [Google Scholar] [CrossRef]

- Pirsalami, A.G.; Yousefifard, M.; Nowruzi, H. Interference effects on hydrodynamic characteristics of twin-hull ship in calm water and regular waves. Ships Offshore Struct. 2025, 1–13. [Google Scholar] [CrossRef]

- Ni, B.Y.; Semenov, Y.A. Impulsive impact of a twin hull. J. Fluid Mech. 2024, 983, A16. [Google Scholar] [CrossRef]

- Prokofiev, V.V.; Arkhangelsky, E.A.; Boyko, A.V.; Filatov, E.V. Using the Wave Propulsors in a Small-Waterplane-Area-Twin-Hull Boat. Fluid Dyn. 2023, 58, 19–30. [Google Scholar] [CrossRef]

- Kunugi, M.; Fujimori, K.; Nakano, T. Development of observation systems for global-scale marine pollution with persistent organic pollutants deployed on voluntary observation ships. Bunseki Kagaku 2006, 55, 835–845. [Google Scholar] [CrossRef]

- Dubrovsky, V.A.; Matveev, K.I. Small waterplane area ship models: Reanalysis of test results based on scale effect and form drag. Ocean Eng. 2006, 33, 950–963. [Google Scholar] [CrossRef]

- Davis, M.R.; Holloway, D.S. The influence of hull form on the motions of high speed vessels in head seas. Ocean Eng. 2003, 30, 2091–2115. [Google Scholar] [CrossRef]

- Techet, A.H. Propulsive performance of biologically inspired flapping foils at high Reynolds number. J. Exp. Biol. 2008, 211, 274–279. [Google Scholar] [CrossRef]

- Qian, P.; Yi, H.; Li, Y. Numerical and experimental studies on hydrodynamic performance of a small-waterplane-area-twin- hull (swath) vehicle with inclined struts. Ocean Eng. 2015, 96, 181–191. [Google Scholar] [CrossRef]

- Torben, T.R.; Teel, A.R.; Kjerstad, O.K.; Wittemann, E.H.T.; Skjetne, R. A Resetting Observer for Linear Time-Varying Systems With Application to Dynamic Positioning of Marine Surface Vessels. IEEE Trans. Control Syst. Technol. 2024, 32, 1048–1056. [Google Scholar] [CrossRef]

- Fossen, T.I. Handbook of Marine Craft Hydrodynamics and Motion Control; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Bargoth, N.; Dalen, C.; Di Ruscio, D. Dynamic positioning, system identification and control of marine vessels. Model. Identif. Control 2022, 43, 111–117. [Google Scholar] [CrossRef]

- Athanasia, A.; Anne-Bénédicte, G.; Jacopo, M. The offshore wind market deployment: Forecasts for 2020, 2030 and impacts on the European supply chain development. Energy Procedia 2012, 24, 2–10. [Google Scholar] [CrossRef]

- Neves, K.L.S.; Dotta, R.; Malta, E.B.; Neto, A.G.; Franzini, G.R.; Bitencourt, L.A.G.B. A digital twin to predict failure probability of an FPSO hull based on corrosion models. J. Mar. Sci. Technol. 2023, 28, 862–875. [Google Scholar] [CrossRef]

- Mu, D.D.; Feng, Y.P.; Wang, G.F.; Fan, Y.S.; Zhao, Y.S. Single-parameter-learning-based robust adaptive control of dynamic positioning ships considering thruster system dynamics in the input saturation state. Nonlinear Dyn. 2022, 110, 395–412. [Google Scholar] [CrossRef]

- Li, L.; Yang, H.T.; Zhang, Y.; Ma, Q. Dynamic positioning error analysis and modeling of CNC machine tool guideway system. J. Mech. Sci. Technol. 2021, 35, 1955–1967. [Google Scholar] [CrossRef]

- Fossen, T.I. A survey on nonlinear ship control: From theory to practice. IFAC Proc. Vol. 2000, 33, 1–16. [Google Scholar] [CrossRef]

- Tannuri, E.A.; Donha, D.C.; Pesce, C.P. Dynamic positioning of a turret moored FPSO using sliding mode control. Int. J. Robust Nonlinear Control 2001, 11, 1239–1256. [Google Scholar] [CrossRef]

- Arditti, F.; Souza, F.L.; Martins, T.C.; Tannuri, E.A. Thrust allocation algorithm with efficiency function dependent on the azimuth angle of the actuators. Ocean Eng. 2015, 105, 206–216. [Google Scholar] [CrossRef]

- Ruth, E. Propulsion Control and Thrust Allocation on Marine Vessels. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, July 2008. [Google Scholar]

- Balchen, J.G.; Jenssen, N.A.; Sælid, S. Dynamic positioning using Kalman filtering and optimal control theory. In Proceedings of the IFAC/IFIP Symposium on Automation in Offshore Oil Field Operation, Bergen, Norway, 14–17 June 1976; pp. 183–186. [Google Scholar]

- Saelid, S.; Jenssen, N.; Balchen, J. Design and analysis of a dynamic positioning system based on Kalman filtering and optimal control. IEEE Trans. Autom. Control 1983, AC-28, 331–339. [Google Scholar] [CrossRef]

- Grimble, M.J.; Johnson, M.A. Optimal Control and Stochastic Estimation: Theory and Applications; Wiley: Hoboken, NJ, USA, 1986. [Google Scholar]

- Fossen, T.I.; Sagatun, S.I.; Sørensen, A.J. Identification of dynamically positioned ships. Control Eng. Pract. 1996, 4, 369–376. [Google Scholar] [CrossRef]

- Tannuri, E.A.; Donha, D.C. H∞ controller design for dynamic positioning of a turret moored FPSO. IFAC Proc. Vol. 2000, 33, 263–268. [Google Scholar] [CrossRef]

- Perez, T.; Donaire, A. Constrained control design for dynamic positioning of marine vehicles with control allocation. Model. Identif. Control 2009, 30, 57–70. [Google Scholar] [CrossRef]

- Stephens, R.I.; Burnham, K.J.; Reeve, P.J. A practical approach to the design of fuzzy controllers with application to dynamic ship positioning. IFAC Proc. Vol. 1995, 28, 370–377. [Google Scholar] [CrossRef]

- Fossen, T.I.; Grovlen, A. Nonlinear output feedback control of dynamically positioned ships using vectorial observer backstepping. IEEE Trans. Control Syst. Technol. 1998, 6, 121–128. [Google Scholar] [CrossRef]

- Tannuri, E.A.; Agostinho, A.C.; Morishita, H.M.; Moratelli, L. Dynamic positioning systems: An experimental analysis of sliding mode control. Control Eng. Pract. 2010, 18, 1121–1132. [Google Scholar] [CrossRef]

- Hespanha, J.P.; Morse, A.S. Switching between stabilizing controllers. Automatica 2002, 38, 1905–1917. [Google Scholar] [CrossRef]

- Hespanha, J.P.; Liberzon, D.; Morse, A.S. Hysteresis-based switching algorithms for supervisory control of uncertain systems. Automatica 2003, 39, 263–272. [Google Scholar] [CrossRef]

- Sørensen, A.J.; Quek, S.T.; Nguyen, T.D. Improved operability and safety of DP vessels using hybrid control concept. In Proceedings of the International Conference on Technology & Operation of Offshore Support Vessels, Singapore, 20–21 September 2005; pp. 11–21. [Google Scholar]

- Nguyen, D.T.; Blanke, M.; Sørensen, A.J. Diagnosis and fault tolerant control for thruster-assisted position mooring. IFAC Proc. Vol. 2007, 40, 287–292. [Google Scholar] [CrossRef]

- Blanke, M.; Kinnaert, M.; Lunze, J.; Staroswiecki, M.; Schröder, J. Diagnosis and Fault-Tolerant Control; Springer: Heidelberg, Germany, 2006. [Google Scholar]

- Nguyen, T.D.; Sørensen, A.J.; Quek, S.T. Design of hybrid con troller for dynamic positioning from calm to extreme sea conditions. Automatica 2007, 43, 768–785. [Google Scholar] [CrossRef]

- Fang, S.; Blanke, M. Fault monitoring and fault recovery control for position-moored vessels. Int. J. Appl. Math. Comput. Sci. 2011, 21, 467–478. [Google Scholar] [CrossRef]

- Kalikatzarakis, M.; Coraddu, A.; Oneto, L.; Anguita, D. Optimizing Fuel Consumption in Thrust Allocation for Marine Dynamic Positioning Systems. IEEE Trans. Autom. Sci. Eng. 2022, 19, 122–142. [Google Scholar] [CrossRef]

- Fossen, T.I. A survey of control allocation methods for ships and underwater vehicles. In Proceedings of the 2006 14th Mediterranean Conference on Control and Automation, Ancona, Italy, 28–30 June 2006; pp. 1–6. [Google Scholar]

- Sørensen, A.J. A survey of dynamic positioning control systems. Annu. Rev. Control 2011, 35, 123–136. [Google Scholar] [CrossRef]

- Wynn, P. A note on the generalised Euler transformation. Comput. J. 1971, 14, 437–441. [Google Scholar] [CrossRef]

- IMCA. Specification for DP Capability Plots; The International Marine Contractors Association: London, UK, 2000. [Google Scholar]

- Akgün, M.A.; Garcelon, J.H.; Haftka, R.T. Fast exact linear and non-linear structural reanalysis and the Sherman–Morrison–Woodbury formulas. Int. J. Numer. Methods Eng. 2001, 50, 1587–1606. [Google Scholar] [CrossRef]

- De Kat, J.O.; Wichers, J.E.W. Behavior of a moored ship in unsteady current, wind, and waves. Mar. Technol. SNAME News 1991, 28, 251–264. [Google Scholar] [CrossRef]

- Faltinsen, O. Sea Loads on Ships and Offshore Structures; Cambridge Univ. Press: Cambridge, UK, 1993. [Google Scholar]

- He, C.D. Design of Dynamically Positioning System of Scientific Survey Ship “Ocean No. 1”. Ship Eng. 2004, 26, 2. (In Chinese) [Google Scholar]

| Main | Total Length | 60.9 m |

|---|---|---|

| Parameters | Breadth | 26 m |

| Depth | 10.5 m | |

| Draft | 6.5 m | |

| Gross Tonnage | 3071 | |

| Net Tonnage | 921 | |

| Maximum Speed | 15 knots | |

| Endurance | 8000 n miles | |

| Sustainability | 40 days | |

| Capacity | 72 | |

| Ship Type | SWATH | |

| Powertrain | Main Propulsion | 1700 kW × 2 |

| Bow Thruster | 440 kW | |

| Generator Set | 1600 kw × 3 + 380 kW |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ying, J.; Mao, H.; Wei, Z.; Qi, Y.; Wu, B.; Xuan, C.; Yu, L.; Qi, Z.; Wang, X.; Li, X.; et al. Upgrade and Application of the Dynamic Positioning System for a Small Waterplane Area Twin Hull Vessel. J. Mar. Sci. Eng. 2025, 13, 2198. https://doi.org/10.3390/jmse13112198

Ying J, Mao H, Wei Z, Qi Y, Wu B, Xuan C, Yu L, Qi Z, Wang X, Li X, et al. Upgrade and Application of the Dynamic Positioning System for a Small Waterplane Area Twin Hull Vessel. Journal of Marine Science and Engineering. 2025; 13(11):2198. https://doi.org/10.3390/jmse13112198

Chicago/Turabian StyleYing, Jinling, Huabin Mao, Zhiyuan Wei, Yongfeng Qi, Biqing Wu, Chuyin Xuan, Linghui Yu, Ze Qi, Xingyue Wang, Xianpeng Li, and et al. 2025. "Upgrade and Application of the Dynamic Positioning System for a Small Waterplane Area Twin Hull Vessel" Journal of Marine Science and Engineering 13, no. 11: 2198. https://doi.org/10.3390/jmse13112198

APA StyleYing, J., Mao, H., Wei, Z., Qi, Y., Wu, B., Xuan, C., Yu, L., Qi, Z., Wang, X., Li, X., & Wu, K. (2025). Upgrade and Application of the Dynamic Positioning System for a Small Waterplane Area Twin Hull Vessel. Journal of Marine Science and Engineering, 13(11), 2198. https://doi.org/10.3390/jmse13112198