Experimental Study on Three-Degree-of-Freedom Ventilated Cavities for Underwater Vehicles Considering the Air Mass near the Tube

Abstract

1. Introduction

2. Experimental Setup

2.1. Experimental Equipment

2.2. Parameter Settings

2.3. Experimental Reliability Verification

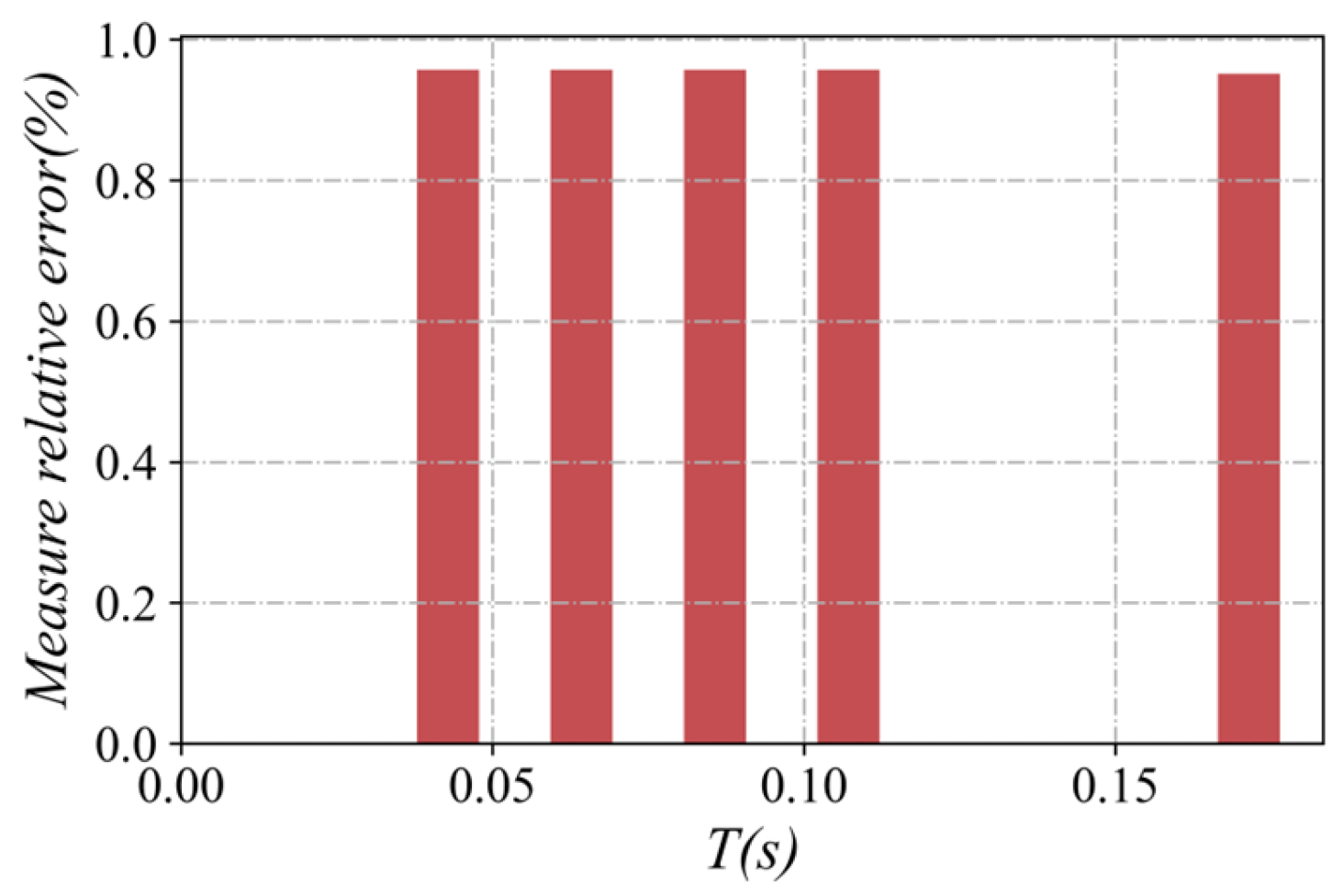

2.3.1. Repeatability Test

2.3.2. Measurement Uncertainty Analysis

3. Results

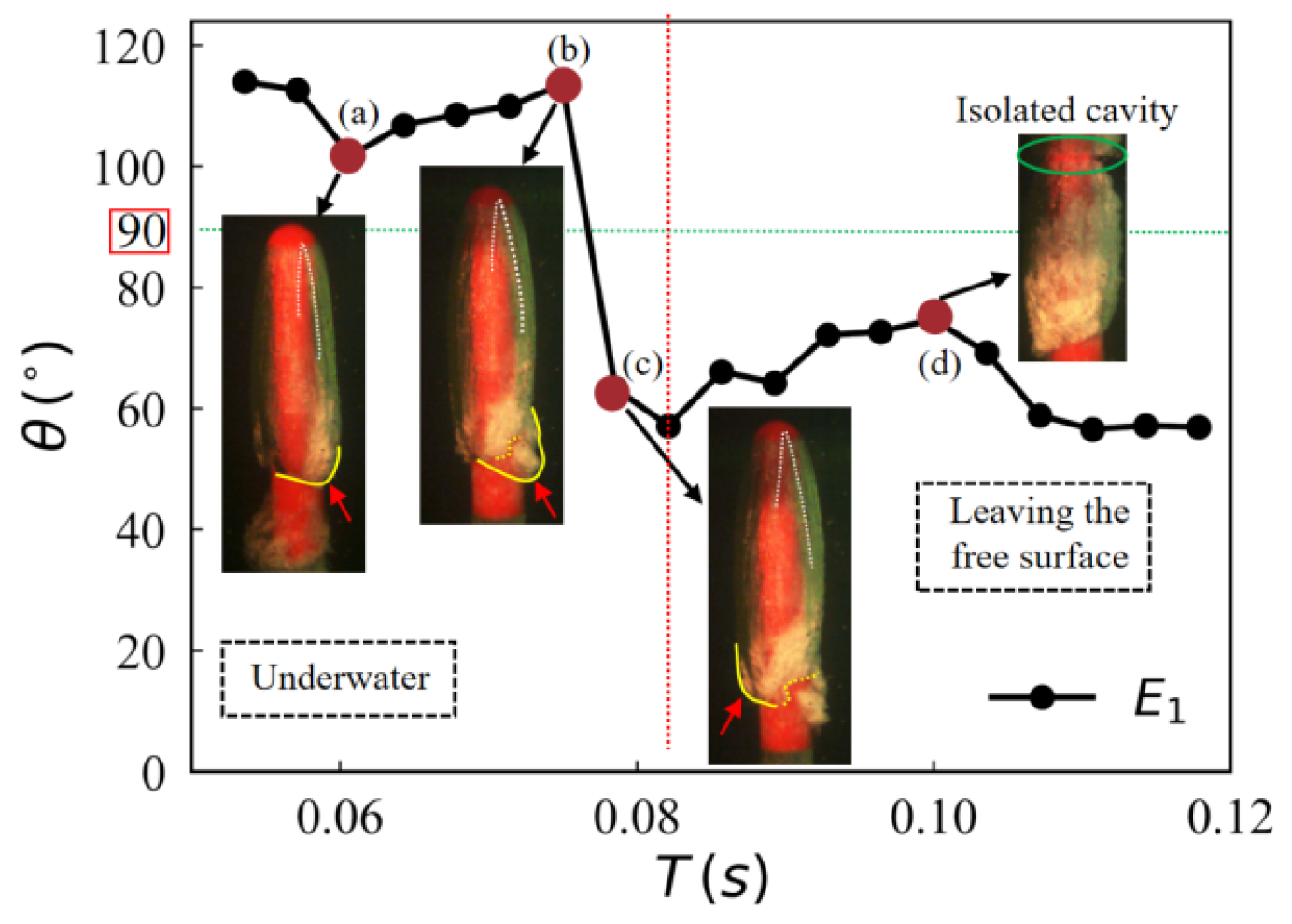

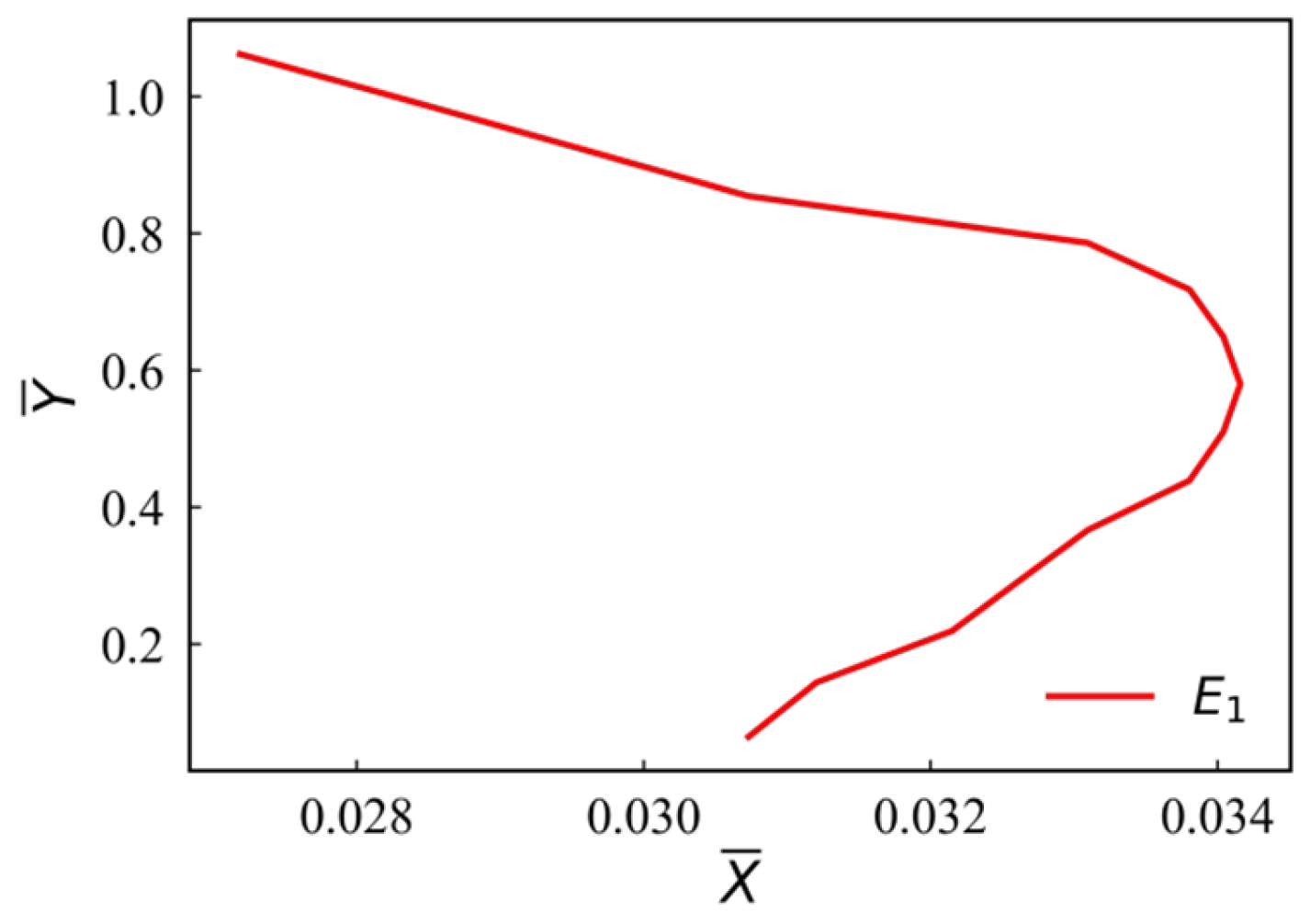

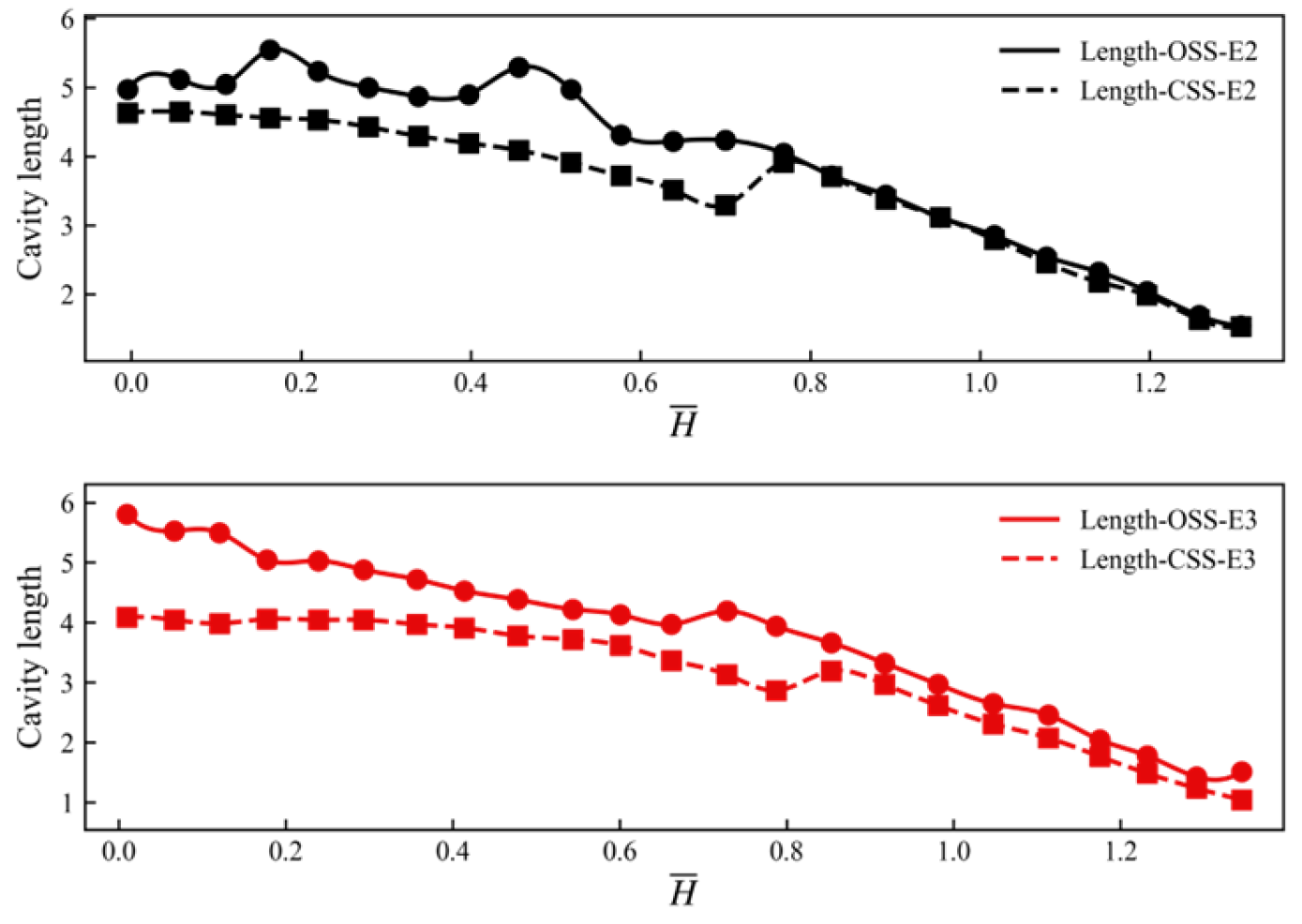

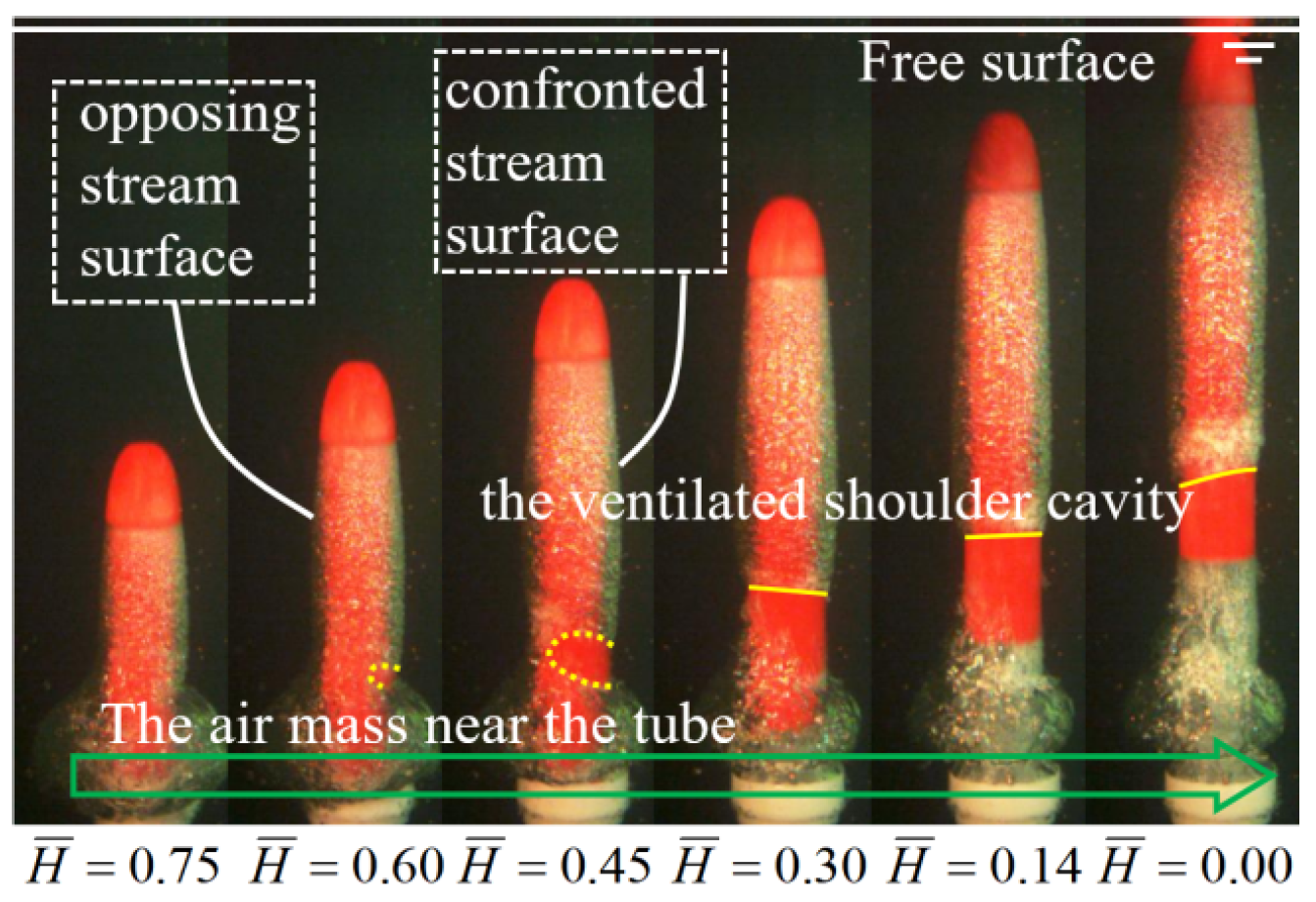

3.1. Effect of Transverse Velocity on the Ventilated Cavity of a Hemispherical-Headed Vehicle

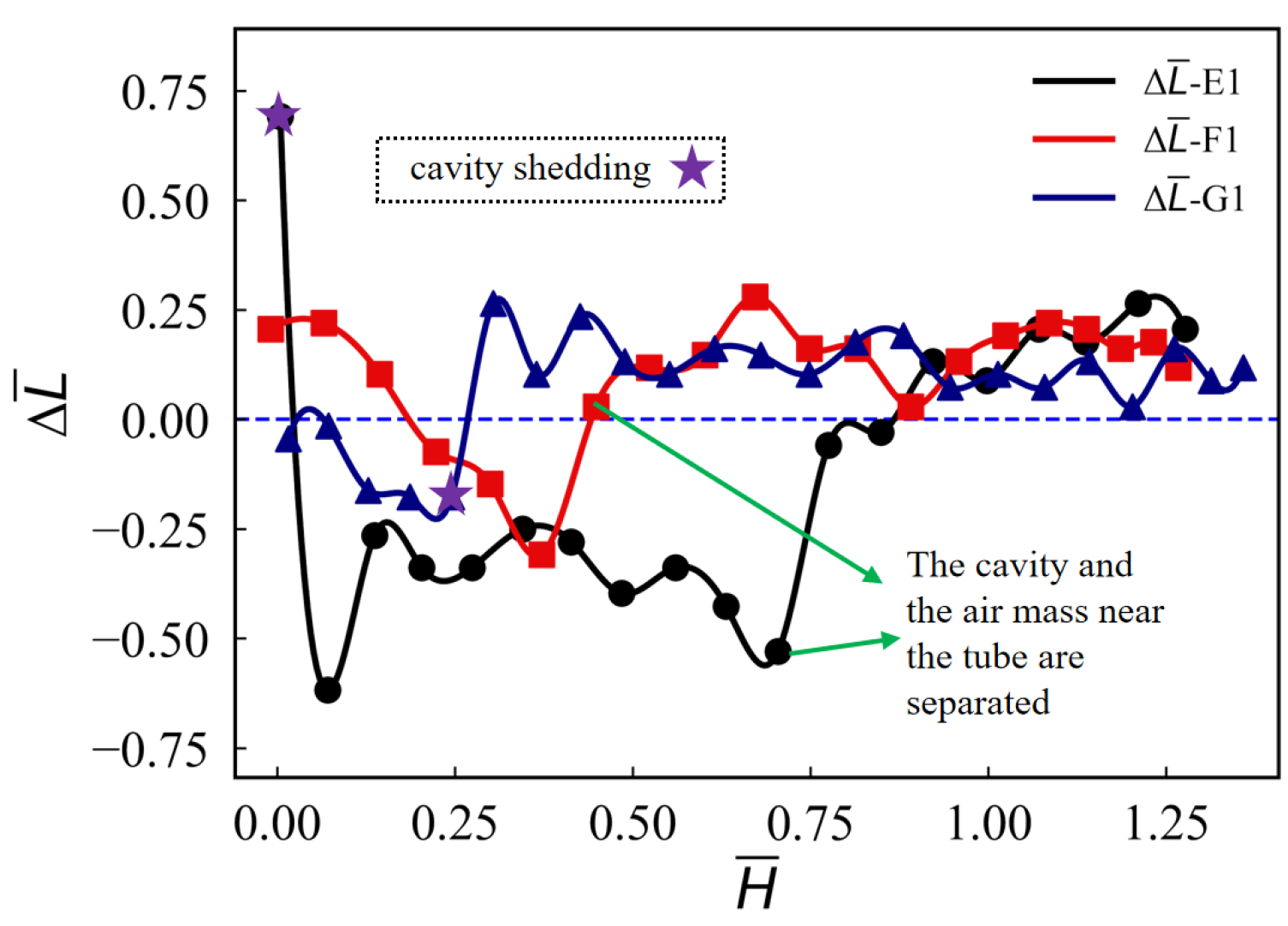

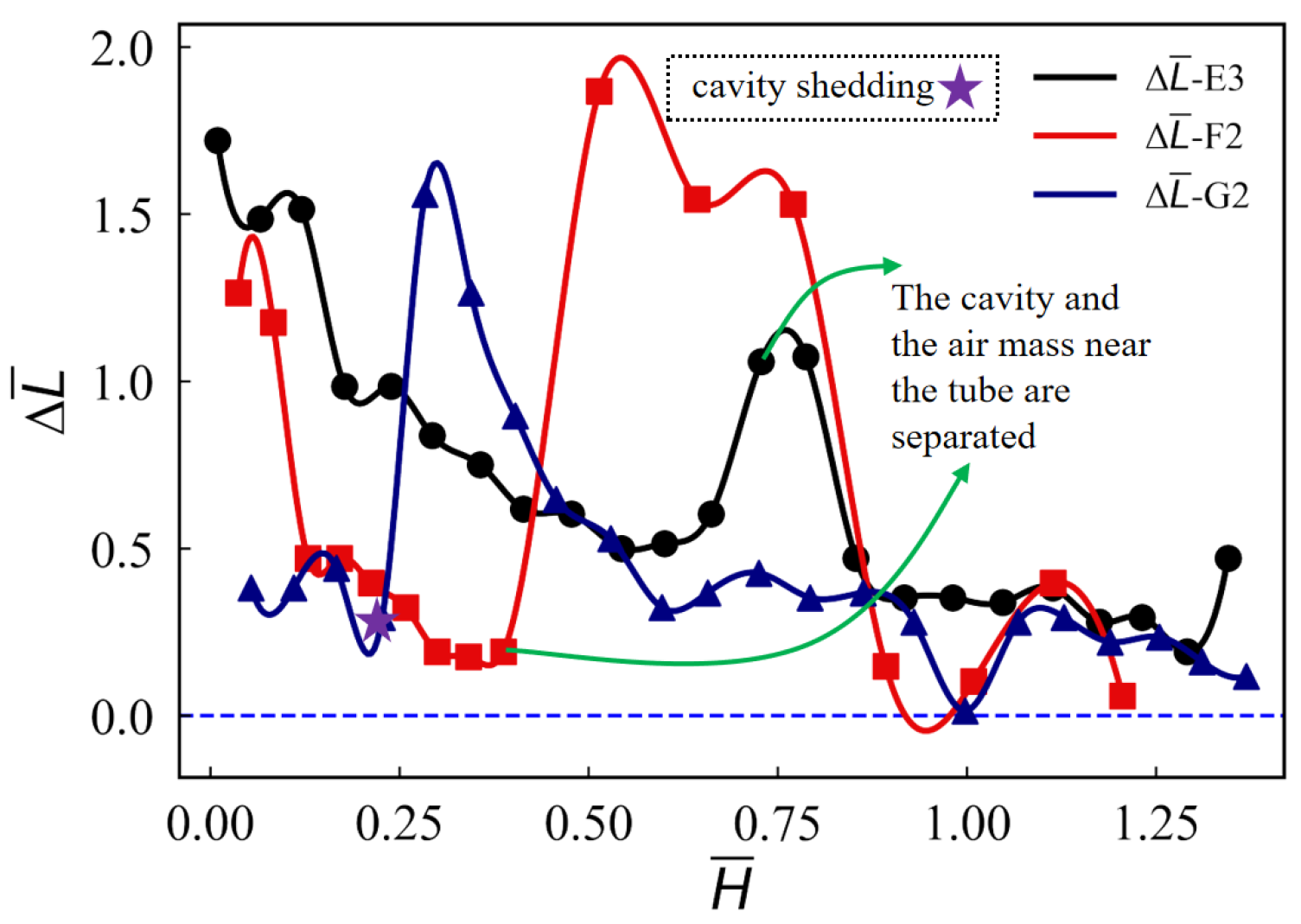

3.2. Effects of Different Transverse Velocities on the Evolution of Ventilated Cavities

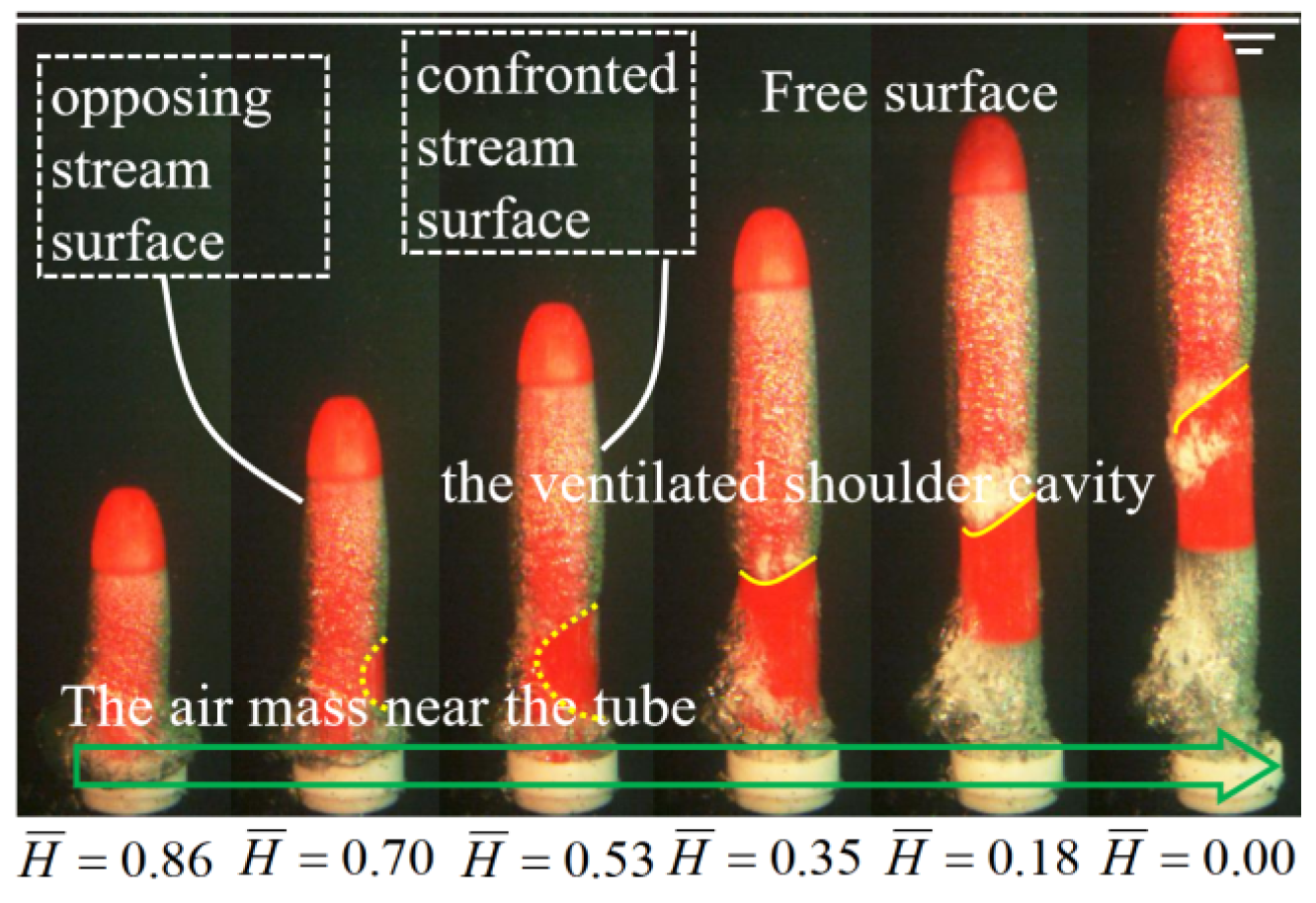

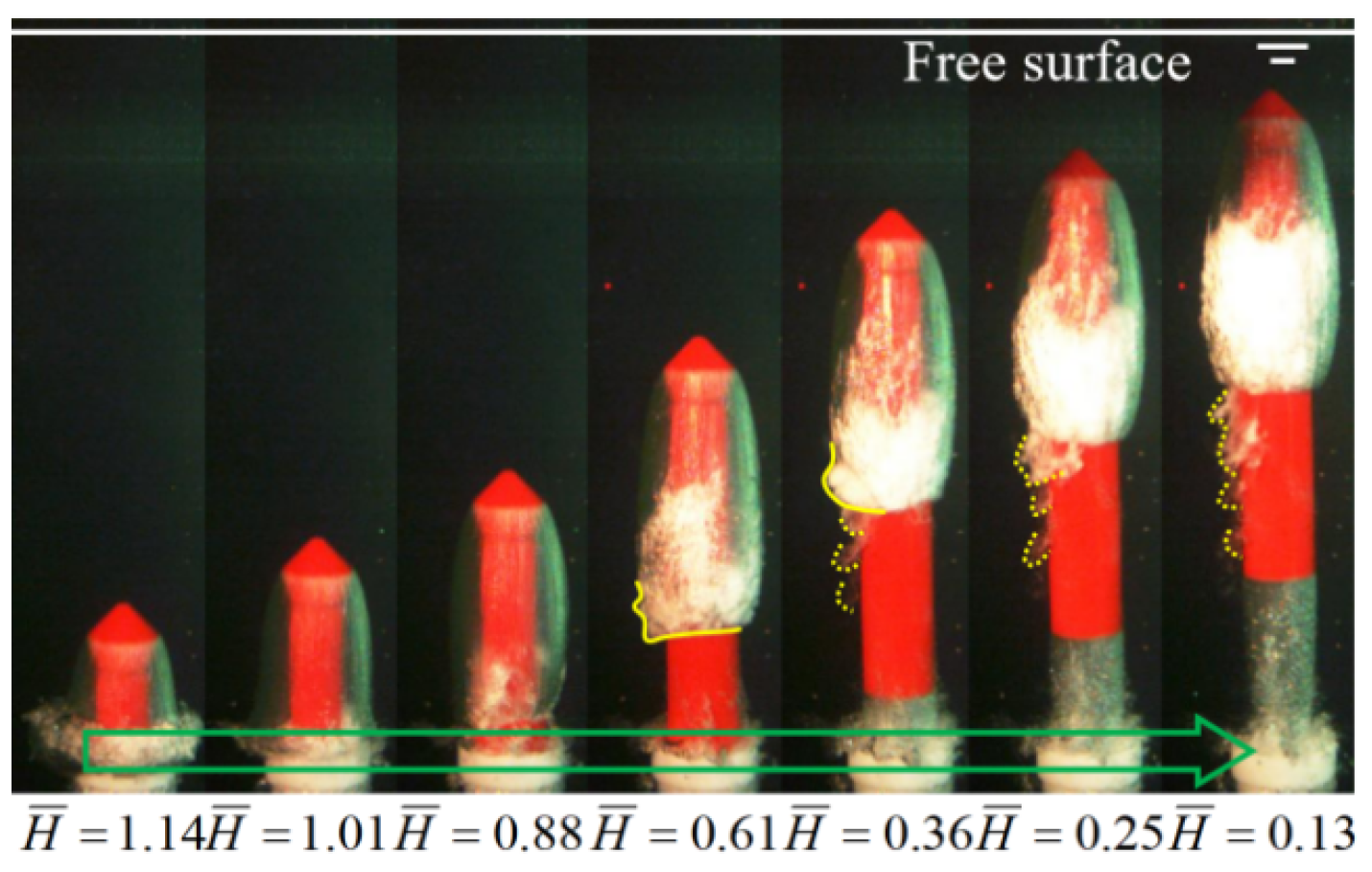

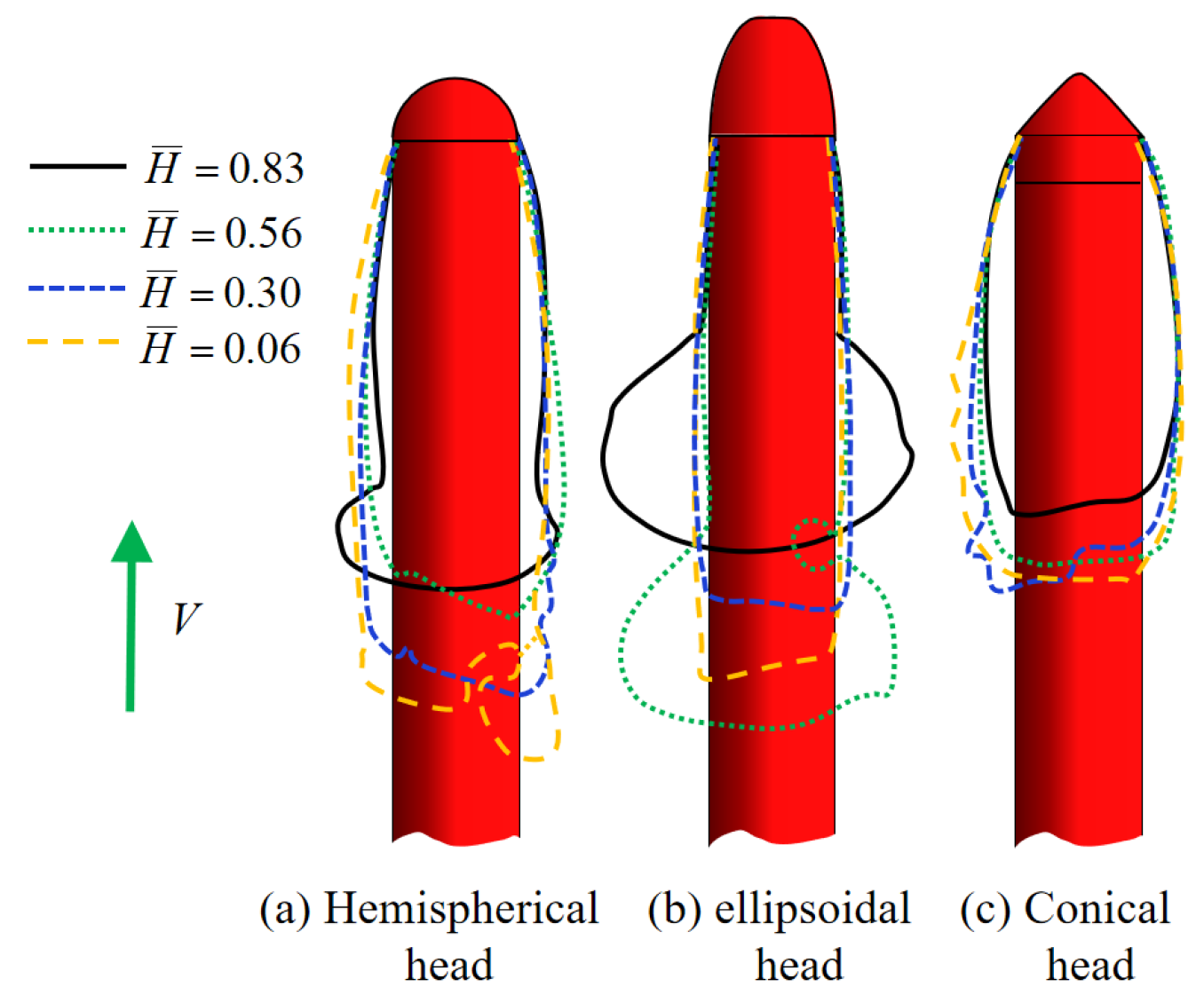

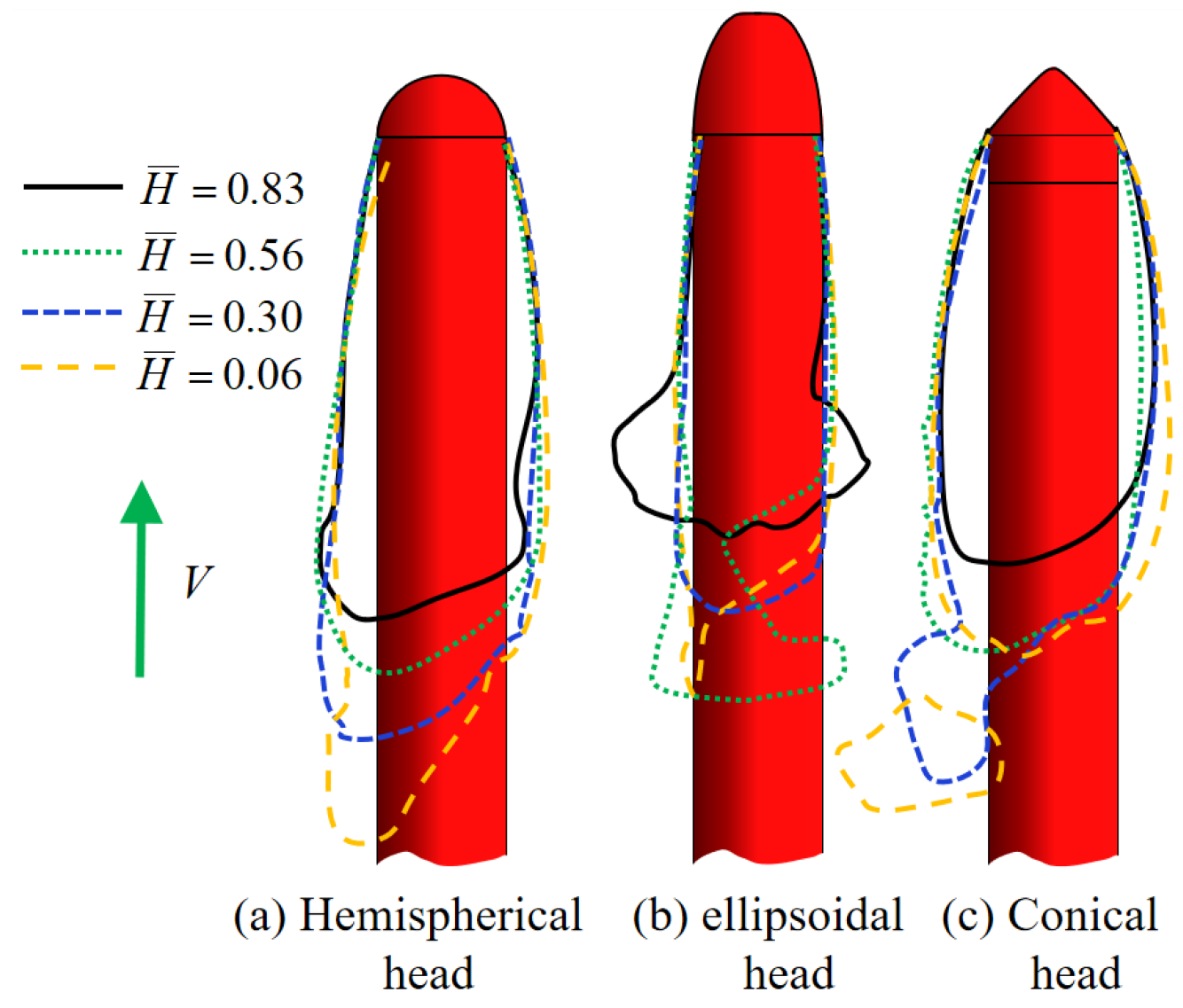

3.3. Effect of Vehicle Head Shape on the Evolution of Ventilated Cavities

4. Conclusions

- (1)

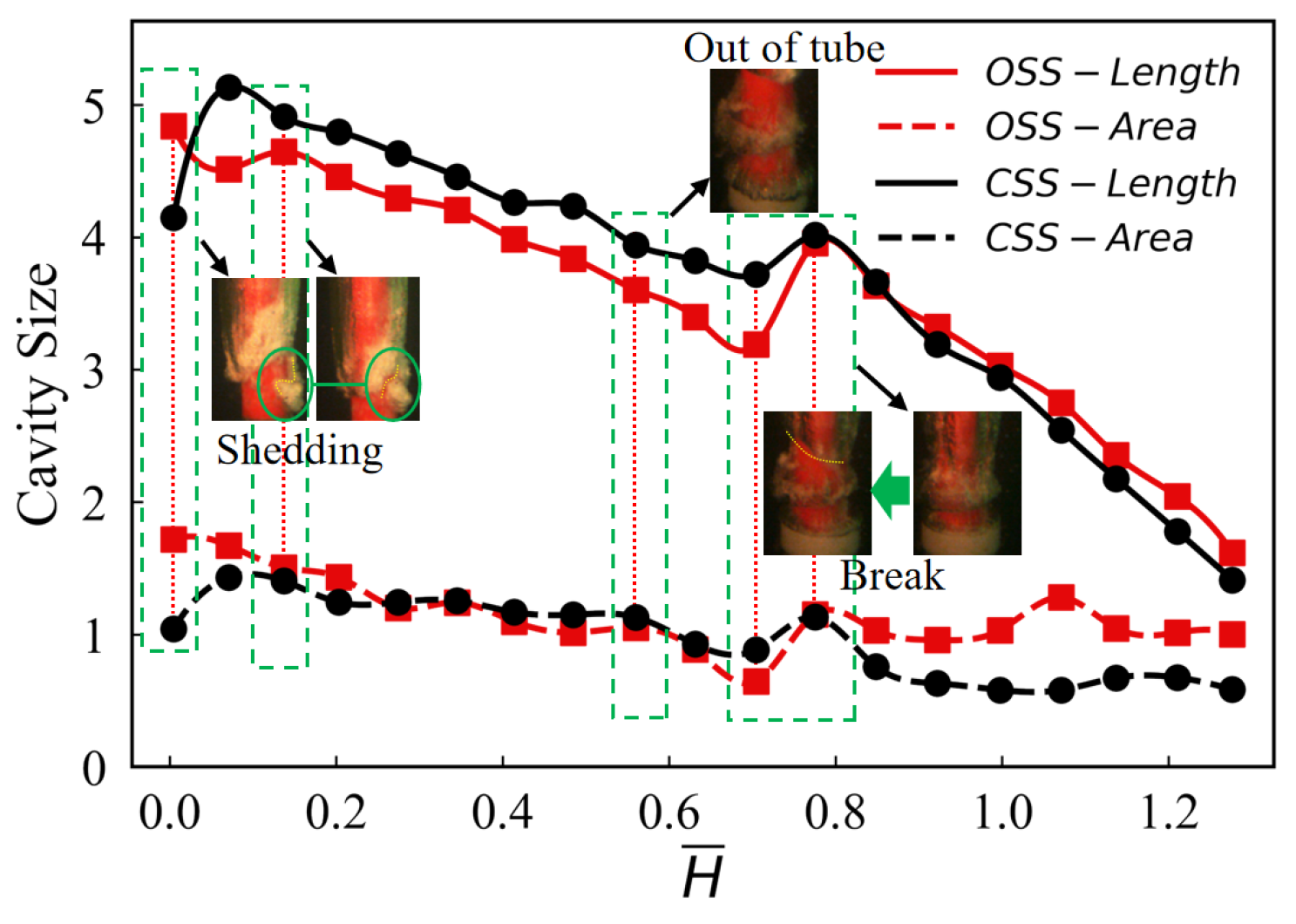

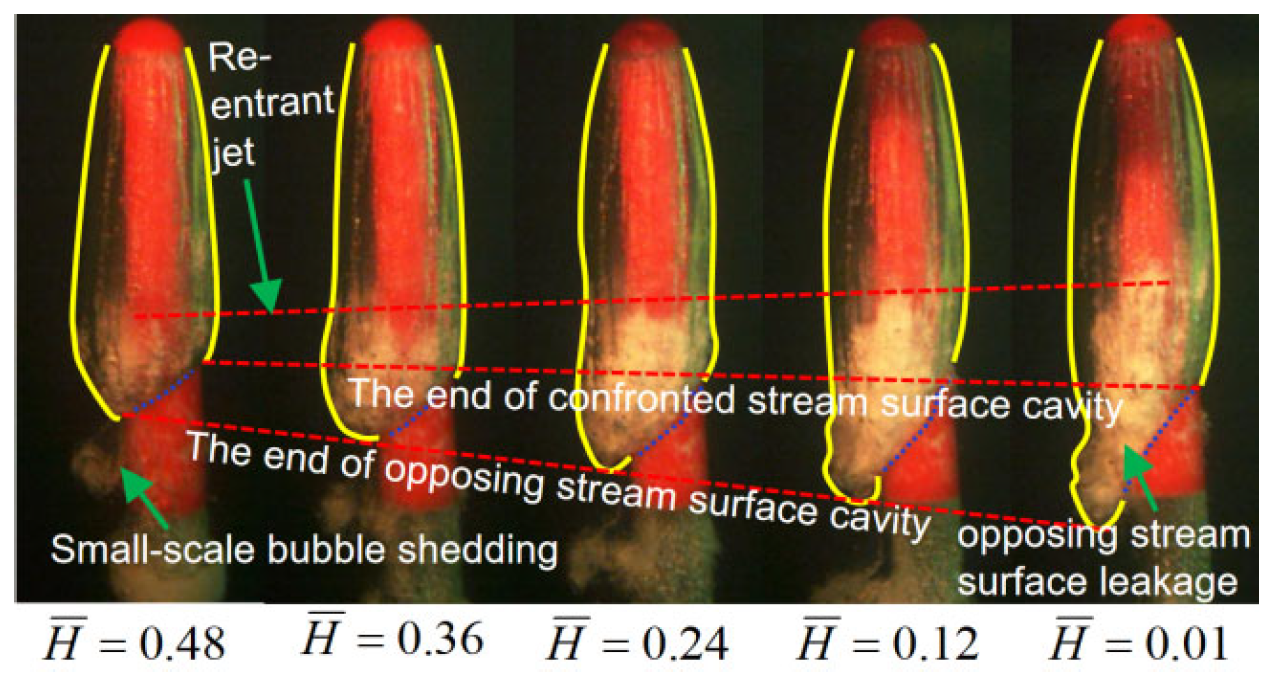

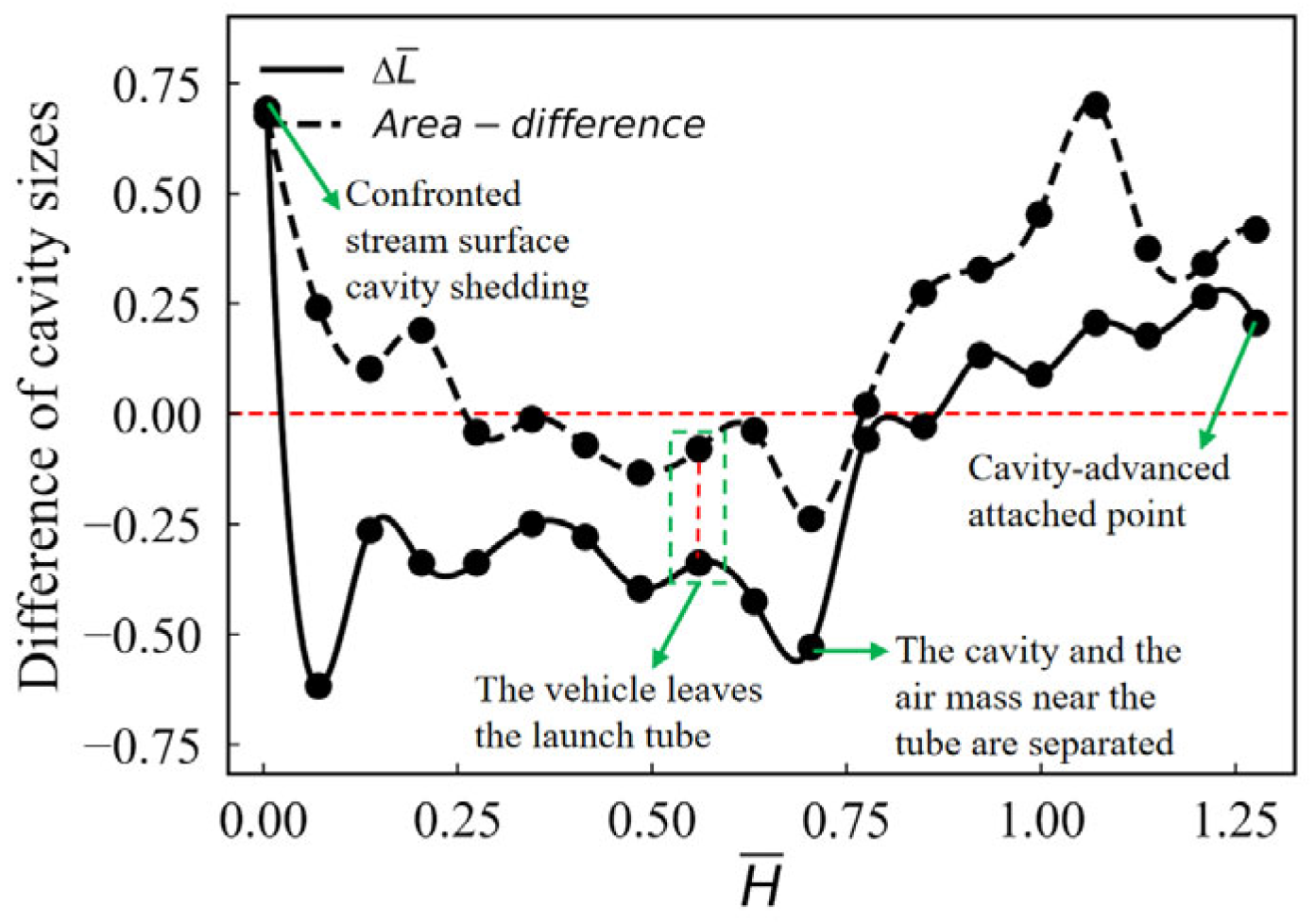

- The transverse motion of the launch tube induces asymmetry in the flow of AMNT and the ventilated shoulder cavity toward the OSS. The shoulder region of hemispherical-headed vehicle is prone to developing cavity pre-positioning point. The cavity pre-positioning point appearing on the CSS significantly increases the axial dimension of the CSS cavity. However, the flushing effect of the transverse flow on the CSS cavity suppresses the difference in the projected area between the CSS and OSS cavity caused by axial dimensional changes. Under the effect of transverse velocity, the underwater trajectory of the vehicle underwent transverse deceleration and movement in the direction opposite that of the launch tube.

- (2)

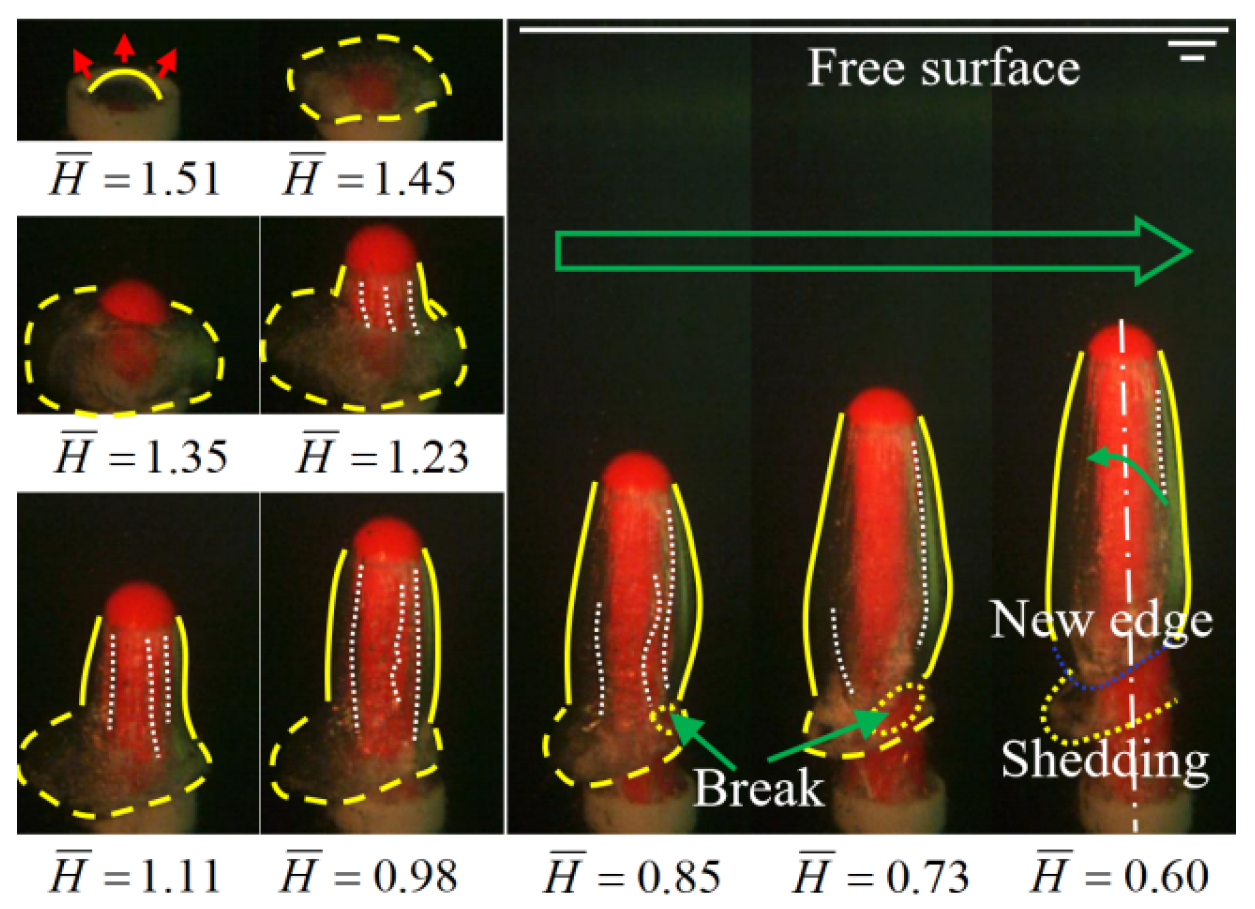

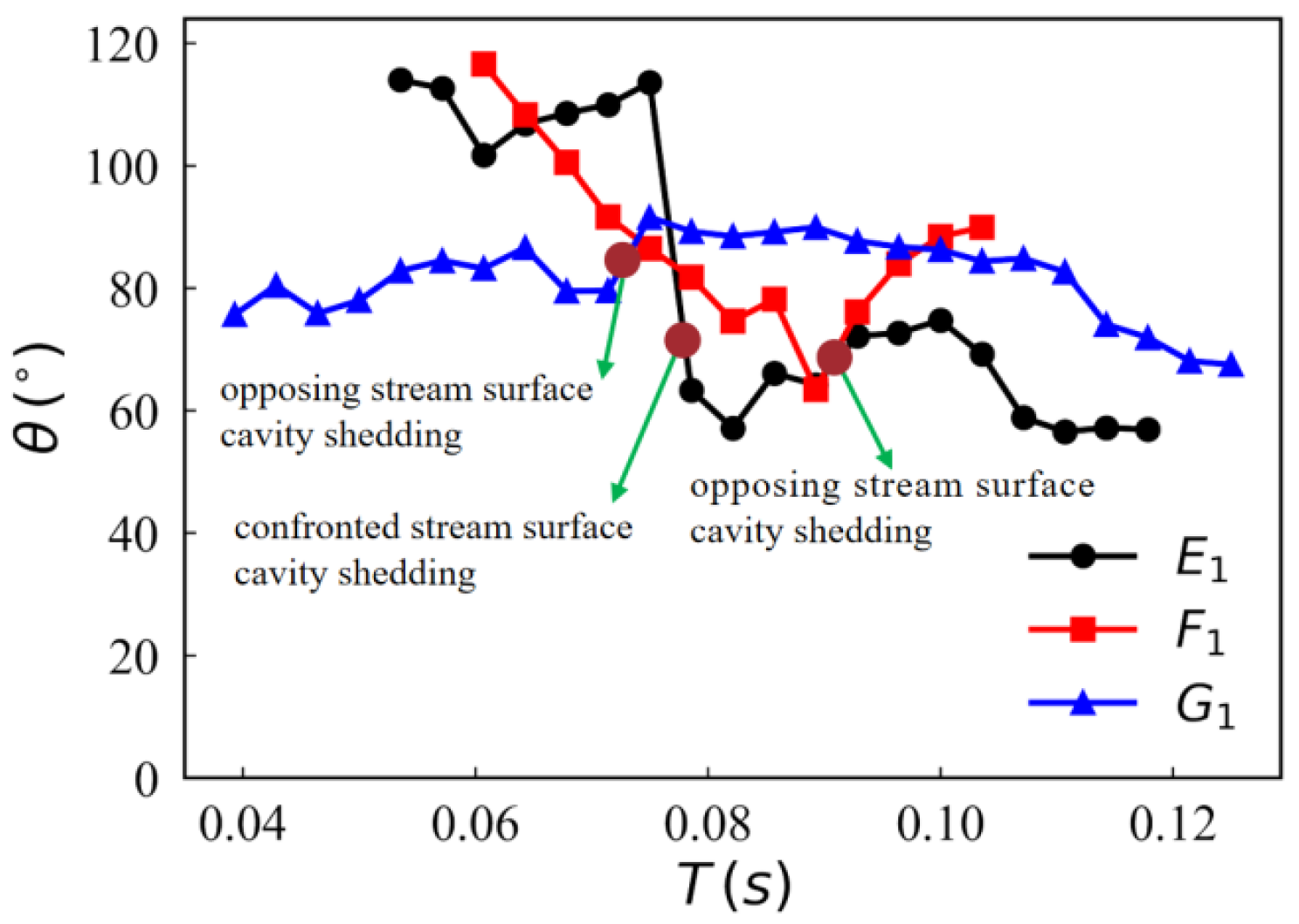

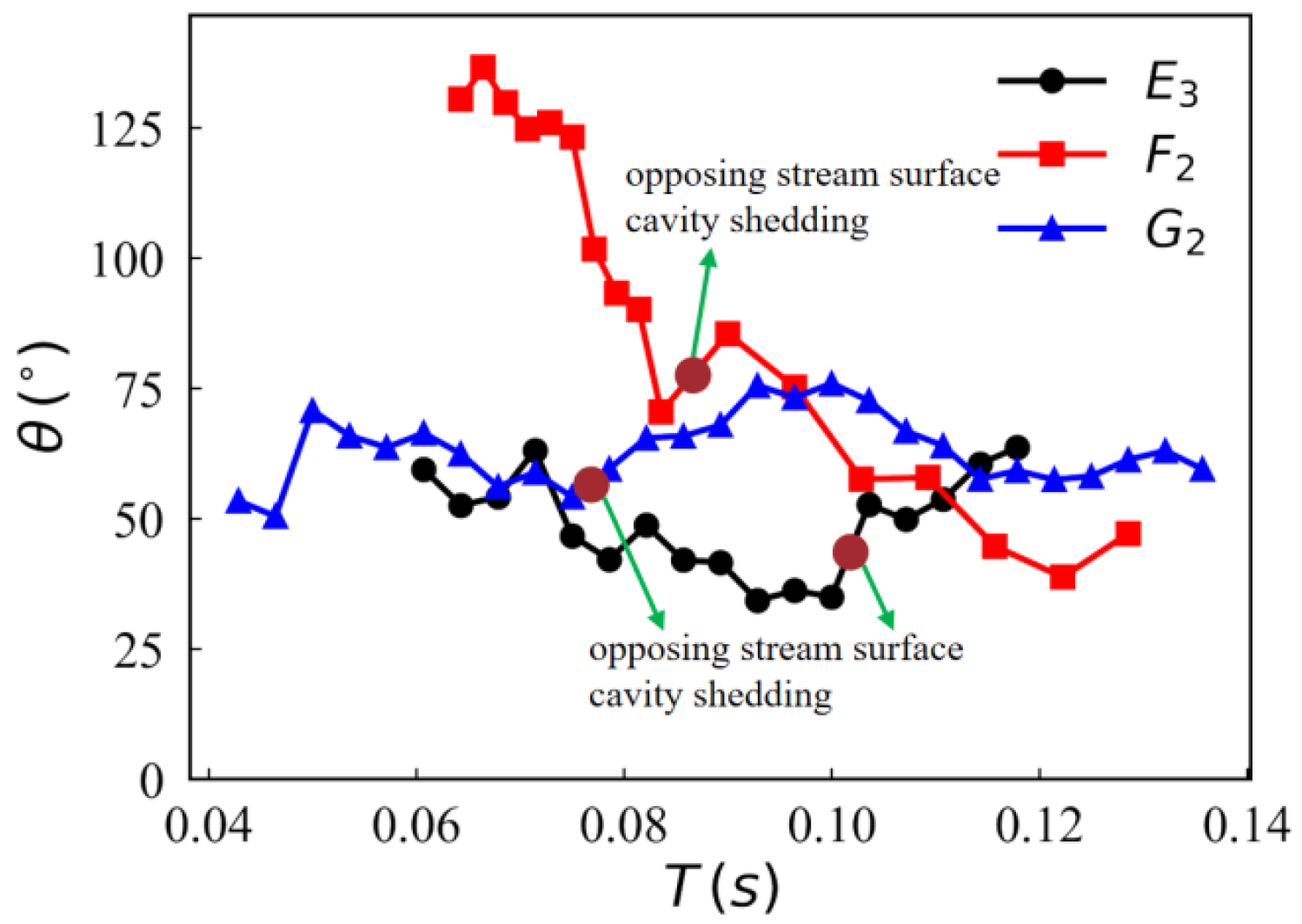

- The transverse velocity’s increase leads to the transverse displacement’s increase in the vehicle out of the tube. The degree of trajectory deflection due to horizontal reverse displacement after the vehicle exits the tube increases with increasing transverse velocity. The cavity pre-positioning point of the hemispherical-headed vehicle’s shoulder cavity moves toward the OSS as the transverse velocity increases, until it disappears. The OSS and CSS cavity difference increases with increasing transverse velocity. The flushing action of the transverse flow enhances the stability of the CSS cavity. The shedding phenomenon at the end of the OSS cavity is enhanced with increasing transverse velocity. The shedding pattern of cavities has transformed from a hairpin vortex shedding one by one to a vortex pile-up shedding. The primary reasons for varying the closure angle at the cavity end are separation from AMNT and shedding at the cavity end.

- (3)

- The starting position of the cavity’s leading edge is directly related to the curvature of the vehicle’s head shape. The shoulder curvature of the conical-headed vehicle undergoes an abrupt change. The starting position of the cavity’s leading edge is located at the point of maximum curvature above the venting seam. The hemispherical-headed vehicle is prone to developing a pre-positioning point. The elliptical-headed vehicle exhibits good shoulder transition with no significant pre-positioning point. The gas shedding volume at the end of the ventilated cavity of an ellipsoidal-headed vehicle is minimal. Under small transverse velocity (vt = 0.2 m/s), if no cavity pre-positioning point exists, the cavity difference oscillates around the zero mark. The trajectory deflection is minimal after the vehicle exits the tube. Under large transverse velocity (vt = 0.6 m/s), the cavity difference undergoes violent changes when the closing line at the cavity end regenerates. The trajectory deflection is greatest after the vehicle exits the tube. Due to the influence of the vehicle’s ability to carry AMNT out of the tube, the initial closure angle at the end of the cavity of the ellipsoidal-headed vehicle is greater than 90°.

- (4)

- Under the influence of transverse velocity, the asymmetrical development of the ventilated shoulder cavity occurs. The shoulder–tail cavity of the ellipsoidal-headed vehicle exhibits a “layered progressive fusion” pattern. The two cavities of the hemispherical-headed vehicle exhibit a “wrapping and pinching fusion” pattern. The contact point between the shoulder cavity and tail cavity of the conical-headed vehicle is located near the free surface. The mixed-phase end of the OSS exhibits a “unilateral contact fusion” pattern with the tail cavity. Moreover, as the transverse velocity increases, the shedding residual gas gradually moves toward the OSS.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, S.; Xu, H.; Sun, T.; Duan, J. Water-exit dynamics of a ventilated underwater vehicle in wave environments with a combination of computational fluid dynamics and machine learning. Phys. Fluids 2024, 36, 023312. [Google Scholar] [CrossRef]

- Mirsandi, H.; Smit, W.; Kong, G.; Baltussen, M.; Peters, E.; Kuipers, J. Bubble formation from an orifice in liquid cross-flow. Chem. Eng. J. 2020, 386, 120902. [Google Scholar] [CrossRef]

- Zhuang, Q.; Zhang, H.; Zhao, C.; He, X.; Liu, Y.; Liu, Z.; Li, S.; Zhu, R.; Wu, D. Effects of the launch parameters on trans-phase stability performance and mechanism for submarine-launched missiles model. Ocean Eng. 2023, 283, 115083. [Google Scholar] [CrossRef]

- Lu, Q.; Ma, X.; Zhao, J.; Shen, L. A Review on Research of Load Reduction and Ballistic Stability During Cross-Media Water Entry Processes. J. Mar. Sci. Eng. 2025, 13, 703. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, K.; Kong, D.; Zhang, J.; Liu, T. Numerical simulation of subsonic and transonic water entry with compressibility effect considered. Ocean Eng. 2023, 281, 114984. [Google Scholar] [CrossRef]

- Hao, L.; Zhang, H.; Yang, Q.; Liu, T.; Huang, B. Experimental investigation on the ventilated cavitating flow characteristics around an axisymmetric body with an unsteady ventilation. Ocean Eng. 2024, 313, 119307. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, J.; Sun, T.; Jiang, Y. Ventilated cavity dynamics of an axisymmetric body under the influence of a structure. Phys. Fluids 2023, 35, 055112. [Google Scholar] [CrossRef]

- Yu, A.; Li, L.; Zhou, D. Large eddy simulation of the cavity shedding characteristics of ventilated cavitation around the underwater vehicle. Ocean Eng. 2024, 301, 117546. [Google Scholar] [CrossRef]

- Qu, Z.; Cui, J.; Chen, X.; Huang, X.; Ma, G.; Qiu, G. Study on vortex structure and hydrodynamic characteristics of water-exit projectile with shoulder ventilation. Ocean Eng. 2024, 313, 119622. [Google Scholar] [CrossRef]

- Ceccio, S.L. Friction drag reduction of external flows with bubble and gas injection. Annu. Rev. Fluid Mech. 2010, 42, 183–203. [Google Scholar] [CrossRef]

- Skrucany, T.; Semanova, S.; Milojević, S.; Ašonja, A. New technologies improving aerodynamic properties of freight vehicles. Appl. Eng. Lett. 2019, 4, 48–54. [Google Scholar] [CrossRef]

- Shereena, S.G.; Vengadesan, S.; Idichandy, V.G.; Bhattacharyya, S.K. CFD study of drag reduction in axisymmetric underwater vehicles using air jets. Eng. Appl. Comput. Fluid Mech. 2013, 7, 193–209. [Google Scholar] [CrossRef]

- Gan, N.; Yao, X.; Su, B.; Cui, X. Study on the dynamic behaviors of a near wall ventilated bubble using OpenFOAM. Ocean Eng. 2022, 257, 111650. [Google Scholar] [CrossRef]

- Gao, S.; Shi, Y.; Pan, G.; Quan, X. A study on the performance of the cavitating flow structure and load characteristics of the vehicle launched underwater. Phys. Fluids 2023, 34, 125108. [Google Scholar] [CrossRef]

- Gao, S.; Shi, Y.; Pan, G.; Quan, X. A study on the cavitation vortex dynamics and loads of water-exiting axisymmetric projectile. Phys. Fluids 2023, 35, 085112. [Google Scholar] [CrossRef]

- Gao, S.; Shi, Y.; Pan, G.; Quan, X. Simulation of the wake vortex and trajectory characteristics of successively launched multiple projectiles. Ocean Eng. 2022, 249, 110962. [Google Scholar] [CrossRef]

- Guo, Z.; Zhao, Y.; Zhang, X.; Lyu, X. On the cavity flow of a cylinder exiting water obliquely. Ocean Eng. 2023, 281, 114683. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.; Gong, Z.; Chen, X.; Lu, C. LES investigation on cavitating flow structures and loads of water-exiting submerged vehicles using a uniform filter of octree-based grids. Ocean Eng. 2021, 225, 108811. [Google Scholar] [CrossRef]

- Manshadi, M.; Hejranfar, K.; Farajollahi, A. Effect of vortex generators on hydrodynamic behavior of an underwater axisymmetric hull at high angles of attack. J. Vis. 2017, 20, 559–579. [Google Scholar] [CrossRef]

- Zhang, L.; Gu, L.; Jiao, J.; Pei, Z.; Wang, R. Effects of cross flow on the launching process of submarine-launched vehicle considering the 6-DOF motion at barrel-exit stage. Ocean Eng. 2024, 309, 118418. [Google Scholar] [CrossRef]

- Liu, T.; Huang, B.; Wang, G.; Zhang, M. Experimental investigation of ventilated partial cavitating flows with special emphasis on flow pattern regime and unsteady shedding behavior around an axisymmetric body at different angles of attack. Ocean Eng. 2018, 147, 289–303. [Google Scholar] [CrossRef]

- Wang, G.; Kong, D.; Wu, Q.; Liu, T.; Zheng, Y.; Huang, B. Physical and numerical study on unsteady shedding behaviors of ventilated partial cavitating flow around an axisymmetric body. Ocean Eng. 2020, 197, 106884. [Google Scholar] [CrossRef]

- Cheng, S.; Quan, X.; Sha, Y.; Yang, Q.; Wang, C.; Xu, Y. Experimental investigation of the underwater ventilated tail cavity at different angles of attack. Ocean Eng. 2022, 261, 111916. [Google Scholar] [CrossRef]

- Hao, L.; Liu, T.; Kong, D.; Huang, B.; Wang, G.; Wu, Y. Flow pattern regime and unsteady characteristics of ventilated cavitating flow around the axisymmetric bodies with different headforms. Phys. Fluids 2024, 35, 124103. [Google Scholar] [CrossRef]

- Zhao, Q.; Chen, T.; Xiao, W.; Chen, X.; Yao, X.; Wang, W. Research on the characteristics of cavitation flow and pressure load during vertical water exit of different head-shaped vehicles. Ocean Eng. 2022, 265, 112663. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, Y.; Zhang, X. Research on multiphase flow field characteristics of underwater gun double-tube parallel firing. Propellants Explos. Pyrotech. 2022, 48, e202300068. [Google Scholar] [CrossRef]

- Hu, C.; Wang, G.; Wang, X.; Huang, B. Experimental investigation of inception cavitating flows around axisymmetric bodies with different headforms. J. Mech. Sci. Technol. 2016, 30, 3193–3201. [Google Scholar] [CrossRef]

- Lu, J.; Wang, C.; Song, W.; Wei, Y.; Yu, D.; Li, Y. Experimental investigation on interference characteristics of projectiles launched successively underwater. Ocean Eng. 2022, 250, 110824. [Google Scholar] [CrossRef]

- Moghimi, M.; Nouri, N.; Molavi, E. Experimental investigation on supercavitating flow over parabolic cavitators. J. Appl. Fluid Mech. 2017, 10, 95. [Google Scholar] [CrossRef]

| Name | Information | Origin or Manufacturer |

|---|---|---|

| Decompression tank | Dimensions: 2 m × 1.2 m × 2.4 m | Harbin Engineering University, Harbin, China |

| Slide | Effective stroke greater than 1.5 m, enabling fully automatic vertical lifting and transverse movement. | Harbin Engineering University, Harbin, China |

| Launch tube | Height: 0.5 m, with an initial volume chamber and a three-ring seal inside. | Harbin Engineering University, Harbin, China |

| Vehicle | L/D is approximately 6.5, and the head taper angle is 90°. | Harbin Engineering University, Harbin, China |

| Vacuum | Bipolar rotary vane vacuum pump, pumping speed 70 L/s | Nanguang Pump Industry Co., Ltd., Wenzhou, China |

| Air compressor | Oil-free air compressor, rated discharge pressure 0.7 MPa | Dongcheng Electromechanical Co., Ltd., Qidong, China |

| Gas tank | Diameter: 0.133 m, Length: 0.33 m, Volume: 4 L, Maximum pressure: 1.25 MPa | Harbin Engineering University, Harbin, China |

| Yellow-headed lamp | Power: 2000 W, Color temperature: 3200 K, Dimensions: 0.21 m × 0.35 m × 0.4 m | Tianjin Deshun Film & Television Co., Ltd., Tainjin, China |

| High-speed camera | Phantom Miro C321, At 1920 × 1080 resolution, the capture speed is 1480 fps. | AMETEK, Berwyn, PA, USA |

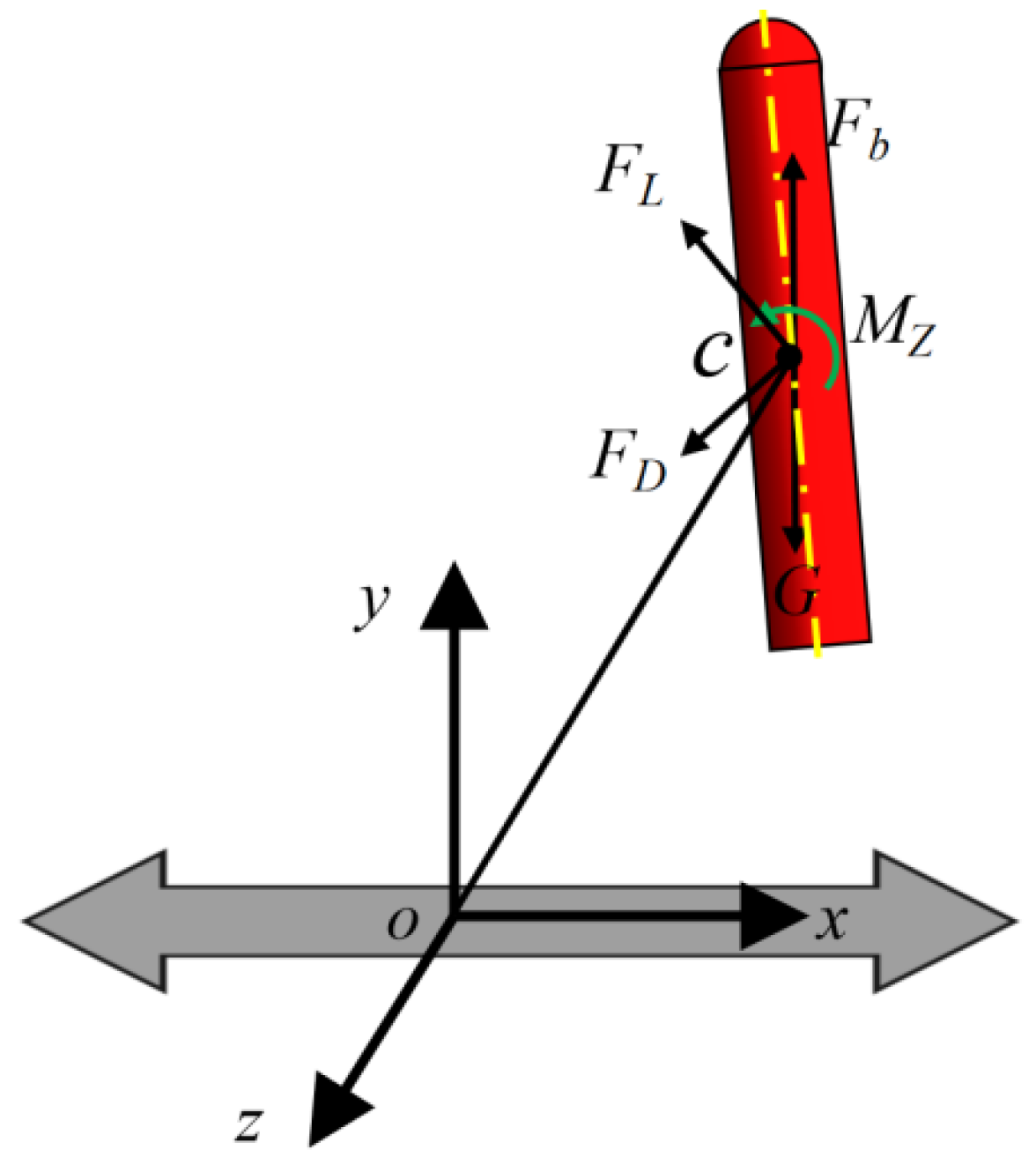

| Symbol | Details | Symbol | Details |

|---|---|---|---|

| Fb | Buoyancy of vehicle | FL | Lift of vehicle |

| G | Gravity of vehicle | FD | Resistance of vehicle |

| c | Center of gravity of the vehicle | Mz | Pitch moment of vehicle |

| D | Vehicle diameter | Fr | The Froude number |

| L | Vehicle length | LB | OSS cavity length |

| Lw | CSS cavity length | Vehicle’s dimensionless water depth | |

| Transverse dimensionless displacement of the vehicle | Vertical dimensionless displacement of the vehicle | ||

| θ | Angle between the CSS and the closure line at the end of the ventilated cavity | Frl | The Froude number at which the vehicle leaves the launch tube |

| ΔL | The difference between the length of the OSS and the CSS | The dimensionless difference between the length of the OSS and the CSS | |

| vt | Transverse velocity of the launch tube | Vl | The speed at which the vehicle leaves the launch tube |

| Num | Case | Head Shape | Frl | Pdifference | vt (m/s) | Detailed Name |

|---|---|---|---|---|---|---|

| 1 | E1 | Hemispherical | 9.3 | 5 | 0.2 | E1-PE20-Frl9.3-vt0.2 |

| 2 | E2 | Hemispherical | 8.0 | 5 | 0.4 | E2-PE20-Frl8.0-vt0.4 |

| 3 | E3 | Hemispherical | 7.8 | 5 | 0.6 | E3-PE20-Frl7.8-vt0.6 |

| 4 | F1 | Ellipsoid | 8.5 | 5 | 0.2 | F1-PE20-Frl8.5-vt0.2 |

| 5 | F2 | Ellipsoid | 8.5 | 5 | 0.6 | F2-PE20-Frl8.5-vt0.6 |

| 6 | G1 | Conical | 8.5 | 5 | 0.2 | G1-PE20-Frl8.5-vt0.2 |

| 7 | G2 | Conical | 8.3 | 5 | 0.6 | G2-PE20-Frl8.3-vt0.6 |

| Head Shape | vt (m/s) | Contact Point | Contact Pattern |

|---|---|---|---|

| Hemispherical | 0.2 | Underwater | wrapping and pinching fusion |

| 0.6 | Underwater | wrapping and pinching fusion | |

| Ellipsoidal | 0.2 | Underwater | unilateral contact fusion |

| 0.6 | Underwater | unilateral contact fusion | |

| Conical | 0.2 | Near the free surface | unilateral contact fusion |

| 0.6 | Near the free surface | unilateral contact fusion |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Shi, D.; Ma, G.; Lu, J.; Wang, R. Experimental Study on Three-Degree-of-Freedom Ventilated Cavities for Underwater Vehicles Considering the Air Mass near the Tube. J. Mar. Sci. Eng. 2025, 13, 2111. https://doi.org/10.3390/jmse13112111

Wang J, Shi D, Ma G, Lu J, Wang R. Experimental Study on Three-Degree-of-Freedom Ventilated Cavities for Underwater Vehicles Considering the Air Mass near the Tube. Journal of Marine Science and Engineering. 2025; 13(11):2111. https://doi.org/10.3390/jmse13112111

Chicago/Turabian StyleWang, Jiazhao, Dongyan Shi, Guihui Ma, Jiaxing Lu, and Runtian Wang. 2025. "Experimental Study on Three-Degree-of-Freedom Ventilated Cavities for Underwater Vehicles Considering the Air Mass near the Tube" Journal of Marine Science and Engineering 13, no. 11: 2111. https://doi.org/10.3390/jmse13112111

APA StyleWang, J., Shi, D., Ma, G., Lu, J., & Wang, R. (2025). Experimental Study on Three-Degree-of-Freedom Ventilated Cavities for Underwater Vehicles Considering the Air Mass near the Tube. Journal of Marine Science and Engineering, 13(11), 2111. https://doi.org/10.3390/jmse13112111