Removing Ice from Frozen Structures Using Bubble Pulsation Energy

Abstract

1. Introduction

2. Working Principle of Bubble-Generating Device

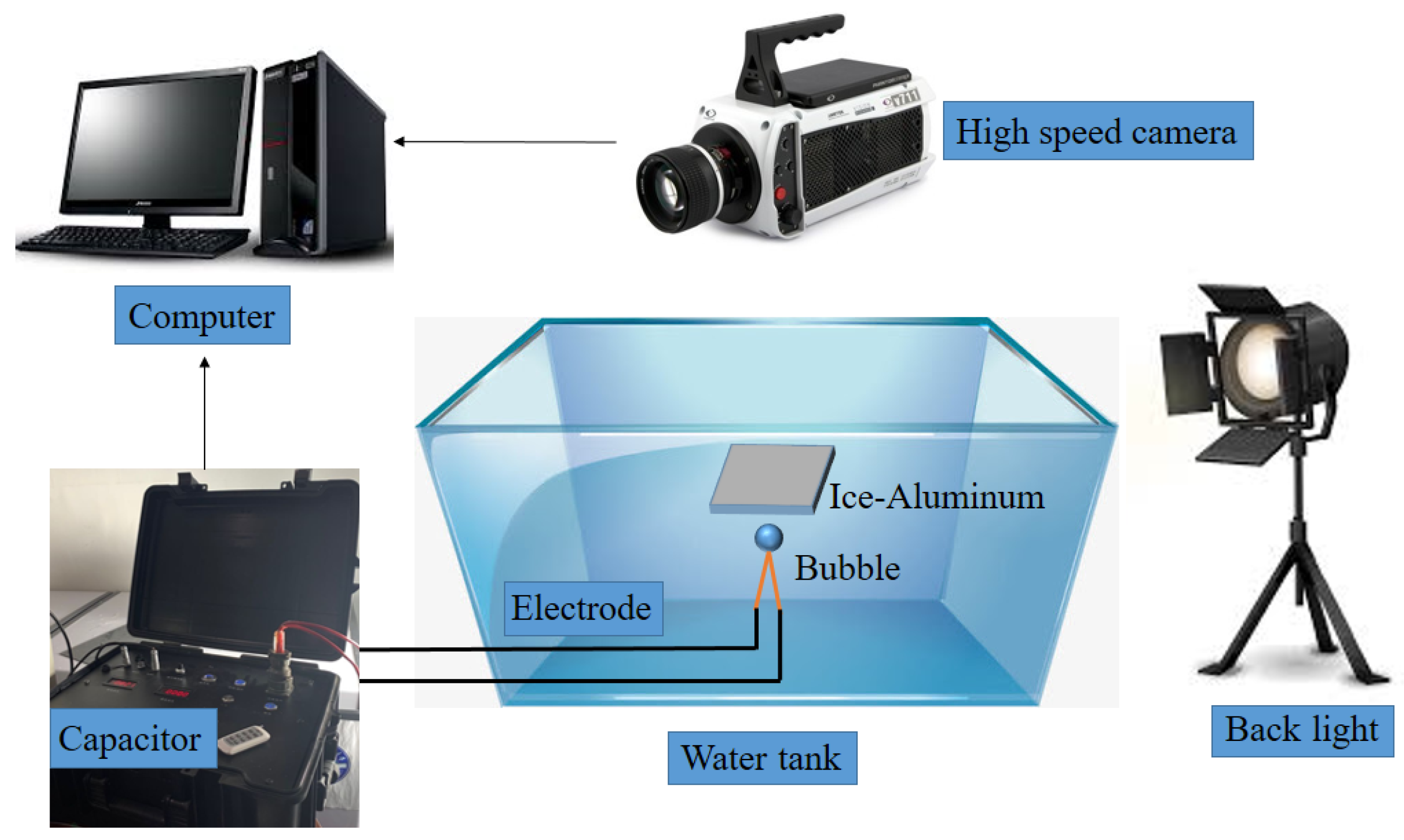

2.1. Electric Spark Bubble Experiment Device

2.2. EDM Bubble Scale Law

3. Aluminum Plate Icing Technology

4. Bubble Deicing System Set-Up

5. Experimental Study of Efficiency of Bubble Deicing

5.1. Dimensionless Parameters

5.2. Bubble Distance and Deicing Efficiency

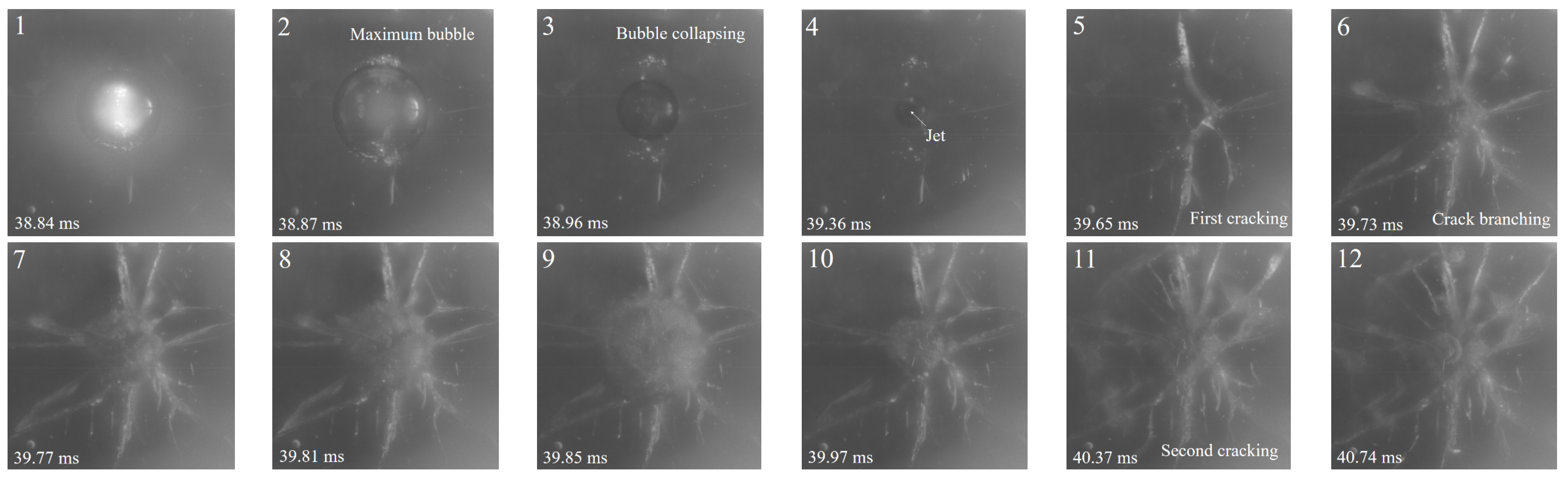

5.2.1. Large-Distance Deicing

5.2.2. Middle-Distance Deicing

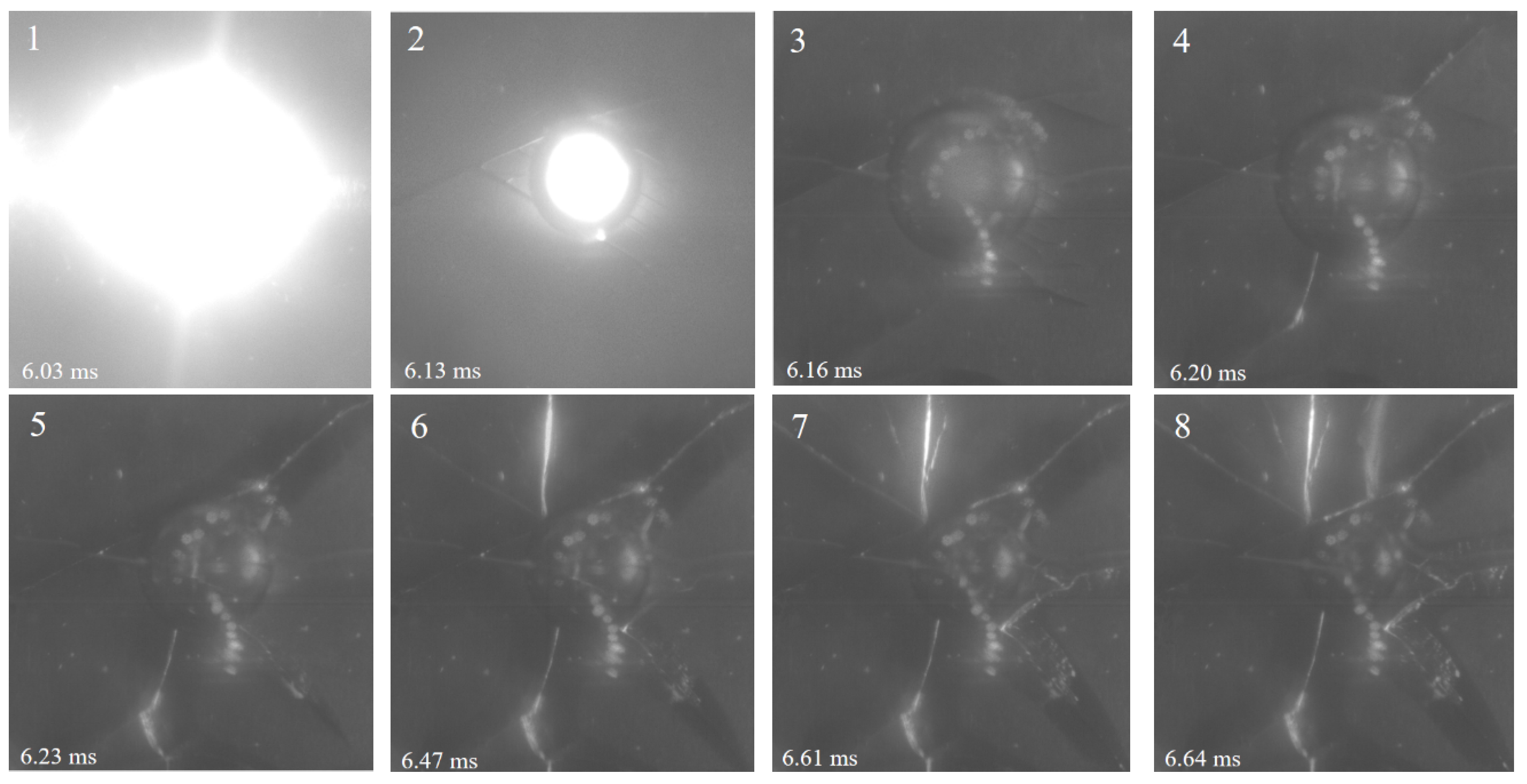

5.2.3. Near-Distance Eeicing

5.3. Influence of Ice Type on Deicing Efficiency

5.3.1. Thick, Lumpy Ice

5.3.2. Medium, Lumpy Ice

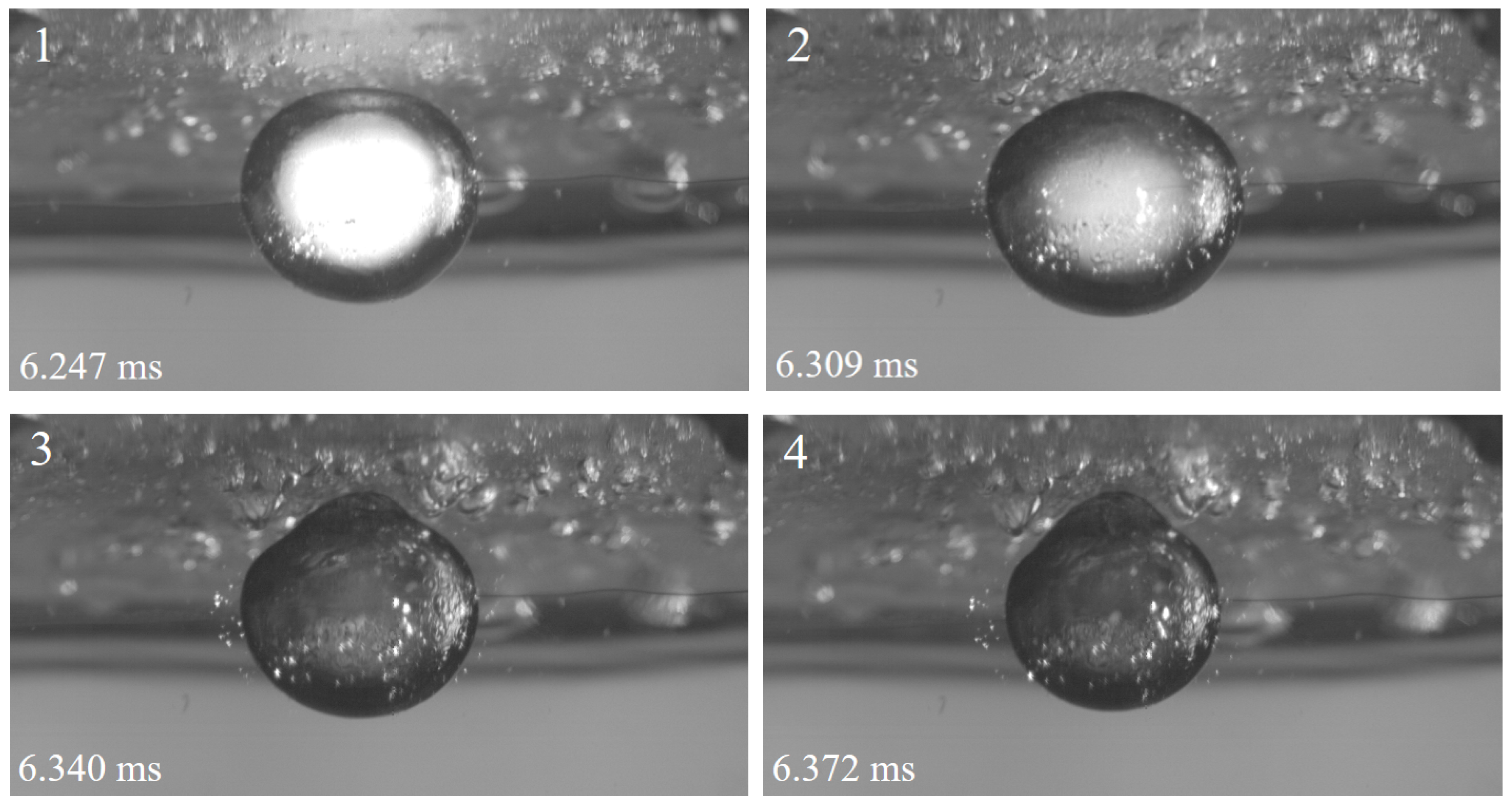

5.3.3. Thin, Lumpy Ice

5.3.4. Frost Ice

5.3.5. Deicing Mode

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Xu, Y.; Huang, Q. Progress on ultrasonic guided waves deicing techniques in improving aviation energy efficiency. Renew. Sustain. Energy Rev. 2017, 79, 638–645. [Google Scholar] [CrossRef]

- Wang, S.; Liu, L.; Xu, Q.; Liang, D.; Ji, S. A unified Minkowski sum model for largely deformed granular materials with arbitrary morphologies. Comput. Methods Appl. Mech. Eng. 2024, 432, 117427. [Google Scholar] [CrossRef]

- Wang, Q.; Yi, X.; Liu, Y.; Ren, J.; Li, W.; Wang, Q.; Lai, Q. Simulation and analysis of wind turbine ice accretion under yaw condition via an improved multi-shot icing computational model. Renew. Energy 2020, 162, 1854–1873. [Google Scholar] [CrossRef]

- Zhang, A.M.; Li, S.-M.; Xu, R.-Z.; Pei, S.-C.; Li, S.; Liu, Y.-L. A theoretical model for compressible bubble dynamics considering phase transition and migration. J. Fluid Mech. 2024, A58, 999. [Google Scholar] [CrossRef]

- Ding, L.; Chang, S.; Yi, X.; Song, M. Coupled thermo-mechanical analysis of stresses generated in impact ice during in-flight deicing. Appl. Therm. Eng. 2020, 181, 115681. [Google Scholar] [CrossRef]

- Zhou, L.; Riska, K.; und Polach, R.; Moan, T.; Su, B. Experiments on level ice loading on an icebreaking tanker with different ice drift angles. Cold Regions Sci. Technol. 2013, 85, 79–93. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, Z.; Gao, L.; Liu, Y.; Hu, H. An exploratory study on using slippery-liquid-infused-porous-surface (slips) for wind turbine icing mitigation. Renew. Energy 2020, 162, 2344–2360. [Google Scholar] [CrossRef]

- Sun, J.; Huang, Y. Investigations on the ship-ice impact: Part 1. Experimental methodologies. Mar. Struct. 2020, 72, 102772. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Y.; Su, F. Damage accumulation model of ice detach behavior in ultrasonic deicing technology. Renew. Energy 2020, 153, 1396–1405. [Google Scholar] [CrossRef]

- Zhang, A.; Chuang, Z.; Liu, S.; Zhou, L.; Qu, Y.; Lu, Y. Dynamic performance optimization of an arctic semi-submersible production system. Ocean Eng. 2022, 244, 110353. [Google Scholar] [CrossRef]

- Habibi, H.; Cheng, L.; Zheng, H.; Kappatos, V.; Selcuk, C.; Gan, T.H. A dual deicing system for wind turbine blades combining high-power ultrasonic guided waves and low-frequency forced vibrations. Renew. Energy 2015, 83, 859–870. [Google Scholar] [CrossRef]

- Chai, W.; Leira, B.J.; Naess, A. Probabilistic methods for estimation of the extreme value statistics of ship ice loads. Cold Reg. Sci. Technol. 2018, 146, 87–97. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Y.; Lei, Y. An effect assessment and prediction method of ultrasonic deicing for composite wind turbine blades. Renew. Energy 2018, 118, 1015–1023. [Google Scholar] [CrossRef]

- Zhang, J.; Gaidai, O.; Wang, K.; Xu, J.; Ye, R.; Xu, X. A stochastic method for the prediction of icebreaker bow extreme stresses. Appl. Ocean Res. 2019, 87, 95–101. [Google Scholar] [CrossRef]

- Gao, L.; Liu, Y.; Zhou, W.; Hu, H. An experimental study on the aerodynamic performance degradation of a wind turbine blade model induced by ice accretion process. Renew. Energy 2019, 133, 663–675. [Google Scholar] [CrossRef]

- Sun, S.; Shen, H.H. Simulation of pancake ice load on a circular cylinder in a wave and current field. Cold Reg. Sci. Technol. 2012, 78, 31–39. [Google Scholar] [CrossRef]

- Rashid, T.; Khawaja, H.A.; Edvardsen, K. Review of marine icing and anti-/deicing systems. J. Mar. Eng. Technol. 2016, 15, 79–87. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, G.; Yue, Q. Evaluation of ice-induced fatigue life for a vertical offshore structure in the Bohai Sea. Cold Reg. Sci. Technol. 2018, 154, 103–110. [Google Scholar] [CrossRef]

- Huttunen-Saarivirta, E.; Kuokkala, V.T.; Kokkonen, J.; Paajanen, H. Corrosion behaviour of aircraft coating systems in acetate-and formate-based deicing chemicals. Mater. Corros. 2009, 60, 173–191. [Google Scholar] [CrossRef]

- Nguyen, T.B.; Park, S.; Lim, H. Effects of morphology parameters on anti-icing performance in superhydrophobic surfaces. Appl. Surf. Sci. 2018, 435, 585–591. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, G.; Tao, J.; Zhu, C.; Liu, S.; Jin, M.; Xie, Y.; Chen, Z. Anti-icing performance of superhydrophobic texture surfaces depending on reference environments. Adv. Mater. Interfaces 2017, 4, 1700836. [Google Scholar] [CrossRef]

- Thomas, S.K.; Cassoni, R.P.; MacArthur, C.D. Aircraft anti-icing and deicing techniques and modeling. J. Aircr. 1996, 33, 841–854. [Google Scholar] [CrossRef]

- Mohammed, A.G.; Ozgur, G.; Sevkat, E. Electrical resistance heating for deicing and snow melting applications: Experimental study. Cold Reg. Sci. Technol. 2019, 160, 128–138. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, H.; Liu, X.; Liu, H.; Zhang, D. Development of high-efficient synthetic electric heating coating for anti-icing/deicing. Surf. Coatings Technol. 2018, 349, 340–346. [Google Scholar] [CrossRef]

- Li, B.; He, L.; Liu, Y.; Luo, J.; Zhang, G. Influences of key factors in hot-air deicing for live substation equipment. Cold Reg. Sci. Technol. 2019, 160, 89–96. [Google Scholar] [CrossRef]

- Wang, Y.; Yue, Q.; Guo, F.; Bi, X.; Shi, Z.; Qu, Y. Performance evaluation of a new ice-resistant jacket platform based on field monitoring. Cold Reg. Sci. Technol. 2012, 71, 44–53. [Google Scholar] [CrossRef]

- Shu, L.; Qiu, G.; Hu, Q.; Jiang, X.; McClure, G.; Liu, Y. Numerical and experimental investigation of threshold deicing heat flux of wind turbine. J. Wind. Eng. Ind. Aerodyn. 2018, 174, 296–302. [Google Scholar] [CrossRef]

- Yue, Q.; Guo, F.; Kärnä, T. Dynamic ice forces of slender vertical structures due to ice crushing. Cold Reg. Sci. Technol. 2009, 56, 77–83. [Google Scholar] [CrossRef]

- Liu, Y.; Kolbakir, C.; Hu, H.; Hu, H. A comparison study on the thermal effects in dbd plasma actuation and electrical heating for aircraft icing mitigation. Int. J. Heat Mass Transf. 2018, 124, 319–330. [Google Scholar] [CrossRef]

- Ding, L.; Wang, X.; Cui, X.; Zhang, M.; Chen, B. Development and performance research of new sensitive materials for microwave deicing pavement at different frequencies. Cold Reg. Sci. Technol. 2021, 181, 103176. [Google Scholar] [CrossRef]

- Liu, X.; Chen, H.; Zhao, Z.; Yan, Y.; Zhang, D. Slippery liquid-infused porous electric heating coating for anti-icing and deicing applications. Surf. Coatings Technol. 2019, 374, 889–896. [Google Scholar] [CrossRef]

- Hao, L.; Li, Q.; Pan, W.; Li, B. Icing detection and evaluation of the electro-impulse deicing system based on infrared images processing. Infrared Phys. Technol. 2020, 109, 103424. [Google Scholar] [CrossRef]

- Koenig, G.G.; Ryerson, C.C. An investigation of infrared deicing through experimentation. Cold Reg. Sci. Technol. 2011, 65, 79–87. [Google Scholar] [CrossRef]

- Zeng, J.; Song, B. Research on experiment and numerical simulation of ultrasonic deicing for wind turbine blades. Renew. Energy 2017, 113, 706–712. [Google Scholar] [CrossRef]

- Daniliuk, V.; Xu, Y.; Liu, R.; He, T.; Wang, X. Ultrasonic deicing of wind turbine blades: Performance comparison of perspective transducers. Renew. Energy 2020, 145, 2005–2018. [Google Scholar] [CrossRef]

- Zilioniene, D.; Laurinavicius, A. deicing experience in lithuania. Balt. J. Road Bridge Eng. 2007, 2, 73–79. [Google Scholar]

- Deng, Y.; Li, Z.; Li, Z.; Wang, J. The experiment of fracture mechanics characteristics of Yellow River Ice. Cold Reg. Sci. Technol. 2019, 168, 102896. [Google Scholar] [CrossRef]

- Zhang, A.; Liu, Y. Improved three-dimensional bubble dynamics model based on boundary element method. J. Comput. Phys. 2015, 294, 208–223. [Google Scholar] [CrossRef]

- Zhang, A.; Yang, W.S.; Huang, C.; Ming, F. Numerical simulation of column charge underwater explosion based on sph and bem combination. Comput. Fluids 2013, 71, 169–178. [Google Scholar] [CrossRef]

- Cui, P.; Zhang, A.M.; Wang, S.; Khoo, B.C. Ice breaking by a collapsing bubble. J. Fluid Mech. 2018, 841, 287. [Google Scholar] [CrossRef]

- Cui, P.; Zhang, A.M.; Wang, S.P.; Liu, Y.L. Experimental study on interaction, shock wave emission and ice breaking of two collapsing bubbles. J. Fluid Mech. 2020, 897, A25. [Google Scholar] [CrossRef]

- Zhang, A.M.; Li, S.-M.; Cui, P.; Li, S.; Liu, Y.-L. A unified theory for bubble dynamics. Phys. Fluids 2023, 35, 3. [Google Scholar] [CrossRef]

- Kan, X.Y.; Zhang, A.M.; Yan, J.L.; Wu, W.B.; Liu, Y.L. Numerical investigation of ice breaking by a high-pressure bubble based on a coupled bem-pd model. J. Fluids Struct. 2020, 96, 103016. [Google Scholar] [CrossRef]

- Yuan, G.Y.; Ni, B.Y.; Wu, Q.G.; Xue, Y.Z.; Zhang, A.M. An experimental study on the dynamics and damage capabilities of a bubble collapsing in the neighborhood of a floating ice cake. J. Fluids Struct. 2020, 92, 102833. [Google Scholar] [CrossRef]

- Buogo, S.; Plocek, J.; Vokurka, K. Efficiency of energy conversion in underwater spark discharges and associated bubble oscillations: Experimental results. Acta Acust. United Acust. 2009, 95, 46–59. [Google Scholar] [CrossRef]

- Lu, P.; Leppäranta, M.; Cheng, B.; Li, Z. Influence of melt-pond depth and ice thickness on Arctic sea-ice albedo and light transmittance. Cold Reg. Sci. Technol. 2016, 124, 1–10. [Google Scholar] [CrossRef]

- Zhang, A.; Ni, B. Influences of different forces on the bubble entrainment into a stationary gaussian vortex. Sci. China Physics Mech. Astron. 2013, 56, 2162–2169. [Google Scholar] [CrossRef]

- Sun, Y.; Timoshkin, I.V.; Given, M.J.; Wilson, M.P.; Wang, T.; MacGregor, S.J.; Bonifaci, N. Acoustic impulses generated by air-bubble stimulated underwater spark discharges. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1915–1923. [Google Scholar] [CrossRef]

- Gong, S.; Goh, B.; Ohl, S.W.; Khoo, B.C. Interaction of a spark-generated bubble with a rubber beam: Numerical and experimental study. Phys. Rev. E 2012, 86, 026307. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Z.; Lei, R.; Lu, P.; Han, H. Estimation of the uniaxial compressive strength of Arctic Sea ice during melt season. Cold Reg. Sci. Technol. 2018, 151, 9–18. [Google Scholar] [CrossRef]

- Aleshkin, M. A technique for suppressing bubble oscillations from an air gun during shallow-water marine seismic surveying. Mosc. Univ. Geol. Bull. 2020, 75, 305–308. [Google Scholar] [CrossRef]

- Zhang, A.; Li, S.; Cui, J. Study on splitting of a toroidal bubble near a rigid boundary. Phys. Fluids 2015, 27, 062102. [Google Scholar] [CrossRef]

- Li, S.; Zhang, A.M.; Han, R.; Ma, Q. 3D full coupling model for strong interaction between a pulsating bubble and a movable sphere. J. Comput. Phys. 2019, 392, 713–731. [Google Scholar] [CrossRef]

- Zhang, A.; Wu, W.; Liu, Y.; Wang, Q. Nonlinear interaction between underwater explosion bubble and structure based on fully coupled model. Phys. Fluids 2017, 29, 082111. [Google Scholar] [CrossRef]

- Liu, Y.L.; Zhang, A.M.; Tian, Z.L.; Wang, S.P. Dynamical behavior of an oscillating bubble initially between two liquids. Phys. Fluids 2019, 31, 092111. [Google Scholar]

- Li, S.; Zhang, A.M.; Han, R.; Cui, P. Experimental and numerical study of two underwater explosion bubbles: Coalescence, fragmentation and shock wave emission. Ocean. Eng. 2019, 190, 106414. [Google Scholar] [CrossRef]

- Han, R.; Li, S.; Zhang, A.; Wang, Q. Modelling for three dimensional coalescence of two bubbles. Phys. Fluids 2016, 28, 062104. [Google Scholar] [CrossRef]

- Zhang, A.; Cui, P.; Cui, J.; Wang, Q. Experimental study on bubble dynamics subject to buoyancy. J. Fluid Mech. 2015, 776, 15. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Zhang, S.; Wang, S.; Kang, Z. Removing Ice from Frozen Structures Using Bubble Pulsation Energy. J. Mar. Sci. Eng. 2024, 12, 2211. https://doi.org/10.3390/jmse12122211

Song Y, Zhang S, Wang S, Kang Z. Removing Ice from Frozen Structures Using Bubble Pulsation Energy. Journal of Marine Science and Engineering. 2024; 12(12):2211. https://doi.org/10.3390/jmse12122211

Chicago/Turabian StyleSong, Ying, Shuai Zhang, Shiping Wang, and Zhuang Kang. 2024. "Removing Ice from Frozen Structures Using Bubble Pulsation Energy" Journal of Marine Science and Engineering 12, no. 12: 2211. https://doi.org/10.3390/jmse12122211

APA StyleSong, Y., Zhang, S., Wang, S., & Kang, Z. (2024). Removing Ice from Frozen Structures Using Bubble Pulsation Energy. Journal of Marine Science and Engineering, 12(12), 2211. https://doi.org/10.3390/jmse12122211