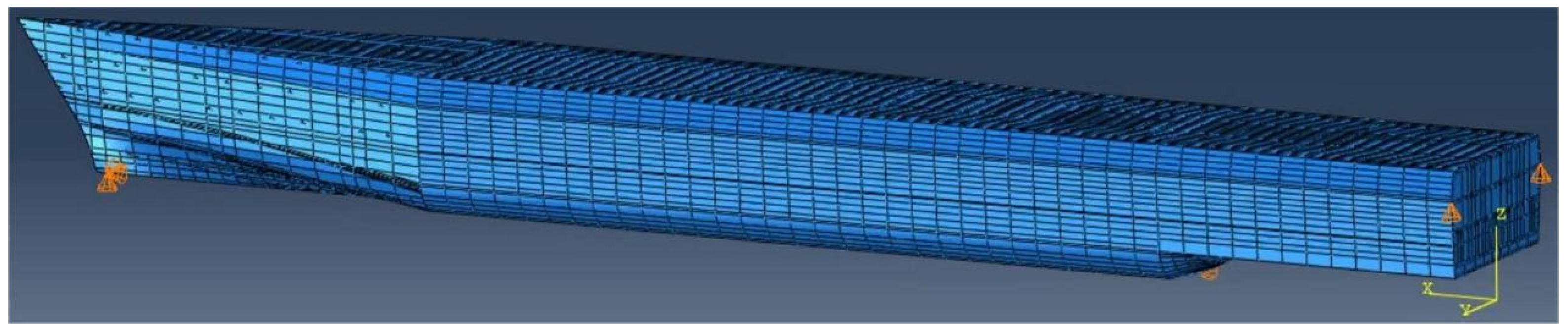

This research proposes a novel design methodology for the ship hull girder of its targeted real ship, addressing the aforementioned inherent shortcomings of existing methods. This new design approach presents a full-scale FE beam model for its targeted real ship hull. Not only can this model be used to directly analyze the global longitudinal structural responses of the real ship, but it also provides direct guidance for the design of hydroelastic experimental ship hull girders that strictly satisfy Equation (6). Furthermore, this new design methodology could lead to an upgrade of the classical ship structural estimation method, aligning the upgraded method with the modern development trends in computational ship structural mechanics.

3.1. Design of Ship Hull Girder Components

The proposed new ship hull girder design method is founded on the basic premise that the targeted real ship hull can be modeled as a system of Euler–Bernoulli beams. By setting

L1 = L2 and

λ = 1 in Equation (6), the corresponding design principle for the full-scale ship hull girder of the real ship hull is

As mentioned in

Section 2.3, achieving strict similarity in structural rigidity is challenging [

33,

34,

35,

36,

37,

38,

39,

40,

41,

42,

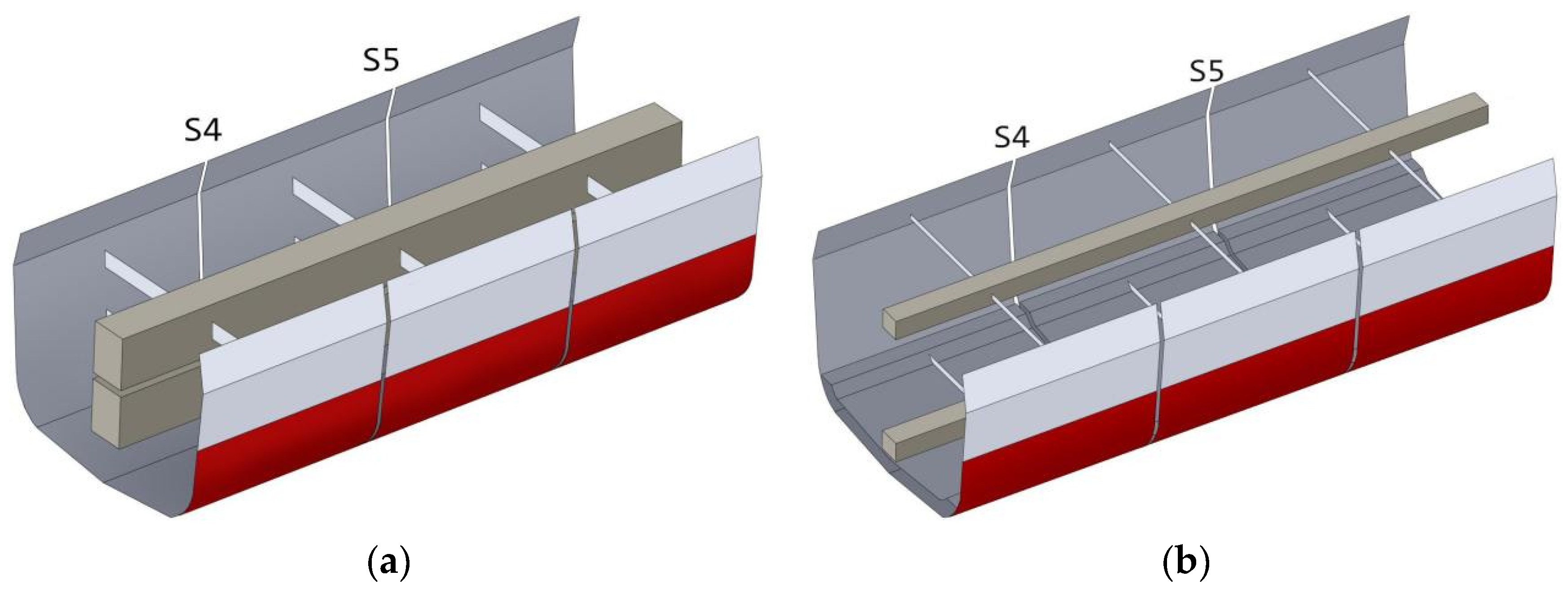

43]. Designing the cross-sectional rigidity of a full-scale hull girder for the real ship using existing methods is more difficult than designing a scaled hull girder for the same real ship. For a scaled hull girder, the cross-sectional rigidity is scaled to be much smaller, which significantly reduces the difficulty of the design task. This research proposes a new hull girder design approach that combines the Euler–Bernoulli beam theory with the FE modeling techniques and employs a two-step strategy to strictly meet the design principles outlined in Equation (7). The resulting full-scale hull girder is essentially an FE model system, primarily composed of deformable hull girders and undeformable segmented outer ship shells, akin to the familiar segmented hydroelastic ship model. These undeformable segmented outer ship shells serve as the medium for applying external loading to the ship, causing the hull girders to deform as a result of the external loading on the shells.

The first step of the new design approach is to satisfy the mass density requirement specified in Equation (7) while distinguishing between the masses of the ship structure and the cargo. With reference to Equation (7), the mass per unit volume

ρ2(

x) and area

A2(

x) of the cross-section

x of the full-scale ship hull girder can be determined as follows:

where

ρ1i(

x) denotes the mass per unit volume of the

i-th ship structural material on cross-section

x of the targeted real ship hull and

N(

x) is the number of structural components on cross-section

x. Equation (8) ensures that the newly designed ship hull girder corresponds solely to the targeted real ship structures, without accounting for the cargo. The vertical position of the COG of

A2(

x), denoted as

ZGs2(

x), must be equal to

ZGs1(

x), as required by Equation (7). This requirement will be addressed later, once the exact geometry of

A2(

x) is determined.

The second step of the proposed method is to satisfy the cross-sectional rigidity requirement specified in Equation (7). If the full-scale beam is assumed to be a single rectangular beam, as is the case with existing methods, then the cross-section

x of the beam model in question satisfies the following equations:

where

b(

x) and

h(

x) are the width and the height of the cross-section of the single rectangular beam, respectively. Equation (9) is thus in fact an over-determined system for the height

h(

x). Substituting the first equation into the second equation of Equation (9) yields

The first equation of Equation (10) may not be compatible with the second, which poses a central problem for the existing methods. This issue stems from the stereotypical assumption that the ship hull girder must always be a single rectangular beam. The proposed new design approach, also within the Euler–Bernoulli beam theoretic framework, allows the ship hull girder system to be composed of multiple beams along the vertical direction of the cross-section for the targeted real ship. The sub-cross-section of each beam component can take any one of the following common shapes: a triangle, a rectangle, or a trapezium. For any type of real ship, this newly proposed hull girder system of multiple beams always exists: the interior region of each cross-section (from the outer boundary of the cross-section inwards, excluding the outer boundary of the upper deck) is guaranteed to provide sufficient space to accommodate these multiple beams with desired geometrical shapes, provided the cross-section is a hollow, composite plate structure, regardless of its structural complexity. Note that the number of the beam components should not exceed 3, considering that the effect of the local response of the final full-scale hull girder system should be kept negligible.

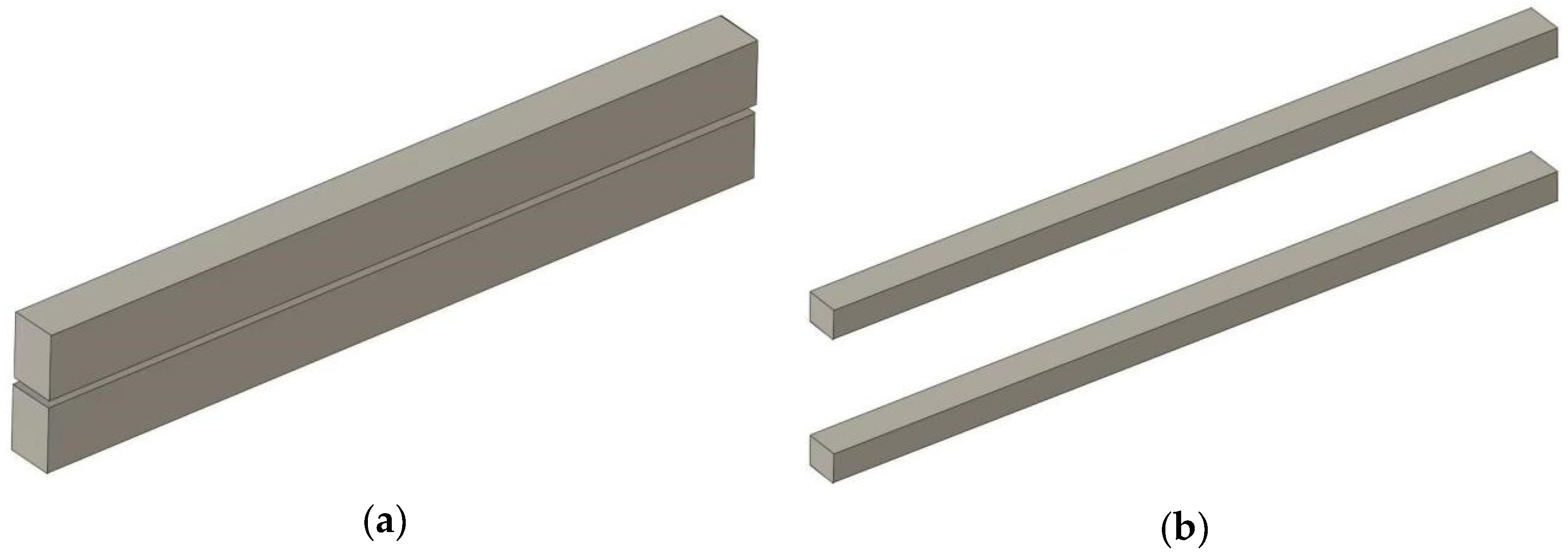

To illustrate, we first present a two-rectangular-beam hull girder system using the proposed hull girder design methodology. The upper beam is labeled

U, and the lower beam is labeled

D. The width and height of the upper beam are denoted as

wU(

x) and

hU(

x), respectively, while those of the lower beam are denoted as

wD(

x) and

hD(

x), respectively. If such a two-rectangular-beam system exists, then it must be determined by the following equations:

where

IU0(

x) and

ID0(

x) denote the second moments of area of the cross-sections relative to their respective neutral axes for the upper beam

U and the lower beam

D, respectively.

dU(

x) and

dD(

x) denote the parallel distances between the neutral axis of the entire cross-section and the neutral axes of the upper and lower beam cross-sections, respectively. Equation (11) is thus an under-determined system. One feasible approach to obtain a unique solution from Equation (11) is to introduce the following three additional equations:

where

β(

x),

αU(

x), and

αD(

x) are coefficients that determine the detailed cross-sectional geometry of the two beams. The values of these three coefficients are specified by the users. In general, Equations (11) and (12) provide a unique solution for a two-rectangular-beam system, which serves as the full-scale ship hull girder for many kinds of targeted real ships.

A general composite hull girder system design can be obtained by generalizing the previously introduced two-rectangular-beam system design. For generality, consider a cross-section extracted from the bow region of a real ship, which has a shape that is a smooth combination of a triangle and a bulb. The bottleneck-shaped smooth transition region is assumed to be quite narrow. The geometrical characteristics of this chosen cross-section are representative of the bow region for ships with a pronounced bulbous bow structure. Similar to the meshing technique in FEM, the upper single beam Ω is assumed to be an isosceles trapezoidal beam, while the lower beams form a double-isosceles-trapezoidal-beam system, ensuring a satisfactory hull girder cross-section model of the chosen real ship’s overall cross-section. The upper and lower isosceles trapeziums of the lower beam system are denoted as

B and C, respectively. The distances from the top side of the overall cross-section to the upper and lower parallel sides of Ω are denoted as d

Ωu and d

Ωl, respectively, where the subscripts

u and

l denote the upper and lower parallel sides, respectively. The distances from the bottom base line of the overall cross-section to the upper and lower parallel sides of

B are denoted as

dBu and

dBl, respectively, with the corresponding distances for

C denoted as

dCu and

dCl. The design principles are then precisely expressed by the following equations:

where symbol

A denotes the area, symbol

z denotes the vertical position of the neutral axis, symbol

I denotes the second moment of area, and symbol

T denotes the parallel distances between the neutral axis of the overall cross-section of the real ship and the neutral axis of the sub-cross-section of a beam component. The subscript 0 refers to the neutral axis of the sub-cross-section of a beam component. The meaning of any term in Equation (13) can be directly and easily understood by the readers; for example, the composite symbol

AΩ denotes the cross-sectional area of beam Ω. To ensure that Equation (13) yields a unique solution, the following complementary equations should first be added:

which in fact just explicitly define every term in Equation (13) for the chosen shapes of the beam components. The composite symbol

hΩe denotes the vertical distance from the COG of beam Ω to its own upper parallel side; h

Be, the vertical distance for beam

B; and

hCe, the vertical distance for beam

C.

H denotes the overall height of the overall cross-section, which is a known parameter. The symbol

W in Equation (14) denotes the length of any parallel side of a trapezium. Then, the meaning of any term in Equation (14) can accordingly be directly inferred by the readers; for example,

WΩu and

WΩl denote the lengths of the upper and lower parallel sides of beam Ω, respectively. To complete Equations (13) and (14), the following constraint equations are required:

where

R denotes the length of the uppermost base of the overall cross-section and

θ denotes the angle between the uppermost base and its neighboring leg.

R and

θ are known parameters of the overall cross-section. The symbol

α denotes the angle between the leg and the longer parallel side of an isosceles trapezoidal beam component.

αΩ,

αB, and

αC are thus also known parameters for those isosceles trapeziums, adjusted by users during the design or solution processes. The length of each quantity associated with the

W-symbol in Equation (15) is then prescribed by the local largest width of the overall cross-section, denoted by each

Q-symbol-associated quantity, which is known a priori. This ensures that the finally obtained beam system is positioned totally within the geometrical boundary of the overall cross-section. It is evident that by combining Equations (13)–(15), a unique design of the composite beam system can be achieved, which precisely meets the design principles expressed by Equation (7).

Equations (13)–(15) are recommended to be solved using the “progressive searching” method rather than seeking a purely analytical solution. This recommendation stems from the first six inequalities in Equation (15), each of which describes the general characteristics of its corresponding W-symbol quantity. The progressive searching method provides users with the flexibility to apply these six inequalities to various overall cross-sections that may be encountered. Once the W-symbol quantities, along with the corresponding d-symbol quantities, are found to satisfy the remaining equations within the united equations, the desired solution for the sub-cross-sections corresponding to the beam components is finally obtained.

Note that, even for the simpler case of a two-rectangular-beam system described by Equations (11) and (12), a progressive searching approach is also necessary. Users have to experiment with different values for αU, αD, and β to find a solution for the two-rectangular-beam system. This case is considered simpler because, once the three basic parameters are suitably selected, dU and dD can be analytically solved using Equations (11) and (12). Consequently, by integrating the design techniques for both a two-rectangular-beam model and a more complex composite beam model, a comprehensive full-scale ship hull girder system can be developed for any type of targeted real ship.

It has been further observed that both the two-rectangular-beam and the composite beam cases discussed above serve as examples within a general ship hull girder design framework. The primary design procedures are as follows: (1) presenting the expressions of the structural requirements, (2) providing interpretations for each term in the first procedure, and (3) providing supplementary geometrical constraints. Note that the deck is not considered part of the boundary of the original ship cross-section, which implies that the resulting beam component may extend beyond the upper deck, as will be detailed in subsequent sections of this research. The generalized design framework thus affords designers the greatest flexibility in establishing an appropriate ship hull girder system. The solution procedures for the composite hull girder system are demonstrated in

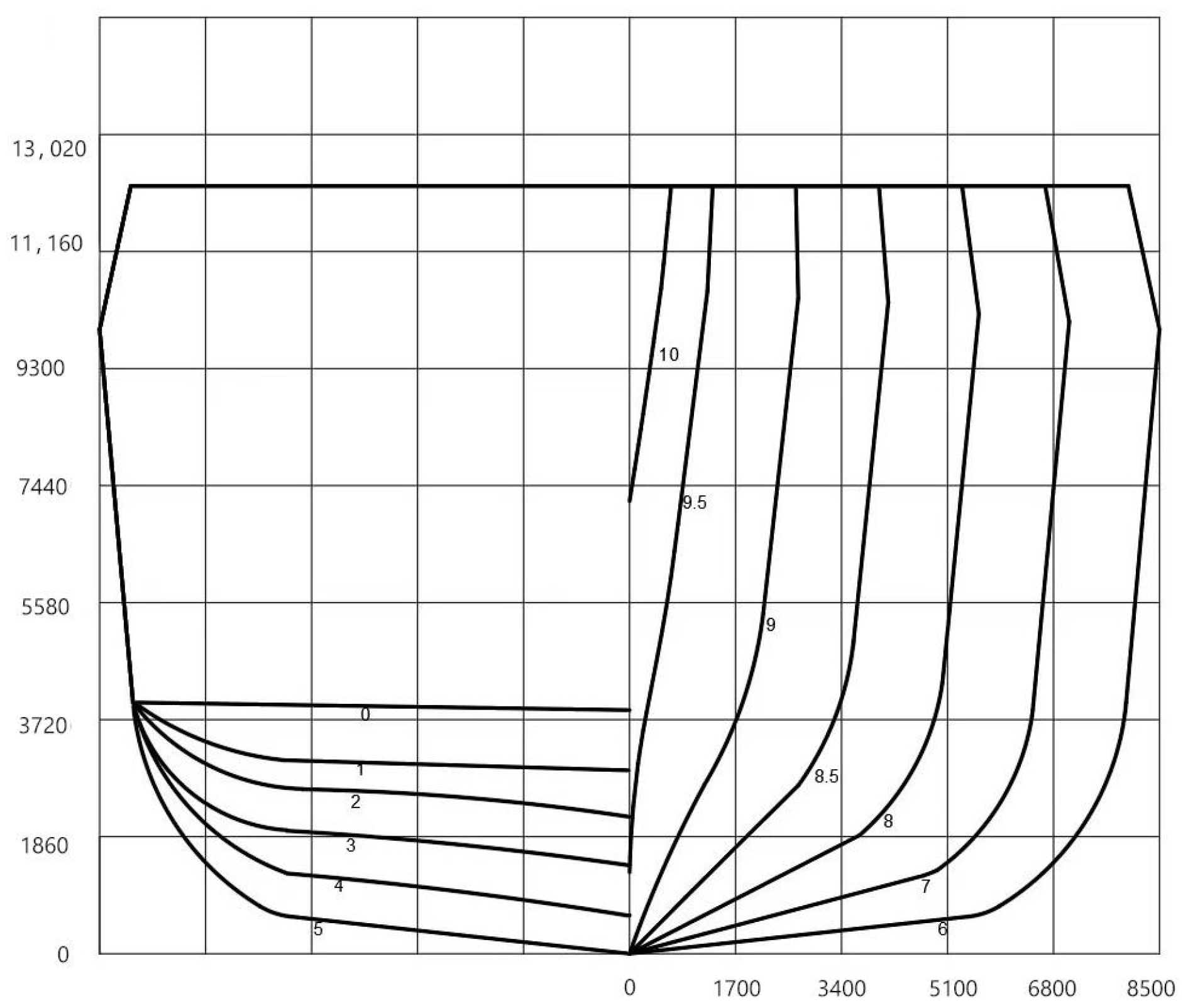

Figure 1.