1. Introduction

The Voith Schneider Propeller (VSP) is a specialized marine propulsion system that generates vectored thrust in any horizontal direction through vertically mounted blades attached to a rotating disk. The blades are uniformly distributed along the disk’s circumference, with each blade undergoing uniform revolution around the disk while simultaneously rotating about its own axis at variable speeds [

1]. By altering the deflection angle of blade rotation, VSP changes the angle of attack between the blades and the resultant inflow during motion, thereby generating planar vector thrust. This allows the modulation of thrust magnitude and direction while providing primary propulsion for vessels [

2]. Consequently, vessels equipped with VSP maintain excellent maneuverability during mooring or at low speeds, and demonstrate superior control capabilities compared to screw propellers in dynamic positioning applications [

3].

VSP was improved by Schneider [

4] based on Kirsten [

5] and successfully commercialized [

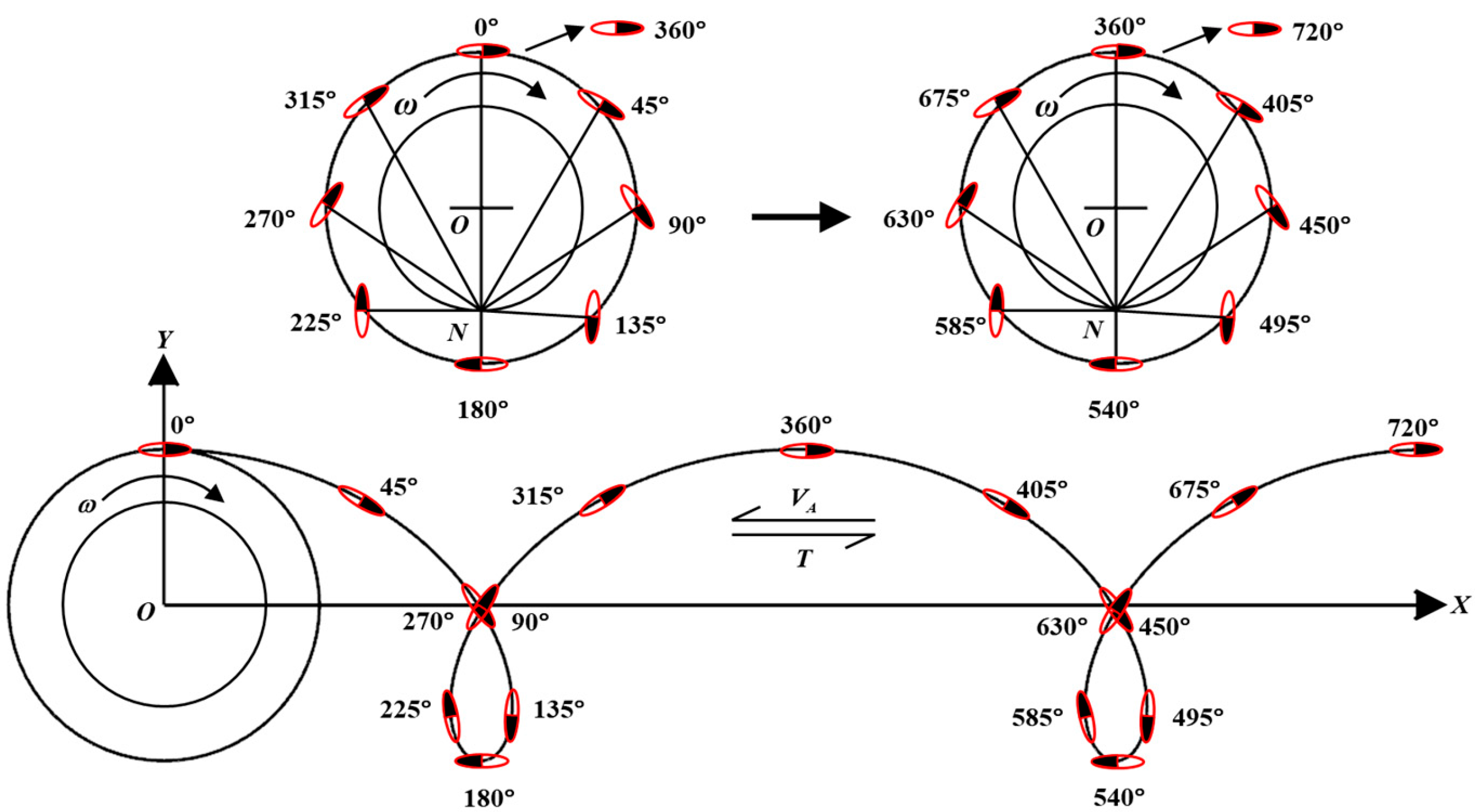

6]. Combining the revolution of VSP blades with the vessel’s forward motion, the trajectory of a single blade forms a cycloid. Thus, VSP can be classified as a variable low-pitch cycloidal propeller. In current research nomenclature, “cycloidal propeller” encompasses most studies focusing on different “cycloidal” blade motion strategies featuring straight blades as the primary characteristic. Initial research on cycloidal propellers primarily employed simplified models to estimate time-averaged hydrodynamic performance. W. Just [

7] segmented cycloidal propeller blades spanwise into multiple micro-elements based on airfoil theory, calculating hydrodynamic characteristics of each micro-element using two-dimensional wing theory, achieving the earliest theoretical method for hydrodynamic performance calculation of cycloidal propellers. Although the calculated results aligned with hydrodynamic parameter trends from Voith’s (Voith GmbH., Heidenheim, Germany) experimental data, the model’s applicability remained limited. To date, following airfoil theory and other approaches, numerous scholars have proposed various theoretical methods for hydrodynamic performance prediction of cycloidal propellers, including representative approaches such as the lifting-line theory by Isay [

8], momentum theory by Taniguchi [

9,

10,

11], and vortex theory by M.R. Mendenhall and S.B. Spangler [

12].

Recent research on theoretical models has adopted more sophisticated methods to describe and predict unsteady flow and hydrodynamic performance. Prabhu et al. [

13,

14] employed the panel method to discretize blade surfaces into straight panels, distributing sources and vortices as singularities on each panel. By solving potential flow equations, the velocity potential and pressure distribution across the flow field were computed, effectively capturing the unsteady flow field and hydrodynamic characteristics of cycloidal propellers. Halder et al. [

15] comprehensively considered physical phenomena including dynamic virtual camber effects, near-wake and shed-wake interactions, and leading-edge vortices. This study integrated a nonlinear lifting-line model with the Polhamus leading-edge suction analogy, Theodorsen’s method, and a modified double-multiple streamtube model to establish a low-order unsteady hydrodynamic model, which was validated against time-history data from single-blade hydrodynamic measurements at low Reynolds numbers. Epps et al. [

16] developed a low-order computational model based on the vortex-lattice method, enhancing viscous flow prediction through viscous-thickness and load coupling techniques. Wake stability was optimized using the Panel-Averaged Wake-Induced Velocity method, achieving model accuracy meeting preliminary design requirements.

Synthesizing the aforementioned theoretical model research, calculation methods based on theoretical models typically neglect three-dimensional flow effects or viscous effects in their assumptions, requiring experimental data for model coefficient corrections. Their reliance on empirical formulas for unsteady flow phenomena such as turbulence and dynamic stall results in limited computational accuracy for complex geometries and unsteady flow fields. With advancements in viscous Computational Fluid Dynamics (CFD) numerical simulation methods based on solving Navier–Stokes equations [

2], CFD approaches demonstrate advantages in capturing high-precision flow details, adapting to complex geometries, and coupling multiphysics. Consequently, in recent years, numerous scholars have employed CFD methods to investigate the influence of various parameters on the hydrodynamic performance of cycloidal propellers.

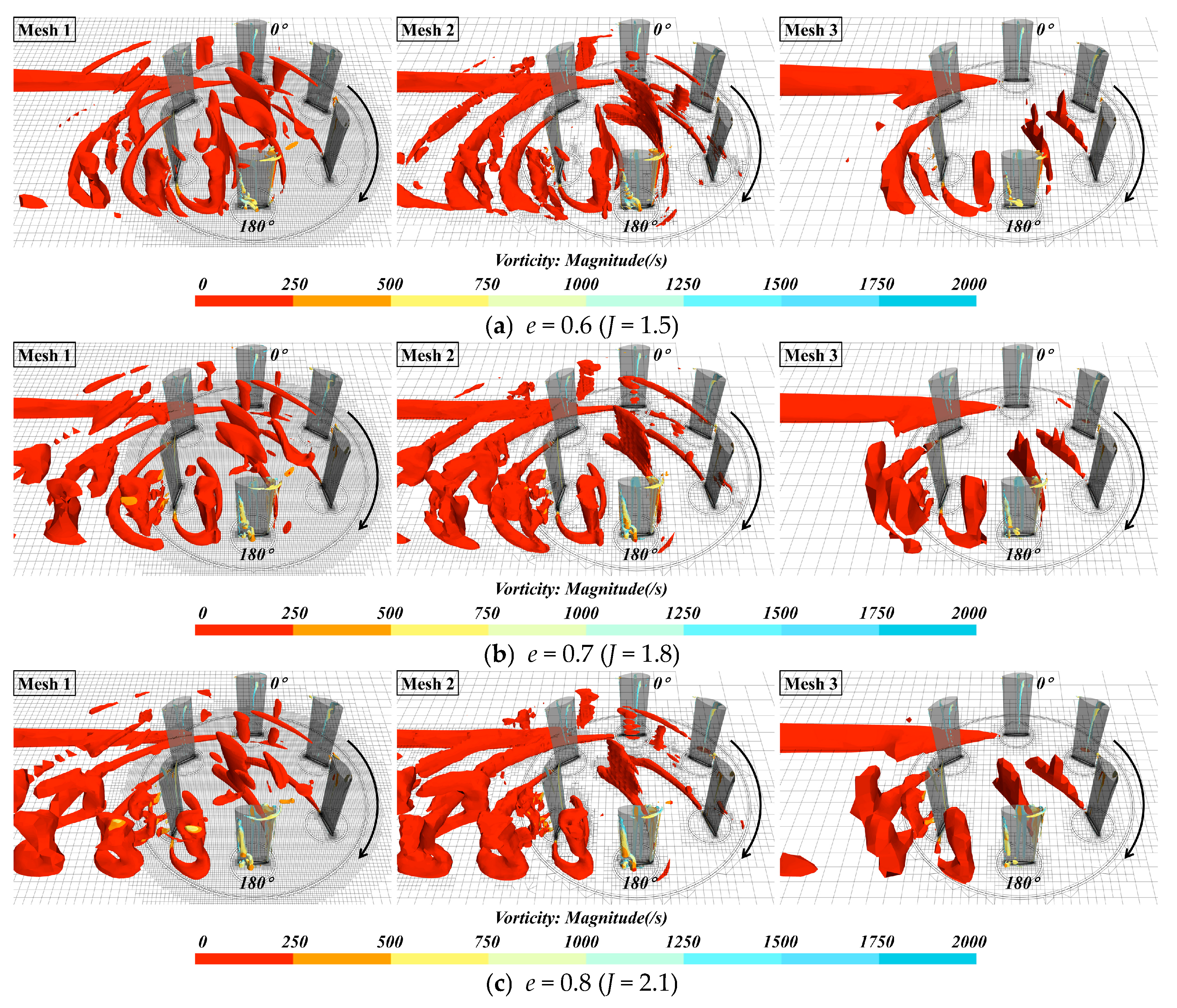

Hu et al. [

17,

18] systematically analyzed the vortex structure evolution of cycloidal propellers under blade rotational motion. The study revealed that sudden changes in blade rotational speed trigger boundary layer separation, forming a dual “suction vortex-lift vortex” structure that induces periodic load fluctuations. The influence of parameters such as eccentricity and blade rotation center position on vortex structures was further summarized. Yan et al. [

19] established kinematic models for cycloidal propellers using planar linkage mechanisms—specifically four-bar and mixed four-bar/five-bar mechanisms. Research demonstrated that blade rotation angle and angular velocity range are core factors affecting hydrodynamic performance, as control mechanism parameters alter blade motion laws and thereby impact propulsion effectiveness. Hu et al. [

20] developed a two-dimensional numerical model for cycloidal propellers. Results indicate that adjusting eccentricity optimizes the matching between thrust and advance coefficient, enhances efficiency, reduces blade interference, and reveals that azimuthal angle variations under high advance coefficients intensify turbulent fluctuations and increase side thrust. Liu et al. [

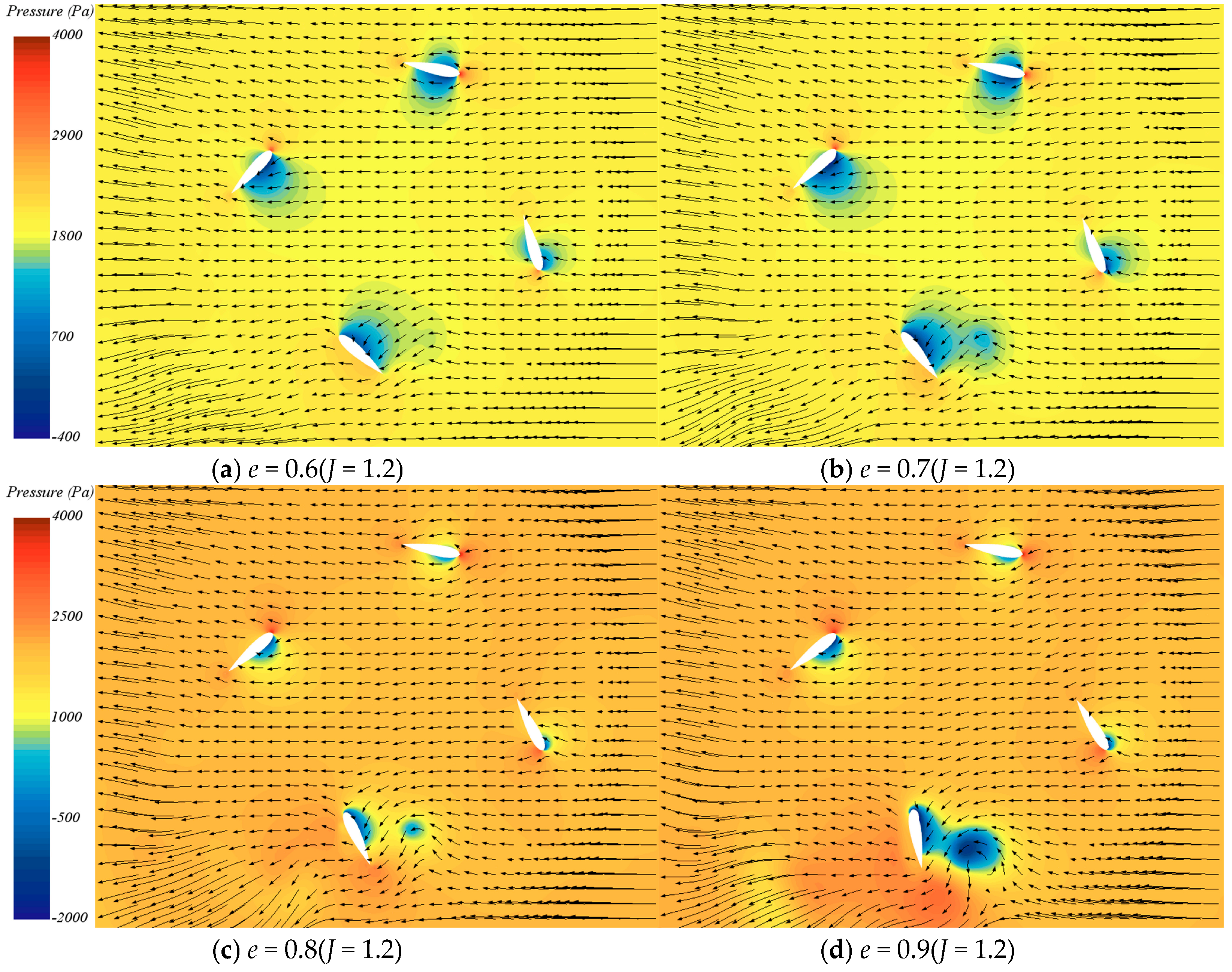

21] investigated directional thrust stability of cycloidal propellers under VSP and Cyclorotor motion modes. Findings show the Cyclorotor mode—where blade deflection angles follow a near-sinusoidal variation—exhibits smaller side thrust fluctuations and a more concentrated spatiotemporal distribution of total thrust.

In the development of theoretical models and CFD methods, the correction of theoretical model parameters based on experimental data and the validation of numerical calculation accuracy are indispensable. Early cycloidal propellers were primarily driven by mechanical structures (connecting rods, cranks, camshafts, gears, etc.) [

22]. Given the fixed mechanical design, blade motion patterns were highly standardized. With advancements in high-performance electric motor development and control technology upgrades, the model testing methods for cycloidal propellers have progressively evolved.

Fasse et al. [

23] independently controlled the pitch motion of each blade using servo motors, conducting systematic experiments on sinusoidal pitch control of cycloidal propellers. The study revealed the hydrodynamic center offset characteristics of cycloidal propellers and validated the necessity of asymmetric pitch control. Halder et al. [

15] measured transient hydrodynamic time-history data of a single-blade cycloidal propeller under different advance coefficients in a water tunnel. The study discovered that during blade reversal, flow separation causes a sudden change in the angle of attack and generates negative side thrust. Additionally, negative virtual camber during the first half of the blade motion cycle reduces both thrust and side thrust, while positive virtual camber in the latter half enhances thrust, resulting in thrust asymmetry phenomena.

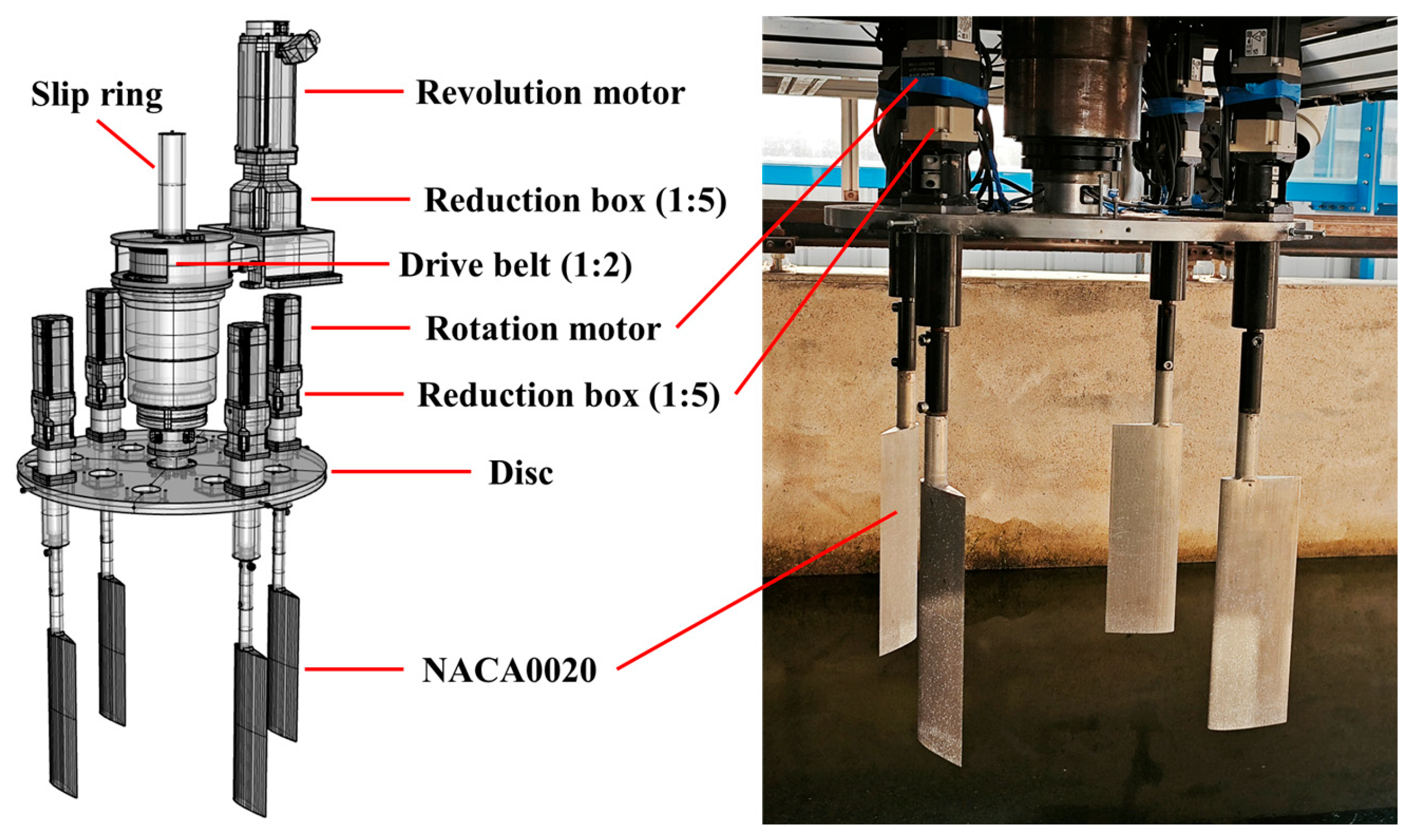

Research synthesizing the above findings reveals that during the complex coupled motion of cycloidal propeller blades, blade-water interactions coexist with blade-blade interactions. Additionally, dynamic stall phenomena accompany large-angle-of-attack conditions. Under the combined influence of these factors, a highly unsteady complex flow field forms in cycloidal propellers, which features multi-scale vortex generation, evolution, and dissipation. Consequently, hydrodynamic forces on blades exhibit unsteady characteristics. Therefore, whether employing theoretically modeled assumptions, CFD methods incorporating turbulence equations, or experimentally testing cycloidal propellers via complex mechanical-structure designs and high-performance electric motors, accurately calculating and measuring unsteady hydrodynamic performance and flow fields remains a significant challenge. In summary, this study focuses on the transient hydrodynamic characteristics during the coupled motion of VSP blades. A numerical method for predicting VSP unsteady hydrodynamics was established based on publicly available experimental data. Furthermore, breaking through the limitations of traditional mechanical structures, a servo motor-controlled VSP device was designed to achieve precise blade rotation control under high eccentricity conditions. The variation patterns of unsteady transient hydrodynamics with eccentricity were thoroughly analyzed, providing solid experimental support for theoretical investigations.

Building upon the aforementioned research landscape, this paper focuses on VSP as a practical application of cycloidal propellers, investigating numerical calculation and experimental measurement methods for unsteady transient hydrodynamics induced by blade-coupled motion.

Section 2.1 analyzes the coupled motion of uniform blade revolution and variable-speed blade rotation, deriving kinematic equations for VSP blades.

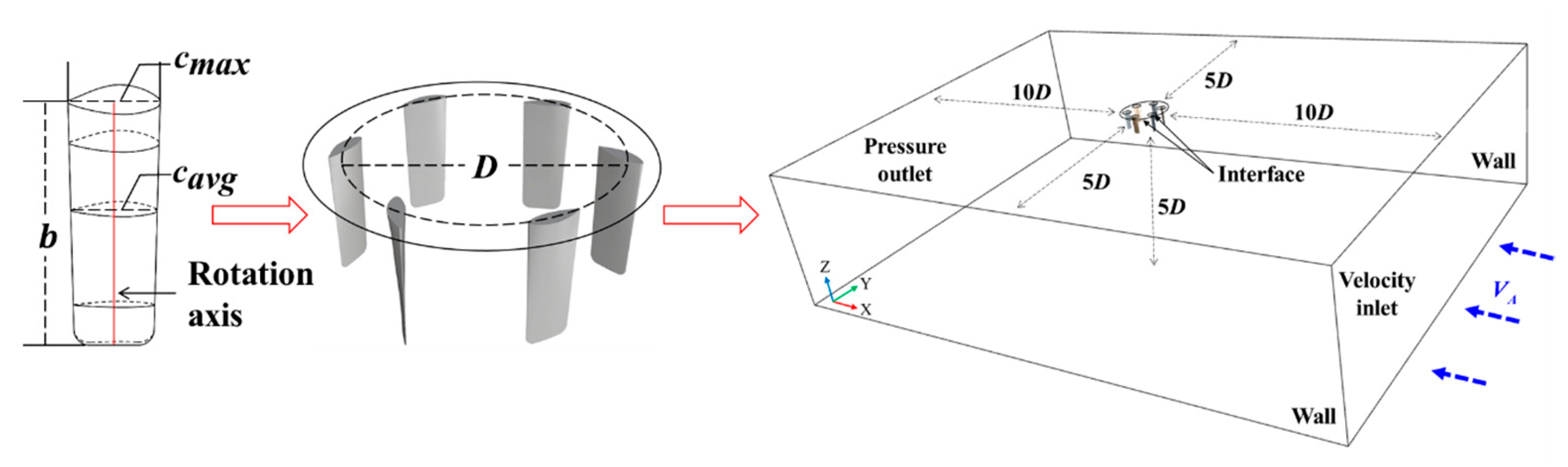

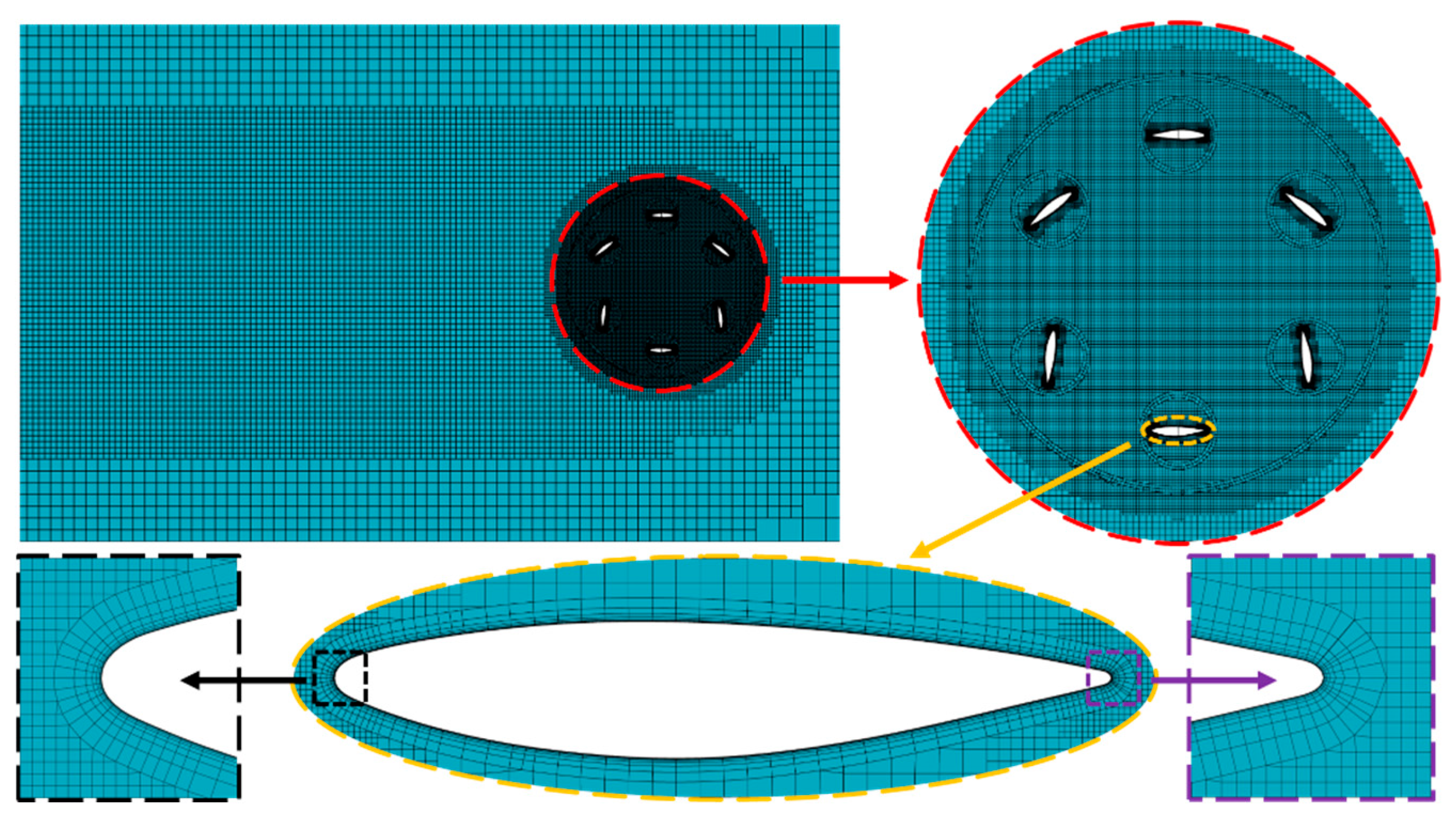

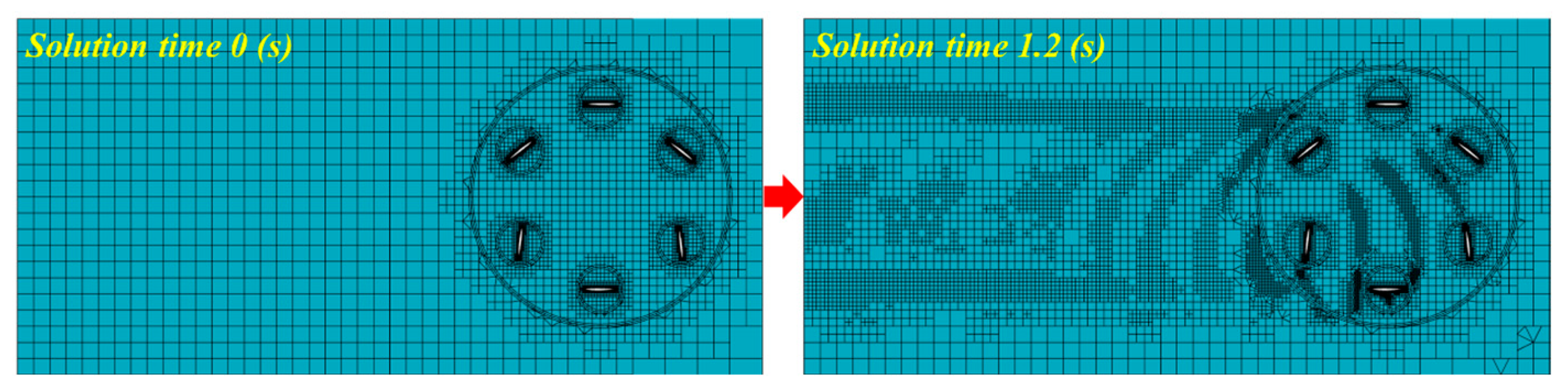

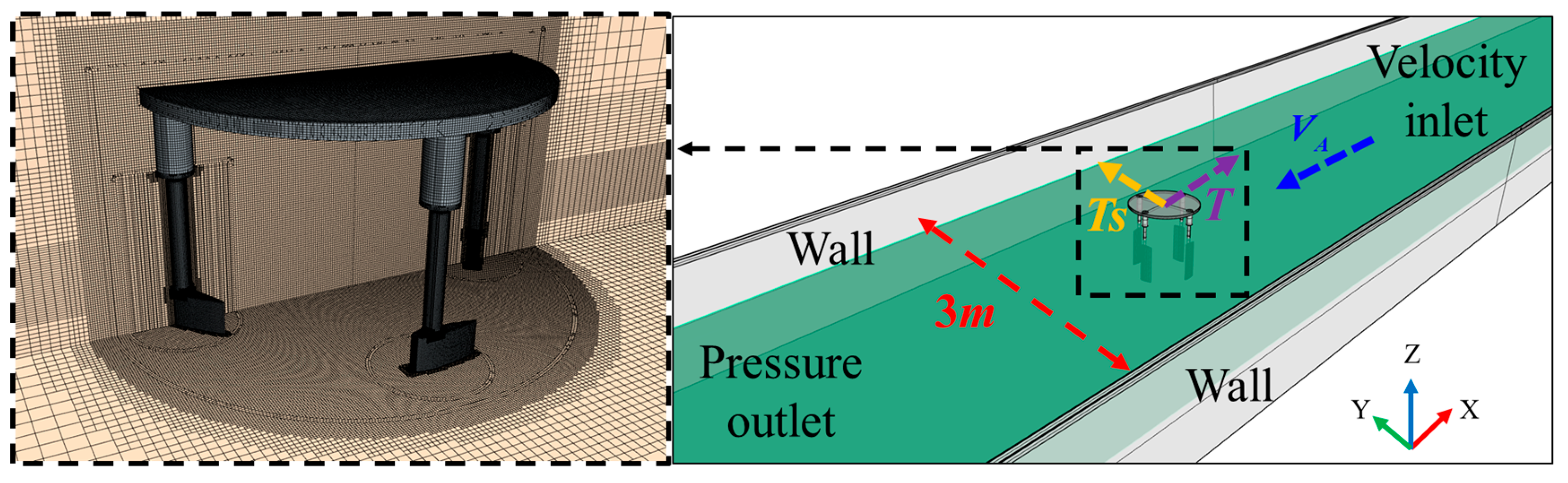

Section 2.2 discusses and verifies the computational method for VSP unsteady hydrodynamics, enhancing numerical accuracy through vortex-region identification using the Omega vortex criterion and adaptive mesh refinement.

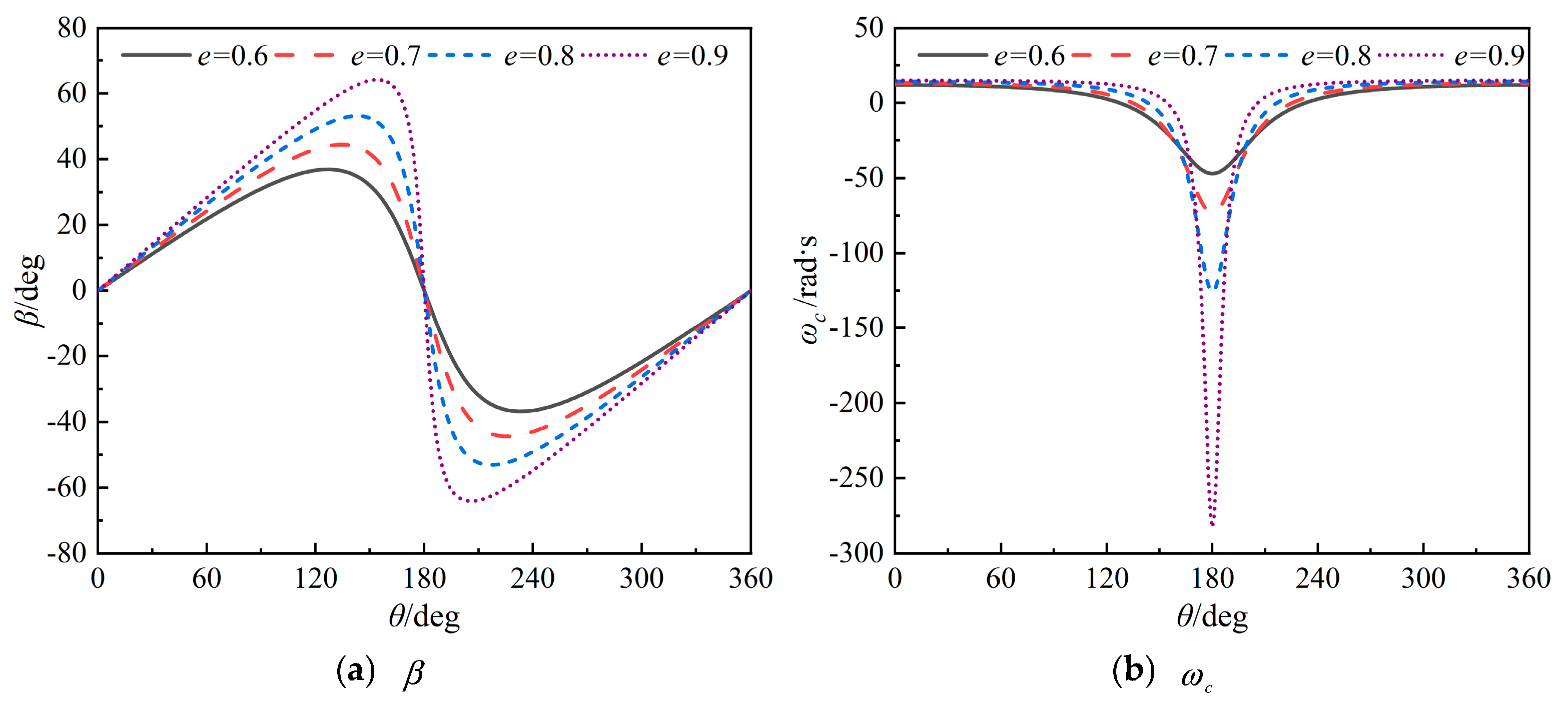

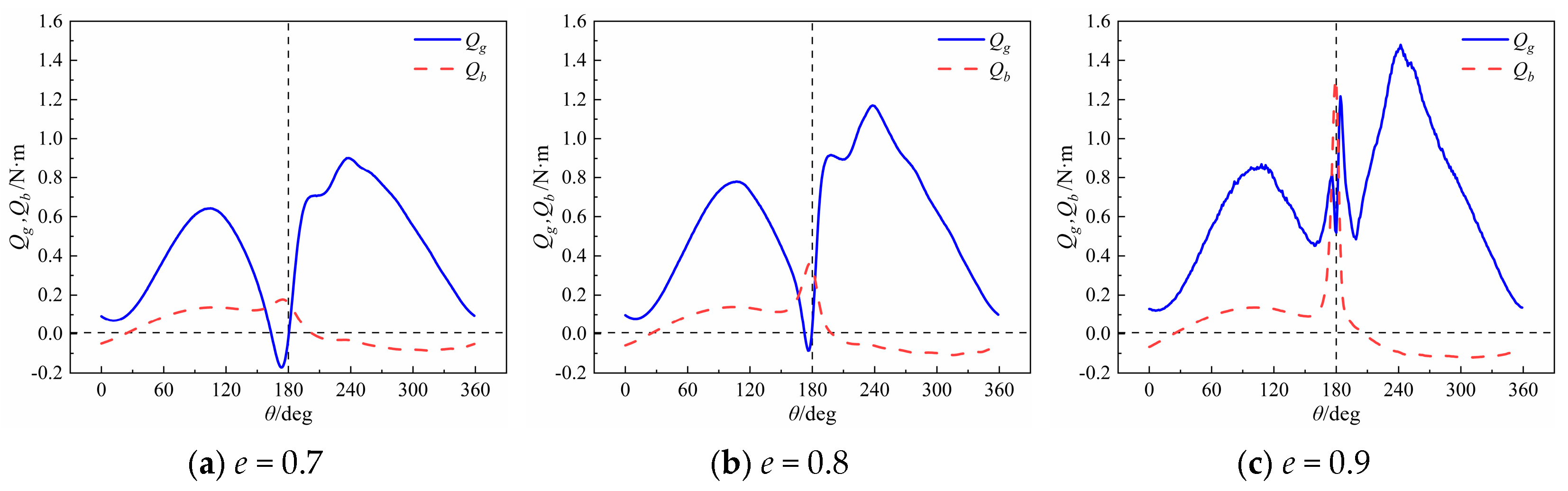

Section 3.1 examines variation patterns of blade unsteady transient hydrodynamics with eccentricity based on VSP blade-coupling kinematics.

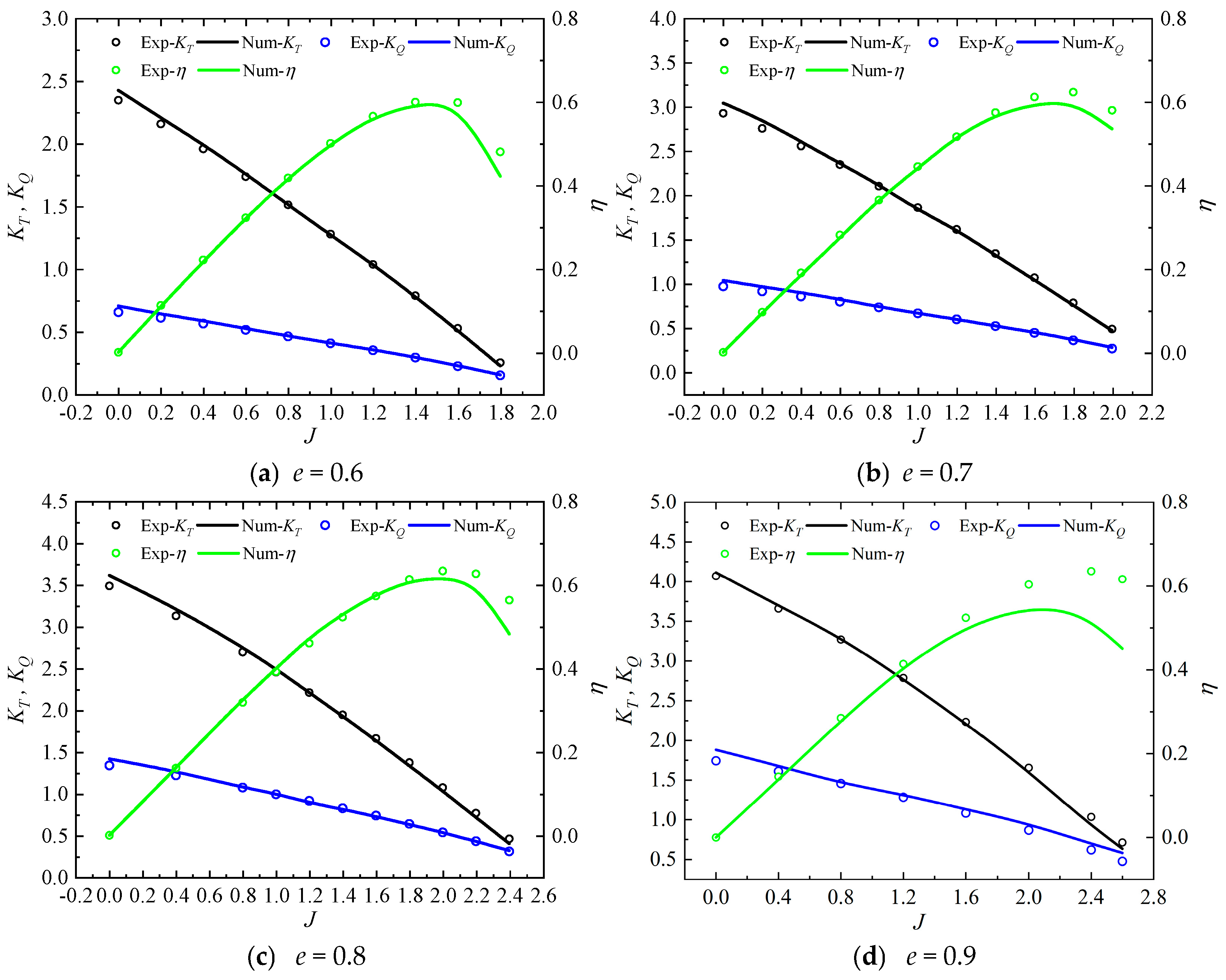

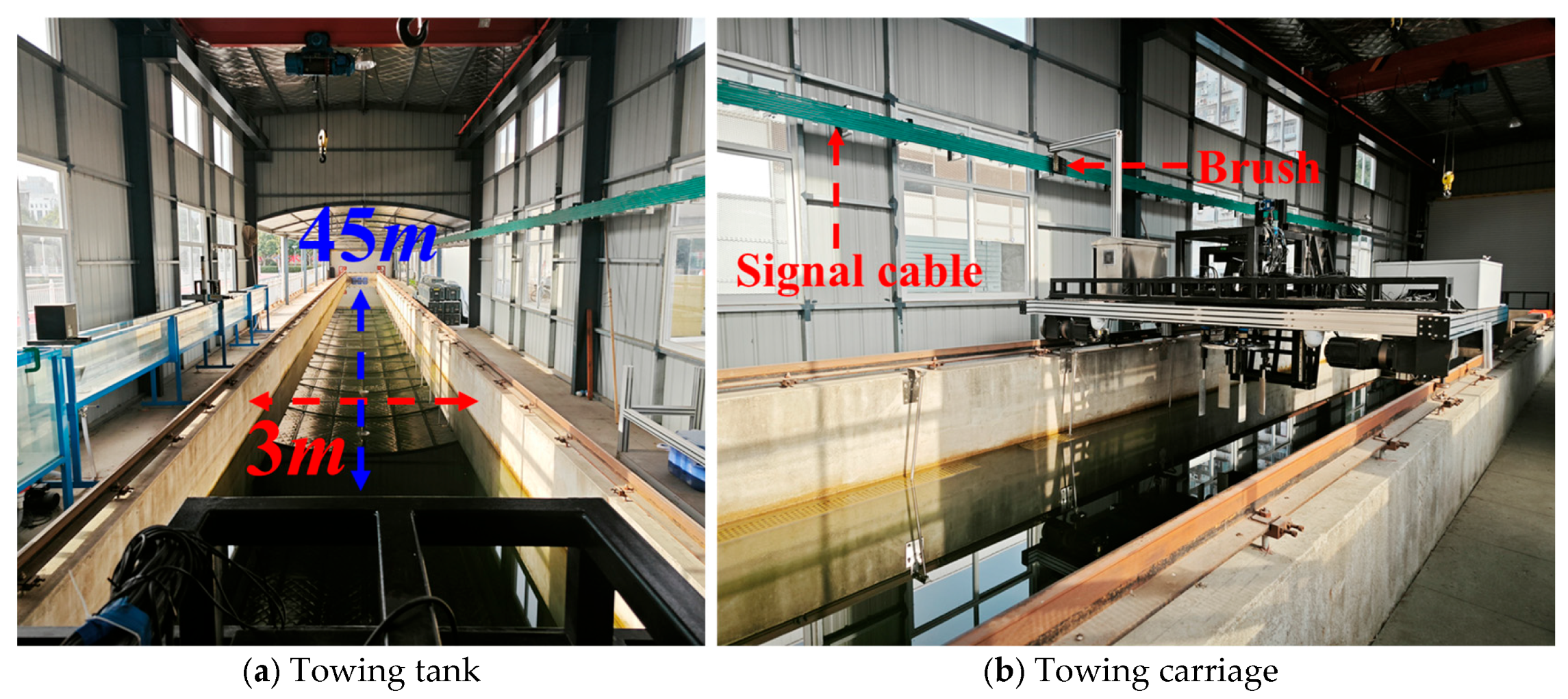

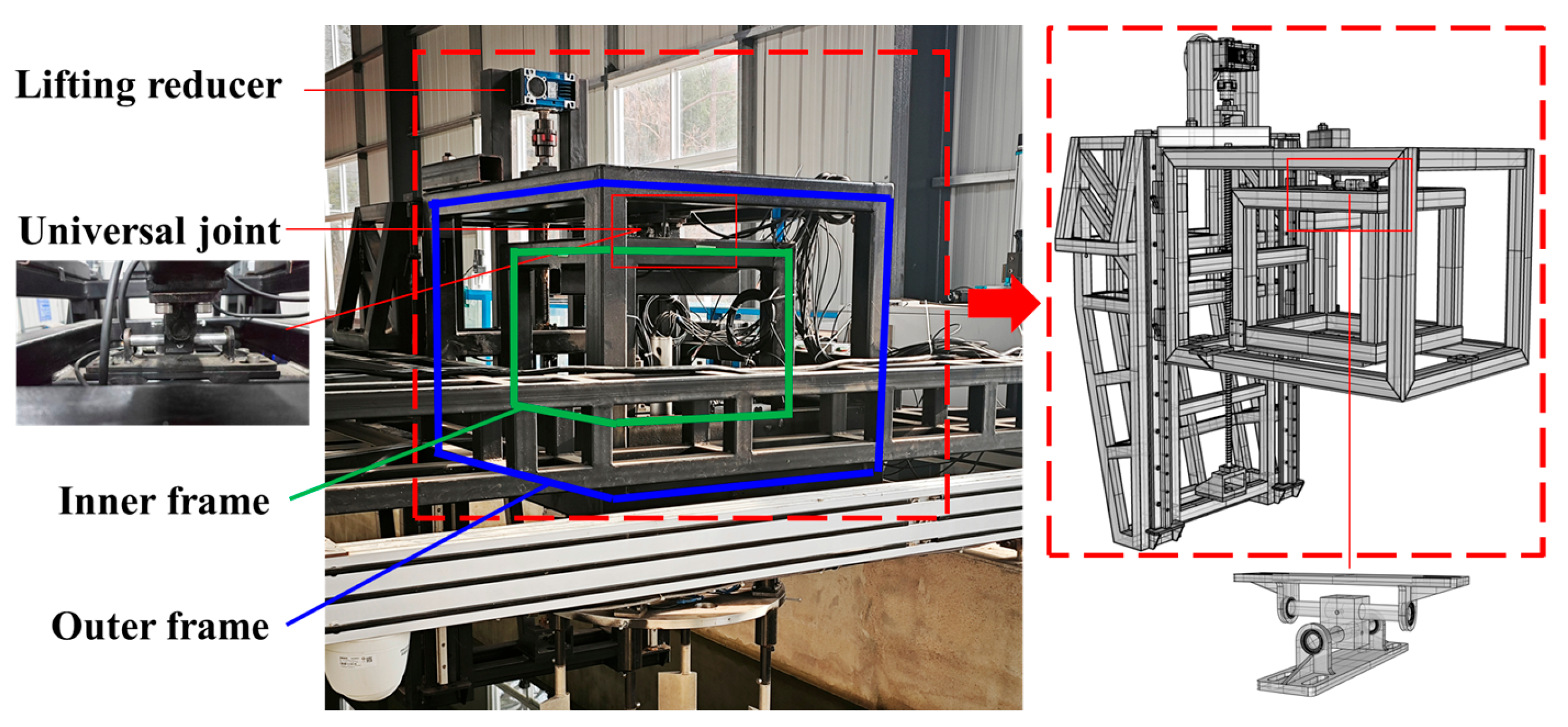

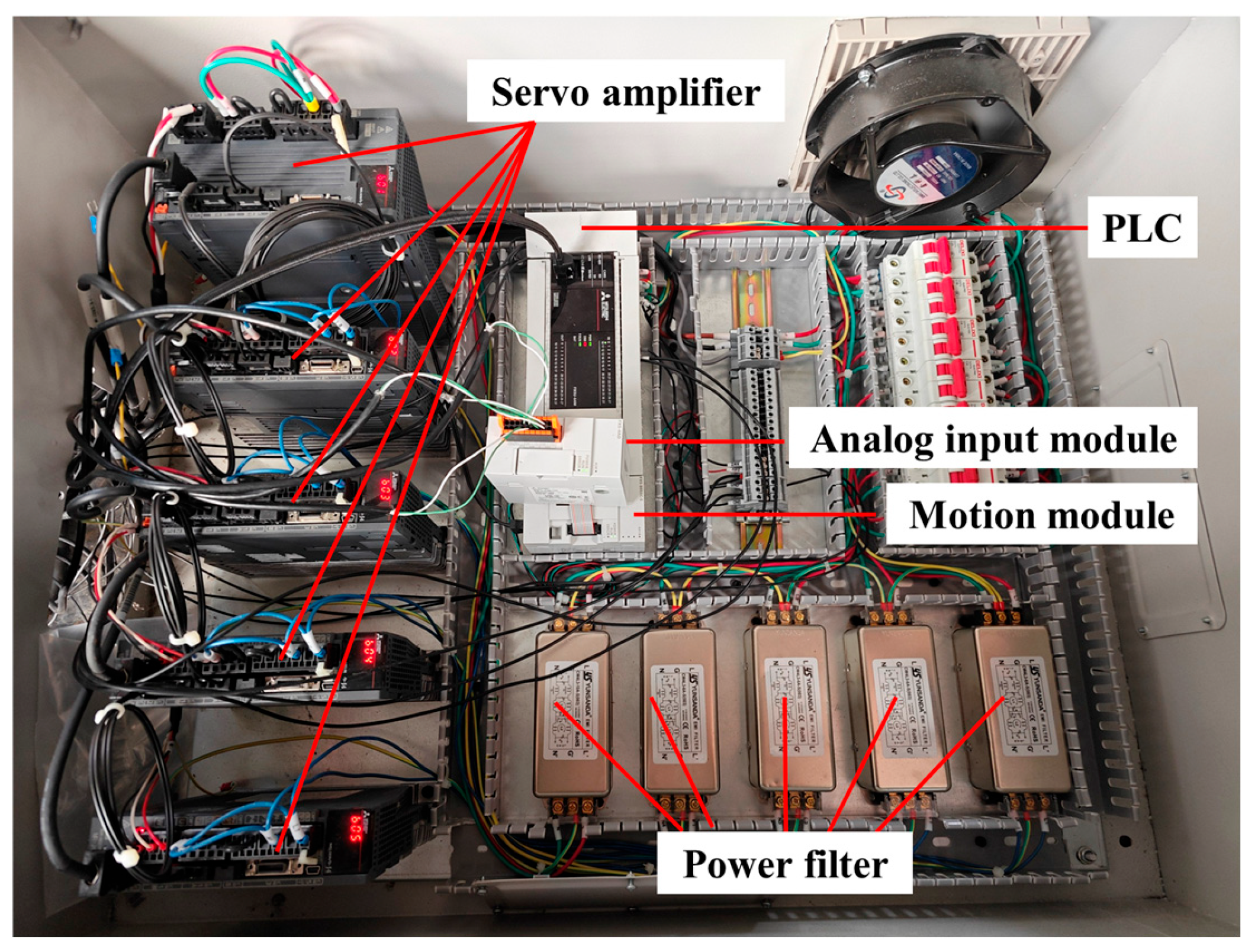

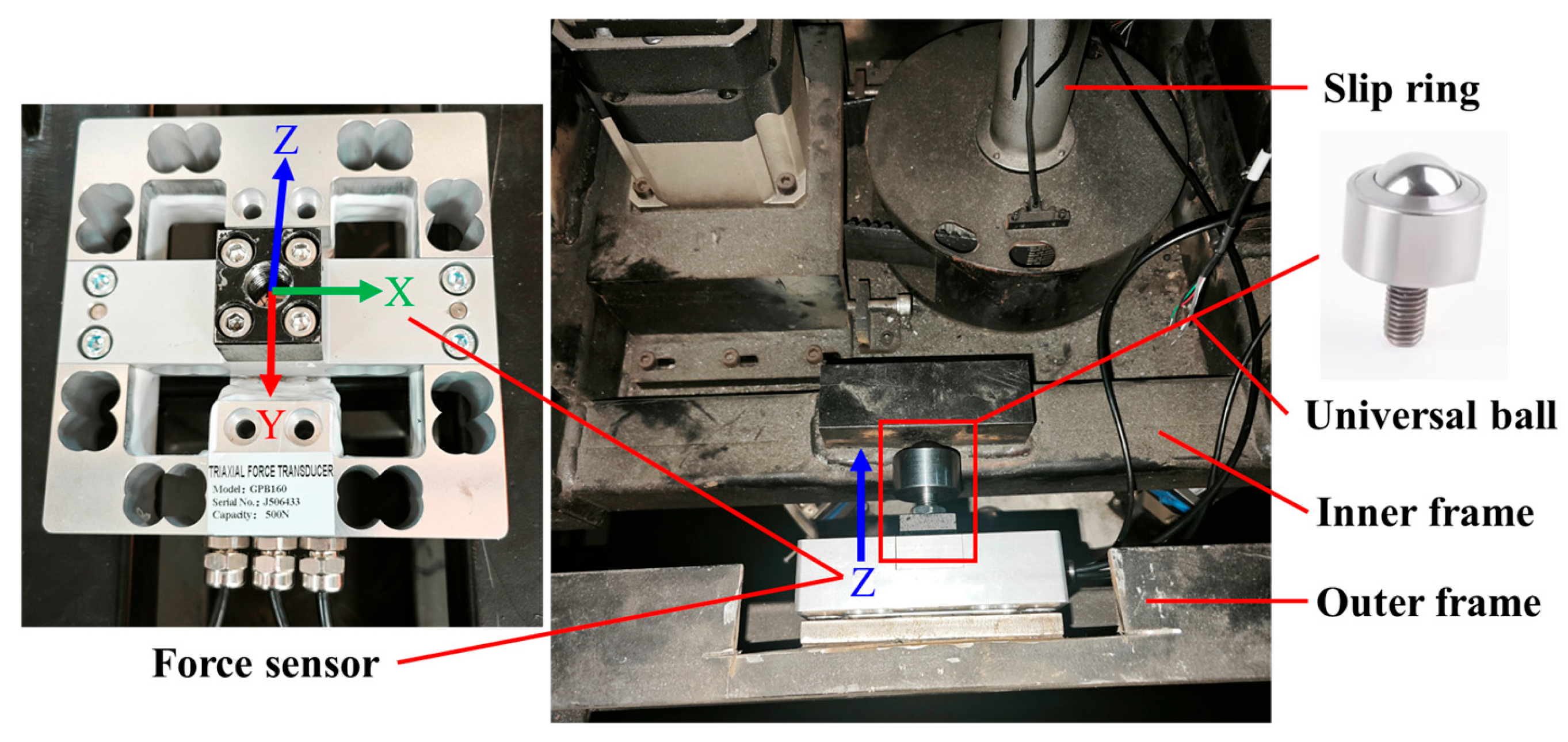

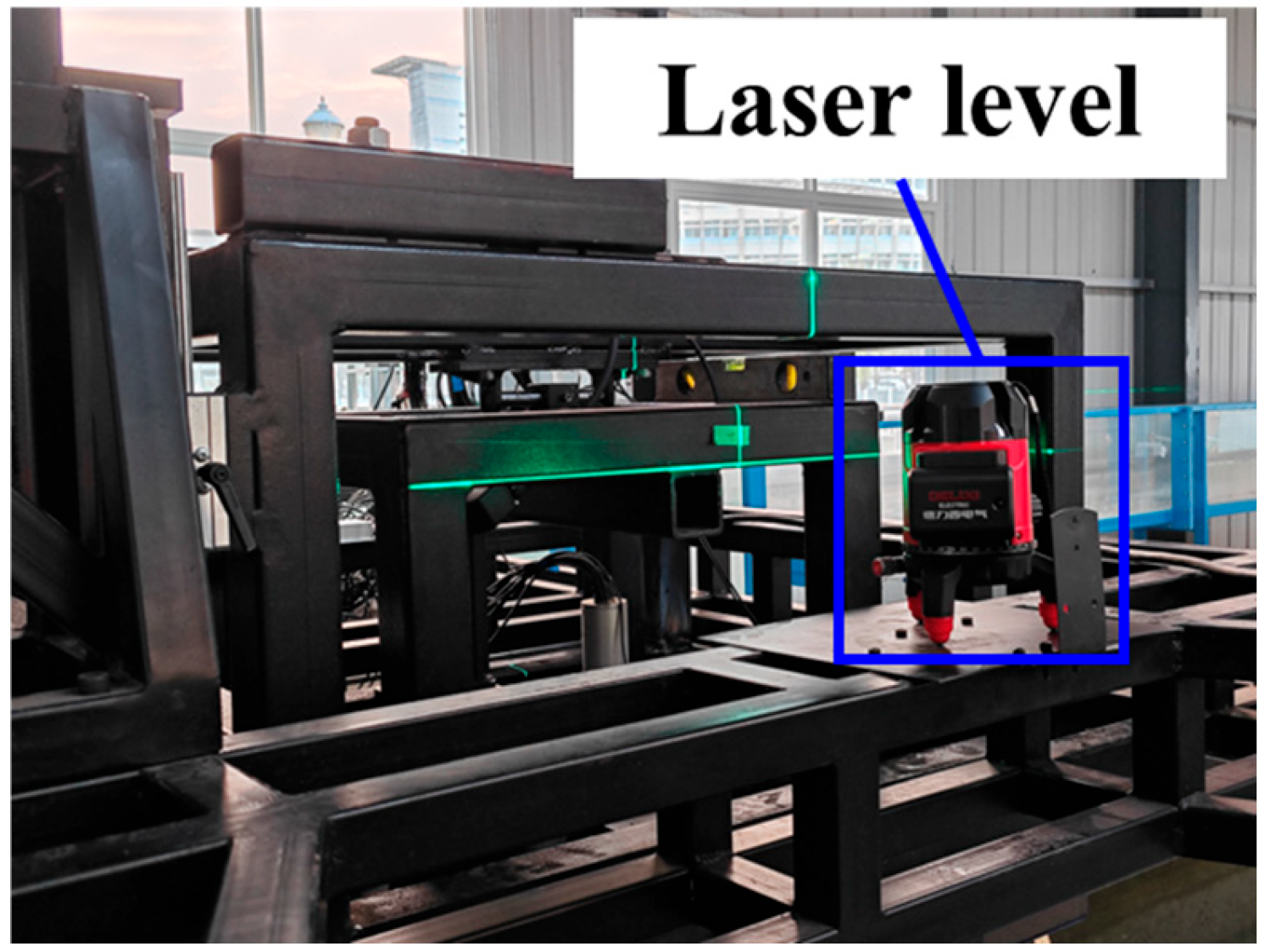

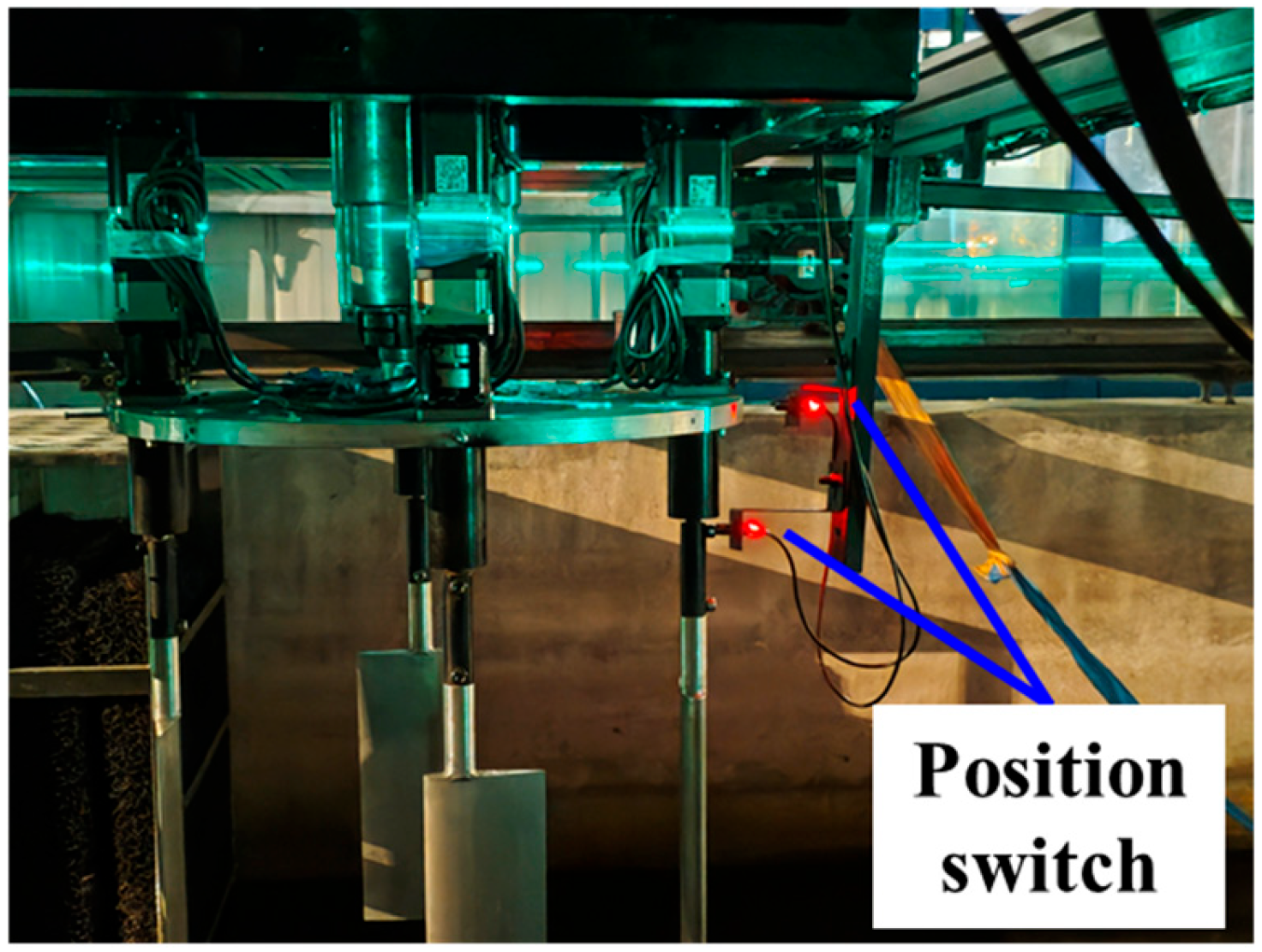

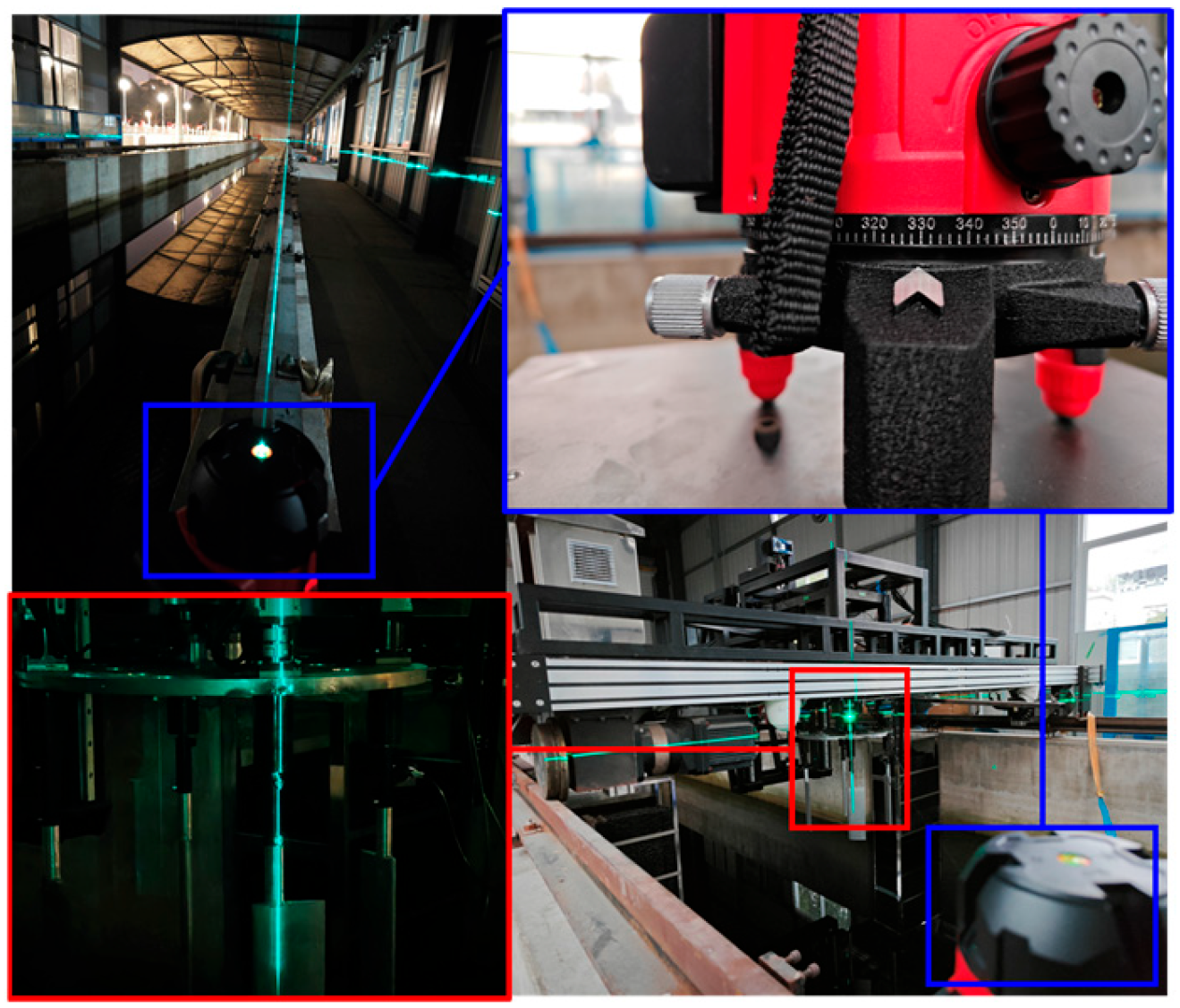

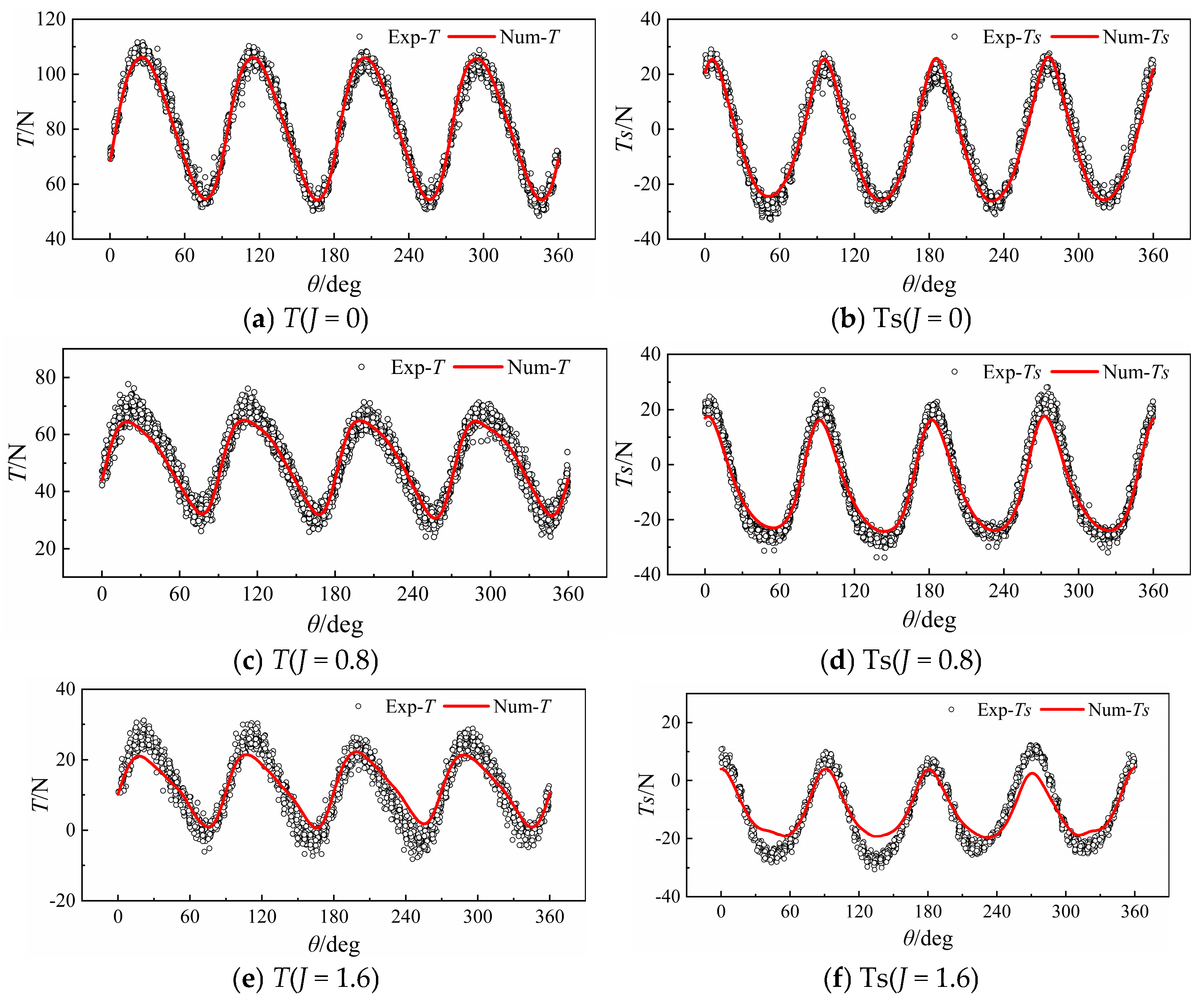

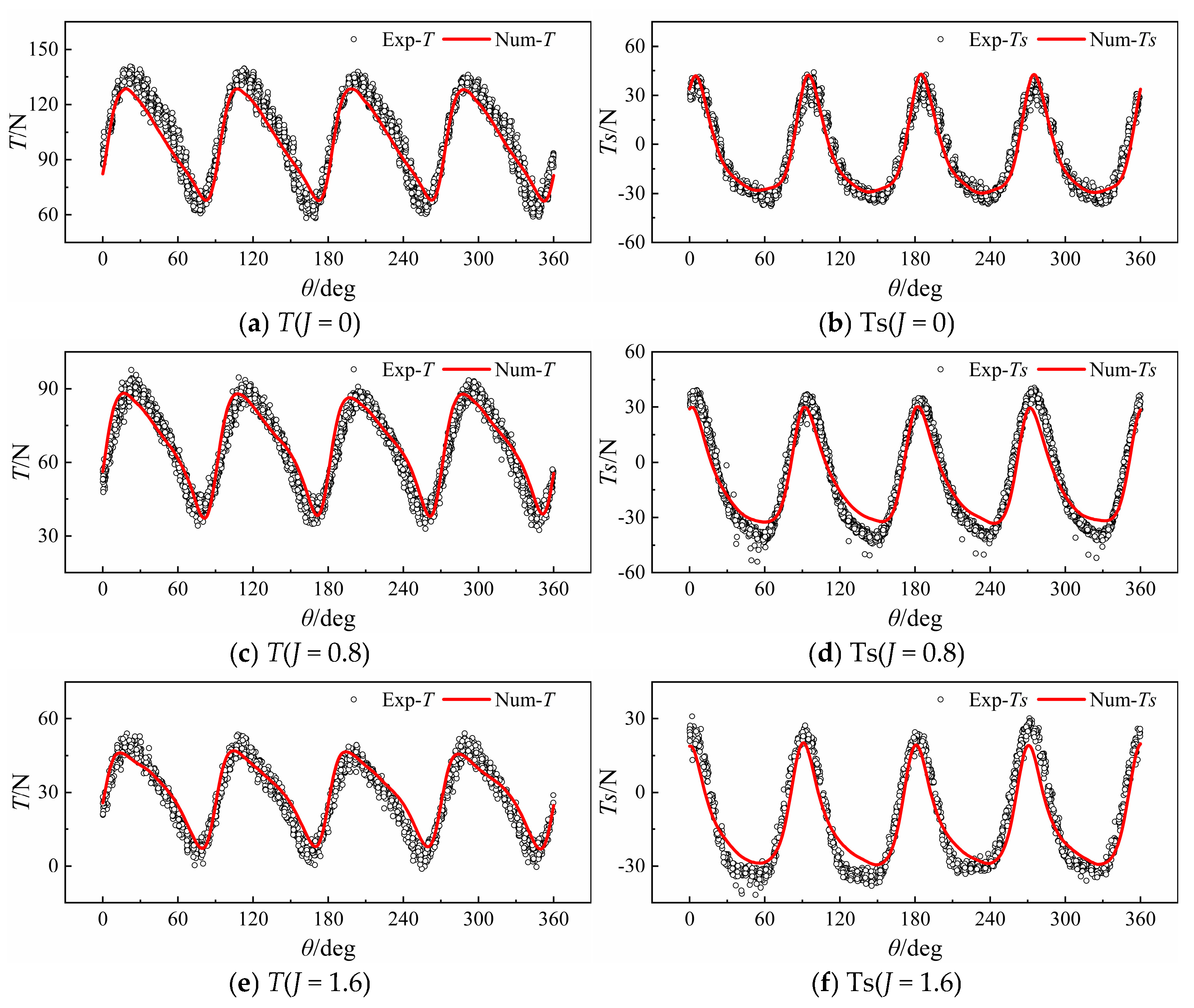

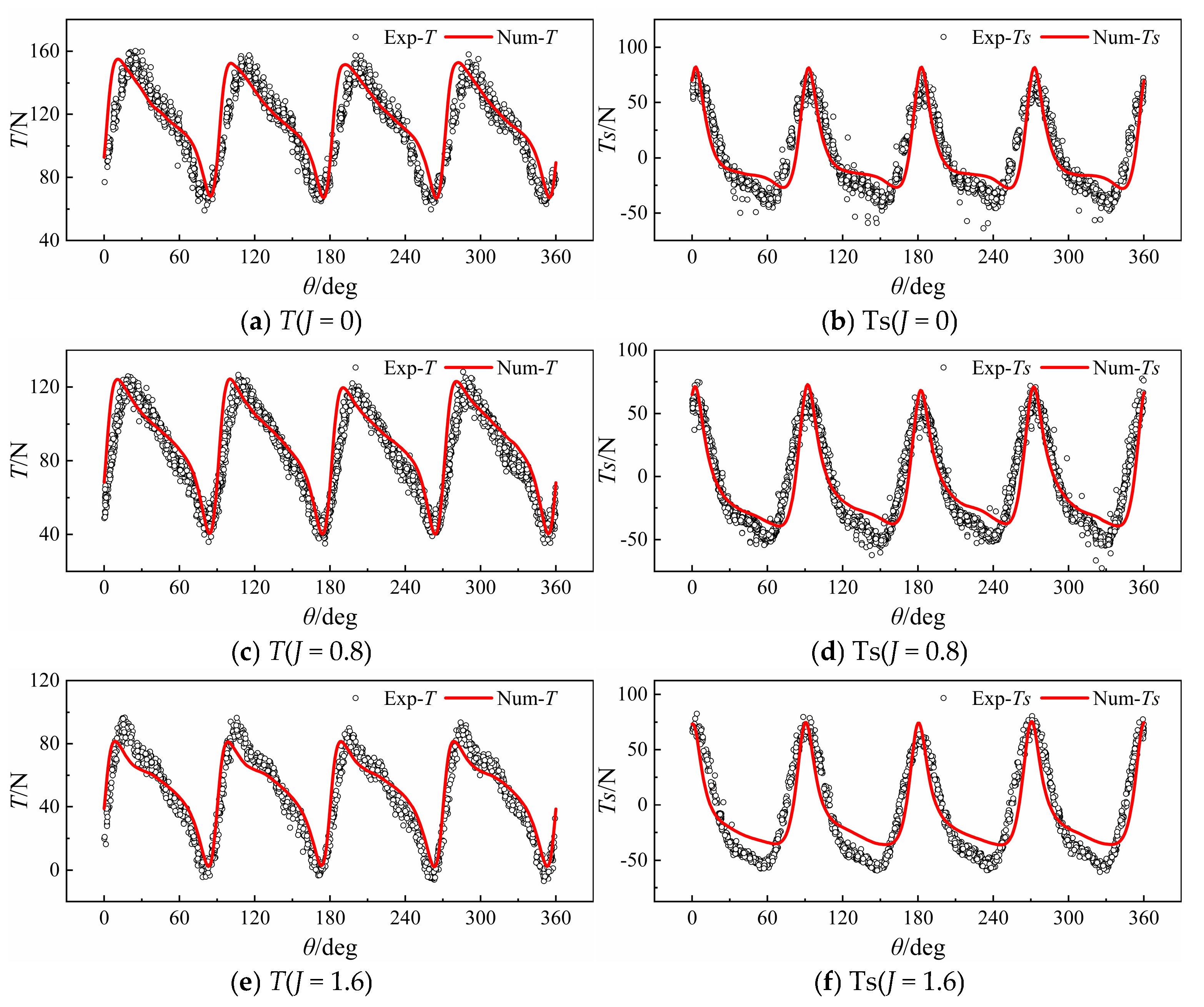

Section 3.2 introduces a planar vector thrust measurement test platform for VSP. Utilizing a towing tank platform, calibration of horizontal static balance and blade-disk dynamic balance was completed. By comparing transient experimental measurements with numerical simulations under varying eccentricity conditions and analyzing flow field characteristics during blade-coupled motion, this study evaluates the feasibility of servo-motor-based synchronized motion control, planar vector thrust measurement, and numerical methods. Finally, unsteady hydrodynamic characteristics of VSP under different eccentricities and advance coefficients are systematically summarized.

4. Conclusions

This study targets the unsteady hydrodynamics of VSP, focusing on its transient hydrodynamic characteristics during blade coupled motion. Systematic numerical simulations and experimental investigations on VSP hydrodynamic performance were conducted. Based on force analysis during blade coupled motion and nonlinear flow interactions, an unsteady hydrodynamic numerical method was established using publicly available test data. Numerical accuracy was enhanced through the Ω-vortex criterion for vortex-adaptive mesh refinement. Numerically, variation patterns of VSP unsteady transient hydrodynamics with eccentricity were analyzed considering blade motion coupling. Experimentally, a VSP plane-vector-thrust measurement platform was developed. The feasibility of servo-motor-based blade synchronous motion control, thrust measurement, and numerical methods was evaluated, with further analysis of VSP unsteady transient hydrodynamic characteristics. The main conclusions follow:

(1) Based on the coupled motion characteristics of steady revolution and unsteady rotation in VSP cycloidal propellers, unsteady hydrodynamic features during large attack angle variations were investigated. A hydrodynamic numerical method was established, combining vortex identification with adaptive meshing according to VSP unsteady flow characteristics, enhancing computational accuracy.

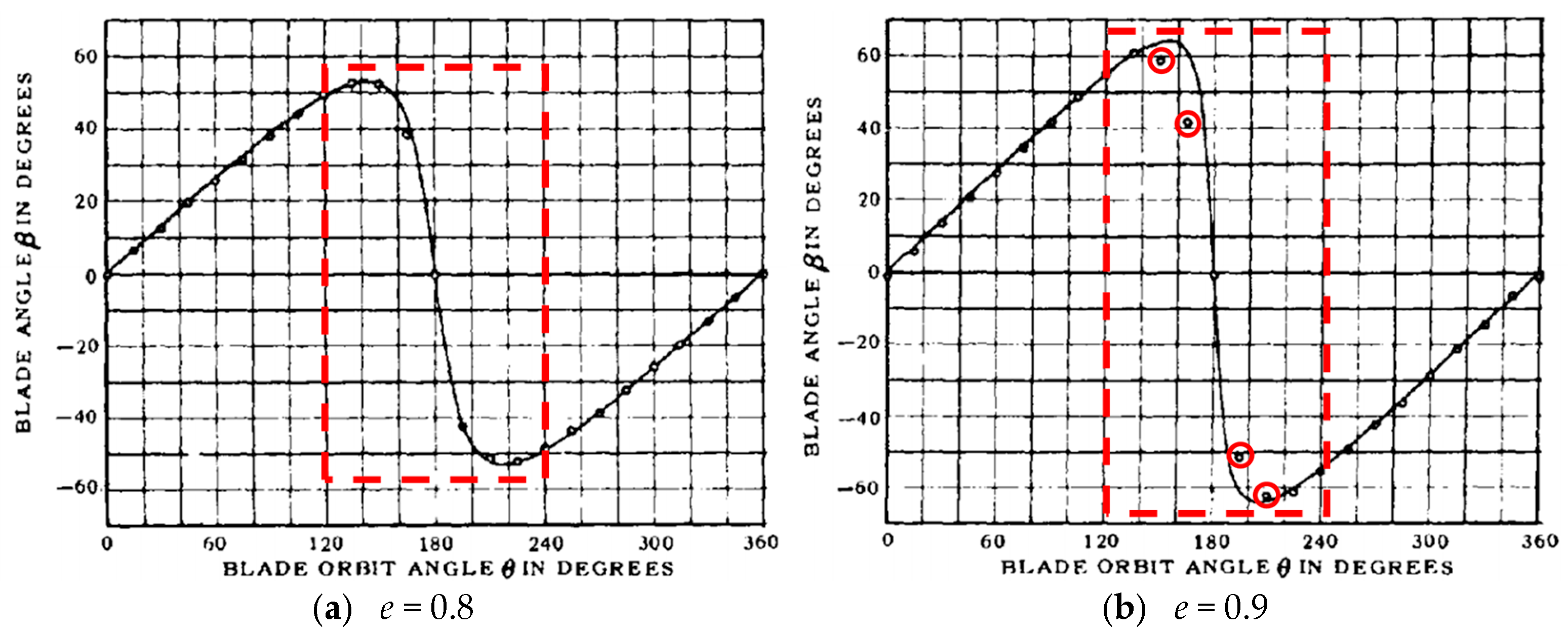

(2) As eccentricity increases under the “chord-normal intersection” motion strategy, peak blade rotation angular velocity rises sharply, intensifying unsteady effects and causing nonlinear growth in VSP hydrodynamic pulsation amplitudes. At constant revolution, higher eccentricity significantly increases rotation power’s proportion to total power, becoming the key factor limiting propulsion efficiency.

(3) VSP transient hydrodynamic calculations and experimental measurements reveal that side thrust exhibits periodic nonlinear positive/negative variations with blade deflection angles. This results in periodic deflection of synthesized plane-vector thrust within specific angular ranges, accompanied by transient negative thrust intervals at high advance coefficients, necessitating hydrodynamic pulsation optimization.

(4) For side thrust coefficient nonlinearity with increasing advance coefficient, flow separation during rapid blade flipping near eccentricity control points—amplified by coupled separated flow and shed vortices—is identified as the primary cause of asymmetric flow distribution driving nonlinear side thrust variations.

(5) Mutual verification of VSP synchronous motion control systems and transient hydrodynamic measurement/numerical methods was achieved through experimental and simulated data. Future work will focus on hydrodynamic optimization of coupled blade motion strategies, though test platform stability requires enhancement.