A Method for Aliasing Metal Particle Recognition Based on Three-Coil Sensor Using Frequency Conversion

Abstract

1. Introduction

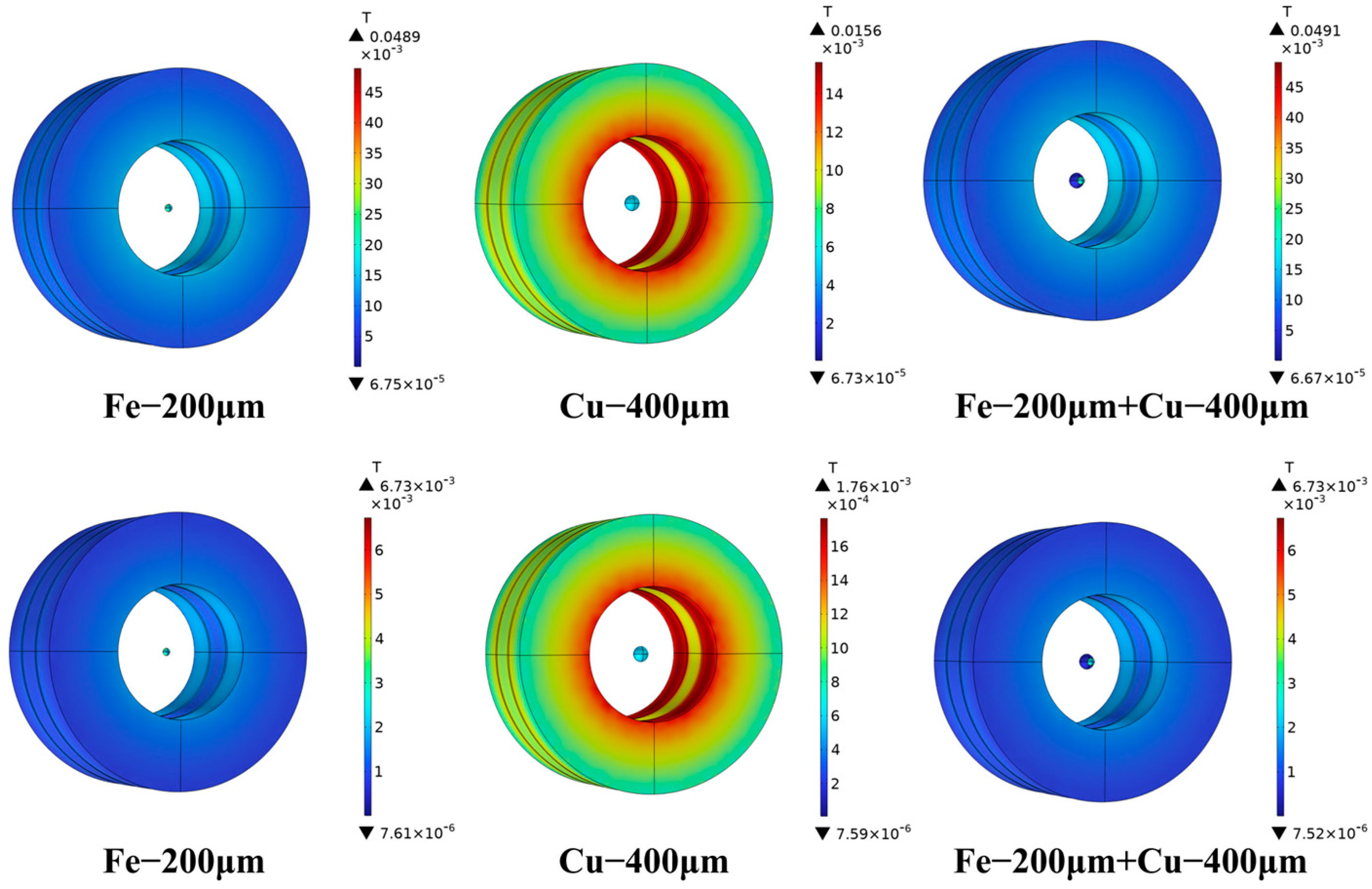

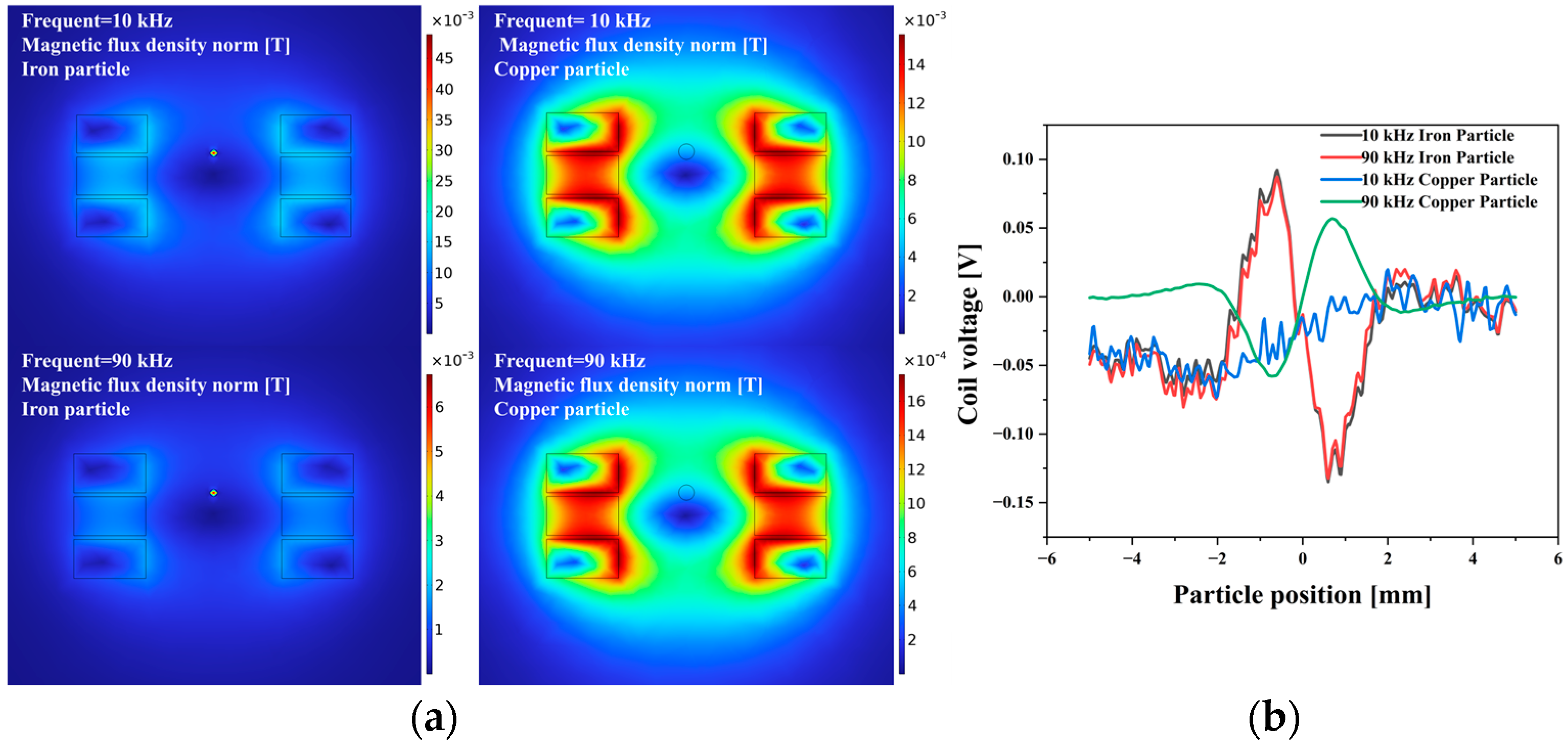

2. Modeling and Simulation

3. Experimental System Design

4. Experiment on the Frequency of Metal Particles

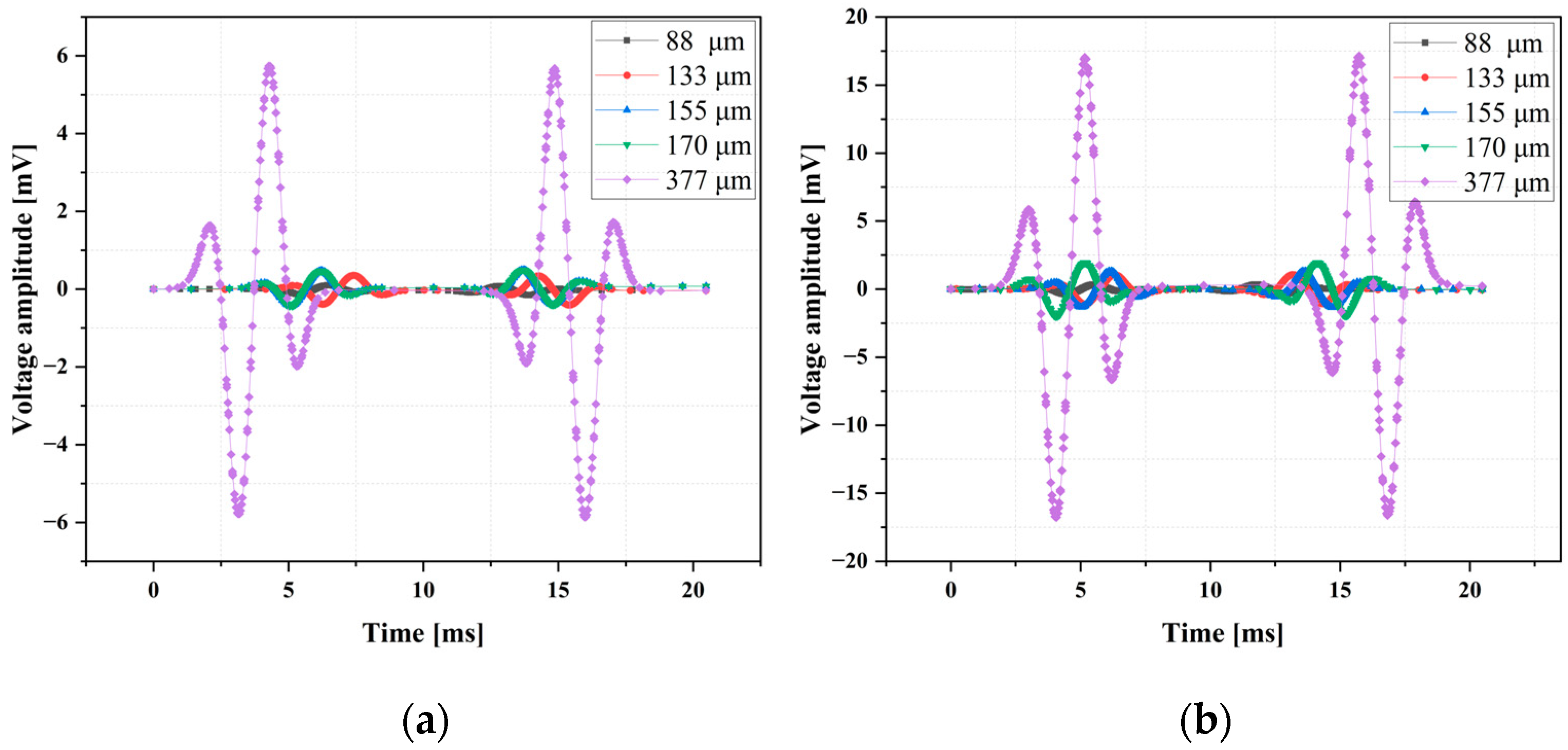

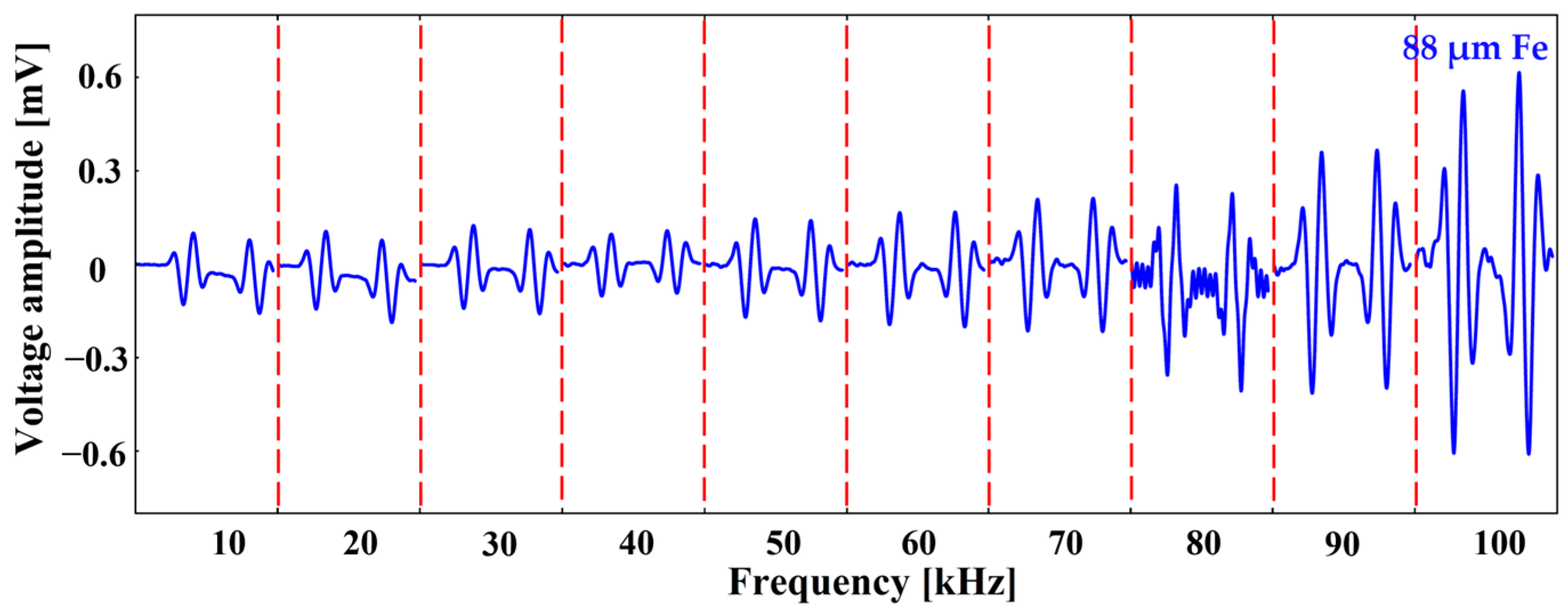

4.1. Study of Iron Particle Frequency Characteristics

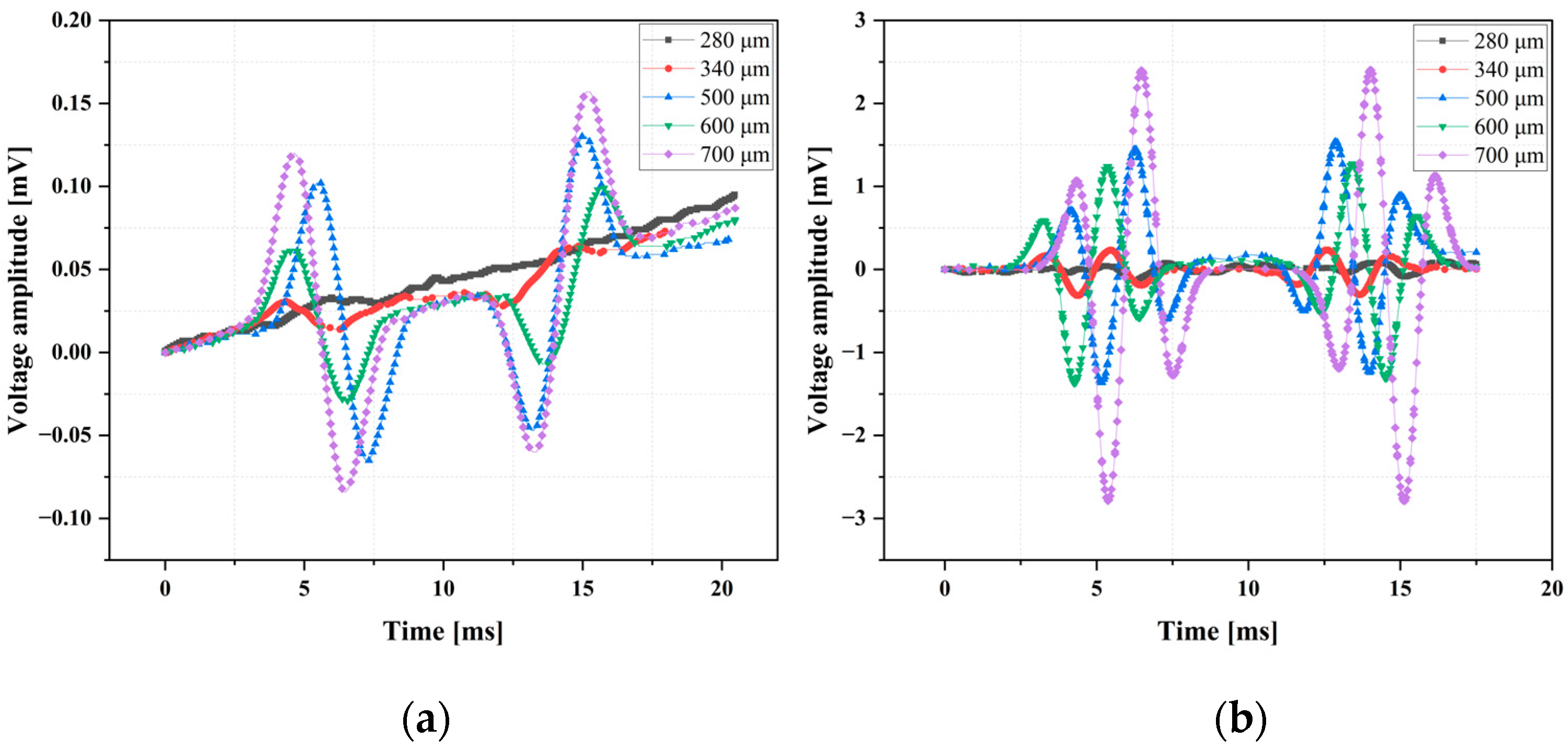

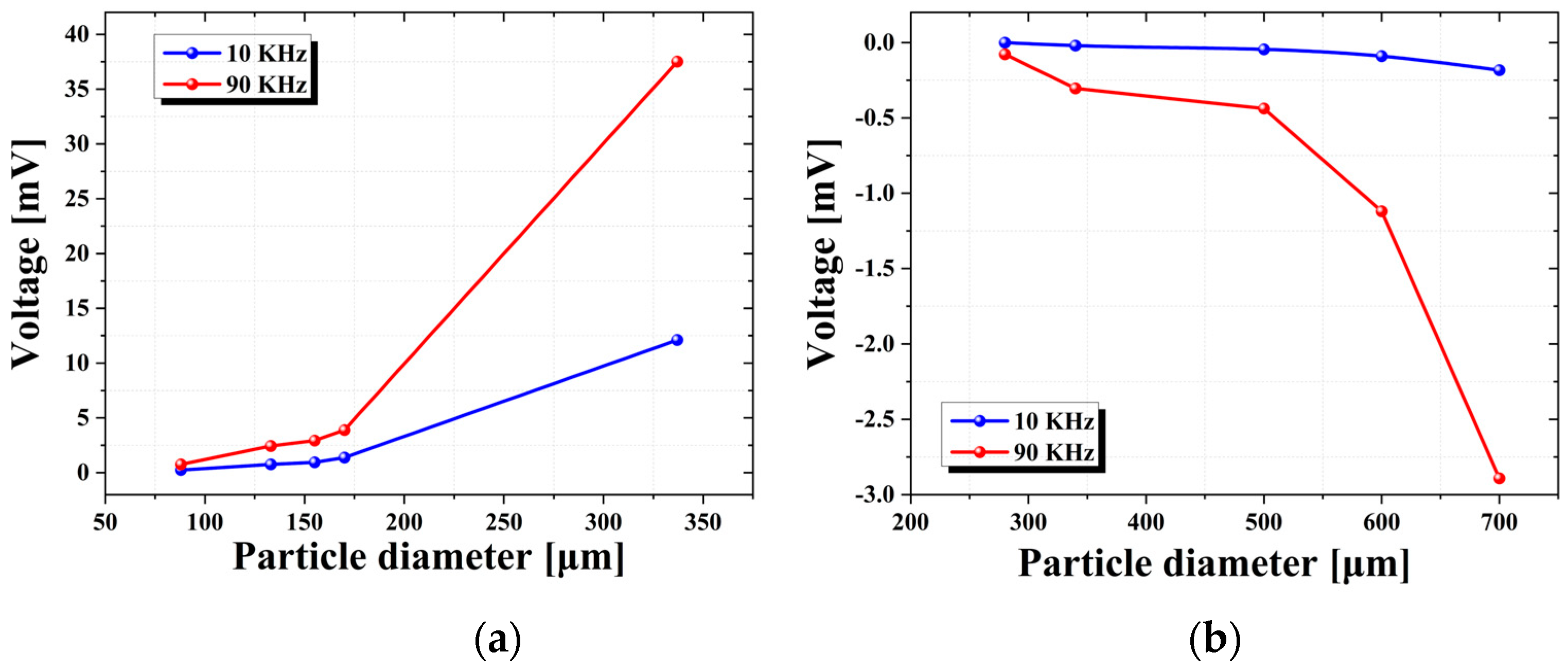

4.2. Study of Copper Particle Frequency Characteristics

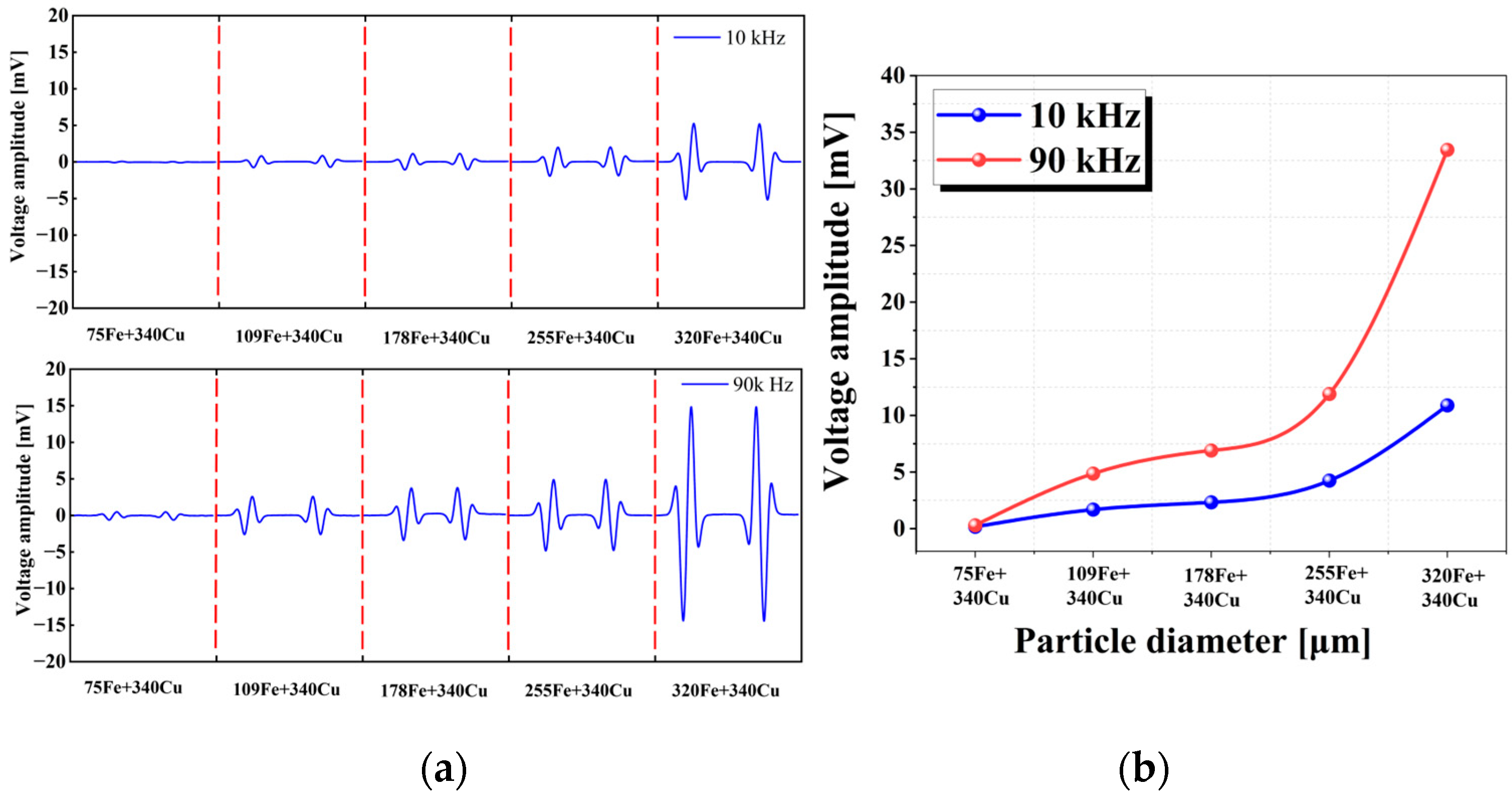

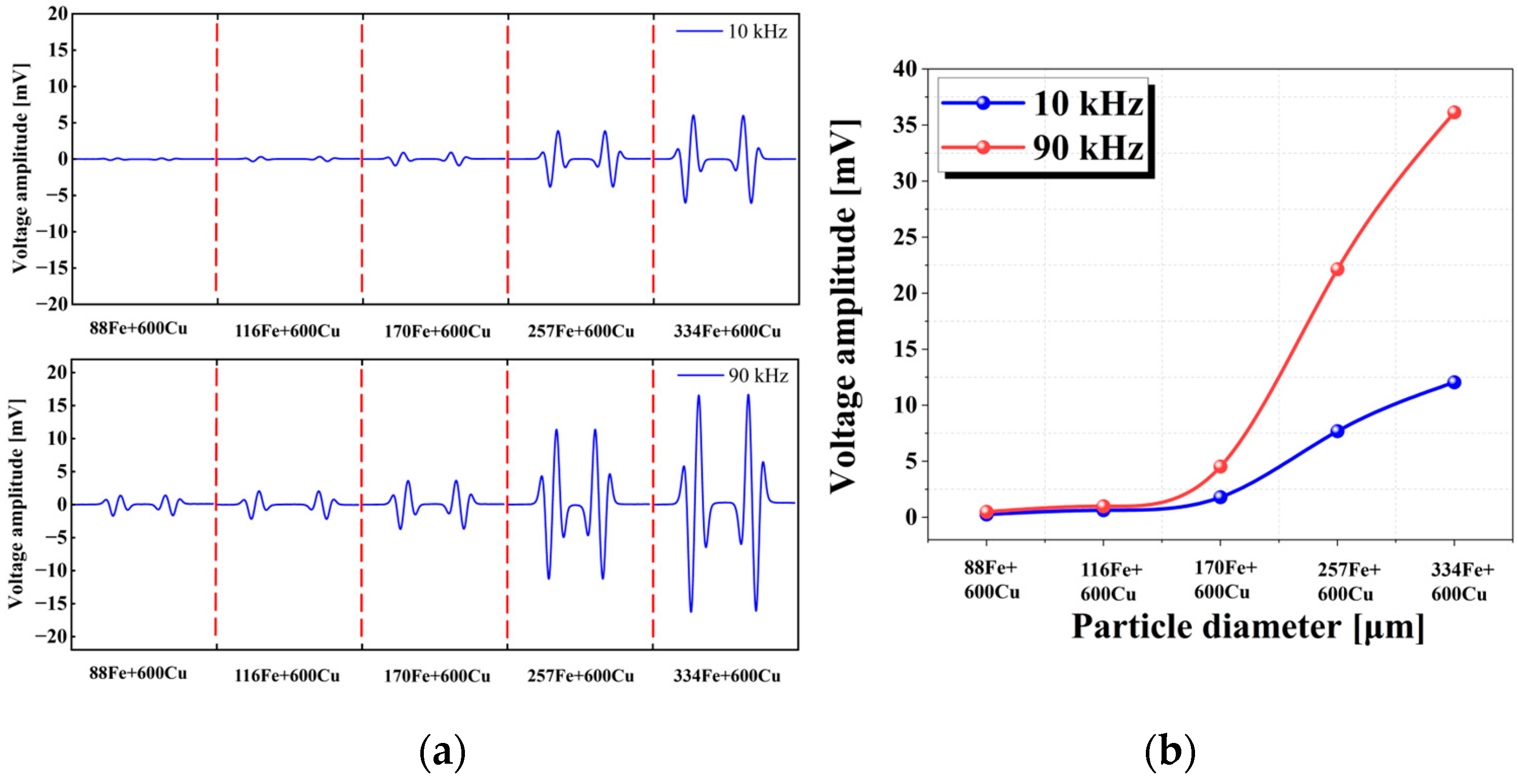

4.3. Frequency Characteristics of Metal Particles with Mixed Attributes

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, P.; Powrie, H.E.; Wood, R.J.; Harvey, T.J.; Harris, N.R. Early wear detection and its significance for condition monitoring. Tribol. Int. 2021, 159, 106946. [Google Scholar] [CrossRef]

- Li, Y.; Wu, J.; Guo, Q. Design on Electromagnetic Detection Sensor on Wear Debris in Lubricating Oil. In Proceedings of the 2019 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Auckland, New Zealand, 20–23 May 2019; IEEE: Piscataway, NJ, USA; pp. 1–5. [Google Scholar] [CrossRef]

- Han, W.; Mu, X.; Liu, Y.; Wang, X.; Li, W.; Bai, C.; Zhang, H. A Critical Review of On-Line Oil Wear Debris Particle Detection Sensors. J. Mar. Sci. Eng. 2023, 11, 2363. [Google Scholar] [CrossRef]

- Kattelus, J.; Miettinen, J.; Lehtovaara, A. Detection of gear pitting failure progression with on-line particle monitoring. Tribol. Int. 2018, 118, 458–464. [Google Scholar] [CrossRef]

- Jia, R.; Wang, L.; Zheng, C.; Chen, T. Online Wear Particle Detection Sensors for Wear Monitoring of Mechanical Equipment—A Review. IEEE Sens. J. 2022, 22, 2930–2947. [Google Scholar] [CrossRef]

- Chuma, E.L.; Iano, Y.; Roger, L.L.B.; de Oliveira, G.G.; Vaz, G.C. Novelty Sensor for Detection of Wear Particles in Oil Using Integrated Microwave Metamaterial Resonators With Neodymium Magnets. IEEE Sens. J. 2022, 22, 10508–10514. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, Q. Investigation of the Design and Fault Prediction Method for an Abrasive Particle Sensor Used in Wind Turbine Gearbox. Energies 2020, 13, 365. [Google Scholar] [CrossRef]

- Roylance, B.J.; Williams, J.A.; Dwyer-Joyce, R. Wear debris and associated wear phenomena—Fundamental research and practice. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2000, 214, 79–105. [Google Scholar] [CrossRef]

- Ren, Y.J.; Zhao, G.F.; Qian, M.; Feng, Z.H. A highly sensitive triple-coil inductive debris sensor based on an effective unbalance compensation circuit. Meas. Sci. Technol. 2019, 30, 015108. [Google Scholar] [CrossRef]

- Sun, Y.; Jia, L.; Zeng, Z. Hyper-Heuristic Capacitance Array Method for Multi-Metal Wear Debris Detection. Sensors 2019, 19, 515. [Google Scholar] [CrossRef]

- Zhao, Y.; Ge, P.; Bi, W.; Zheng, J.; Lan, J. Machine vision online detection for abrasive protrusion height on the surface of electroplated diamond wire saw. Int. J. Adv. Manuf. Technol. 2022, 121, 7923–7932. [Google Scholar] [CrossRef]

- Qian, M.; Ren, Y.J.; Feng, Z.H. Interference reducing by low-voltage excitation for a debris sensor with triple-coil structure. Meas. Sci. Technol. 2020, 31, 025103. [Google Scholar] [CrossRef]

- Jia, R.; Ma, B.; Zheng, C.; Wang, L.; Du, Q.; Wang, K. Improvement of Sensitivity and Detectability of the Three-Coil Wear Debris Detection Sensor Using LC Resonance Method and Modified Lock-in Amplifier. Preprints 2017. [Google Scholar] [CrossRef]

- Huang, H.; He, S.; Xie, X.; Feng, W.; Zhen, H. Research on the Influence of Coil LC Parallel Resonance on Detection Effect of Inductive Wear Debris Sensor. Sensors 2022, 22, 7493. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Yang, L.; Qiu, G.; Luo, J.; Li, R.; Mao, J. An Inductive Debris Sensor Based on a High-Gradient Magnetic Field. IEEE Sens. J. 2019, 19, 2879–2886. [Google Scholar] [CrossRef]

- Kim, M.K.; Chung, D.D.L. Inductance-based sensing of surface roughness, with application to wear sensing. J. Mater. Sci. 2024, 59, 15816–15829. [Google Scholar] [CrossRef]

- Ren, Y.J.; Li, W.; Zhao, G.F.; Feng, Z.H. Inductive debris sensor using one energizing coil with multiple sensing coils for sensitivity improvement and high throughput. Tribol. Int. 2018, 128, 96–103. [Google Scholar] [CrossRef]

- Zhang, Y.; Cao, Y.; Si, E.; Zheng, L. Study on a High Sensitive Online Sensor for Wear Particles in Lubricant. J. Phys. Conf. Ser. 2019, 1237, 042082. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, H.; Xie, Y.; Shi, H.; Zheng, W. Investigation on the superimposed characteristics of aliasing signals by multiple wear particles. Tribol. Int. 2023, 178, 107909. [Google Scholar] [CrossRef]

- Wang, X.; Sun, H.; Wang, S.; Huang, W. Cross-Correlation Algorithm-Based Optimization of Aliasing Signals for Inductive Debris Sensors. Sensors 2020, 20, 5949. [Google Scholar] [CrossRef]

- Li, T.; Wang, S.; Zio, E.; Shi, J.; Yang, Z. Aliasing Signal Separation for Superimposition of Inductive Debris Detection Using CNN-Based DUET. In Proceedings of the 2019 14th IEEE Conference on Industrial Electronics and Applications (ICIEA), Xi’an, China, 19–21 June 2019; IEEE: Piscataway, NJ, USA; pp. 211–215. [Google Scholar] [CrossRef]

- Olalere, I.O.; Olanrewaju, O.A. Tool and Workpiece Condition Classification Using Empirical Mode Decomposition (EMD) with Hilbert–Huang Transform (HHT) of Vibration Signals and Machine Learning Models. Appl. Sci. 2023, 13, 2248. [Google Scholar] [CrossRef]

- Shen, K.; Zhao, D. An EMD-LSTM Deep Learning Method for Aircraft Hydraulic System Fault Diagnosis under Different Environmental Noises. Aerospace 2023, 10, 55. [Google Scholar] [CrossRef]

- Li, Y.; Wu, J.; Guo, Q. Electromagnetic Sensor for Detecting Wear Debris in Lubricating Oil. IEEE Trans. Instrum. Meas. 2020, 69, 2533–2541. [Google Scholar] [CrossRef]

- Xie, Y.; Shi, H.; Zheng, Y.; Zhang, Y.; Zhang, H.; Sun, Y.; Zhang, X.; Zhang, S. An Asymmetric Micro-Three-Coil Sensor Enabling Non-Ferrous Metals Distinguishment. IEEE Trans. Instrum. Meas. 2023, 72, 3508909. [Google Scholar] [CrossRef]

- Wan, Z.; Wang, Y.; Du, C. A High Sensitivity and Throughput Inductive Debris Sensor Using a Built-In Planar Energizing Coil. IEEE Trans. Instrum. Meas. 2024, 73, 9501709. [Google Scholar] [CrossRef]

| Particle Samples | Particle Size | ||||

|---|---|---|---|---|---|

| Iron particles | 88 μm | 133 μm | 155 μm | 170 μm | 337 μm |

| Copper particles | 280 μm | 340 μm | 500 μm | 600 μm | 700 μm |

| Aliasing particles 1 | 80 μm Fe +280 μm Cu | 88 μm Fe +340 μm Cu | 80 μm Fe +500 μm Cu | 88 μm Fe +600 μm Cu | 83 μm Fe +700 μm Cu |

| Aliasing particles 2 | 75 μm Fe +340 μm Cu | 109 μm Fe +340 μm Cu | 178 μm Fe +340 μm Cu | 255 μm Fe +340 μm Cu | 320 μm Fe +340 μm Cu |

| Aliasing particles 3 | 88 μm Fe +600 μm Cu | 116 μm Fe +600 μm Cu | 170 μm Fe +600 μm Cu | 257 μm Fe +600 μm Cu | 334 μm Fe +600 μm Cu |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, D.; Xie, Y.; Wang, C.; Gu, X.; Gu, F.; Li, G.; Zhang, H.; An, Y.; Li, R.; Gu, C. A Method for Aliasing Metal Particle Recognition Based on Three-Coil Sensor Using Frequency Conversion. J. Mar. Sci. Eng. 2024, 12, 2273. https://doi.org/10.3390/jmse12122273

Wu D, Xie Y, Wang C, Gu X, Gu F, Li G, Zhang H, An Y, Li R, Gu C. A Method for Aliasing Metal Particle Recognition Based on Three-Coil Sensor Using Frequency Conversion. Journal of Marine Science and Engineering. 2024; 12(12):2273. https://doi.org/10.3390/jmse12122273

Chicago/Turabian StyleWu, Di, Yucai Xie, Chenyong Wang, Xian’an Gu, Feng Gu, Guoqing Li, Hongpeng Zhang, Yunsheng An, Rui Li, and Changzhi Gu. 2024. "A Method for Aliasing Metal Particle Recognition Based on Three-Coil Sensor Using Frequency Conversion" Journal of Marine Science and Engineering 12, no. 12: 2273. https://doi.org/10.3390/jmse12122273

APA StyleWu, D., Xie, Y., Wang, C., Gu, X., Gu, F., Li, G., Zhang, H., An, Y., Li, R., & Gu, C. (2024). A Method for Aliasing Metal Particle Recognition Based on Three-Coil Sensor Using Frequency Conversion. Journal of Marine Science and Engineering, 12(12), 2273. https://doi.org/10.3390/jmse12122273