Evaluation of Thermal and Mechanical Properties of Foamed Phosphogypsum-Based Cementitious Materials for Well Cementing in Hydrate Reservoirs

Abstract

1. Introduction

2. Experimental Work

2.1. Experimental Materials

2.2. Experimental Methods

2.2.1. Porosity

2.2.2. Thermal Conductivity

2.2.3. Compressive Strength

2.3. Experimental Results

3. Theoretical Work

3.1. Thermal Conductivity Model

- (1)

- (2)

- As the preparation technology of foamed PGCs includes the sample drying process [9], the residual water in the composite cementitious material is neglected in this work.

- (3)

3.2. Compressive Strength Model

3.3. Workflow of Theoretical Models

4. Results and Discussion

4.1. Model Validation against Experimental Results

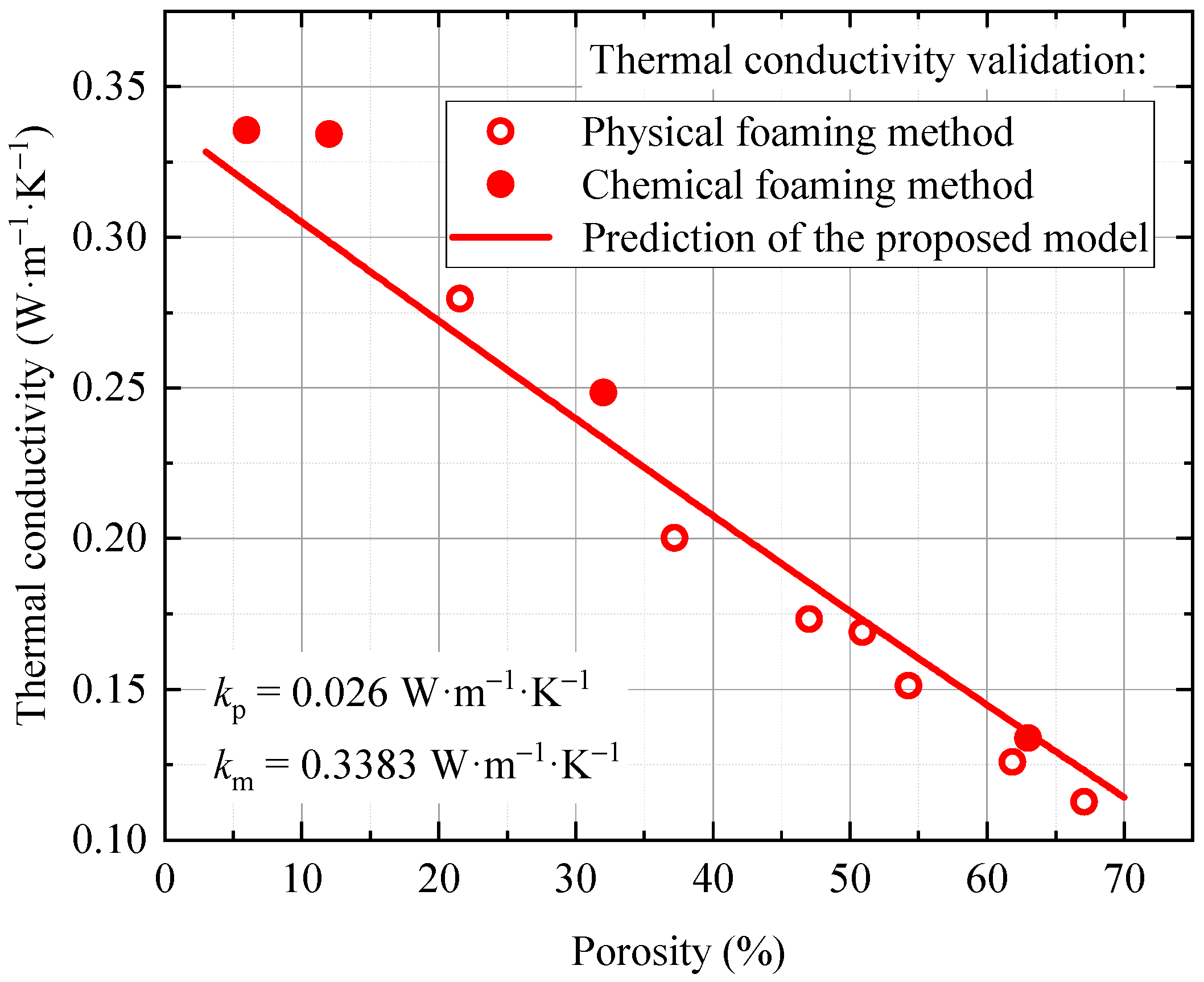

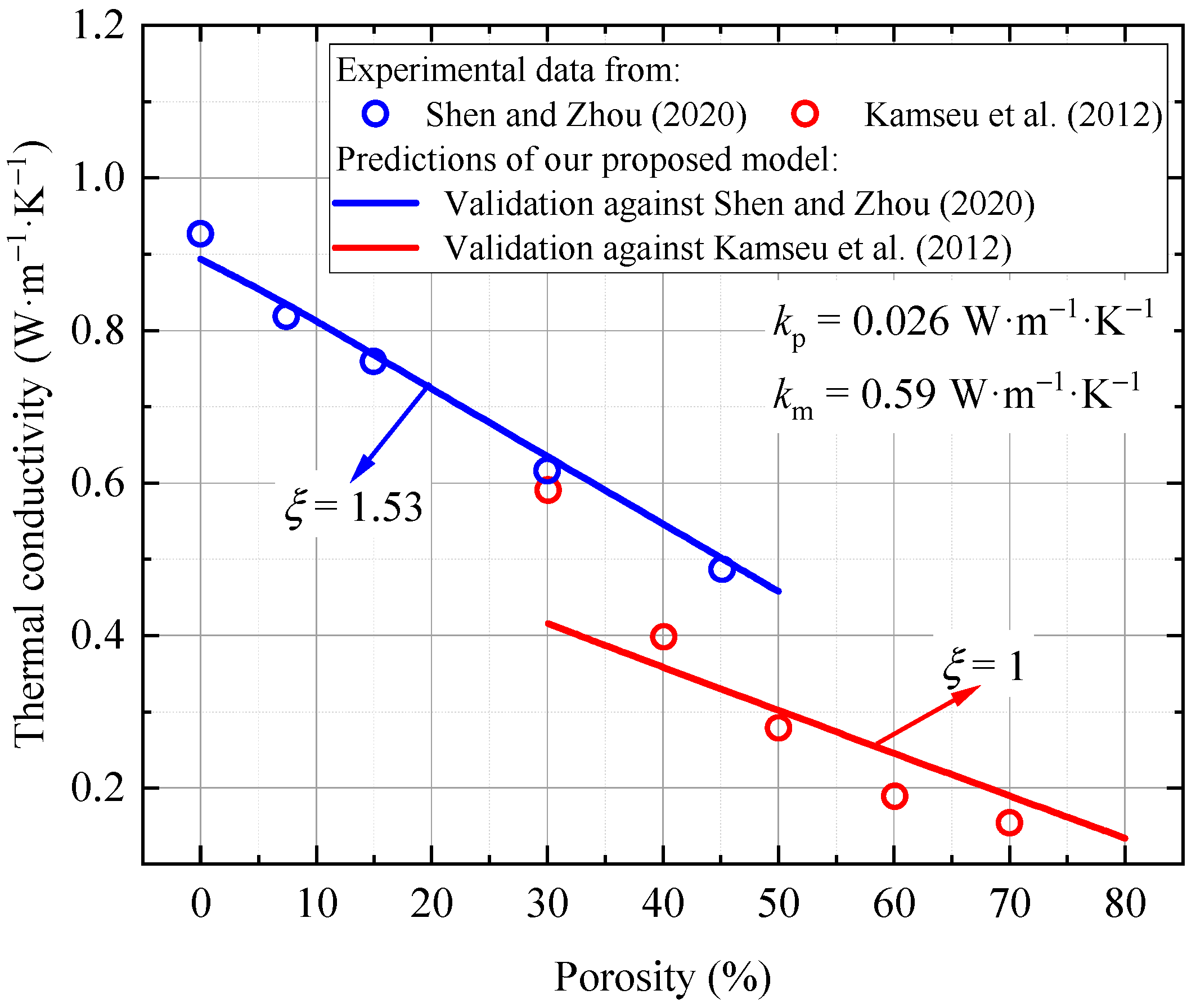

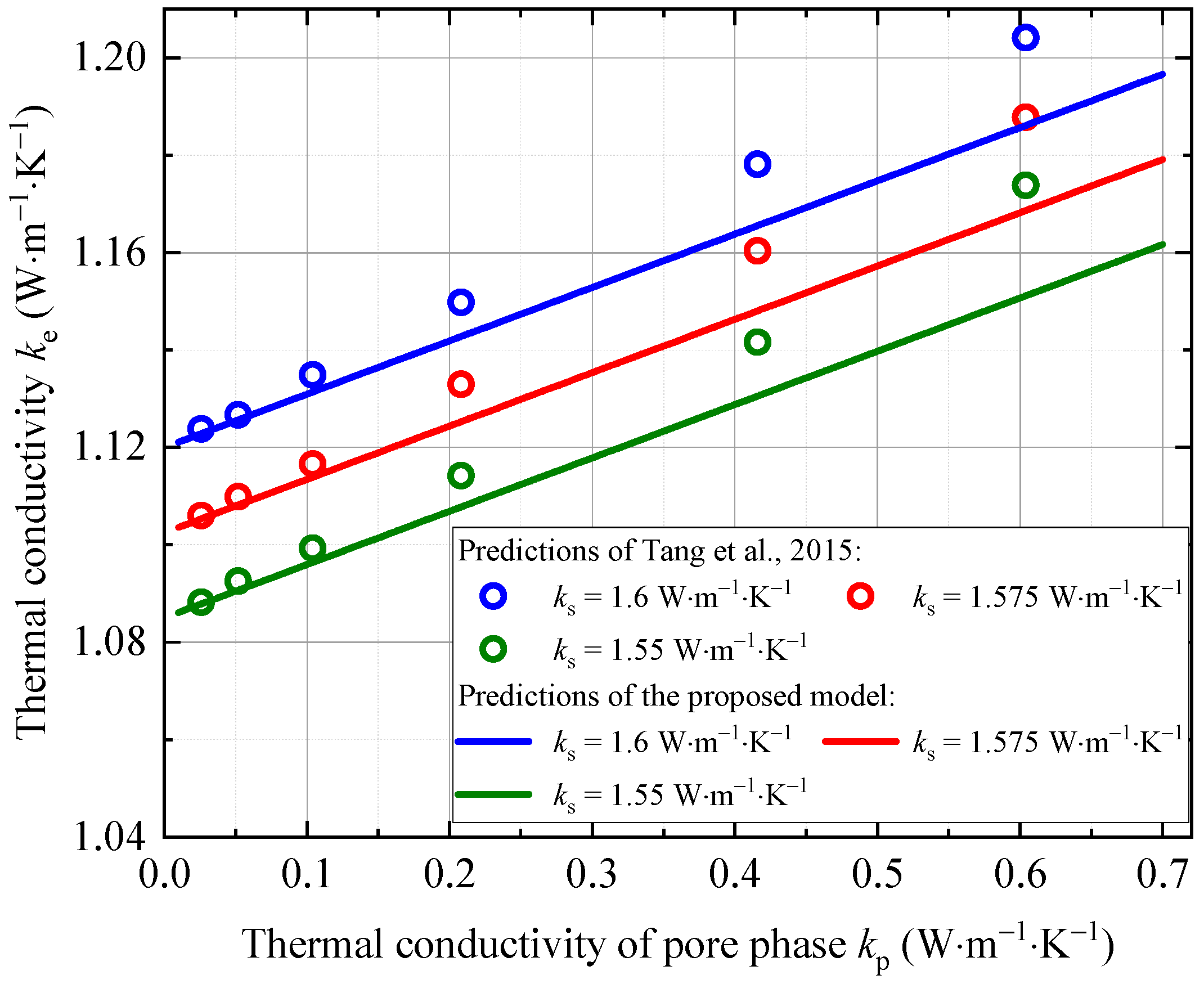

4.1.1. Validation of Thermal Conductivity

4.1.2. Validation of Compressive Strength

4.2. Overall Performance Index Evaluation

4.3. Advantages and Limitations

5. Conclusions

- (1)

- The predicted results of the derived thermal conductivity model of foamed PGCs for well cementing in NGH reservoirs are more accurate in comparison with previous fractal models because the tortuosity of the pores in foamed PGCs is taken into account.

- (2)

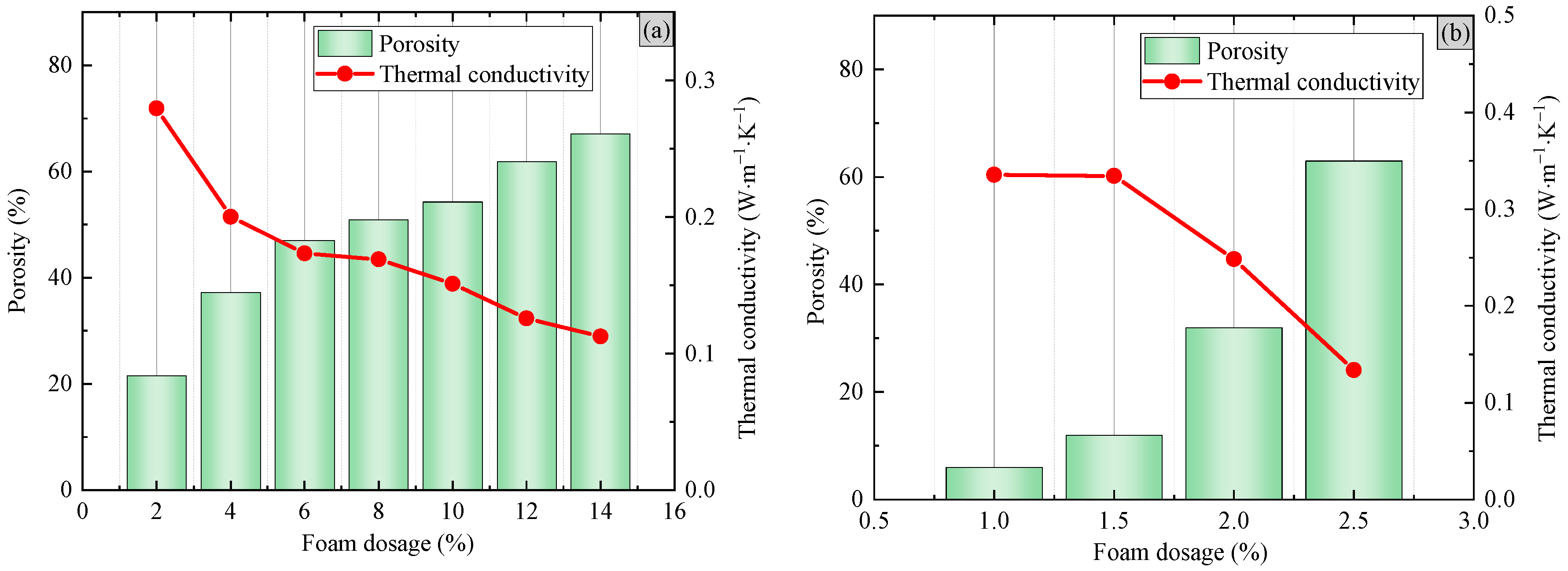

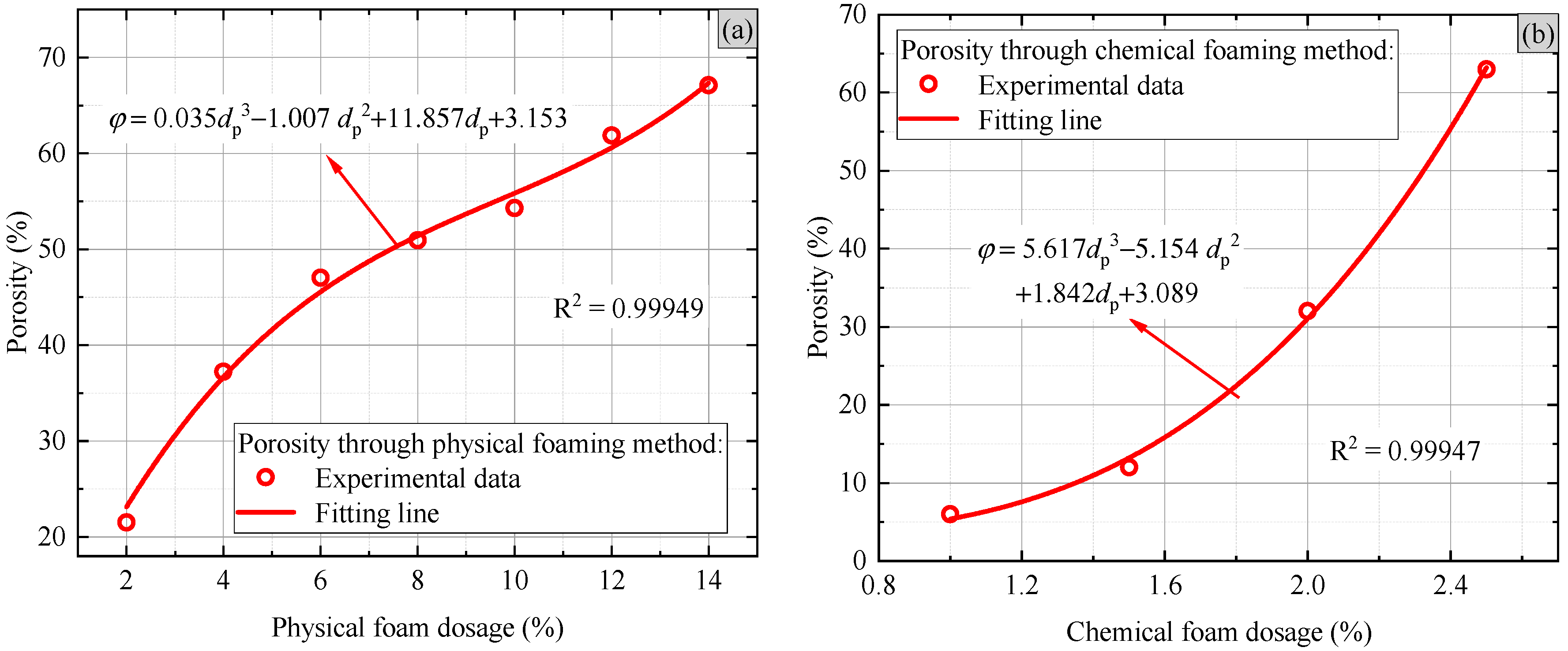

- As the foam dosage increases, the porosity increases. Under identical dosage conditions, the chemical foaming method is more effective than the physical foaming method, leading to larger porosity. To be specific, when the porosity of foamed PGCs increases up to about 65%, the dosage of the chemical foaming agent is only about 2.4%; however, that of the physical foaming agent is about 14%. Nevertheless, the chemical foaming method is more uncontrollable, which tends to generate aggregated and connected pores.

- (3)

- Affected by increasing porosity, the mechanical properties of foamed PGCs deteriorate rapidly in the early stage and the deterioration rate slows down gradually, but the temperature control performance steadily enhances. Thus, the mechanical properties and the temperature control performance of foamed PGCs for well cementing in NGH reservoirs can be described as a competitive system. Additionally, foamed PGCs for welling cement are expected to have larger compressive strength and lower thermal conductivity in NGH exploitation to enhance wellbore stability and prevent gas channeling.

- (4)

- For general foamed PGCs for well cementing, the best overall performance corresponds with porosity φ = 8% (dp = 0.424%, dc = 1.229%). And in deep ocean work confronted with high pressure, the best porosity for foamed PGCs is φ = 5% (dp = 0.158%, dc = 0.950%). In addition, for foamed PGCs for well cementing in formations with poor thermal stability, the best porosity is φ = 65% (dp = 13.282%, dc = 2.521%).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Latin symbols | |

| a | Radius fluctuation amplitude (dimensionless) |

| A | Maximum strength-developing capacity of the cement (MPa) |

| Ac | Cross-sectional area of the REV in porous composite cementitious material (μm2) |

| B | Water sensitivity of cement (dimensionless) |

| c | Cement content ratio (dimensionless) |

| Cc | Normalized 28 d compressive strength (dimensionless) |

| Ct | Inverse membership degree parameter of normalized thermal conductivity (dimensionless) |

| d | Pore diameter (μm) |

| dc | Chemical foam dosage (%) |

| dp | Physical foam dosage (%) |

| Df | Pore fractal dimension (dimensionless) |

| DT | Tortuosity fractal dimension of pores (dimensionless) |

| fc′ | Compressive strength (MPa) |

| m | Mass of PGC without foaming agent (kg) |

| M | Absolute dry mass of test sample (kg) |

| ke | Thermal conductivity of porous composite cementitious material (W·m−1·K−1) |

| km | Thermal conductivity of the matrix phase (W·m−1·K−1) |

| kp | Thermal conductivity of the pore phase (W·m−1·K−1) |

| L0 | Characteristic length of composite cementitious material REV (μm) |

| m | Empirical parameter (m3/kg) |

| Rm | Total thermal resistance of the matrix phase (K·W−1) |

| Rp | Total thermal resistance of the pore phase (K·W−1) |

| Rt | Total thermal resistance of composite cementitious material (K·W−1) |

| v | Volume of PGC without foaming agent (m3) |

| V | Volume of the sample (m3) |

| w/c | Water–cement ratio (Dimensionless) |

| Greek symbols | |

| γ | Experimental parameter (dimensionless) |

| λc | Weighting parameter of mechanical properties (dimensionless) |

| λt | Weighting parameter of temperature control performance (dimensionless) |

| ξ | Correction parameter considering other additives (dimensionless) |

| ρs | Density of base solid material (kg/m3) |

| τ | Overall performance index (dimensionless) |

| φ | Porosity of composite cementitious material (dimensionless) |

| Subscript | |

| max | Maximum value |

| min | Minimum value |

Appendix A. Derivations of Thermal Resistances

References

- Dai, S.; Santamarina, J.C.; Waite, W.F.; Kneafsey, T.J. Hydrate morphology: Physical properties of sands with patchy hydrate saturation. J. Geophys. Res. Solid Earth 2012, 117, B11205. [Google Scholar] [CrossRef]

- Sloan, E.D. Fundamental principles and applications of natural gas hydrates. Nature 2003, 426, 353–359. [Google Scholar] [CrossRef]

- Cui, Y.; Lu, C.; Wu, M.; Peng, Y.; Yao, Y.; Luo, W. Review of exploration and production technology of natural gas hydrate. Adv. Geo-Energy Res. 2018, 2, 53–62. [Google Scholar] [CrossRef]

- Wang, X.; Liu, D.; Sun, B.; Liu, S.; Wang, Z.; Gao, Y. Investigation of multi-field coupling mechanisms during well cement through gas hydrate layer in horizontal well. Constr. Build. Mater. 2023, 407, 133505. [Google Scholar] [CrossRef]

- Zhang, W.; Liang, J.; Wan, Z.; Su, P.; Huang, W.; Wang, L.; Lin, L. Dynamic accumulation of gas hydrates associated with the channel-levee system in the Shenhu area, northern South China sea. Mar. Pet. Geol. 2020, 117, 104354. [Google Scholar] [CrossRef]

- Hua, S.; Wang, K.; Yao, X. Developing high performance phosphogypsum-based cementitious materials for oil-well cementing through a step-by-step optimization method. Cem. Concr. Compos. 2016, 72, 299–308. [Google Scholar] [CrossRef]

- Da Silva, G.A.; Kulay, L.A. Environmental performance comparison of wet and thermal routes for phosphate fertilizer production using LCA—A brazilian experience. J. Clean. Prod. 2005, 13, 1321–1325. [Google Scholar] [CrossRef]

- Geraldo, R.H.; Costa, A.R.D.; Kanai, J.; Silva, J.S.; Souza, J.D.; Andrade, H.M.C.; Gonçalves, J.P.; Fontanini, P.S.P.; Camarini, G. Calcination parameters on phosphogypsum waste recycling. Constr. Build. Mater. 2020, 256, 119406. [Google Scholar] [CrossRef]

- Chen, M.; Liu, P.; Kong, D.; Wang, Y.; Wang, J.; Huang, Y.; Yu, K.; Wu, N. Influencing factors of mechanical and thermal conductivity of foamed phosphogypsum-based composite cementitious materials. Constr. Build. Mater. 2022, 346, 128462. [Google Scholar] [CrossRef]

- Zhou, J.; Li, X.; Zhao, Y.; Shu, Z.; Wang, Y.; Zhang, Y.; Shen, X. Preparation of paper-free and fiber-free plasterboard with high strength using phosphogypsum. Constr. Build. Mater. 2020, 243, 118091. [Google Scholar] [CrossRef]

- Ding, C.; Sun, T.; Shui, Z.; Xie, Y.; Ye, Z. Physical properties, strength, and impurities stability of phosphogypsum-based cold-bonded aggregates. Constr. Build. Mater. 2022, 331, 127307. [Google Scholar] [CrossRef]

- Zhou, J.; Gao, H.; Shu, Z.; Wang, Y.; Yan, C. Utilization of waste phosphogypsum to prepare non-fired bricks by a novel hydration–recrystallization process. Constr. Build. Mater. 2012, 34, 114–119. [Google Scholar] [CrossRef]

- Singh, M.; Garg, M. Phosphogypsum—Fly ash cementitious binder—Its hydration and strength development. Cem. Concr. Res. 1995, 25, 752–758. [Google Scholar] [CrossRef]

- Hermawan; Djayaprabha, H.S.; Nguyen, H.A. Utilizing phosphogypsum waste to improve the mechanical and durability performances of cement-free structural mortar containing ground granulated blast furnace slag and calcium oxide. J. Build. Eng. 2023, 72, 106557. [Google Scholar] [CrossRef]

- Zhang, L.; Mo, K.H.; Yap, S.P.; Gencel, O.; Ling, T.C. Effect of fibers addition on mechanical properties of eco-friendly phosphogypsum-based composite at high temperatures. J. Build. Eng. 2022, 61, 105247. [Google Scholar] [CrossRef]

- Kacimi, L.; Simon-Masseron, A.; Ghomari, A.; Derriche, Z. Reduction of clinkerization temperature by using phosphogypsum. J. Hazard. Mater. 2006, 137, 129–137. [Google Scholar] [CrossRef] [PubMed]

- Calderón-Morales, B.R.S.; García-Martínez, A.; Pineda, P.; García-Tenório, R. Valorization of phosphogypsum in cement-based materials: Limits and potential in eco-efficient construction. J. Build. Eng. 2021, 44, 102506. [Google Scholar] [CrossRef]

- Meskini, S.; Samdi, A.; Ejjaouani, H.; Remmal, T. Valorization of phosphogypsum as a road material: Stabilizing effect of fly ash and lime additives on strength and durability. J. Clean. Prod. 2021, 323, 129161. [Google Scholar] [CrossRef]

- Meskini, S.; Remmal, T.; Ejjaouani, H.; Samdi, A. Formulation and optimization of a phosphogypsum—Fly ash—Lime composite for road construction: A statistical mixture design approach. Constr. Build. Mater. 2022, 315, 125786. [Google Scholar] [CrossRef]

- Pereira, V.M.; Geraldo, R.H.; Cruz, T.A.M.; Camarini, G. Valorization of industrial by-product: Phosphogypsum recycling as green binding material. Clean. Eng. Technol. 2021, 5, 100310. [Google Scholar] [CrossRef]

- Zhang, L.; Cao, P.; Radha, K.C. Evaluation of rock strength criteria for wellbore stability analysis. Int. J. Rock Mech. Min. Sci. 2010, 47, 1304–1316. [Google Scholar] [CrossRef]

- Ma, X.; Jiang, Y.; Yan, P.; Luan, H.; Wang, C.; Shan, Q.; Cheng, X. A review on submarine geological risks and secondary disaster issues during natural gas hydrate depressurization production. J. Mar. Sci. Eng. 2024, 12, 840. [Google Scholar] [CrossRef]

- Feng, L.; Jin, K.; Wang, H. Research on the thermal conductivity and water resistance of foamed phosphogypsum. Coatings 2021, 11, 802. [Google Scholar] [CrossRef]

- Wang, Q.; Jia, R. A novel gypsum-based self-leveling mortar produced by phosphorus building gypsum. Constr. Build. Mater. 2019, 226, 11–20. [Google Scholar] [CrossRef]

- Wang, T.; Gao, X.; Wang, J. Preparation of foamed phosphogypsum lightweight materials by incorporating cementitious additives. Mater. Sci. 2019, 25, 340–347. [Google Scholar] [CrossRef]

- Liao, Y.; Yao, J.; Deng, F.; Li, H.; Wang, K.; Tang, S. Hydration behavior and strength development of supersulfated cement prepared by calcined phosphogypsum and slaked lime. J. Build. Eng. 2023, 80, 108075. [Google Scholar] [CrossRef]

- Xue, Y.; Wang, C.; Chen, Z.; Yang, S.; Chen, L.; Wang, E.; Li, Y. Enhanced cement formation for well completion in gas hydrates reservoirs. Geoenergy Sci. Eng. 2023, 230, 212258. [Google Scholar] [CrossRef]

- Wang, X.; Sun, B.; Gao, Y.; Wang, Z.; Li, H.; Chen, Y. Numerical simulation of the stability of hydrate layer during well cementing in deep-water region. J. Petrol. Sci. Eng. 2019, 176, 893–905. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, R.; Cheng, W.L. Temperature control performance of a spaceborne PTC heating system: Dynamic modeling and parametric analysis. Therm. Sci. Eng. Prog. 2023, 44, 102062. [Google Scholar] [CrossRef]

- Tian, T.; Yan, Y.; Hu, Z.; Xu, Y.; Chen, Y.; Shi, J. Utilization of original phosphogypsum for the preparation of foam concrete. Constr. Build. Mater. 2016, 115, 143–152. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. Experimental investigation on the compressive strength of foamed concrete: Effect of curing conditions, cement type, foaming agent and dry density. Constr. Build. Mater. 2018, 165, 735–749. [Google Scholar] [CrossRef]

- Capasso, I.; Pappalardo, L.; Romano, R.A.; Iucolano, F. Foamed gypsum for multipurpose applications in building. Constr. Build. Mater. 2021, 307, 124948. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, X.; Li, X.; Ma, M.; Zhang, Z.; Ji, X. Slurry rheological behaviors and effects on the pore evolution of fly ash/metakaolin-based geopolymer foams in chemical foaming system with high foam content. Constr. Build. Mater. 2023, 379, 131259. [Google Scholar] [CrossRef]

- Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Enhancing the chemical foaming process using superplasticizer in aerated geopolymer concrete. Constr. Build. Mater. 2022, 324, 126535. [Google Scholar] [CrossRef]

- Zheng, T.; Lu, Y.; Luo, S.; Kong, D.; Fu, R. Effect of the phosphogypsum calcination time on the compressive mechanical properties of phosphogypsum-based composite cementitious materials. Mater. Res. Express 2022, 9, 035506. [Google Scholar] [CrossRef]

- GB/T 17669.3-1999[S]; Gypsum Plasters-Determination of Mechanical Properties. The State Bureau of Quality and Technical Supervision: Beijing, China, 1999.

- Xu, X.; Shu, X.; Pei, Q.; Qin, H.; Guo, R.; Wang, X.; Wang, Q. Effects of porosity on the tribological and mechanical properties of oil-impregnated polyimide. Tribol. Int. 2022, 170, 107502. [Google Scholar] [CrossRef]

- GB/T 10294-2008[S]; Thermal Insulation-Determination of Steady-State Thermal Resistance and Related Properties-Guarded Hot Plate Apparatus. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- Lei, G.; Tang, J.; Zhang, L.; Wu, Q.; Li, J. Effective thermal conductivity for hydrate-bearing sediments under stress and local thermal stimulation conditions: A novel analytical model. Energy 2024, 288, 129704. [Google Scholar] [CrossRef]

- Tang, J.; Lei, G.; Li, X.; Zhang, L.; Cheng, W.; Pang, J.; Jiang, G. A novel analytical model of the effective thermal conductivity of porous materials under stress. Fractals 2023, 31, 2340176. [Google Scholar] [CrossRef]

- Liu, S.; Wang, L.; Yu, B. Effect of modified phosphogypsum on the hydration properties of the phosphogypsum-based supersulfated cement. Constr. Build. Mater. 2019, 214, 9–16. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Effect of nano-silica on the hydration and microstructure development of ultra-high performance concrete (UHPC) with a low binder amount. Constr. Build. Mater. 2014, 65, 140–150. [Google Scholar] [CrossRef]

- Hao, Y.; Yang, G.; Liang, K. Development of fly ash and slag based high-strength alkali-activated foam concrete. Cem. Concr. Compos. 2022, 128, 104447. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Huang, M.; Yin, H.; Jiang, K.; Xiao, K.; Tang, S. Influence of different alkali sulfates on the shrinkage, hydration, pore structure, fractal dimension and microstructure of low-heat Portland cement, medium-heat Portland cement and ordinary Portland cement. Fractal Fract. 2021, 5, 79. [Google Scholar] [CrossRef]

- Wang, L.; Zeng, X.; Li, Y.; Yang, H.; Tang, S. Influences of MgO and PVA fiber on the abrasion and cracking resistance, pore structure and fractal features of hydraulic concrete. Fractal Fract. 2022, 6, 674. [Google Scholar] [CrossRef]

- Wang, L.; Huang, Y.; Zhao, F.; Huo, T.; Chen, E.; Tang, S. Comparison between the influence of finely ground phosphorous slag and fly ash on frost resistance, Pore structures and fractal features of hydraulic concrete. Fractal Fract. 2022, 6, 598. [Google Scholar] [CrossRef]

- Zeng, Y.; Ji, B.; Zhang, Y.; Feng, J.; Luo, J.; Wang, M. A fractal model for effective thermal conductivity in complex geothermal media. Front. Earth Sci. 2022, 10, 786290. [Google Scholar] [CrossRef]

- Yang, S.; Liang, M.; Yu, B.; Zou, M. Permeability model for fractal porous media with rough surfaces. Microfluid. Nanofluid. 2015, 18, 1085–1093. [Google Scholar] [CrossRef]

- Yu, B.; Li, J. Some fractal characters of porous media. Fractals 2001, 09, 365–372. [Google Scholar] [CrossRef]

- Al-Raoush, R.; Papadopoulos, A. Representative elementary volume analysis of porous media using X-Ray computed tomography. Powder Technol. 2010, 200, 69–77. [Google Scholar] [CrossRef]

- Yio, M.H.N.; Wong, H.S.; Buenfeld, N.R. Representative elementary volume (REV) of cementitious materials from three-dimensional pore structure analysis. Cem. Concr. Res. 2017, 102, 187–202. [Google Scholar] [CrossRef]

- Lei, G.; Qu, J.; Wu, Q.; Pang, J.; Su, D.; Guan, J.; Lu, C. Theoretical analysis of threshold pressure in tight porous media under stress. Phys. Fluids 2023, 35, 073313. [Google Scholar] [CrossRef]

- Qin, X.; Zhou, Y.; Sasmito, A.P. An effective thermal conductivity model for fractal porous media with rough surfaces. Adv. Geo-Energy Res. 2019, 3, 149–155. [Google Scholar] [CrossRef]

- Wei, W.; Cai, J.; Hu, X.; Han, Q. An Electrical conductivity model for fractal porous media. Geophys. Res. Lett. 2015, 42, 4833–4840. [Google Scholar] [CrossRef]

- Popovics, S.; Ujhelyi, J. Contribution to the concrete strength versus water-cement ratio relationship. J. Mater. Civil. Eng. 2008, 20, 459–463. [Google Scholar] [CrossRef]

- Andersland, O.B.; Ladanyi, B. Frozen Ground Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Kamseu, E.; Nait-Ali, B.; Bignozzi, M.C.; Leonelli, C.; Rossignol, S.; Smith, D.S. Bulk composition and microstructure dependence of effective thermal conductivity of porous inorganic polymer cements. J. Eur. Ceram. Soc. 2012, 32, 1593–1603. [Google Scholar] [CrossRef]

- Shen, Z.; Zhou, H. Predicting effective thermal and elastic properties of cementitious composites containing polydispersed hollow and core-shell micro-particles. Cem. Concr. Compos. 2020, 105, 103439. [Google Scholar] [CrossRef]

- Tang, S.W.; Chen, E.; Shao, H.Y.; Li, Z.J. A fractal approach to determine thermal conductivity in cement pastes. Constr. Build. Mater. 2015, 74, 73–82. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, L.; Zhou, P.; Zhang, Y.; Liu, H. Multi-objective optimization design and test of compound diatomite and basalt fiber asphalt mixture. Materials 2019, 12, 1461. [Google Scholar] [CrossRef]

- Dong, L.; Wu, N.; Zhang, Y.; Liao, H.; Hu, G.; Li, Y. Improved Duncan-Chang model for reconstituted hydrate-bearing clayey silt from the South China Sea. Adv. Geo-Energy Res. 2023, 8, 136–140. [Google Scholar] [CrossRef]

- Hyodo, M.; Yoneda, J.; Yoshimoto, N.; Nakata, Y. Mechanical and dissociation properties of methane hydrate-bearing sand in deep seabed. Soils Found. 2013, 53, 299–314. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, W.; Peng, Y.; Tang, S.; Wang, L.; Shi, Y.; Li, Y.; Wang, Y.; Geng, Z.; Wu, K. Hydration and fractal analysis on low-heat Portland cement pastes using thermodynamics-based methods. Fractal Fract. 2023, 7, 606. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, Y.; He, X.; Su, Y.; Strnadel, B.; Miao, W. Hydration and compressive strength of supersulfated cement with low-activity high alumina ferronickel slag. Cem. Concr. Compos. 2023, 136, 104892. [Google Scholar] [CrossRef]

- Yan, Y.; Tian, L.; Zhao, W.; Lazaro, S.A.M.; Li, X.; Tang, S. Dielectric and mechanical properties of cement pastes incorporated with magnetically aligned reduced graphene oxide. Dev. Built Environ. 2024, 18, 100471. [Google Scholar] [CrossRef]

- Aria Hosseini, S.; Khanniche, S.; Alex Greaney, P.; Romano, G. Universal effective medium theory to predict the thermal conductivity in nanostructured materials. Int. J. Heat Mass Tran. 2022, 183, 122040. [Google Scholar] [CrossRef]

- Berthier, S.; Lafait, J. Effective medium theory: Mathematical determination of the physical solution for the dielectric constant. Opt. Commun. 1980, 33, 303–306. [Google Scholar] [CrossRef]

- Gong, L.; Wang, Y.; Cheng, X.; Zhang, R.; Zhang, H. A novel effective medium theory for modelling the thermal conductivity of porous materials. Int. J. Heat Mass Tran. 2014, 68, 295–298. [Google Scholar] [CrossRef]

- Benazzouk, A.; Douzane, O.; Mezreb, K.; Laidoudi, B.; Quéneudec, M. Thermal conductivity of cement composites containing rubber waste particles: Experimental study and modelling. Constr. Build. Mater. 2008, 22, 573–579. [Google Scholar] [CrossRef]

- Akçaözoğlu, S.; Akçaözoğlu, K.; Atiş, C.D. Thermal Conductivity, Compressive strength and ultrasonic wave velocity of cementitious composite containing waste pet lightweight aggregate (WPLA). Compos. Part B-Eng. 2013, 45, 721–726. [Google Scholar] [CrossRef]

| Cement Strength Grade | Chemical Evaluation Index (%) | Finess (mm) | Setting Time (min) | Flexural Strength (MPa) | Compressive Strength (MPa) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| MgO | SO3 | Loss on Ignition | Cl | Initial Setting Time | Final Setting Time | 3 d | 28 d | 3 d | 28 d | ||

| 42.5 | 5.00 | 3.50 | 5.00 | 0.06 | 0.08 | 45 | 600 | 3.50 | 6.50 | 16.00 | 42.50 |

| CaO | SO3 | Al2O3 | SiO2 | P2O5 | Fe2O3 | Na2O | K2O | TiO2 | SrO | Cl | MgO | Other |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5.22 | 1.24 | 36.87 | 49.10 | 0.40 | 3.13 | 0.34 | 0.98 | 1.83 | 0.03 | 0.05 | 0.68 | 0.13 |

| Sample | HPG (1) (%) | FA (2) (%) | Quicklime (%) | Cement (%) | Water–Cement Ratio | Foaming Agent (%) | |

|---|---|---|---|---|---|---|---|

| Physical foaming method | P-1 | 60 | 30 | 8 | 70 | 0.300 | 2 |

| P-2 | 4 | ||||||

| P-3 | 6 | ||||||

| P-4 | 8 | ||||||

| P-5 | 10 | ||||||

| P-6 | 12 | ||||||

| P-7 | 14 | ||||||

| Chemical foaming method | C-1 | 60 | 30 | 8 | 70 | 0.300 | 1 |

| C-2 | 1.5 | ||||||

| C-3 | 2 | ||||||

| C-4 | 2.5 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, J.; Zhao, Y.; Cheng, W.; Liu, T.; Yang, G.; Chen, M.; Lei, G.; Xu, J.; Huang, Y. Evaluation of Thermal and Mechanical Properties of Foamed Phosphogypsum-Based Cementitious Materials for Well Cementing in Hydrate Reservoirs. J. Mar. Sci. Eng. 2024, 12, 1056. https://doi.org/10.3390/jmse12071056

Tang J, Zhao Y, Cheng W, Liu T, Yang G, Chen M, Lei G, Xu J, Huang Y. Evaluation of Thermal and Mechanical Properties of Foamed Phosphogypsum-Based Cementitious Materials for Well Cementing in Hydrate Reservoirs. Journal of Marine Science and Engineering. 2024; 12(7):1056. https://doi.org/10.3390/jmse12071056

Chicago/Turabian StyleTang, Jiadi, Yusheng Zhao, Wan Cheng, Tianle Liu, Guokun Yang, Mingsheng Chen, Gang Lei, Jian Xu, and Yongning Huang. 2024. "Evaluation of Thermal and Mechanical Properties of Foamed Phosphogypsum-Based Cementitious Materials for Well Cementing in Hydrate Reservoirs" Journal of Marine Science and Engineering 12, no. 7: 1056. https://doi.org/10.3390/jmse12071056

APA StyleTang, J., Zhao, Y., Cheng, W., Liu, T., Yang, G., Chen, M., Lei, G., Xu, J., & Huang, Y. (2024). Evaluation of Thermal and Mechanical Properties of Foamed Phosphogypsum-Based Cementitious Materials for Well Cementing in Hydrate Reservoirs. Journal of Marine Science and Engineering, 12(7), 1056. https://doi.org/10.3390/jmse12071056