Experimental Study on Creep Characteristics and Mechanisms of Wenzhou Soft Soil

Abstract

1. Introduction

2. Experimental Methodology

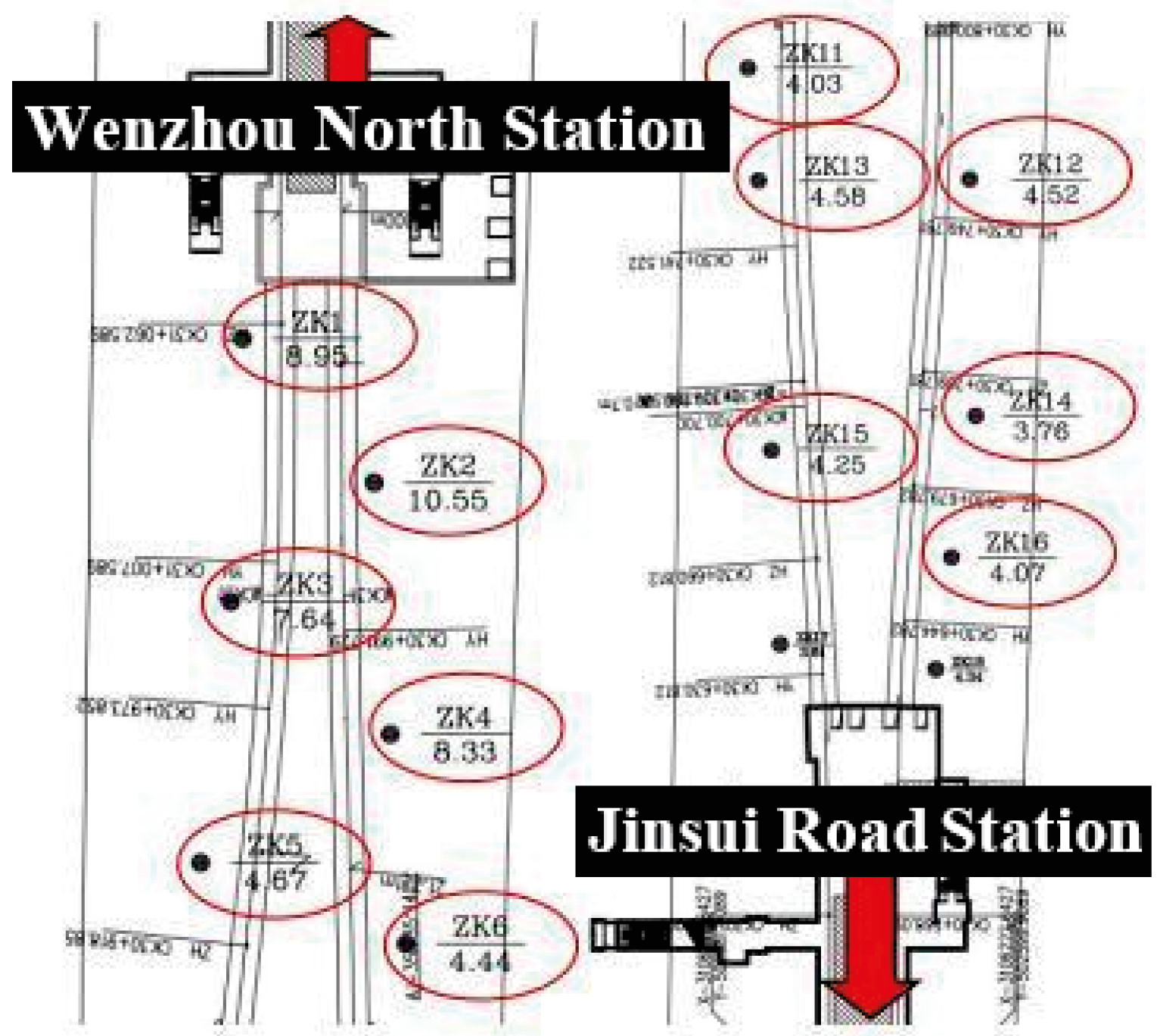

2.1. Basic Physical Properties of Test Materials

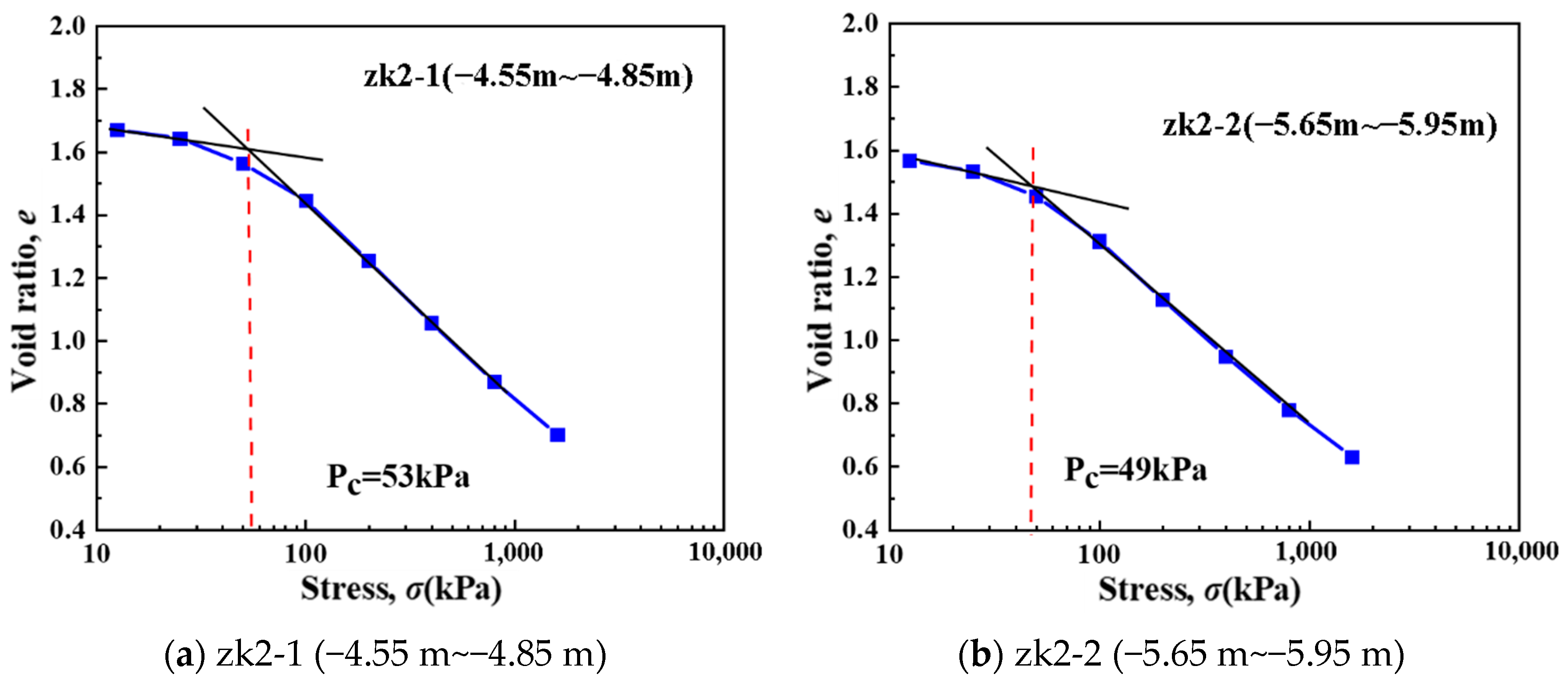

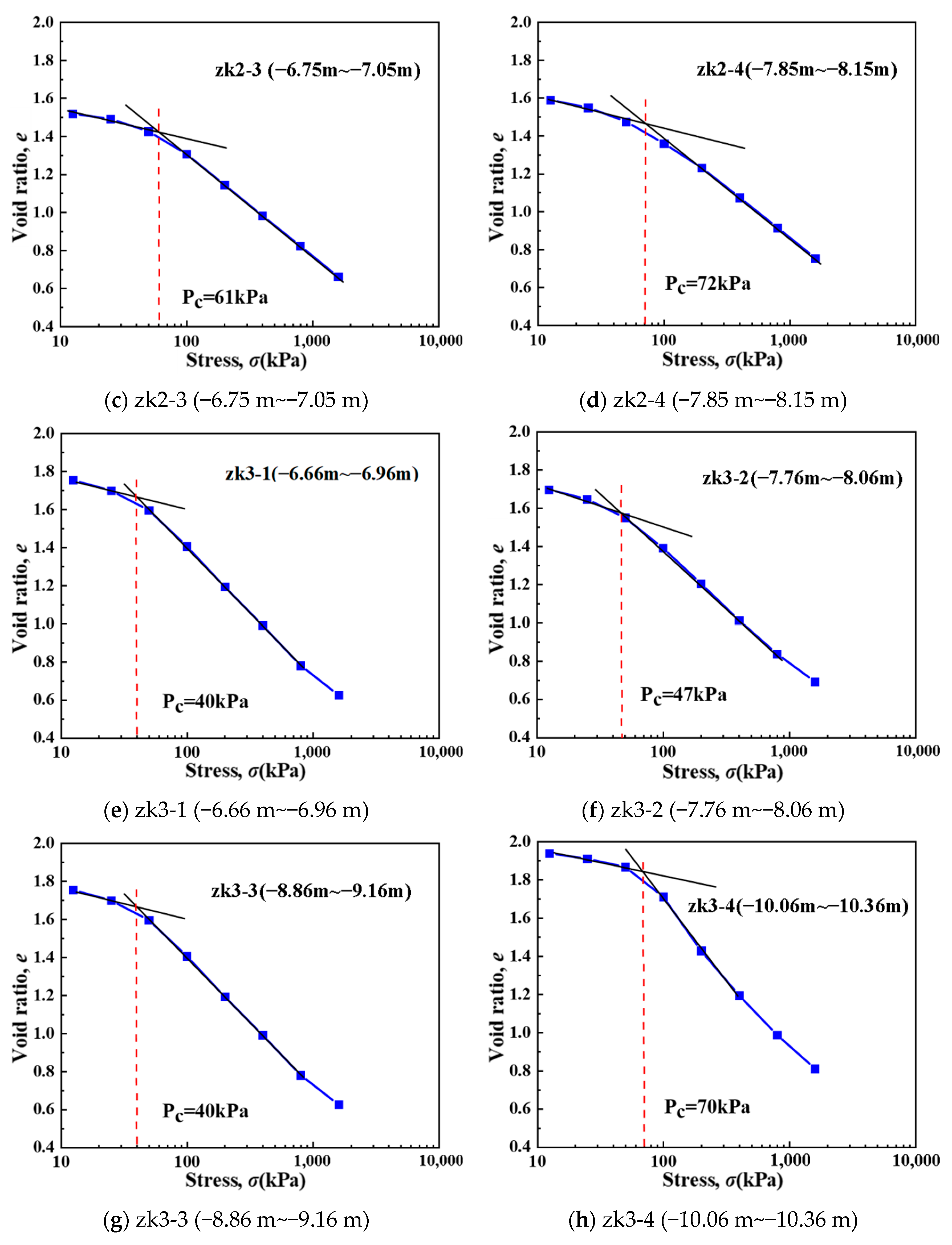

2.2. Sample Disturbance Verification

2.3. Sample Preparation

- Preparation of specimens in their original state

- 2.

- Preparation of specimens for detailed structural testing

2.4. Test Plan and Test Steps

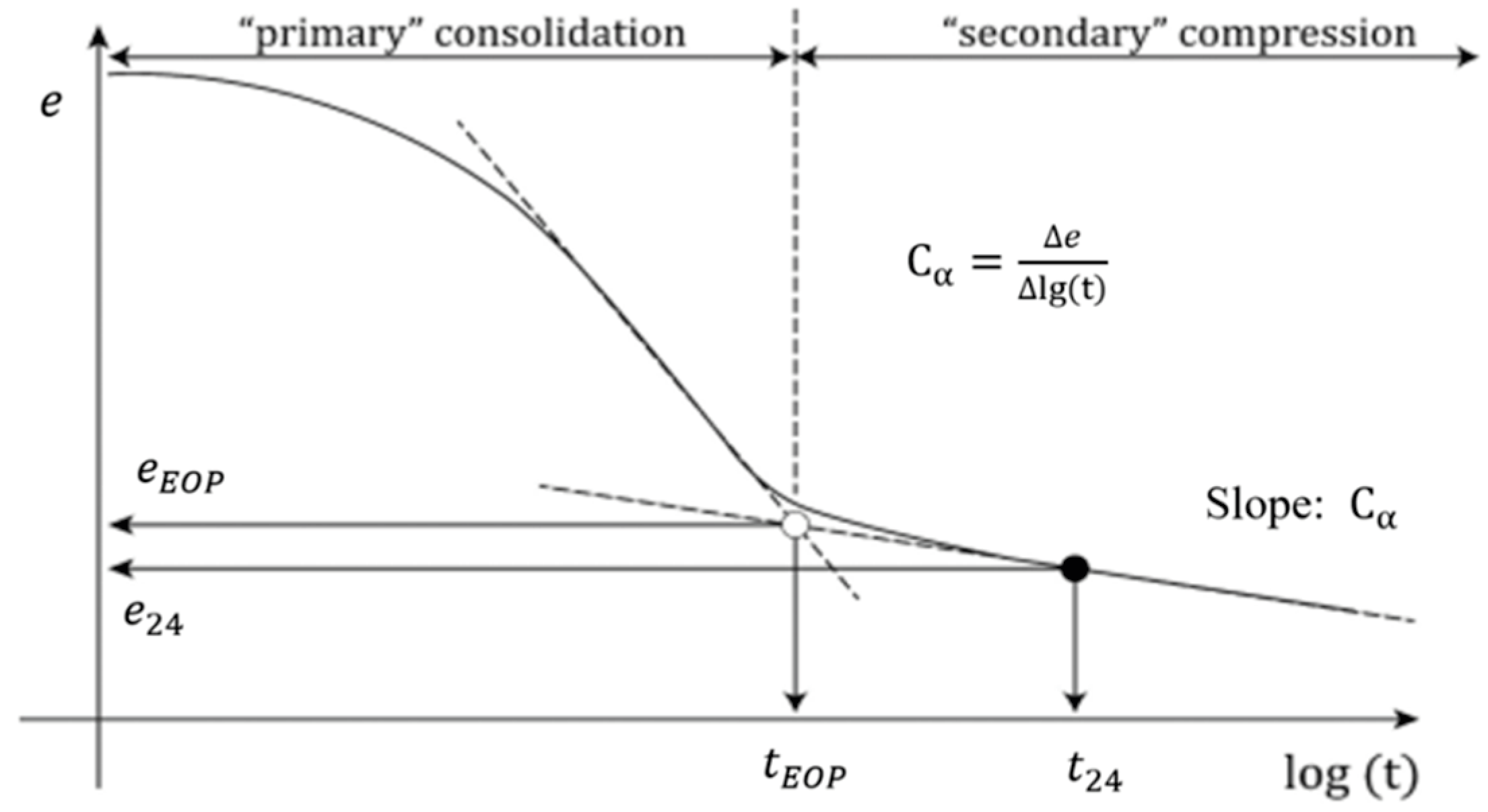

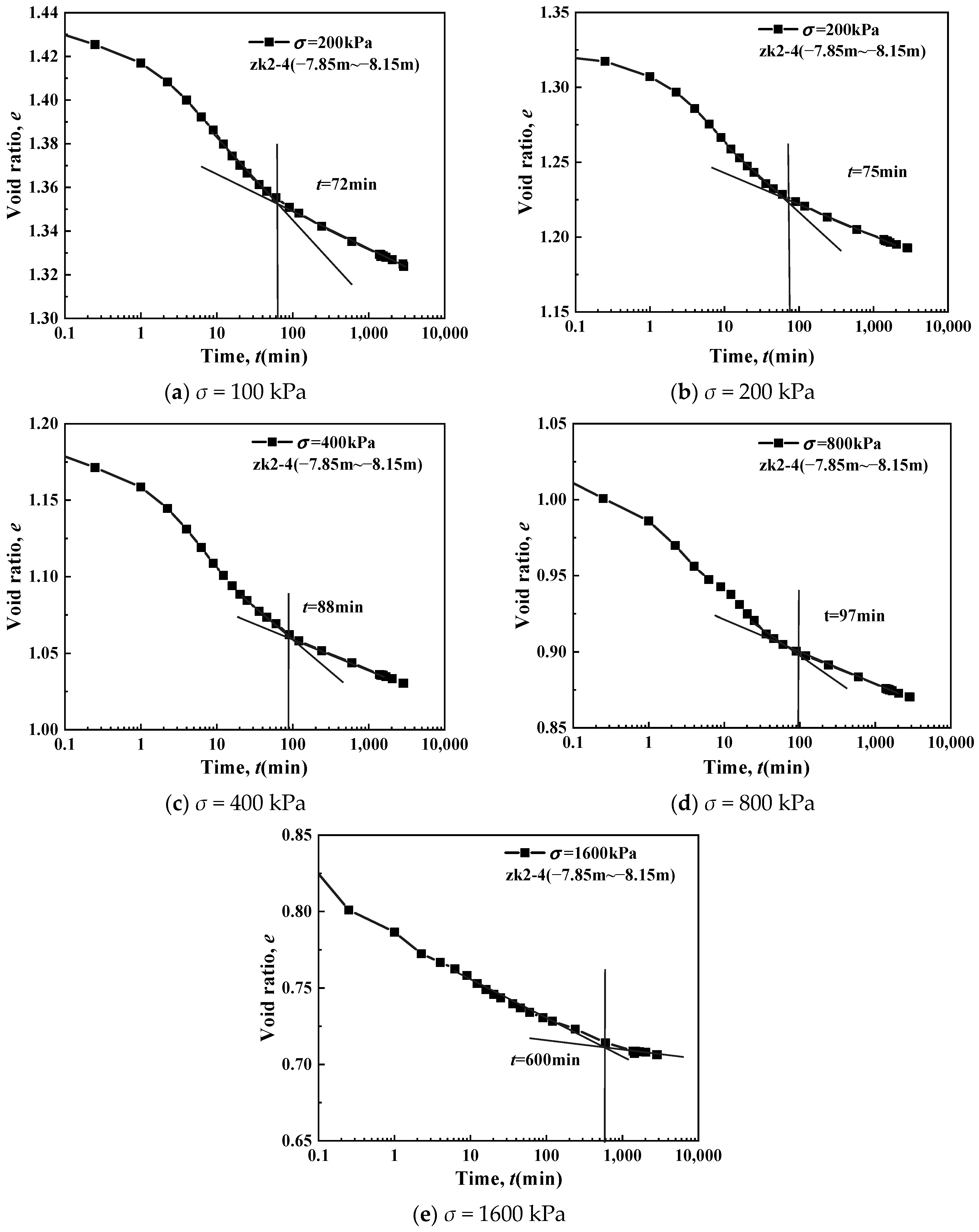

2.5. Secondary Consolidation Coefficient

3. One-Dimensional Creep Characteristics

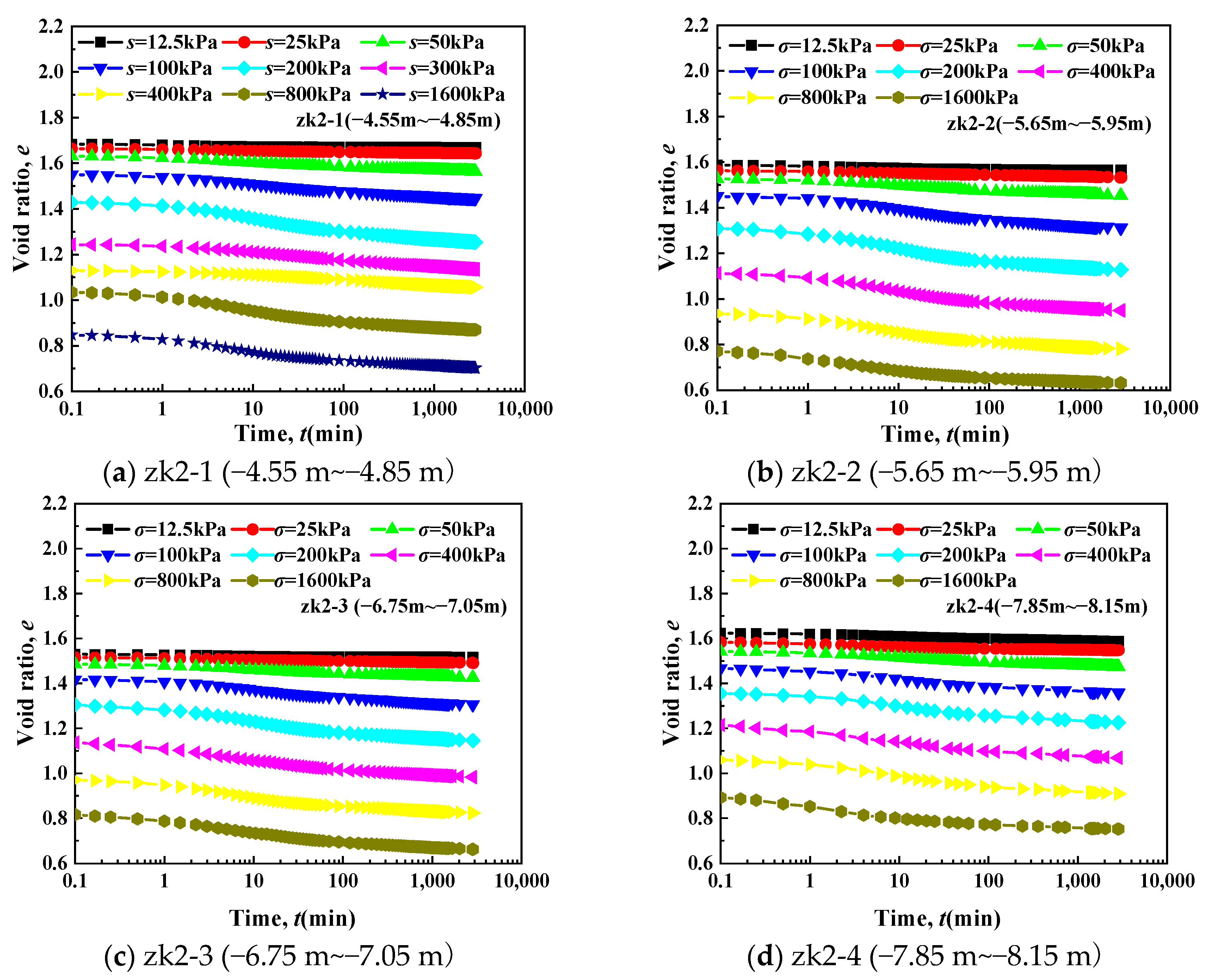

3.1. The Effect of Stress Level on Creep Characteristics

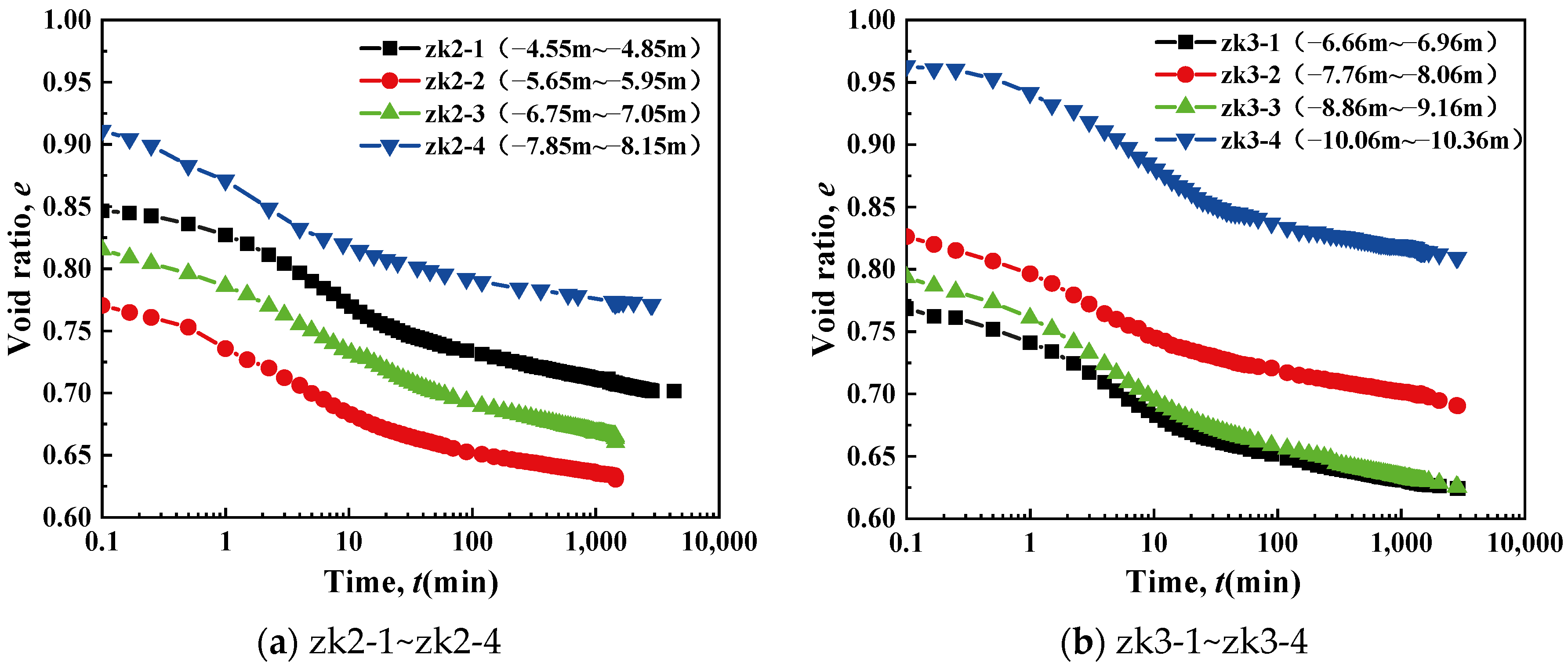

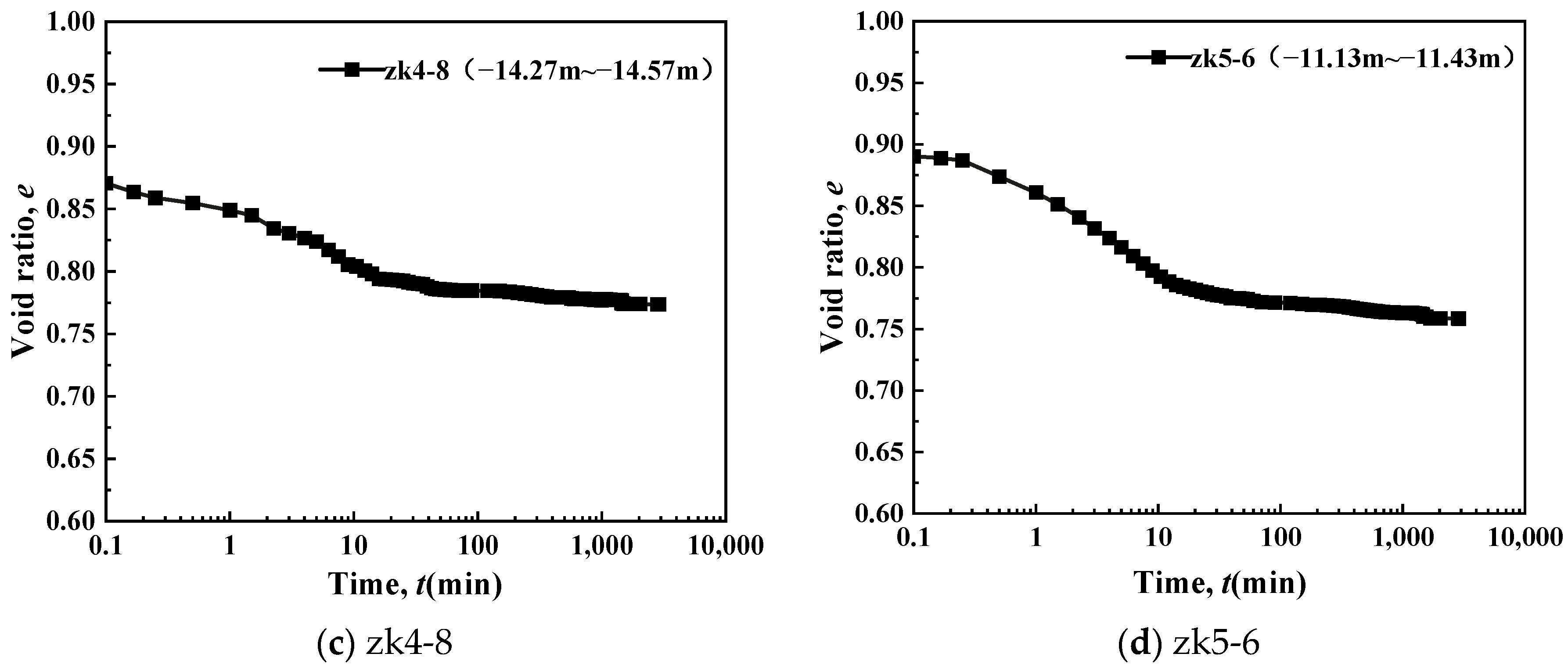

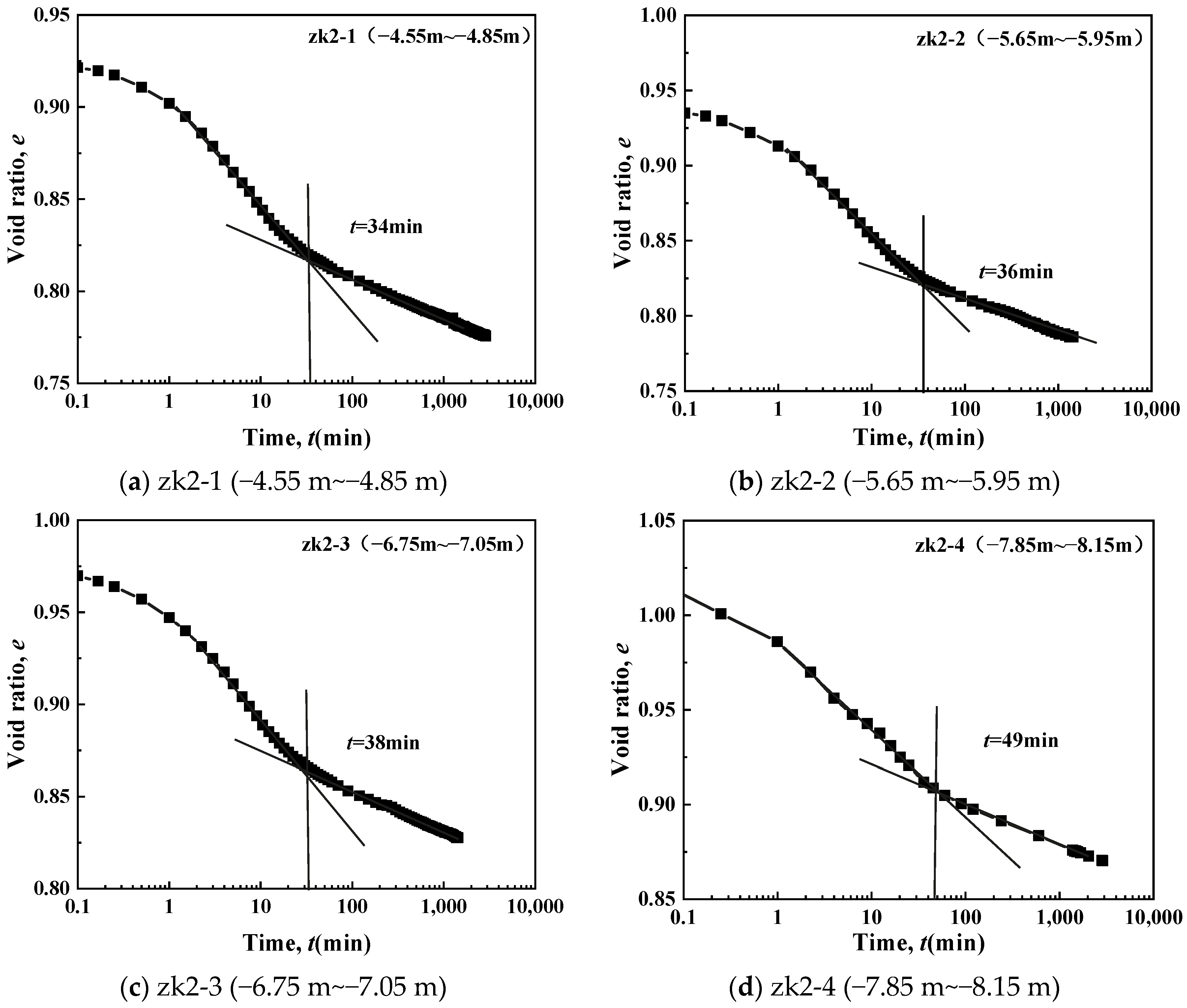

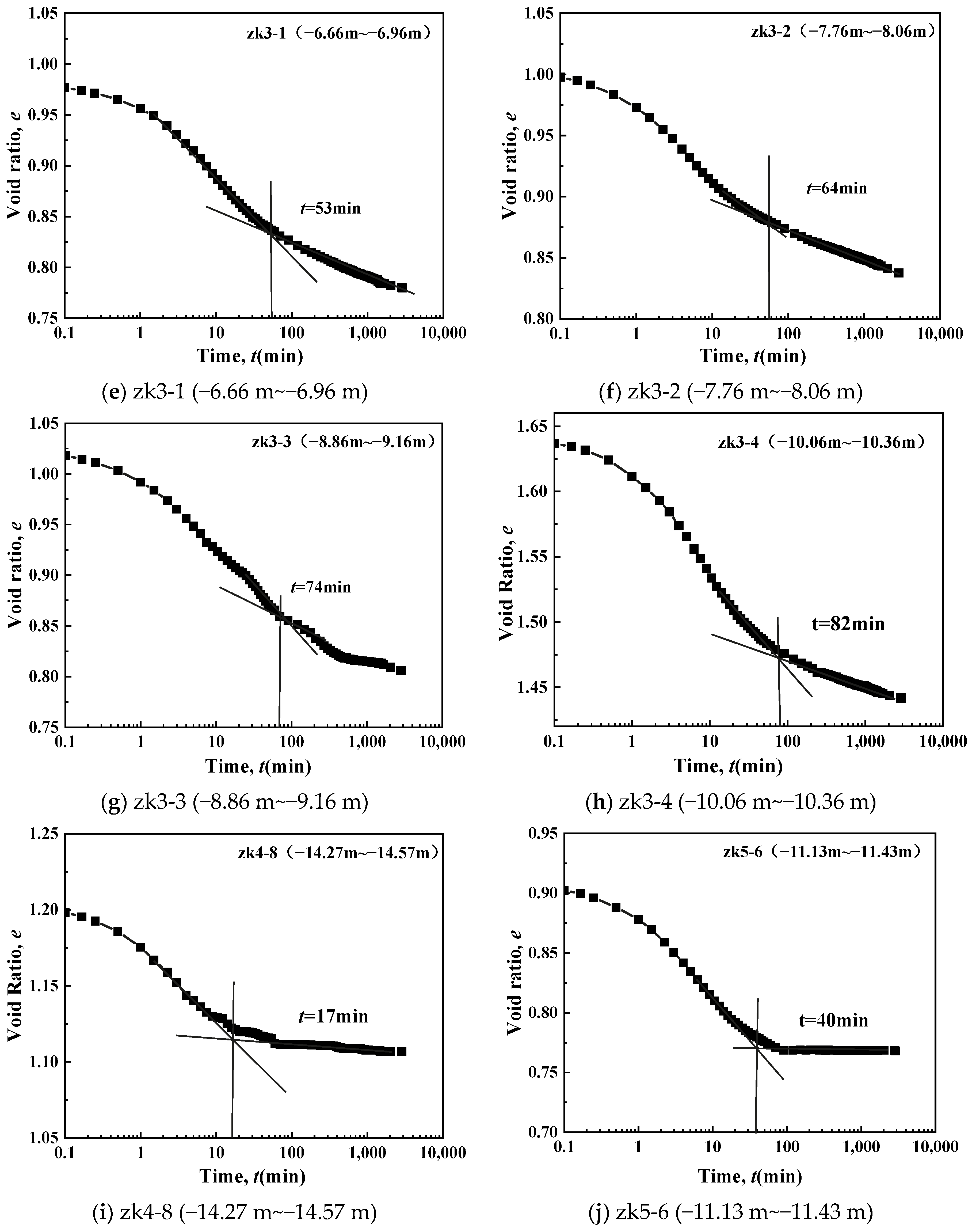

- Pore ratio–time relationship

- 2.

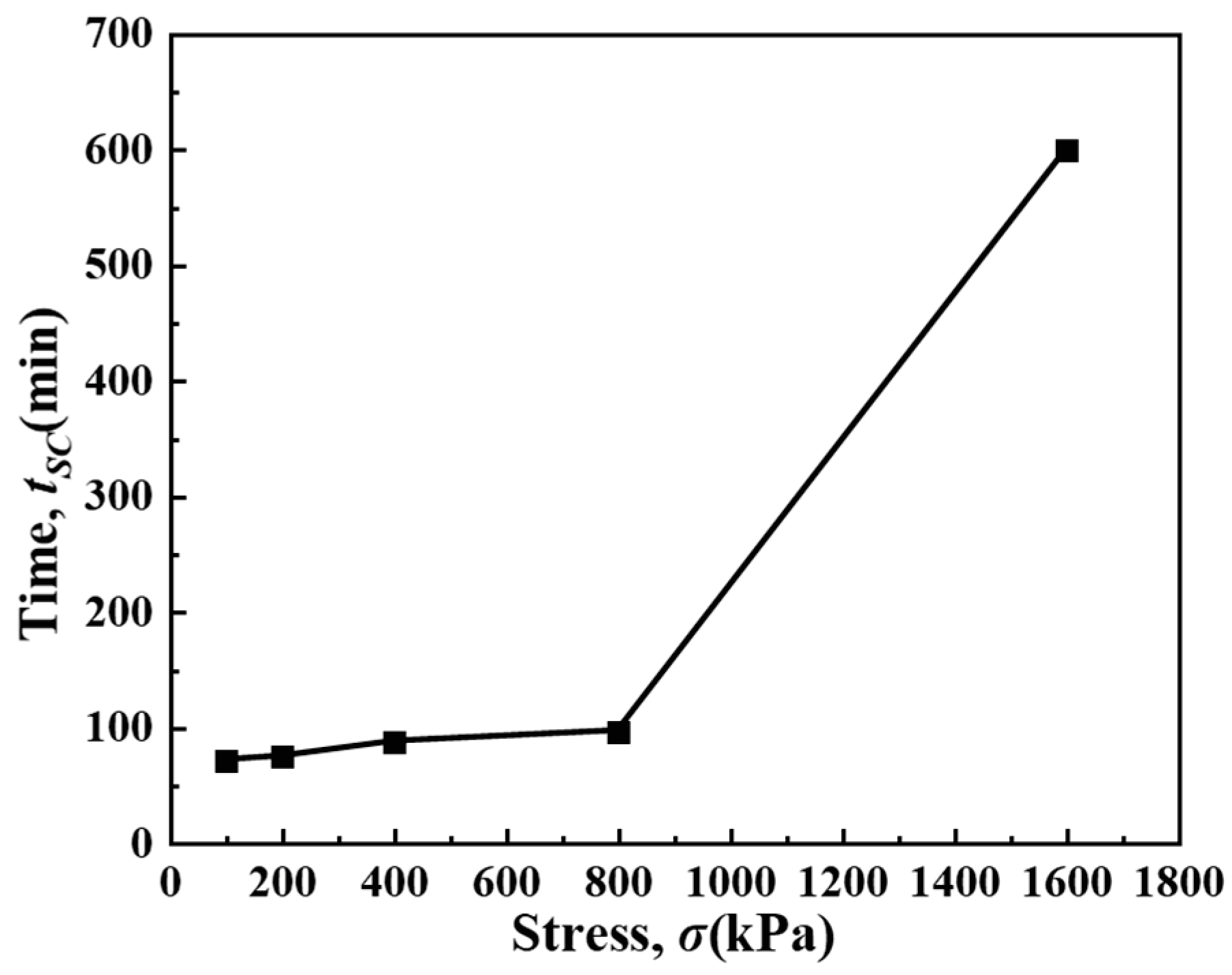

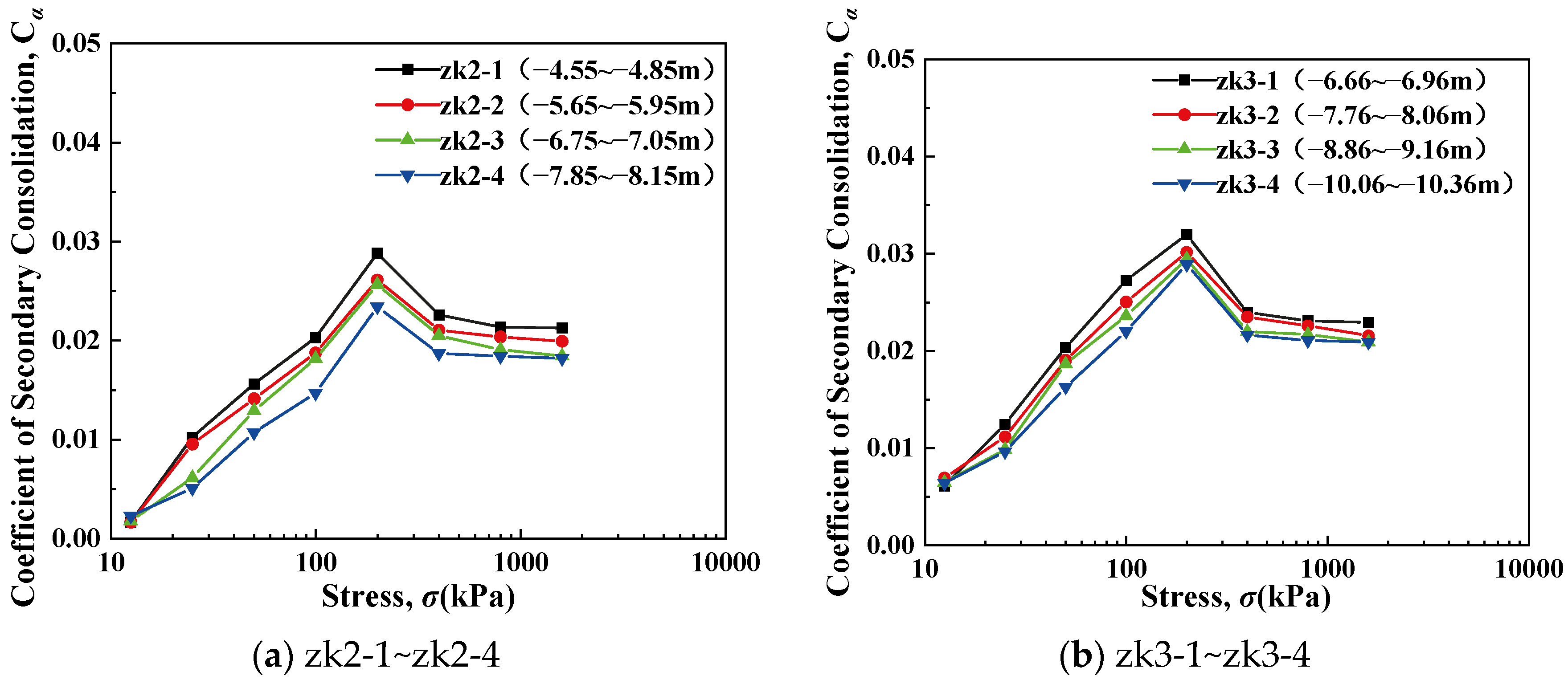

- Secondary consolidation coefficient

3.2. Effect of Time on Creep Characteristics

- 1.

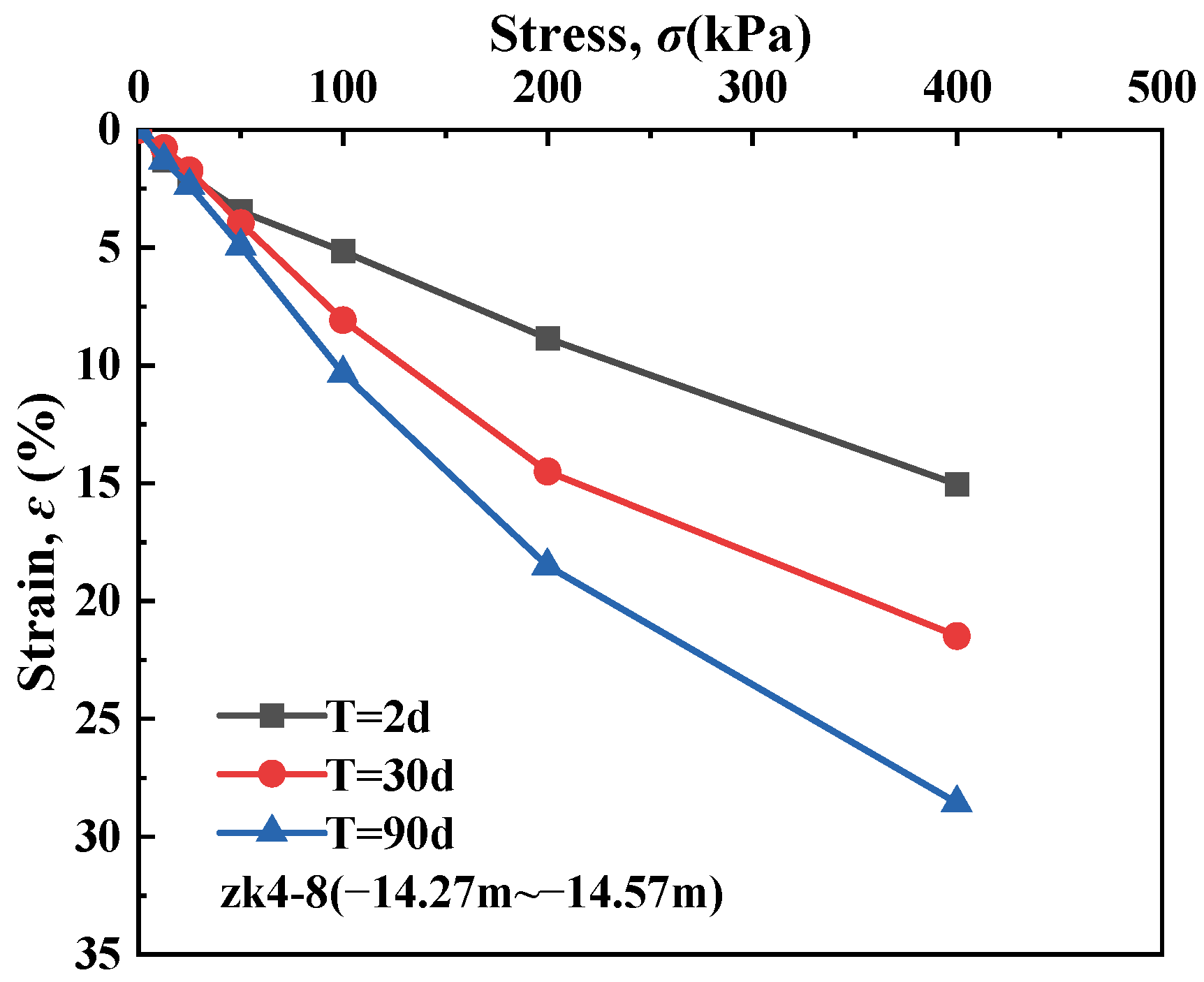

- Stress–strain relationship

- 2.

- Pore ratio–time relationship

- 3.

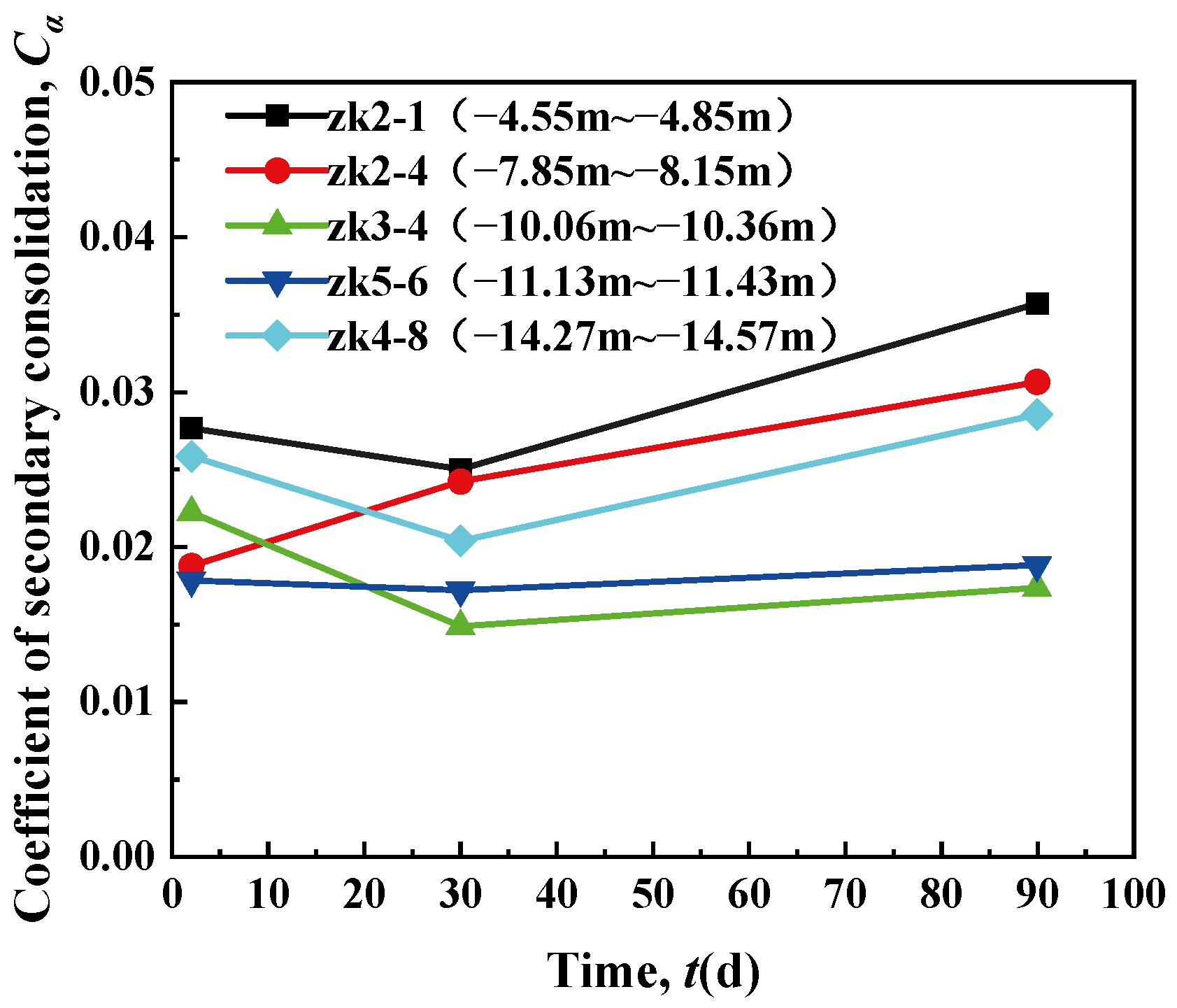

- Secondary consolidation coefficient

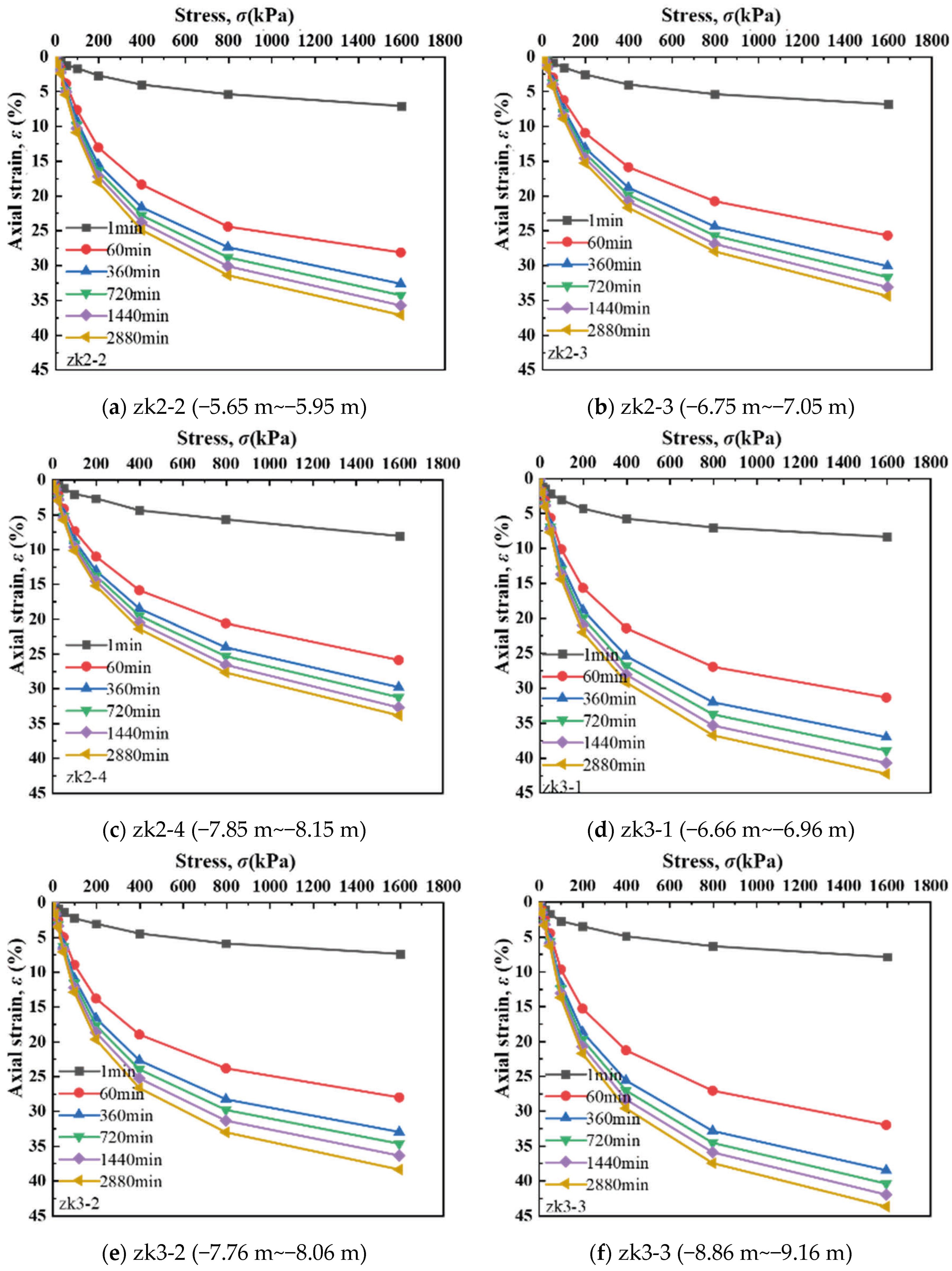

3.3. Stress–Strain Isochronous Relationship Curve

4. Three-Axis Creep Characteristics

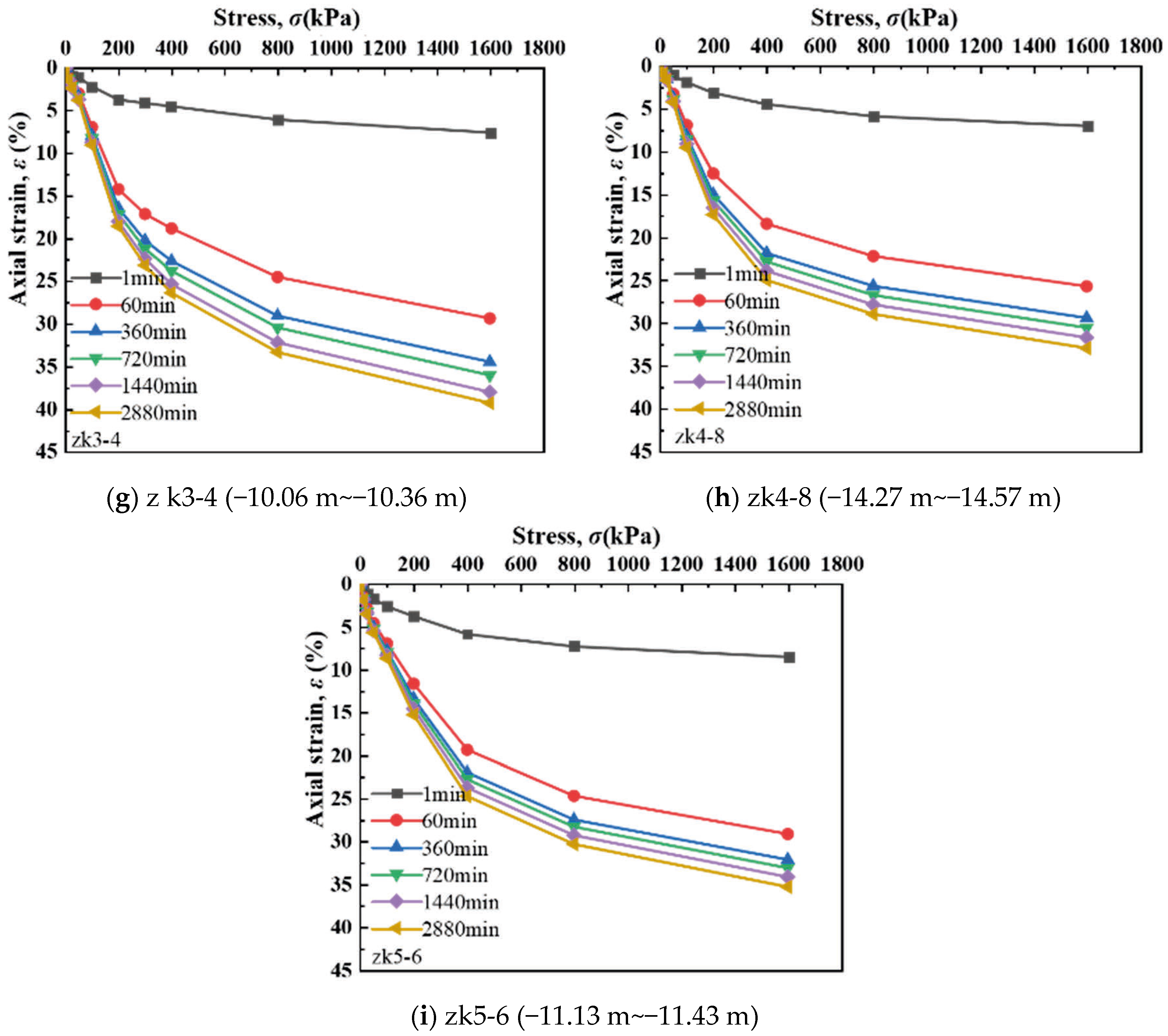

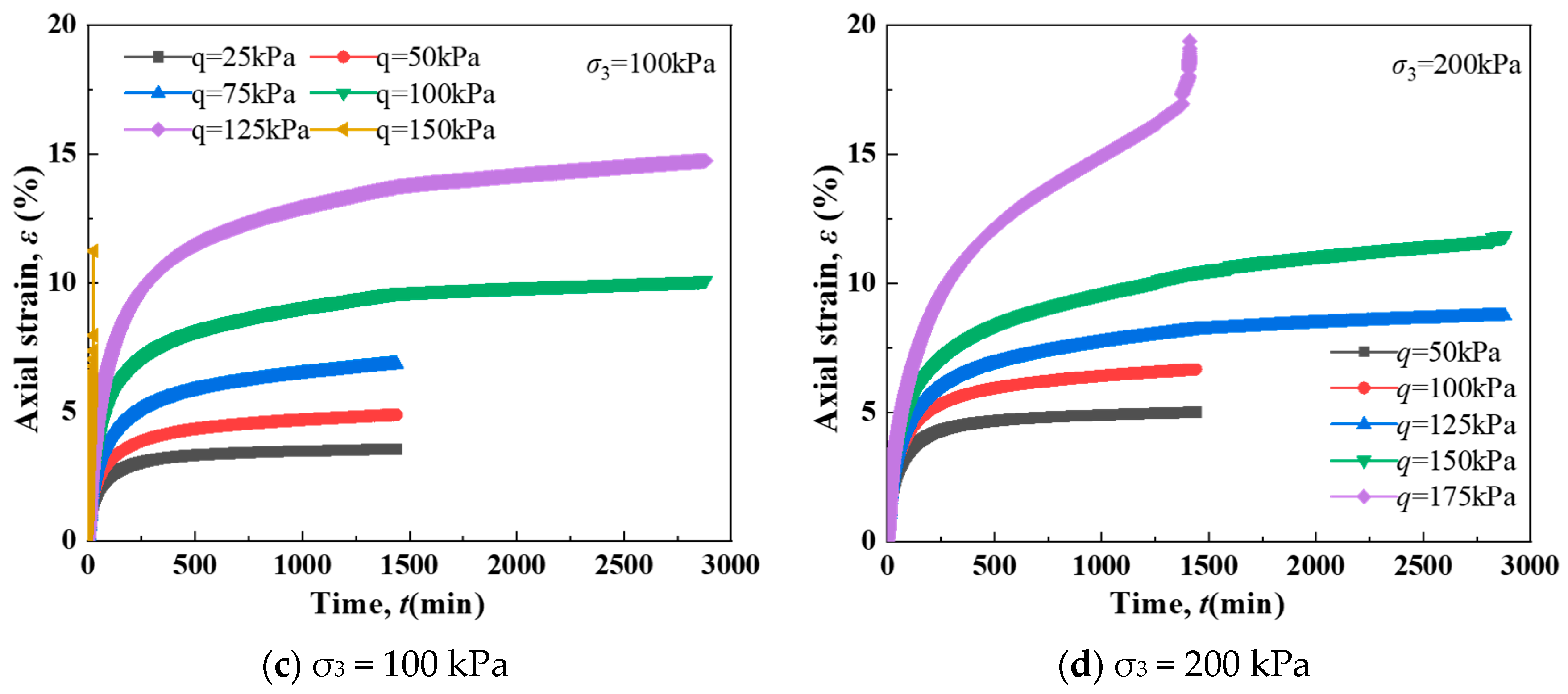

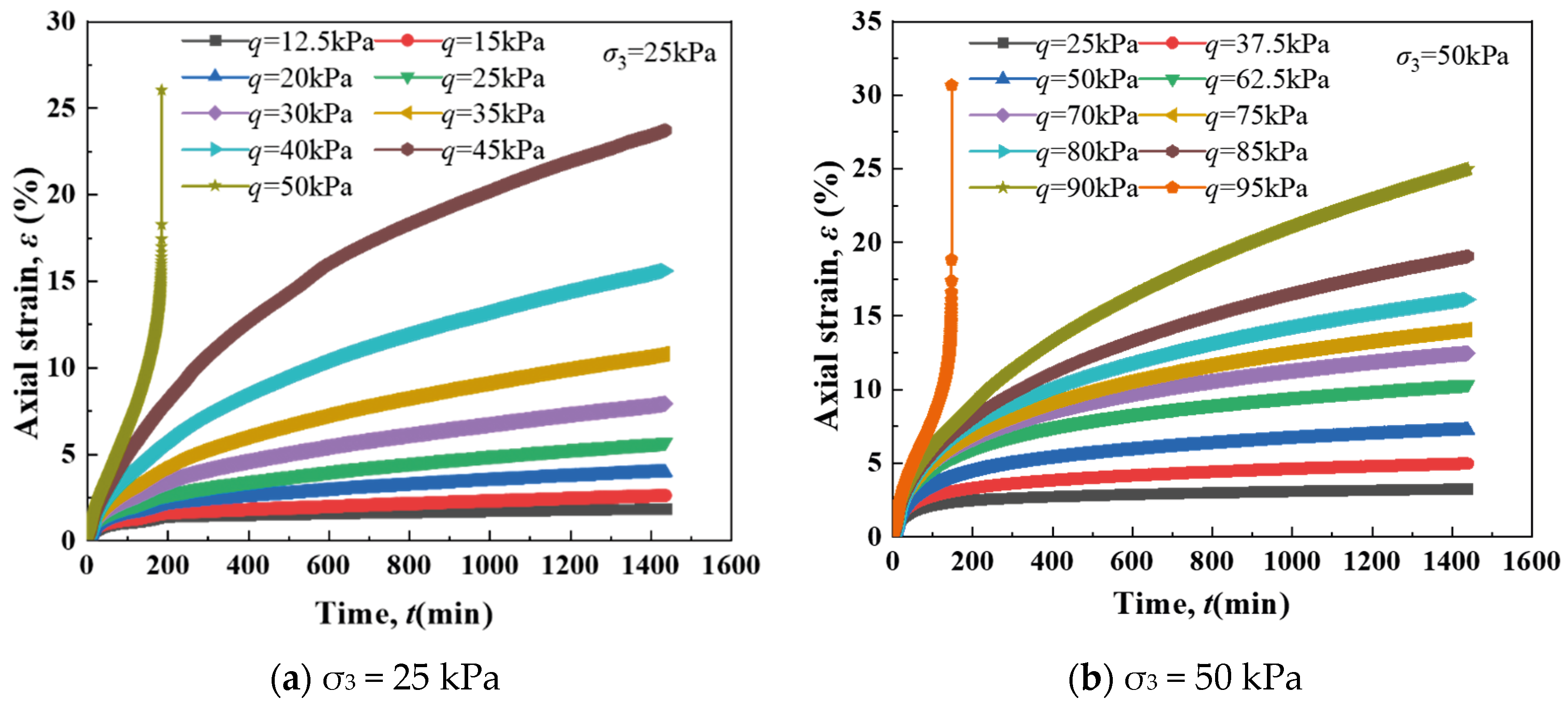

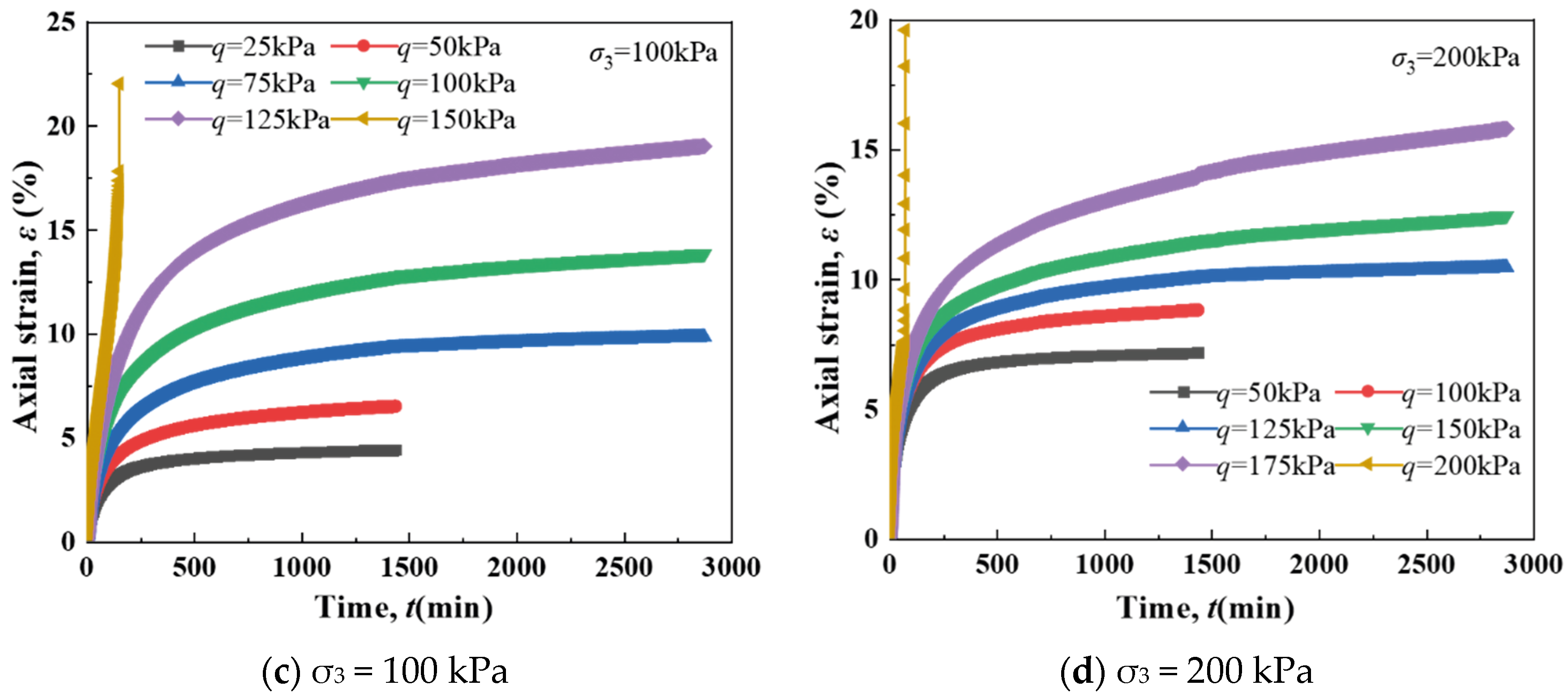

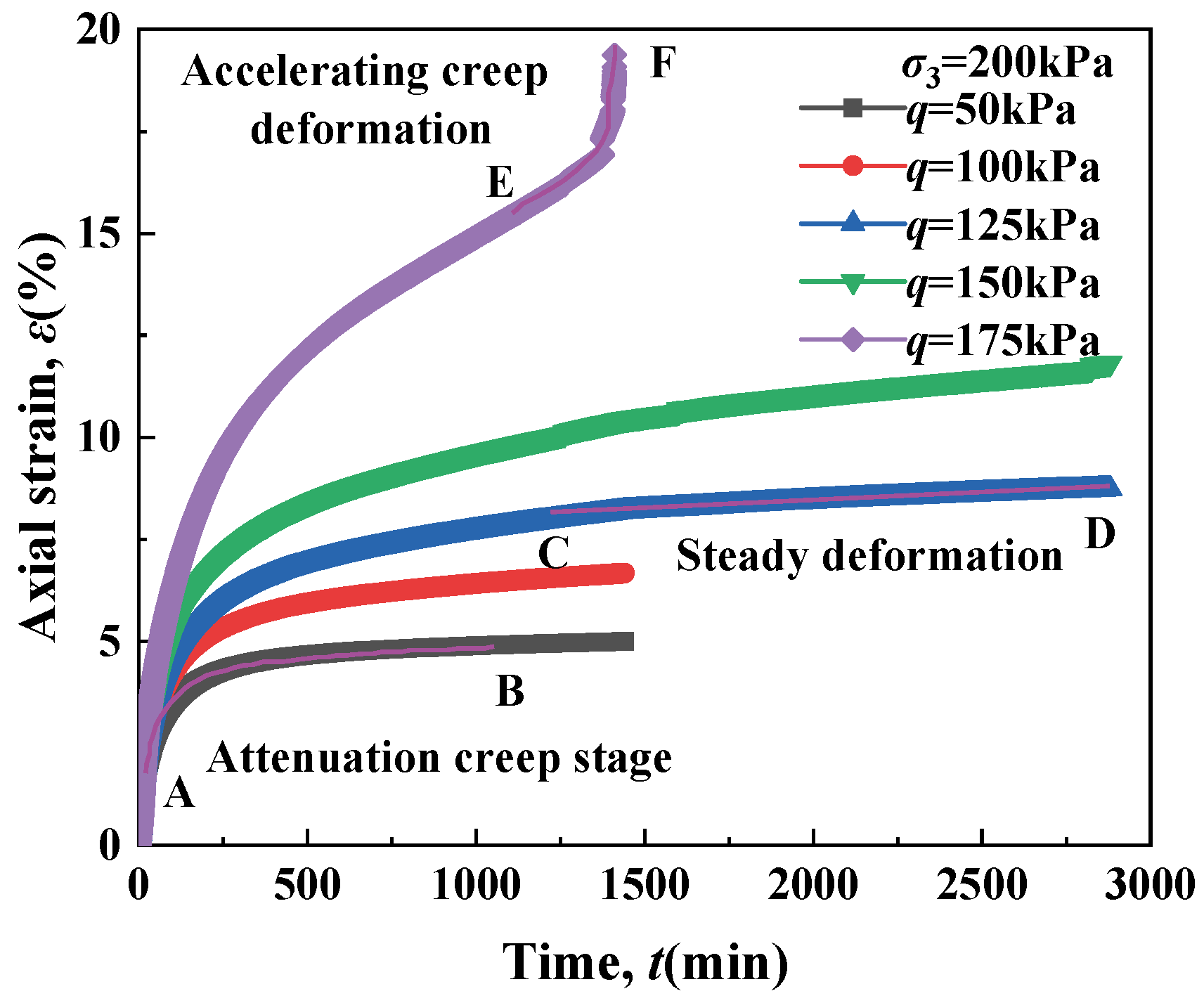

4.1. Axial Strain–Time Relationship

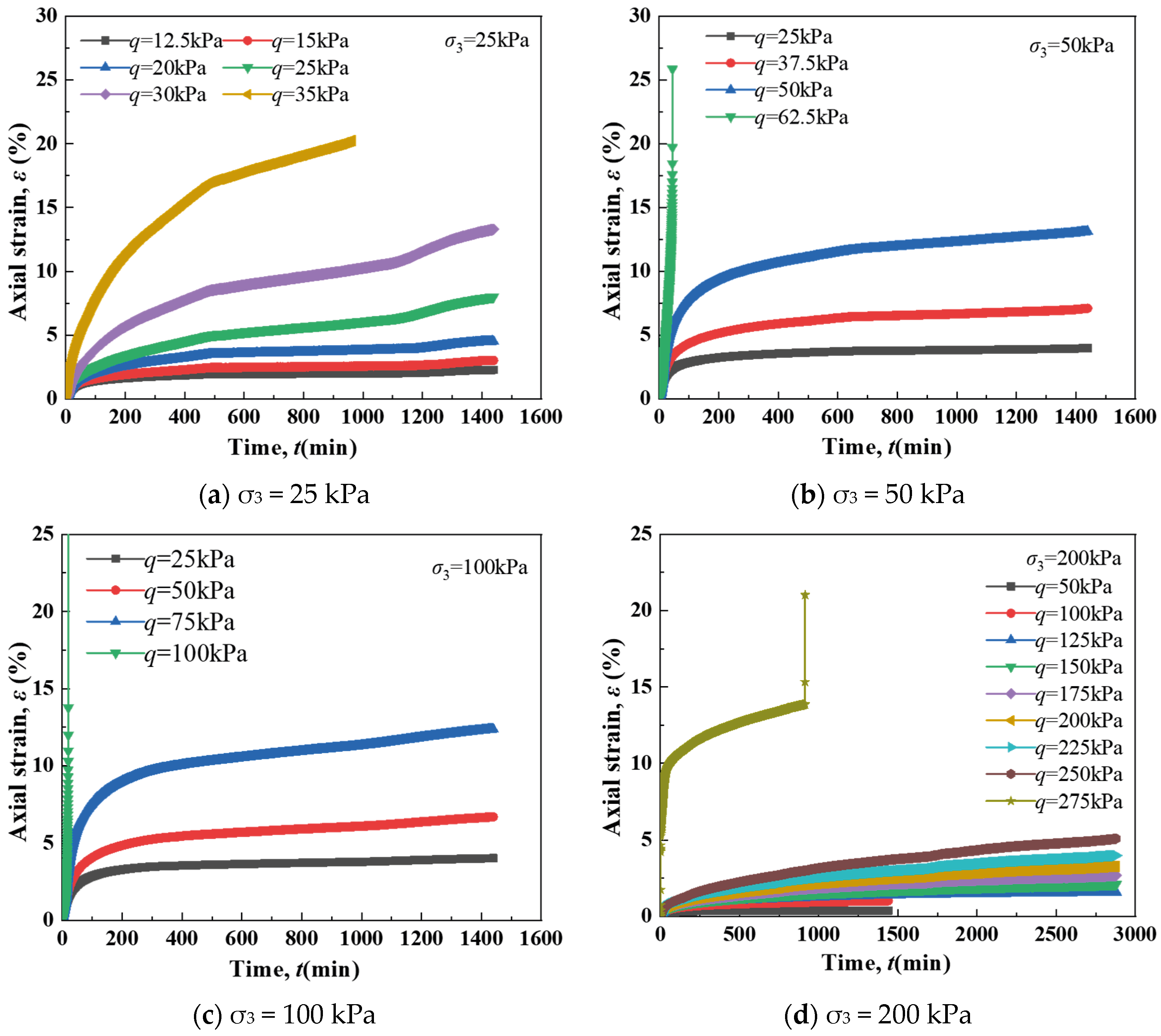

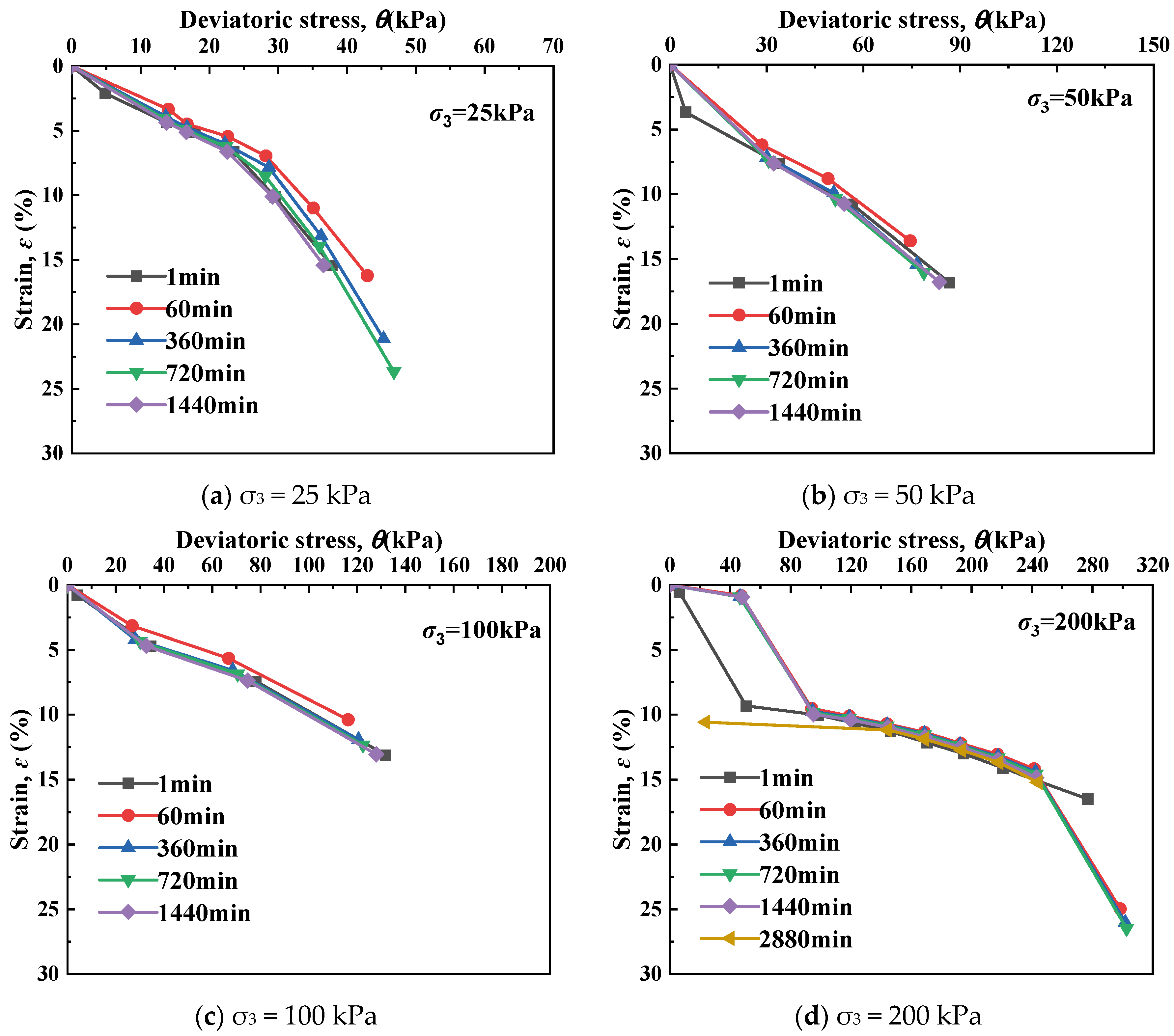

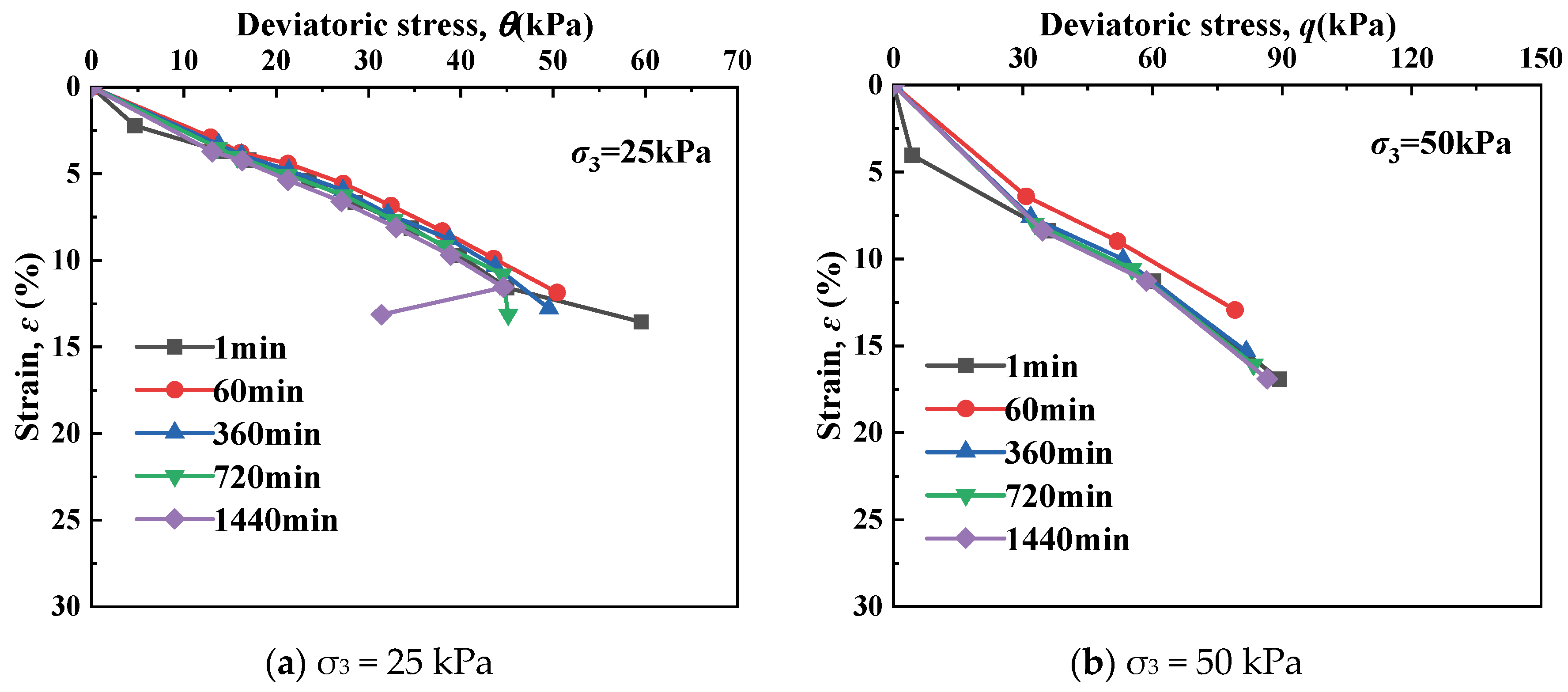

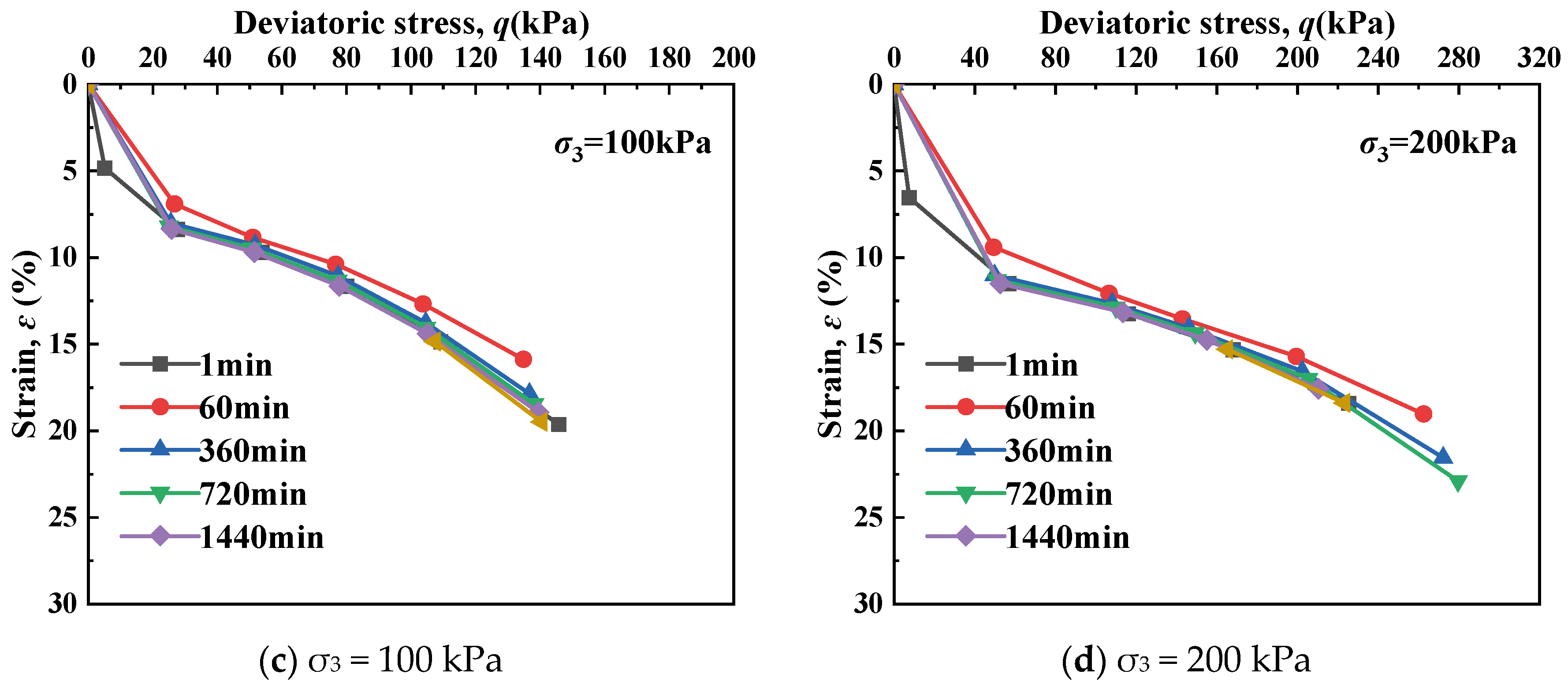

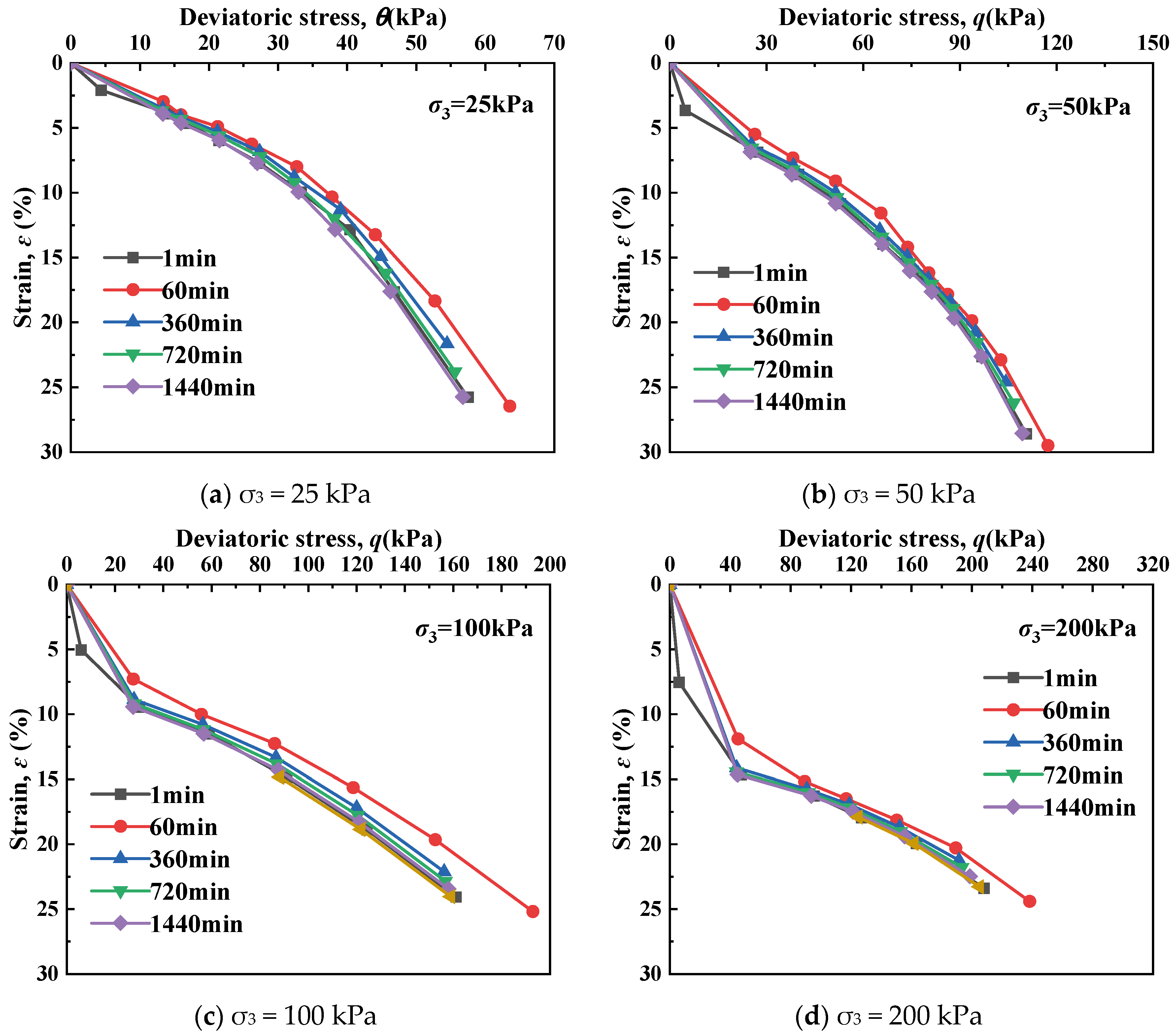

4.2. Stress–Strain Isochronous Relationship Curve

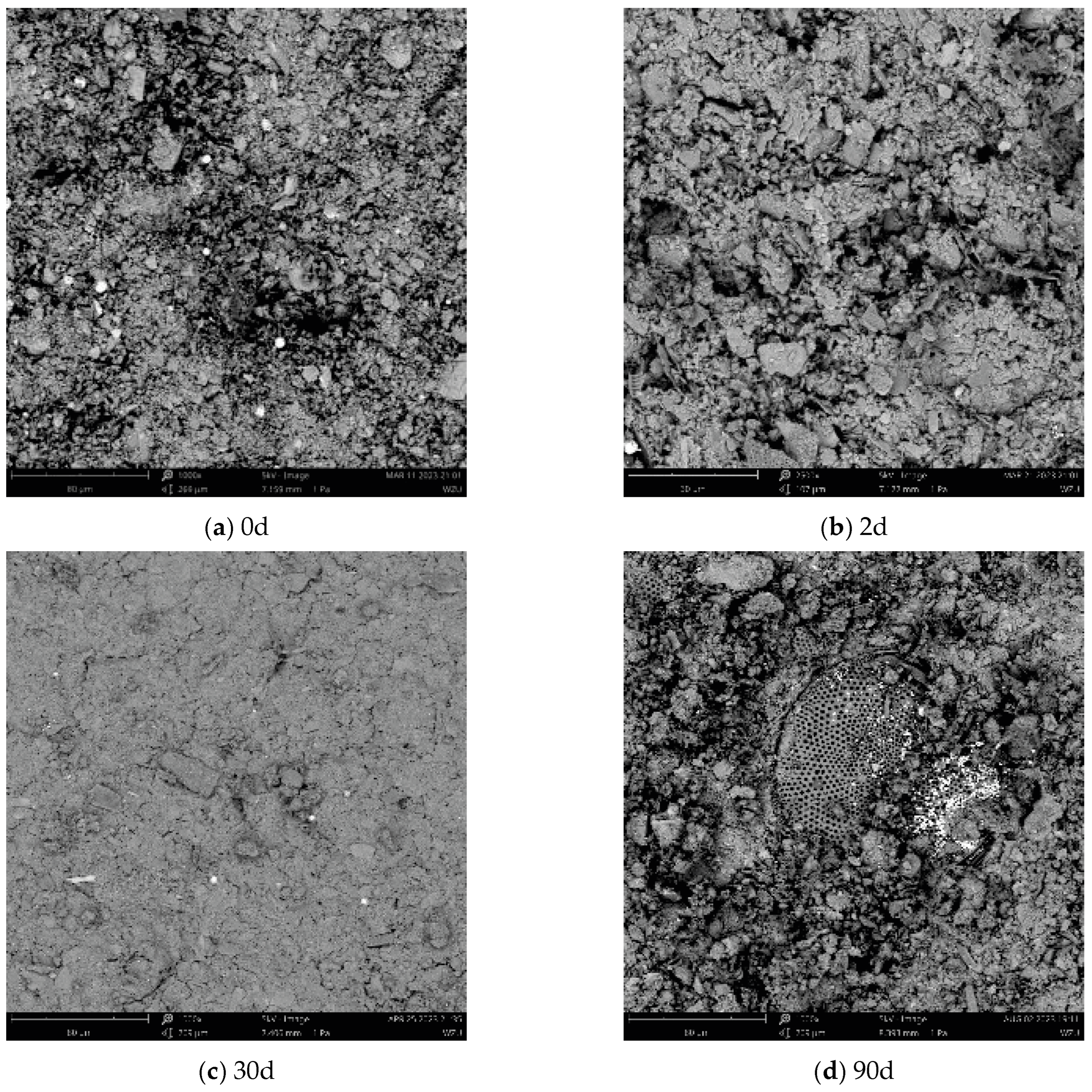

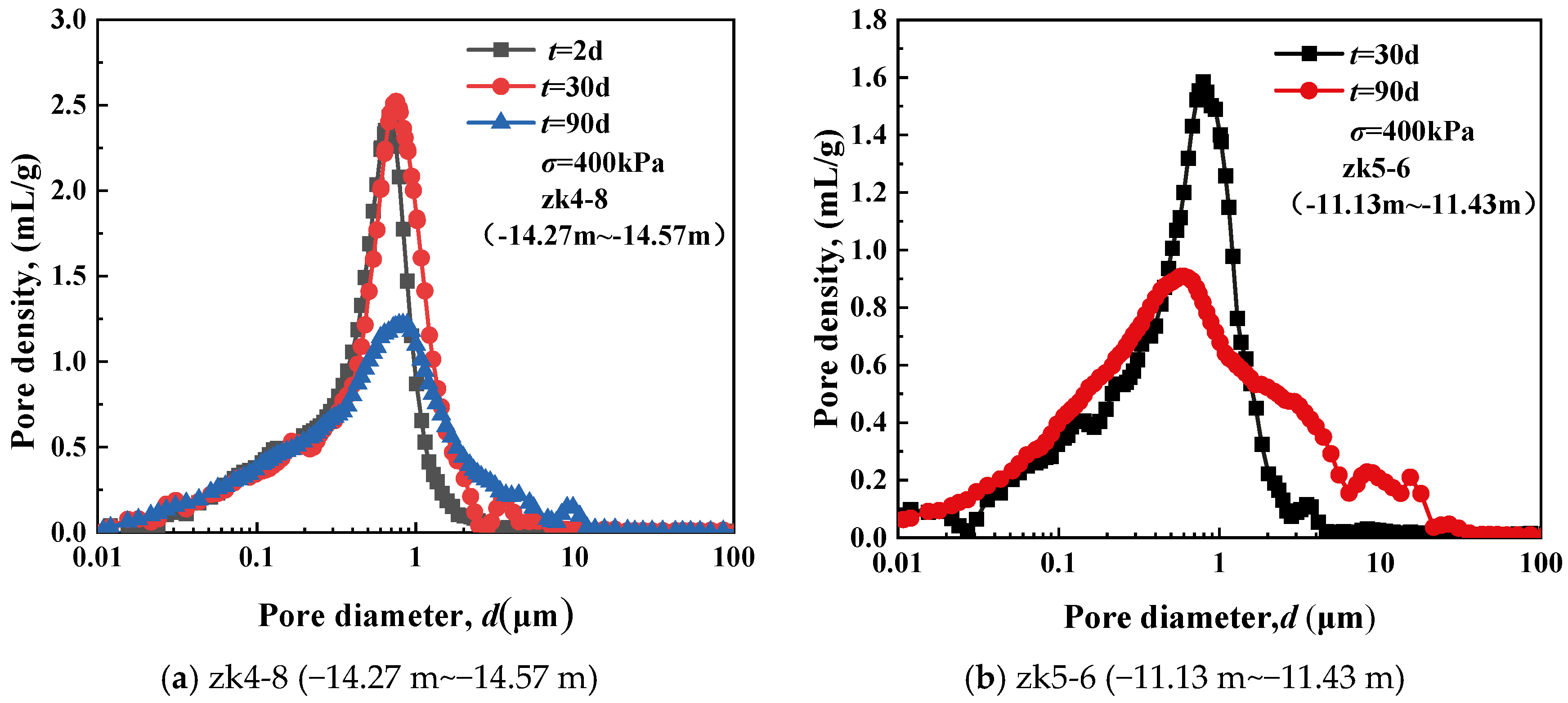

5. Creep Microstructural Evolution

5.1. Evolutionary Patterns with Loading

5.2. Evolutionary Patterns with Respect to Soil Depth

5.3. Evolutionary Patterns over Creep Time

6. Conclusions

Author Contributions

Data Availability Statement

Conflicts of Interest

References

- Ren, X.-W.; Xu, Q.; Teng, J.-D.; Zhao, N.; Lv, L. A Novel Model for the Cumulative Plastic Strain of Soft Marine Clay under Long-Term Low Cyclic Loads. Ocean Eng. 2018, 149, 194–204. [Google Scholar] [CrossRef]

- Qin, W.; Cai, S.-Y.; Dai, G.-L.; Wang, D.; Chang, K.-T. Soil Resistance during Driving of Offshore Large-Diameter Open-Ended Thin-Wall Pipe Piles Driven into Clay by Impact Hammers. Comput. Geotech. 2023, 153, 105085. [Google Scholar] [CrossRef]

- Zhang, T.; Li, T.; Feng, S. Elastoplastic Modelling for Long-Term Cyclic Stability of Soft Clays with Consideration of Structure Damage. Soil Dyn. Earthq. Eng. 2023, 166, 107727. [Google Scholar] [CrossRef]

- Chen, Z.-W.; Deng, H.-Y.; Dai, G.-L.; Zhu, M.-X.; Gong, W.-M.; Azadi, M.R. Study on the Influence of Unsymmetrical Surcharge on Adjacent Pile Foundations in a Coastal Soft Soil Area. Soil Dyn. Earthq. Eng. 2025, 194, 109365. [Google Scholar] [CrossRef]

- Zhou, Q.-J.; Chen, X.-P. Experimental Study on Creep Characteristics of Soft Soils. Chin. J. Geotech. Eng. 2006, 28, 626–630. [Google Scholar]

- Liang, R.-K.; Zhang, Q.-J.; Zhang, C.; Dong, L.I.; Dong, S.U.; Qiang, L.I. Creep Characteristics and Model Parameters of Qianhai Soft Soil. Chin. J. Geotech. Eng. 2021, 43, 133–136. [Google Scholar] [CrossRef]

- De-An, S.; Chen, B. Mechanical Behavior of Remolded Overconsolidated Shanghai Soft Clay and Its Elastoplastic Simulation. Rock Soil Mech. 2010, 31, 1739–1743. [Google Scholar]

- Shao, G.-H.; Liu, S.-Y. Research on Secondary Consolidation of Structural Marine Clays. Rock Soil Mech. 2013, 29, 2057–2062. [Google Scholar]

- Sun, M.-Q.; Wang, Q.; Niu, C.-C.; Sun, T. Consolidation and Creep Theory Based on Terzaghi Consolidation Theory and Empirical Creep Model. J. Northeast. Univ. (Nat. Sci.) 2016, 37, 1188. [Google Scholar] [CrossRef]

- Chen, X.-P.; Zhou, Q.-J.; Zhu, H.-H.; Zhang, B. Research on Creep and Consolidation Characteristics of Soft Soil. Rock Soil Mech. 2014, 28, 1–10. [Google Scholar]

- Chen, X.-P.; Zhu, H.-H.; Zhang, F.-Z.; Zhang, B. Experimental Study on Time-Dependent Deformation of Soft Soil. Chin. J. Rock Mech. Eng. 2005, 24, 2142–2148. [Google Scholar]

- Zhu, H.-H.; Chen, X.-P.; Cheng, X.-J.; Zhang, B. Study on Creep Characteristics and Model of Soft Soil Considering Drainage Condition. Rock Soil Mech. 2013, 27, 694–698. [Google Scholar]

- Yang, A.-W.; Zhang, Z.-J.; Kong, L.-W. Experimental Study of Creep Property of Soft Clay under Different Stress Conditions. Rock Soil Mech. 2014, 35, 53–60. [Google Scholar]

- Lapierre, C.; Leroueil, S.; Locat, J. Mercury Intrusion and Permeability of Louiseville Clay. Can. Geotech. J. 1990, 27, 761–773. [Google Scholar] [CrossRef]

- Gutierrez, N.H.M.; de Nóbrega, M.T.; Vilar, O.M. Influence of the Microstructure in the Collapse of a Residual Clayey Tropical Soil. Bull. Eng. Geol. Env. 2009, 68, 107–116. [Google Scholar] [CrossRef]

- Xie, X.; Qi, S.-W.; Zhao, F.-S.; Wang, D.-H. Creep Behavior and the Microstructural Evolution of Loess-like Soil from Xi’an Area, China. Eng. Geol. 2018, 236, 43–59. [Google Scholar] [CrossRef]

- Asadoullahtabar, S.R.; Asgari, A.; Mohammad Rezapour Tabari, M. Assessment, Identifying, and Presenting a Plan for the Stabilization of Loessic Soils Exposed to Scouring in the Path of Gas Pipelines, Case Study: Maraveh-Tappeh City. Eng. Geol. 2024, 342, 107747. [Google Scholar] [CrossRef]

- Burton, G.J.; Pineda, J.A.; Sheng, D.; Airey, D. Microstructural Changes of an Undisturbed, Reconstituted and Compacted High Plasticity Clay Subjected to Wetting and Drying. Eng. Geol. 2015, 193, 363–373. [Google Scholar] [CrossRef]

- Sun, H.; Chen, J.F.; Ge, X.R. Deformation Characteristics of Silty Clay Subjected to Triaxial Loading, by Computerised Tomography. Geotechnique 2004, 54, 307–314. [Google Scholar] [CrossRef]

- Sun, H.; Hou, M.-X.; Chen, C.; Ge, X.-R. Microstructure Investigation of Soft Clay Subjected to Triaxial Loading. Eng. Geol. 2020, 274, 105735. [Google Scholar] [CrossRef]

- Kuo, Y.S.; Lin, C.S.; Chai, J.F.; Chang, Y.W.; Tseng, Y.H. Case Study of the Ground Motion Analyses and Seabed Soil Liquefaction Potential of Changbin Offshore Wind Farm. J. Mar. Sci. Technol. 2019, 27, 448–462. [Google Scholar] [CrossRef]

- Adalier, K.; Elgamal, A.; Meneses, J.; Baez, J.I. Stone Columns as Liquefaction Countermeasure in Non-Plastic Silty Soils. Soil Dyn. Earthq. Eng. 2003, 23, 571–584. [Google Scholar] [CrossRef]

- Asgari, A.; Ahmadtabar Sorkhi, S.F. Wind Turbine Performance under Multi-Hazard Loads: Wave, Wind, and Earthquake Effects on Liquefiable Soil. Results Eng. 2025, 26, 104647. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Code for Soil Physical Property Tests. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- ASTM D2216-19; Standard Test Method for Laboratory Determination of Water (Moisture) Content of Soil by Mass. ASTM International: West Conshohocken, PA, USA, 2019.

- SL 237-054-1999; Test Method for One-Dimensional Creep of Soil. Ministry of Water Resources of the People’s Republic of China: Beijing, China, 1999.

- ASTM D7181-11; Standard Test Method for Consolidated Drained Triaxial Compression Test for Soils. ASTM International: West Conshohocken, PA, USA, 2011.

- GB/T 21650.1-2008; Test Method for Pore Size Distribution of Porous Materials—Mercury Intrusion Method. Standardization Administration of China: Beijing, China, 2008.

- ASTM D4404-18; Standard Test Method for Determination of Pore Volume and Pore Volume Distribution of Soil and Rock by Mercury Intrusion Porosimetry. ASTM International: West Conshohocken, PA, USA, 2018.

- NY/T 1121.13-2006; Method for Electron Microscopy Analysis of Soil. Ministry of Agriculture of the People’s Republic of China: Beijing, China, 2006.

- JY/T 0584-2020; General Rules for Analytical Methods of Scanning Electron Microscopy. Ministry of Education of the People’s Republic of China: Beijing, China, 2020.

| Specific Gravity (Gs) | Liquid Limit (WL) | Plastic Limit (WP) | Plasticity Index (IP) | Porosity Ratio (e) | Moisture Content (w) |

|---|---|---|---|---|---|

| 2.65 | 65.56% | 32.73% | 32.93 | 1.588 | 64.41% |

| Test Items | Physical Appearance | Proportion | Test Items | Physical Appearance | Proportion |

|---|---|---|---|---|---|

| Lithological analysis | Calcite | 4 ± 1% | Lithological analysis | Amphibolite | 0.5% |

| Dolomite | 21 ± 1% | Clinochlore | 5 ± 1% | ||

| Quartz | 22 ± 2% | Hematite | 4 ± 1% | ||

| Albite | 9 ± 2% | Anatase | 0.7% | ||

| Microcline | 4 ± 2% | Illite | 3 ± 1% | ||

| Kaolinite | 10 ± 2% | Amorphous-phase material | 15 ± 3% | ||

| Mica | 21 ± 1% | ||||

| Specific surface area | / | 31.3 m2/g |

| Drill Hole Number | Soil Sample Number | Sampling Depth | Mechanical Properties | |||

|---|---|---|---|---|---|---|

| Compression Coefficient | Compressive Modulus | Compression Index | Preliminary Consolidation Pressure | |||

| a | Es | Cc | Pc | |||

| MPa−1 | MPa | - | kPa | |||

| ZK2 | 1 | −4.55 m~−4.85 m | 1.93 | 1.394 | 0.641 | 53 |

| ZK2 | 2 | −5.65 m~−5.95 m | 1.85 | 1.403 | 0.615 | 49 |

| ZK2 | 3 | −6.75 m~−7.05 m | 1.61 | 1.574 | 0.535 | 61 |

| ZK2 | 4 | −7.85 m~−8.15 m | 1.33 | 1.975 | 0.442 | 72 |

| ZK3 | 1 | −6.66 m~−6.96 m | 2.14 | 1.314 | 0.711 | 40 |

| ZK3 | 2 | −7.76 m~−8.06 m | 1.87 | 1.467 | 0.621 | 47 |

| ZK3 | 3 | −8.86 m~−9.16 m | 2.32 | 1.245 | 0.771 | 45 |

| ZK3 | 4 | −10.06 m~−10.36 m | 2.83 | 1.054 | 0.940 | 70 |

| ZK4 | 8 | −14.27 m~−14.57 m | 2.07 | 1.278 | 0.688 | 60 |

| ZK5 | 6 | −13.53 m~−13.83 m | 1.78 | 1.524 | 0.592 | 90 |

| Soil | Drill Hole Number | σ (kPa) | T (d) |

|---|---|---|---|

| Undisturbed soft soil | zk2-1, zk2-2, zk2-3, zk2-4, zk3-1, zk3-2, zk3-3, zk3-4, zk4-8, zk5-6 | 1600 | 2 |

| 400 | 2, 30, 90 |

| Soil | Confining Pressure σ3 (kPa) | Axial Stress σ1 (kPa) | Axial Deviatoric Stress q (kPa) | Each Level of Time (d) |

|---|---|---|---|---|

| Undisturbed Soft Soil (zk3-1, zk3-2, zk3-3) | 25 | 37.5 | 12.5 | 1 |

| 40 | 15 | |||

| 45 | 20 | |||

| 50 | 25 | |||

| 55 | 30 | |||

| 60 | 35 | |||

| 50 | 75 | 25 | 1 | |

| 87.5 | 37.5 | |||

| 100 | 50 | |||

| 112.5 | 62.5 | |||

| 120 | 70 | |||

| 125 | 75 | |||

| 100 | 125 | 25 | 1 | |

| 150 | 50 | |||

| 175 | 75 | |||

| 200 | 100 | 2 | ||

| 225 | 125 | |||

| 250 | 150 | |||

| 200 | 250 | 50 | 1 | |

| 300 | 100 | |||

| 325 | 125 | 2 | ||

| 350 | 150 | |||

| 375 | 175 | |||

| 400 | 200 |

| Drill Hole Number Soil Sampling Depth | Water Content W (%) | Specific Gravity Gs | Density ρ (g/cm3) | Porosity Ratio e | Liquid Limit WL (%) | Plastic Limit Wp (%) |

|---|---|---|---|---|---|---|

| zk3-1 (−6.66 m~−6.96 m) | 68.21 | 2.648 | 1.583 | 1.813 | 57.70 | 25.03 |

| zk3-2 (−7.76 m~−8.06 m) | 65.05 | 2.631 | 1.583 | 1.744 | 57.70 | 29.64 |

| zk3-3 (−8.86 m~−9.16 m) | 70.87 | 1.889 | 1.561 | 1.889 | 59.23 | 33.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Shi, Y.; Qiu, J.; Qin, W.; Zhou, Z.; Peng, G.; Lou, K.; Liu, Y. Experimental Study on Creep Characteristics and Mechanisms of Wenzhou Soft Soil. J. Mar. Sci. Eng. 2025, 13, 1943. https://doi.org/10.3390/jmse13101943

Chen Y, Shi Y, Qiu J, Qin W, Zhou Z, Peng G, Lou K, Liu Y. Experimental Study on Creep Characteristics and Mechanisms of Wenzhou Soft Soil. Journal of Marine Science and Engineering. 2025; 13(10):1943. https://doi.org/10.3390/jmse13101943

Chicago/Turabian StyleChen, Yongwei, Yi Shi, Junju Qiu, Wei Qin, Zhijin Zhou, Guoxiang Peng, Kun Lou, and Yuanyuan Liu. 2025. "Experimental Study on Creep Characteristics and Mechanisms of Wenzhou Soft Soil" Journal of Marine Science and Engineering 13, no. 10: 1943. https://doi.org/10.3390/jmse13101943

APA StyleChen, Y., Shi, Y., Qiu, J., Qin, W., Zhou, Z., Peng, G., Lou, K., & Liu, Y. (2025). Experimental Study on Creep Characteristics and Mechanisms of Wenzhou Soft Soil. Journal of Marine Science and Engineering, 13(10), 1943. https://doi.org/10.3390/jmse13101943