Calculation and Analysis on Mechanical Properties of the Perforated Offshore Casing with Defects

Abstract

1. Introduction

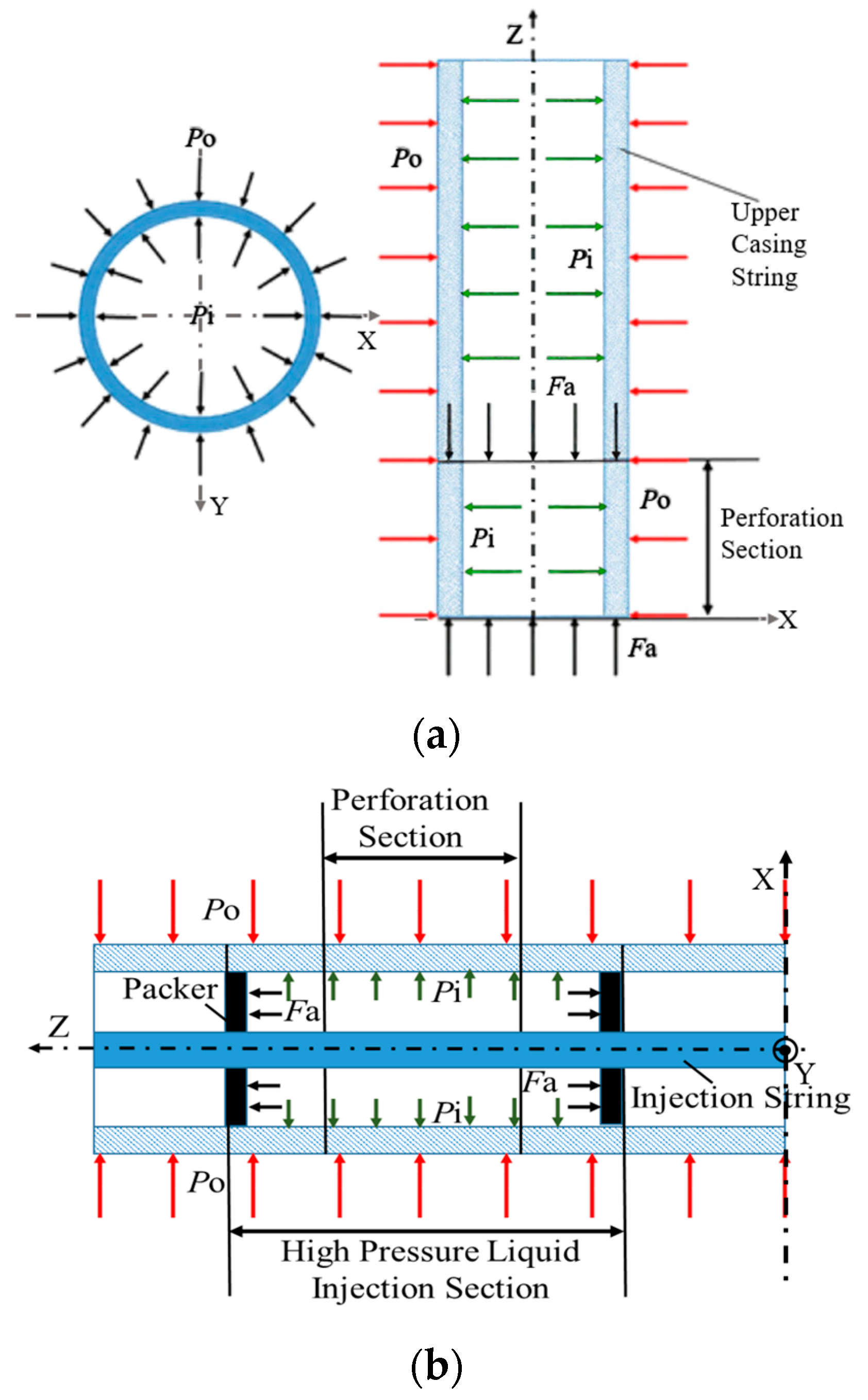

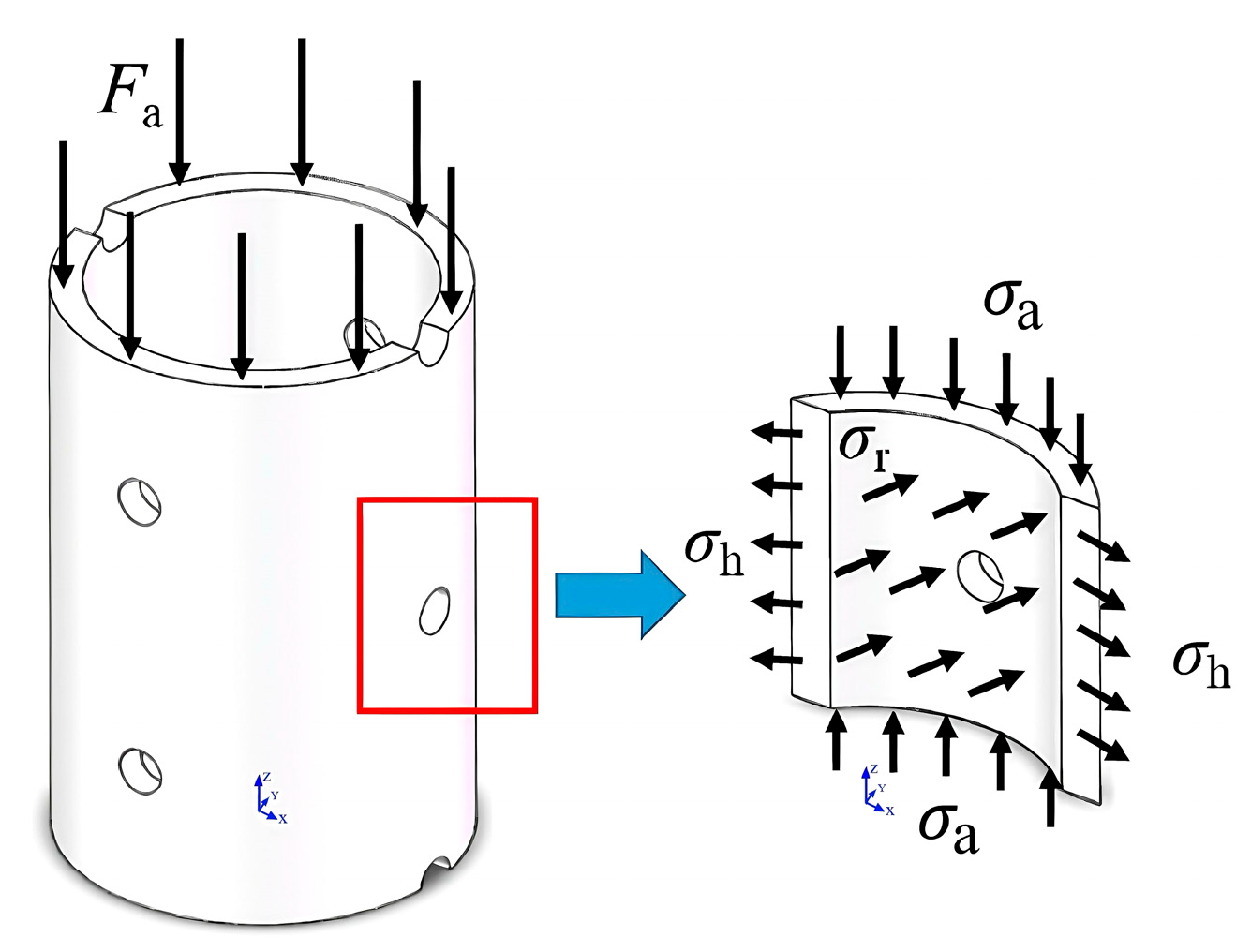

2. Mechanical Property Analysis of Casing Pipe Body

2.1. Load Analysis on Perforated Section of Casing String

2.2. Equations for Critical Loads of Casing Pipe Body

- (1)

- Triaxial yield limit state equation

- (2)

- Collapse pressure formulas

- Yield strength collapse pressure formula

- Plastic collapse pressure formula

- Transition collapse pressure formula

- Elastic collapse pressure formula

- (3)

- Yield internal pressure formulas

2.3. Solving Critical Loads and Equivalent Stress of Casing Pipe Body in Perforation Section

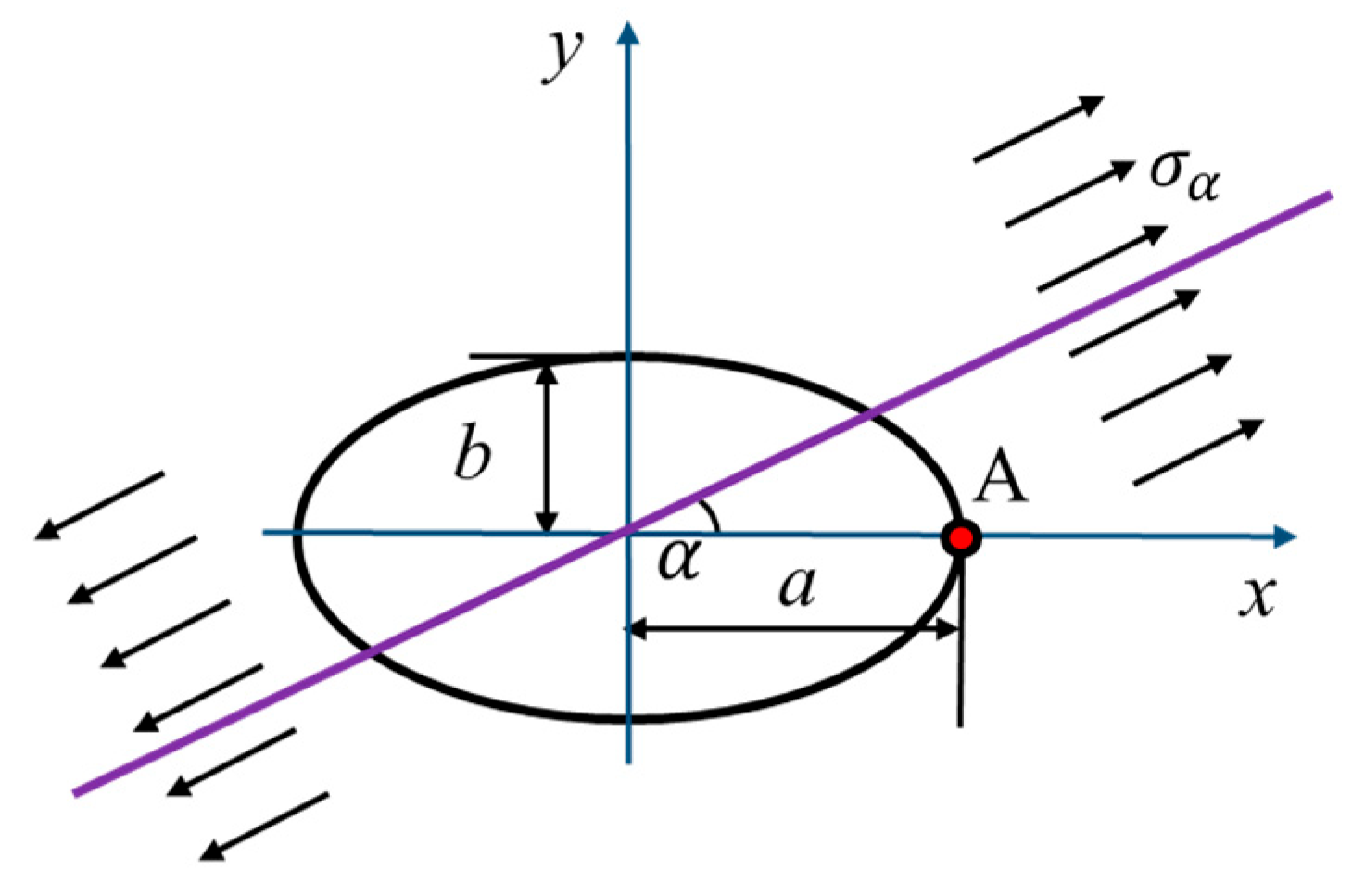

3. Theoretical Models and Calculation Methods

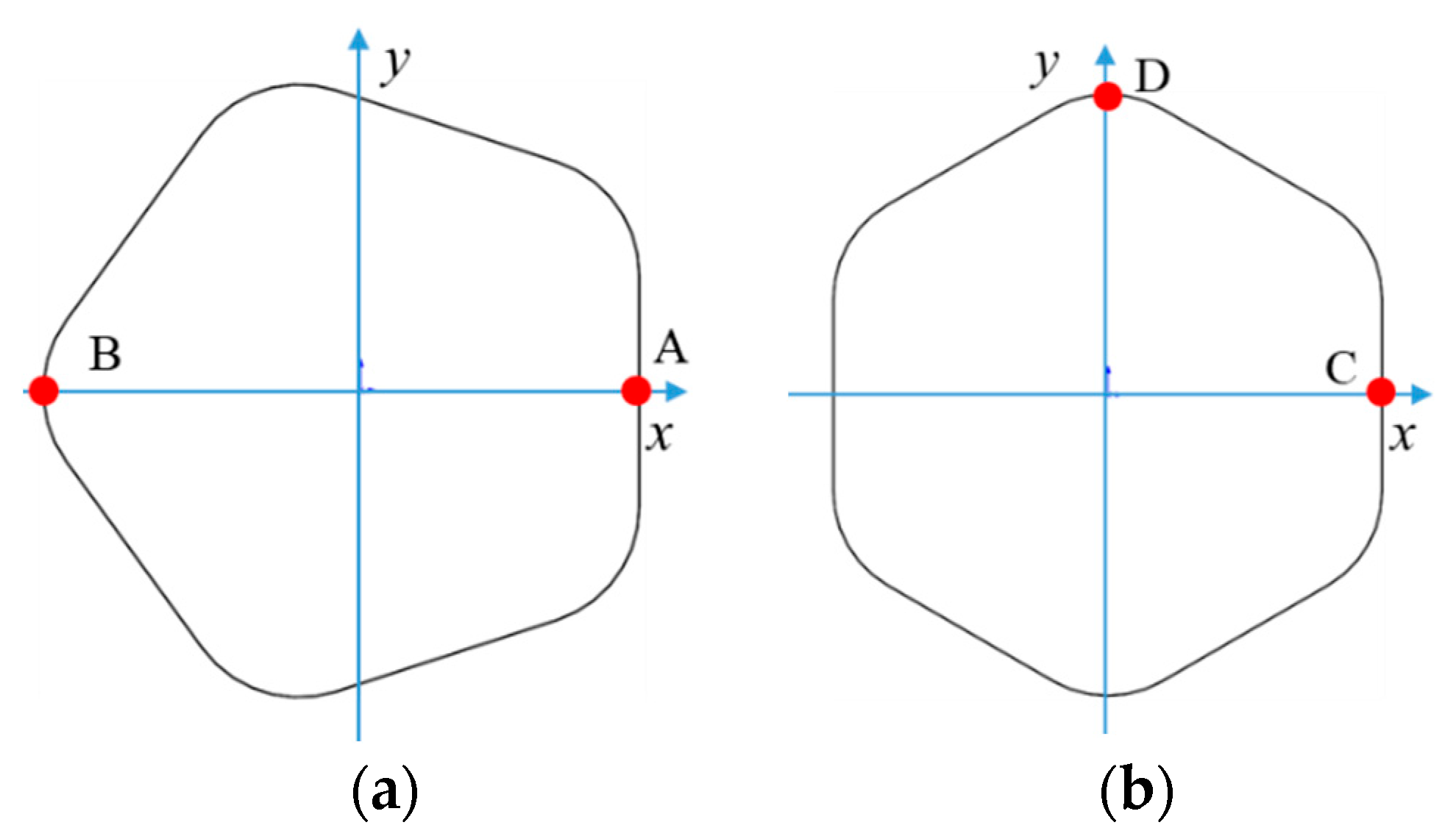

3.1. Stress Calculation Models for Different Perforation Defect Shapes

- (1)

- Circular hole [45]

- (2)

- Ellipse hole

- (3)

- Polygonal hole

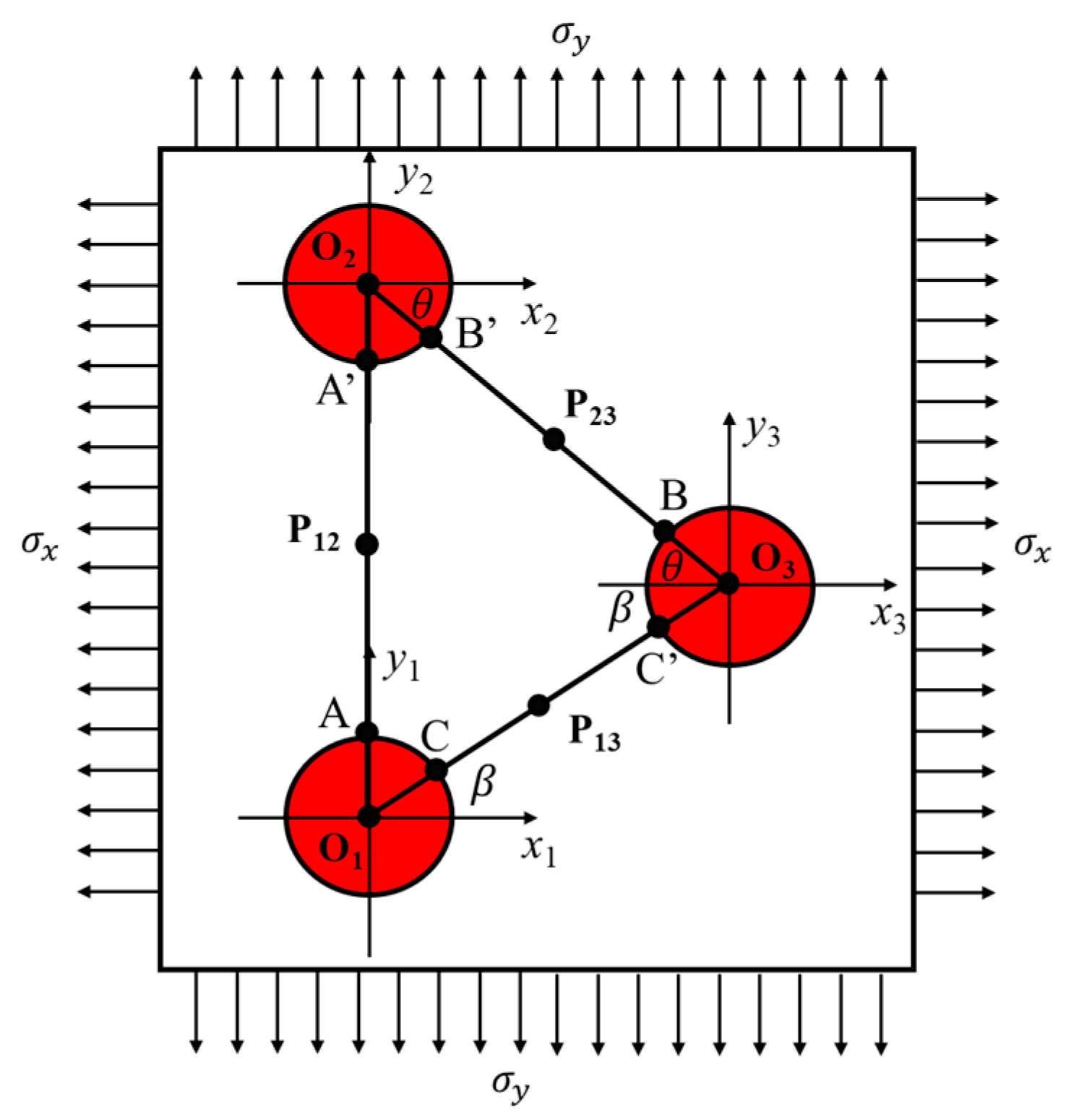

3.2. Location Parameter Calculation for Perforation Defects

- (1)

- In most cases, the hole spacing l12 is closer to l23’s value. Only when the shot density and phase angle are both high, the hole spacing l23 is closer to the l13’s value. According to this, it can be judged that the common combinations of shot density and phase angle, which are listed in Table 3, meet the general engineering requirements for casing safety.

- (2)

- When the shot density is a fixed value, the hole spacing l12 and the angles of β and θ decrease with the increase in the phase angle. However, the hole spacing l13 increases with the increase in the phase angle. In most cases, the β is smaller than the θ, and the l12 and l23 are bigger than the l13. Based on this, it can be deduced that the overlap of the elastoplastic stress zone is more likely to occur between Hole 1 and Hole 3, which are on the spiral line.

- (3)

- Under a constant phase angle, increasing the shot density reduces the values of l12, l13, l23, β, and θ. While the hole spacing l13 and the angle θ exhibit similar variations with the phase angle across different shot densities, the sensitivity of l12, l23, and β to phase angle changes diminishes as shot density increases. This shows us that the distance between Hole 1 and Hole 3 on the spiral line is almost unaffected by the change in shot density, and the larger shot density, the less degree of the other parameters l12, l23, and β affected by the change in phase angle.

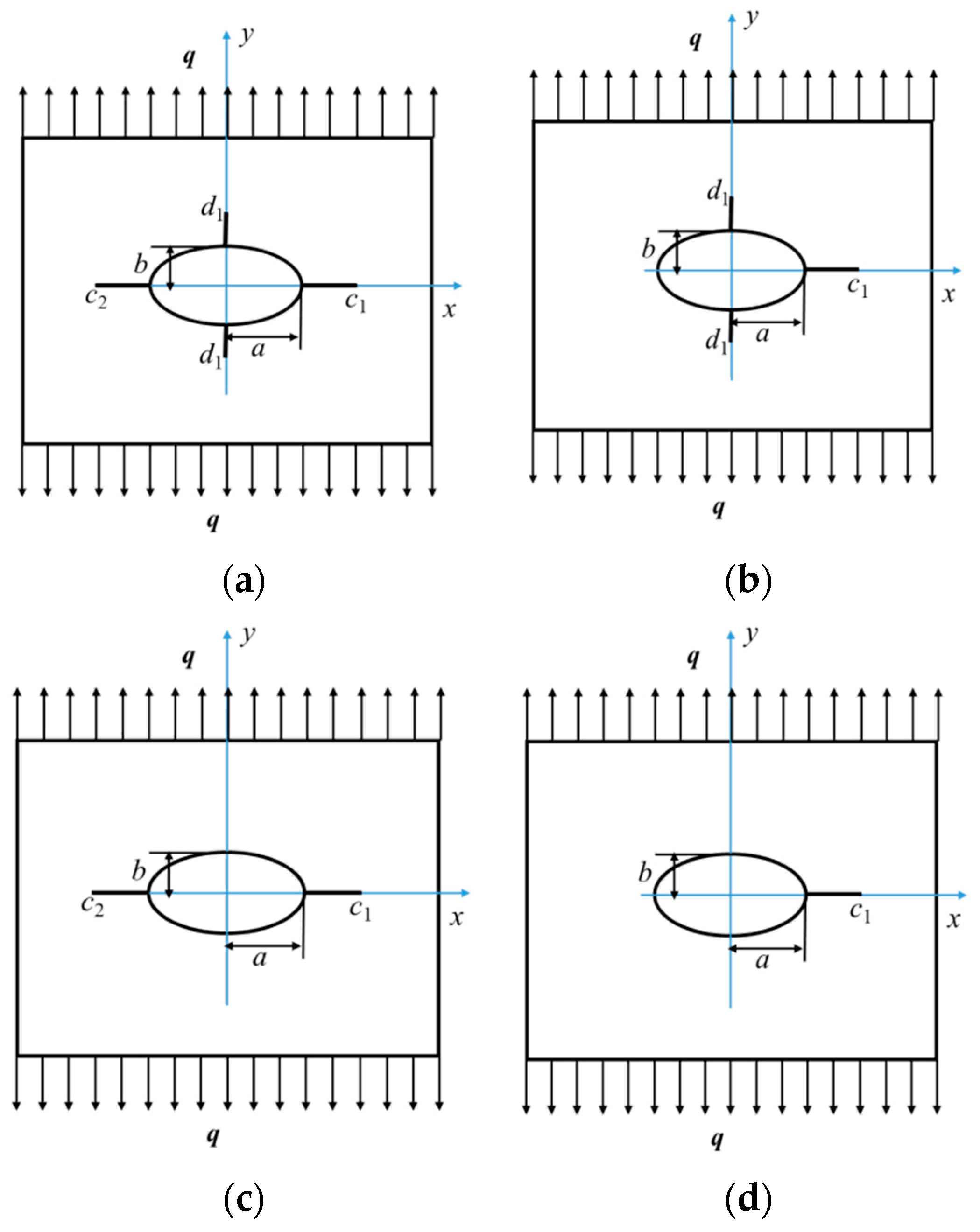

3.3. Calculation Models for Stress Intensity Factors with Cracks

- (1)

- Four cracks

- (2)

- Three cracks

- (3)

- Two cracks

- (4)

- One crack

4. Presentation and Analysis of Results

4.1. Stress Concentration Analysis of Casing with Perforation Defects

4.1.1. Mechanical Property Analysis of Casing with Circular Defects

- (1)

- Uniform external pressure (76.54 MPa)

- (2)

- External pressure (76.54 MPa) + Compression stress (−232.68 MP)

- (3)

- Uniform internal pressure (86.35 MPa)

- (4)

- Uniform internal pressure (94.55 MPa) + Tension stress (174.51 MPa)

- (5)

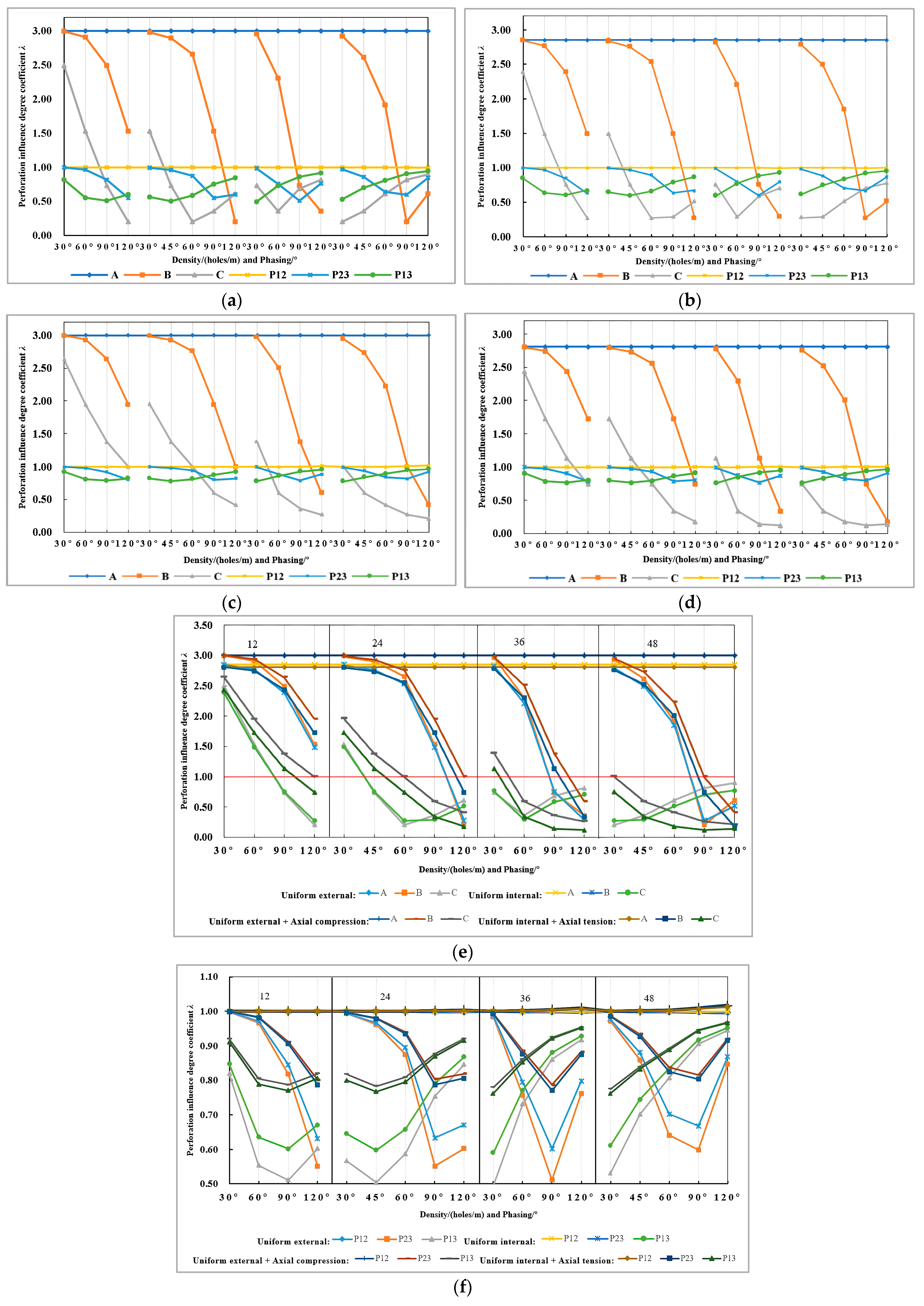

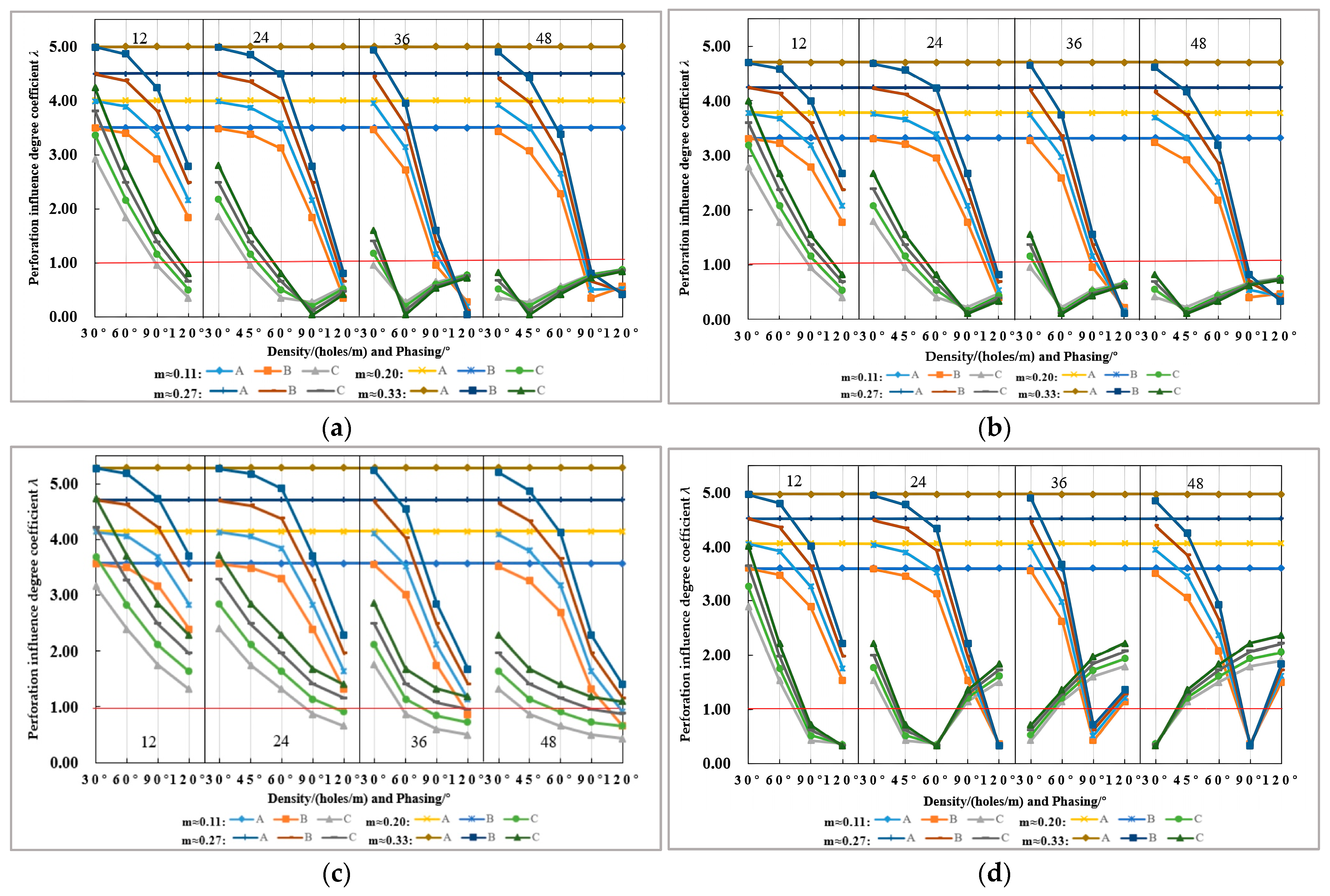

- Comparative analysis of the influence degree of perforated casing

- (1)

- The maximum λ value consistently appears at point A across all loads: λ ≈ 3 under uniform external pressure and λ ≈ 2.85 under uniform internal pressure, with no variation against shot density or phasing. This confirms that the hole centerline parallel to the casing axis is the most significant stress concentration zone, where perforation most significantly compromises the mechanical properties of the casing, resulting in the lowest safety performance of the pipe body.

- (2)

- The analysis of points B and C under various loads consistently demonstrates that a higher shot density and a larger phase angle generally enhance the safety performance of the perforated casing by reducing the stress concentration factor (λ). For both points, for λ > 1, a larger phase angle reduces the λ value, with the effect being more pronounced at higher shot densities—indicating a mitigation of perforation’s negative impact. Conversely, for λ < 1, increasing the shot density allows more points to enter this beneficial region, demonstrating a positive mechanical benefit. However, the λ values at point B (e.g., rising from 0.2 to 0.61 under external pressure as the phase angle increases to 120°) confirm that an optimal range also exists for combining these parameters to maximize safety performance.

- (3)

- Mechanical analysis of key points reveals distinct perforation effects under various loads. At point P12, λ remains approximately 1, indicating negligible influence from perforation. From the data in Table 5, Table 6, Table 7 and Table 8, while stress concentrations are highest at hole-edge points A and A’, no significant elastoplastic stress overlap occurs between adjacent holes within common parameter ranges, and the overall casing safety remains comparable to its non-perforated state. In contrast, points P23 and P13 consistently exhibit λ < 1, reflecting a beneficial stress reduction and improved safety. Although high shot density and large phase angle generally enhance performance, their interaction requires optimization. As shown in Figure 10f, the optimal phase angles for P23 and P13 vary with shot density, with minimal λ values occurring at 36 holes/m (90° for P23, 30° for P13). Synthesizing the λ values across all points (P12, P23, P13), the optimal parameter combination is determined to be a shot density of 36 holes/m with a phase angle of 60°.

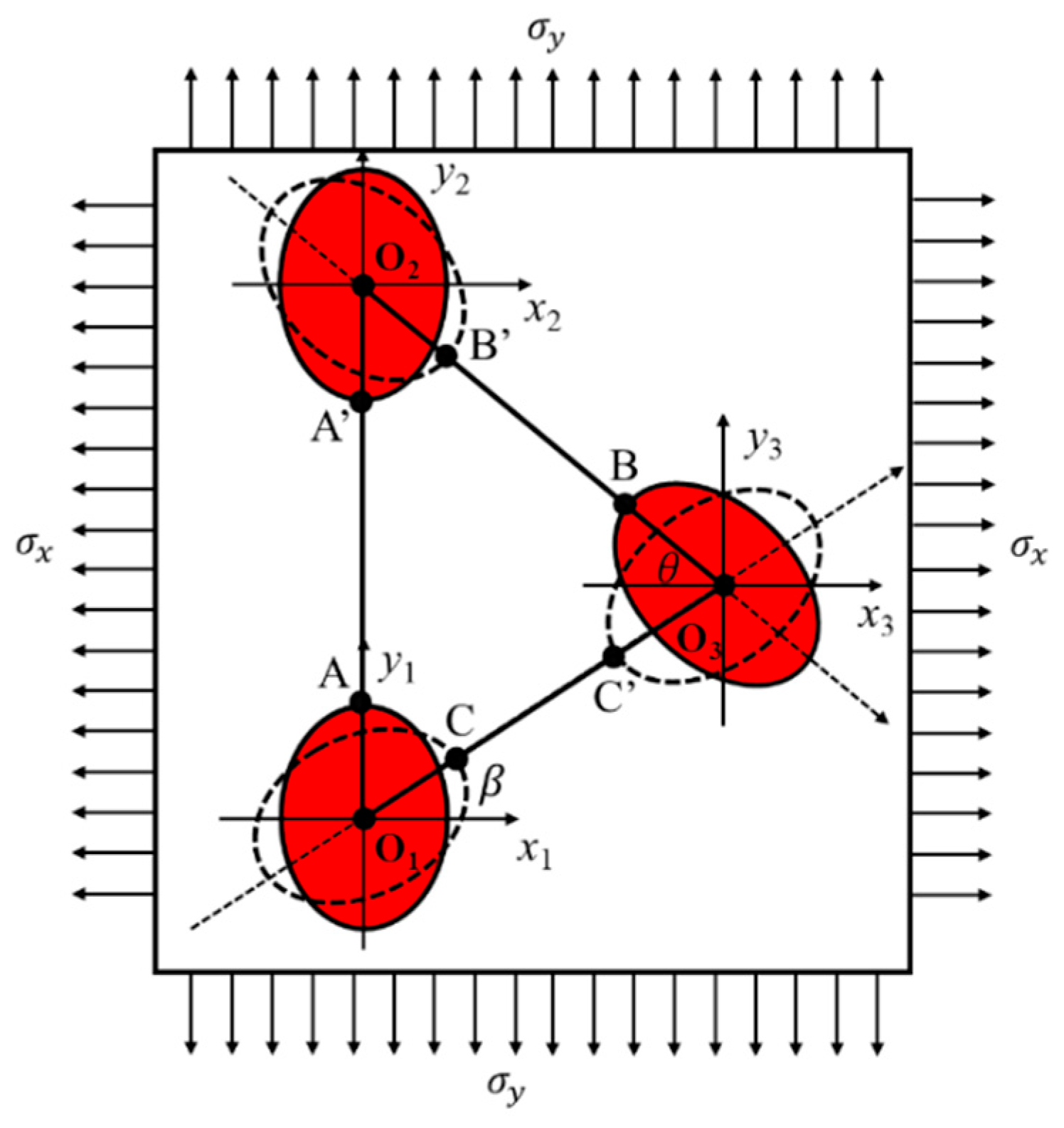

4.1.2. Mechanical Property Analysis of Casing with Elliptical Defects

- (1)

- Uniform external pressure (76.54 MPa)

- (2)

- External pressure (76.54 MPa) + Compression stress (−232.68 MP)

- (3)

- Uniform internal pressure (86.35 MPa)

- (4)

- Uniform internal pressure (94.55 MPa) + Tension stress (174.51 MPa)

- (5)

- Comparative analysis of the influence degree of perforated casing

- (1)

- When the major axis of elliptical defects Hole 1 and Hole 2 are on the O1O2 line, the perforation influence degree coefficient λ at point A and point A’ is always the maximum under different loads. Its value is independent of shot density and phase angle but increases with the aspect ratio coefficient m. For instance, as m rises from 0.11 to 0.33, λ increases from 3.50 to 5.00 under external pressure and exhibits similar growth trends under other loads. This identifies the line connecting the major axis endpoints of adjacent ellipses as the zone of maximum stress concentration, where perforation most significantly reduces casing safety. Furthermore, comparing all the calculated data for point A in Figure 12a,b, λ values under external pressure are consistently slightly higher than under internal pressure, indicating that the perforated section is more susceptible to collapse failure than internal yield when subjected to its respective critical load.

- (2)

- When the major axis of elliptical defects Hole 2 and Hole 3 are on the O2O3 line, comparing the data of point B in Figure 12a–d it can be seen that point B exhibits a consistent trend: for λ > 1, its value decreases as the phase angle increases, with higher shot densities accelerating this reduction; for λ < 1, more points enter this beneficial region as shot density rises. Both trends confirm that the high shot density and large phase angle can improve the safety performance of the casing in the perforation section. However, the optimal combination is also influenced by the elliptical aspect ratio (m). For example, at a phase angle of 120°, the λ value at point B is minimum at m ≈ 0.11 for 24 holes/m but maximum at the same m for 36 and 48 holes/m. Furthermore, at 48 holes/m and m ≈ 0.11, the optimal phase angle shifts from 120° to 90°. This indicates that the axis ratio m is a critical factor in determining the optimal pairing of shot density and phase angle.

- (3)

- When the major axis of elliptical defects Hole 1 and Hole 3 are on the O1O3 line, from the perforation influence degree coefficient λ of point C in Figure 12a–d, it can be seen that a high shot density and large phase angle improve casing safety by reducing λ (for λ > 1) and promoting more points into the beneficial λ < 1 region. When the perforated casing is subjected to external and internal pressure load separately, the phase angle of the minimum λ value decreases from 90° to 45°, corresponding to the shot density increases from 24 holes/m to 48 holes/m, as shown in Figure 12a,b. This trend proves that there is an optimal combination scheme between shot density and phase angle which can ensure the safety performance of the casing. The calculated data at point C in Figure 12c,d show that the application of axial compression/tension in combined loading increases the number of points with λ > 1, thereby reducing safety compared to scenarios involving only internal or external pressure. A comprehensive comparison of the three defect orientations reveals that aligning the major axis along the perforation spiral (O1O3 line) yields the highest casing safety, while aligning it parallel to the casing axis (O1O2 line) results in the lowest.

4.1.3. Mechanical Property Analysis of Casing with Polygonal Perforation Defect

4.2. Fracture Mechanics Analysis of Casing with Cracks at Perforation Defects

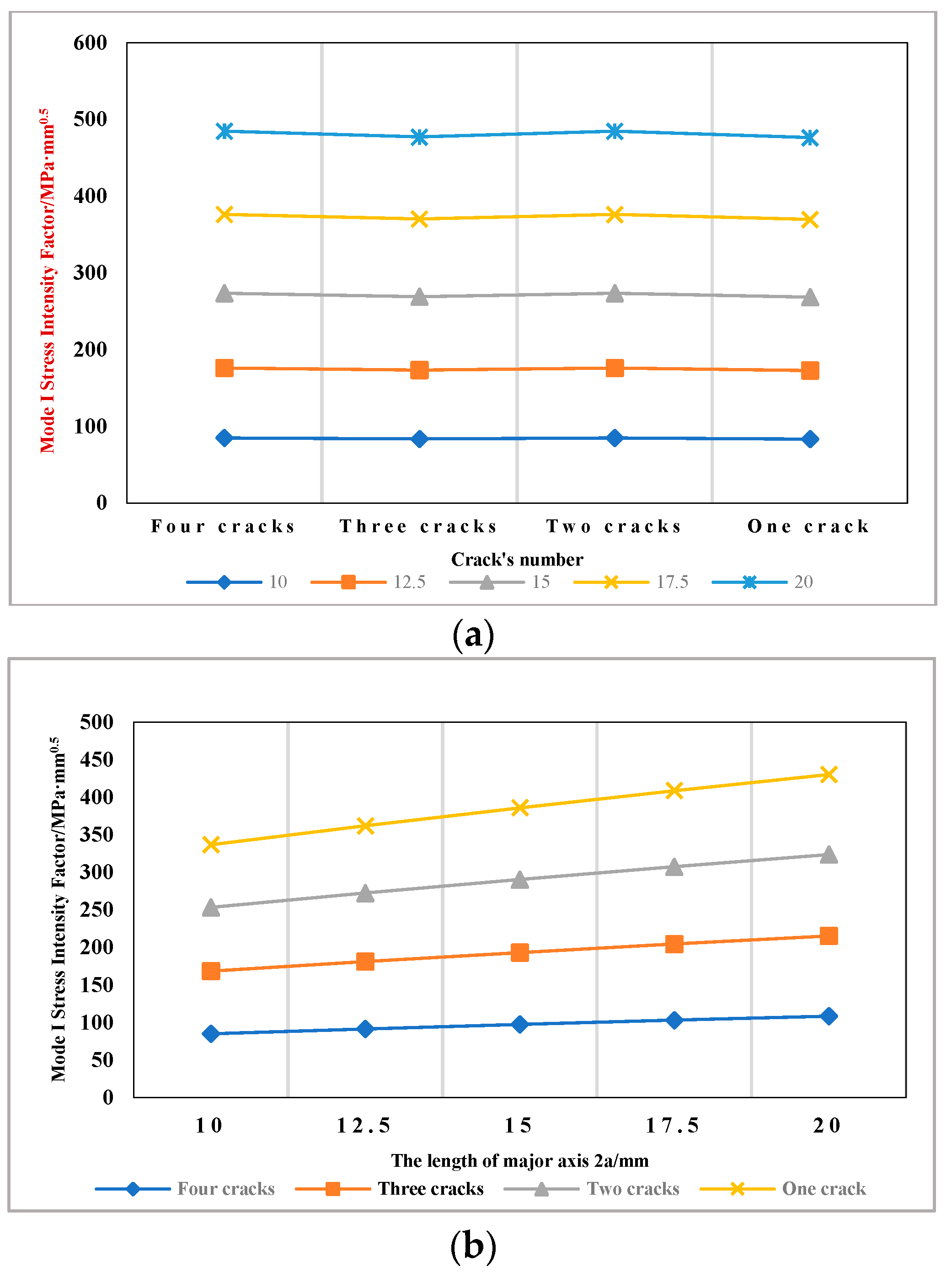

4.2.1. Crack Numbers and Defect Shapes

- (1)

- The Mode I stress intensity factor at the crack tip (c1, 0) for the four-crack configuration in Figure 12a is nearly identical to that for the two-crack case in Figure 12c. The maximum difference between the three-crack and one-crack configurations is only 0.22 MPa·mm0.5 when the major axis length 2a is 10 mm. This indicates that adding a crack (d1-b) parallel to the tensile load has a negligible effect.

- (2)

- The maximum SIF difference at (c1, 0) reaches 1.60 MPa·mm0.5 (between four and three cracks) and 1.68 MPa·mm0.5 (between two and one crack) when 2a = 20 mm. Based on this, it is inferred that the addition of a crack (c2-a) perpendicular to the tensile load has a more significant effect on the Mode I stress intensity factor at the crack tip (c1, 0) than that of the crack (d1-b) parallel to the tensile load.

- (3)

- The SIF at (c1, 0) consistently increases with the length of the elliptical defect’s major axis. This indicates that greater ellipticity (a larger difference between the major and minor axes) elevates the crack-tip stress, thereby increasing the risk of fracture failure in the perforated casing under tension.

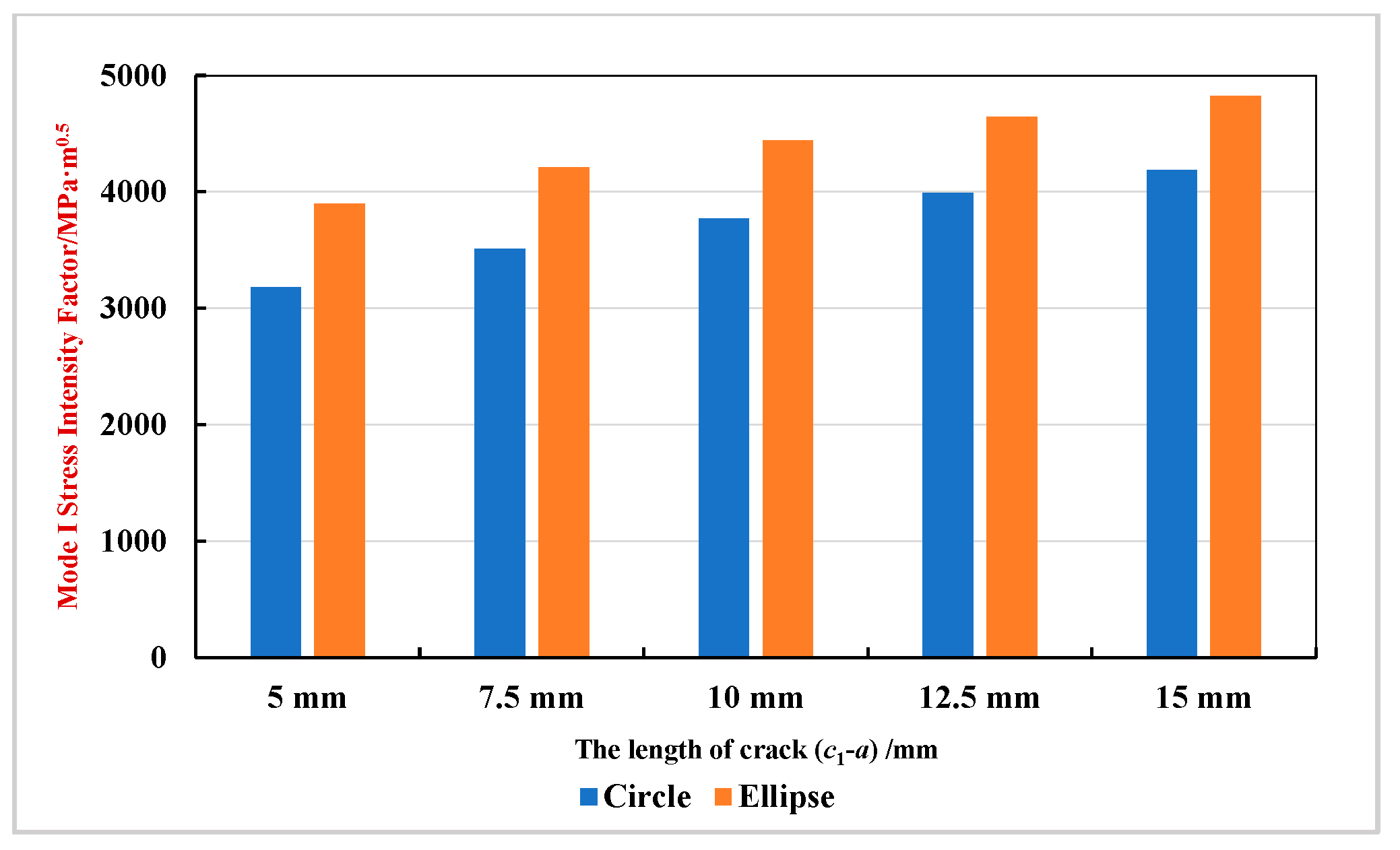

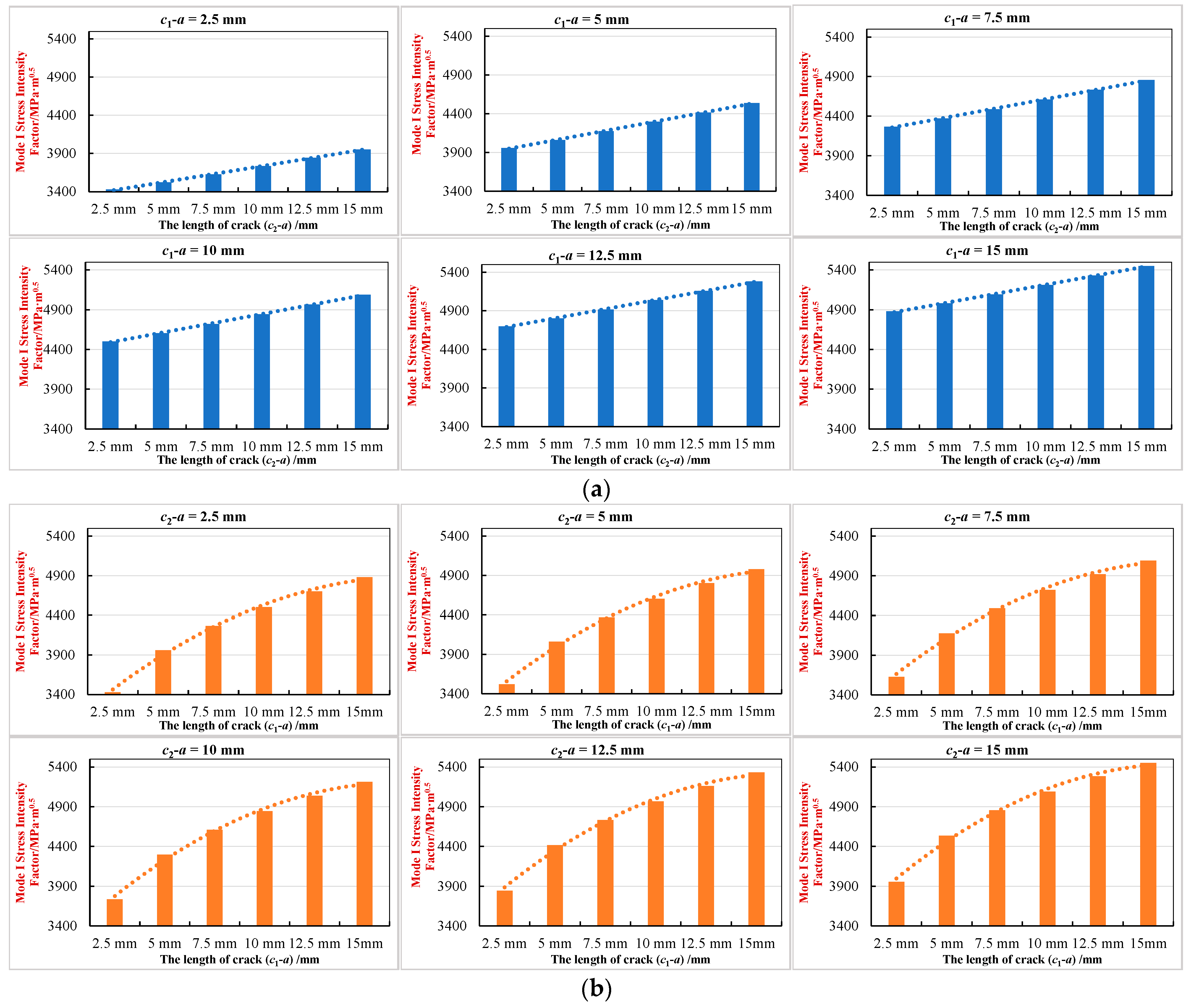

4.2.2. Crack Lengths

5. Conclusions

- (1)

- In this paper, there are four forms of critical loads: uniform external pressure, uniform external pressure + axial compression stress, uniform internal pressure, and uniform internal pressure + axial tension stress are applied to the casing in the perforation section, respectively. According to the case study of the equivalent stress between the circular perforation defects, it can be seen that the general combination of the shot density (12 holes/m to 48 holes/m) and phase angle (30° to 120°) in the spiral distribution scheme can meet the requirements of the casing safety performance in engineering standards, and the yield failure of the perforated casing pipe body will not occur because of the excessive interference between defects. This analysis, based on stress concentration and equivalent stress, provides the foundation for assessing collapse and yield failure risks. In addition, by comparing the perforation influence degree coefficients of all defects with different geometric shapes when they independently bear the critical limit load of internal pressure and external pressure, it is found that the maximum stress at the boundary of the hole caused by external pressure is always slightly higher than that caused by internal pressure. Therefore, compared with the internal yield failure, the casing in the perforation section is more prone to collapse failure. Meanwhile, it is also evident that the addition of axial compression/tension changes the trend of perforation’s influence on the mechanical properties of the casing and reduces the safety performance of the perforated casing section when the main load is external or internal pressure.

- (2)

- When the shape of the perforation defect is a circle, the maximum value of the perforation influence coefficient λ is the smallest compared with the other shapes such as an ellipse, a pentagon, and a hexagon (circle: λ ≈ 3, ellipse: λ ≈ 5.29, pentagon: λ ≈ 6.58, hexagon: λ ≈ 5.75). When λ > 1, the greater the value, the greater the difference in the equivalent stress before and after perforation; that is, under the same load, the equivalent stress after perforation is higher than that before perforation. The negative influence on the mechanical properties of the casing increases, which greatly reduces the safety performance of casing in the perforation section. Therefore, in the well completion and perforation operations, it is necessary to ensure that the shape of the perforation defects is approximately circular. At the same time, ellipses with a large difference between the major axis and minor axis and polygons with small angles should be avoided.

- (3)

- When the production casing is perforated according to the spiral distribution, the maximum value of the equivalent stress at the defect’s boundary is always located on the connecting line of the holes’ centers parallel to the casing axis. This value does not change with the perforation parameters (shot density and phase angle). However, this value is affected by the form and magnitude of the applied load and increases with the increase in the difference between the major and minor axes of the ellipse and the decrease in the polygon angle.

- (4)

- The combined findings from the stress concentration analysis (Section 2) and the fracture mechanics analysis (Section 3) offer a comprehensive framework for evaluating the safety performance of perforated casings. The stress concentration factor (λ) helps identify locations and conditions most susceptible to yielding or collapse initiation, while the Stress Intensity Factor (SIF) directly quantifies the risk of fracture failure due to crack propagation.

- (5)

- Generally speaking, choosing higher shot density (>24 holes/m) and larger phase angle (>60°) can reduce the negative influence on the mechanical properties and improve the safety performance of the casing in the perforation section. However, there is an optimal combination scheme between them. According to the calculation and analysis results in this paper, when perforation defects are approximately circular, the recommended values are 36 holes/m and 60°.

- (6)

- Under the same tensile load, compared with the number of cracks, the difference between the major and minor axes of the elliptical defect has a more significant effect on the Mode I stress intensity factor. The greater the difference value between the major axis and minor axis of the elliptical defect, the faster the Mode I stress intensity factor increases, which means that the stress and deformation at the crack tip increase with the difference value, and the casing in this perforation section is more prone to fracture failure caused by crack propagation.

- (7)

- For the cracks in different directions at the edge of the perforation defect, the effects of the crack’s length change on the Mode I stress intensity factor are different. Cracks parallel to the tensile stress direction have a small effect on the Mode I stress intensity factor, while cracks perpendicular to the tensile stress direction have a significant influence on it. It can be seen from the calculation example that the influence degree of the crack’s length on the crack tip side is about 3 times that of the crack’s length change on the symmetrical side.

6. Discussion

- (1)

- Although there are four types of loads considered in this study, including external pressure and internal pressure loads acting alone, as well as the combination of external pressure + axial compression, internal pressure + axial tension, the characteristics of all the loads are uniformly distributed. According to the analysis of Casero et al. [52], deep and high-pressure unconventional wells located in active tectonic regions with dominant SS (Strike-Slip Faulting) or TF/RF (Thrust-Fault/Reverse-Faulting) stress regimes can be prone to casing deformation resulting from natural-fracture/fault and/or bedding plane reactivation. The statistical data analysis of casing deformation by Han et al. [53] shows that the non-uniformity of geological load leads to a non-uniform external pressure on the casing. Compared with a uniformly distributed load, the casing is prone to collapse and damage in the non-uniformly distributed load area. An example of the extreme non-uniform load action is that in the geological fracture development area, stratum sliding causes a directional concentrated load, which leads to shear deformation of the casing. Li et al. [54] also believed that the shear deformation of the casing stems from the fracture sliding in the high-angle geology. Therefore, the follow-up research should focus on the non-uniformity of the casing equivalent stress in the perforation section under the non-uniform applied load.

- (2)

- This time, the research object of the casing strength is only the pipe body itself. The research goal of the perforated casing with different defects is to determine the quantitative influence of the perforation parameters. In most cases, there is a layer of cement ring between the casing string and the formation in the perforation section of the well. The non-uniform external pressure load caused by geological movement is transferred to the casing body through the cement ring. Chen et al. [55] mentioned that the strength improvement of the cement ring and the high cementing quality can prevent casing deformation. However, the lack of a cement ring and the low cementing quality will lead to stress concentration and casing deformation [56]. Therefore, more and more studies [57,58,59] claim that the influence of applied load on the casing can be reduced by adjusting the thickness, strength, and toughness of the cement ring. In order to make the theoretical analysis results have a higher reference value in actual engineering applications, the mechanical property analysis model should be established by taking the “casing-cement ring-formation” as a whole in the subsequent research.

- (3)

- The traditional casing design standard does not allow the pipe body to yield. The triaxial equivalent stress and casing safety performance involved in this research were calculated and judged by the beginning of pipe yield. When the applied load is lower than the critical yield load, the mechanical property analysis of the casing is based on the stress–strain relationship of linear elasticity. However, the casing has typical elastic–plastic mechanical properties because its material is metal. When the applied load exceeds the critical yield load, plastic deformation of the pipe body will occur. The high temperature and impact effect caused by the perforation will generate a plastic zone near the perforation defect. After multi-stage fracturing and repeated fracturing in an oil and gas well, the strain hardening or the strength softening effect of the material will occur in the perforated casing. All these actual engineering scenarios will result in a nonlinear stress–strain relationship of the pipe body, which makes the traditional calculation standard for mechanical properties and the evaluation methods of casing safety performance no longer applicable. Therefore, the follow-up research should refer to more mechanical knowledge and practical engineering cases, thereby broadening the theoretical calculation basis and field application scope of the casing design standard.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, L.; Hu, P.; Li, Y.; Qiu, N.; Chen, G.; Liu, X. Improved Fatigue Reliability Analysis of Deepwater Risers Based on RSM and DBN. J. Mar. Sci. Eng. 2023, 11, 688. [Google Scholar] [CrossRef]

- Wei, R.; Deng, S.; Yan, X.; Peng, M.; Ke, K.; Wang, L.; Hu, Z.; Yang, K.; Huo, B.; Cao, L. A Review of Intelligent Methods for Environmental Risk Identification in Polar Drilling and Well Completion. Processes 2025, 13, 1873. [Google Scholar] [CrossRef]

- Peng, Y.; Fu, G.; Sun, B.; Sun, X.; Chen, J.; Estefen, S.F. Bending Deformation and Ultimate Moment Calculation of Screen Pipes in Offshore Sand Control Completion. J. Mar. Sci. Eng. 2023, 11, 754. [Google Scholar] [CrossRef]

- Li, J.Z. Oil Drilling and Production Machinery Introduction, 2nd ed.; China University of Petroleum Press: Qingdao, China, 2015. (In Chinese) [Google Scholar]

- Pogrebnyak, V.G.; Chudyk, I.I.; Pogrebnyak, A.V.; Perkun, I.V. High-efficiency Casing Perforation Oil and Gas Wells. SOCAR Proc. 2021, 2021, 112–120. [Google Scholar] [CrossRef]

- Roostaei, M.; Soroush, M.; Mohammadtabar, F.; Mohammadtabar, M.; Hosseini, S.A.; Mahmoudi, M.; Sadrzadeh, M.; Ghalambor, A.; Fattahpour, V. Design for Reliability: Experimental and Numerical Simulation of Cased and Perforated Completions with Standalone Screen. SPE Drill. Complet. 2021, 36, 680–706. [Google Scholar] [CrossRef]

- Byrom, T.G. Casing and Liners for Drilling and Completion: Design and Application, 2nd ed.; Gulf Professional Publishing: Waltham, MA, USA, 2015. [Google Scholar]

- Li, M.F.; Zhang, M.Y.; Huang, J.F.; Liang, J.W.; Dou, Y.H.; Jing, S.Y. Residual strength analysis of perforating casing with coplanar surface. Well Test. 2024, 33, 1–8. [Google Scholar] [CrossRef]

- Dong, Q.; Xu, G.; Hu, Y.; Peng, Z. Research on the Residual Strength of Cracked Plate Considering Fatigue Crack Propagation under Cyclic Load. J. Mar. Sci. Eng. 2023, 11, 706. [Google Scholar] [CrossRef]

- Saad-Eldeen, S.; Garbatov, Y. Experimental and Numerical Analysis of Structural Capacity of Perforated Stiffened Plates. J. Mar. Sci. Eng. 2023, 11, 842. [Google Scholar] [CrossRef]

- He, X.; Zhang, M.; Xu, T.; Lei, L.; Li, Y. Evaluation of Mechanical Properties of Different Casing Drilling Steels. Metals 2023, 13, 427. [Google Scholar] [CrossRef]

- Smith, M.B.; Pattillo, P.D. A finite element analysis of collapse of perforated casing. J. Press. Vessel Technol. 1983, 105, 234–240. [Google Scholar] [CrossRef]

- Li, W.; Yang, B.; Chen, S.T. Finite element analysis of perforated casing high stress area compressed volume coefficient. Adv. Pet. Explor. Dev. 2014, 8, 69–72. [Google Scholar] [CrossRef]

- Li, M.F.; Xu, F.; Dou, Y.H.; Zhang, W.J. Safety Analysis of Reperforated Casing under Fracturing Conditions. China Pet. Mach. 2018, 46, 92–99. (In Chinese) [Google Scholar]

- Zhao, X.F.; Guan, Z.C.; Zhang, H.; Liao, H.L.; Sun, B.J.; Zhou, Y.B. Mechanical response of perforated cement sheath through hydraulic fracturing. Fault-Block Oil Gas Field 2017, 24, 695–699. (In Chinese) [Google Scholar]

- Bi, G.; Han, F.; Wu, J.-M.; Yuan, P.-J.; Fu, S.-S.; Ma, Y. Dynamic simulation of double-cased perforation in deepwater high temperature and high-pressure oil and gas wells. Pet. Sci. 2024, 5, 3482–3495. [Google Scholar] [CrossRef]

- Ding, Z.P.; Luo, Y.Y.; Han, B.; Deng, C.F. Influence of perforating on casing collapsing strength and its test. Drill. Prod. Technol. 2016, 39, 15–18. (In Chinese) [Google Scholar]

- Cao, Y.P.; Li, M.F.; Dou, Y.H.; Yu, Y. Simulation analysis on the stress intensity coupling of perforation gun and casing under the action of detonation and shaped charge jet. Drill. Prod. Technol. 2016, 39, 15–18. (In Chinese) [Google Scholar] [CrossRef]

- Sun, J.; Zhang, L.; Fan, J.; Liu, Y.; Yang, Y.; Yang, Z.; Zhang, Z. Experimental study on deformation and cracking of casing with defects under non-uniform load. Exp. Tech. 2025, 28, 3209–3223. [Google Scholar] [CrossRef]

- Zong, Y.; Zhao, H.; Bu, J. Collapse testing of perforated tubing. ACTA Pet. Sin. 1988, 9, 84–97. (In Chinese) [Google Scholar] [CrossRef]

- Yu, Y.N. Analysis of elastic collapse of perforated casing. Mech. Eng. 2004, 26, 24–26. (In Chinese) [Google Scholar]

- Yu, Y.N.; Yang, X.J. Remaining collapse resistance analysis of perforated casing. J. Univ. Pet. China 2004, 28, 77–80+84. (In Chinese) [Google Scholar]

- Tang, B.; Lian, Z.H.; Liu, G.; Liu, Y.G.; Huang, S.Y.; Zhang, P.; Yang, J.X. Theoretical analysis of collapsing strength of the perforated casing. China Pet. Mach. 2004, 32, 11–13+19. (In Chinese) [Google Scholar]

- Mnzool, M.; Al-Mukhtar, A.; Majeed, A.J.; Arafat, A.; Gomaa, E. Simulation and performance characteristics of rock with borehole using Visual Finite Element Analysis. Min. Miner. Deposits 2024, 18, 33–41. [Google Scholar] [CrossRef]

- Liu, Z.P.; Wang, H.W.; Yan, X.Z. Analysis of casing strength after perforation using plastic-elasticity theory. Pet. Drill. Tech. 2007, 35, 31–35. (In Chinese) [Google Scholar]

- Xue, Y.; Wang, S.; Zhang, Q.; Ding, L.; Luo, W.; Yao, L.; Zhou, X.; Zhao, Y. A refined analytical model for stress concentration in perforated casings under complex loading conditions in deep oil and gas wells. Geoenergy Sci. Eng. 2025, 253, 214003. [Google Scholar] [CrossRef]

- Zhanghua, L.; Yuheng, T.; Qiang, Z.; Hao, Y.; Yisheng, M.; Weixing, Y. Strength analysis of perforated casing in ultra-deep horizontal shale wells during sublevel acidizing and hydraulic fracturing process. Adv. Mech. Eng. 2022, 14, 16878132221114592. [Google Scholar] [CrossRef]

- Tong, S.K.; Xu, X.H.; Feng, Q.; Ju, Q.L.; Lv, Z.G. Fracture mechanical analysis of completion perforating casing in high temperature and high pressure deep well. Oil Field Equip. 2013, 42, 31–37. (In Chinese) [Google Scholar]

- Xu, Z.Q.; Liang, Y.H.; Yan, Y.F.; Wang, B.B. Analysis of hole edge cracking behavior of perforating casing based on fracture mechanics. Press. Vessel Technol. 2020, 37, 50–56. (In Chinese) [Google Scholar]

- Majeed, A.J.; Alshara, A.K.; Al-Mukhtar, A.M.; Abood, F.A. Fracturing parameters in petroleum reservoirs and simulation. In Advances in Material Sciences and Engineering; Springer: Singapore, 2019; pp. 491–498. [Google Scholar]

- SY/T 6238.1-1996; Procedures of Full Scale Oil Tube and Collapse Test. Petroleum Industry Press: Beijing, China, 1996. (In Chinese)

- Li, Z.B. Perforation test of SEW oil casing under simulated well conditions. Welded Pipe Tube 2017, 40, 22–26. (In Chinese) [Google Scholar] [CrossRef]

- Jia, B.G.; Wang, W.; Huan, G.Q.; Zhang, J.B.; Wang, S.L.; Lyu, X. Experimental study on perforating test in model well of 140 grade steel casing for ultra-deep well. Oil Field Equip. 2015, 44, 38–43. (In Chinese) [Google Scholar]

- Fu, J.; Zhang, C.; Wu, C.; Tian, D.; Zou, W. Perforation test on casing under simulation well condition. Spec. Steel 2000, 21, 31–34. (In Chinese) [Google Scholar]

- Wu, C.H.; Lin, Q.; Fu, J.C.; Sun, K.M. Perforation test of TP65 oil casing under simulated well conditions. Steel Pipe 2001, 30, 7–10. (In Chinese) [Google Scholar]

- Dou, Y.H.; Cao, Y.P.; Li, M.F.; Zhang, Y.F. Experimental and theoretical study on the mechanical characteristics of perforated casings. Procedia Struct. Integr. 2019, 22, 33–42. [Google Scholar] [CrossRef]

- Jia, X.; Wang, S.; Ma, F.; Tang, K.; Chen, H.; Ma, X.; Pan, D. Influence of perforation shock-induced phase transformation on the collapsing strength of perforated casing. Acta Pet. Sin. 2017, 38, 348–355. (In Chinese) [Google Scholar]

- Godfrey, W.K.; Methven, N.E. Casing damage caused by jet perforating. In Proceedings of the Fall Meeting of the Society of Petroleum Engineers of AIME, Houston, TX, USA, 4–7 October 1970. [Google Scholar]

- Qiu, H.; Wen, M.; Cao, Y.F.; Hou, Z.; Ma, N.; Han, F.; Bi, G. Simulation test on the feasibility of double-layer casing perforation technology in deepwater high-temperature and high-pressure gas field. China Offshore Oil Gas 2023, 35, 124–133. [Google Scholar]

- King, G.E. The effect of high-density perforating on the mechanical crush resistance of casing. In Proceedings of the SPE Production Operations Symposium, Oklahoma City, OK, USA, 13–14 March 1989. [Google Scholar] [CrossRef]

- King, G.E. Casing crush resistance loss to high-density perforating: Casing tests. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 23–26 September 1990. [Google Scholar] [CrossRef]

- ISO/TR 10400; Petroleum and Natural Gas Industries—Formulae and Calculations for the Properties of Casing, Tubing, Drill Pipe, and Line Pipe Used as Casing or Tubing. International Organization for Standardization: Geneva, Switzerland, 2007.

- American Petroleum Institute. Bulletin of Performance Properties of Casing, Tubing, and Drill Pipe: API Bulletin 5C2; American Petroleum Institute: Washington, DC, USA, 1999. [Google Scholar]

- American Petroleum Institute. Bulletin on Formulas and Calculations for Casing, Tubing, Drill Pipe and Line Pipe Properties: API Bulletin 5C3; American Petroleum Institute: Washington, DC, USA, 1994. [Google Scholar]

- Kirsch, G. The theory of elasticity and the requirement of resistance of materials. Z. Vereneis Dtsch. Ingenieure 1898, 42, 797–807. (In German) [Google Scholar]

- Inglis, C.E. Stresses in a plate due to the presence of cracks and sharp comers. Trans. Inst. Nav. Archit. 1913, 55, 219–230. [Google Scholar]

- Kolosov, G.V. On an Application of Complex Function Theory to a Plane Problem of the Mathematical Theory of Elasticity; Mattisen: Yuriev, Russia, 1983. (In Russian) [Google Scholar]

- Mark, K.; Boris, S.; Igor, T. Handbook of Elasticity Solutions; Kluwer Academic Publishers: Dordrecht, The Netherland, 2003. [Google Scholar]

- Li, Z.X.; Yang, L.X. An analysis of the elastic plane problem of an elliptical hole with four edge cracks. J. Inn. Mong. Univ. (Nat. Sci. Ed.) 2013, 44, 133–140. (In Chinese) [Google Scholar]

- Guo, J.H.; Liu, G.T. Stress analysis of the problem about a circular hole with asymmetry collinear cracks. J. Inn. Mong. Norm. Univ. (Nat. Sci. Ed.) 2007, 36, 418–422. (In Chinese) [Google Scholar]

- Guo, H.M.; Liu, G.T.; Pi, J.D. Stress analysis of an ellipse hole with a straight edge crack by complex variable method. ACTA Mech. Solida Sin. 2007, 28, 308–312. (In Chinese) [Google Scholar] [CrossRef]

- Casero, A.; Rylance, M. The unconventional unconventionals: Tectonically influenced regions, stress states and casing failure. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2020. [Google Scholar]

- Han, L.H.; Yang, S.Y.; Wei, F.Q.; Ye, X.Q.; Wang, J.J. Casing deformation mechanism and controlling method for shale gas well under complex fracture environment. Pet. Tubul. Goods Instrum. 2020, 6, 16–23. (In Chinese) [Google Scholar] [CrossRef]

- Li, L.; Wang, G.; Lian, Z.; Zhang, L.; Mei, J.; He, Y. Deformation mechanism of horizontal shale gas well production casing and its engineering solution: A case study on the Huangjinba block of the Zhaotong national shale gas demonstration zone. Nat. Gas Ind. B 2018, 5, 261–269. [Google Scholar] [CrossRef]

- Chen, Z.; Shi, L.; Xiang, D. Mechanism of casing deformation in the Changning—Weiyuan national shale gas demonstration area and countermeasures. Nat. Gas Ind. B 2017, 4, 1–6. [Google Scholar] [CrossRef]

- Mai, Y.; Mo, L.; Fu, D.; Wang, X.; Fan, Y.; Nie, R. Effect of cementing quality on casing failure in horizontal section of shale gas well. China Pet. Mach. 2019, 47, 123–130. (In Chinese) [Google Scholar] [CrossRef]

- Li, Y.; Liu, S.Q.; Wang, Z.H. Effect of cement thickness and its mechanical parameters on cement stress. Oil Drill. Prod. Technol. 2010, 32, 37–41. (In Chinese) [Google Scholar] [CrossRef]

- Zeng, J.; Gao, D.L.; Wang, Y.B. Study on tensile failure mechanism of cement in volume fractured wellbore. Drill. Prod. Technol. 2019, 42, 1–4. (In Chinese) [Google Scholar]

- Musaed, N.; Alawad, J.; Khalid, A. Characterization of Oil Well Cement–Formation Sheath Bond Strength. Eng 2025, 6, 117. [Google Scholar] [CrossRef]

| Terms and Definitions | Symbols | Values |

|---|---|---|

| Grade | P110 | |

| Specified minimum yield strength | Y | 758 MPa |

| Specified pipe outside diameter | do | 139.7 mm |

| Pipe inside diameter | di | 121.36 mm |

| Specified pipe wall thickness | t | 9.17 mm |

| Calculated mass per unit length | M | 29.76 kg/m |

| Load Forms | External Pressure po/MPa | Internal Pressure pi/MPa | Axial Stress σa/MPa | Locations | Radial Stress σr/MPa | Hoop Stress σh/MPa | Equivalent Stress σe/MPa | Critical Collapse Pressure/MPa | Yield Internal Pressure/MPa |

|---|---|---|---|---|---|---|---|---|---|

| Uniform external pressure | 76.54 | 0 | 0 | Inner surface | 0 | −623.96 | 623.96 | 76.54 | - |

| Outer surface | −76.54 | −547.42 | 513.45 | ||||||

| External + compression | 76.54 | 0 | −232.68 | Inner surface | 0 | −623.96 | 546.15 | 82.41 | - |

| Outer surface | −76.54 | −547.42 | 415.44 | ||||||

| External + compression + internal | 76.54 | 86.35 | −232.68 | Inner surface | −86.35 | −6.38 | 198.77 | 157.42 | - |

| Outer surface | −76.54 | −16.19 | 193.51 | ||||||

| Uniform internal pressure | 0 | 86.35 | 0 | Inner surface | −86.35 | 617.57 | 664.96 | 86.35 | |

| Outer surface | 0 | 531.23 | 531.23 | ||||||

| Internal + tension | 0 | 94.55 | 174.51 | Inner surface | −94.55 | 676.26 | 677.60 | - | 94.55 |

| Outer surface | −0 | 581.71 | 517.03 | ||||||

| Internal + tension + external | 76.54 | 86.35 | 174.51 | Inner surface | −86.35 | −6.38 | 231.48 | - | - |

| Outer surface | −76.54 | −16.19 | 226.97 |

| Density/(holes/m) | Phasing/ ° | l12/ mm | l23/ mm | l13/ mm | β/ ° | θ/ ° |

|---|---|---|---|---|---|---|

| 12 | 30 | 1000 | 917.22 | 89.18 | 69.13 | 88.01 |

| 60 | 500 | 421.48 | 104.80 | 52.67 | 81.32 | |

| 90 | 333.33 | 267.55 | 126.61 | 41.16 | 69.13 | |

| 120 | 250 | 209.59 | 151.97 | 33.25 | 52.67 | |

| 24 | 30 | 500 | 459.43 | 52.40 | 52.67 | 86.03 |

| 45 | 333.33 | 295.53 | 63.03 | 41.16 | 80.72 | |

| 60 | 250 | 217.81 | 75.99 | 33.25 | 73.04 | |

| 90 | 166.67 | 157.19 | 104.03 | 23.61 | 52.67 | |

| 120 | 125 | 151.97 | 133.74 | 18.15 | 33.25 | |

| 36 | 30 | 333.33 | 307.20 | 42.20 | 41.16 | 84.06 |

| 60 | 166.67 | 152.73 | 69.35 | 23.61 | 65.42 | |

| 90 | 111.11 | 126.61 | 99.28 | 16.25 | 41.16 | |

| 120 | 83.33 | 138.70 | 130.09 | 12.33 | 23.61 | |

| 48 | 30 | 250 | 231.36 | 37.99 | 33.25 | 82.11 |

| 45 | 166.67 | 153.42 | 52.01 | 23.61 | 71.90 | |

| 60 | 125 | 122.02 | 66.87 | 18.15 | 58.62 | |

| 90 | 83.33 | 113.98 | 97.57 | 12.33 | 33.25 | |

| 120 | 62.5 | 133.74 | 128.78 | 9.31 | 18.15 |

| Point | Distance/ mm | Angle/ ° | Point | Distance / mm | Angle / ° |

|---|---|---|---|---|---|

| A | 5 | 90 | P12 | l12/2 | 90 |

| B | 5 | 180-θ | P23 | l23/2 | 180-θ |

| C | 5 | β | P13 | l13/2 | β |

| Density/(holes/m) | Phasing/ ° | Hoop Stress /MPa | P12/MPa | P23/MPa | P13/MPa | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | Hoop Stress | Radial Stress | Hoop Stress | Radial Stress | Hoop Stress | Radial Stress | ||

| 12 | 30 | −1871.88 | −1868.89 | −1555.12 | −623.99 | −0.09 | −623.25 | −0.86 | −548.80 | −86.86 |

| 60 | −1871.88 | −1815.15 | −954.24 | −624.08 | −0.37 | −609.95 | −14.68 | −397.41 | −229.56 | |

| 90 | −1871.88 | −1555.12 | −457.31 | −624.24 | −0.84 | −545.21 | −80.05 | −272.26 | −350.66 | |

| 120 | −1871.88 | −954.24 | −126.49 | −624.46 | −1.50 | −395.26 | −229.45 | −188.96 | −432.85 | |

| 24 | 30 | −1871.88 | −1859.94 | −954.24 | −624.08 | −0.37 | −621.12 | −3.42 | −406.24 | −229.75 |

| 45 | −1871.88 | −1806.98 | −457.31 | −624.24 | −0.84 | −608.09 | −17.22 | −278.02 | −341.78 | |

| 60 | −1871.88 | −1659.45 | −126.49 | −624.46 | −1.50 | −571.51 | −54.63 | −192.90 | −422.44 | |

| 90 | −1871.88 | −954.24 | 223.54 | −625.10 | −3.36 | −395.82 | −229.48 | −102.93 | −513.19 | |

| 120 | −1871.88 | −126.49 | 381.72 | −626.00 | −5.95 | −188.96 | −432.85 | −62.28 | −556.06 | |

| 36 | 30 | −1871.88 | −1845.18 | −457.31 | −624.24 | −0.84 | −617.62 | −7.64 | −287.44 | −327.16 |

| 60 | −1871.88 | −1439.88 | 223.54 | −625.10 | −3.36 | −517.31 | −110.15 | −106.32 | −500.02 | |

| 90 | −1871.88 | −457.31 | 428.58 | −626.55 | −7.52 | −272.26 | −350.66 | −51.93 | −561.35 | |

| 120 | −1871.88 | 223.54 | 510.16 | −628.65 | −13.28 | −101.71 | −517.84 | −30.26 | −586.99 | |

| 48 | 30 | −1871.88 | −1824.81 | −126.49 | −624.46 | −1.50 | −612.78 | −13.42 | −207.43 | −382.06 |

| 45 | −1871.88 | −1631.05 | 223.54 | −625.10 | −3.36 | −565.09 | −63.15 | −110.77 | −481.86 | |

| 60 | −1871.88 | −1195.00 | 381.72 | −626.00 | −5.95 | −456.85 | −170.94 | −67.16 | −534.31 | |

| 90 | −1871.88 | −126.49 | 510.16 | −628.65 | −13.28 | −189.99 | −430.14 | −31.63 | −580.41 | |

| 120 | −1871.88 | 381.72 | 558.65 | −632.56 | −23.35 | −62.28 | −556.06 | −18.18 | −598.65 | |

| Density/(holes/m) | Phasing/ ° | Hoop Stress /MPa | P12/MPa | P23/MPa | P13/MPa | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | Hoop Stress | Radial Stress | Hoop Stress | Radial Stress | Hoop Stress | Radial Stress | ||

| 12 | 30 | −1639.20 | −1637.32 | −1440.57 | −624.00 | −232.72 | −623.54 | −233.19 | −579.76 | −284.23 |

| 60 | −1639.20 | −1603.63 | −1063.76 | −624.13 | −232.82 | −615.31 | −241.75 | −484.01 | −374.51 | |

| 90 | −1639.20 | −1440.57 | −752.13 | −624.35 | −233.00 | −574.90 | −282.56 | −404.86 | −451.13 | |

| 120 | −1639.20 | −1063.76 | −544.68 | −624.65 | −233.25 | −481.07 | −376.04 | −352.18 | −503.11 | |

| 24 | 30 | −1639.20 | −1631.72 | −1063.76 | −624.13 | −232.82 | −622.29 | −234.72 | −495.91 | −368.28 |

| 45 | −1639.20 | −1598.50 | −752.13 | −624.35 | −233.00 | −614.28 | −243.21 | −412.83 | −441.20 | |

| 60 | −1639.20 | −1505.99 | −544.68 | −624.65 | −233.25 | −591.56 | −266.45 | −357.68 | −493.56 | |

| 90 | −1639.20 | −1063.76 | −325.18 | −625.51 | −233.95 | −481.83 | −375.64 | −299.38 | −552.35 | |

| 120 | −1639.20 | −544.68 | −225.99 | −626.73 | −234.92 | −352.18 | −503.11 | −273.04 | −580.08 | |

| 36 | 30 | −1639.20 | −1622.46 | −752.13 | −624.35 | −233.00 | −620.23 | −237.22 | −425.99 | −424.78 |

| 60 | −1639.20 | −1368.29 | −325.18 | −625.51 | −233.95 | −558.08 | −300.76 | −304.19 | −541.40 | |

| 90 | −1639.20 | −752.13 | −196.60 | −627.47 | −235.51 | −404.86 | −451.13 | −267.60 | −582.34 | |

| 120 | −1639.20 | −325.18 | −145.44 | −630.25 | −237.66 | −297.67 | −556.21 | −253.03 | −599.40 | |

| 48 | 30 | −1639.20 | −1609.68 | −544.68 | −624.65 | −233.25 | −617.38 | −240.66 | −378.88 | −456.15 |

| 45 | −1639.20 | −1488.18 | −325.18 | −625.51 | −233.95 | −588.03 | −271.29 | −310.74 | −526.25 | |

| 60 | −1639.20 | −1214.73 | −225.99 | −626.73 | −234.92 | −520.73 | −338.31 | −280.00 | −562.54 | |

| 90 | −1639.20 | −544.68 | −145.44 | −630.25 | −237.66 | −353.61 | −500.63 | −254.96 | −594.21 | |

| 120 | −1639.20 | −225.99 | −115.04 | −635.31 | −241.36 | −273.04 | −580.08 | −245.48 | −606.69 | |

| Density/(holes/m) | Phasing/ ° | Hoop Stress /MPa | P12/MPa | P23/MPa | P13/MPa | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | Hoop Stress | Radial Stress | Hoop Stress | Radial Stress | Hoop Stress | Radial Stress | ||

| 12 | 30 | 1852.71 | 1849.75 | 1539.20 | 617.60 | 0.09 | 616.87 | 0.85 | 543.18 | 85.97 |

| 60 | 1852.71 | 1796.56 | 944.47 | 617.69 | 0.37 | 603.71 | 14.53 | 393.34 | 227.21 | |

| 90 | 1852.71 | 1539.20 | 452.62 | 617.85 | 0.83 | 539.62 | 79.23 | 269.47 | 347.07 | |

| 120 | 1852.71 | 944.47 | 125.19 | 618.07 | 1.48 | 391.21 | 227.10 | 187.02 | 428.42 | |

| 24 | 30 | 1852.71 | 1840.90 | 944.47 | 617.69 | 0.37 | 614.76 | 3.39 | 402.08 | 227.40 |

| 45 | 1852.71 | 1788.47 | 452.62 | 617.85 | 0.83 | 601.86 | 17.05 | 275.18 | 338.28 | |

| 60 | 1852.71 | 1642.46 | 125.19 | 618.07 | 1.48 | 565.66 | 54.07 | 190.93 | 418.11 | |

| 90 | 1852.71 | 944.47 | −221.25 | 618.69 | 3.32 | 391.76 | 227.13 | 101.88 | 507.94 | |

| 120 | 1852.71 | 125.19 | −377.81 | 619.58 | 5.89 | 187.02 | 428.42 | 61.64 | 550.36 | |

| 36 | 30 | 1852.71 | 1826.29 | 452.62 | 617.85 | 0.83 | 611.29 | 7.56 | 284.50 | 323.81 |

| 60 | 1852.71 | 1425.13 | −221.25 | 618.69 | 3.32 | 512.01 | 109.02 | 105.23 | 494.90 | |

| 90 | 1852.71 | 452.62 | −424.19 | 620.13 | 7.44 | 269.47 | 347.07 | 51.40 | 555.60 | |

| 120 | 1852.71 | −221.25 | −504.94 | 622.21 | 13.15 | 100.67 | 512.54 | 29.95 | 580.98 | |

| 48 | 30 | 1852.71 | 1806.12 | 125.19 | 618.07 | 1.48 | 606.50 | 13.29 | 205.31 | 378.15 |

| 45 | 1852.71 | 1614.35 | −221.25 | 618.69 | 3.32 | 559.30 | 62.50 | 109.63 | 476.93 | |

| 60 | 1852.71 | 1182.76 | −377.81 | 619.58 | 5.89 | 452.18 | 169.19 | 66.47 | 528.84 | |

| 90 | 1852.71 | 125.19 | −504.94 | 622.21 | 13.15 | 188.05 | 425.73 | 31.31 | 574.47 | |

| 120 | 1852.71 | −377.81 | −552.92 | 626.08 | 23.11 | 61.64 | 550.36 | 17.99 | 592.52 | |

| Density/(holes/m) | Phasing/ ° | Hoop Stress/MPa | P12/MPa | P23/MPa | P13/MPa | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | Hoop Stress | Radial Stress | Hoop Stress | Radial Stress | Hoop Stress | Radial Stress | ||

| 12 | 30 | 1854.27 | 1851.86 | 1599.55 | 676.30 | 174.57 | 675.70 | 175.18 | 618.02 | 242.17 |

| 60 | 1854.27 | 1808.65 | 1116.36 | 676.43 | 174.74 | 665.09 | 186.21 | 495.67 | 357.52 | |

| 90 | 1854.27 | 1599.55 | 716.76 | 676.64 | 175.03 | 613.17 | 238.64 | 394.53 | 455.40 | |

| 120 | 1854.27 | 1116.36 | 450.74 | 676.94 | 175.43 | 492.75 | 358.62 | 327.21 | 521.83 | |

| 24 | 30 | 1854.27 | 1844.67 | 1116.36 | 676.43 | 174.74 | 674.06 | 177.18 | 507.54 | 352.90 |

| 45 | 1854.27 | 1802.08 | 716.76 | 676.64 | 175.03 | 663.70 | 188.16 | 402.43 | 444.99 | |

| 60 | 1854.27 | 1683.45 | 450.74 | 676.94 | 175.43 | 634.45 | 218.07 | 332.65 | 511.19 | |

| 90 | 1854.27 | 1116.36 | 169.26 | 677.80 | 176.58 | 493.51 | 358.34 | 258.90 | 585.58 | |

| 120 | 1854.27 | 450.74 | 42.06 | 679.01 | 178.18 | 327.21 | 521.83 | 225.57 | 620.68 | |

| 36 | 30 | 1854.27 | 1832.80 | 716.76 | 676.64 | 175.03 | 671.34 | 180.47 | 415.45 | 427.80 |

| 60 | 1854.27 | 1506.88 | 169.26 | 677.80 | 176.58 | 591.24 | 262.34 | 263.63 | 572.97 | |

| 90 | 1854.27 | 716.76 | 4.38 | 679.75 | 179.14 | 394.53 | 455.40 | 218.04 | 624.14 | |

| 120 | 1854.27 | 169.26 | −61.22 | 682.54 | 182.68 | 257.21 | 590.02 | 199.88 | 645.50 | |

| 48 | 30 | 1854.27 | 1816.42 | 450.74 | 676.94 | 175.43 | 667.59 | 184.98 | 353.41 | 469.65 |

| 45 | 1854.27 | 1660.61 | 169.26 | 677.80 | 176.58 | 629.66 | 224.55 | 270.03 | 555.54 | |

| 60 | 1854.27 | 1309.96 | 42.06 | 679.01 | 178.18 | 543.05 | 310.80 | 232.42 | 600.27 | |

| 90 | 1854.27 | 450.74 | −61.22 | 682.54 | 182.68 | 328.63 | 519.06 | 201.78 | 639.41 | |

| 120 | 1854.27 | 42.06 | −100.21 | 687.64 | 188.82 | 225.57 | 620.68 | 190.18 | 654.86 | |

| Point | Angle Between and Major Axis/° | Angle Between and Major Axis/° |

|---|---|---|

| A | 90 | 0 |

| B | θ | −(90 − θ) |

| C | −β | 90 − β |

| Density/(holes/m) | Phasing/ ° | m ≈ 0.11 (2a = 12.5 mm) | m ≈ 0.20 (2a = 15 mm) | m ≈ 0.27 (2a = 17.5 mm) | m ≈ 0.33 (2a = 20 mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | A | B | C | A | B | C | A | B | C | ||

| 12 | 30 | −2183.9 | −2180.5 | −1827.5 | −2495.8 | 617.1 | 132.1 | −2807.8 | 616.4 | 82.9 | −3119.8 | 615.8 | 33.7 |

| 60 | −2183.9 | −2120.0 | −1151.5 | −2495.8 | −1677.9 | −1657.3 | −2807.8 | −1908.1 | −1885.4 | −3119.8 | −2138.3 | −2113.5 | |

| 90 | −2183.9 | −1827.5 | −592.5 | −2495.8 | 132.1 | −122.8 | −2807.8 | 82.9 | −197.5 | −3119.8 | 33.7 | −272.2 | |

| 120 | −2183.9 | −1151.5 | −220.3 | −2495.8 | −1657.3 | −969.5 | −2807.8 | −1885.4 | −1128.8 | −3119.8 | −2113.5 | −1288.2 | |

| 24 | 30 | −2183.9 | −2170.4 | −1151.5 | −2495.8 | 587.3 | −1657.3 | −2807.8 | 583.7 | −1885.4 | −3119.8 | 580.0 | −2113.5 |

| 45 | −2183.9 | −2110.8 | −592.5 | −2495.8 | −1228.7 | −122.8 | −2807.8 | −1414.0 | −197.5 | −3119.8 | −1599.2 | −272.2 | |

| 60 | −2183.9 | −1944.9 | −220.3 | −2495.8 | 580.4 | −969.5 | −2807.8 | 576.0 | −1128.8 | −3119.8 | 571.6 | −1288.2 | |

| 90 | −2183.9 | −1151.5 | 173.5 | −2495.8 | −1657.3 | −2124.0 | −2807.8 | −1885.4 | −2398.8 | −3119.8 | −2113.5 | −2673.6 | |

| 120 | −2183.9 | −220.3 | 351.4 | −2495.8 | −969.5 | −35.8 | −2807.8 | −1128.8 | −101.7 | −3119.8 | −1288.2 | −167.7 | |

| 36 | 30 | −2183.9 | −2153.8 | −592.5 | −2495.8 | 500.8 | −122.8 | −2807.8 | 488.5 | −197.5 | −3119.8 | 476.2 | −272.2 |

| 60 | −2183.9 | −1697.9 | 173.5 | −2495.8 | −2279.2 | −2124.0 | −2807.8 | −2569.6 | −2398.8 | −3119.8 | −2859.9 | −2673.6 | |

| 90 | −2183.9 | −592.5 | 404.2 | −2495.8 | −122.8 | −912.7 | −2807.8 | −197.5 | −1066.4 | −3119.8 | −272.2 | −1220.0 | |

| 120 | −2183.9 | 173.5 | 495.9 | −2495.8 | −2124.0 | −1681.6 | −2807.8 | −2398.8 | −1912.1 | −3119.8 | −2673.6 | −2142.7 | |

| 48 | 30 | −2183.9 | −2130.9 | −220.3 | −2495.8 | 286.0 | −969.5 | −2807.8 | 252.2 | −1128.8 | −3119.8 | 218.4 | −1288.2 |

| 45 | −2183.9 | −1912.9 | 173.5 | −2495.8 | 341.6 | −2124.0 | −2807.8 | 313.4 | −2398.8 | −3119.8 | 285.2 | −2673.6 | |

| 60 | −2183.9 | −1422.4 | 351.4 | −2495.8 | −2100.2 | −35.8 | −2807.8 | −2372.6 | −101.7 | −3119.8 | −2645.1 | −167.7 | |

| 90 | −2183.9 | −220.3 | 495.9 | −2495.8 | −969.5 | −1681.6 | −2807.8 | −1128.8 | −1912.1 | −3119.8 | −1288.2 | −2142.7 | |

| 120 | −2183.9 | 351.4 | 550.5 | −2495.8 | −35.8 | −1506.6 | −2807.8 | −101.7 | −1719.7 | −3119.8 | −167.7 | −1932.8 | |

| Density/(holes/m) | Phasing/ ° | m ≈ 0.11 (2a = 12.5 mm) | m ≈ 0.20 (2a = 15 mm) | m ≈ 0.27 (2a = 17.5 mm) | m ≈ 0.33 (2a = 20 mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | A | B | C | A | B | C | A | B | C | ||

| 12 | 30 | −1951.2 | −1949.1 | −1727.7 | −2263.2 | 847.3 | 181.4 | −2575.1 | 846.3 | 113.9 | −2887.1 | 845.4 | 46.3 |

| 60 | −1951.2 | −1911.2 | −1303.8 | −2263.2 | −2303.6 | −2275.3 | −2575.1 | −2619.6 | −2588.5 | −2887.1 | −2935.6 | −2901.7 | |

| 90 | −1951.2 | −1727.7 | −953.2 | −2263.2 | 181.4 | −168.6 | −2575.1 | 113.9 | −271.2 | −2887.1 | 46.3 | −373.7 | |

| 120 | −1951.2 | −1303.8 | −719.8 | −2263.2 | −2275.3 | −1331.0 | −2575.1 | −2588.5 | −1549.8 | −2887.1 | −2901.7 | −1768.6 | |

| 24 | 30 | −1951.2 | −1942.8 | −1303.8 | −2263.2 | 806.3 | −2275.3 | −2575.1 | 801.3 | −2588.5 | −2887.1 | 796.3 | −2901.7 |

| 45 | −1951.2 | −1905.4 | −953.2 | −2263.2 | −1686.9 | −168.6 | −2575.1 | −1941.2 | −271.2 | −2887.1 | −2195.6 | −373.7 | |

| 60 | −1951.2 | −1801.3 | −719.8 | −2263.2 | 796.8 | −1331.0 | −2575.1 | 790.8 | −1549.8 | −2887.1 | 784.8 | −1768.6 | |

| 90 | −1951.2 | −1303.8 | −472.9 | −2263.2 | −2275.3 | −2916.1 | −2575.1 | −2588.5 | −3293.4 | −2887.1 | −2901.7 | −3670.6 | |

| 120 | −1951.2 | −719.8 | −361.3 | −2263.2 | −1331.0 | −49.1 | −2575.1 | −1549.8 | −139.7 | −2887.1 | −1768.6 | −230.2 | |

| 36 | 30 | −1951.2 | −1932.3 | −953.2 | −2263.2 | 687.6 | −168.6 | −2575.1 | 670.7 | −271.2 | −2887.1 | 653.8 | −373.7 |

| 60 | −1951.2 | −1646.4 | −472.9 | −2263.2 | −3129.2 | −2916.1 | −2575.1 | −3527.8 | −3293.4 | −2887.1 | −3926.4 | −3670.6 | |

| 90 | −1951.2 | −953.2 | −328.3 | −2263.2 | −168.6 | −1253.1 | −2575.1 | −271.2 | −1464.0 | −2887.1 | −373.7 | −1675.0 | |

| 120 | −1951.2 | −472.9 | −270.7 | −2263.2 | −2916.1 | −2308.7 | −2575.1 | −3293.4 | −2625.2 | −2887.1 | −3670.6 | −2941.7 | |

| 48 | 30 | −1951.2 | −1918.0 | −719.8 | −2263.2 | 392.7 | −1331.0 | −2575.1 | 346.3 | −1549.8 | −2887.1 | 299.9 | −1768.6 |

| 45 | −1951.2 | −1781.3 | −472.9 | −2263.2 | 469.0 | −2916.1 | −2575.1 | 430.3 | −3293.4 | −2887.1 | 391.5 | −3670.6 | |

| 60 | −1951.2 | −1473.7 | −361.3 | −2263.2 | −2883.4 | −49.1 | −2575.1 | −3257.4 | −139.7 | −2887.1 | −3631.4 | −230.2 | |

| 90 | −1951.2 | −719.8 | −270.7 | −2263.2 | −1331.0 | −2308.7 | −2575.1 | −1549.8 | −2625.2 | −2887.1 | −1768.6 | −2941.7 | |

| 120 | −1951.2 | −361.3 | −236.5 | −2263.2 | −49.1 | −2068.5 | −2575.1 | −139.7 | −2361.0 | −2887.1 | −230.2 | −2653.5 | |

| Density/(holes/m) | Phasing/ ° | m ≈ 0.11 (2a = 12.5 mm) | m ≈ 0.20 (2a = 15 mm) | m ≈ 0.27 (2a = 17.5 mm) | m ≈ 0.33 (2a = 20 mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | A | B | C | A | B | C | A | B | C | ||

| 12 | 30 | 2161.5 | 2158.2 | 1808.8 | 2470.3 | −610.8 | −130.8 | 2779.1 | −610.1 | −82.1 | 3087.9 | −609.5 | −33.4 |

| 60 | 2161.5 | 2098.3 | 1139.7 | 2470.3 | 1660.7 | 1640.3 | 2779.1 | 1888.5 | 1866.1 | 3087.9 | 2116.4 | 2091.9 | |

| 90 | 2161.5 | 1808.8 | 586.4 | 2470.3 | −130.8 | 121.6 | 2779.1 | −82.1 | 195.5 | 3087.9 | −33.4 | 269.4 | |

| 120 | 2161.5 | 1139.7 | 218.0 | 2470.3 | 1640.3 | 959.6 | 2779.1 | 1866.1 | 1117.3 | 3087.9 | 2091.9 | 1275.0 | |

| 24 | 30 | 2161.5 | 2148.2 | 1139.7 | 2470.3 | −581.3 | 1640.3 | 2779.1 | −577.7 | 1866.1 | 3087.9 | −574.1 | 2091.9 |

| 45 | 2161.5 | 2089.2 | 586.4 | 2470.3 | 1216.1 | 121.6 | 2779.1 | 1399.5 | 195.5 | 3087.9 | 1582.8 | 269.4 | |

| 60 | 2161.5 | 1925.0 | 218.0 | 2470.3 | −574.4 | 959.6 | 2779.1 | −570.1 | 1117.3 | 3087.9 | −565.8 | 1275.0 | |

| 90 | 2161.5 | 1139.7 | −171.7 | 2470.3 | 1640.3 | 2102.3 | 2779.1 | 1866.1 | 2374.3 | 3087.9 | 2091.9 | 2646.2 | |

| 120 | 2161.5 | 218.0 | −347.8 | 2470.3 | 959.6 | 35.4 | 2779.1 | 1117.3 | 100.7 | 3087.9 | 1275.0 | 166.0 | |

| 36 | 30 | 2161.5 | 2131.8 | 586.4 | 2470.3 | −495.7 | 121.6 | 2779.1 | −483.5 | 195.5 | 3087.9 | −471.3 | 269.4 |

| 60 | 2161.5 | 1680.5 | −171.7 | 2470.3 | 2255.9 | 2102.3 | 2779.1 | 2543.3 | 2374.3 | 3087.9 | 2830.6 | 2646.2 | |

| 90 | 2161.5 | 586.4 | −400.0 | 2470.3 | 121.6 | 903.4 | 2779.1 | 195.5 | 1055.4 | 3087.9 | 269.4 | 1207.5 | |

| 120 | 2161.5 | −171.7 | −490.9 | 2470.3 | 2102.3 | 1664.4 | 2779.1 | 2374.3 | 1892.6 | 3087.9 | 2646.2 | 2120.8 | |

| 48 | 30 | 2161.5 | 2109.1 | 218.0 | 2470.3 | −283.1 | 959.6 | 2779.1 | −249.6 | 1117.3 | 3087.9 | −216.2 | 1275.0 |

| 45 | 2161.5 | 1893.3 | −171.7 | 2470.3 | −338.1 | 2102.3 | 2779.1 | −310.2 | 2374.3 | 3087.9 | −282.3 | 2646.2 | |

| 60 | 2161.5 | 1407.8 | −347.8 | 2470.3 | 2078.7 | 35.4 | 2779.1 | 2348.3 | 100.7 | 3087.9 | 2618.0 | 166.0 | |

| 90 | 2161.5 | 218.0 | −490.9 | 2470.3 | 959.6 | 1664.4 | 2779.1 | 1117.3 | 1892.6 | 3087.9 | 1275.0 | 2120.8 | |

| 120 | 2161.5 | −347.8 | −544.8 | 2470.3 | 35.4 | 1491.2 | 2779.1 | 100.7 | 1702.1 | 3087.9 | 166.0 | 1913.0 | |

| Density/(holes/m) | Phasing/ ° | m ≈ 0.11 (2a = 12.5 mm) | m ≈ 0.20 (2a = 15 mm) | m ≈ 0.27 (2a = 17.5 mm) | m ≈ 0.33 (2a = 20 mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | A | B | C | A | B | C | A | B | C | ||

| 12 | 30 | 2394.2 | 2389.6 | 1908.6 | 2703.0 | −380.7 | −81.5 | 3011.7 | −380.3 | −51.2 | 3320.5 | −379.8 | −20.8 |

| 60 | 2394.2 | 2307.2 | 987.4 | 2703.0 | 1035.0 | 1022.3 | 3011.7 | 1177.0 | 1163.0 | 3320.5 | 1319.0 | 1303.7 | |

| 90 | 2394.2 | 1908.6 | 225.6 | 2703.0 | −81.5 | 75.8 | 3011.7 | −51.2 | 121.8 | 3320.5 | −20.8 | 167.9 | |

| 120 | 2394.2 | 987.4 | −281.5 | 2703.0 | 1022.3 | 598.0 | 3011.7 | 1163.0 | 696.3 | 3320.5 | 1303.7 | 794.6 | |

| 24 | 30 | 2394.2 | 2375.9 | 987.4 | 2703.0 | −362.3 | 1022.3 | 3011.7 | −360.0 | 1163.0 | 3320.5 | −357.8 | 1303.7 |

| 45 | 2394.2 | 2294.7 | 225.6 | 2703.0 | 757.9 | 75.8 | 3011.7 | 872.2 | 121.8 | 3320.5 | 986.5 | 167.9 | |

| 60 | 2394.2 | 2068.5 | −281.5 | 2703.0 | −358.0 | 598.0 | 3011.7 | −355.3 | 696.3 | 3320.5 | −352.6 | 794.6 | |

| 90 | 2394.2 | 987.4 | −818.1 | 2703.0 | 1022.3 | 1310.2 | 3011.7 | 1163.0 | 1479.7 | 3320.5 | 1303.7 | 1649.2 | |

| 120 | 2394.2 | −281.5 | −1060.6 | 2703.0 | 598.0 | 22.1 | 3011.7 | 696.3 | 62.8 | 3320.5 | 794.6 | 103.4 | |

| 36 | 30 | 2394.2 | 2353.2 | 225.6 | 2703.0 | −308.9 | 75.8 | 3011.7 | −301.3 | 121.8 | 3320.5 | −293.7 | 167.9 |

| 60 | 2394.2 | 1731.9 | −818.1 | 2703.0 | 1406.0 | 1310.2 | 3011.7 | 1585.0 | 1479.7 | 3320.5 | 1764.1 | 1649.2 | |

| 90 | 2394.2 | 225.6 | −1132.4 | 2703.0 | 75.8 | 563.0 | 3011.7 | 121.8 | 657.8 | 3320.5 | 167.9 | 752.6 | |

| 120 | 2394.2 | −818.1 | −1257.5 | 2703.0 | 1310.2 | 1037.3 | 3011.7 | 1479.7 | 1179.5 | 3320.5 | 1649.2 | 1321.7 | |

| 48 | 30 | 2394.2 | 2322.0 | −281.5 | 2703.0 | −176.4 | 598.0 | 3011.7 | −155.6 | 696.3 | 3320.5 | −134.7 | 794.6 |

| 45 | 2394.2 | 2025.0 | −818.1 | 2703.0 | −210.7 | 1310.2 | 3011.7 | −193.3 | 1479.7 | 3320.5 | −175.9 | 1649.2 | |

| 60 | 2394.2 | 1356.5 | −1060.6 | 2703.0 | 1295.5 | 22.1 | 3011.7 | 1463.6 | 62.8 | 3320.5 | 1631.6 | 103.4 | |

| 90 | 2394.2 | −281.5 | −1257.5 | 2703.0 | 598.0 | 1037.3 | 3011.7 | 696.3 | 1179.5 | 3320.5 | 794.6 | 1321.7 | |

| 120 | 2394.2 | −1060.6 | −1331.8 | 2703.0 | 22.1 | 929.4 | 3011.7 | 62.8 | 1060.8 | 3320.5 | 103.4 | 1192.2 | |

| Load Form | Load Magnitude σα/MPa | Load Direction α/° | Point A | Point B | ||

|---|---|---|---|---|---|---|

| Hoop Stress | λ | Hoop Stress | λ | |||

| External pressure | −623.96 | 90 | −4003 | 6.41 | −995 | 1.59 |

| Internal pressure | 617.57 | 90 | 3962 | 6.02 | 985 | 1.55 |

| External+ compression | −623.96 −232.68 | 90 0 | −3596 | 6.58 | −823 | 1.51 |

| Internal+ tension | 676.26 174.51 | 90 0 | 4080 | 6.09 | 970 | 1.51 |

| Load Form | Load Magnitude σα/MPa | α/° | Point C | α/° | Point D | ||

|---|---|---|---|---|---|---|---|

| Hoop Stress | λ | Hoop Stress | λ | ||||

| External pressure | −623.96 | 90 | −3525 | 5.65 | 0 | −1071 | 1.72 |

| Internal pressure | 617.57 | 90 | 3488 | 5.31 | 0 | 1060 | 1.66 |

| External+ compression | −623.96 −232.68 | 90 0 | −3141 | 5.75 | 0 90 | −973 | 1.78 |

| Internal+ tension | 676.26 174.51 | 90 0 | 3532 | 5.28 | 0 90 | 1087 | 1.68 |

| The Length of Major Axis 2a /mm | 10 | 12.5 | 15 | 17.5 | 20 |

|---|---|---|---|---|---|

| Four cracks | 84.92 | 91.23 | 97.22 | 102.92 | 108.38 |

| Three cracks | 83.49 | 89.73 | 95.67 | 101.34 | 106.78 |

| Two cracks | 84.92 | 91.23 | 97.22 | 102.92 | 108.38 |

| One crack | 83.27 | 89.57 | 95.54 | 101.24 | 106.70 |

| The Length of Crack (c1-a) /mm | 5 | 7.5 | 10 | 12.5 | 15 |

|---|---|---|---|---|---|

| Circle | 3179.57 | 3511.31 | 3768.38 | 3989.49 | 4189.45 |

| Ellipse | 3900.24 | 4207.26 | 4441.46 | 4641.38 | 4821.62 |

| c1-a | 2.5 mm | 5 mm | 7.5 mm | 10 mm | 12.5 mm | 15 mm | |

| c2-a | |||||||

| 2.5 mm | 3427.29 | 3958.52 | 4266.47 | 4500.30 | 4699.35 | 4878.51 | |

| 5 mm | 3520.70 | 4060.82 | 4370.52 | 4603.82 | 4801.43 | 4978.78 | |

| 7.5 mm | 3625.60 | 4175.88 | 4487.71 | 4720.58 | 4916.73 | 5092.15 | |

| 10 mm | 3734.38 | 4295.36 | 4609.58 | 4842.16 | 5036.94 | 5210.51 | |

| 12.5 mm | 3844.00 | 4415.91 | 4732.71 | 4965.18 | 5158.71 | 5330.54 | |

| 15 mm | 3953.06 | 4536.00 | 4855.52 | 5088.02 | 5280.45 | 5450.66 | |

| c1-a | 2.5 mm | 5 mm | 7.5 mm | 10 mm | 12.5 mm | 15 mm | |

| d1-b | |||||||

| 2.5 mm | 3376.62 | 3907.06 | 4217.63 | 4454.43 | 4656.18 | 4837.69 | |

| 5 mm | 3382.41 | 3922.62 | 4241.68 | 4484.95 | 4691.41 | 4876.26 | |

| 7.5 mm | 3388.99 | 3940.84 | 4270.63 | 4522.54 | 4735.59 | 4925.35 | |

| 10 mm | 3395.10 | 3958.33 | 4299.28 | 4560.69 | 4781.40 | 4977.14 | |

| 12.5 mm | 3400.32 | 3973.72 | 4325.22 | 4596.13 | 4824.90 | 5027.24 | |

| 15 mm | 3404.62 | 3986.72 | 4347.71 | 4627.60 | 4864.34 | 5073.49 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; Yang, K.; Sui, L.; Liu, Y.; Liu, X. Calculation and Analysis on Mechanical Properties of the Perforated Offshore Casing with Defects. J. Mar. Sci. Eng. 2025, 13, 1948. https://doi.org/10.3390/jmse13101948

Xu Z, Yang K, Sui L, Liu Y, Liu X. Calculation and Analysis on Mechanical Properties of the Perforated Offshore Casing with Defects. Journal of Marine Science and Engineering. 2025; 13(10):1948. https://doi.org/10.3390/jmse13101948

Chicago/Turabian StyleXu, Zhiqian, Ke Yang, Le Sui, Yanxin Liu, and Xiuquan Liu. 2025. "Calculation and Analysis on Mechanical Properties of the Perforated Offshore Casing with Defects" Journal of Marine Science and Engineering 13, no. 10: 1948. https://doi.org/10.3390/jmse13101948

APA StyleXu, Z., Yang, K., Sui, L., Liu, Y., & Liu, X. (2025). Calculation and Analysis on Mechanical Properties of the Perforated Offshore Casing with Defects. Journal of Marine Science and Engineering, 13(10), 1948. https://doi.org/10.3390/jmse13101948