1. Introduction

The global transition toward renewable energy has placed offshore wind at the forefront of sustainable electricity generation. Offshore wind turbines (OWTs) are increasingly being designed for greater power capacities and deployed in deeper waters, which requires reliable, durable, and cost-efficient foundation systems capable of withstanding harsh marine environments [

1,

2,

3]. Among the various foundation solutions, such as jackets, gravity-based structures, and floating platforms, monopiles have emerged as the most widely adopted due to their structural simplicity, ease of fabrication, and cost-effective installation procedures [

4,

5,

6]. Over the last two decades, monopiles have accounted for more than 70% of installed offshore wind turbine foundations worldwide, demonstrating their dominant role in the sector [

7,

8].

Despite their widespread application, monopiles face several engineering challenges, particularly with respect to structural connections. Traditional joints, including welded and bolted connections, often introduce fabrication complexity, extended construction times, and increased susceptibility to fatigue and corrosion under cyclic loading from waves, wind, and currents [

9,

10]. One of the widely used conventional joint systems is the bolted flange joint, which facilitates modular assembly and improved structural efficiency in offshore support structures [

11,

12,

13]. However, bolted joints in wind turbine towers are prone to fatigue failure, bolt loosening, and corrosion due to constant cyclic loads. These issues are compounded by the complex and costly installation and maintenance required to ensure joint integrity over the tower’s lifespan. These limitations hinder the overall structural reliability and impose significant costs during both installation and maintenance. Consequently, research has shifted toward exploring innovative connection concepts that can enhance structural robustness while reducing construction and lifecycle costs.

A promising alternative is the pipe-in-pipe (PIP) slip joint, which consists of two overlapping tubular members that transfer load primarily through frictional resistance [

14,

15,

16]. This arrangement eliminates the need for extensive bolting or welding, thereby simplifying installation and reducing on-site labor. Moreover, PIP slip joints demonstrate inherent self-aligning properties, enabling easier turbine assembly at sea while also redistributing stresses to improve structural resilience against dynamic environmental loads [

17,

18]. Experimental and numerical studies on circular hollow section (CHS) slip joints have highlighted their effectiveness under combined axial and bending loads, confirming their potential as a cost-effective and structurally robust alternative to conventional connections [

15,

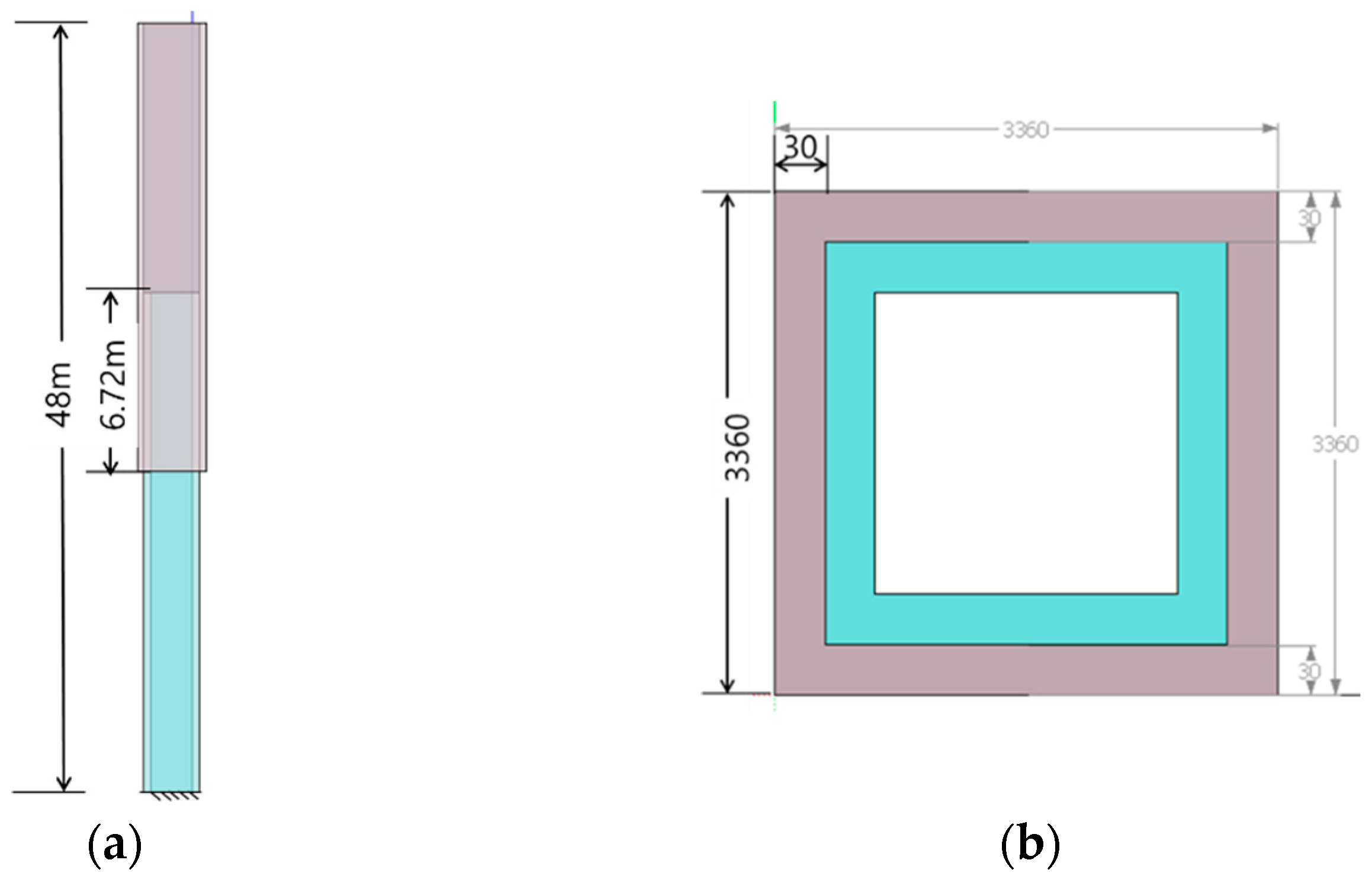

19]. A PIP slip joint consists of two overlapping tubular members, where the outer pile accommodates an inner pile with a designed overlapping length, as shown in

Figure 1. Load transfer between the members occurs primarily through frictional resistance and contact pressure, and the ring stopper resists the axial compression due to the self-weight of the turbine and environmental loading [

18]. This mechanism eliminates the need for extensive welding or bolting and enables a self-locking, self-aligning connection, which simplifies installation procedures at sea.

However, the application of PIP slip joints has predominantly been investigated in the context of CHS geometries, leaving other tubular profiles underexplored. In particular, SHSs offer distinct advantages that could further improve fabrication and structural performance. SHSs play a critical role in offshore and high-velocity structural applications due to their beneficial fluid dynamic characteristics. Research shows that closed hollow sections—like SHSs—exhibit lower drag coefficients than open or sharp-edged profiles. This is particularly evident under high wind or current conditions where drag forces are significant [

20]. From an aerodynamic viewpoint, flow experiments on square prisms reveal that rounded corner radius substantially alters drag and lift characteristics. For instance, transitioning from sharp edges towards a rounded geometry reduces drag, suppresses vortex shedding, and enhances flow stability—especially at high Reynolds numbers [

21,

22]. The smoother flow behavior around rounded SHSs improves aerodynamic efficiency and mitigates oscillatory loads. Moreover, SHS geometries may facilitate modular construction approaches, which are becoming increasingly relevant for large-scale offshore projects. Nonetheless, SHS members are also prone to local buckling at the corners, raising concerns about their load-carrying capacity under critical loading conditions [

23,

24,

25]. This duality highlights the necessity of a rigorous investigation into the feasibility of SHS-based slip joints for offshore wind applications.

To address this research gap, this study numerically investigates the structural performance of an SHS PIP slip joint under pure bending, lateral load, and axial compression. A finite element (FE) model is developed to evaluate stress distribution, corner buckling, and load capacity, and is validated against published CHS experimental results. The findings reveal the structural vulnerabilities of SHS joints and suggest mitigation strategies, such as optimized overlap ratios and local strengthening. This work advances the understanding of PIP slip joints in non-circular geometries and highlights the SHS configuration as a promising, cost-efficient alternative for next-generation offshore monopile connections.

3. Results of FEA Analysis

3.1. Pure Bending Case

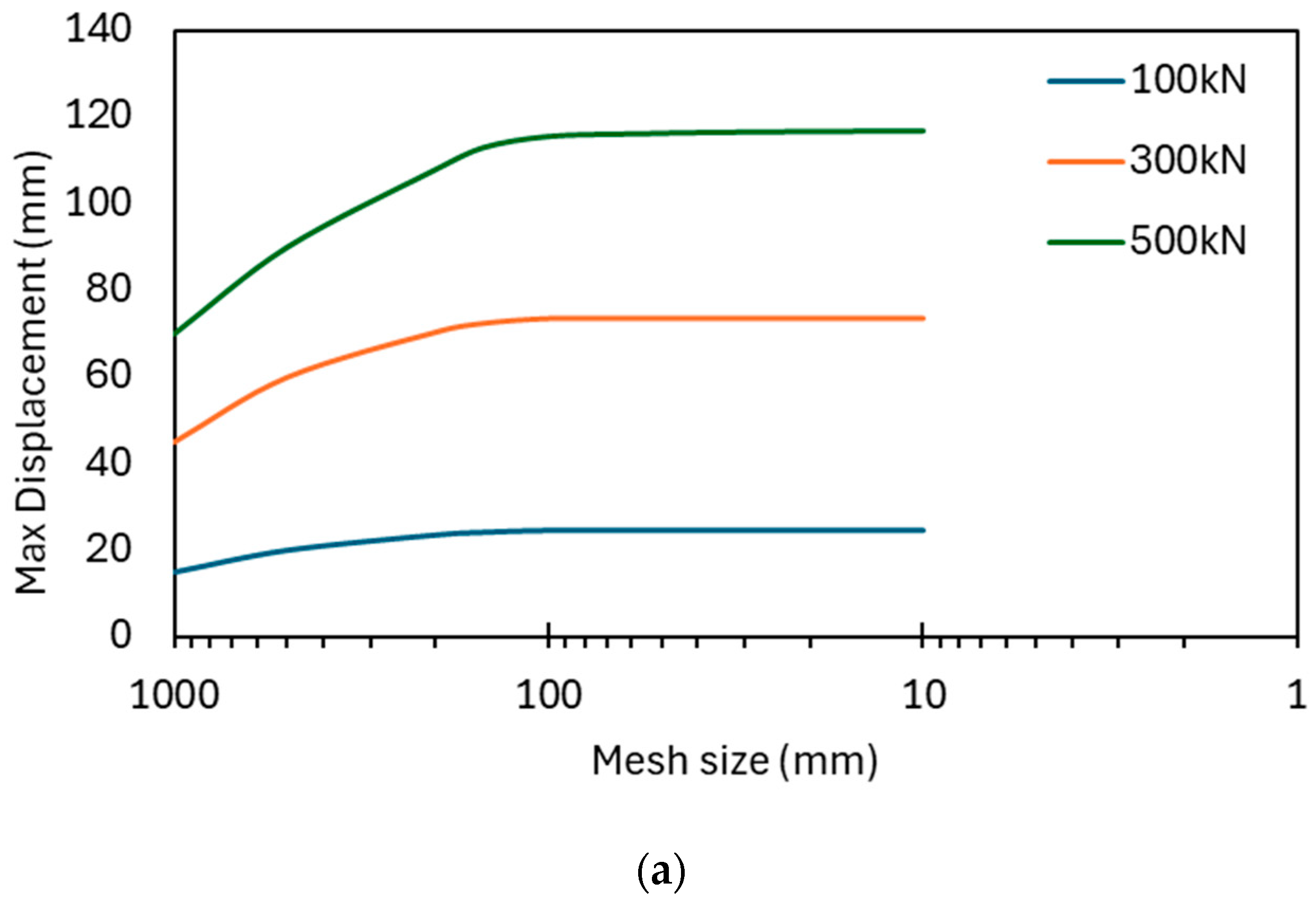

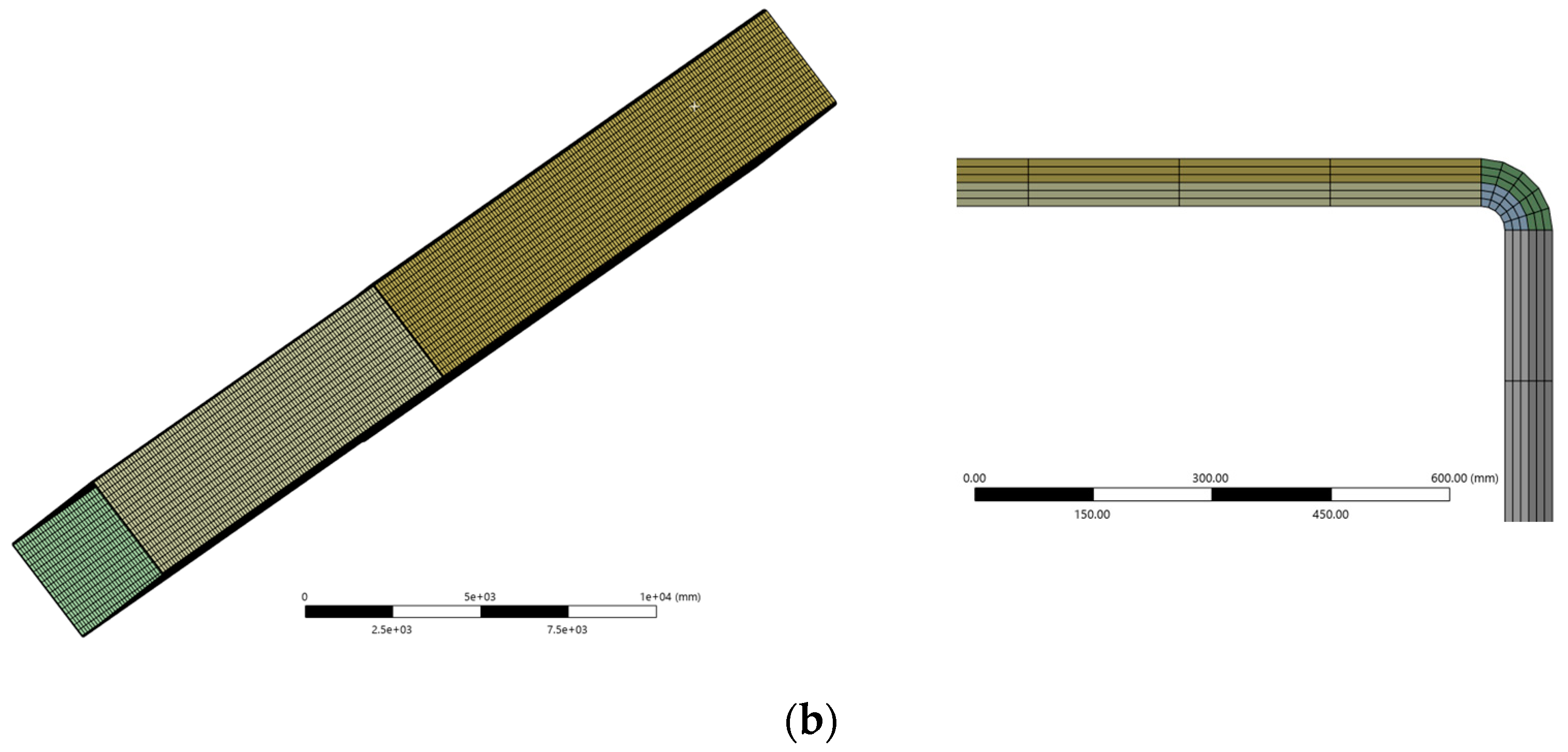

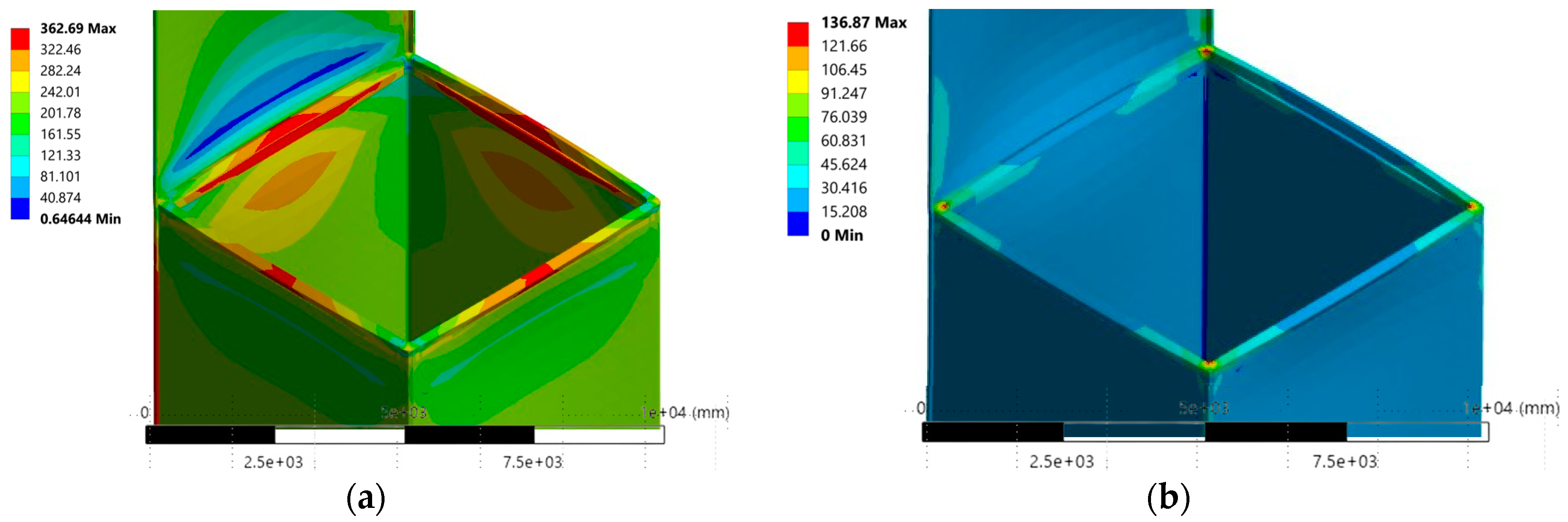

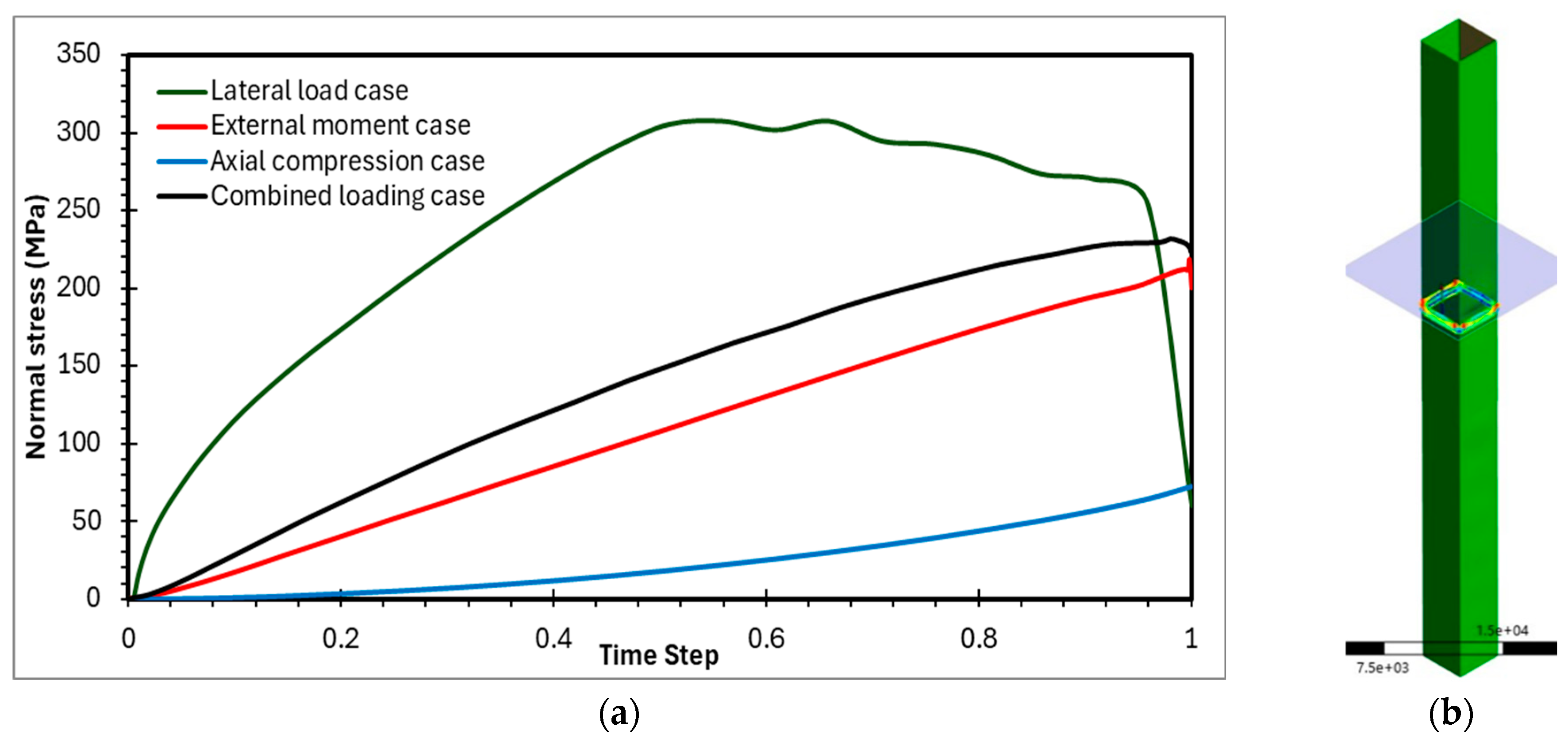

In the case of pure bending, the numerical analysis of the SHS slip joint demonstrated a continuous, almost linear increase in maximum principal stress, which reached a peak of 385.25 MPa towards the end of the simulation. This value exceeds the material’s 355 MPa yield stress, indicating significant plastic deformation. In contrast, for the axial load case, the maximum principal stress showed a clear, continuous increase, reaching 124.82 MPa at the end of the simulation, which remained well within the elastic limits of the material. A key observation is that the stress concentration points consistently showed maximums over time, highlighting that these localized high-stress areas, particularly at the sharp corners and transition regions, are critical for fatigue analysis and potential crack initiation. Furthermore, the analysis of the force–displacement curve revealed that the dynamic friction model provided results that were closer to the experimental data compared to the static friction model. This confirms the importance of using a pressure-dependent friction approach for accurate simulation of the slip joint’s behavior. In

Figure 7, the stress concentration in the shell near and around the ring stopper is shown.

In the axial loading scenario, the analysis revealed that the minimum principal stress exhibits a distinctive rippling effect in the vicinity of the ring stoppers. This localized phenomenon is indicative of minor compressive stress fluctuations, which, while not leading to yielding in this particular case, highlights the complex stress distribution at these critical support points. In all pure bending cases, the maximum principal stress (

σ1) reached significantly higher values, exceeding the material’s yield strength and demonstrating that compressive yielding and potential fracture are the primary failure modes for the PIP slip joint under these conditions. Furthermore, the results from the combined loading simulations revealed a clear interaction between the bending and compression effects, producing a unique stress and deformation pattern not observed in the individual loading cases. This underscores the necessity of a comprehensive structural assessment that considers all potential loading scenarios to ensure the design’s reliability and integrity. In

Figure 8, the maximum and minimum stress for the different loading conditions are provided.

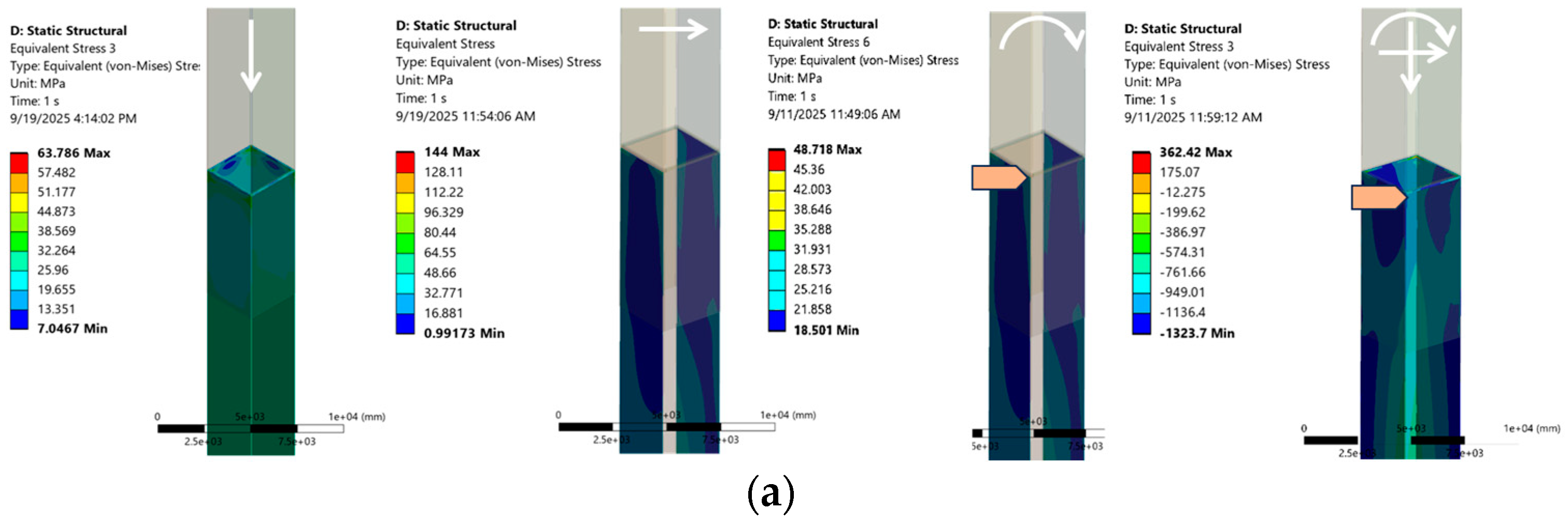

For the pure bending case, the analysis showed that the peak von Mises stress reached 402.26 MPa. This value exceeds the material’s yield stress of 355 MPa, which indicates that plastic deformation occurred.

Figure 9 illustrates that with an increasing external moment, plastic deformation spreads through the localized high-stress zones, as indicated by the stress values exceeding the yield point. In stark contrast, in the axial loading case, the stress values remained well within the material’s elastic limits, indicating a safe operational state without any permanent plastic deformation. This highlights that the PIP slip joint’s primary structural vulnerability is under bending conditions rather than axial compression. In

Figure 9, the equivalent von Mises for the different loading cases are provided.

The analysis of the axial loading case showed a strong linear relationship between normal stress and displacement, as depicted in the provided graph. This linearity is a clear indication that the SHS slip joint material remains well within its elastic range under these loads, which aligns perfectly with the previous von Mises stress analysis for axial stress. The steep, linear slope of this curve, with a maximum compression stress of around 150 MPa, directly represents the effective axial stiffness of the joint, signifying that a relatively small displacement results in a significant increase in axial stress. This demonstrates that the joint efficiently resists axial stretching or compression. From a deformation and stress perspective (

Figure 10), the joint is expected to perform reliably under axial loads without significant wear or yielding.

In contrast, the pure bending and lateral bending cases exhibited clear nonlinear behavior, with maximum principal stresses reaching significantly higher values. This indicates that plastic deformation occurred, highlighting compressive yielding and fracture as the primary structural concerns under these bending conditions.

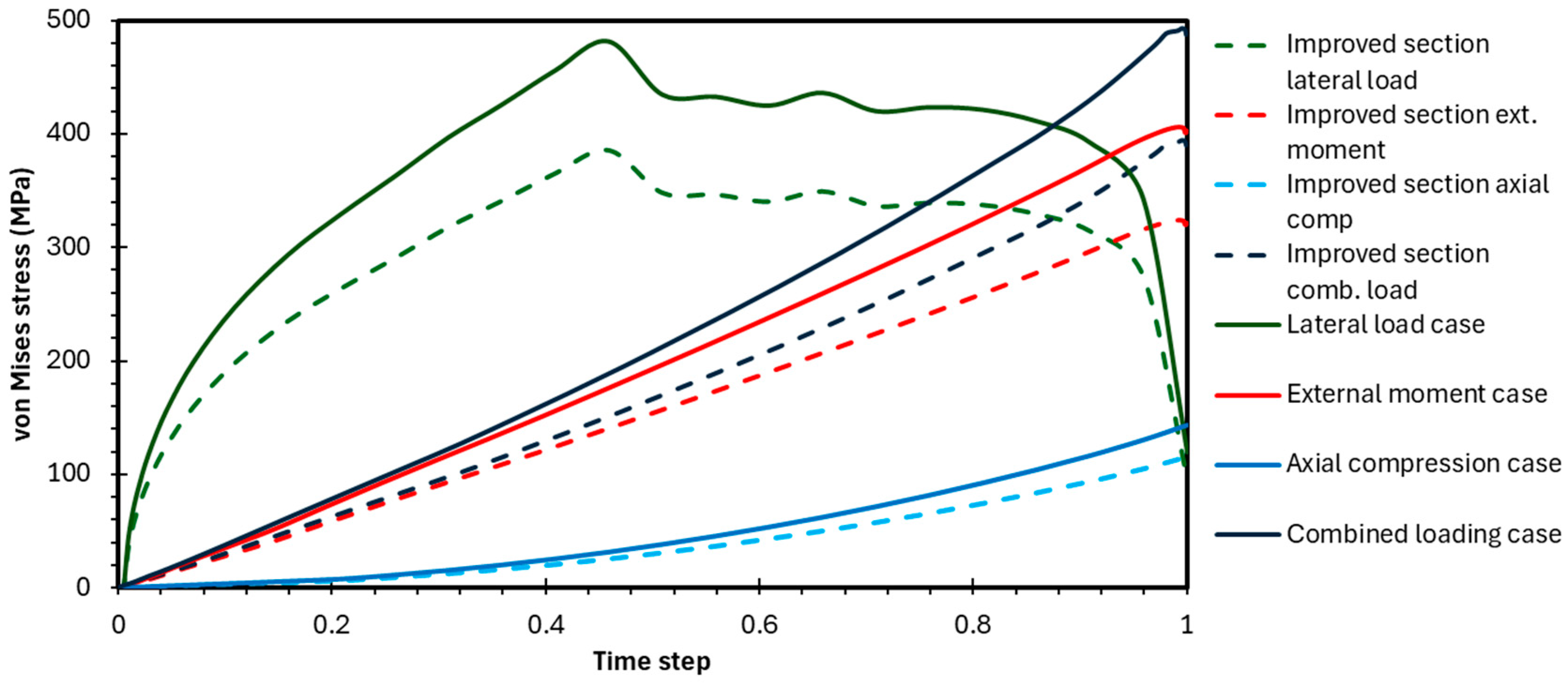

3.2. Contact Parameters

In a frictional slip joint, accurate contact parameters are crucial because they directly govern the joint’s function and durability. Since friction is the primary means of transferring load, precisely understanding contact pressure and the coefficient of friction is essential for predicting the joint’s load-bearing capacity and preventing design failures. Moreover, these parameters are key to predicting failure modes, as high contact pressures can lead to localized material yielding and local buckling. For long-term performance, frictional contact is a major source of wear and tear, making it vital to analyze these parameters to estimate the joint’s lifespan and the need for maintenance. Finally, for joints designed to allow for movement, such as for thermal expansion, high friction can cause the joint to lock up, compromising its functional performance and requiring excessive force to operate.

The significantly higher contact pressures and frictional stresses under bending indicate that the bending load is the primary driver of wear and potential material degradation at the slip interface. This is a major concern for the operational lifespan of the joint. If the slip joint is designed to allow for relative motion (e.g., thermal expansion/contraction, or movement due to ground settlement), the high frictional stresses during bending could prevent this intended slip, potentially locking the joint or requiring excessively large forces to overcome friction.

Figure 11 is a diagram that visually explains the sliding mechanism in a pile-in-pile (PIP) connection under different loading conditions. Moreover, the graphs in

Figure 12 clearly illustrate that pure bending with an external moment induces significantly higher frictional stresses and contact pressures at the slip joint interface compared to axial and combined loading. For example, the frictional stress under pure bending is approximately 14 MPa, which is considerably higher than the values for the other loading conditions. This indicates that bending loads are the primary cause of wear and potential material degradation at the slip interface. This is a major concern for the operational lifespan of the joint.

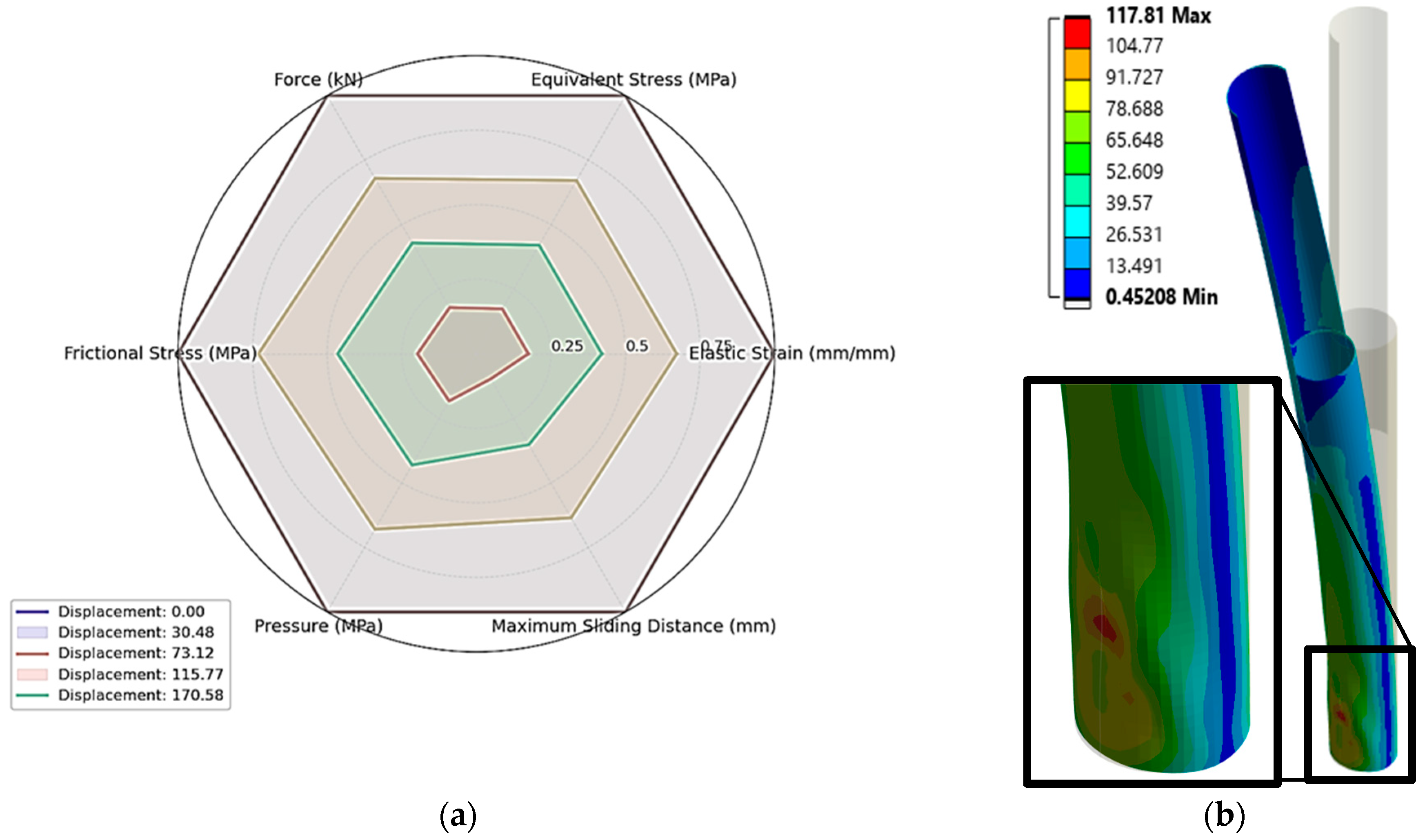

3.3. Strengthened Section

To mitigate the identified vulnerabilities, the wall thickness was increased from 30 mm to 50 mm. This specific increment was selected to significantly reduce the section slenderness (C/t ratio from 109 to 67.2), providing an optimal balance between performance gain and material use. A parametric study confirmed that this 20 mm increase offered a decisive improvement in buckling resistance and stress reduction compared to smaller increments. This enhancement led to an increase in the section modules, resulting in a notable improvement in the joint’s performance, as demonstrated in the following results. As demonstrated in the graph, the original von Mises stress curve shows a higher stress level compared to the improved scenario’s dashed green line, which achieved a 20% reduction in stress. This decrease in stress concentration indicates a more robust and reliable design. The results suggest that, in addition to increasing the section modules, further improvements can be achieved by implementing other design changes such as increasing the overlapping length or adding local reinforcements. These measures can effectively manage and reduce stress concentrations, ultimately leading to a more reliable and durable structural design. In the following

Figure 13, the comparison of the improved section and the original section is shown.

3.4. Comparison with CHS

After a thorough analysis of the CHS with pressure-dependent friction, it was observed that the maximum stress was localized at the bottom of the section, precisely where it met the fixed support. This is also the same point where local buckling occurred, highlighting this specific area as a critical point of failure.

The analysis also revealed a direct and linear relationship between increasing pressure and increasing frictional stress, which is an expected outcome as frictional stress is directly influenced by the normal pressure on the contact surface, as shown in

Figure 14. The specific contact parameters, including the pressure and frictional stress values, are illustrated in the accompanying

Figure 14. This finding underscores the importance of considering pressure-dependent friction in numerical models, as it accurately identifies the highest-stress zones and potential buckling locations, which are crucial for the integrity and safety of the design.

An eigenvalue buckling analysis revealed that the CHSs (circular hollow sections) consistently have higher bifurcation loads across all buckling modes compared to the SHSs (square hollow sections), as shown in the provided

Figure 15. This finding indicates a greater probability of buckling for the SHSs, which can be attributed to fundamental differences in their geometries. The inherent symmetry of the CHS allows for a uniform distribution of directional loads, ensuring that every point on the outer surface is equidistant from the center. In contrast, the SHS’s corners are overextended from the center, making these edges more prone to failure as each face acts separately. As a result, the SHS, which can be classified as a Type 4 section, struggles to distribute loads to adjacent surfaces due to these weak edge points, causing it to buckle more easily than the symmetrically robust CHSs.

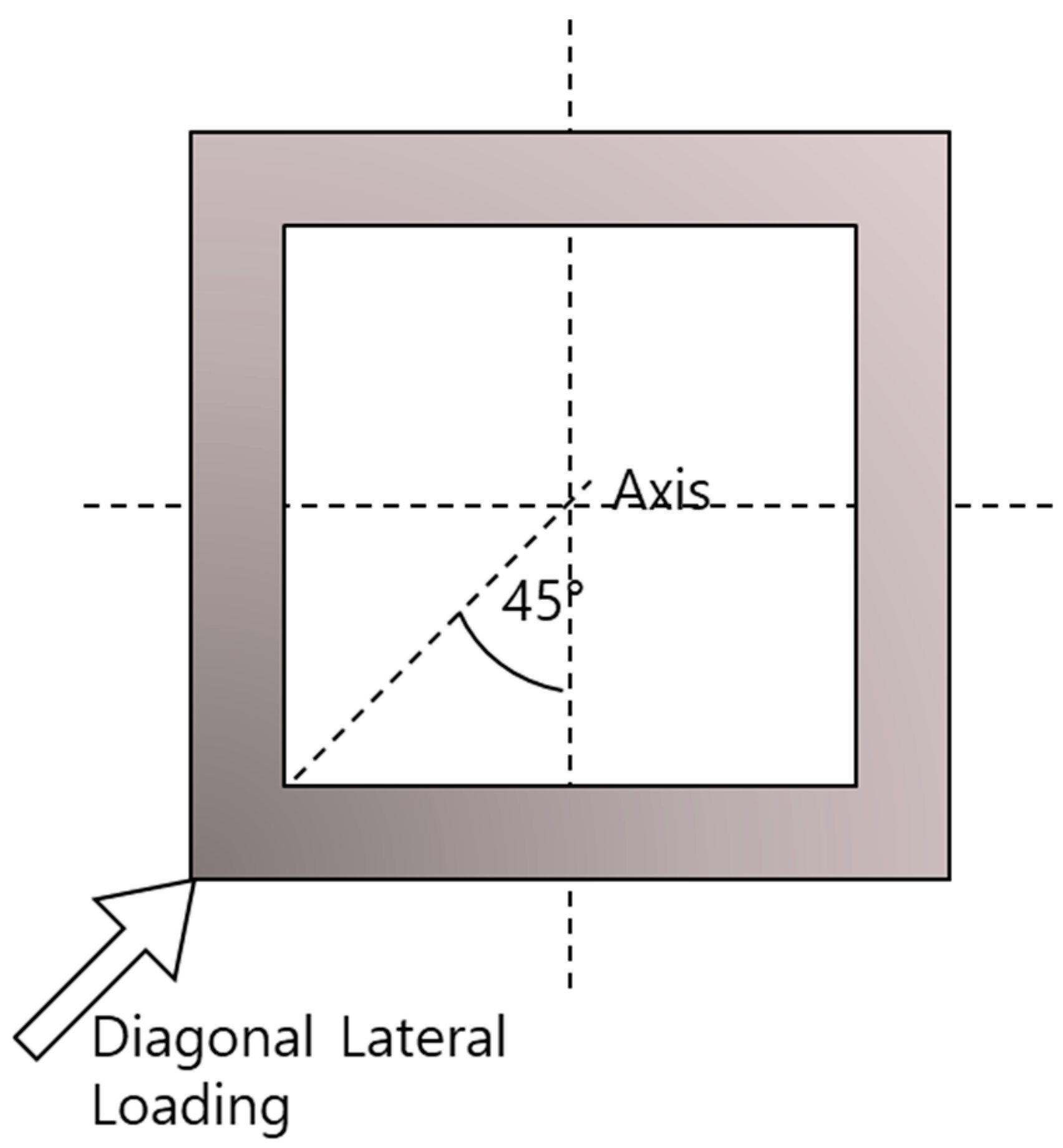

3.5. Effect of Diagonal Lateral Loadings in SHS

In a real-world offshore environment, lateral loads can originate from any direction, making it crucial to assess the structural integrity of the joint under diagonal loading conditions. For this reason, each of the loads was applied at a 45-degree angle to the main plane, as per

Figure 16.

Under these diagonal loads, the leg exhibited a distinctive failure pattern characterized by local buckling exclusively at the leg’s tip. This failure occurred because the applied loading could not effectively propagate through the overlapping area. As previously noted, the edges of the SHS are more prone to buckling due to their distance from the section’s center. When the diagonal load was directed toward these vulnerable edges, local buckling occurred at a much lower load than in axial cases.

The graph in

Figure 17 presents the variation in equivalent von Mises stress with time for three loading conditions: combined loading, pure bending, and lateral load. The lateral load (orange curve) shows the lowest stress response, increasing gradually to about 80 MPa before dropping slightly, while the pure bending case (green curve) produces higher stresses, reaching around 165 MPa with a steady rise. In contrast, the combined loading case (blue curve) exhibits a much more severe response, with stresses rising rapidly and peaking near 360 MPa, after which it drops sharply due to material yielding, redistribution, and instability effects. Overall, the combined loading generates stresses more than twice those from pure bending and nearly five times those from lateral loading, demonstrating the critical influence of load interaction on structural performance.

4. Conclusions

This numerical analysis investigated the structural performance of an SHS PIP slip joint for offshore wind monopile applications, comparing its behavior to a conventional CHS design under various loading conditions. The study’s key findings highlight critical aspects of the joint’s performance and design.

Under pure bending, the SHS’s maximum equivalent von Mises stress reached 405.6 MPa, exceeding the material’s yield stress of 335 MPa and indicating plastic deformation. In stark contrast, the axial load case resulted in a stress of only 144 MPa, remaining well within the elastic range. This confirms that pure bending is the primary driver of failure for this joint. The analysis of frictional stress at the slip interface further supports this, with pure bending inducing a significantly higher stress of 8.419 MPa compared to 0.4106 MPa for axial compression, which points to greater wear and sliding resistance during bending.

The comparative analysis indicated that circular hollow sections (CHSs) generally exhibit superior resistance to buckling due to their ability to distribute loads uniformly. An eigenvalue buckling analysis confirmed that CHSs consistently have higher bifurcation loads compared to square hollow sections (SHSs), making them less susceptible to failure. However, it is essential to note that SHSs demonstrated better capacity under axial compression.

The study also highlighted the significant impact of diagonal lateral loading. These loadings consistently resulted in localized buckling, primarily due to stress concentrations at the corners of the SHSs. This pattern of failure occurred at lower loads than in axial compression, emphasizing the vulnerabilities present in the corners of the SHS design.

Finally, the research demonstrated that simple design modifications can effectively mitigate these issues. By increasing the section thickness from 30 mm to 50 mm (resulting in a C/t ratio of 67.2), a 20% reduction in von Mises stress was achieved. This proves that implementing strategic improvements—such as increasing overlapping length or adding local reinforcements—can lead to a more robust and reliable SHS joint design.

This study advances offshore slip joint research by presenting the first comprehensive numerical analysis of square hollow section (SHS) PIP slip joints under critical loading, including pure bending, axial compression, and diagonal lateral loading. The findings identify SHS-specific failure modes, notably, increased corner buckling vulnerability under diagonal loads, but also demonstrate its improved axial compression performance relative to circular hollow sections (CHSs). Validated mitigation strategies are also proposed, achieving significant stress reductions. This work expands design options, positioning SHS as a viable and advantageous solution where axial strength and fabrication efficiency are required. The study also outlines directions for future research on SHS geometry optimization and specialized design guidelines for non-circular offshore wind foundation joints.