5.1. Linearization of Morison’s Equation

Under the standing condition of wind turbine installation, the legs of the self-elevating wind turbine installation vessel penetrate into the seabed, and sufficient foundation bearing capacity is established through preloading. The hull platform is then supported by the legs and elevated above the water surface, thereby achieving a stable operational posture.

At this stage, the environmental loads are dominated by wave actions, which primarily act on slender members such as the exposed legs, supporting trusses, and spudcans. For structural members whose diameters are small relative to the wavelength, the hydrodynamic force in the flow direction can be decomposed into inertia and drag components according to Morison’s concept. In engineering practice, the Morison equation is applied by segmental integration along the water depth to estimate the loads acting on the legs.

In the marine environment, wave loads exhibit stochastic characteristics, and engineering evaluations are generally conducted using frequency-domain methods within the framework of superposition and spectral analysis. However, the drag term in Morison’s equation is proportional to the square of the relative velocity, representing a nonlinear component.

When substituted into spectral analysis, this nonlinearity introduces frequency convolution in the frequency domain, making it difficult to directly solve the structural response and perform fatigue assessments using conventional spectral methods. To maintain the feasibility of frequency-domain analysis under random sea states and to establish a practical engineering approach, this drag term is linearized under conditions applicable to engineering practice.

This simplified method introduces errors, and we will briefly discuss the impact of linearization. The error tends to increase with lower significant wave height and observation height, often leading to an underestimation of fatigue damage, which negatively affects fatigue assessment. Additionally, the wave period also influences the error. In the sea area we are considering, where the significant wave height is relatively low, the impact of these errors is particularly important. At the lowest significant wave height and observation height, the fatigue damage error can reach 40%. As the observation height increases, the error decreases. However, the error at the lowest observation height does not represent the average total error, but rather the maximum error near the water surface. Therefore, under the worst-case scenario, the fatigue damage error will not exceed 40%. The drag term in Morison’s equation is expressed as follows [

23]:

where

is the density,

is the drag coefficient, and

is the diameter of the pile leg of the wind turbine installation vessel.

For an Airy wave in finite water depth, the velocity potential can be expressed as:

In the equation, is the angular frequency, is the first-order wave number, and is the water depth.

Then the fluid particle velocity can be expressed as:

By combining Equations (12) and (14), the drag term becomes:

In the equation,

a is the wave amplitude. For the form

in Equation (15), its Fourier series expansion can be written as:

where

.

By retaining only the first term, the first-order linear expression of the drag is obtained as follows:

Through the above treatment, the drag term in Morison’s equation has been equivalently linearized under engineering application conditions, as shown in Equation (17). On this basis, the linearized drag term can be combined with the wave spectrum to establish the statistical distribution of wave loads under different wave heights and periods, thereby enabling the calculation of the equivalent wave drag acting on the pile legs. Furthermore, by applying this wave drag to the structural finite element model, the corresponding structural dynamic response can be obtained. Finally, based on spectral analysis theory, the fatigue damage of the structure under random sea states can be evaluated.

5.2. Fatigue Spectral Analysis Method

In ocean engineering, accurately simulating the irregularity of ocean waves is crucial for predicting the structural response of ships and offshore platforms. One of the most commonly used methods to describe the ocean surface in spectral fatigue analysis is through the wave spectrum, which approximately represents the energy distribution of waves at different frequencies [

8]. The most commonly used wave spectrum is the two-parameter Pierson–Moskowitz (PM) spectrum,

, which is expressed as:

where

HS is a significant wave height,

TZ is the zero-crossing period, and ω is the wave frequency.

In the analysis, the actual response frequency should be the encounter frequency ω

e, which is related to the wave frequency

ω, heading angle

θ, and ship speed

as follows:

Accordingly, the input wave spectrum

should be converted into a wave spectrum

, expressed in terms of the encounter frequency and related to the wave heading angle

θ. This can be achieved by applying the energy conservation relationship for the differential elements of the corresponding wave frequency.

According to Equation (20), the wave spectrum expressed in terms of the encounter frequency can be obtained as:

Under the assumption that the ship structure is a linear system, the stress energy spectrum

can be obtained from the following:

where

is the stress transfer function.

Then, the nth order spectral moment of the response process for a given heading can be described as follows:

To obtain the number of stress cycles within a given time, the mean zero-crossing rate

of the alternating stress process must be provided, which represents the average number of times the process crosses the zero mean with a positive slope per unit time [

24]. Its expression is:

The cumulative fatigue damage from spectral analysis is obtained directly by combining the cumulative fatigue damage values from each short-term distribution, as calculated using Equation (25). Considering

Nload loading conditions, the cumulative fatigue damage over the design service life is expressed as:

where

D is the cumulative fatigue damage over the fatigue calculation return period;

is the operation rate coefficient, selected according to the vessel’s actual operating conditions, and taken as 0.5 in this study;

TL is the vessel’s design fatigue life, taken as 20 years in this study;

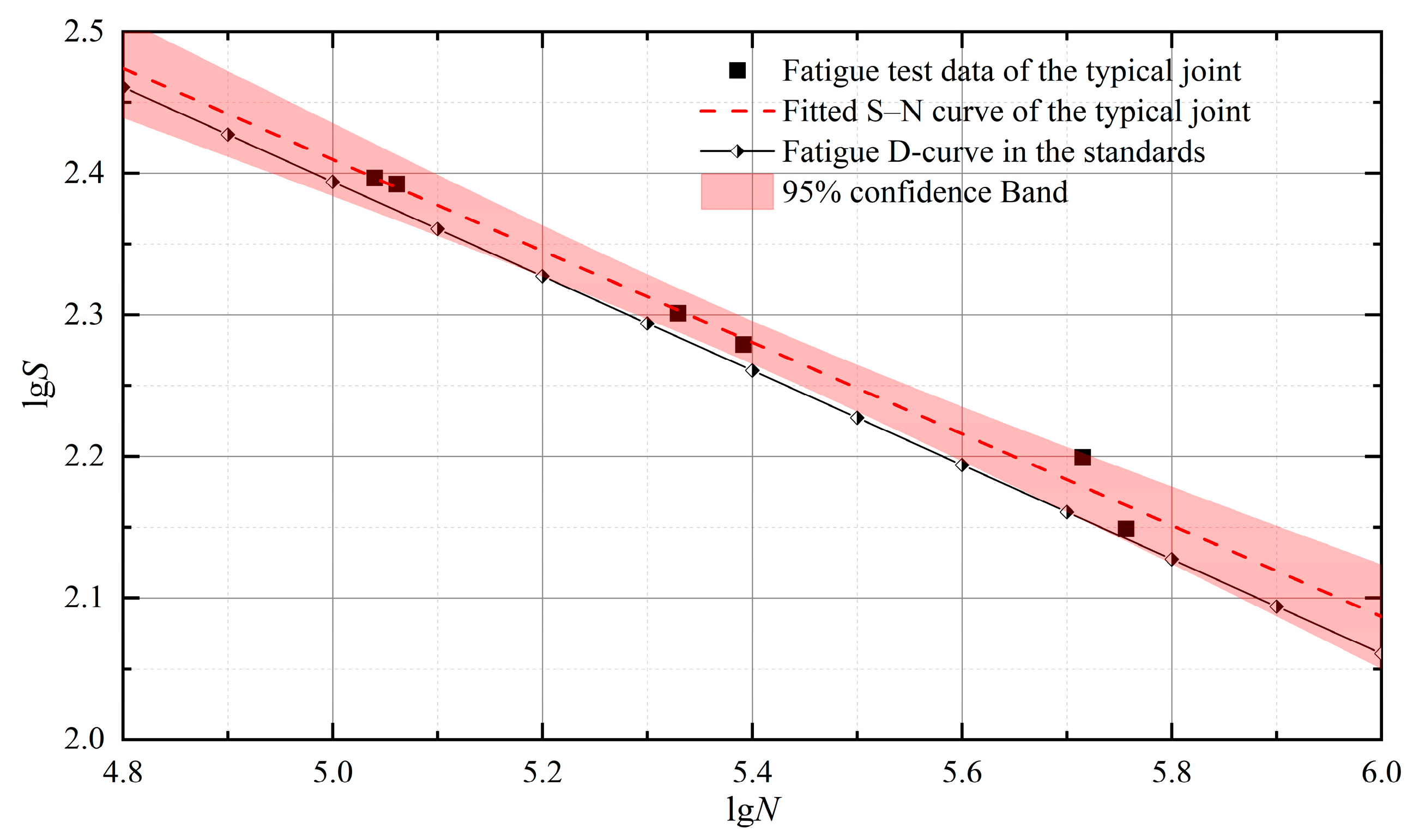

A and

m are the two parameters of the S–N curve;

is the zeroth-order moment of the stress response spectrum for the

loading condition under sea state

and heading

;

and

are the occurrence probabilities of sea state

and heading

, respectively; and

is the zero-crossing rate of the stress response under sea state

and heading

, calculated using Equation (24).

5.3. Fatigue Damage Analysis

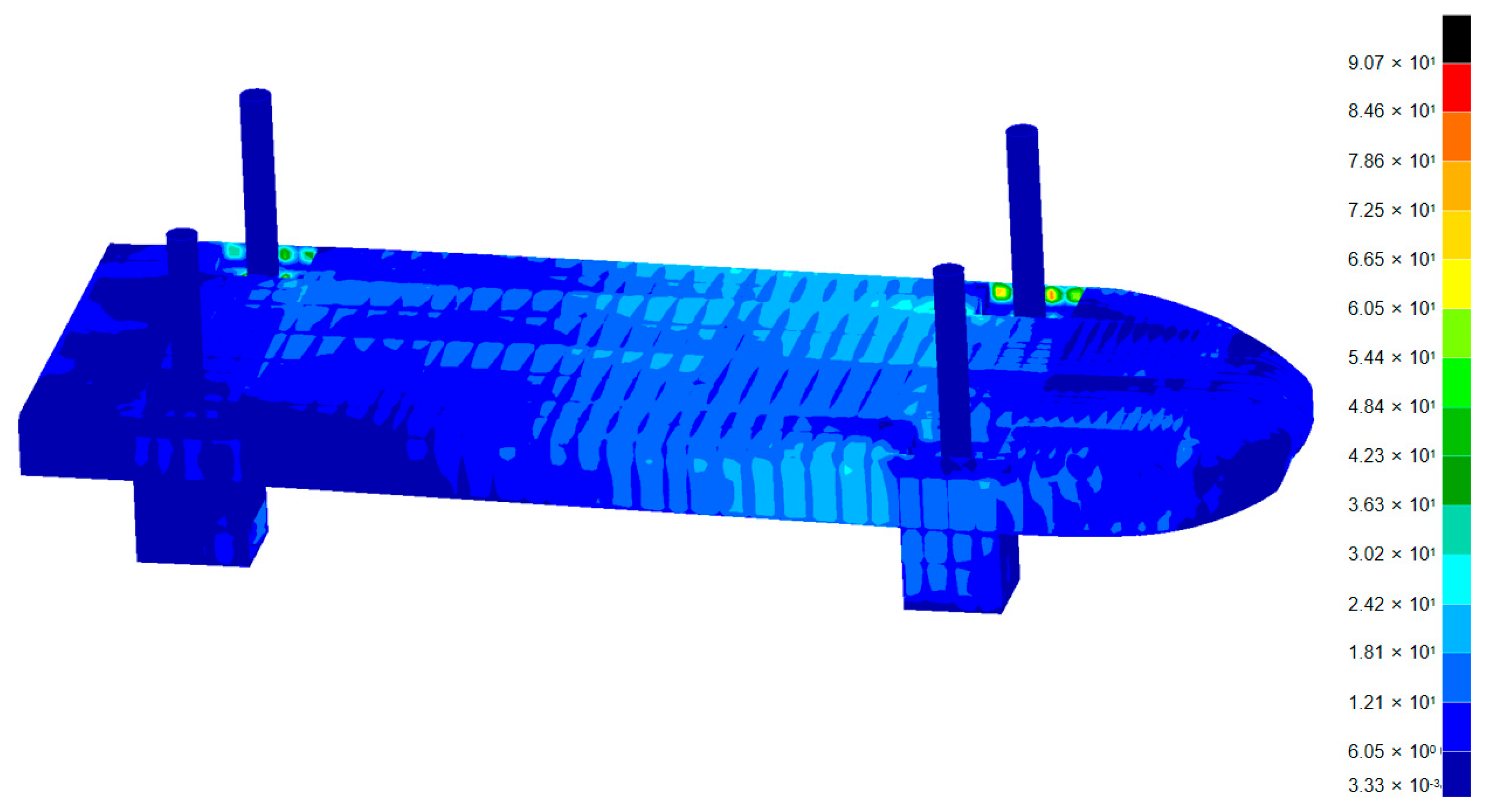

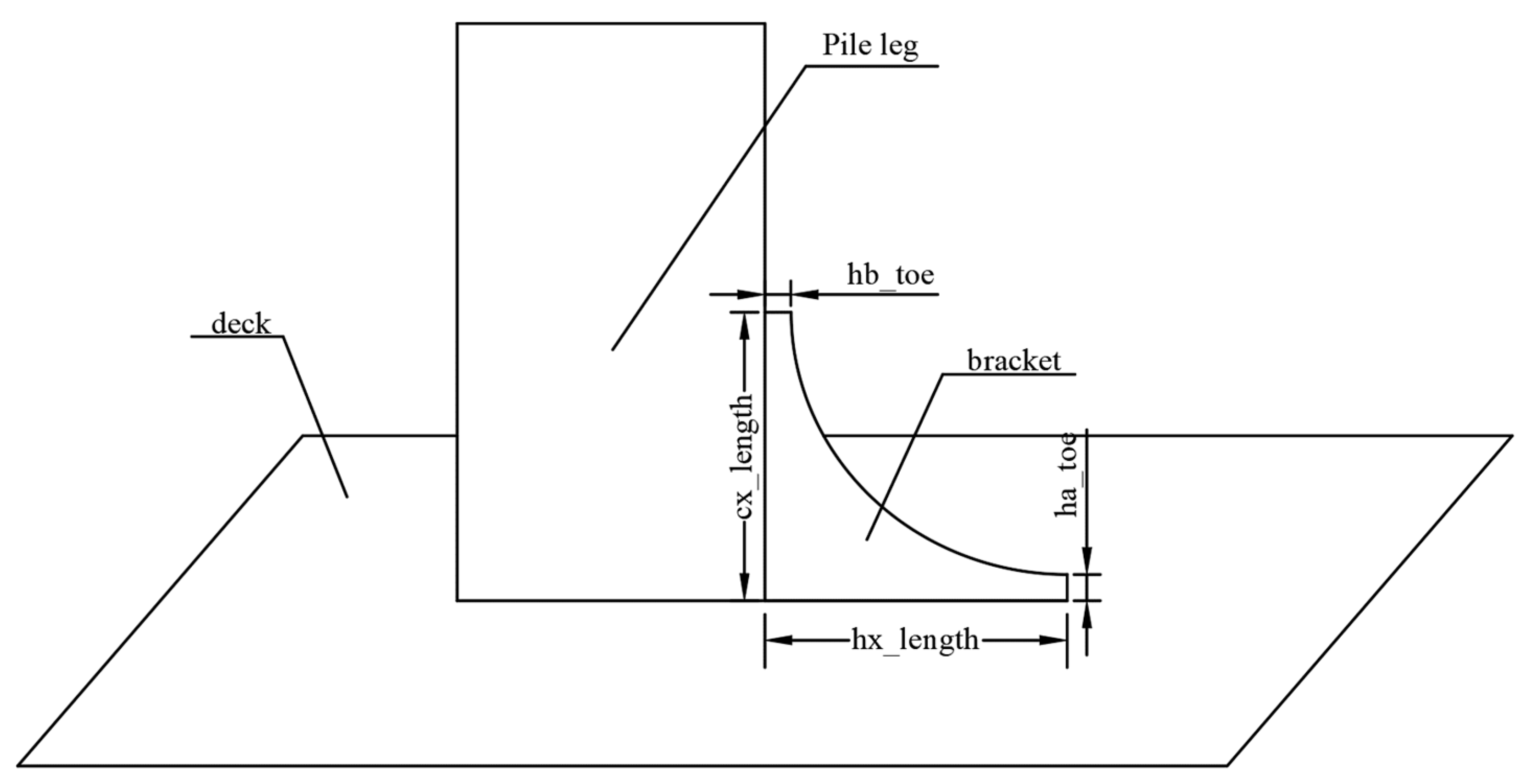

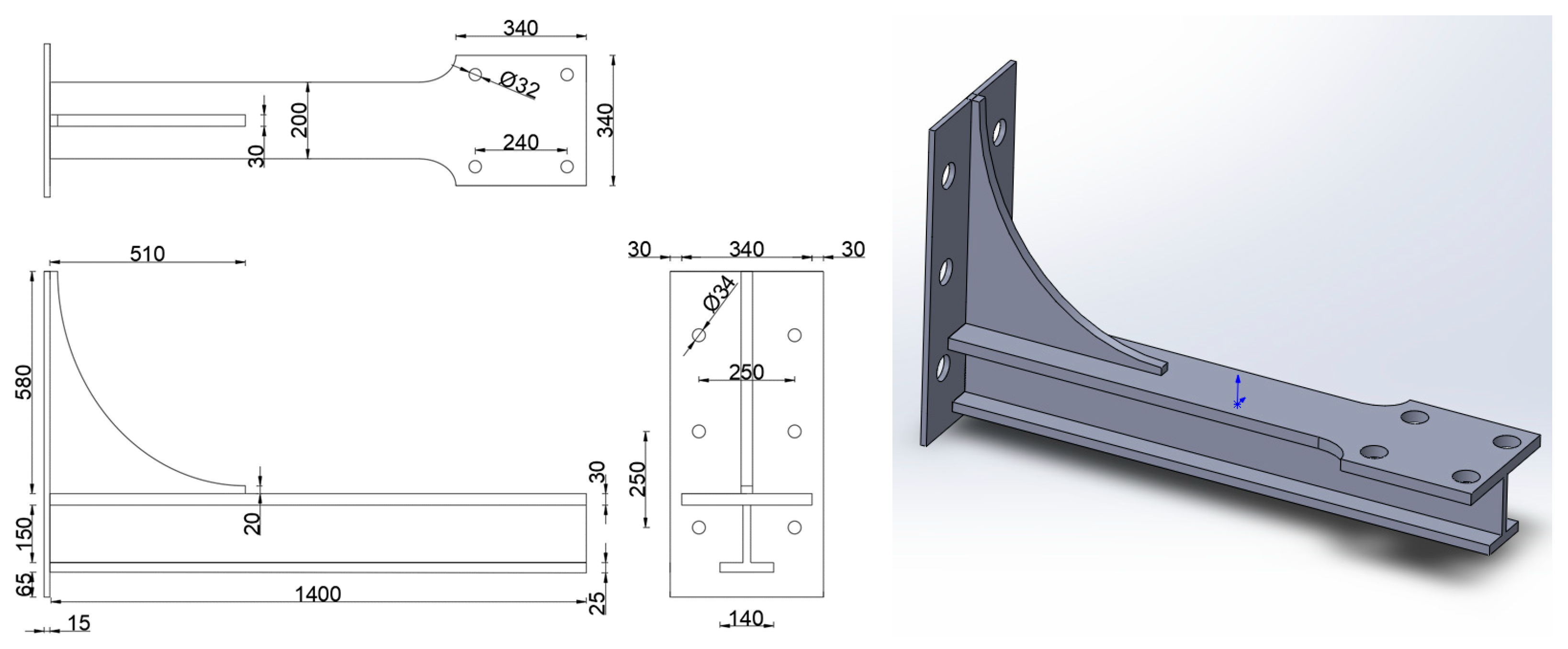

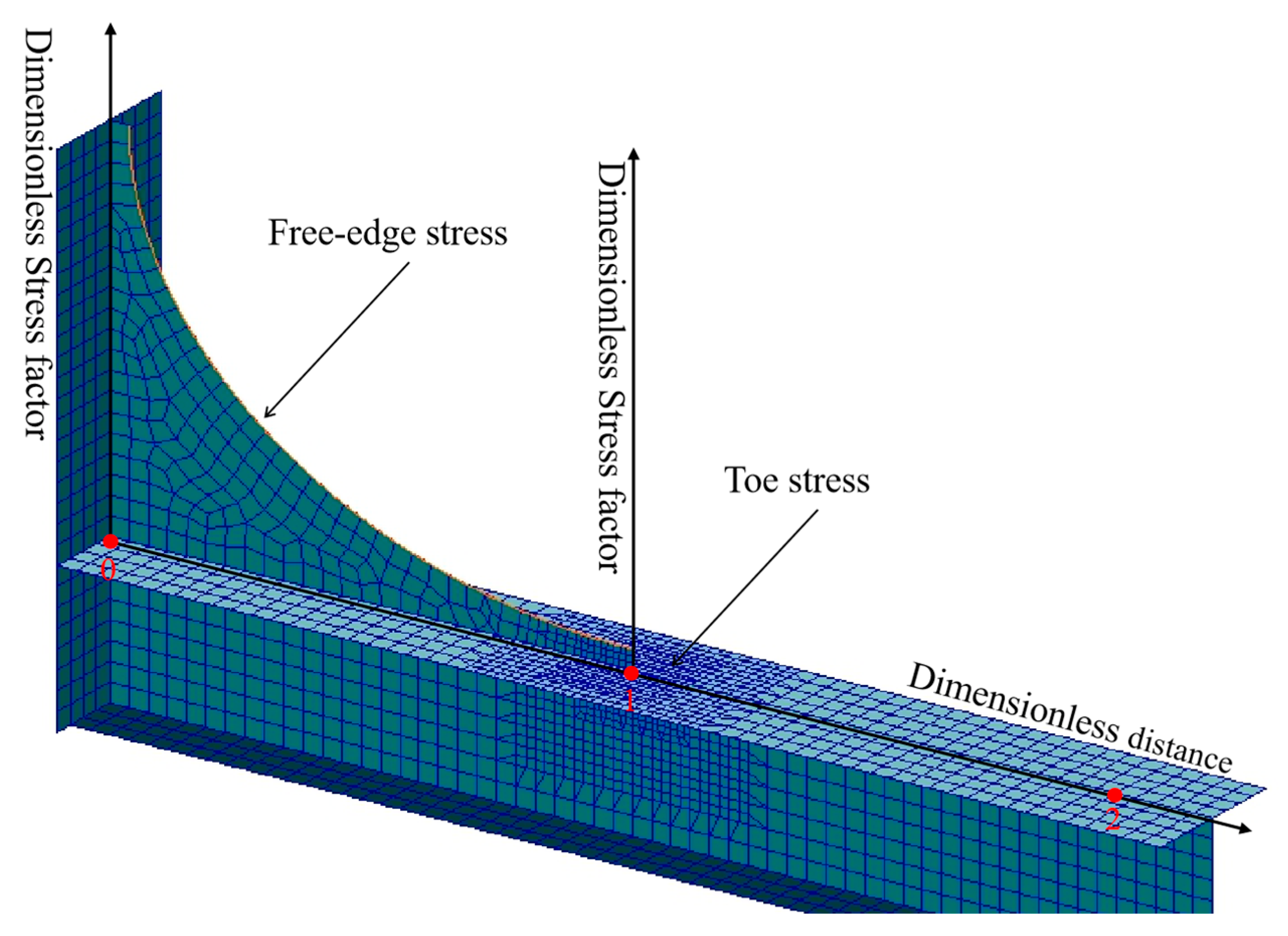

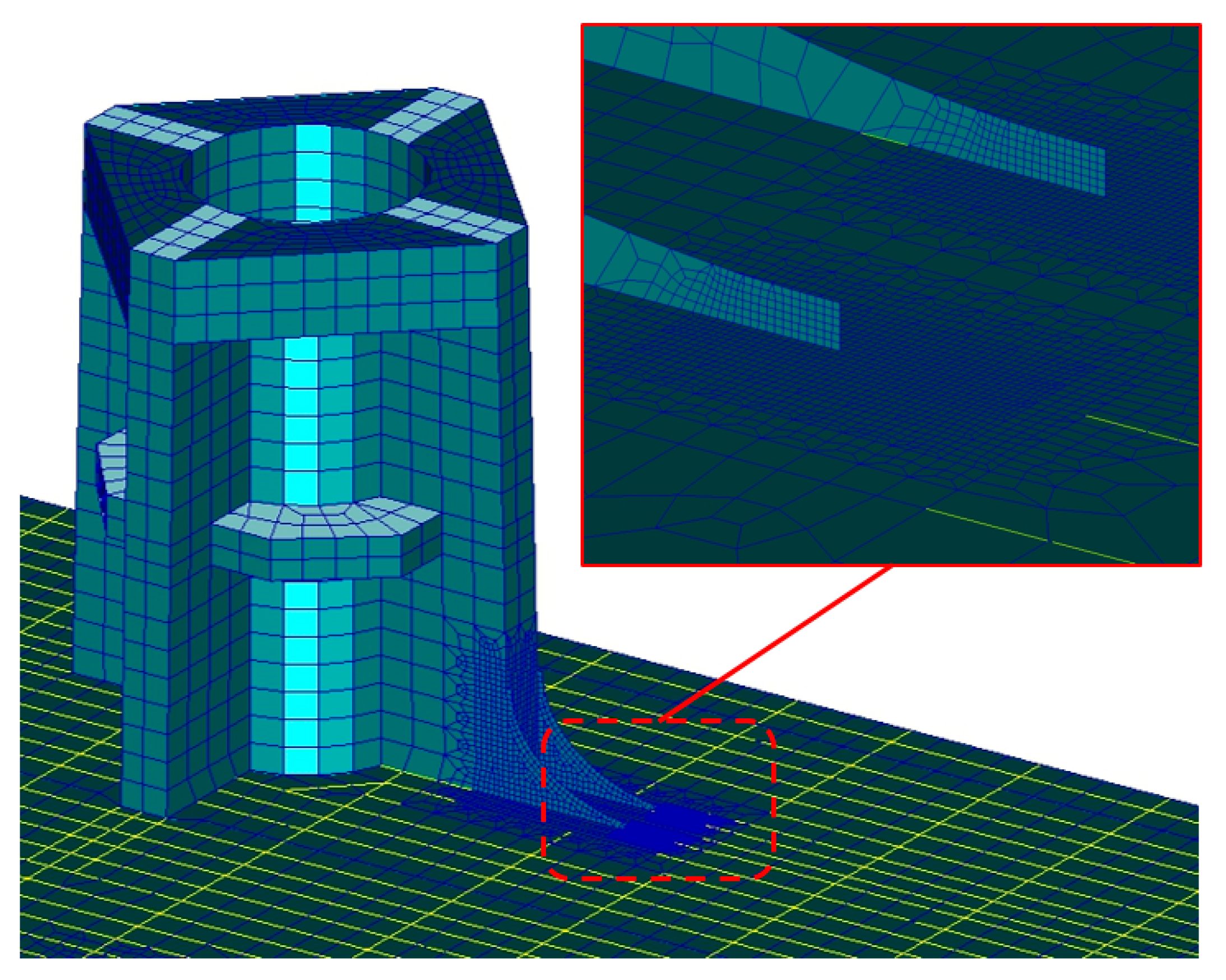

This study primarily focuses on calculating and analyzing the fatigue damage at the hotspot of the bracket toe at the root of the pile-support frame. During fatigue calculations, the finite element mesh near the hotspot should be sufficiently refined to capture variations in the stress gradient.

In accordance with commonly used fatigue design standards, such as DNV-RP-C203 and CCS [

21,

22], the following meshing rules were applied when refining the finite element model around the fatigue hotspots in this study. The mesh size at the hotspot was limited to not exceed the local plate thickness t. The refined mesh region was extended in all directions from the hotspot by at least 10t. A smooth transition in mesh density was maintained between the refined and coarse mesh regions. In the refined mesh area, four-node quadrilateral elements were employed, and the use of triangular elements was avoided as much as possible. The results of the mesh refinement are shown in

Figure 10.

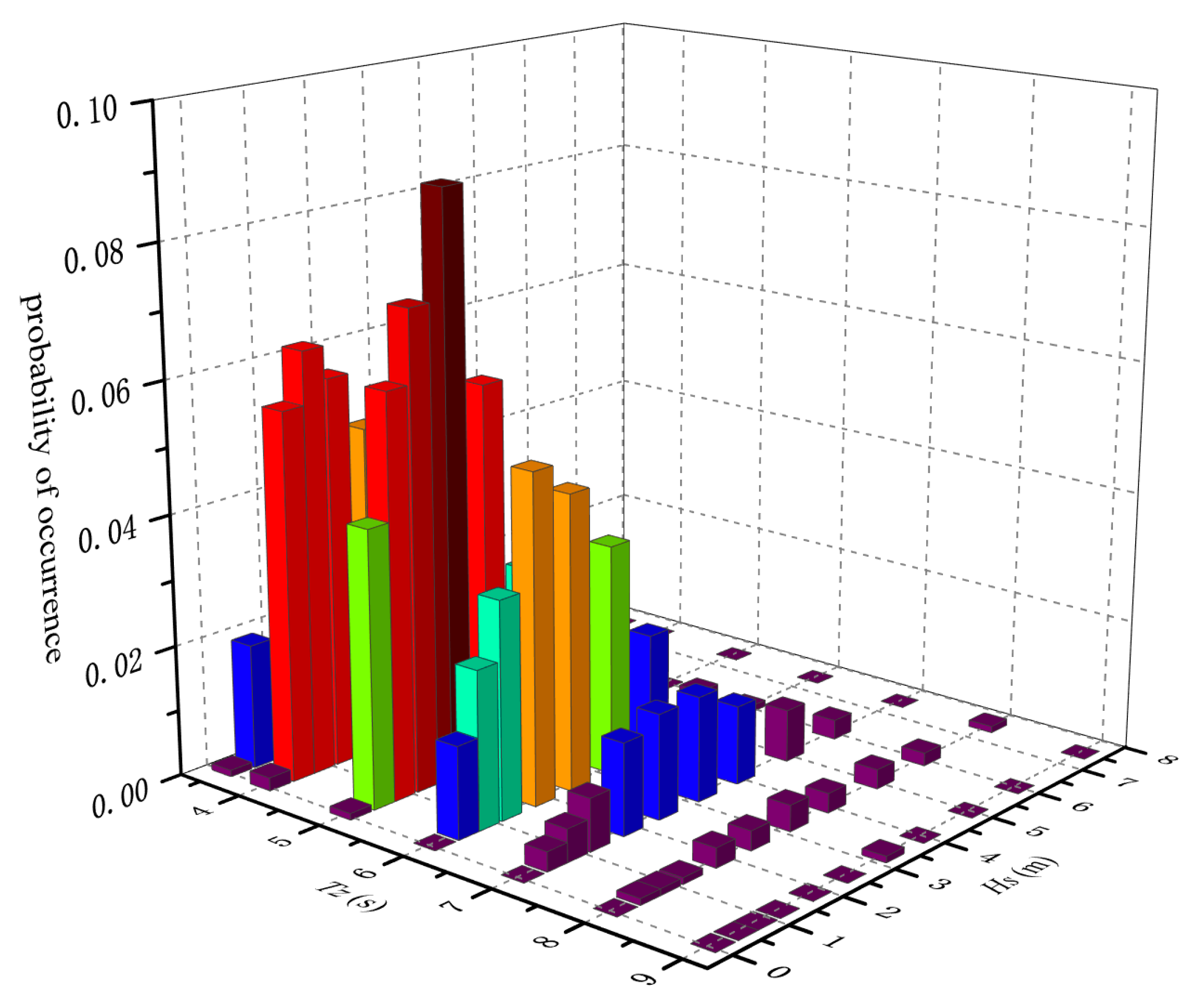

The significant wave height is a key factor affecting the strength of ship structures. Fatigue damage is not only related to the significant wave height Hs, but also to the zero-crossing period Tz, the probability of different sea states, and other factors. Therefore, fatigue damage is highly sensitive to scatter diagrams. Considering the ship operating area, wave scatter data from the coastal regions of China were selected for calculating the structural stress response transfer function [

9]. The probability distribution of waves under different periods and wave heights is shown in

Figure 11.

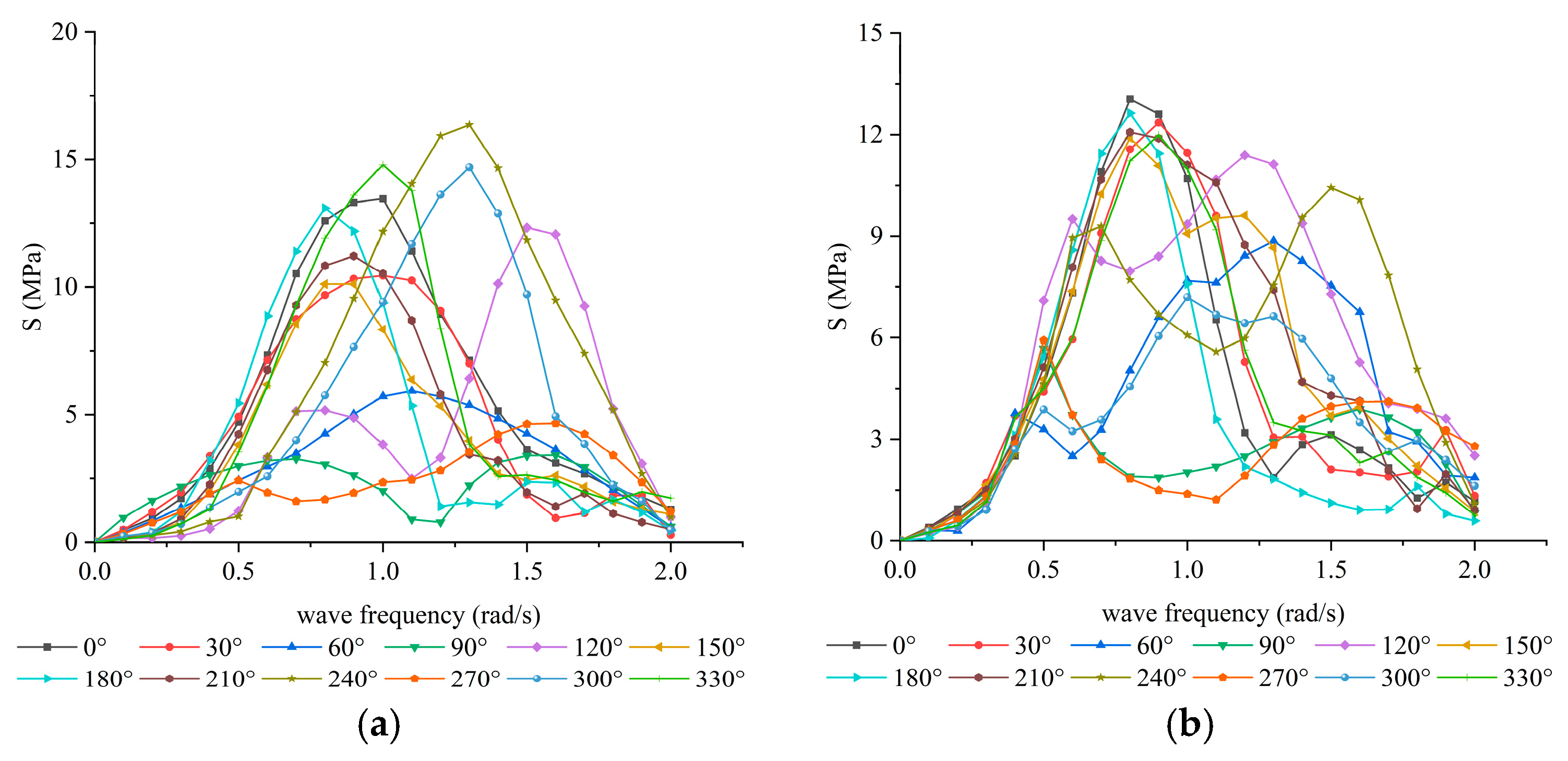

According to DNV-RP-C203 [

21], the wave heading range for fatigue analysis should cover 0–360° with intervals not larger than 30°. In this study, 12 wave directions were selected at 30° intervals, with the occurrence probability of each direction set to 1/12. The calculated natural frequency range was 0.1 rad/s to 2.0 rad/s, with an interval of 0.1 rad/s, giving a total of 20 frequencies. For the standing condition, the hydrodynamic loads were directly calculated using the linear Morison equation described earlier. For the sailing condition, the hydrodynamic calculations were performed using the COMPASS-WALCS 2.0 wave load software developed by the China Classification Society. In this way, the pressure on each element of the ship’s wetted surface under unit wave amplitude could be obtained for different operating conditions.

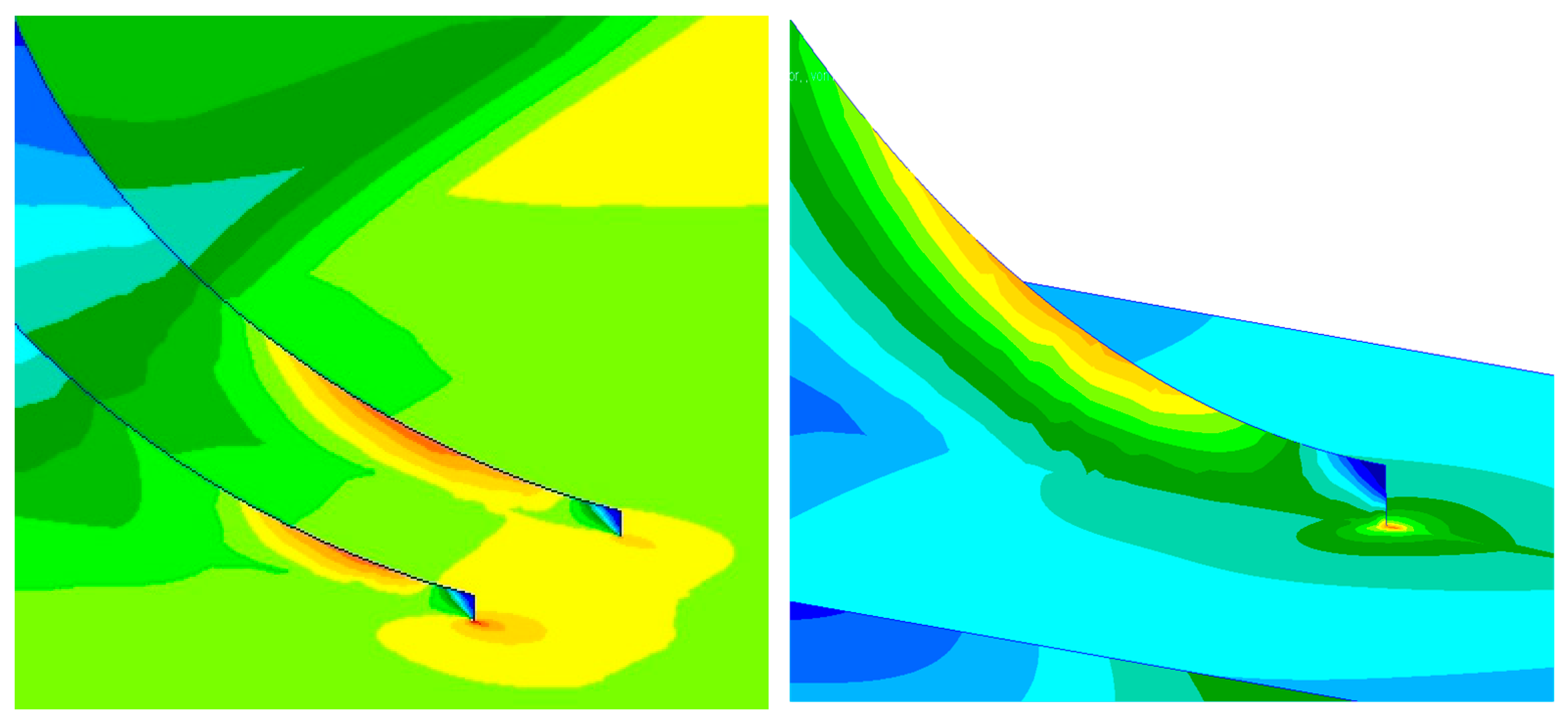

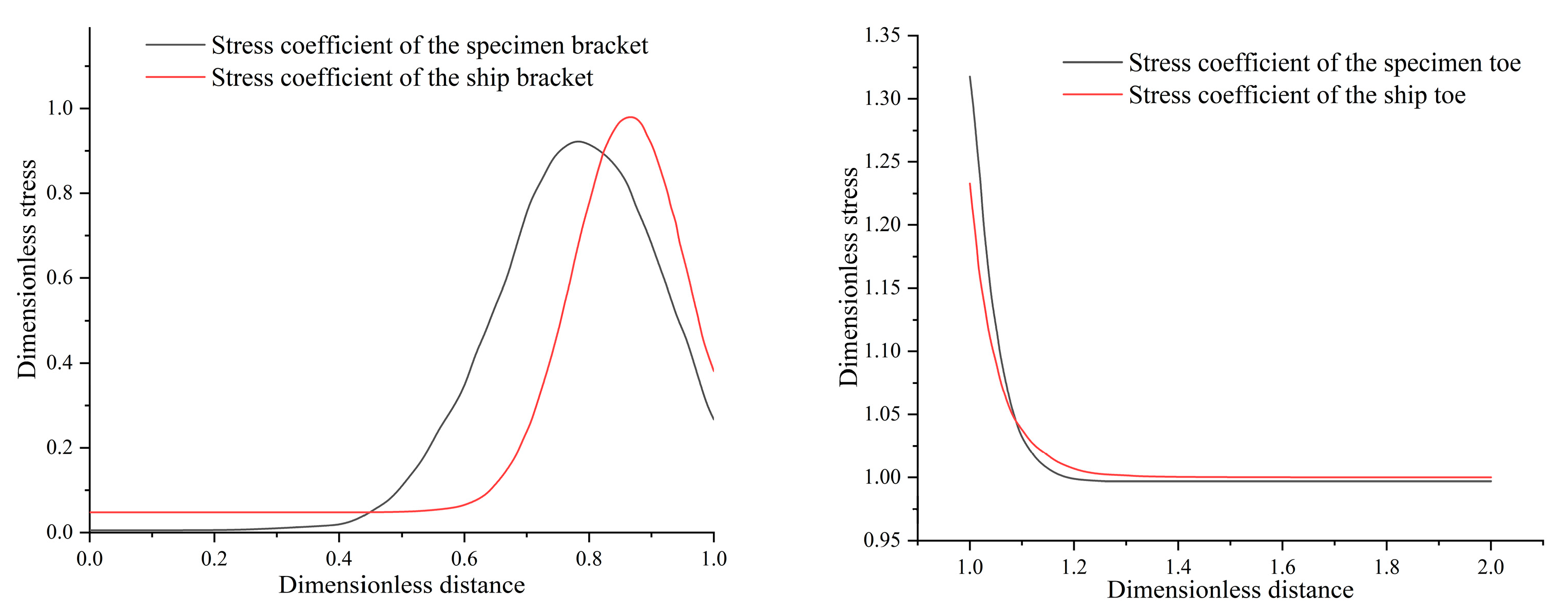

In Patran 2019, the water pressure was applied, and the inertia release method was used to calculate the structural response. After obtaining the stress response distribution of the structure, the interpolation method described in Equation (5) and illustrated in

Figure 8 was employed to derive the stress response at the hotspot. Consequently, the stress response transfer functions under different wave directions and frequencies were obtained, as shown in

Figure 12.

For the wind turbine installation vessel examined in this study, the design service life is 20 years, and the duration distributions of the sailing and standing conditions are shown in

Table 5.

At this stage, by combining the stress response transfer function with the spectral fatigue analysis method, the total fatigue damage of the target vessel over 20 years can be calculated. The results are presented in

Table 6.

A comparison of the fatigue damage data in

Table 6 reveals that the damage under the standing condition is significantly higher than that under the sailing condition. This difference is primarily attributed to two factors: first, the standing condition lasts longer, leading to more pronounced cumulative effects; second, once the pile legs penetrate into the seabed and extend above the water, the bending moment acting on the pile-support frame increases, thereby causing stronger stress concentration.

This trend can also be verified by the stress responses in

Figure 12: the maximum stress response under the standing condition is 32.8 MPa, whereas that under the sailing condition is 26.2 MPa. The difference between the two results in distinct damage distributions.

Over the design service life, the total damage of the pile-support frame of the target vessel is 0.60, which is below the allowable limit specified in the standards. In comparison, the damage of the pre-optimized structure was 1.08, exceeding the limit and not meeting the fatigue safety requirements.

After considering the error introduced by the linearization of Morison’s equation, the results still meet the design requirements. This indicates that the optimization design proposed in this study can effectively satisfy fatigue safety requirements and demonstrates both rationality and engineering applicability.

The distribution of fatigue damage across different wave headings varies significantly depending on the operating condition. Under the Standing condition, the most severe fatigue damage occurs at a wave heading of 240°, corresponding to oblique waves. Similarly, for the Sailing condition, the maximum fatigue damage is observed at a wave heading of 210°, also associated with oblique waves. This directional dependence highlights the importance of considering wave orientation in fatigue analysis. The specific values of the fatigue damage for each condition are presented in

Table 7.

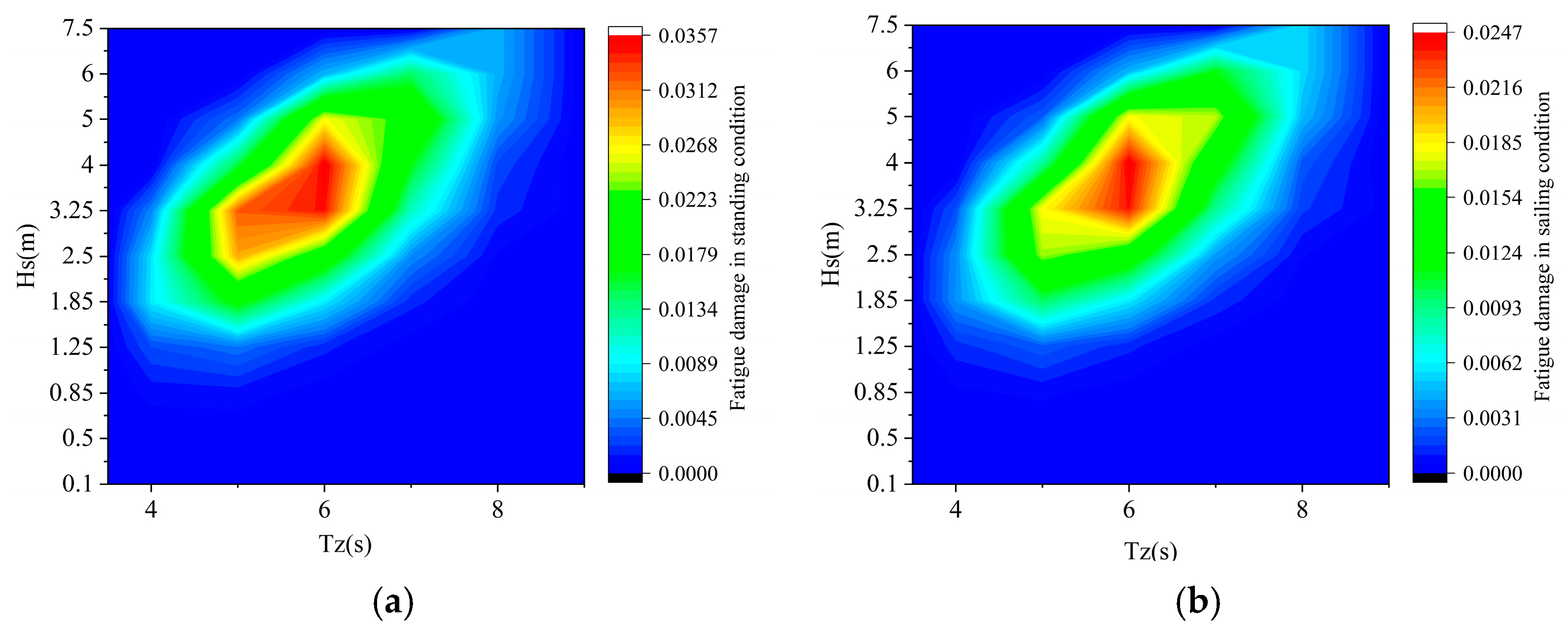

The distribution of fatigue damage varies significantly across different sea states. Under the Standing condition, the most severe fatigue damage occurs in a sea state with a wave height of 3.25 m and a wave period of 6 s. Similarly, under the Sailing condition, the maximum fatigue damage is observed in a sea state with the same wave height of 3.25 m and wave period of 6 s. This indicates that the combination of these particular wave characteristics contributes most significantly to fatigue damage in both conditions. The specific values of fatigue damage under these sea states are presented in

Figure 13, providing a clearer comparison of the damage distribution in different operational conditions.