Advancements in Drainage Consolidation Technology for Marine Soft Soil Improvement: A Review

Abstract

1. Introduction

2. Traditional Techniques and Their Optimization Progress

2.1. Surcharge Preloading Method

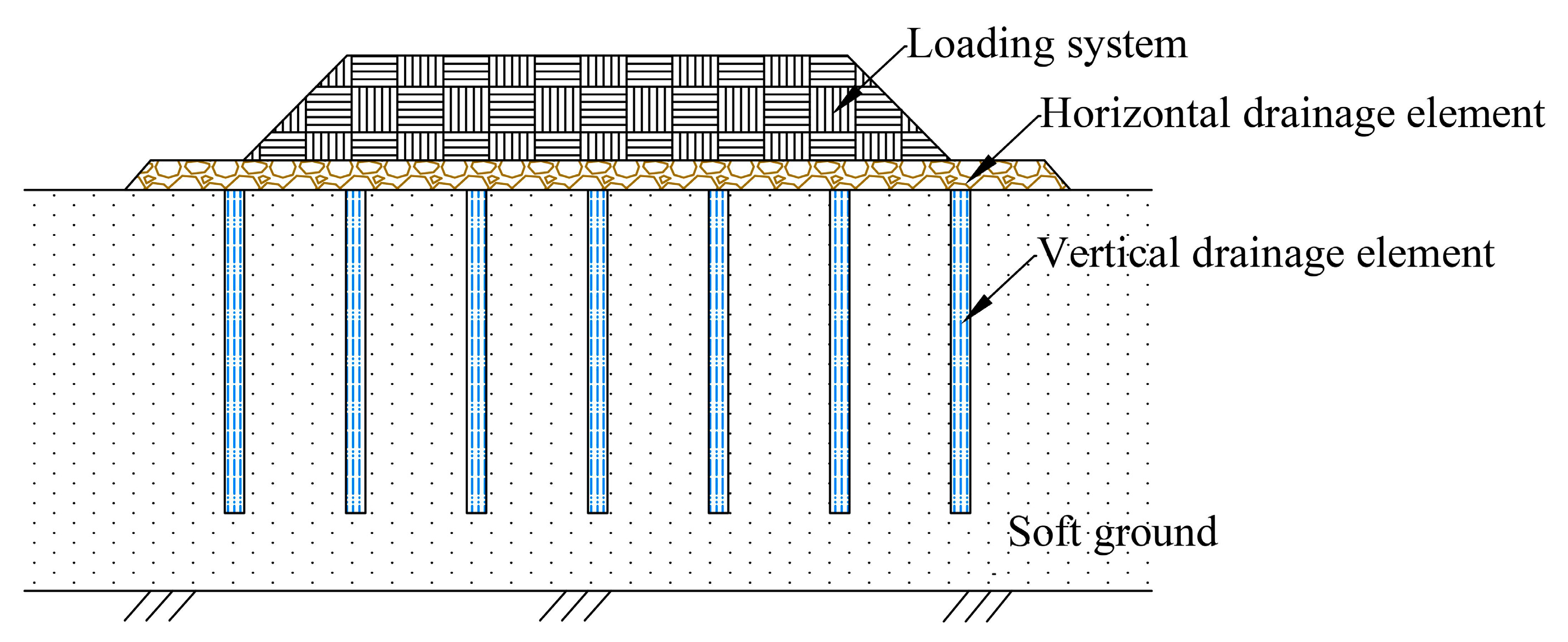

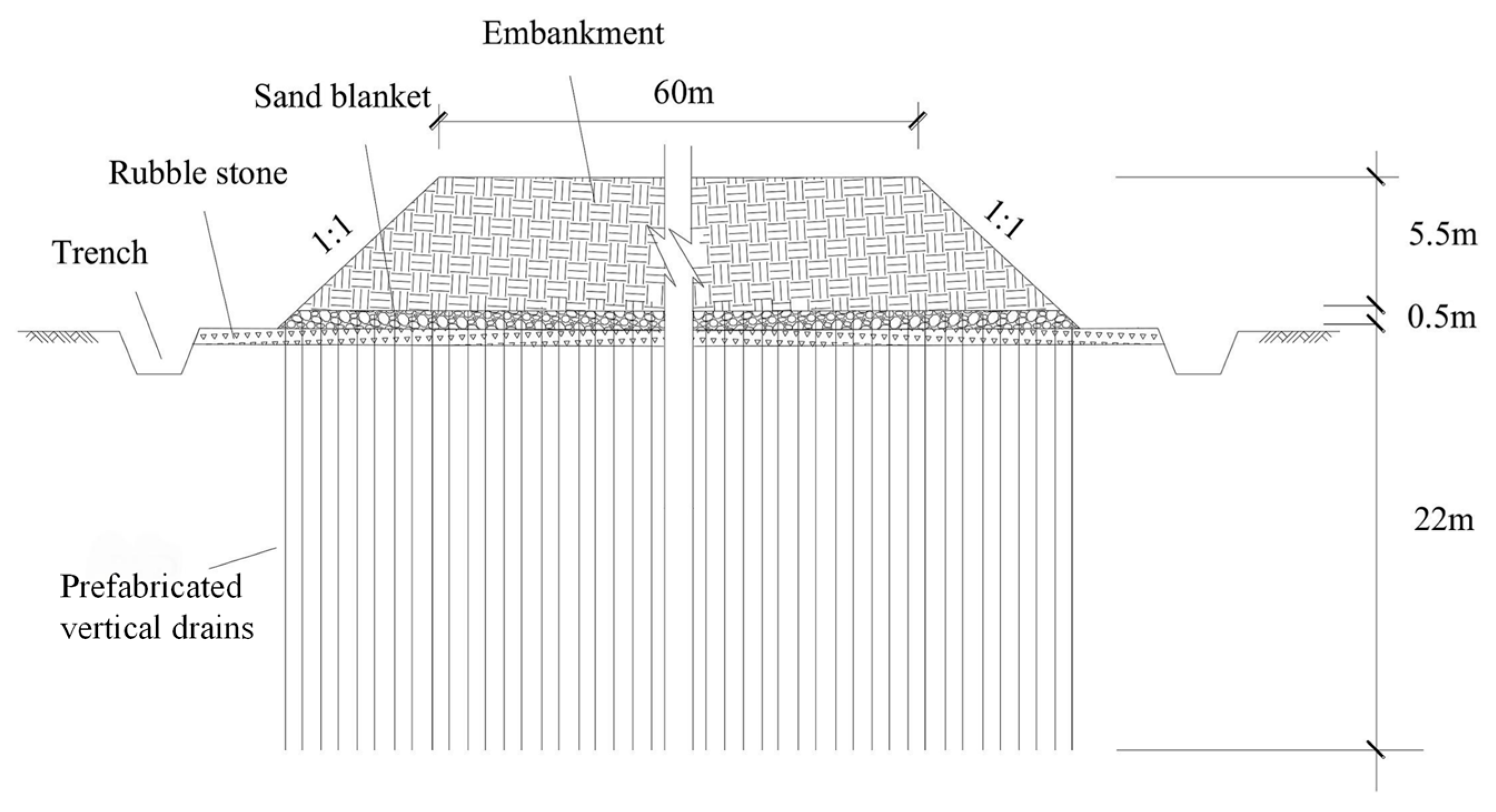

2.1.1. Technical Principle and Optimization Directions

2.1.2. Optimization Advances

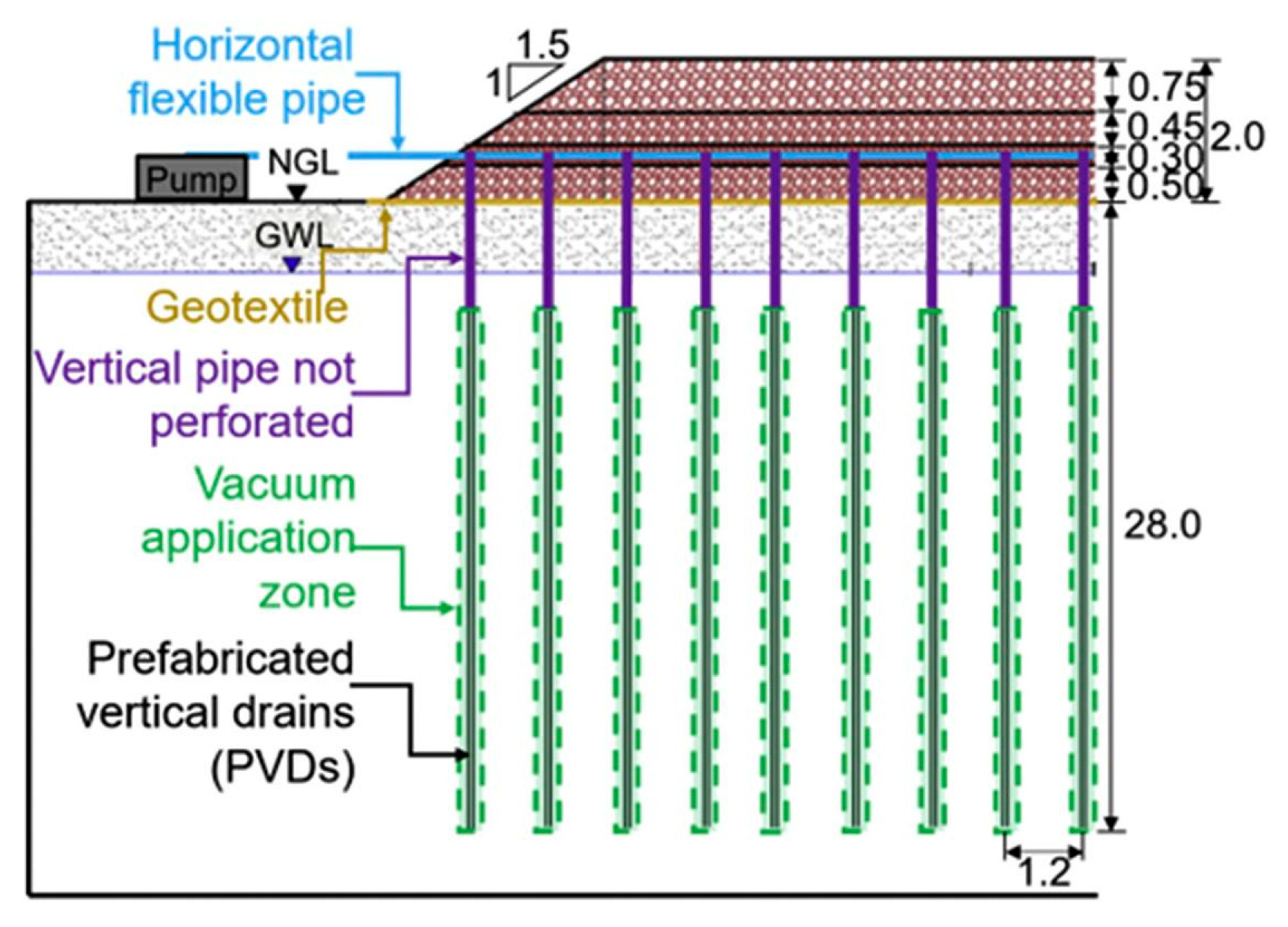

2.2. Vacuum Preloading Method

2.2.1. Technical Principle and Optimization Directions

- Improving sealing materials and methods to reduce air leakage.

- Optimizing drainage channel designs to reduce vacuum transmission losses.

- Reducing the negative impact of soft soil consolidation on vacuum pressure transmission.

- Adding external measures to increase pore water pressure within the soft soil.

2.2.2. Optimization Advances

- (1)

- Membrane-less Vacuum Preloading.

- (2)

- Flocculation Combined with Vacuum Preloading.

- (3)

- Pressure-variable Vacuum Preloading.

- (4)

- Air-boosted Vacuum Preloading.

- (5)

- Horizontal Drainage Vacuum Preloading.

2.3. Electroosmotic Drainage

2.3.1. Technical Principle and Optimization Directions

- Improving electrode materials, electrode types, and electrode configurations to reduce energy consumption and corrosion;

- Optimizing power supply modes and applied voltages to improve drainage uniformity and energy efficiency;

- Developing electro-chemo-bio synergistic consolidation, in which chemical agents or microorganisms are introduced to alter inter-particle forces and optimize soil microstructure.

2.3.2. Optimization Advances

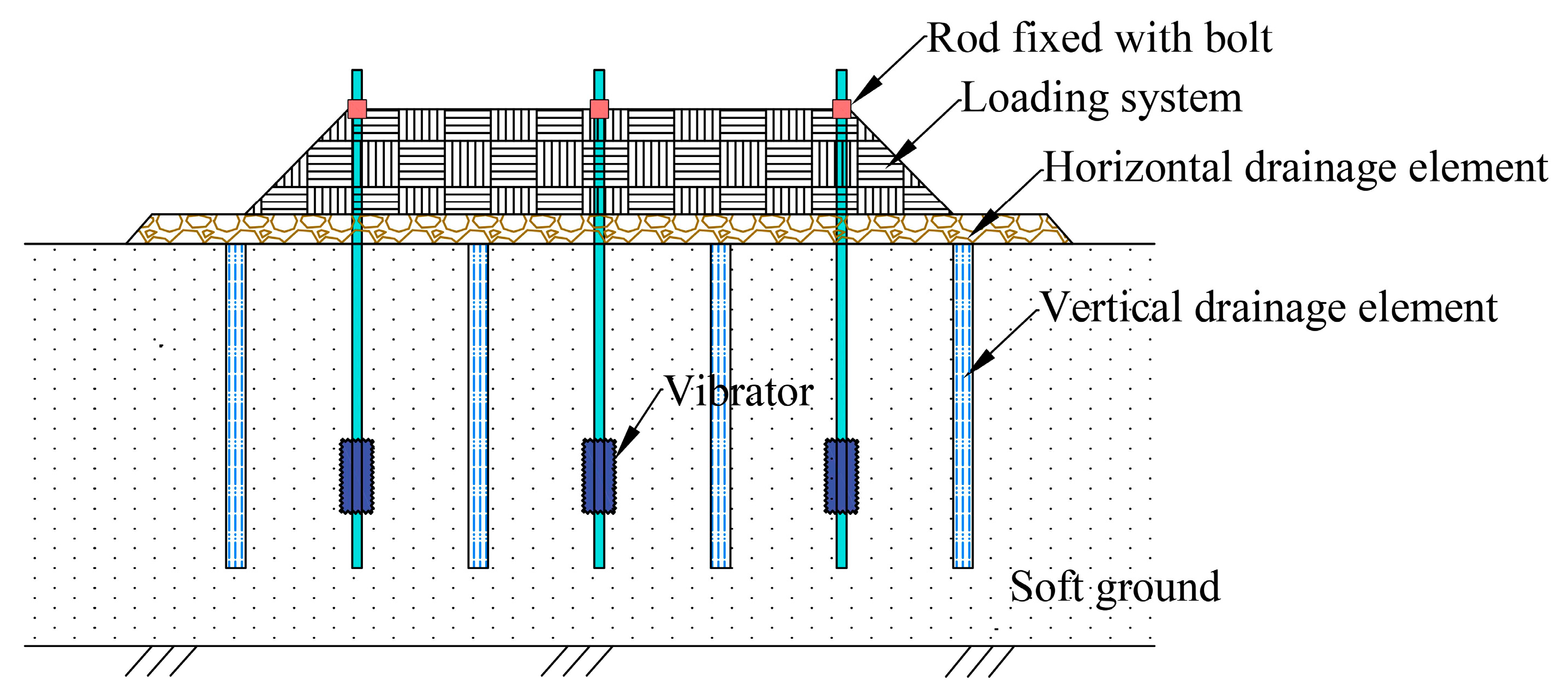

2.4. Vibration-Drainage Consolidation Method (VDCM)

2.4.1. Technical Principle and Optimization Directions

2.4.2. Optimization Advances

2.5. Dewatering Preloading Method

2.5.1. Technical Principle and Optimization Directions

2.5.2. Optimization Advances

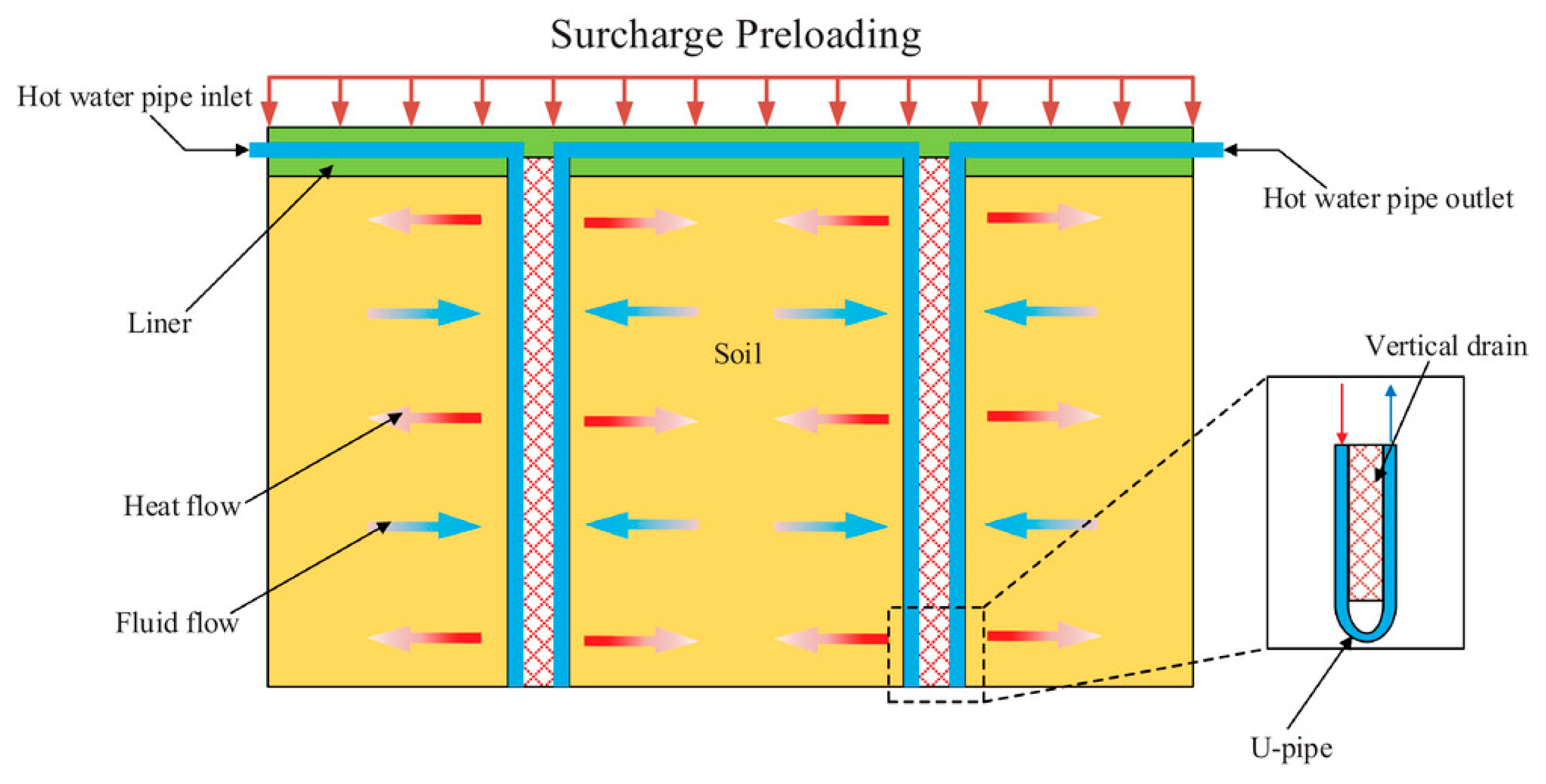

2.6. Thermal Consolidation Method

2.6.1. Technical Principle and Optimization Directions

2.6.2. Optimization Advances

2.7. Combined Applications of Multiple Techniques

3. Emerging Drainage Consolidation Methods

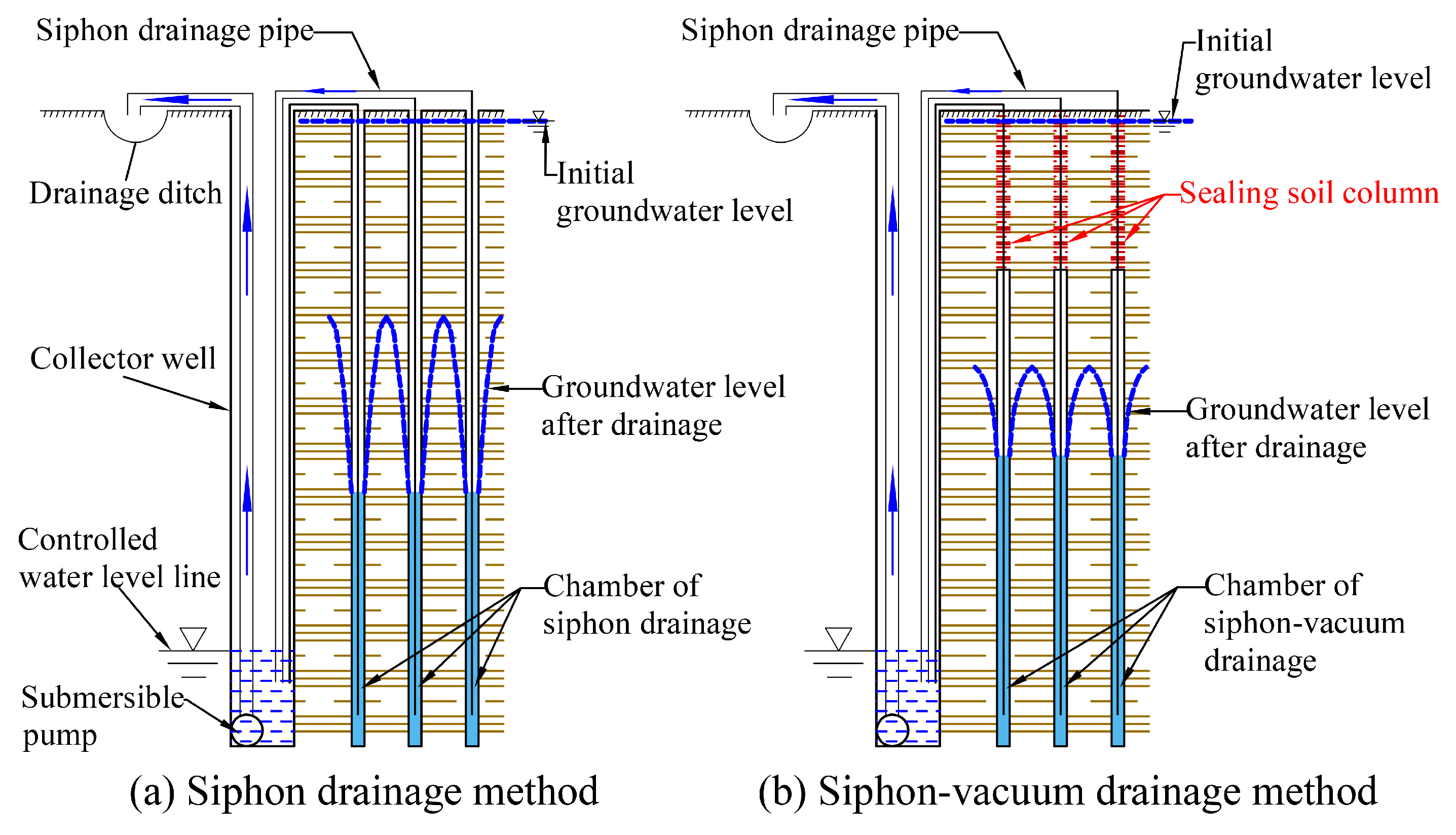

3.1. Siphon Drainage Method

3.1.1. Technical Overview

3.1.2. Research Status

3.1.3. Engineering Application Progress

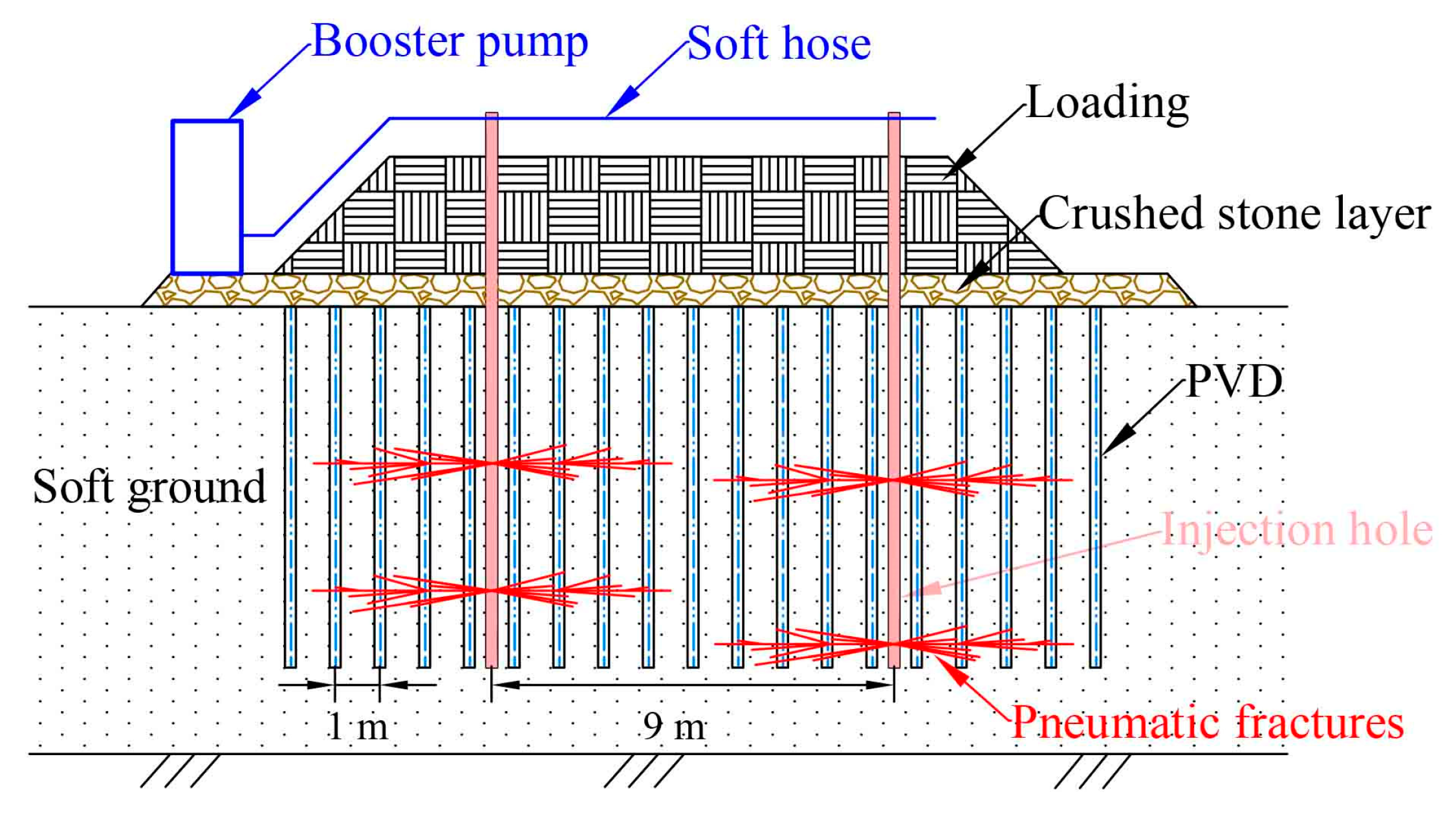

3.2. Aerosol Injection Technique (AIT)

3.2.1. Technical Overview

- Deep-layer three-dimensional drainage: High-pressure gas cuts through the soil to form multiple horizontal drainage channels at different depths, accelerating pore water dissipation.

- Deep pressurization effect: The gas pressure generated within drainage channels enhances vertical drainage efficiency.

- Air-lift effect: The injected high-pressure gas strongly interacts with the water inside the drains, producing numerous bubbles that carry water to the surface. This significantly reduces pore water pressure and promotes consolidation.

3.2.2. Research Status

3.2.3. Engineering Application Progress

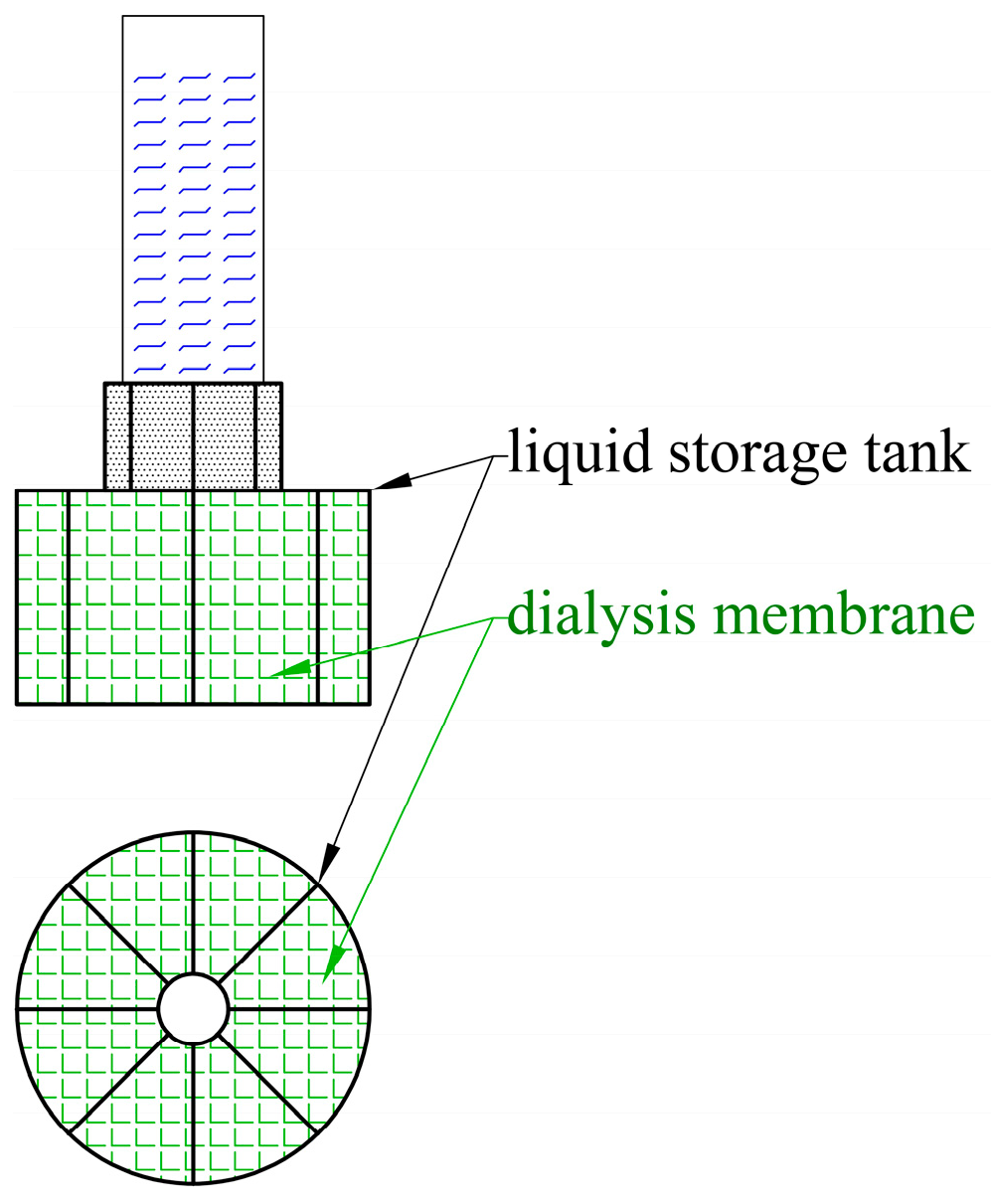

3.3. Other Exploratory Techniques

3.3.1. Osmosis-Based Drainage Technique

3.3.2. Cellular Fluidics Drainage

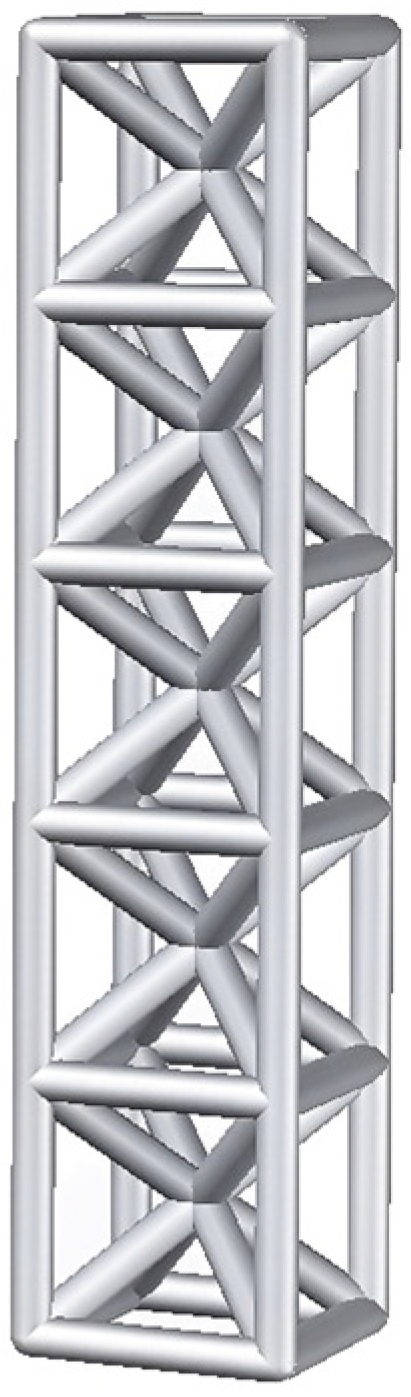

4. Innovations and Advances in Drainage Elements

4.1. Novel Drainage Element Structures

4.1.1. Geotextile Encased Columns (GEC)

4.1.2. Integrated Drainage Boards

4.1.3. Multi-Channel Expanded Drainage Boards

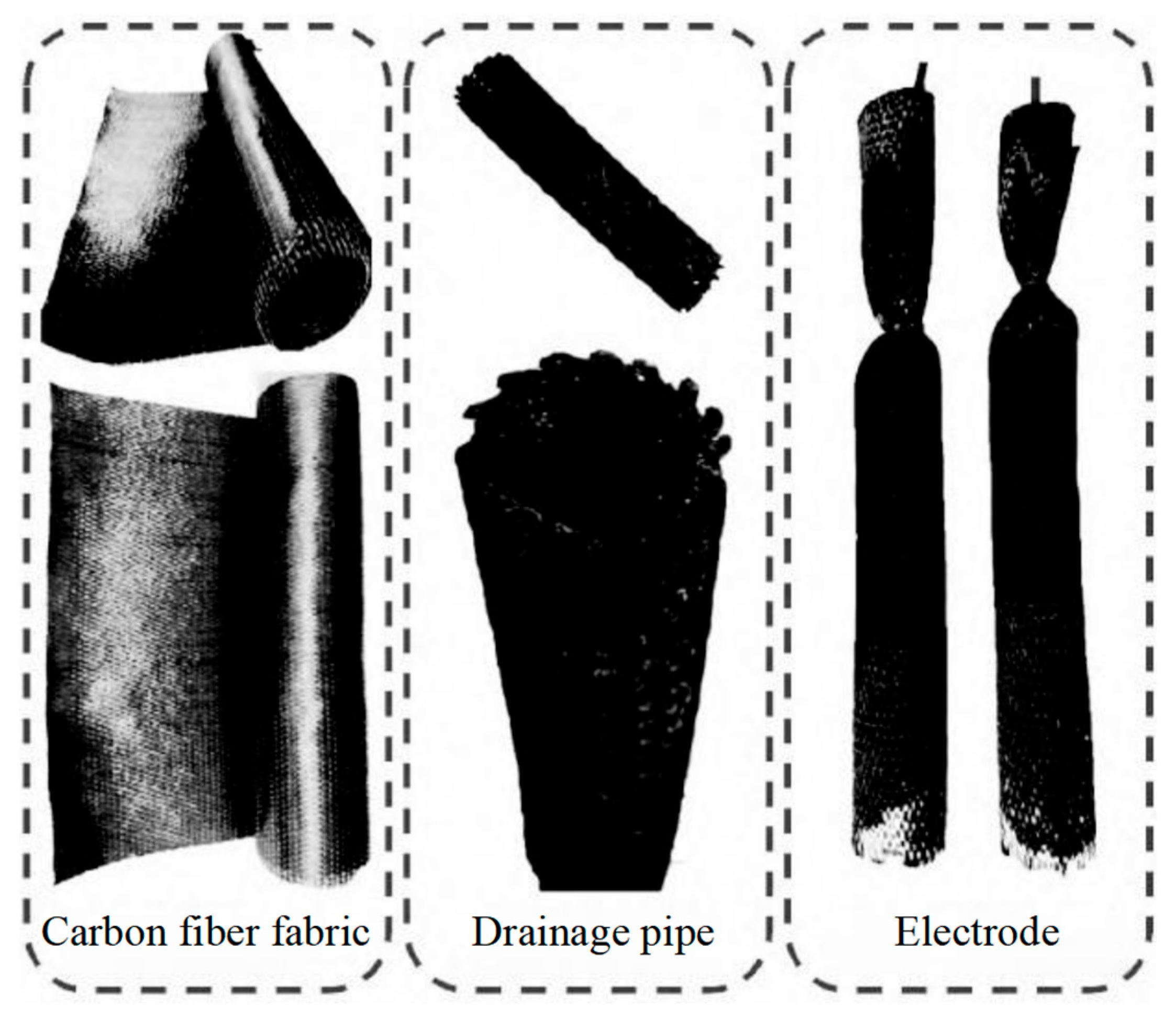

4.1.4. Tubular EKG

4.2. Novel Materials for Drainage Elements

4.2.1. Biodegradable Drainage Elements

4.2.2. Waste-Recycling Materials

4.3. Multifunctional Composite Drainage Elements

4.3.1. Air–Drainage Composite Elements

4.3.2. Thermal–Drainage Composite Elements

4.3.3. Electroosmotic–Vacuum Composite Elements

5. Discussion and Perspectives

5.1. Summary of Current Technological Advances

5.1.1. Evolution of Traditional Techniques

5.1.2. Exploration and Potential of Emerging Techniques

5.1.3. Synergistic Effects of Combined Techniques

5.1.4. Innovations and Breakthroughs in Drainage Elements

5.2. Challenges Facing Current Techniques

5.2.1. Ranges and Limitations of Technical Applications

5.2.2. Environmental and Sustainability Concerns

5.2.3. Obstacles to Green and Low-Carbon Transition

5.3. Future Directions and Prospects

5.3.1. Development and Optimization of Green and Low-Carbon Technologies

5.3.2. Multi-Field Coupling and Synergistic Mechanisms

5.3.3. Sustainable Materials and Waste Utilization

5.3.4. Deep Integration of Intelligence and Digitalization

5.3.5. Concluding Remarks

6. Conclusions

- (1)

- Established techniques such as surcharge preloading, vacuum preloading, electroosmosis, dynamic loading, dewatering, and thermal consolidation are now optimized in several ways. These include refined loading schemes and staged application, pressure-variable or intermittent operation, improved sealing and vacuum-transmission control, energy-efficient pump management, probabilistic or AI-assisted design and monitoring, and the use of renewable heat or power. Emerging methods, including siphon drainage and aerosol injection, provide alternatives for deeper or more energy-efficient treatment. Hybrid approaches that combine multiple methods show promise for complex soils. However, the applicability of these techniques under highly variable field conditions and their long-term reliability remains insufficiently validated.

- (2)

- Innovations in drainage elements. As the core of drainage consolidation systems, innovations in the structure and materials of drainage elements have become research hotspots. Integrated, multi-channel, radial drainage boards and tubular electrokinetic geosynthetics (EKG) have demonstrated remarkable improvements in drainage efficiency and stability. Meanwhile, studies on natural fibers (e.g., jute, coir, straw), waste-recycled materials (e.g., face mask fibers), and biodegradable drains provide new pathways to address the environmental burdens of conventional plastic drains. These innovations have laid a foundation for the sustainable development of soft soil improvement. Yet, their durability, degradation rates, and mechanical performance in large-scale projects still require systematic testing and long-term monitoring.

- (3)

- Challenges and future focuses. At present, the applicability of drainage consolidation technologies remains limited under special conditions such as thick soft clay layers and ultra-soft sludge. Large-scale applications of emerging methods still face cost and technical barriers. Issues related to environmental safety, long-term material performance, and energy dependence also require urgent solutions. Future development should focus on low-energy and renewable-energy-driven green technologies; multi-field coupling mechanisms integrating electro, chemical, bio, thermal, air, and dynamic effects; the development of sustainable materials and waste reutilization; and the deep integration of intelligent and digital technologies to enable real-time monitoring and dynamic control of consolidation processes.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Stanchev, H.; Stancheva, M.; Young, R. Implications of Population and Tourism Development Growth for Bulgarian Coastal Zone. J. Coast. Conserv. 2015, 19, 59–72. [Google Scholar] [CrossRef]

- Wang, D.; Wiltshire, J. Special Issue: Land Reclamation and Enhancement of Soft Marine Sediment for Building. Mar. Georesour. Geotechnol. 2018, 36, 1. [Google Scholar] [CrossRef]

- Pickles, A.R.; Tosen, R. Settlement of Reclaimed Land for the New Hong Kong International Airport. Proc. Inst. Civ. Eng. Geotech. Eng. 1998, 131, 191–209. [Google Scholar] [CrossRef]

- Indraratna, B.; Rujikiatkamjorn, C.; Baral, P.; Ameratunga, J. Performance of Marine Clay Stabilised with Vacuum Pressure: Based on Queensland Experience. J. Rock Mech. Geotech. Eng. 2019, 11, 598–611. [Google Scholar] [CrossRef]

- Furudoi, T. The Second Phase Construction of Kansai International Airport Considering the Large and Long-Term Settlement of the Clay Deposits. Soils Found. 2010, 50, 805–816. [Google Scholar] [CrossRef]

- Wang, L.; Kwok, J.S.H.; Tsang, D.C.W.; Poon, C.-S. Mixture Design and Treatment Methods for Recycling Contaminated Sediment. J. Hazard. Mater. 2015, 283, 623–632. [Google Scholar] [CrossRef] [PubMed]

- López-Acosta, N.P.; Espinosa-Santiago, A.L. Vacuum Consolidation Effect on the Hydromechanical Properties of the Unusual Soft Clays of the Former Texcoco Lake. Soils Found. 2024, 64, 101410. [Google Scholar] [CrossRef]

- Konkol, J.; Międlarz, K.; Bałachowski, L. Geotechnical Characterization of Soft Soil Deposits in Northern Poland. Eng. Geol. 2019, 259, 105187. [Google Scholar] [CrossRef]

- Dehghanbanadaki, A.; Ahmad, K.; Ali, N. Experimental Investigations on Ultimate Bearing Capacity of Peat Stabilized by a Group of Soil–Cement Column: A Comparative Study. Acta Geotech. 2016, 11, 295–307. [Google Scholar] [CrossRef]

- Sadaoui, O.; Bahar, R. Field Measurements and Back Calculations of Settlements of Structures Founded on Improved Soft Soils by Stone Columns. Eur. J. Environ. Civ. Eng. 2019, 23, 85–111. [Google Scholar] [CrossRef]

- Consoli, N.C.; Moreira, E.B.; Festugato, L.; Caballero, R.D.; Foppa, D.; Ruver, C.A. Enhancing Bearing Capacity of Shallow Foundations through Cement-Stabilised Sand Layer over Weakly Bonded Residual Soil. Géotechnique 2021, 72, 872–881. [Google Scholar] [CrossRef]

- Ghosh, B.; Fatahi, B.; Khabbaz, H.; Nguyen, H.H.; Kelly, R. Field Study and Numerical Modelling for a Road Embankment Built on Soft Soil Improved with Concrete Injected Columns and Geosynthetics Reinforced Platform. Geotext. Geomembr. 2021, 49, 804–824. [Google Scholar] [CrossRef]

- Karunaratne, G.P. Prefabricated and Electrical Vertical Drains for Consolidation of Soft Clay. Geotext. Geomembr. 2011, 29, 391–401. [Google Scholar] [CrossRef]

- Mesri, G.; Khan, A.Q. Ground Improvement Using Vacuum Loading Together with Vertical Drains. J. Geotech. Geoenviron. Eng. 2012, 138, 680–689. [Google Scholar] [CrossRef]

- Barron, R.A. Consolidation of Fine-Grained Soils by Drain Wells by Drain Wells. Trans. Am. Soc. Civ. Eng. 1948, 113, 718–742. [Google Scholar] [CrossRef]

- Gangaputhiran, S.; Robinson, R.G.; Karpurapu, R. Properties of Soil after Surcharge or Vacuum Preloading. Proc. Inst. Civ. Eng. Ground Improv. 2016, 169, 217–230. [Google Scholar] [CrossRef]

- Ngo, D.H.; Horpibulsuk, S.; Suddeepong, A.; Hoy, M.; Udomchai, A.; Doncommul, P.; Rachan, R.; Arulrajah, A. Consolidation Behavior of Dredged Ultra-Soft Soil Improved with Prefabricated Vertical Drain at the Mae Moh Mine, Thailand. Geotext. Geomembr. 2020, 48, 561–571. [Google Scholar] [CrossRef]

- Nguyen, B.-P.; Kim, Y.-T. Radial Consolidation of PVD-Installed Normally Consolidated Soil with Discharge Capacity Reduction Using Large-Strain Theory. Geotext. Geomembr. 2019, 47, 243–254. [Google Scholar] [CrossRef]

- Wang, J.; Fang, Z.; Cai, Y.; Chai, J.; Wang, P.; Geng, X. Preloading Using Fill Surcharge and Prefabricated Vertical Drains for an Airport. Geotext. Geomembr. 2018, 46, 575–585. [Google Scholar] [CrossRef]

- Wu, S.; Zhan, L. Study on water bag surcharge-combined vacuum preloading without sand cushion for shallow soft foundation treatment. Water Resour. Hydropower Eng. 2021, 52, 225–235. (In Chinese) [Google Scholar] [CrossRef]

- Liao, J.; Xu, S.; Zhang, C.; Bai, G.; Li, T. Experimental Study on the Consolidation Characteristics of Soilbags-Reinforced Soft Soil Foundation with Surcharge Preloading. Case Stud. Constr. Mater. 2025, 22, e04746. [Google Scholar] [CrossRef]

- Han, C.; Fan, Z.; Zhang, R.; Cheng, J.; Sun, K.; Peng, Q. Consolidation Characteristics of High-Water-Content Slurries Improved by Flocculation-Enhanced Surcharge (Vacuum) Preloading Method. Front. Mater. 2023, 10, 1166551. [Google Scholar] [CrossRef]

- Spross, J.; Larsson, S. Probabilistic Observational Method for Design of Surcharges on Vertical Drains. Géotechnique 2021, 71, 226–238. [Google Scholar] [CrossRef]

- Baral, P.; Indraratna, B.; Rujikiatkamjorn, C.; Kelly, R.; Vincent, P. Consolidation by Vertical Drains beneath a Circular Embankment under Surcharge and Vacuum Preloading. J. Geotech. Geoenviron. Eng. 2021, 147, 5021004. [Google Scholar] [CrossRef]

- Pham, H.T.; Rühaak, W.; Schulte, D.; Sass, I. Application of the Vimoke–Taylor Concept for Fully Coupled Models of Consolidation by Prefabricated Vertical Drains. Comput. Geotech. 2019, 116, 103201. [Google Scholar] [CrossRef]

- Zhang, Z.; Ye, G.-B.; Xu, Y. Comparative Analysis on Performance of Vertical Drain Improved Clay Deposit under Vacuum or Surcharge Loading. Geotext. Geomembr. 2018, 46, 146–154. [Google Scholar] [CrossRef]

- López-Acosta, N.P.; Espinosa-Santiago, A.L.; Pineda-Núñez, V.M.; Ossa, A.; Mendoza, M.J.; Ovando-Shelley, E.; Botero, E. Performance of a Test Embankment on Very Soft Clayey Soil Improved with Drain-to-Drain Vacuum Preloading Technology. Geotext. Geomembr. 2019, 47, 618–631. [Google Scholar] [CrossRef]

- Griffin, H.; O’Kelly, B.C. Ground Improvement by Vacuum Consolidation—A Review. Proc. Inst. Civ. Eng. Ground Improv. 2014, 167, 274–290. [Google Scholar] [CrossRef]

- Liang, A.; Liu, J.; Li, M.; Li, W. Vacuum preloading technology for ultra-soft soils with footed-in filter tubes and its field tests. Chin. J. Geotech. Eng. 2013, 35, 712–716. (In Chinese) [Google Scholar]

- Liang, A.; Zhuge, A.; Li, J.; Li, W. Research and application of a new quick-improvement technique for hydraulic filled ultra-soft soil ground. J. Hydraul. Eng. 2015, 46, 148–152. (In Chinese) [Google Scholar] [CrossRef]

- Sun, L.; Guo, W.; Chu, J.; Nie, W.; Ren, Y.; Yan, S.; Hou, J. A Pilot Test on a Membraneless Vacuum Preloading Method. Geotext. Geomembr. 2017, 45, 142–148. [Google Scholar] [CrossRef]

- Lam, K.P.; Wu, S.; Chu, J. Field Trial of a Membraneless Vacuum Preloading System for Soft Soil Improvement. Proc. Inst. Civ. Eng. Ground Improv. 2018, 173, 40–50. [Google Scholar] [CrossRef]

- Lin, W.; Zhan, X.; Zhan, T.L.; Chen, Y.; Jin, Y.; Jiang, J. Effect of FeCl3-Conditioning on Consolidation Property of Sewage Sludge and Vacuum Preloading Test with Integrated PVDs at the Changan Landfill, China. Geotext. Geomembr. 2014, 42, 181–190. [Google Scholar] [CrossRef]

- Wang, J.; Ni, J.; Cai, Y.; Fu, H.; Wang, P. Combination of Vacuum Preloading and Lime Treatment for Improvement of Dredged Fill. Eng. Geol. 2017, 227, 149–158. [Google Scholar] [CrossRef]

- Lei, H.; Xu, Y.; Li, X.; Jiang, M.; Liu, L. Effect of Polyacrylamide on Improvement of Dredger Fill with Vacuum Preloading Method. J. Mater. Civ. Eng. 2019, 31, 4019193. [Google Scholar] [CrossRef]

- Wang, J.; Shi, W.; Wu, W.; Liu, F.; Fu, H.; Cai, Y.; Hai, J.; Hu, X.; Zhu, X. Influence of Composite Flocculant FeCl3–APAM on Vacuum Drainage of River-Dredged Sludge. Can. Geotech. J. 2019, 56, 868–875. [Google Scholar] [CrossRef]

- Song, D.-B.; Pan, Y.; Chen, W.-B.; Yin, Z.-Y.; Feng, W.-Q.; Yin, J.-H. Experimental and Numerical Modeling on Vacuum Consolidation Behavior of Staged-Filled Soil Slurry with Prefabricated Horizontal Drain and Flocculant. J. Rock Mech. Geotech. Eng. 2024, 16, 5231–5248. [Google Scholar] [CrossRef]

- Yuan, X.; Wang, Q.; Sun, T.; Xia, Y.; Chen, H.; Song, J. Pore Distribution Characteristics of Dredger Fill During Hierarchical Vacuum Preloading. Jilin Univ. J. Earth Sci. 2012, 42, 169–176. (In Chinese) [Google Scholar] [CrossRef]

- Xu, K.; Lin, S.; Geng, Z.; Han, R. Experimental Study on Effects of Vacuum Loading Modes on Clogging of Drainage Board Filtration Membranes. Chin. J. Geotech. Eng. 2016, 38, 123–129. (In Chinese) [Google Scholar]

- Liu, J.; Lei, H.; Zheng, G.; Zhou, H.; Zhang, X. Laboratory Model Study of Newly Deposited Dredger Fills Using Improved Multiple-Vacuum Preloading Technique. J. Rock Mech. Geotech. Eng. 2017, 9, 924–935. [Google Scholar] [CrossRef]

- Wang, J.; Cai, Y.; Fu, H.; Hu, X.; Cai, Y.; Lin, H.; Zheng, W. Experimental Study on a Dredged Fill Ground Improved by a Two-Stage Vacuum Preloading Method. Soils Found. 2018, 58, 766–775. [Google Scholar] [CrossRef]

- Li, J.; Chen, H.; Yuan, X.; Shan, W. Analysis of the Effectiveness of the Step Vacuum Preloading Method: A Case Study on High Clay Content Dredger Fill in Tianjin, China. J. Mar. Sci. Eng. 2020, 8, 38. [Google Scholar] [CrossRef]

- Wang, J.; Cai, Y.; Liu, F.Y.; Li, Z.; Yuan, G.H.; Du, Y.G.; Hu, X.Q. Effect of a Vacuum Gradient on the Consolidation of Dredged Slurry by Vacuum Preloading. Can. Geotech. J. 2021, 58, 1036–1044. [Google Scholar] [CrossRef]

- Lei, H.; Qi, Z.; Zhang, Z.; Zheng, G. New Vacuum-Preloading Technique for Ultrasoft-Soil Foundations Using Model Tests. Int. J. Geomech. 2017, 17, 4017049. [Google Scholar] [CrossRef]

- Liu, J.; Lei, H.; Zheng, G.; Feng, S.; Rahman, M.S. Improved Synchronous and Alternate Vacuum Preloading Method for Newly Dredged Fills: Laboratory Model Study. Int. J. Geomech. 2018, 18, 4018086. [Google Scholar] [CrossRef]

- Lei, H.; Li, J.; Feng, S.; Liu, A. Reinforcement Effect and Mechanism Analysis of Dredged Sludge Treated by Alternating Prefabricated Radiant Drain Vacuum Preloading Method. Geotext. Geomembr. 2023, 51, 56–72. [Google Scholar] [CrossRef]

- Wang, J.; Shi, L.; Sun, H.; Cai, Y.; Yu, Y. An Energy-Saving Loading Strategy: Cyclic Vacuum Preloading Treatment of Soft Ground. Can. Geotech. J. 2024, 61, 1935–1954. [Google Scholar] [CrossRef]

- Wang, J.; Cai, Y.; Ma, J.; Chu, J.; Fu, H.; Wang, P.; Jin, Y. Improved Vacuum Preloading Method for Consolidation of Dredged Clay-Slurry Fill. J. Geotech. Geoenviron. Eng. 2016, 142, 6016012. [Google Scholar] [CrossRef]

- Anda, R.; Fu, H.; Wang, J.; Lei, H.; Hu, X.; Ye, Q.; Cai, Y.; Xie, Z. Effects of Pressurizing Timing on Air Booster Vacuum Consolidation of Dredged Slurry. Geotext. Geomembr. 2020, 48, 491–503. [Google Scholar] [CrossRef]

- Lei, H.; Hu, Y.; Liu, J.; Liu, X.; Li, C. Consolidation Behavior of Tianjin Dredged Clay Using Two Air-Booster Vacuum Preloading Methods. J. Zhejiang Univ.-Sci. A 2021, 22, 147–164. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, R.; Lu, Y.; Zhang, X.; Zhang, H.; Tran, Q.C. Experimental Study of PVD-Improved Dredged Soil with Vacuum Preloading and Air Pressure. Geotext. Geomembr. 2022, 50, 668–676. [Google Scholar] [CrossRef]

- Feng, S.; Lei, H.; Lin, C. Analysis of Ground Deformation Development and Settlement Prediction by Air-Boosted Vacuum Preloading. J. Rock Mech. Geotech. Eng. 2022, 14, 272–288. [Google Scholar] [CrossRef]

- Lei, H.; Feng, S. Vacuum Preloading Techniques for Development and Innovation of Strengthening Dredged Soft Ground: A Review. Mar. Georesour. Geotechnol. 2024, 43, 1808–1827. [Google Scholar] [CrossRef]

- Tran-Nguyen, H.H.; Edil, T.B.; Schneider, J.A. Effect of Deformation of Prefabricated Vertical Drains on Discharge Capacity. Geosynth. Int. 2010, 17, 431–442. [Google Scholar] [CrossRef]

- Chai, J.; Horpibulsuk, S.; Shen, S.; Carter, J.P. Consolidation Analysis of Clayey Deposits under Vacuum Pressure with Horizontal Drains. Geotext. Geomembr. 2014, 42, 437–444. [Google Scholar] [CrossRef]

- Shinsha, H.; Kumagai, T. Bulk Compression of Dredged Soils by Vacuum Consolidation Method Using Horizontal Drains. Geotech. Eng. J. SEAGS AGSSEA 2014, 45, 78–85. [Google Scholar] [CrossRef]

- Yin, J.H.; Chen, W.B.; Tan, D.Y.; Wu, P.C. A Sustainable Approach to Marine Reclamations Using Local Dredged Marine Soils and Wastes: Soft Soil Improvement, Physical Modelling Study, and Settlement Prediction-Control. In Proceedings of the HKIE Geotechnical Division 42nd Annual Seminar: A New Era of Metropolis and Infrastructure Developments in Hong Kong, Challenges and Opportunities to Geotechnical Engineering; AIJR Proceedings; AIJR Publisher: Balrampur, India, 2022. [Google Scholar] [CrossRef]

- Yang, K.; Lu, M.; Sun, J. Consolidation Analysis of Dredged Slurry Treated by Crosswise-Arranged Prefabricated Horizontal Drains: Analytical and Experimental Insights. Int. J. Geomech. 2024, 24, 4024257. [Google Scholar] [CrossRef]

- Song, D.-B.; Pan, Y.; Chen, W.-B.; Wu, P.-C.; Yin, J.-H. Study of Design Parameters for Staged-Filled Slurry Treated by Prefabricated Horizontal Drains under Vacuum Preloading. Geotext. Geomembr. 2024, 52, 985–998. [Google Scholar] [CrossRef]

- Pan, Y.; Song, D.-B.; Yin, Z.-Y.; Yin, J.-H. Effect of Spacing of Grid PHD on Performance of Combined PHD–PVD Vacuum Preloading Method for Treatment of Clayey Slurry. Can. Geotech. J. 2025, 62, 1–16. [Google Scholar] [CrossRef]

- Song, D.-B.; Pan, Y.; Yin, J.-H.; Yin, Z.-Y.; Pu, H.-F. Consolidation Analysis of Staged-Filled Soil Slurry with Combined Grid-Horizontal and Vertical Drains System under Vacuum Preloading. Geotext. Geomembr. 2025, 53, 1281–1298. [Google Scholar] [CrossRef]

- Chu, J.; Wu, S.F.; Chen, H.; Pan, X.H.; Chiam, K. New Solutions to Geotechnical Challenges for Coastal Cities. Geotech. Eng. J. SEAGS AGSSEA 2021, 52, 61–66. [Google Scholar] [CrossRef]

- Chen, H.; Chu, J.; Guo, W.; Wu, S. Land Reclamation Using the Horizontal Drainage Enhanced Geotextile Sheet Method. Geotext. Geomembr. 2023, 51, 131–150. [Google Scholar] [CrossRef]

- Ge, S.; Jiang, W.; Zheng, L.; Xie, X.; Xie, K.; Feng, G.; Zhang, X. Theoretical Analysis and Experimental Verification of Large Deformation Electro-Osmosis Consolidation Treatment of Dredged Slurry. Eng. Geol. 2023, 312, 106924. [Google Scholar] [CrossRef]

- Bibak, H.; Ganjian, N.; Khazaei, J.; Bahmanpour, A. Shear Modulus Variations in Soft Clay Soil Improved by Electroosmosis Method. Iran. J. Sci. Technol. Trans. Civ. Eng. 2025. [Google Scholar] [CrossRef]

- Zang, J.; Zheng, L.; Xie, X.; Wang, H.; Liu, Y.; Pang, J. Comparative Experiments on Electro-Osmotic Treatment Effect of Polluted Soil Using EKG and Iron Electrodes. J. Cent. South Univ. 2018, 25, 3052–3061. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, X.; Zheng, L.; Li, J. Electroosmotic Stabilization on Soft Soil: Experimental Studies and Analytical Models (a Historical Review). Int. J. Electrochem. Sci. 2018, 13, 9051–9068. [Google Scholar] [CrossRef]

- Ling, J.; Li, X.; Qian, J.; Li, X. Performance Comparison of Different Electrode Materials for Electro-Osmosis Treatment on Subgrade Soil. Constr. Build. Mater. 2021, 271, 121590. [Google Scholar] [CrossRef]

- Mahalleh, H.A.M.; Siavoshnia, M.; Yazdi, M. Effects of Electro-Osmosis on the Properties of High Plasticity Clay Soil: Chemical and Geotechnical Investigations. J. Electroanal. Chem. 2021, 880, 114890. [Google Scholar] [CrossRef]

- Jin, H.; Zhang, L.; Wang, B.; Fang, C.; Wang, L. Effects of Electrode Materials and Potential Gradient on Electro-Osmotic Consolidation for Marine Clayey Soils. Front. Earth Sci. 2024, 12, 1260045. [Google Scholar] [CrossRef]

- Ahmad, S.; Ahmad, S.; Akhtar, S.; Ahmad, F.; Ansari, M.A. Data-Driven Assessment of Corrosion in Reinforced Concrete Structures Embedded in Clay Dominated Soils. Sci. Rep. 2025, 15, 22744. [Google Scholar] [CrossRef] [PubMed]

- Fu, H.; Fang, Z.; Wang, J.; Chai, J.; Cai, Y.; Geng, X.; Jin, J.; Jin, F. Experimental Comparison of Electroosmotic Consolidation of Wenzhou Dredged Clay Sediment Using Intermittent Current and Polarity Reversal. Mar. Georesour. Geotechnol. 2018, 36, 131–138. [Google Scholar] [CrossRef]

- Sun, Z.; Wu, T.; Yao, K.; Kasu, C.M.; Zhao, X.; Li, Z.; Gong, J. Consolidation of Soft Clay by Cyclic and Progressive Electroosmosis Using Electrokinetic Geosynthetics. Arab. J. Geosci. 2022, 15, 1193. [Google Scholar] [CrossRef]

- Fu, H.; Yuan, L.; Wang, J.; Cai, Y.; Hu, X.; Geng, X. Influence of High Voltage Gradients on Electrokinetic Dewatering for Wenzhou Clay Slurry Improvement. Soil Mech. Found. Eng. 2019, 55, 400–407. [Google Scholar] [CrossRef]

- Sadeghian, F.; Jahandari, S.; Haddad, A.; Rasekh, H.; Li, J. Effects of Variations of Voltage and pH Value on the Shear Strength of Soil and Durability of Different Electrodes and Piles during Electrokinetic Phenomenon. J. Rock Mech. Geotech. Eng. 2022, 14, 625–636. [Google Scholar] [CrossRef]

- Zhuang, Y. Large Scale Soft Ground Consolidation Using Electrokinetic Geosynthetics. Geotext. Geomembr. 2021, 49, 757–770. [Google Scholar] [CrossRef]

- Wang, B.; Li, G.; Zhang, L.; Jin, H.; Wu, T.; Jia, Z.; Jin, D. Influences of Additives Materials on Electro-osmosis Consolidation for Soft Soils. J. Nat. Disasters 2024, 33, 86–97. (In Chinese) [Google Scholar] [CrossRef]

- Ge, S.; Jiang, W.; Wang, J.-P.; Feng, G.; Zheng, L.; Xie, X. Coupled Model for Electro-Osmosis Consolidation and Ion Transport Considering Chemical Osmosis in Saturated Clay Soils. Int. J. Numer. Anal. Methods Geomech. 2024, 48, 3455–3474. [Google Scholar] [CrossRef]

- Tian, Z.; Tang, X.; Li, J.; Xiu, Z.; Xue, Z. Improving Settlement and Reinforcement Uniformity of Marine Clay in Electro-Osmotic Consolidation Using Microbially Induced Carbonate Precipitation. Bull. Eng. Geol. Environ. 2021, 80, 6457–6471. [Google Scholar] [CrossRef]

- Nabizadeh, M.; Soroush, A.; Fattahi, S.M.; Eslami, A. Bio-Electrokinetic Improvement of Deltaic Soil. J. Rock Mech. Geotech. Eng. 2025, 17, 3253–3264. [Google Scholar] [CrossRef]

- Miao, Y.; Zhou, F.; Yin, J.; Sun, Y.; Li, R.; Lu, J. Effects of Frequency and Confining Pressure on Consolidation Drainage Behavior of Soft Marine Clays. Mar. Georesour. Geotechnol. 2019, 37, 746–754. [Google Scholar] [CrossRef]

- Yin, J.; Tang, Y.; Miao, Y.; Sheng, R. An Experimental Investigation on Dynamic Characteristics of Soft Soils Treated by Vibration-Drainage Method. Adv. Civ. Eng. 2020, 2020, 8890562. [Google Scholar] [CrossRef]

- Dai, C.; Zhang, Q.; He, S.; Zhang, A.; Shan, H.; Xia, T. Variation in Micro-Pores during Dynamic Consolidation and Compression of Soft Marine Soil. J. Mar. Sci. Eng. 2021, 9, 750. [Google Scholar] [CrossRef]

- Zhang, W. Soft Soil Foundation Treatment of Hydraulic Fill Site Based on Vibration Boosting Drainage Consolidation Method. Arch. Civ. Eng. 2024, 70, 431–444. [Google Scholar] [CrossRef]

- Du, G.; Gao, C.; Liu, S.; Guo, Q.; Luo, T. Evaluation Method for the Liquefaction Potential Using the Standard Penetration Test Value Based on the CPTU Soil Behavior Type Index. Adv. Civ. Eng. 2019, 2019, 5612857. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Y.; Gao, W. Experimental study of foundation treatment with vacuum well-point dewatering. Rock Soil Mech. 2014, 35, 2667–2672. (In Chinese) [Google Scholar] [CrossRef]

- Vu, V.; Yao, L.; Wei, Y. Laboratory Investigation of Axisymmetric Single Vacuum Well Point. J. Cent. South Univ. 2016, 23, 750–756. [Google Scholar] [CrossRef]

- Zeng, B.; Zhen, Y.; Zhang, D.; Meng, T.; Gong, Z.; Liu, S. A Case Study of Vacuum Tube-Well Dewatering Technology for Improving Deep Soft Soil in Yangtze River Floodplain. Environ. Earth Sci. 2021, 80, 598. [Google Scholar] [CrossRef]

- Heng, D.L.K.; Takahashi, M.S.; Ohashi, M.T. Super Well Point Technology with Advancements in Soil Improvements for Land Reclamations. Energy Procedia 2017, 143, 442–447. [Google Scholar] [CrossRef]

- Koh, J.W.; Chew, S.H.; Yim, H.M.A.; Chua, K.E.; Goh, P.L. Evaluation of “Super Well Point” as a Ground Improvement Method for Soft Clay. Int. J. Geosynth. Ground Eng. 2022, 8, 23. [Google Scholar] [CrossRef]

- Lei, H.; Feng, S.; Hao, Q.; Zhang, Y.; Abdi, F.A. Experimental Study on Thermal Consolidation and Strength Characteristics of Dredger Fill. J. Tianjin Univ. 2020, 53, 17–26. (In Chinese) [Google Scholar]

- Houhou, R.; Sutman, M.; Sadek, S.; Laloui, L. Microstructure Observations in Compacted Clays Subjected to Thermal Loading. Eng. Geol. 2021, 287, 105928. [Google Scholar] [CrossRef]

- Cao, G.; Deng, Y.; Li, H.; Mao, W. Test on Thermal Consolidation Characteristics of Coastal Soft Soil under Cyclic Varying Temperature. China Meas. Test 2022, 48, 170–176. (In Chinese) [Google Scholar]

- Huancollo, H.J.M.; Saboya, F., Jr.; Tibana, S.; McCartney, J.S.; Garske Borges, R. Thermal Triaxial Tests to Evaluate Improvement of Soft Marine Clay through Thermal Consolidation. Geotech. Test. J. 2023, 46, 579–597. [Google Scholar] [CrossRef]

- Srisakul, W.; Chub-uppakarn, T.; Chompoorat, T. Strength and Permeability of Thermally Consolidated Soft Ground. Geotech. Geol. Eng. 2025, 43, 178. [Google Scholar] [CrossRef]

- Ahmad, S.; Rizvi, Z.H.; Wuttke, F. Unveiling Soil Thermal Behavior under Ultra-High Voltage Power Cable Operations. Sci. Rep. 2025, 15, 7315. [Google Scholar] [CrossRef]

- Deng, Y.; Han, Y.; Zheng, L.; Zheng, R.; Yao, Y. Model Test Research on Preloading Combined with Solar Thermal Drainage Consolidation Technology. J. Disaster Prev. Mitig. Eng. 2022, 42, 905–912. (In Chinese) [Google Scholar] [CrossRef]

- Xia, C.; Deng, Y.; Zhu, M.; Zheng, L.; Chen, X. Experimental and Computational Analysis of Thermal Consolidation of Prefabricated Vertical Drains Using Solar Energy. J. Clean. Prod. 2023, 387, 135877. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Zhou, Y.; Jin, T.; Li, M. Rapid Treatment Using Vacuum-Surcharge Preloading with Dynamic Consolidation Method: Laboratory Model Test. KSCE J. Civ. Eng. 2023, 27, 1010–1020. [Google Scholar] [CrossRef]

- Zhou, Y.; Cai, Y.; Yuan, G.; Wang, J.; Fu, H.; Hu, X.; Geng, X.; Li, M.; Liu, J.; Jin, H. Effect of Tamping Interval on Consolidation of Dredged Slurry Using Vacuum Preloading Combined with Dynamic Consolidation. Acta Geotech. 2021, 16, 859–871. [Google Scholar] [CrossRef]

- Wu, J.; Xuan, Y.; Deng, Y.; Li, X.; Zha, F.; Zhou, A. Combined Vacuum and Surcharge Preloading Method to Improve Lianyungang Soft Marine Clay for Embankment Widening Project: A Case. Geotext. Geomembr. 2021, 49, 452–465. [Google Scholar] [CrossRef]

- Zhang, L.; Pan, Z.; Wang, B.; Fang, C.; Chen, G.; Zhou, A.; Jiang, P.; Wang, L. Experimental Investigation on Electro-Osmotic Treatment Combined with Vacuum Preloading for Marine Clay. Geotext. Geomembr. 2021, 49, 1495–1505. [Google Scholar] [CrossRef]

- Sun, Z.; Zhou, W.; Pan, Y.; Shi, G. Vacuum Preloading Incorporated with Electroosmosis Strengthening of Soft Clay-an Optimized Approach. Soil Mech. Found. Eng. 2021, 58, 237–243. [Google Scholar] [CrossRef]

- Hu, X.; Gao, Z.; Liu, F.; Tao, Y.; Xu, D.; Du, Y.; Gou, C.; Li, M. The Optimal Combination Form of Vacuum Pre-Loading Combined with Electro-Osmosis and with Dynamic Compaction Method on the Improvement of Dredged Slurry. Mar. Georesour. Geotechnol. 2021, 39, 1192–1204. [Google Scholar] [CrossRef]

- Liu, F.; Tao, Y.; Ni, J.; Gao, Z.; Yuan, G. Slurry Improvement by Vacuum Pre-Loading in Combination with Electro-Osmosis and with Dynamic Compaction Method. Mar. Georesour. Geotechnol. 2021, 39, 709–718. [Google Scholar] [CrossRef]

- Hu, J.; Li, X.; Zhang, D.; Wang, J.; Hu, X.; Cai, Y. Experimental Study on the Effect of Additives on Drainage Consolidation in Vacuum Preloading Combined with Electroosmosis. KSCE J. Civ. Eng. 2020, 24, 2599–2609. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, L. Laboratory Tests of Electro-Osmotic Consolidation Combined with Vacuum Preloading on Kaolinite Using Electrokinetic Geosynthetics. Geotext. Geomembr. 2019, 47, 166–176. [Google Scholar] [CrossRef]

- Liu, H.; Cui, Y.; Shen, Y.; Ding, X. A New Method of Combination of Electroosmosis, Vacuum and Surcharge Preloading for Soft Ground Improvement. China Ocean Eng. 2014, 28, 511–528. [Google Scholar] [CrossRef]

- Xu, C.; Zhou, J.; Jiang, Y.; Tao, Y.; Chen, R. Experimental Study on Improved Method of Electroosmosis Combined with Magnetic Field. Acta Geotech. 2025, 20, 3439–3455. [Google Scholar] [CrossRef]

- Feng, S.; Lei, H.; Wang, L.; Hao, Q. The Reinforcement Analysis of Soft Ground Treated by Thermal Consolidation Vacuum Preloading. Transp. Geotech. 2021, 31, 100672. [Google Scholar] [CrossRef]

- Yuan, W.; Feng, Q.; Huang, H.; Cao, K.; Ying, Z.; Deng, Y. Dewatering Mechanisms of Heating-Assisted Vacuum Preloading of River/Lake Dredged Sediments. Eng. Geol. 2025, 353, 108128. [Google Scholar] [CrossRef]

- Lucke, T.; Beecham, S. Aeration and Gutter Water Levels in Siphonic Roof Drainage Systems. Build. Res. Inf. 2010, 38, 670–685. [Google Scholar] [CrossRef]

- Elgamal, M.; Fouli, H. Sediment Removal from Dam Reservoirs Using Syphon Suction Action. Arab. J. Geosci. 2020, 13, 943. [Google Scholar] [CrossRef]

- Tohari, A.; Wibawa, S.; Koizumi, K.; Oda, K.; Komatsu, M. Effectiveness of Siphon Drainage Method for Landslide Stabilization in a Tropical Volcanic Hillslope: A Case Study of Cibitung Landslide, West Java, Indonesia. Bull. Eng. Geol. Environ. 2021, 80, 2101–2116. [Google Scholar] [CrossRef]

- Shu, J.; Sun, H.; An, N. Theoretical and Field Investigation into the Vacuum Formation in the Siphon-Vacuum Drainage System for Soft Ground Improvement. Can. Geotech. J. 2024, 61, 1593–1605. [Google Scholar] [CrossRef]

- Garrett, R.E. Principles of Siphons. J. World Aquac. Soc. 1991, 22, 1–9. [Google Scholar] [CrossRef]

- Hughes, S.; Gurung, S. Exploring the Boundary between a Siphon and Barometer in a Hypobaric Chamber. Sci. Rep. 2014, 4, 4741. [Google Scholar] [CrossRef]

- Sun, H.; Xiong, X.; Shang, Y.; Cai, Y. Pipe Air Accumulation Causes and Its Control Metod in Slope Siphon Drainage. J. Jilin Univ. Earth Sci. Ed. 2014, 44, 278–284. (In Chinese) [Google Scholar] [CrossRef]

- Cai, Y.; Sun, H.; Shang, Y.; Xiong, X. An Investigation of Flow Characteristics in Slope Siphon Drains. J. Zhejiang Univ. Sci. A 2014, 15, 22–30. [Google Scholar] [CrossRef]

- Sun, H.; Wu, G.; Liang, X.; Yan, X.; Wang, D.; Wei, Z. Laboratory Modeling of Siphon Drainage Combined with Surcharge Loading Consolidation for Soft Ground Treatment. Mar. Georesour. Geotechnol. 2018, 36, 940–949. [Google Scholar] [CrossRef]

- Wu, G.; Xie, W.; Sun, H.; Yan, X.; Tang, B. Consolidation Behaviour with and without Siphon Drainage. Proc. Inst. Civ. Eng. Geotech. Eng. 2018, 171, 462–470. [Google Scholar] [CrossRef]

- Zheng, J.; Guo, J.; Wang, J.; Zhang, Y.; Lü, Q.; Sun, H. Calculation of the Flow Velocity of a Siphon. Phys. Fluids 2021, 33, 17105. [Google Scholar] [CrossRef]

- Shen, Q.; Wang, J.; Sun, H.; Shu, J.; Shang, Y. Analysis of the Influence of Siphon Hole Spacing on Soft-Soil Drainage Effect. Proc. Inst. Civ. Eng. Geotech. Eng. 2024, 177, 768–778. [Google Scholar] [CrossRef]

- Shu, J.; Wang, J.; Chen, K.; Shen, Q.; Sun, H. Analysis of Factors Affecting Vacuum Formation and Drainage in the Siphon-Vacuum Drainage Method for Marine Reclamation. J. Mar. Sci. Eng. 2024, 12, 430. [Google Scholar] [CrossRef]

- Wang, J.; Shen, Q.; Yuan, S.; Wang, X.; Shu, J.; Zheng, J.; Sun, H. A Siphon Drainage Method for Consolidation of Soft Soil Foundation. Appl. Sci. 2023, 13, 3633. [Google Scholar] [CrossRef]

- Wu, H.; Ma, N.; Ma, Q.; Lin, X.; Song, C. Accelerating Consolidation of Soft Ground by Aerosol Injection Technique: A Field Study. Acta Geotech. 2021, 16, 2997–3004. [Google Scholar] [CrossRef]

- Wu, H.; Gong, X.; Lin, X.; Song, C. Study on field model test of improved drainage consolidation by jet air. Chin. J. Ground Improv. 2019, 1, 8–11. (In Chinese) [Google Scholar]

- Wu, H.; Zhao, Z.; Lin, X.; Shi, J.; Gong, X. Model test of active drainage consolidation method on air-lift effect. Rock Soil Mech. 2021, 42, 2151–2159. (In Chinese) [Google Scholar] [CrossRef]

- Wu, H.; Gong, X.; Lin, X.; Song, C.; Ma, Q. In-situ test study on the method of high pressure aerosol injecting structure decomposition drainage consolidation for soft soil ground treatment. Chin. J. Ground Improv. 2020, 2, 98–104. (In Chinese) [Google Scholar]

- Diao, Y.; Guo, X.; Zheng, G. An Intelligent Biomimetic Drainage for the Reinforcement of Soft Soil Foundation. Chinese Patent CN202123148662.8, 2 August 2022. Available online: https://d.wanfangdata.com.cn/Patent/ZL_CN202123148662.8_CN217105036U_20220802 (accessed on 1 September 2025). (In Chinese).

- Dudukovic, N.A.; Fong, E.J.; Gemeda, H.B.; DeOtte, J.R.; Cerón, M.R.; Moran, B.D.; Davis, J.T.; Baker, S.E.; Duoss, E.B. Cellular Fluidics. Nature 2021, 595, 58–65. [Google Scholar] [CrossRef]

- GEC. Stone Columns and Piled Embankments. Available online: https://cofra.com/solutions/elements/geotextile-encased-columns (accessed on 4 October 2025).

- Schnaid, F.; Winter, D.; Silva, A.E.F.; Alexiew, D.; Küster, V. Geotextile Encased Columns (GEC) Used as Pressure-Relief System. Instrumented Bridge Abutment Case Study on Soft Soil. Geotext. Geomembr. 2017, 45, 227–236. [Google Scholar] [CrossRef]

- Pandey, B.K.; Rajesh, S.; Chandra, S. Performance Enhancement of Encased Stone Column with Conductive Natural Geotextile under K0 Stress Condition. Geotext. Geomembr. 2021, 49, 1095–1106. [Google Scholar] [CrossRef]

- Liu, K.; Qiu, R.; Zhou, P.; Wang, T.; Connolly, D.P.; Xiao, J. Geotextile-Encased Cinder Gravel Columns: A Coupled DEM–FDM Analysis. Geosynth. Int. 2025, 32, 302–317. [Google Scholar] [CrossRef]

- Erten, D.; Guler, E.; Detert, O.; Lavasan, A.A.; Taetz, S. Comparing CO2 Emissions: Ordinary Stone vs. Geosynthetic Encased Columns. Geosynth. Int. 2025, 1–14. [Google Scholar] [CrossRef]

- Cai, Y.; Qiao, H.; Wang, J.; Geng, X.; Wang, P.; Cai, Y. Experimental Tests on Effect of Deformed Prefabricated Vertical Drains in Dredged Soil on Consolidation via Vacuum Preloading. Eng. Geol. 2017, 222, 10–19. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Y.; Wu, Y.; Zhang, X.; Ji, J. Comparative test on the effect of freeze-thaw vacuum preloading on landfill sludge under different types of plastic drainage boards. Chin. J. Environ. Eng. 2021, 15, 3669–3676. (In Chinese) [Google Scholar]

- Feng, S.; Lei, H.; Wan, Y.; Qi, Z. Ground Improvement Effect of Prefabricated Radiant Drain Vacuum Preloading Method. J. Cent. South Univ. Sci. Technol. 2021, 52, 790–805. (In Chinese) [Google Scholar]

- Fu, H.; Chai, J. Performance of a Winged PVD (WPVD) for Vacuum Consolidation of Soft Clayey Deposits. Transp. Geotech. 2020, 24, 100370. [Google Scholar] [CrossRef]

- Gan, Q.; Zhou, J.; Li, C.; Zhuang, Y.; Wang, Y. Vacuum Preloading Combined with Electroosmotic Dewatering of Dredger Fill Using the Vertical-Layered Power Technology of a Novel Tubular Electrokinetic Geosynthetics: Test and Numerical Simulation. Int. J. Geomech. 2022, 22, 5021004. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Indraratna, B.; Carter, J. Laboratory Investigation into Biodegradation of Jute Drains with Implications for Field Behavior. J. Geotech. Geoenviron. Eng. 2018, 144, 4018026. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Indraratna, B.; Baral, P. Biodegradable Prefabricated Vertical Drains: From Laboratory to Field Studies. Geotech. Eng. 2020, 51, 39–46. [Google Scholar]

- Asha, B.S.; Mandal, J.N. Laboratory Performance Tests on Natural Prefabricated Vertical Drains in Marine Clay. Proc. Inst. Civ. Eng. Ground Improv. 2015, 168, 45–65. [Google Scholar] [CrossRef]

- Xu, G.; Yu, X.; Wu, F.; Yin, Y. Feasibility of Vacuum Consolidation in Managing Dredged Slurries with Wheat Straw as Drainage Channels. KSCE J. Civ. Eng. 2017, 21, 1154–1160. [Google Scholar] [CrossRef]

- Xu, G.-Z.; Yin, J.; Feng, X.-S.; Ji, F. An Improved Method for Dewatering Sewage Sludge Using Intermittent Vacuum Loading with Wheat Straw as Vertical Drains. KSCE J. Civ. Eng. 2020, 24, 2017–2025. [Google Scholar] [CrossRef]

- Xu, G.; Han, Q.; Wang, Z.; Wu, J.; Yin, J. Eco-Friendly Rice Straw as Vertical Drains for Dredged Slurry Treatment as Construction Fill. Constr. Build. Mater. 2022, 345, 128244. [Google Scholar] [CrossRef]

- Yuan, W.; Deng, Y.; Ying, Z.; Yang, Q.; Su, Y.; Hong, Z. Degradation of Straw-Based Wick Drain and Its Effect on Consolidation. J. Clean. Prod. 2024, 452, 142182. [Google Scholar] [CrossRef]

- Yuan, W.; Ying, Z.; Su, Y.-Q.; Wang, Q.; Chen, S.; Deng, Y. Engineering Properties of Biodegradable Vertical Drains for Soft Ground Improvement. Geosynth. Int. 2025, 1–14. [Google Scholar] [CrossRef]

- Dijkstra, J.W.; Bodamer, R. The Sustainable Future of Vertical Drains. In Geotechnical Engineering Challenges to Meet Current and Emerging Needs of Society; CRC Press: London, UK, 2024; pp. 2245–2248. ISBN 978-1-003-43174-9. [Google Scholar]

- Lou, K.; Yin, Z.-Y.; Song, D.-B.; Huang, W.-F. Experimental Study on the Vacuum Consolidation of Recycled Fibre-Improved Soft Soils Assisted with Prefabricated Vertical Drain. Geotext. Geomembr. 2025, 53, 681–696. [Google Scholar] [CrossRef]

- Cai, Y.; Xie, Z.; Wang, J.; Wang, P.; Geng, X. New Approach of Vacuum Preloading with Booster Prefabricated Vertical Drains (PVDs) to Improve Deep Marine Clay Strata. Can. Geotech. J. 2018, 55, 1359–1371. [Google Scholar] [CrossRef]

- Tang, K.; Wen, M.; Tian, Y.; Zhu, X.; Wu, W.; Zhang, Y.; Mei, G.; Ding, P.; Tu, Y.; Sun, A.; et al. A Multi-Zone Axisymmetric Model for Consolidation of Saturated Soils Improved by PVTD with Interfacial Thermal Resistance. Int. J. Numer. Anal. Methods Geomech. 2025, 49, 1158–1178. [Google Scholar] [CrossRef]

- Zhang, L.; Jin, H.; Lv, Y.; Wang, B.; Jia, Z.; Hou, F.; Fang, C.; Wang, L.; Jin, D. Improvements in Vacuum-Surcharge Preloading Combined with Electro-Osmotic Consolidation on Soft Clayey Soil with High Water Content. Geotext. Geomembr. 2025, 53, 41–54. [Google Scholar] [CrossRef]

- Feng, S.; Lei, H.; Wan, Y.; Qi, Z. Reinforcement and Heavy Metal Cu Removal Effect on Sludge Ground Treated by EKG Prefabricated Radiant Drain Vacuum Preloading-Electroosmotic Method. J. Tianjin Univ. Sci. Technol. 2025, 58, 761–773. (In Chinese) [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Shu, J.; Song, S.; Wu, L.; Ji, Y.; Zhai, C.; Wang, J.; Lai, X. Advancements in Drainage Consolidation Technology for Marine Soft Soil Improvement: A Review. J. Mar. Sci. Eng. 2025, 13, 1951. https://doi.org/10.3390/jmse13101951

Chen Z, Shu J, Song S, Wu L, Ji Y, Zhai C, Wang J, Lai X. Advancements in Drainage Consolidation Technology for Marine Soft Soil Improvement: A Review. Journal of Marine Science and Engineering. 2025; 13(10):1951. https://doi.org/10.3390/jmse13101951

Chicago/Turabian StyleChen, Zhongxuan, Junwei Shu, Sheng Song, Luxiang Wu, Youjun Ji, Chaoqun Zhai, Jun Wang, and Xianghua Lai. 2025. "Advancements in Drainage Consolidation Technology for Marine Soft Soil Improvement: A Review" Journal of Marine Science and Engineering 13, no. 10: 1951. https://doi.org/10.3390/jmse13101951

APA StyleChen, Z., Shu, J., Song, S., Wu, L., Ji, Y., Zhai, C., Wang, J., & Lai, X. (2025). Advancements in Drainage Consolidation Technology for Marine Soft Soil Improvement: A Review. Journal of Marine Science and Engineering, 13(10), 1951. https://doi.org/10.3390/jmse13101951