Research on the Scheme and System Parameter Matching of a Wastewater-Driven Diaphragm Pump Group for Slurry Transport in Deep-Sea Mining

Abstract

1. Introduction

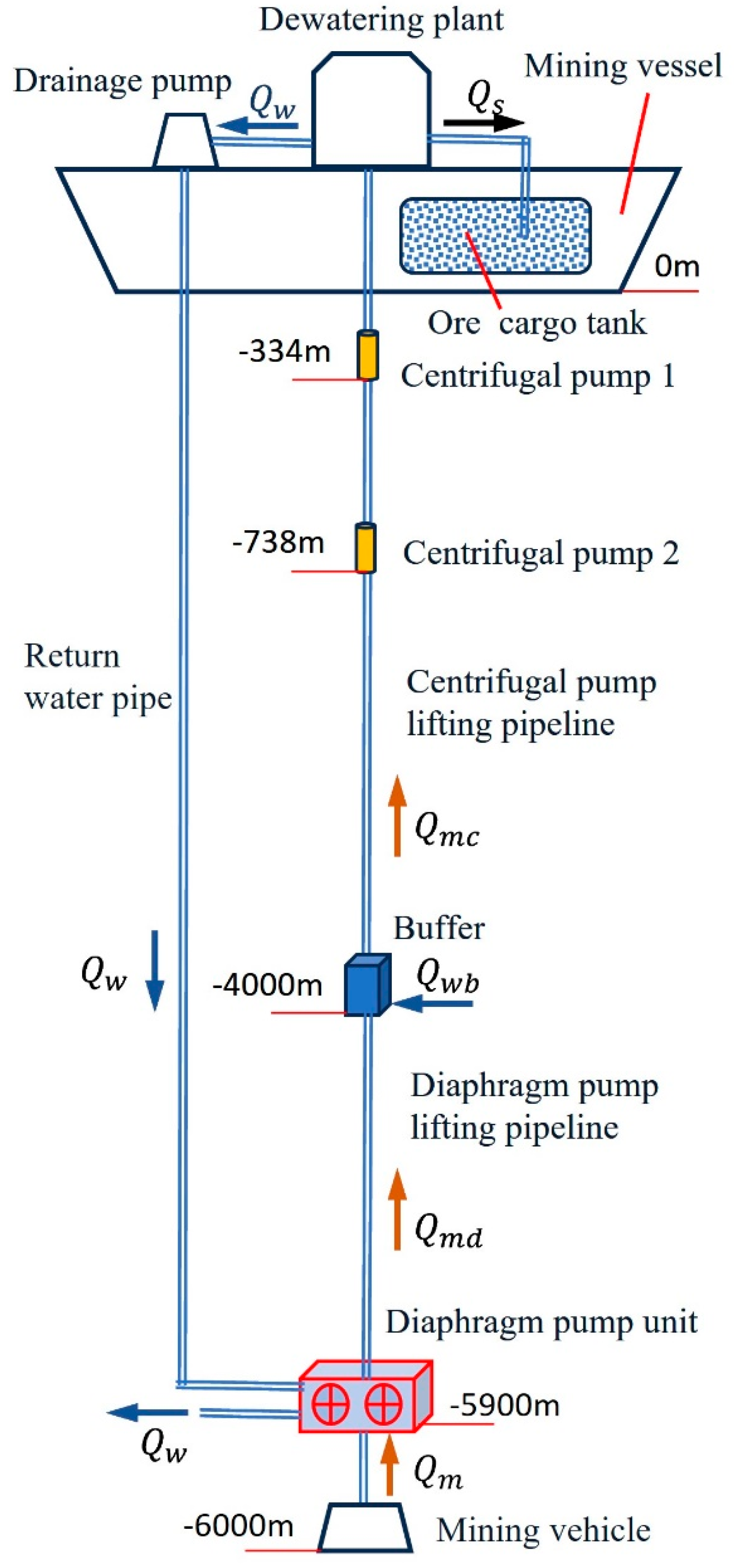

2. Technical Scheme and Parameter Requirements of the Wastewater-Driven Slurry Transport System for Polymetallic Nodule Mining

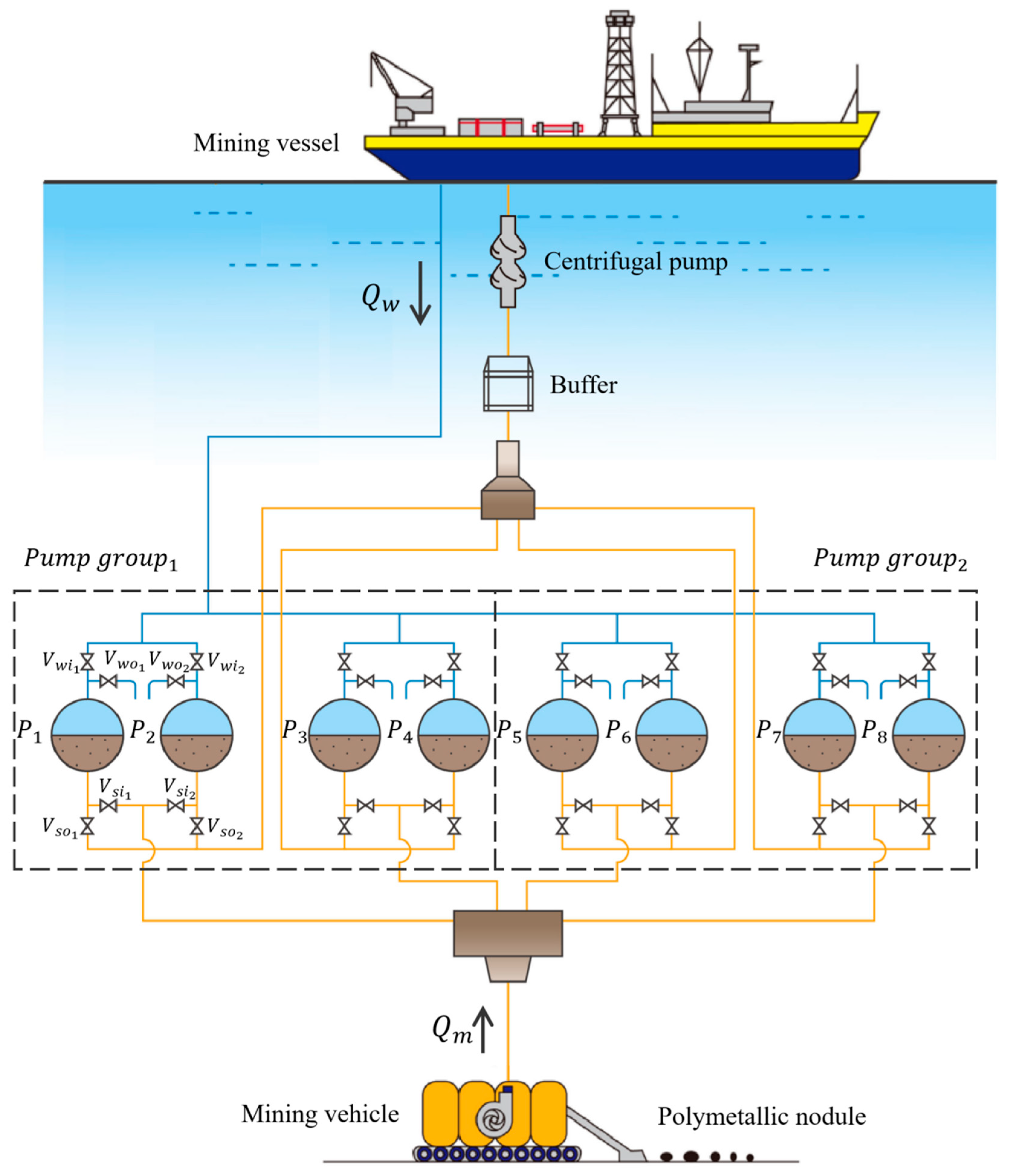

2.1. Technical Scheme of the Coupled Wastewater Discharge and Slurry Transport System Under Commercial Mining Conditions

2.2. Basic Parameter Requirements for the Coupled Wastewater Discharge and Slurry Transport System

3. Technical Scheme and Output Characteristics of the Diaphragm Pump Group for Wastewater-Driven Slurry Transport

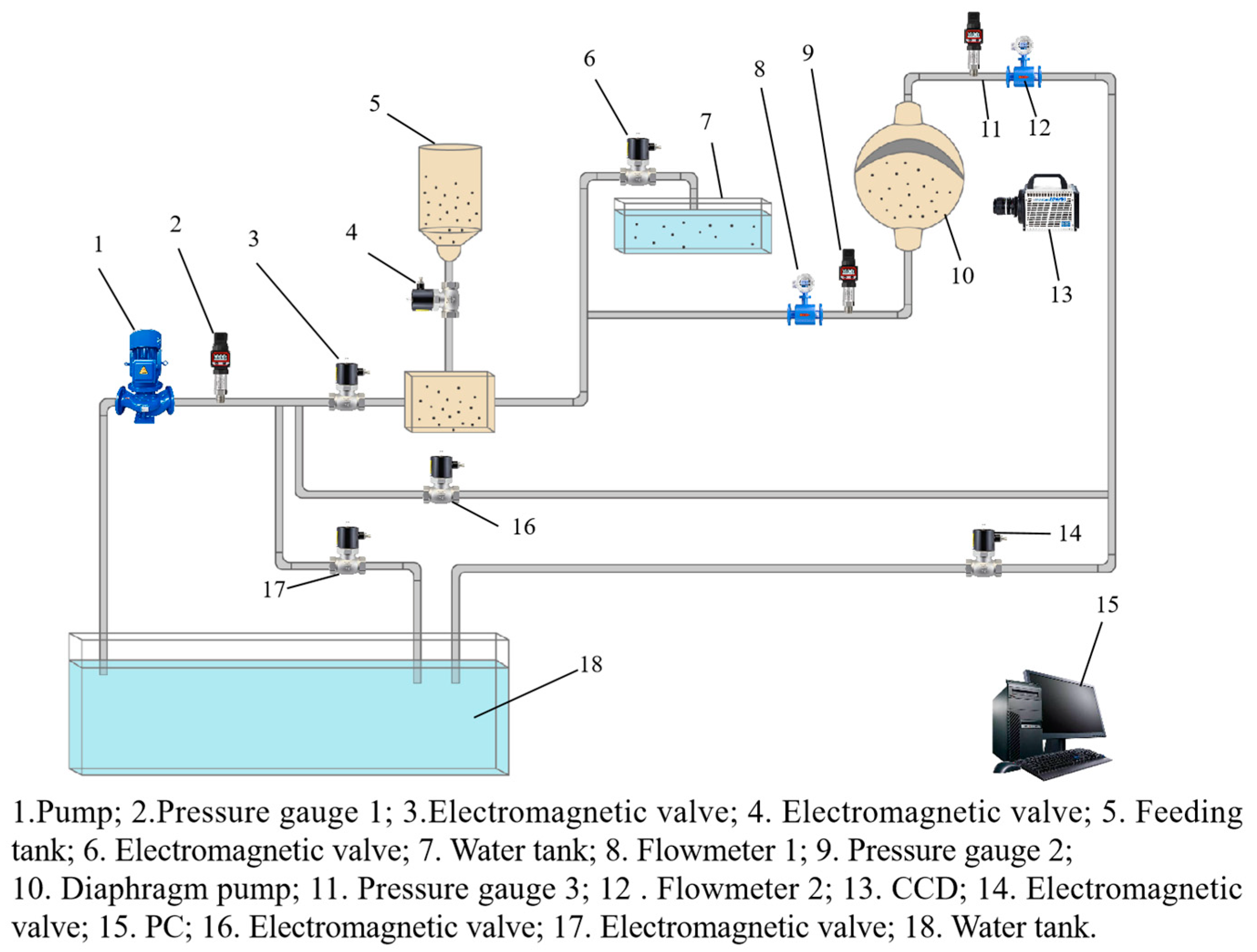

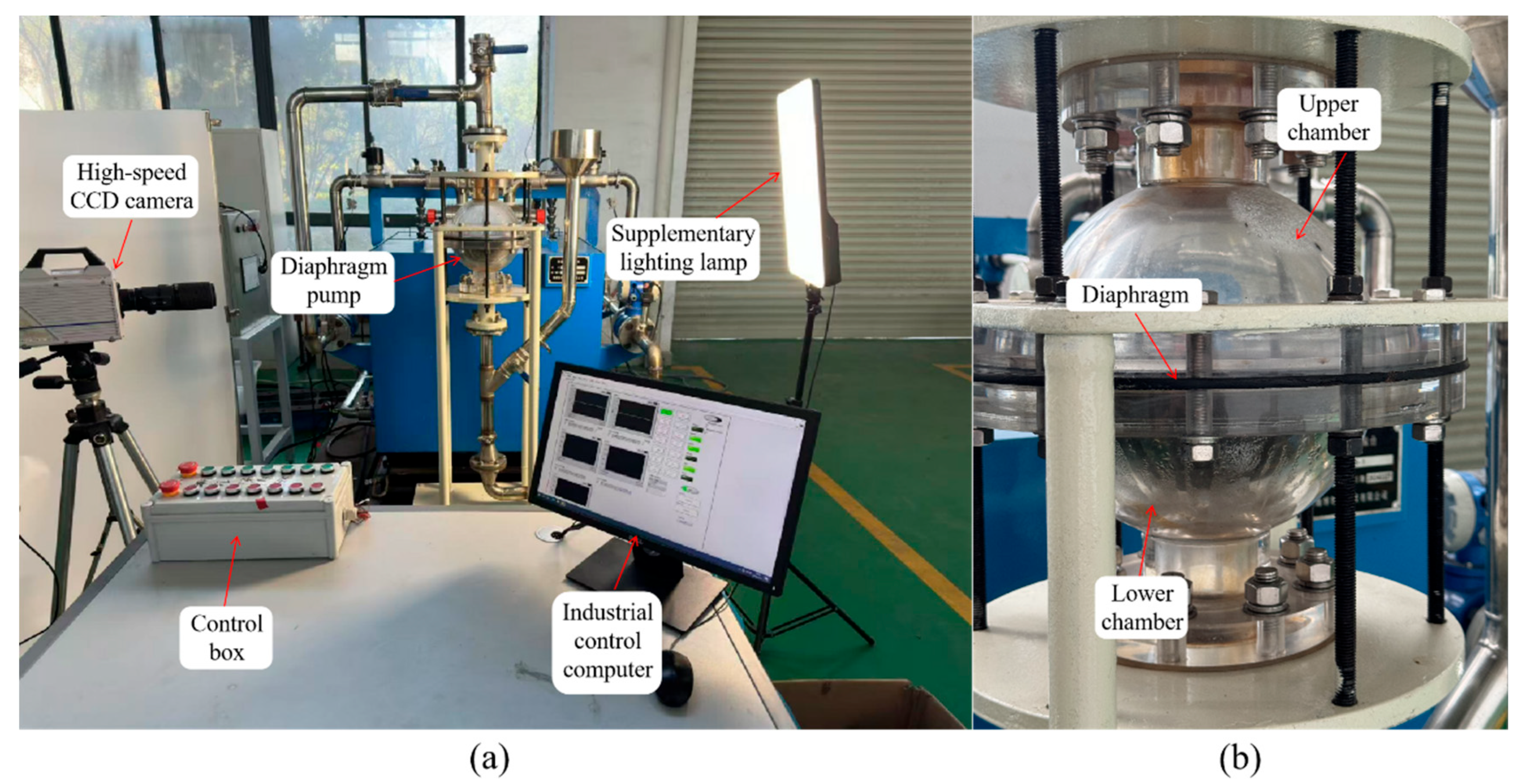

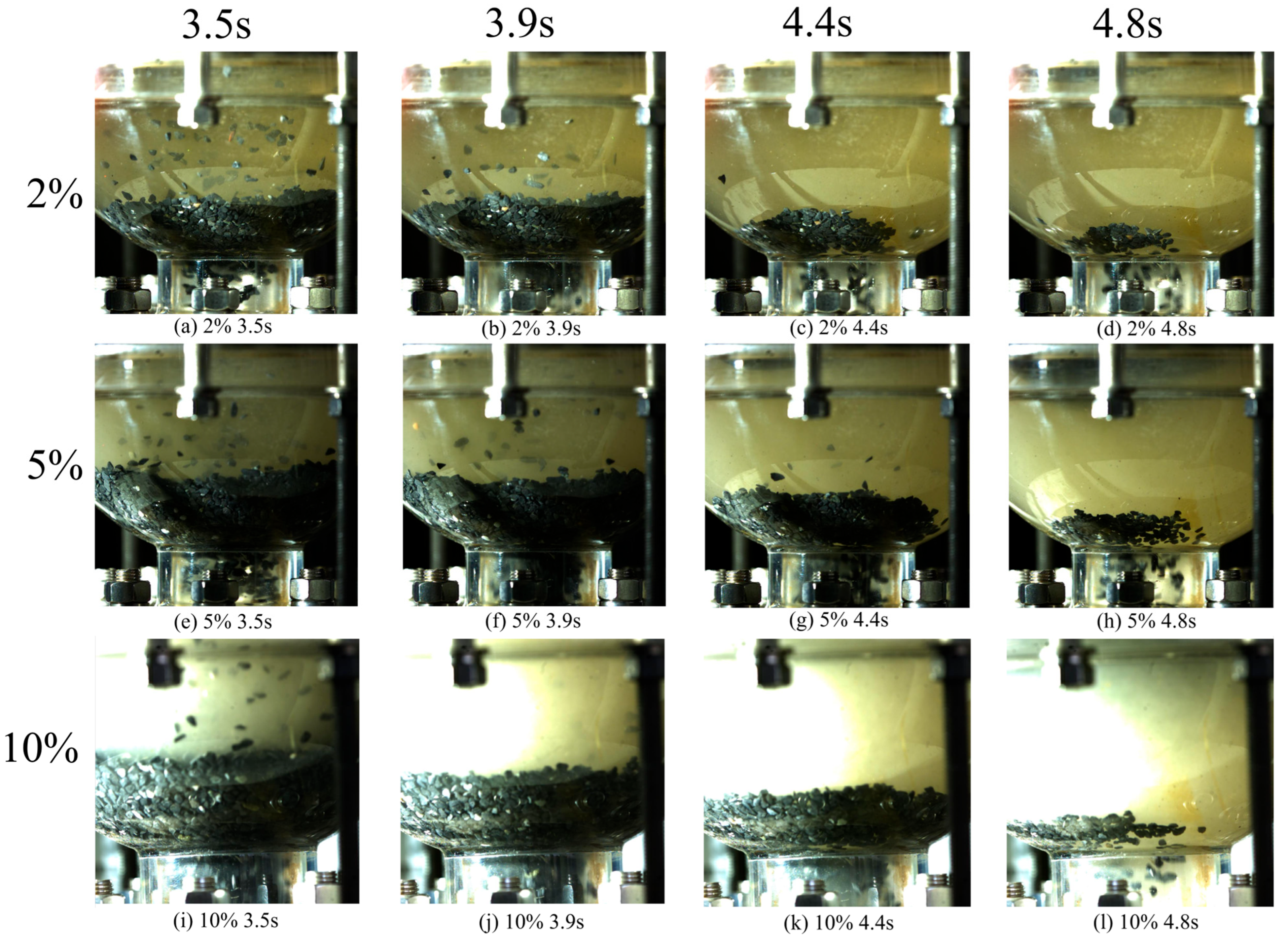

3.1. Experimental Study on the Output Characteristics of Coarse-Particle Solid–Liquid Two-Phase Flow in a Dual-Sided Fluid-Driven Diaphragm Pump

3.2. CFD–DEM Analysis of Polymetallic Nodule Slurry Transport Characteristics in a Wastewater-Driven Diaphragm Pump

- (1)

- CFD–DEM Methodology for Analyzing the Transport Performance of Water-Driven Diaphragm Pumps

- (2)

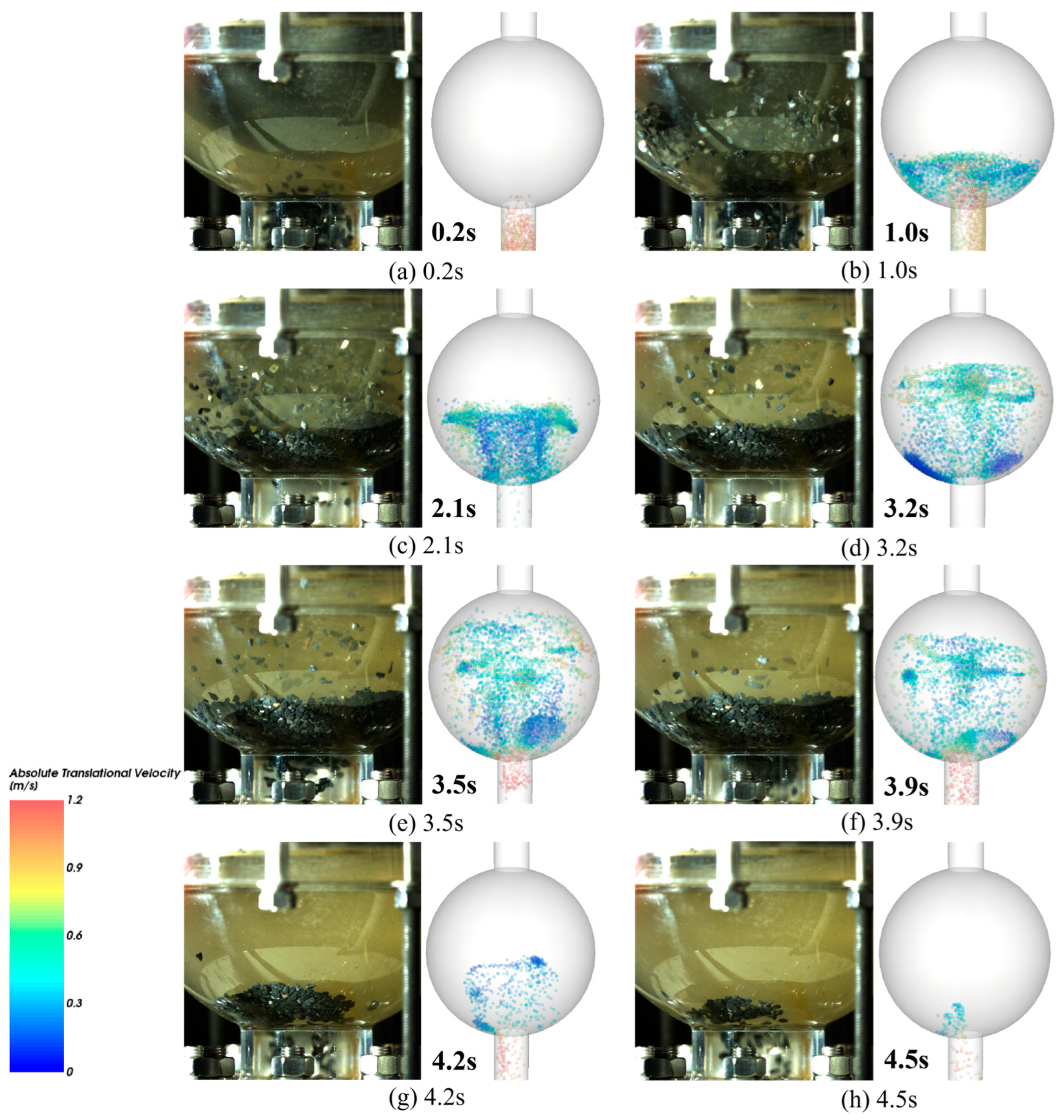

- CFD–DEM Simulation and Experimental Comparison of Solid–Liquid Two-Phase Transport in the Test Pump

- (3)

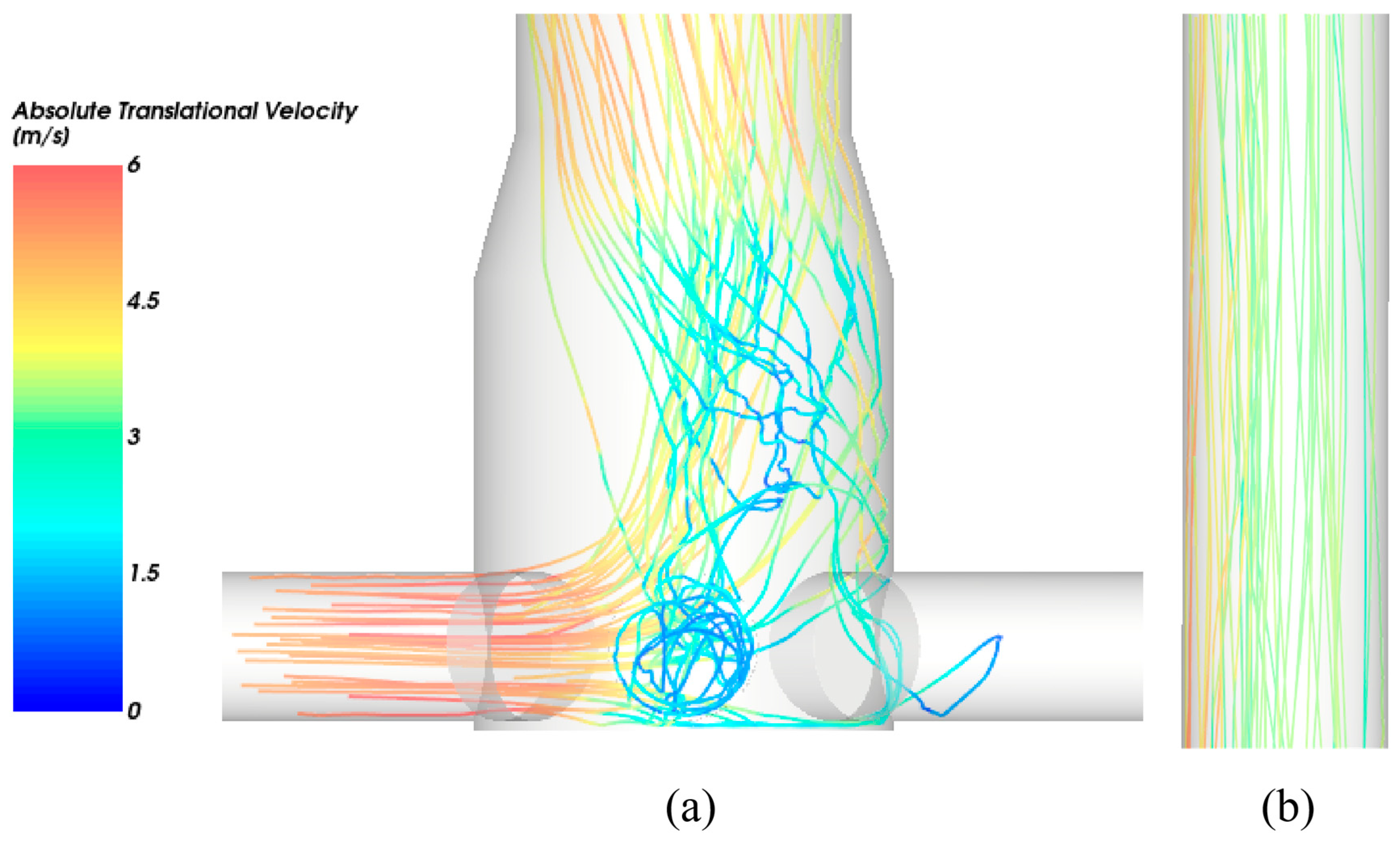

- CFD–DEM Simulation of Slurry Transport by Seabed Diaphragm Pumps under Commercial Mining Conditions

3.3. Design of a Diaphragm Pump Group Configuration for Slurry Transport in a Commercial Wastewater-Driven Mining System

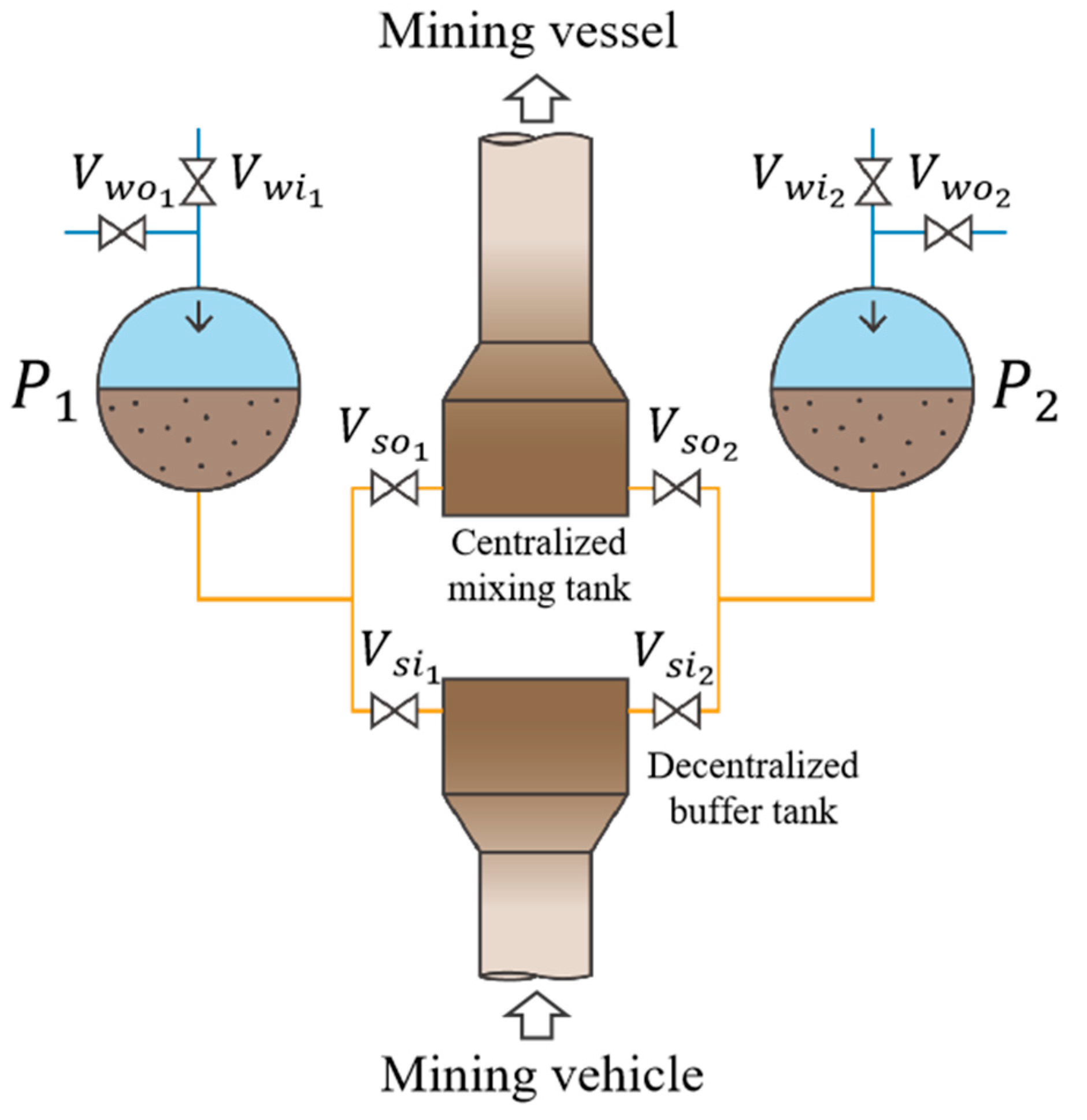

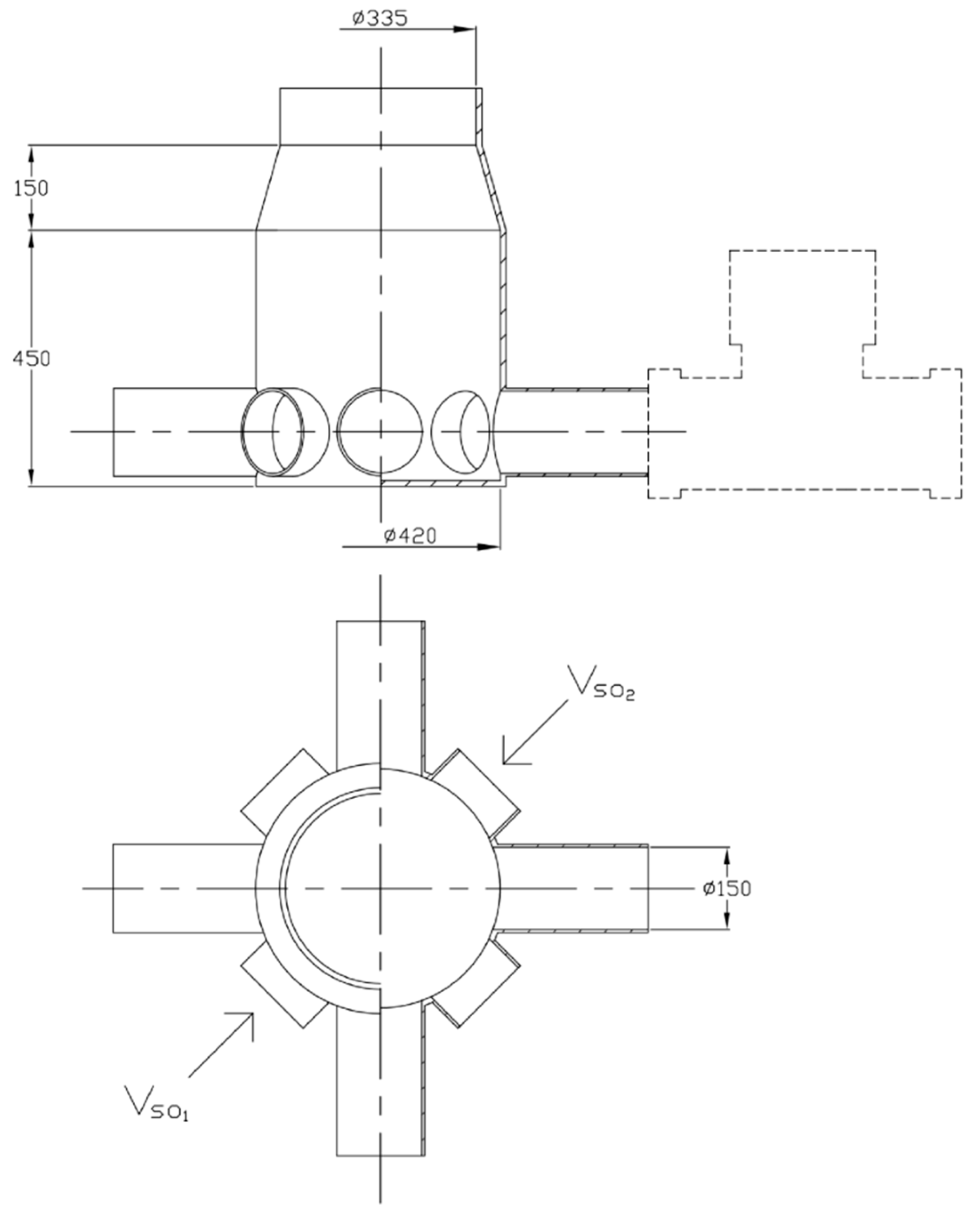

3.4. Structural Design of the Centralized Slurry Output Device for the Diaphragm Pump Group

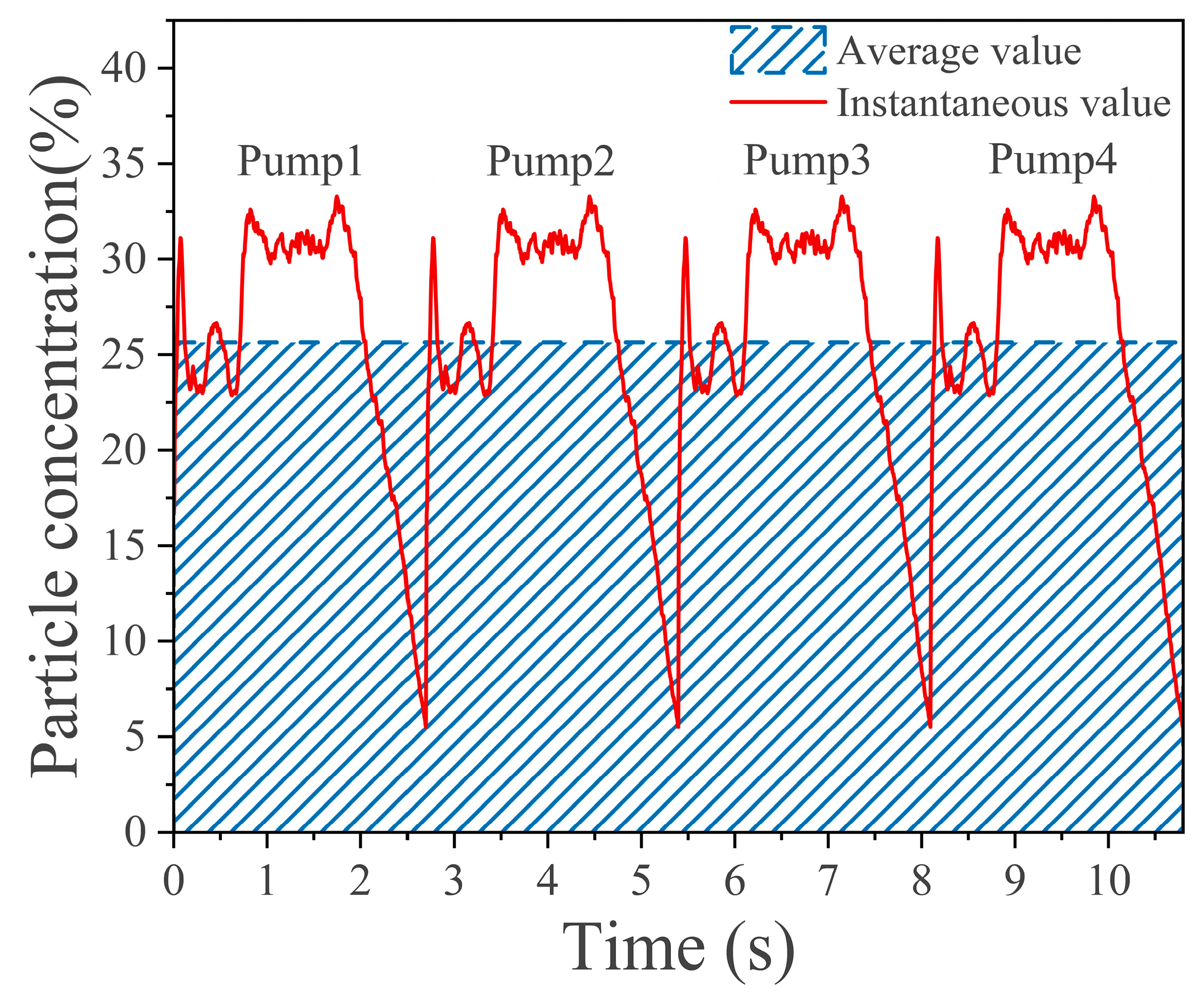

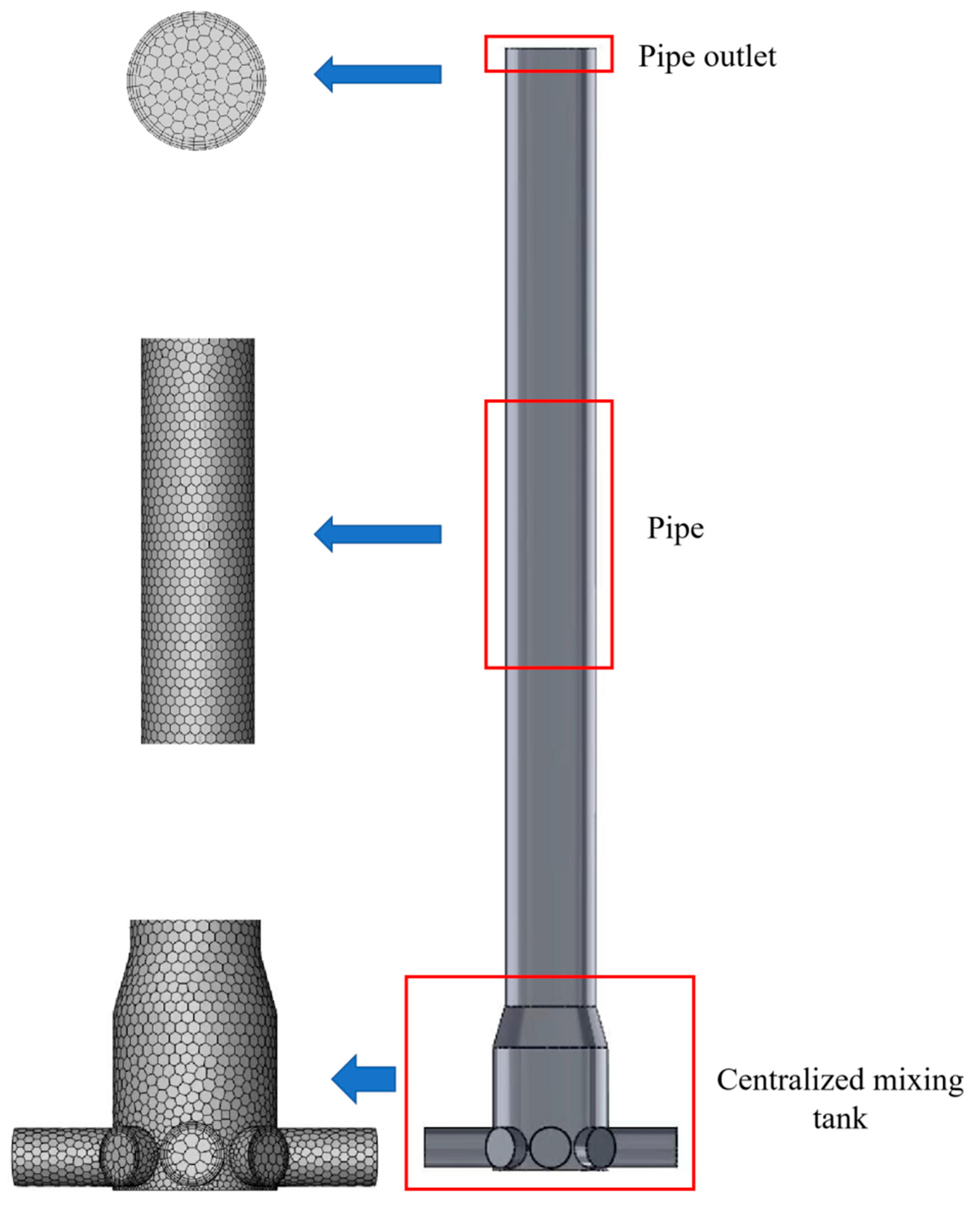

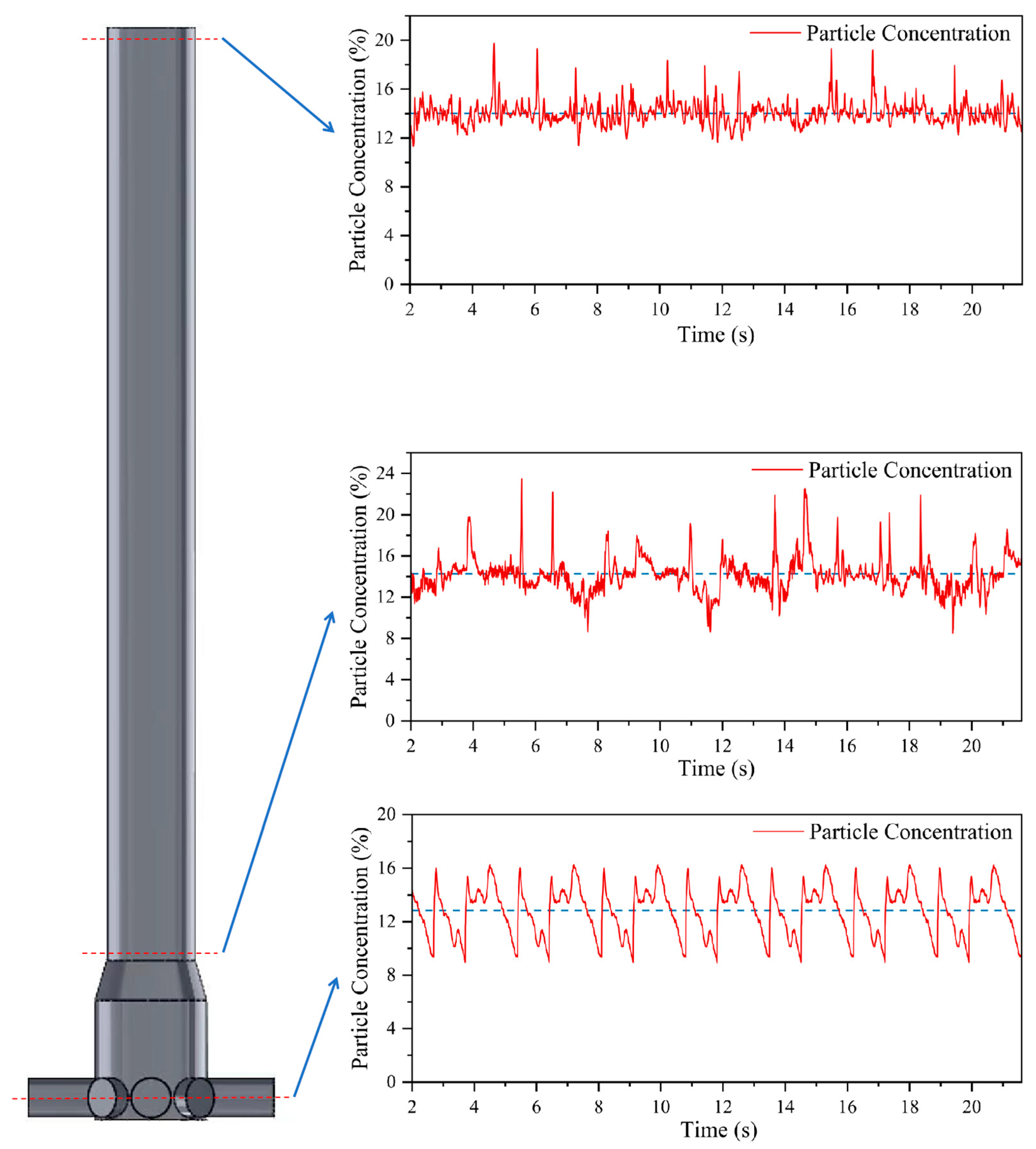

3.5. Analysis of Slurry Output Concentration for the Diaphragm Pump Group, Centralised Tank, and Adjacent Riser Pipeline Section

4. Coupled Slurry Transport and Wastewater Discharge System: Coordination of Transport Parameters and Efficiency Analysis

4.1. Analysis of Hydraulic Parameter Coordination in the Coupled Slurry Transport and Wastewater Discharge System

4.2. Selection of Slurry Concentrations for Diaphragm and Centrifugal Pump Groups with Consideration of Overall System Efficiency Optimization

4.3. Analysis of System Efficiency Improvement Enabled by Higher Slurry Concentration in the Diaphragm Pump Group

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kang, Y.J.; Liu, S.J. The development history and latest progress of deep-sea polymetallic nodule mining technology. Minerals 2021, 11, 1132. [Google Scholar] [CrossRef]

- Amos, A.F.; Roels, O.A. Environmental aspects of manganese nodule mining. Mar. Pol. 1977, 1, 156–163. [Google Scholar] [CrossRef]

- Muñoz-Royo, C.; Peacock, T.; Alford, M.H.; Smith, J.A.; Le Boyer, A.; Kulkarni, C.S.; Lermusiaux, P.F.J.; Haley, P.J., Jr.; Mirabito, C.; Wang, D.; et al. Extent of impact of deep-sea nodule mining midwater plumes is influenced by sediment loading, turbulence and thresholds. Commun. Earth Environ. 2021, 2, 148. [Google Scholar] [CrossRef]

- Alex, R.; Chen, X.D.; Tang, X.X.; Wang, Z.N.; Llc, O.T.; Li, J.; Liu, T.J.; Wang, R.J. A riser and lifting system (RALS) concept for deep sea polymetallic Nodule Mining. In Proceedings of the 50th Underwater Minerals Conference, St. Petersburg, FL, USA, 2–7 October 2022. [Google Scholar]

- Babu, R. Design of Hydraulic Transportation System Using Positive Displacement Pump for Deep Sea Mining. J. Therm. Fluid Sci. 2022, 3, 14–27. [Google Scholar] [CrossRef]

- Kang, Y.J.; Wang, K.L.; Hu, Q.; Liu, S.J. Research on a coupled system design for mineral lifting and wastewater drainage in deep-sea mining applications. Ocean Eng. 2024, 299, 117260. [Google Scholar] [CrossRef]

- Schumacher, J.P.; Dowell, J.D.; Ribbeck, L.R.; Eggemeyer, J.C. Subsea mud lift drilling: Planning and preparation for the first Subsea field test of a full-scale dual gradient drilling system at Green Canyon 136, Gulf of Mexico. In SPE Annual Technical Conference and Exhibition; SPE: Calgary, AB, Canada, 2001; p. SPE-71358-MS. [Google Scholar] [CrossRef]

- Smith, K.L.; Gault, A.D.; Witt, D.E.; Weddle, C.E. Sub Sea Mud Lift drilling joint industry project: Delivering dual gradient drilling technology to industry. In SPE Annual Technical Conference and Exhibition; SPE: Calgary, AB, Canada, 2001; p. SPE-71357-MS. [Google Scholar] [CrossRef]

- Judge, R.A.; Yu, A. Subsea slurry lift pump for Deepsea mining. In Proceedings of the ASME 2010 29th International Conference on Ocean, Offshore and Arctic Engineering, ASMEDC, Shanghai, China, 6–11 June 2010; Volume 3, pp. 181–188. [Google Scholar] [CrossRef]

- Leach, S.; Smith, G.; Berndt, R. SME Special Session: Subsea Slurry Lift Pump Technology—SMS Development. In Proceedings of the Offshore Technology Conference, OTC, Houston, TX, USA, 30 April–3 May 2012; p. OTC-23224-MS. [Google Scholar] [CrossRef]

- Schulte, S. Vertical transport methods in deep sea mining. In Van Oord Dredging & Marine Contractors; Delft University of Technology: Delft, The Netherlands, 2013. [Google Scholar]

- Hu, Q.; Huang, J.Q.; Kang, Y.J.; Liu, S.J.; Feng, J.X.; Wang, K.L. Study on the transportation characteristics of wastewater-driven deep-sea diaphragm pumps for slurry transportation. Appl. Ocean. Res. 2025, 158, 104567. [Google Scholar] [CrossRef]

- Zhai, X.Y. Research on Multi-Objective Optimization Design and Anti-Blocking Measures for Multi-Stage Deep-Sea Mining Pump; Central South University: Changsha, China, 2023. [Google Scholar] [CrossRef]

- UN Ocean Economics Technology Branch. Report for 1986–87 on the Activities in Marine Affairs; UN Ocean Economics Technology Branch: New York, NY, USA, 1987. [Google Scholar]

- Deng, L.W. Numerical and Experimental Study on the Hydraulics and Particle Transport Characteristics of Deep Sea Lifting Pump; Central South University: Changsha, China, 2022. [Google Scholar]

- Chen, G.G.; Yang, N.; Tang, D.S.; Jin, X.; Xiao, H. Study on the settling regularity of solid particles in vertical pipelines. J. Sediment Res. 2010, 4, 16–21. [Google Scholar] [CrossRef]

- Charlton, A.J.; Blandin, G.; Leslie, G.; Leclech, P. Impact of Forward Osmosis Operating Pressure on Deformation, Efficiency and Concentration Polarisation with Novel Links to CFD. Membranes 2021, 11, 161. [Google Scholar] [CrossRef] [PubMed]

- Hu, Q.; Chen, J.; Deng, L.W.; Liu, S.J. CFD-DEM coupled simulation and experimental study of deep sea lifting mine pump under extreme working conditions. Chin. J. Nonferrous Met. 2021, 31, 2926–2937. [Google Scholar] [CrossRef]

- Tang, P.; Xie, B.; Zhao, G.; Zhu, W.; Wang, W.; Ma, W. Study on the crushing characteristics of polymetallic nodules based on the single-tooth roller crusher. Powder Technol. 2025, 462, 121138. [Google Scholar] [CrossRef]

- Johnson, K.L.; Kendall, K.; Roberts, A.D. Surface energy and the contact of elastic solids. Proceed. Royal Society of London. A. Math. Phys. Sci. 1997, 324, 301–313. [Google Scholar] [CrossRef]

- Huilin, L.; Gidaspow, D. Hydrodynamics of binary fluidization in a riser: CFD simulation using two granular temperatures. Chem. Eng. Sci. 2003, 58, 3777–3792. [Google Scholar] [CrossRef]

- Saffman, P.G. The lift on a small sphere in a slow shear flow. J. Fluid Mech. 1965, 22, 385–400. [Google Scholar] [CrossRef]

- Blackburn, J.; Jankowski, P.; Heymann, E.; Chwastiak, P.; See, A.; Munro, P.; Lipton, I. Offshore Production System Definition and Cost Study. 2010. Available online: https://actnowpng.org/sites/default/files/Solwara%201%20Production%20System%20Definition%20and%20Cost%20Study%202010.pdf (accessed on 19 August 2025).

- Kang, Y.J.; Liu, S.J.; Zou, W.S.; Zhao, H.; Hu, X.Z. Design and analysis of an innovative deep-sea lifting motor pump. Appl. Ocean. Res. 2019, 82, 22–31. [Google Scholar] [CrossRef]

- Zou, W.S.; Li, H.T.; Kang, Y.J. Theoretical design on slurry pump hydraulic lift system for marine mineral resources exploitation. Chin. J. Nonferrous Met. 2021, 31, 2953–2962. [Google Scholar]

- Li, P.C. Studies on Mechanism of Hydraulic Hoist of Coarse Particle in Vertical Pipe. Ph.D. Dissertation, Tsinghua University, Beijing, China, 2007. [Google Scholar]

| Number of Cells | Mesh Quality | Velocity (m/s) | Error (Compared to Fine Mesh) |

|---|---|---|---|

| 23,246 | Coarse | 3.893 | 10.83% |

| 35,616 | Medium | 4.243 | 2.82% |

| 57,219 | Good | 4.363 | 0.07% |

| 137,324 | Fine | 4.366 | - |

| Parameter | Value |

|---|---|

| Number of cells | 57,219 |

| Cell volume | 4.11 × 10−8 to 5.03 × 10−5 m3 |

| Cell angles | 9.12° to 89.05° |

| Orthogonal quality | Average: 0.957, Minimum: 0.384 |

| Centrifugal Pump Slurry Concentration (%) | Diaphragm Pump Group Slurry Concentration (%) | Lifting Efficiency (%) |

|---|---|---|

| 10 | 11.23 | 46.48 |

| 10.5 | 11.79 | 49.10 |

| 11 | 12.35 | 51.46 |

| 11.5 | 12.91 | 53.56 |

| 12 | 13.47 | 55.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Q.; Feng, J.; Kang, Y.; Liu, S.; Huang, J.; Wang, K. Research on the Scheme and System Parameter Matching of a Wastewater-Driven Diaphragm Pump Group for Slurry Transport in Deep-Sea Mining. J. Mar. Sci. Eng. 2025, 13, 1934. https://doi.org/10.3390/jmse13101934

Hu Q, Feng J, Kang Y, Liu S, Huang J, Wang K. Research on the Scheme and System Parameter Matching of a Wastewater-Driven Diaphragm Pump Group for Slurry Transport in Deep-Sea Mining. Journal of Marine Science and Engineering. 2025; 13(10):1934. https://doi.org/10.3390/jmse13101934

Chicago/Turabian StyleHu, Qiong, Junxuan Feng, Yajuan Kang, Shaojun Liu, Junqiang Huang, and Kaile Wang. 2025. "Research on the Scheme and System Parameter Matching of a Wastewater-Driven Diaphragm Pump Group for Slurry Transport in Deep-Sea Mining" Journal of Marine Science and Engineering 13, no. 10: 1934. https://doi.org/10.3390/jmse13101934

APA StyleHu, Q., Feng, J., Kang, Y., Liu, S., Huang, J., & Wang, K. (2025). Research on the Scheme and System Parameter Matching of a Wastewater-Driven Diaphragm Pump Group for Slurry Transport in Deep-Sea Mining. Journal of Marine Science and Engineering, 13(10), 1934. https://doi.org/10.3390/jmse13101934