Research on the Influence of Shallow Buried Tunnel Crossing on the Stability of Overlying Frame Structure Building

Abstract

:1. Introduction

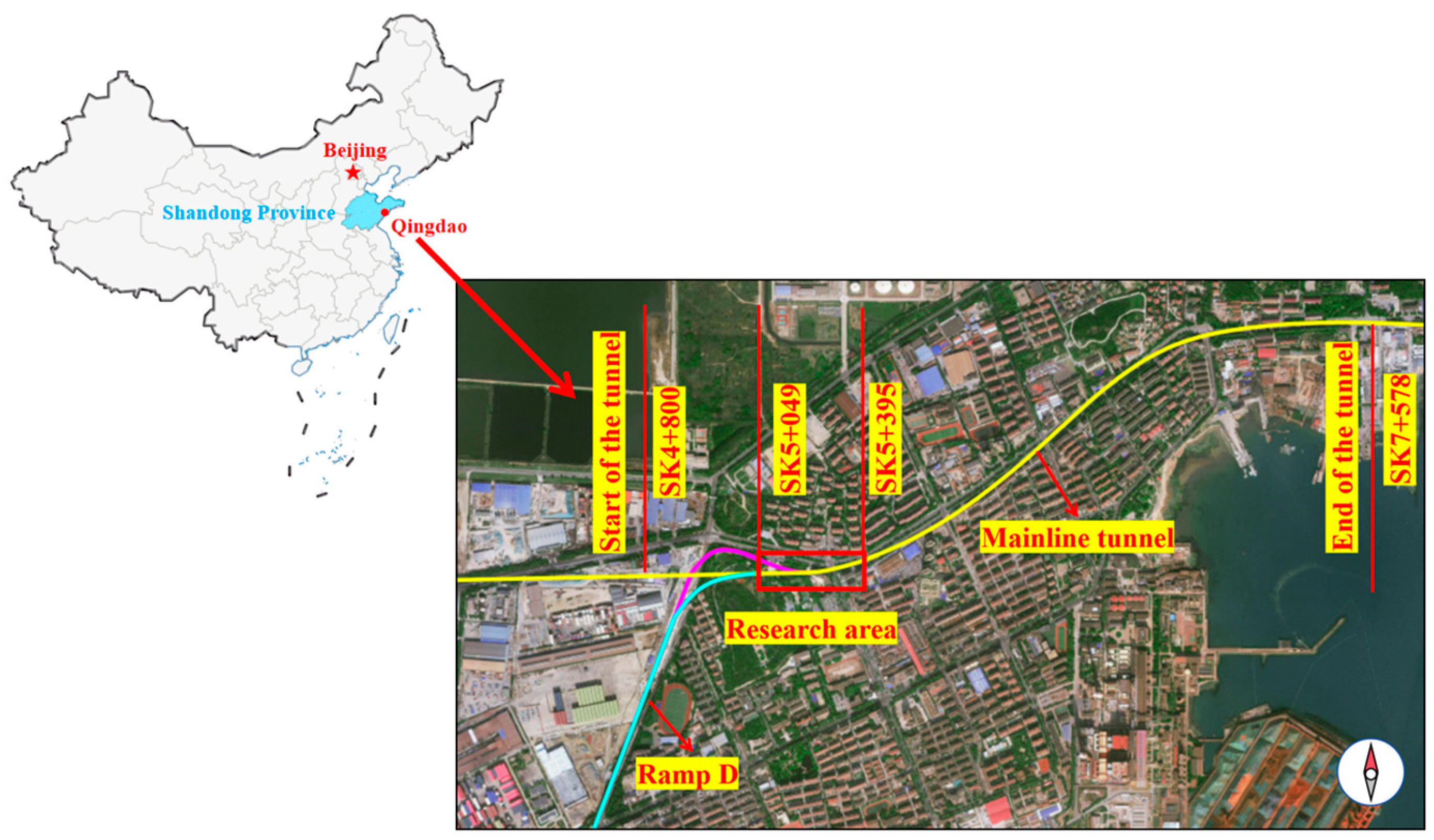

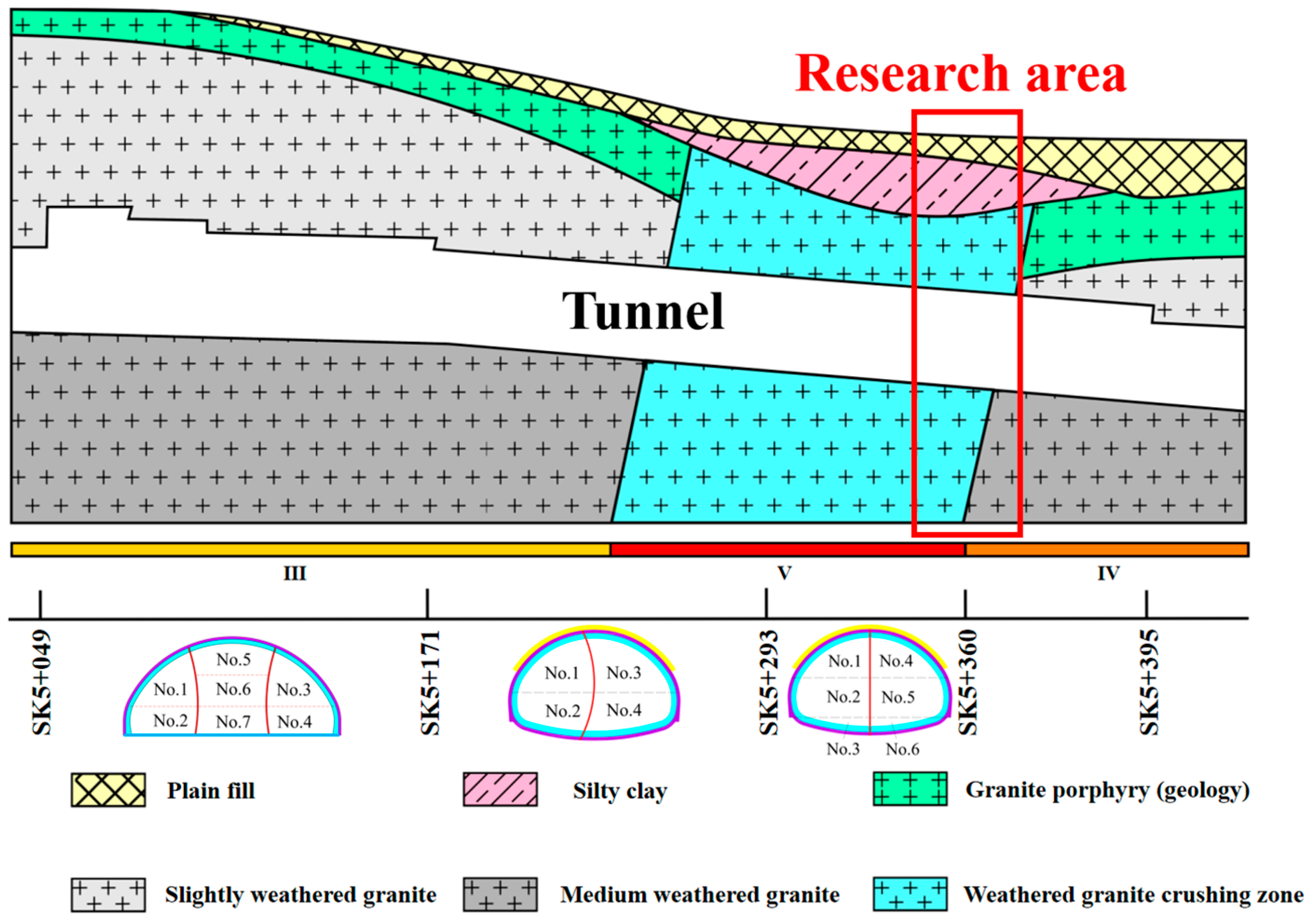

2. Geological Information Survey

2.1. Geological Background

2.2. Project Overview

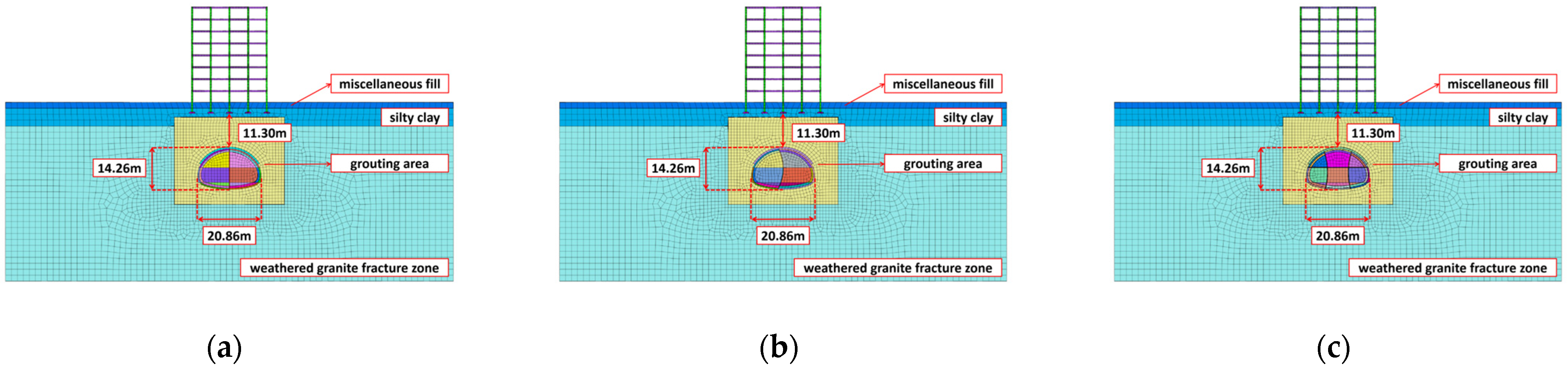

3. Numerical Simulations

3.1. Description of the Numerical Model

3.2. Basic Assumption

- The geotechnical material is a continuous, uniform, isotropic elastoplastic medium;

- The initial stress field considers only self-weight;

- An idealized model of the tunnel crossing directly underneath the building is developed.

3.3. Constitutive Model and Calculation Parameters

3.4. Excavation Simulation

- 1.

- The vertical support CD method and the curved support CD method are divided into 17 specific construction phases.

- 2.

- The double side-wall guided pit method is divided into 23 specific construction phases.

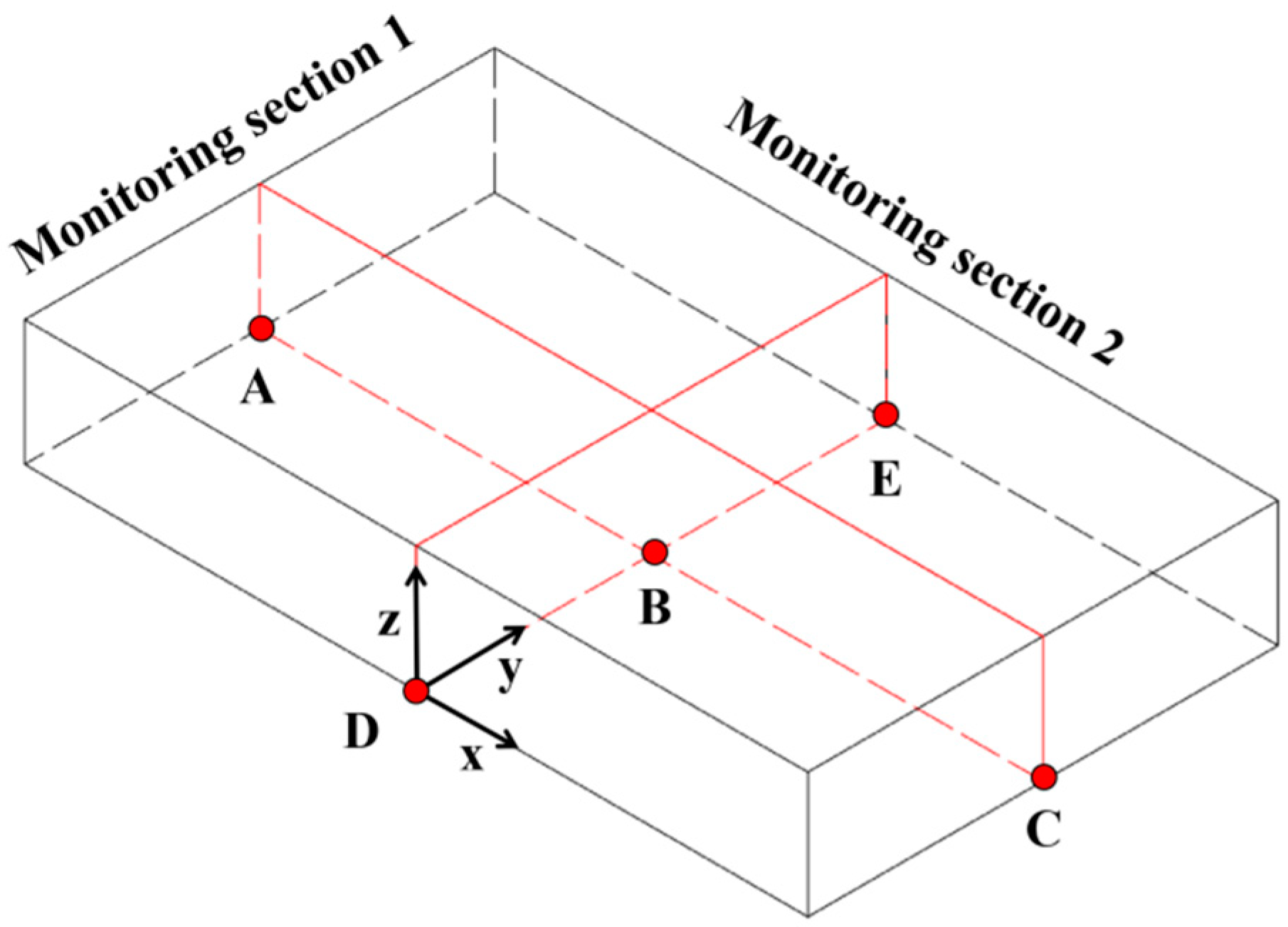

3.5. Layout of Monitoring Sections and Points

3.6. Analysis of Model Validity

4. Numerical Results

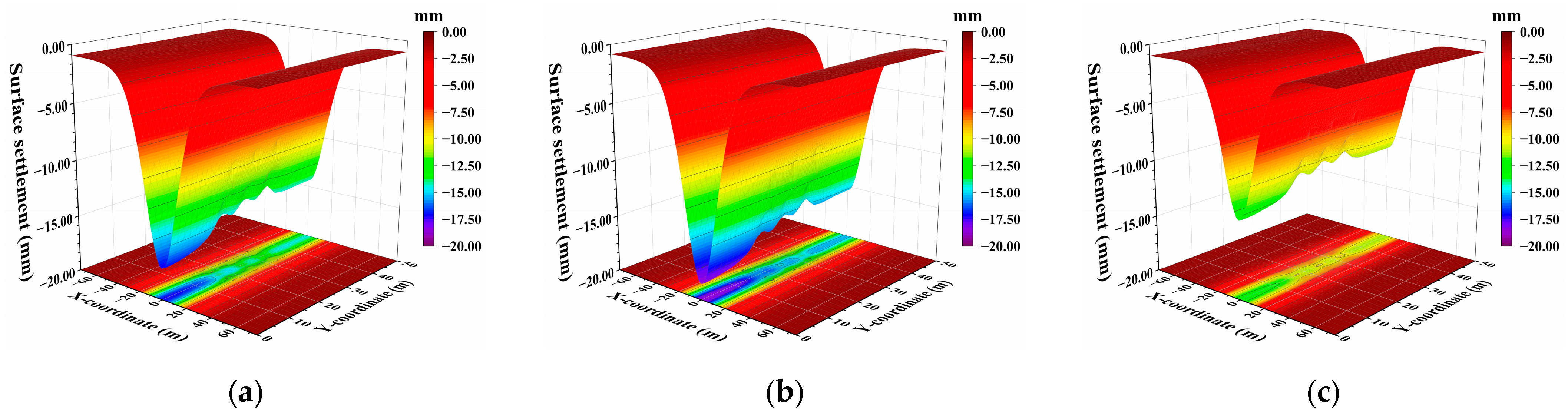

4.1. Characteristics of Surface Settlement

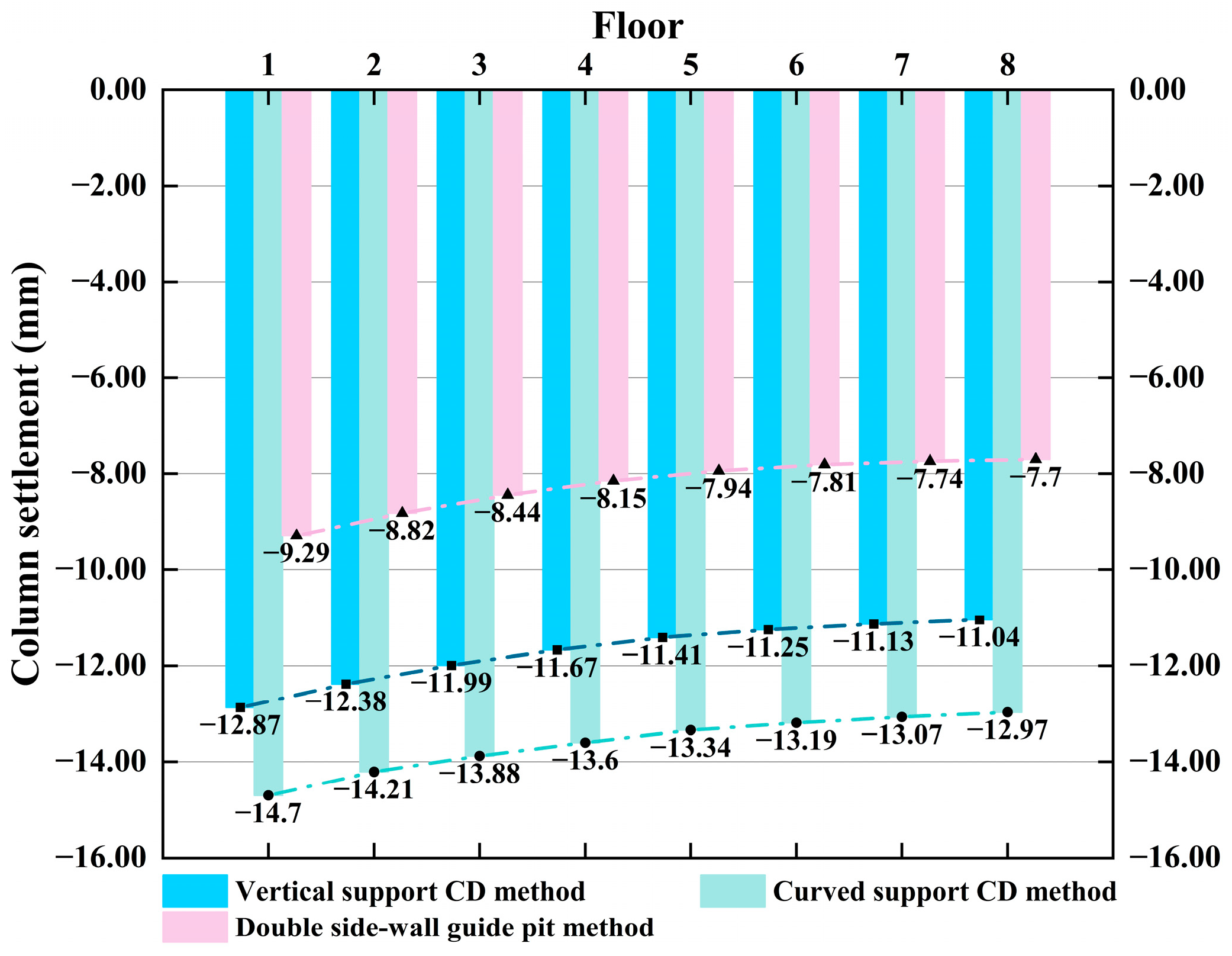

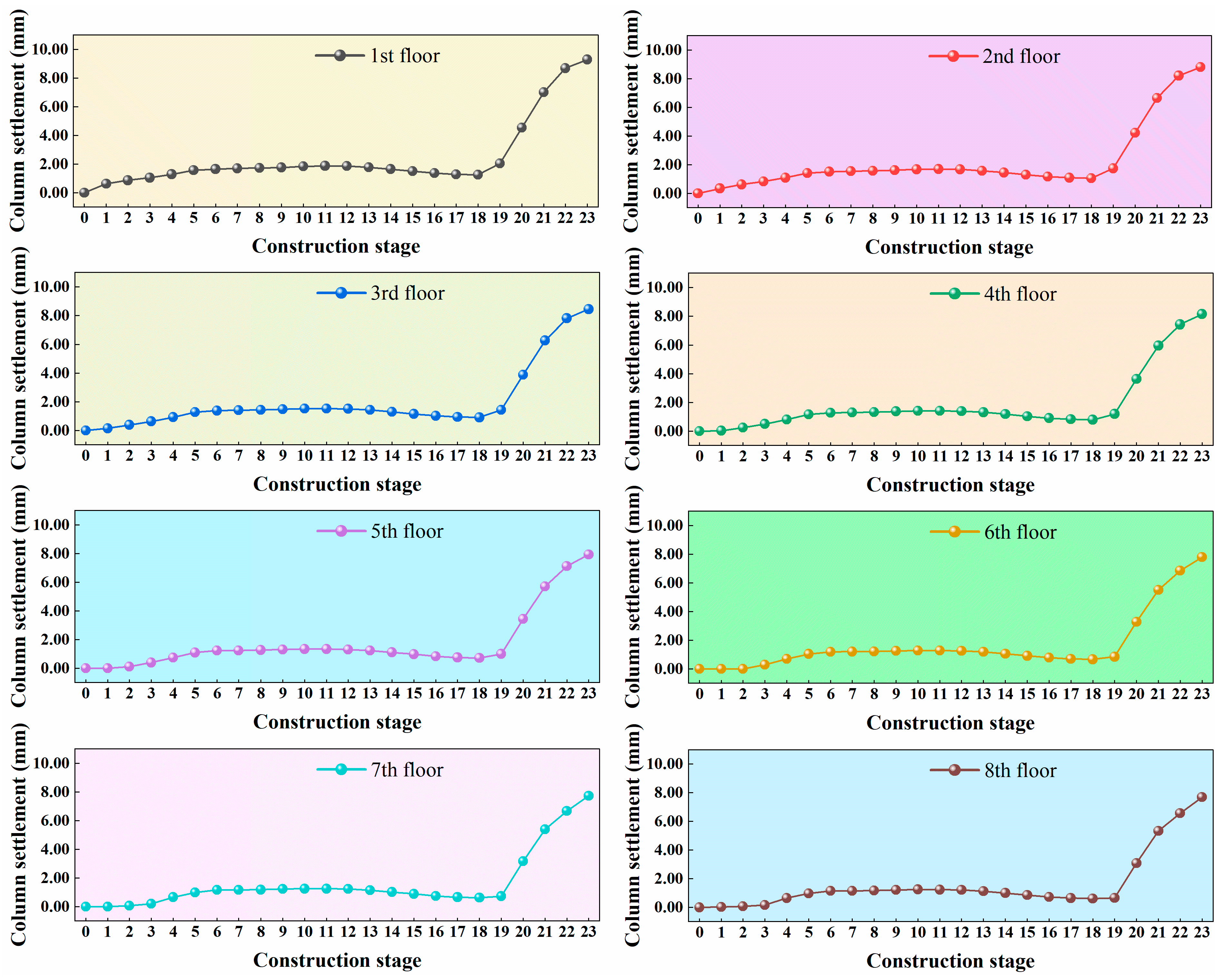

4.2. Characteristics of Building Displacement

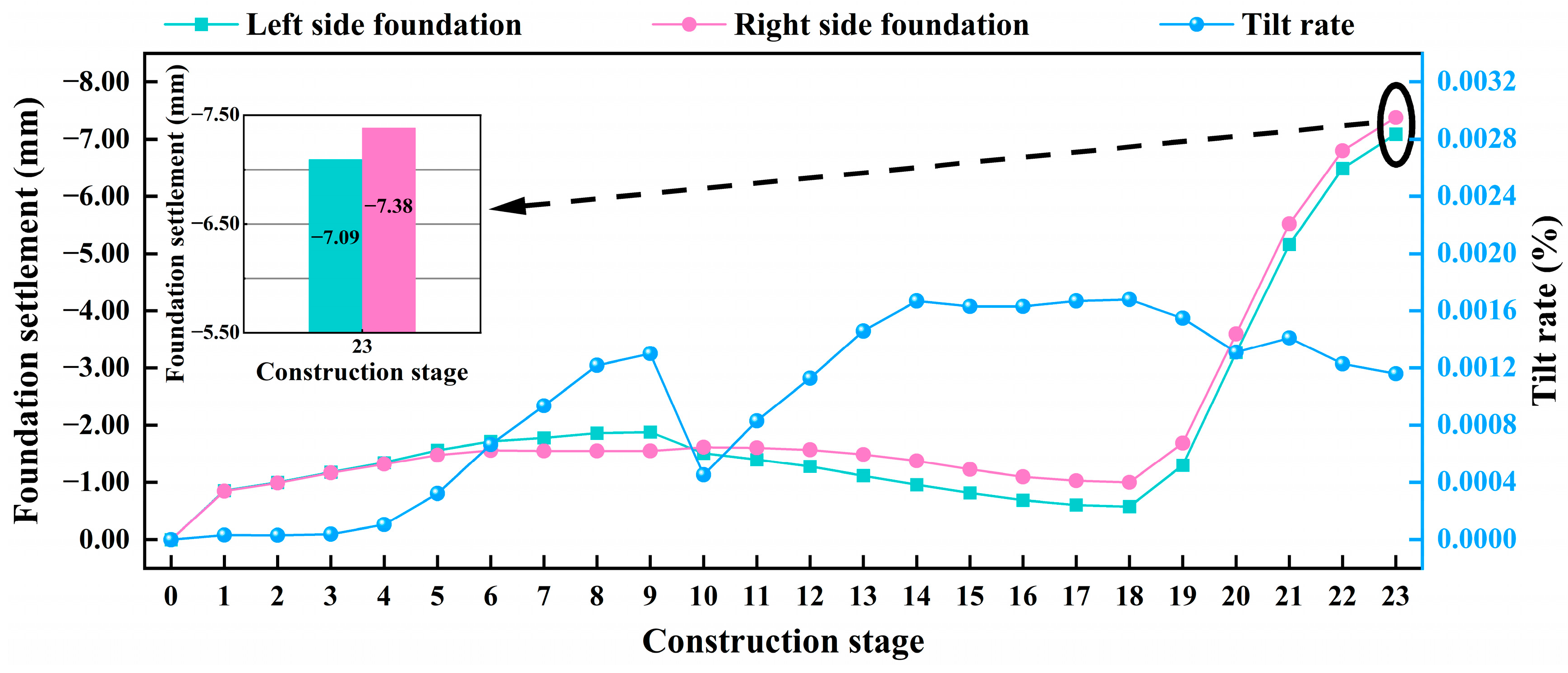

4.3. Laws of Dynamic Changes in Building Tilt Rate

5. Laws of Stress Relief on Building Deformation

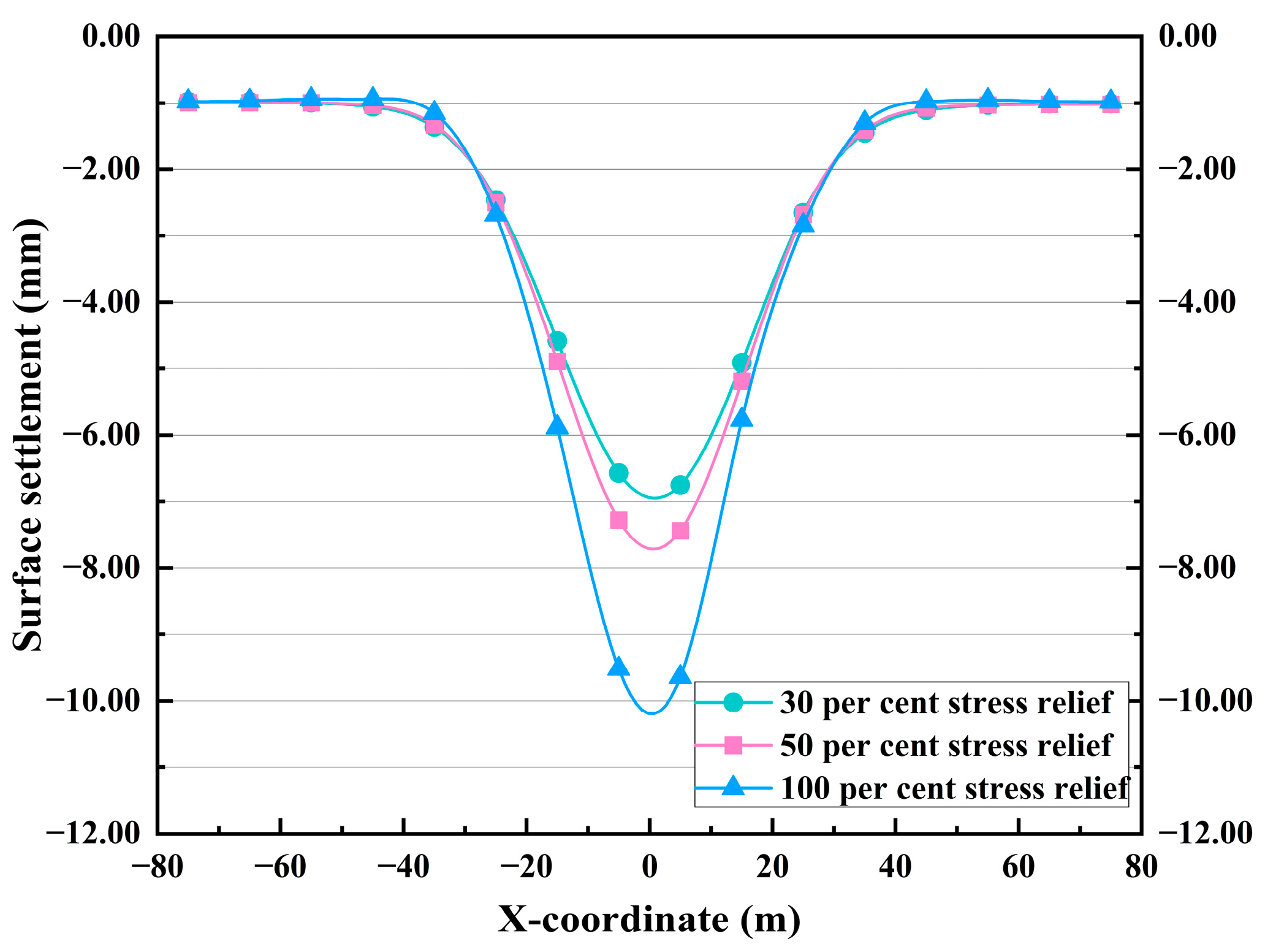

5.1. Surface Settlement for Different Stress Relief States

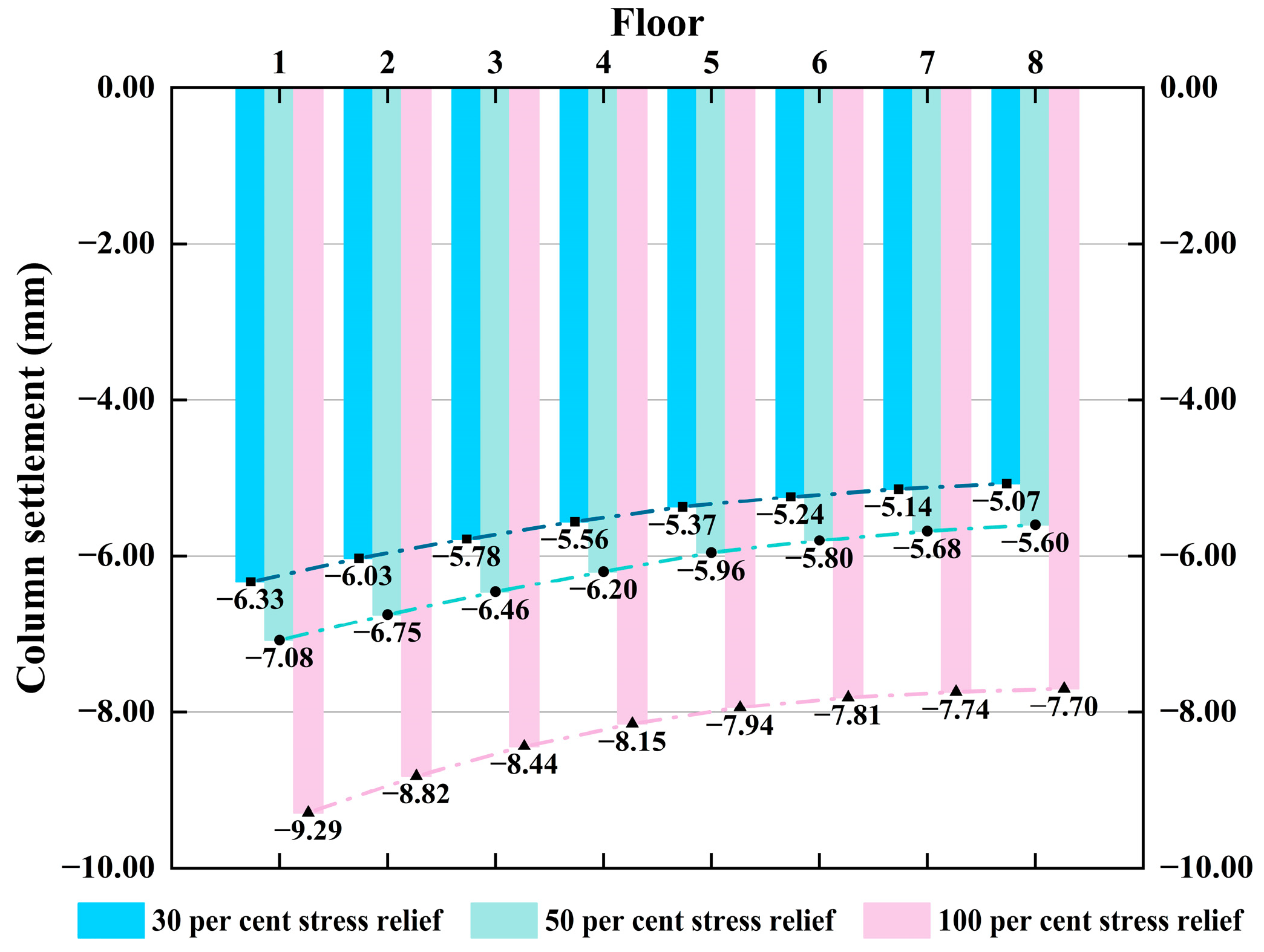

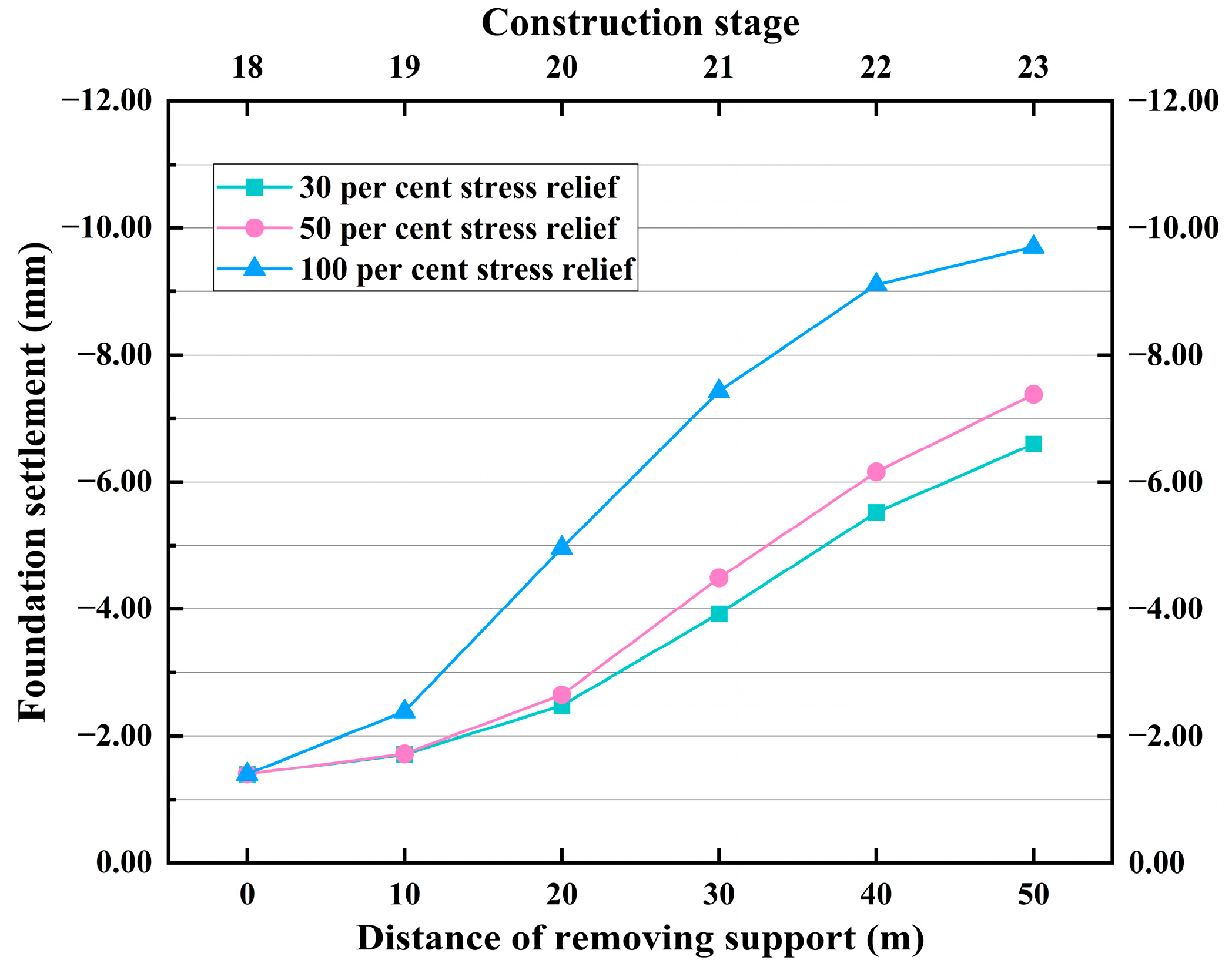

5.2. Dynamic Settlement of Buildings with Different Stress Relief States

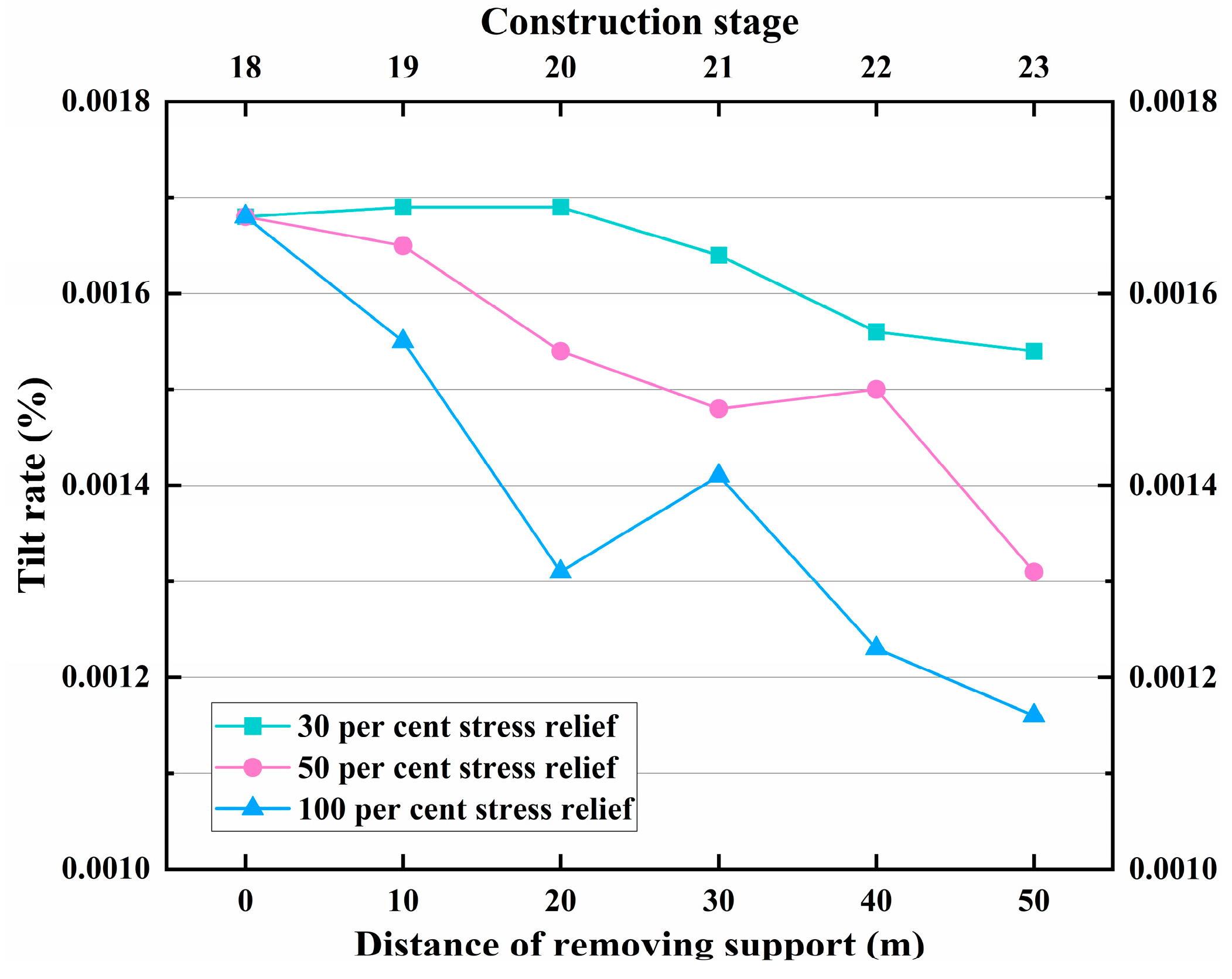

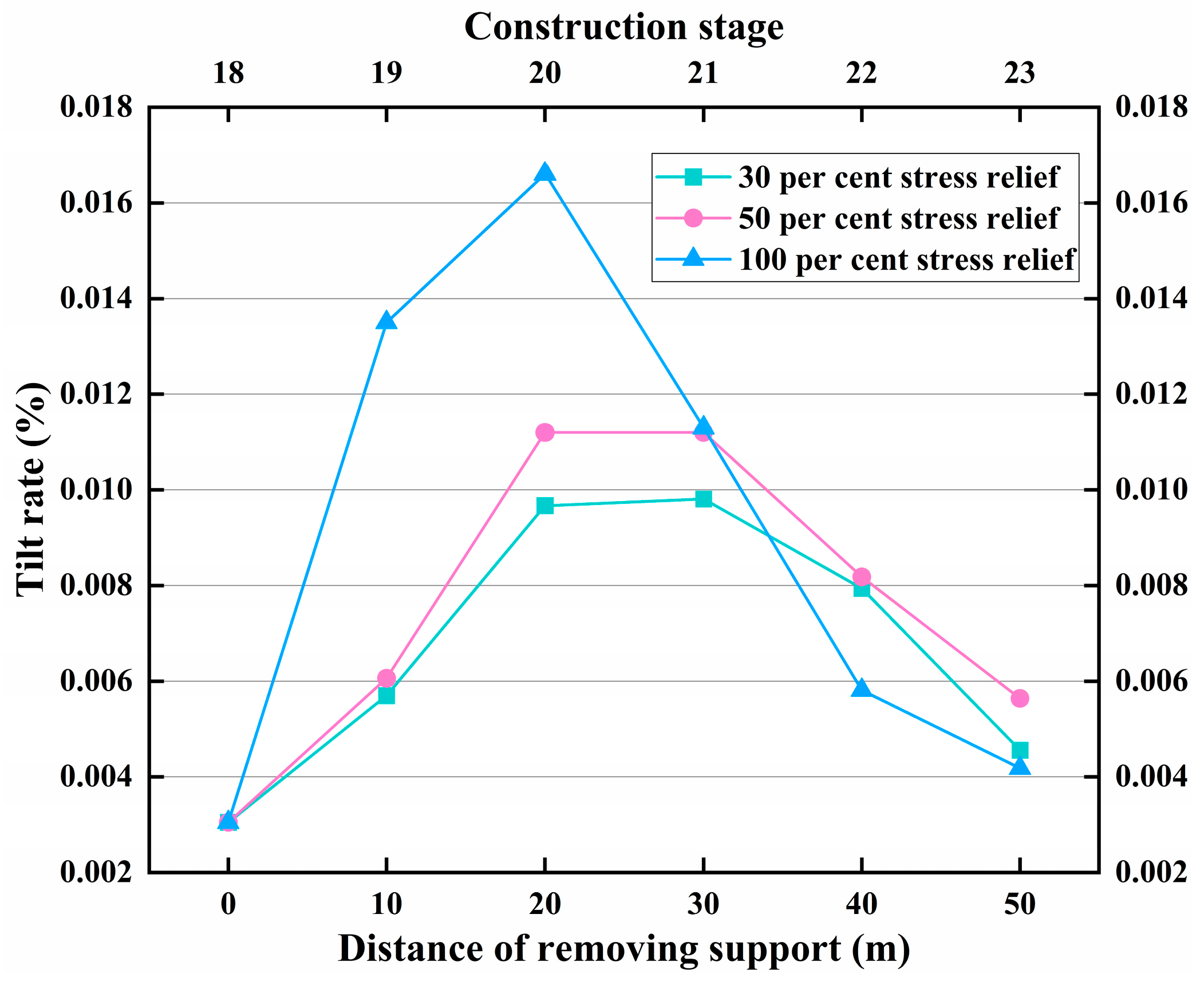

5.3. Dynamic Tilt Rate of Buildings with Different Stress Relief States

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khabbaz, H.; Gibson, R.; Fatahi, B. Effect of Constructing Twin Tunnels under a Building Supported by Pile Foundations in the Sydney Central Business District. Undergr. Space 2019, 4, 261–276. [Google Scholar] [CrossRef]

- Peck, R.B. Deep excavation and tunnelling in soft ground. In Proceedings of the 7th International Conference on Soil Mechanics and Foundation Engineering (Mexico) 7th ICSMFE, Mexico City, Mexico, 1969; pp. 225–290. [Google Scholar]

- Pinto, F.; Whittle, A.J. Ground Movements due to Shallow Tunnels in Soft Ground. I: Analytical Solutions. J. Geotech. Geoenvironmental Eng. 2014, 140, 04013040. [Google Scholar] [CrossRef]

- Pinto, F.; Zymnis, D.M.; Whittle, A.J. Ground Movements due to Shallow Tunnels in Soft Ground. II: Analytical Interpretation and Prediction. J. Geotech. Geoenvironmental Eng. 2014, 140, 04013041. [Google Scholar] [CrossRef]

- Yu, L.; Zhang, D.; Fang, Q.; Xu, T.; Luo, J.; Chen, W. Semi-Analytical Solutions of Three-Dimensional Ground Movements Due to Shallow Tunnelling. Tunn. Undergr. Space Technol. 2023, 136, 105074. [Google Scholar] [CrossRef]

- Zhao, C.; Lavasan, A.A.; Barciaga, T.; Schanz, T. Mechanized Tunneling Induced Ground Movement and Its Dependency on the Tunnel Volume Loss and Soil Properties. Int. J. Numer. Anal. Methods Géoméch. 2019, 43, 781–800. [Google Scholar] [CrossRef]

- Lu, D.; Kong, F.; Du, X.; Shen, C.; Gong, Q.; Li, P. A Unified Displacement Function to Analytically Predict Ground Deformation of Shallow Tunnel. Tunn. Undergr. Space Technol. 2019, 88, 129–143. [Google Scholar] [CrossRef]

- Xue, Y.; Gong, H.; Kong, F.; Yang, W.; Qiu, D.; Zhou, B. Stability Analysis and Optimization of Excavation Method of Double-arch Tunnel with an Extra-Large Span Based on Numerical Investigation. Front. Struct. Civ. Eng. 2021, 15, 136–146. [Google Scholar] [CrossRef]

- Giardina, G.; DeJong, M.J.; Mair, R.J. Interaction Between Surface Structures and Tunnelling in Sand: Centrifuge and Computational Modelling. Tunn. Undergr. Space Technol. 2015, 50, 465–478. [Google Scholar] [CrossRef]

- Ritter, S.; Giardina, G.; DeJong, M.J.; Mair, R.J. Influence of Building Characteristics on Tunnelling-Induced Ground Movements. Geotech. 2017, 67, 926–937. [Google Scholar] [CrossRef]

- Ritter, S.; Giardina, G.; DeJong, M.J.; Mair, R.J. Centrifuge Modelling of Building Response to Tunnel excavation. Int. J. Phys. Model. Geotech. 2018, 18, 146–161. [Google Scholar] [CrossRef]

- Ritter, S.; Giardina, G.; Franza, A.; DeJong, M.J. Building Deformation Caused by Tunneling: Centrifuge Modeling. J. Geotech. Geoenvironmental Eng. 2020, 146, 04020017. [Google Scholar] [CrossRef]

- Hong, X.; Zhang, D.; Zhou, M.; Fang, Q.; Hou, Y.; Fang, H.; Sun, Z. Approximate Analytical Solution of Tunneling-Induced Responses of a Soil–Foundation System Using Contact Mechanics. Int. J. Numer. Anal. Methods Géoméch. 2022, 46, 3442–3464. [Google Scholar] [CrossRef]

- Xu, J.; Franza, A.; Marshall, A.M.; Losacco, N.; Boldini, D. Tunnel–Framed Building Interaction: Comparison Between Raft and Separate Footing Foundations. Géotechnique 2021, 71, 631–644. [Google Scholar] [CrossRef]

- Mylonakis, G.; Gazetas, G. Seismic soil-structure interaction: Beneficial or detrimental? J. Earthq. Eng. 2000, 4, 277–301. [Google Scholar] [CrossRef]

- Savvides, A.-A. On the Numerical Investigation of the Absorbing Boundaries Influence to the Dynamic Soil Structure Interaction. Arab. J. Sci. Eng. 2024, 49, 13957–13973. [Google Scholar] [CrossRef]

- Gong, C.; Ding, W.; Xie, D. Twin EPB Tunneling-Induced Deformation and Assessment of a Historical Masonry Building on Shanghai Soft Clay. Tunn. Undergr. Space Technol. 2020, 98, 103300. [Google Scholar] [CrossRef]

- Cai, L.; Shi, K.; Jiang, F.; Chen, G.; Xiao, Z.; Zheng, C.; Zhang, S.; Wu, Y. Research on the Deformation Laws of Buildings Adjacent to Shield Tunnels in Clay Strata. Sci. Rep. 2024, 14, 265. [Google Scholar] [CrossRef]

- Zhang, D.; Li, P.; Hou, Y.; Fang, Q. Influence Due to Urban Tunnel Excavation on Ground Buildings and Its Countermeasures. Chin. J. Geotech. Eng. 2010, 32, 296–302. (In Chinese) [Google Scholar]

- Feng, X.; Hou, D.; Huang, Z. The Influence of Shield Tunneling Characteristics on the Safety of Buildings Above-Case Study for Shanghai Zone. Sustainability 2022, 14, 13391. [Google Scholar] [CrossRef]

- Sirivachiraporn, A.; Phienwej, N. Ground Movements in EPB Shield Tunneling of Bangkok Subway Project and Impacts on Adjacent Buildings. Tunn. Undergr. Space Technol. 2012, 30, 10–24. [Google Scholar] [CrossRef]

- Chen, J.; Li, Z. Research on optimization of pipe support parameters for shallow buried and small clear distance tunnels under unequal pressure. J. Hebei Univ. Eng. (Nat. Sci. Ed.) 2024, 41, 59–70. (In Chinese) [Google Scholar]

- Zhang, Y.; An, X.; Jin, Y. Centrifugal model tests on settlement of structures caused by tunnel excavation. Chin. J. Geotech. Eng. 2022, 44, 54–57. (In Chinese) [Google Scholar]

- Ministry of Housing and Urban Rural Development of the People’s Republic of China. Code for Deformation Measurement of Building and Structure JGJ8-2016; Construction Industry Press: Beijing, China, 2016.

| Material Name | Unit Weight (kN/m3) | Poisson’s Ratio | Young’s Modulus (MPa) | Cohesion (kPa) | Friction Angle (°) |

|---|---|---|---|---|---|

| Miscellaneous fill soil | 18.4 | 0.4 | 8.5 | 10 | 12 |

| Silty clay | 21 | 0.3 | 26 | 21 | 20 |

| Weathered granite fracture zone | 22.5 | 0.35 | 200 | 150 | 24 |

| Grouting area | 23.7 | 0.3 | 300 | 210 | 27 |

| Material Name | Unit Weight (kN/m3) | Poisson’s Ratio | Young’s Modulus (MPa) |

|---|---|---|---|

| Pipe shed | 25 | 0.2 | 24,000 |

| Initial support | 22 | 0.2 | 30,000 |

| Secondary lining | 25 | 0.2 | 31,500 |

| Temporary support | 22 | 0.2 | 25,000 |

| Beam | 25 | 0.2 | 28,000 |

| Slab | 25 | 0.2 | 33,000 |

| Column | 25 | 0.2 | 28,000 |

| Foundation | 25 | 0.2 | 36,600 |

| Deformation Characteristics | Soil Classification for Foundation | ||

|---|---|---|---|

| Medium and Low Compressibility Soil | High Compressibility Soil | ||

| Settlement difference in adjacent foundations | 0.002 l | 0.003 l | |

| Tilt rate | Hg ≤ 24 | 0.004 | |

| 24 < Hg ≤ 60 | 0.003 | ||

| 60 < Hg ≤ 100 | 0.0025 | ||

| Hg > 100 | 0.002 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Jia, S.; Han, M.; Qu, J.; Gong, H.; Lu, C.; Qu, Z. Research on the Influence of Shallow Buried Tunnel Crossing on the Stability of Overlying Frame Structure Building. J. Mar. Sci. Eng. 2024, 12, 2244. https://doi.org/10.3390/jmse12122244

Wang B, Jia S, Han M, Qu J, Gong H, Lu C, Qu Z. Research on the Influence of Shallow Buried Tunnel Crossing on the Stability of Overlying Frame Structure Building. Journal of Marine Science and Engineering. 2024; 12(12):2244. https://doi.org/10.3390/jmse12122244

Chicago/Turabian StyleWang, Bo, Suizi Jia, Mingyi Han, Jingkai Qu, Huimin Gong, Chao Lu, and Ziming Qu. 2024. "Research on the Influence of Shallow Buried Tunnel Crossing on the Stability of Overlying Frame Structure Building" Journal of Marine Science and Engineering 12, no. 12: 2244. https://doi.org/10.3390/jmse12122244

APA StyleWang, B., Jia, S., Han, M., Qu, J., Gong, H., Lu, C., & Qu, Z. (2024). Research on the Influence of Shallow Buried Tunnel Crossing on the Stability of Overlying Frame Structure Building. Journal of Marine Science and Engineering, 12(12), 2244. https://doi.org/10.3390/jmse12122244