Current Status and Future Trends in Installation, Operation and Maintenance of Offshore Floating Wind Turbines

Abstract

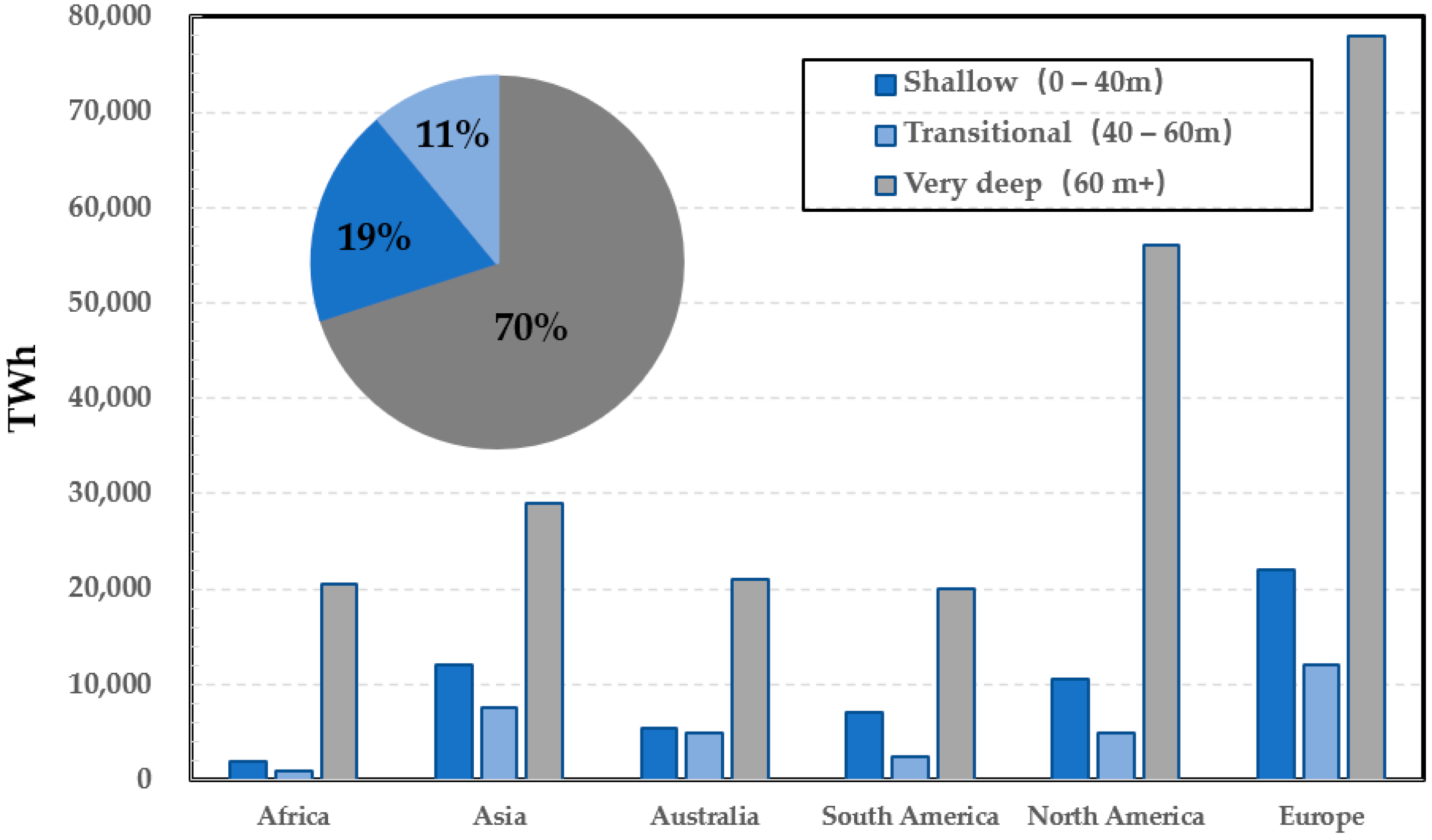

1. Introduction

- Section 2: provides a detailed overview of the installation methods and relevant research for different types of floating wind turbine foundations and superstructures.

- Section 3: elaborates on various operations and maintenance (O&M) strategies and methodologies for floating wind turbines.

- Section 4: explores the interconnections between installation and O&M activities for floating wind turbines.

- Section 5: presents the types and characteristics of tools and equipment used for the installation and O&M of floating wind turbines.

- Section 6: discusses the regulations, industry standards, and studies related to the operability of offshore operations for floating wind turbines.

- Section 7: examines future development trends in the fields of installation and O&M of floating wind turbines.

- Section 8: concludes the paper.

2. Installation Operations of Floating Wind Turbines

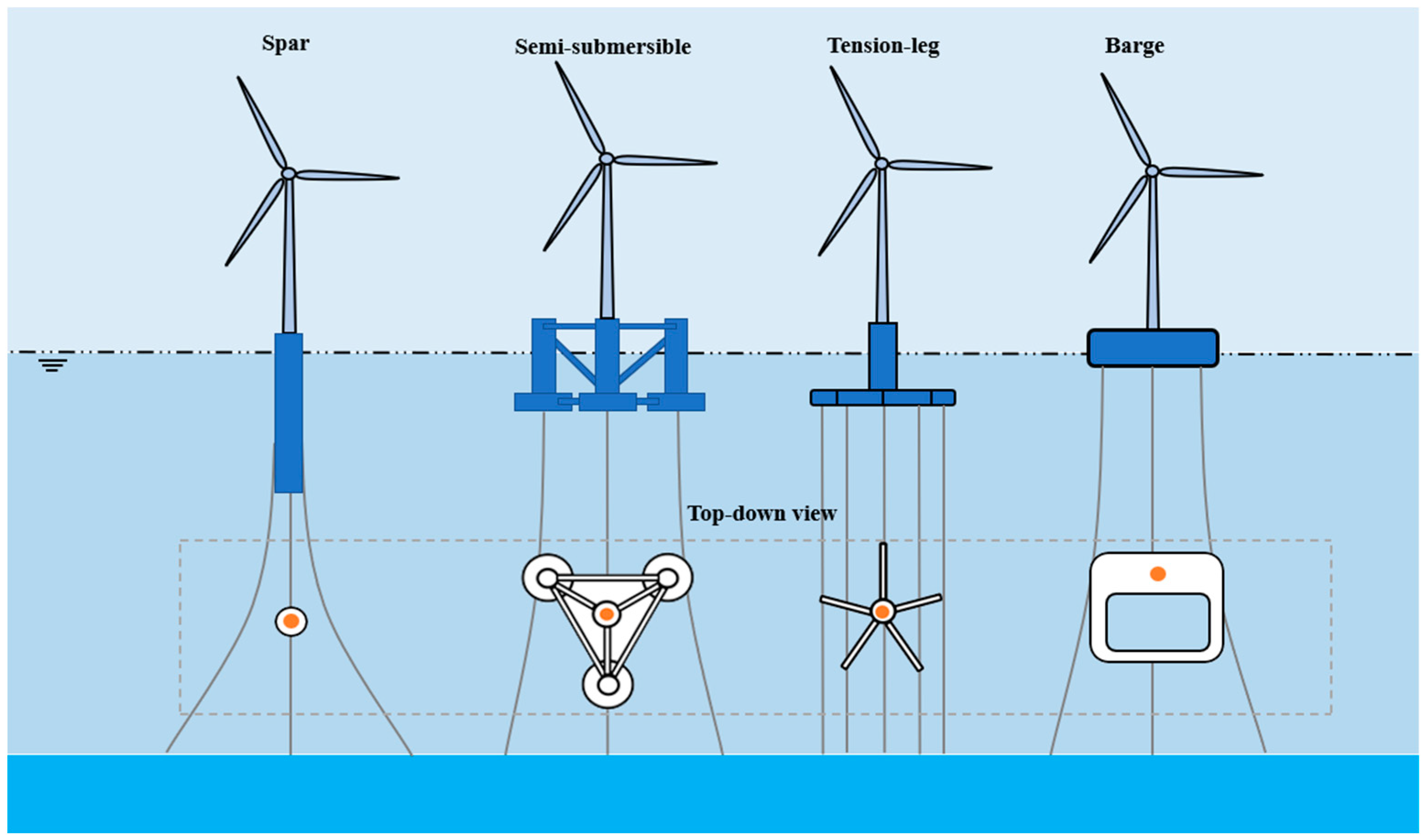

2.1. Installation of Floating Wind Turbine Foundations

2.1.1. Spar

2.1.2. Semi-Submersible

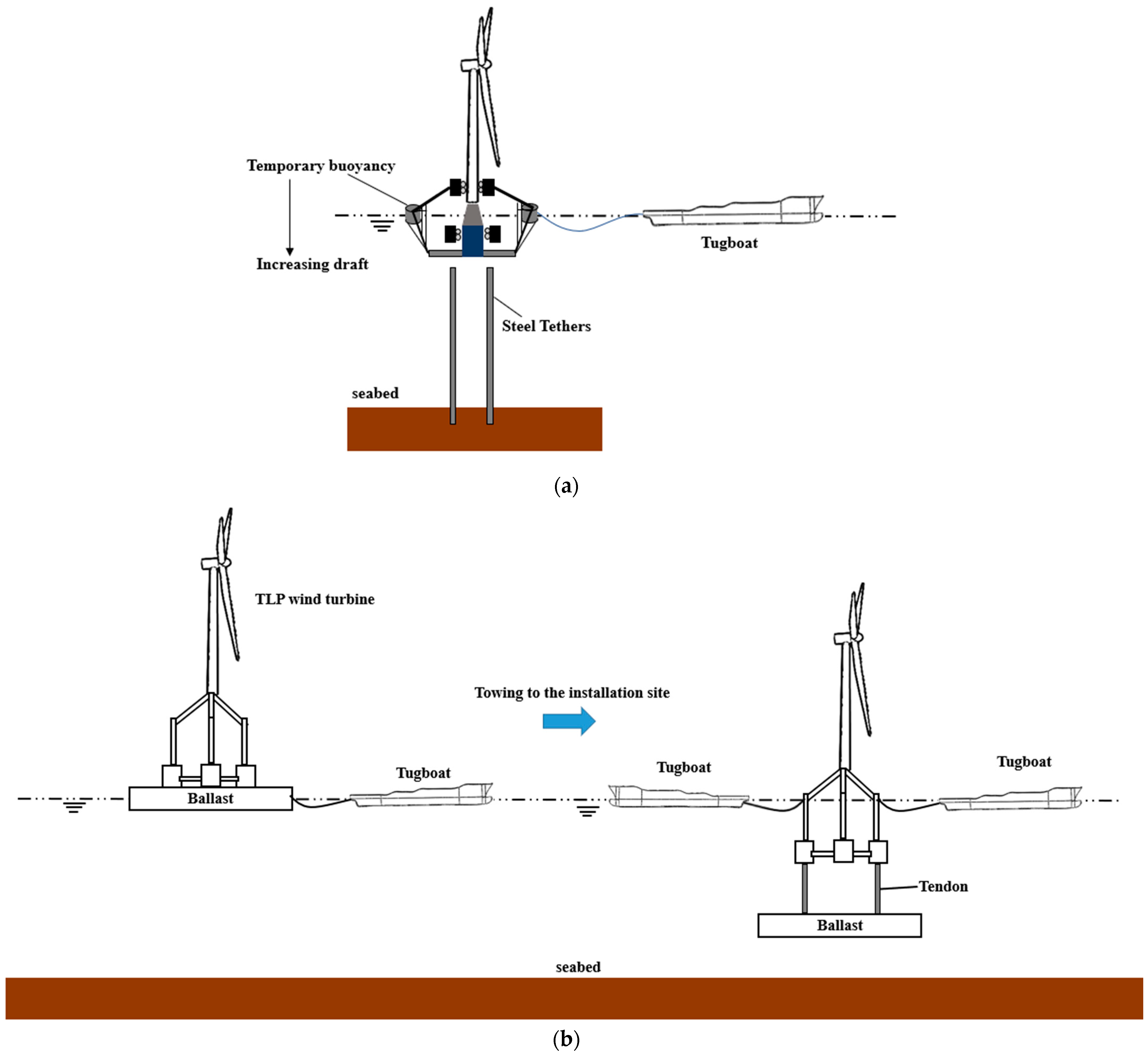

2.1.3. TLP

2.1.4. Barge

2.2. On-Site Installation Operations of Floating Wind Turbines

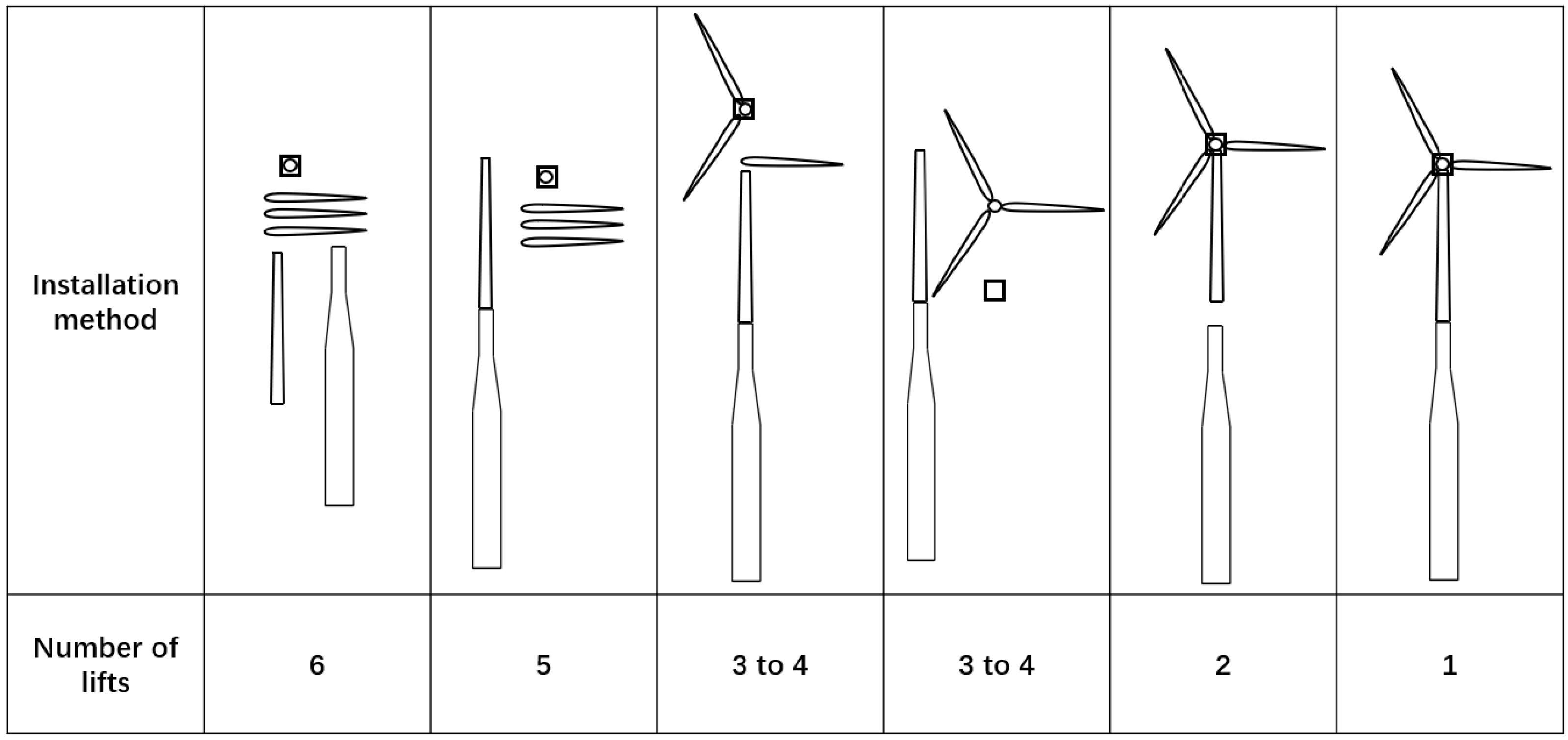

2.2.1. Integrated Lifting of Floating Wind Turbines

2.2.2. Split Installation of Floating Wind Turbines

2.3. Summary

3. Operations and Maintenance of Floating Wind Turbines

3.1. Maintenance Strategies

3.1.1. Corrective Maintenance Strategy

3.1.2. Preventive Maintenance Strategy

3.1.3. Opportunistic Maintenance Strategy

3.1.4. Predictive Maintenance Strategy

3.1.5. Summary

3.2. On-Site Operation and Maintenance of Floating Wind Turbines

3.3. Intelligent Operation and Maintenance of Floating Wind Turbines

3.4. Summary

4. The Relationship Between Installation and Maintenance of Floating Wind Turbines

5. Equipment for Installation and Maintenance of Floating Wind Turbines

5.1. Installation and Maintenance Vessels

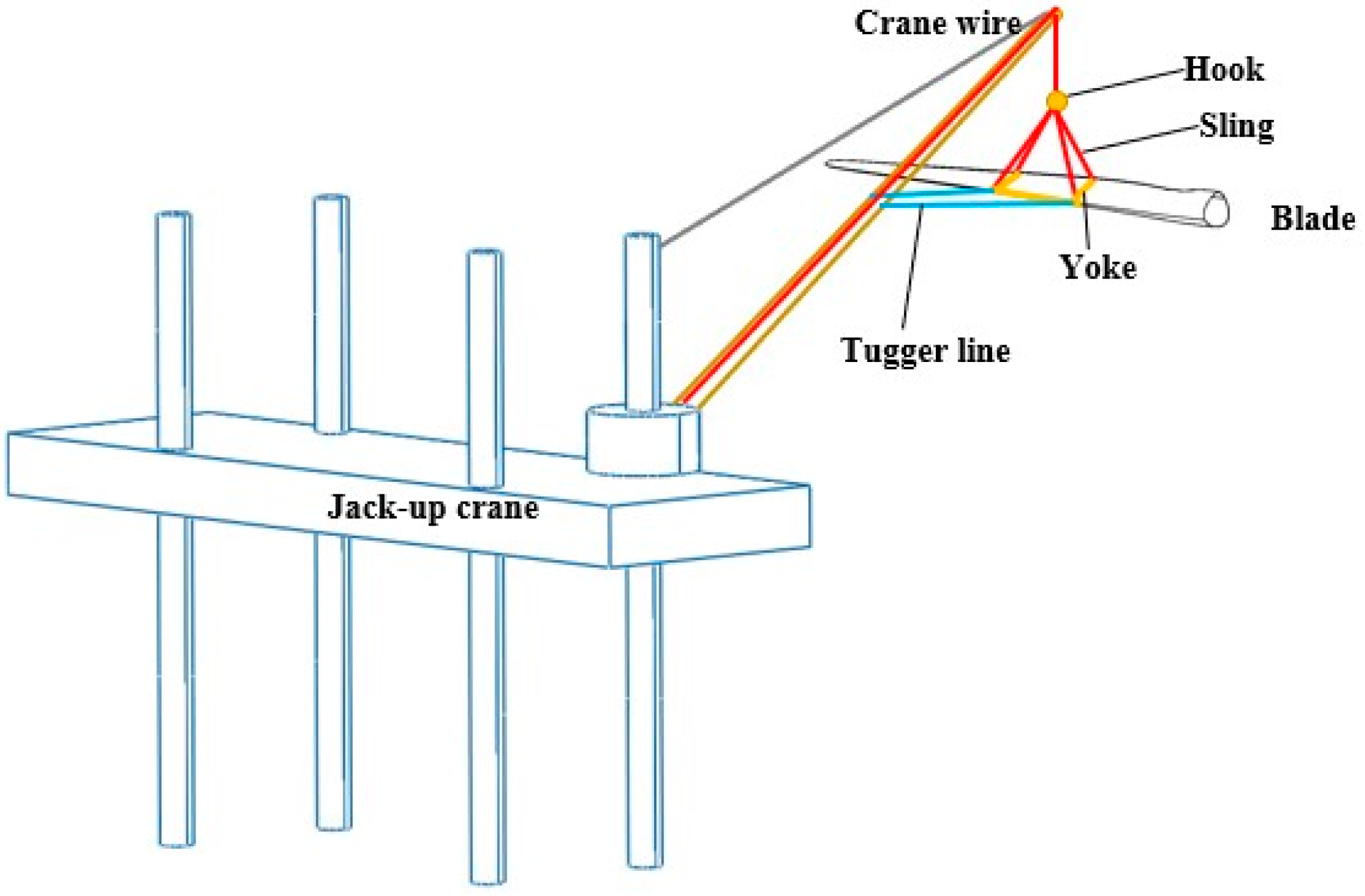

5.2. Blade Lifting Equipment

5.3. Maintenance Robots

6. Standards and Guidelines

7. Future Outlook

7.1. On-Site Installation and Operation Methods

7.2. Specialized Installation and Maintenance Vessels

7.3. Intelligent Maintenance

7.4. Floating Wind Turbine Operational Standards

8. Concluding Remarks

- Floating wind power breaks the limitations of traditional fixed wind turbines concerning water depth and offshore distance. With continuous technological advancement, it is regarded as the primary means for future deep-water offshore wind development. Although some projects have demonstrated significant potential, widespread application still faces numerous challenges. Traditional towing installation and T2S operation methods are susceptible to adverse weather and narrow operational windows, especially against the backdrop of increasingly larger floating wind turbines. The installation and operation of floating offshore wind farms are rapidly developing. Despite notable progress, achieving sustainable development remains a substantial research gap. Future studies should focus on enabling safer and more reliable on-site operational methods to reduce costs and enhance operational efficiency.

- Single-blade lifting technology has shown significant advantages in turbine installation and major component replacement, applicable to both fixed and floating wind turbines. Currently, installation primarily relies on jack-up vessels for static operations; however, the future focus will shift to dynamic operations involving floating crane vessels—specifically the floating-to-floating operational mode. To address higher wind speeds and complex sea conditions while minimizing manual intervention, various innovative processes and tools have been developed. Nevertheless, most technologies are still at a low maturity stage and require further development for practical application.

- As the operational areas of floating wind turbines gradually move into deeper waters, the harshness of the working environment and water depth demands higher safety and feasibility standards for installation and maintenance. There is an urgent need to develop new installation and maintenance vessels capable of maintaining operational stability under adverse conditions, adapting to deep-sea environments, and meeting the demands of larger turbines to ensure safe and efficient operational processes.

- Intelligent condition monitoring and digital operations can effectively enhance fault diagnosis and prevention capabilities of wind power equipment, thereby reducing maintenance costs. By employing digital monitoring and control systems, real-time monitoring and analysis of turbine conditions can promptly identify potential issues, preventing further damage or downtime incidents. Integrating intelligent maintenance strategies can significantly improve operational efficiency, avoid unnecessary blind repairs, and reduce long-term maintenance costs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- GWEC. Global Offshore Wind Report 2024. Available online: https://gwec.net/global-offshore-wind-report-2024/ (accessed on 1 June 2024).

- Chen, M.; Huang, W.; Liu, H.; Hallak, T.S.; Liu, S.; Yang, Y.; Tao, T.; Jiang, Y. A novel SPM wind-wave-aquaculture system: Concept design and fully coupled dynamic analysis. Ocean. Eng. 2025, 315, 119798. [Google Scholar] [CrossRef]

- GWEC. Global Wind Report 2024. Available online: https://gwec.net/global-wind-report-2024/ (accessed on 15 July 2024).

- Jadali, A.; Ioannou, A.; Salonitis, K.; Kolios, A. Decommissioning vs. repowering of offshore wind farms—A techno-economic assessment. Int. J. Adv. Manuf. Technol. 2021, 112, 2519–2532. [Google Scholar] [CrossRef]

- Smythe, T.; Bidwell, D.; Moore, A.; Smith, H.; McCann, J. Beyond the beach: Tradeoffs in tourism and recreation at the first offshore wind farm in the United States. Energy Res. Soc. Sci. 2020, 70, 101726. [Google Scholar] [CrossRef]

- Henderson, A.R.; Witcher, D. Floating offshore wind energy—A review of the current status and an assessment of the prospects. Wind Eng. 2010, 34, 1–16. [Google Scholar] [CrossRef]

- Chen, Z.-C.; Xie, X.-G.; Fang, Z.-F.; He, X.-H. Motion response analysis of floating foundation of offshore wind turbines. In Proceedings of the Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2019; p. 022008. [Google Scholar]

- Ricciardelli, F.; Maienza, C.; Vardaroglu, M.; Avossa, A.M. Wind energy into the future: The challenge of deep-water wind farms. Wind. Struct. 2021, 32, 321–340. [Google Scholar]

- Weinzettel, J.; Reenaas, M.; Solli, C.; Hertwich, E.G. Life cycle assessment of a floating offshore wind turbine. Renew. Energy 2009, 34, 742–747. [Google Scholar] [CrossRef]

- Bosch, J.; Staffell, I.; Hawkes, A.D. Temporally explicit and spatially resolved global offshore wind energy potentials. Energy 2018, 163, 766–781. [Google Scholar] [CrossRef]

- International Energy Agency. World Energy Statistics 2017. Available online: https://www.oecd-ilibrary.org/content/publication/world_energy_stats-2017-en (accessed on 1 July 2024).

- reNEWS. Hywind Scotland Turbines Require ‘Heavy Maintenance’. 2024. Available online: https://www.renews.biz/90572/hywind-scotland-turbines-require-heavy-maintenance/ (accessed on 15 July 2024).

- McMorland, J.; Flannigan, C.; Carroll, J.; Collu, M.; McMillan, D.; Leithead, W.; Coraddu, A. A review of operations and maintenance modelling with considerations for novel wind turbine concepts. Renew. Sustain. Energy Rev. 2022, 165, 112581. [Google Scholar] [CrossRef]

- Zhao, S.; Bai, H.; Xu, K.; Du, J.; Zhang, M.; Yuan, W.; Li, H. Current Status, Development Trends, and Technical Challenges of Floating Offshore Wind Turbine Installation. Ocean Univ. China 2024, 54, 13–28. [Google Scholar]

- Dymarski, P.; Dymarski, C.; Ciba, E. Stability analysis of the floating offshore wind turbine support structure of cell spar type during its installation. Pol. Marit. Res. 2019, 26, 109–116. [Google Scholar] [CrossRef]

- Li, X.; Zeng, X.; Yu, X.; Wang, X. Seismic response of a novel hybrid foundation for offshore wind turbine by geotechnical centrifuge modeling. Renew. Energy 2021, 172, 1404–1416. [Google Scholar] [CrossRef]

- Høeg, C.E.; Zhang, Z. The influence of gyroscopic effects on dynamic responses of floating offshore wind turbines in idling and operational conditions. Ocean Eng. 2021, 227, 108712. [Google Scholar] [CrossRef]

- Ward, J.C.; Goupee, A.J.; Viselli, A.M.; Dagher, H.J. Experimental investigation into the dynamic behavior of a floating offshore wind turbine stabilized via a suspended counterweight. Ocean Eng. 2021, 228, 108906. [Google Scholar] [CrossRef]

- Harte, M.; Basu, B.; Nielsen, S.R. Dynamic analysis of wind turbines including soil-structure interaction. Eng. Struct. 2012, 45, 509–518. [Google Scholar] [CrossRef]

- Empire Engineering. The Empire Engineering Guide to Offshore Wind Foundations Second Edition; Technical Report; Empire Engineering: London, UK, 2023. [Google Scholar]

- The Global Wind Energy Council. Floating Offshore Wind—A Global Opportunity; The Global Wind Energy Council: Lisbon, Portugal, 2022. [Google Scholar]

- Du, A. Semi-Submersible, Spar and TLP–How to Select Floating Wind Foundation Types? Available online: https://www.empireengineering.co.uk/semi-submersible-spar-and-tlp-floating-wind-foundations/ (accessed on 15 August 2024).

- Micallef, D.; Rezaeiha, A. Floating offshore wind turbine aerodynamics: Trends and future challenges. Renew. Sustain. Energy Rev. 2021, 152, 111696. [Google Scholar] [CrossRef]

- Equinor. Hywind Scotland. Available online: https://www.equinor.com/no/energi/flytende-havvind (accessed on 11 July 2024).

- Butterfield, S.; Musial, W.; Jonkman, J.; Sclavounos, P. Engineering Challenges for Floating Offshore Wind Turbines; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2007. [Google Scholar]

- Crome, T. Hywind Demo-Technip Experience with Offshore Wind. Available online: https://www.osti.gov/etdeweb/servlets/purl/993282 (accessed on 15 September 2024).

- Emetcentre. Unitech Zefyros (Hywind Demo). Available online: https://www.norwegianoffshorewind.no/about/initiatives/met-centre (accessed on 15 August 2024).

- Equinor. World’s First Floating Wind Farm Has Started Production. Available online: https://www.equinor.com/news/archive/worlds-first-floating-wind-farm-started-production (accessed on 20 August 2024).

- Steen, K.E. Hywind Scotland–Status and Plans. Available online: https://www.sintef.no/globalassets/project/eera-deepwind2016/presentations/steen_opening-session.pdf (accessed on 15 August 2024).

- Lien, K.H. Hywind Scotland–Marine Operations. Available online: https://www.sintef.no/prosjekter/?topic=281535&pagenumber=4#result (accessed on 15 August 2024).

- AS, W. Windflip—A Specialized Barge for Transportation of Floating wind Turbines. Available online: https://www.youtube.com/watch?v=G0I3HCmANVc (accessed on 20 August 2024).

- Atkins. Hywind Floating Wind Installation Challenge. Available online: https://www.atkinsglobal.com/en-GB/projects/hywind-installation-challenge (accessed on 20 September 2024).

- ASA, U.G. Windlifter. Available online: https://ulstein.com/energy/heavy-offshore-construction-vessel (accessed on 20 September 2024).

- Jiang, Z.; Li, L.; Gao, Z.; Halse, K.H.; Sandvik, P.C. Dynamic response analysis of a catamaran installation vessel during the positioning of a wind turbine assembly onto a spar foundation. Mar. Struct. 2018, 61, 1–24. [Google Scholar] [CrossRef]

- Jiang, Z.; Yttervik, R.; Gao, Z.; Sandvik, P.C. Design, modelling, and analysis of a large floating dock for spar floating wind turbine installation. Mar. Struct. 2020, 72, 102781. [Google Scholar] [CrossRef]

- AS, S. Hywind Installation. Available online: https://www.equinor.com/energy/hywind-scotland (accessed on 10 September 2024).

- Chen, M.; Ouyang, M.; Li, T.; Zou, M.; Ye, J.; Tian, X. Numerical modelling of a catamaran float-over deck installation for a spar platform with complex hydrodynamic interactions and mechanical couplings. Ocean Eng. 2023, 287, 115905. [Google Scholar] [CrossRef]

- Zou, M.; Chen, M.; Zhu, L.; Yun, Q.; Zhao, W.; Liang, Q.; Zhao, Y. Experimental and numerical investigation of gap resonances between side-by-side fixed barges under beam sea excitation. Ocean Eng. 2024, 297, 117150. [Google Scholar] [CrossRef]

- Chen, M.; Zou, M.; Zhu, L.; Ouyang, M.; Liang, Q.; Zhao, W. A fully coupled time domain model capturing nonlinear dynamics of float-over deck installation. Ocean Eng. 2024, 293, 116721. [Google Scholar] [CrossRef]

- Zou, M.; Chen, M.; Zhu, L.; Li, L.; Zhao, W. A constant parameter time domain model for dynamic modelling of multi-body system with strong hydrodynamic interactions. Ocean Eng. 2023, 268, 113376. [Google Scholar] [CrossRef]

- Chen, M.; Zou, M.; Zhu, L.; Ouyang, M.; Zhao, W. An Efficient Time-Domain Model Capturing Nonlinear Dynamics for Multi-Body Offshore Operations. Available online: https://ssrn.com/abstract=4583209 (accessed on 15 September 2024).

- Chen, M.; Guo, H.; Wang, R.; Tao, R.; Cheng, N. Effects of gap resonance on the hydrodynamics and dynamics of a multi-module floating system with narrow gaps. J. Mar. Sci. Eng. 2021, 9, 1256. [Google Scholar] [CrossRef]

- Corporation, T. Sakiyama 2 MW Floating Offshore Wind Turbine. Available online: https://haenkaze.com/en/about-en/about-facility-en/ (accessed on 15 September 2024).

- INPEX. Goto Floating Wind Farm LLC Consortium Postpones Startup of Goto City Offshore Wind Power Generation Project to January 2026. Available online: https://www.inpex.co.jp/english/news/assets/pdf/20230922.pdf (accessed on 15 September 2024).

- Fukushima Offshore Wind Consortium. Fukushima Floating Offshore Wind Farm Demonstration Project (Fukushima FOR-WARD)-Construction of Phase I. Available online: http://www.fukushima-forward.jp/english/index.html (accessed on 15 September 2024).

- Wind, T. Sakiyama 2 MW Floating Wind Turbine. Available online: https://www.4coffshore.com/windfarms/japan/sakiyama-2mw-floating-wind-turbine-japan-jp50.html (accessed on 15 September 2024).

- Stiesdal. The TetraSpar Full-Scale Demonstration Project. Available online: https://www.stiesdal.com/offshore/the-tetraspar-full-scale-demonstration-project/ (accessed on 15 September 2024).

- Li, C.B.; Zhang, Z.; Zhang, J.; Li, X.; Choung, J.; Chen, M. Investigation on local mooring stresses of floating offshore wind turbines considering mooring chain geometrical and material nonlinearity. Ocean Eng. 2024, 312, 119166. [Google Scholar] [CrossRef]

- Alexandre, A.; Percher, Y.; Choisnet, T.; Buils Urbano, R.; Harries, R. Coupled analysis and numerical model verification for the 2 MW Floatgen demonstrator project with IDEOL platform. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Madrid, Spain, 17–22 June 2018; p. V001T001A032. [Google Scholar]

- Karimirad, M.; Michailides, C. V-shaped semisubmersible offshore wind turbine: An alternative concept for offshore wind technology. Renew. Energy 2015, 83, 126–143. [Google Scholar] [CrossRef]

- Liu, Y.; Li, S.; Yi, Q.; Chen, D. Developments in semi-submersible floating foundations supporting wind turbines: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 60, 433–449. [Google Scholar] [CrossRef]

- Roddier, D.; Cermelli, C.; Aubault, A.; Weinstein, A. WindFloat: A floating foundation for offshore wind turbines. J. Renew. Sustain. Energy 2010, 2, 033104. [Google Scholar] [CrossRef]

- Chen, M.; Chen, Y.; Li, T.; Tang, Y.; Ye, J.; Zhou, H.; Ouyang, M.; Zhang, X.; Shi, W.; Sun, X. Analysis of the wet-towing operation of a semi-submersible floating wind turbine using a single tugboat. Ocean Eng. 2024, 299, 117354. [Google Scholar] [CrossRef]

- Power, P. Projects-Unlocking the Full Potential of Floating Offshore Wind. Available online: https://www.principlepower.com/projects (accessed on 15 September 2024).

- EOLINK 5 MW Demonstrator Floating Wind Farm. Available online: https://www.4coffshore.com/windfarms/france/eolink-5-mw-demonstrator-france-fr85.html (accessed on 15 September 2024).

- European Commission. Black Sea fLoating Offshore Wind. Available online: https://cordis.europa.eu/project/id/101084323 (accessed on 15 September 2024).

- OffshoreWind.biz. China’s First Floating Wind Turbine Heads Offshore. Available online: https://www.offshorewind.biz/2021/07/13/chinas-first-floating-wind-turbine-heads-offshore/ (accessed on 15 September 2024).

- OffshoreWind.biz. CSSC Installing ‘Largest Floating Wind Turbine in China’. Available online: https://www.offshorewind.biz/2022/05/30/cssc-installing-largest-floating-wind-turbine-in-china/ (accessed on 15 September 2024).

- NorthWind. China Launches Deep-Sea Floating Wind Platform for off Shore Energy. Available online: https://www.northwindresearch.no/news/china-launches-deep-sea-floating-wind-platform-for-offshore-energy/ (accessed on 15 September 2024).

- Dagher, H.J.; Viselli, A. Final Technical Report-NEW ENGLAND AQUA VENTUS I 100% Hull Design; Technical Report DE-EE0006713; University of Maine: Orono, ME, USA, 2023. [Google Scholar]

- Marshall, R.; Watt, T. Pentland Floating Offshore Wind Farm-Planning and Policy Statement; Technical Report GBPNTD-ENV-PEN-AA-00002; Highland Wind Limited: Bristol, UK, 2022. [Google Scholar]

- TwinHub. Floating Wind Power in the Celtic Sea. Available online: https://www.twinhub.co.uk/ (accessed on 10 September 2024).

- Sclavounos, P.D.; Lee, S.; DiPietro, J.; Potenza, G.; Caramuscio, P.; De Michele, G. Floating offshore wind turbines: Tension leg platform and taught leg buoy concepts supporting 3–5 MW wind turbines. In Proceedings of the European Wind Energy Conference EWEC, Warsaw, Poland, 20–23 April 2010; pp. 20–23. [Google Scholar]

- Crozier, A. Design and Dynamic Modeling of the Support Structure for a 10 MW Offshore Wind Turbine; Institutt for energi-og Prosessteknikk: Trondheim, Norway, 2011. [Google Scholar]

- Kausche, M.; Adam, F.; Dahlhaus, F.; Großmann, J. Floating offshore wind-Economic and ecological challenges of a TLP solution. Renew. Energy 2018, 126, 270–280. [Google Scholar] [CrossRef]

- Uzunoglu, E.; Soares, C.G. Hydrodynamic design of a free-float capable tension leg platform for a 10 MW wind turbine. Ocean Eng. 2020, 197, 106888. [Google Scholar] [CrossRef]

- Wybro, P.G.; Wu, S.; Treu, J.J.; Chaplin, D.E. Method of Installation of a Tension Leg Platform and Tendons Therefor. U.S. Patent No. 7,452,162, 18 November 2008. [Google Scholar]

- Hyland, T.; Adam, F.; Dahlias, F.; Großmann, J. Towing tests with the GICON®-TLP for wind turbines. In Proceedings of the ISOPE International Ocean and Polar Engineering Conference, Busan, Republic of Korea, 15–20 June 2014; p. ISOPE–I-14-065. [Google Scholar]

- Blue H Engineering. Engineering BV, Historical Development. Available online: http://www.bluehengineering.com (accessed on 15 August 2024).

- Chakrabarti, S. Handbook of Offshore Engineering (2-Volume Set); Elsevier: Amsterdam, The Netherlands, 2005; Volume 1. [Google Scholar]

- Wybro, P.G. Tension Leg Platform and Method of Installation Therefor. U.S. Patent No. 5,551,802, 3 September 1996. [Google Scholar]

- Group, P. Provence Grand Large. Available online: https://www.prysmiangroup.com/en/insight/projects/provence-grand-large (accessed on 15 September 2024).

- Bluewater. METCentre & Bluewater Sign Agreement to Install a Floating Wind System Offshore Norway. Available online: https://www.bluewater.com/metcentre-bluewater-sign-agreement-to-install-a-floating-wind-system-offshore-norway/ (accessed on 15 September 2024).

- Wind, X. PivotBuoy Project: X1 Wind Reports Successful Results. Available online: https://www.x1wind.com/news/pivotbuoy-project-x1-wind-reports-successful-results/ (accessed on 15 September 2024).

- European Commission. Next Generation Integrated Floating Wind Optimized for Deep Waters. Available online: https://cordis.europa.eu/project/id/101084300 (accessed on 15 September 2024).

- Chen, M.; Yang, L.; Sun, X.; Pan, J.; Zhang, K.; Lin, L.; Yun, Q.; Chen, Z. Dynamic Analysis of a Barge-Type Floating Wind Turbine Subjected to Failure of the Mooring System. J. Mar. Sci. Eng. 2024, 12, 617. [Google Scholar] [CrossRef]

- WEAMEC. FLOATGEN: The first offshore wind turbine in France. Available online: https://www.weamec.fr/en/synthesis/floatgen/ (accessed on 15 September 2024).

- NEDO. A record of the Construction of Hibiki, a Next-Generation Floating Offshore Wind Turbine System. Available online: https://www.youtube.com/watch?v=XHL4w73kxIk (accessed on 15 September 2024).

- Qair. EOLMED: Floating wind energy in Western France. Available online: https://eolmed.qair.energy/en/ (accessed on 15 September 2024).

- RWE. Floating Wind: The DemoSATH Project Starts Supplying Energy to the Spanish Grid. Available online: https://www.rwe.com/en/press/rwe-offshore-wind-gmbh/2023-09-18-floating-wind-demosath-project-starts-supplying-energy-to-spanish-grid/ (accessed on 15 September 2024).

- Monthly, W. Three Firms Shortlisted for Hywind Installation Challenge. 2015. Available online: https://www.windpowermonthly.com/article/1358772/three-firms-shortlisted-hywind-installation-challenge (accessed on 15 September 2024).

- NTNU, B. RA2 Enhanced Physical Modelling, Numerical Methods and Tools-Installation and Maintenance of Offshore Wind Turbines. 2015. Available online: https://www.ntnu.edu/move/enhanced-physical-modelling-numerical-methods-and-tools (accessed on 15 September 2024).

- Wang, W.; Bai, Y. Investigation on installation of offshore wind turbines. J. Mar. Sci. Appl. 2010, 9, 175–180. [Google Scholar] [CrossRef]

- Zhu, L.; Chen, M.; Wang, J.; Zou, M. Offshore Wind Turbine Installation System. European Patent Specification 18882069.0, 8 September 2021. [Google Scholar]

- Chen, M.; Wang, F.; Zhu, L.; Pedersen, P.T. Dynamic analysis of offshore wind turbine installation based on a novel integrated mating method. In Proceedings of the ISOPE International Ocean and Polar Engineering Conference, Shanghai, China, 11–16 October 2020; p. ISOPE–I-20-1192. [Google Scholar]

- Ren, Z.; Skjetne, R.; Verma, A.S.; Jiang, Z.; Gao, Z.; Halse, K.H. Active heave compensation of floating wind turbine installation using a catamaran construction vessel. Mar. Struct. 2021, 75, 102868. [Google Scholar] [CrossRef]

- Hong, S.; Zhang, H.; Nord, T.S.; Halse, K.H. Effect of fender system on the dynamic response of onsite installation of floating offshore wind turbines. Ocean Eng. 2022, 259, 111830. [Google Scholar] [CrossRef]

- Hong, S.; Zhang, H.; Halse, K.H. Hydrodynamic and environmental modelling influence on numerical analysis of an innovative installation method for floating wind. Ocean Eng. 2023, 280, 114681. [Google Scholar] [CrossRef]

- Liu, T.; Halse, K.H.; Leira, B.J.; Jiang, Z. Comparative study of the mating process for a spar-type floating wind turbine using two alternative installation vessels. Appl. Ocean Res. 2023, 132, 103452. [Google Scholar] [CrossRef]

- Cape, I. Inch Cape Offshore Wind Farm. Available online: https://www.inchcapewind.com/ (accessed on 15 August 2024).

- Equinor, B. Empire Wind- Powering New York Together. Available online: https://www.empirewind.com/ (accessed on 15 August 2024).

- AB, S.a.H. MunmuBaram Floating Offshore Wind Project-Powering the Future of Korea with Floating Wind Technology. Available online: http://www.munmubaram.com/ (accessed on 15 August 2024).

- Shell New Energies US LLC and EDF-RE Offshore Development. Atlantic Shores Offshore Wind. Available online: https://www.atlanticshoreswind.com/ (accessed on 15 August 2024).

- EnBW. EnBW He Dreiht Offshore Wind Farm. Available online: https://www.enbw.com/renewableenergy/wind-energy/our-offshore-wind-farms/he_dreiht/ (accessed on 20 September 2024).

- Jonkman, J.; Butterfield, S.; Musial, W.; Scott, G. Definition of a 5-MW Reference Wind Turbine for Offshore System Development. Available online: https://www.nrel.gov/docs/fy09osti/38060.pdf (accessed on 20 September 2024).

- TGS. 5 M Offshore Wind Turbine. Available online: https://www.4coffshore.com/windfarms/turbine-senvion-5m-tid35.html#:~:text=4C%20Offshore%20|%20Specification%20of%20Offshore%20Wind%20Turbine%205M,%20Senvion (accessed on 20 September 2024).

- Siemens. Siemens D6 Platform–6.0-MW Direct Drive Wind Turbine. Available online: https://assets.new.siemens.com/siemens/assets/api/uuid:1c690d9444b15f1a542d0e3166f43a90814743f2/d6-offshore-brochure-en.pdf#:~:text=specifically%20for%20the%20Siemens%206.0-MW%20wind%20turbine,%20has%20a%20swept (accessed on 20 September 2024).

- Leanwind. Summary Description of LEANWIND 8 MW Reference Turbine. Available online: https://www.leanwind.eu/wp-content/uploads/LEANWIND-8-MW-turbine_Summary.pdf#:~:text=The%20design%20of%20the%20LEANWIND%208%20MW%20turbine%20(LW)%20is (accessed on 20 September 2024).

- Bak, C.; Zahle, F.; Bitsche, R.; Kim, T.; Yde, A.; Henriksen, L.C.; Hansen, M.H.; Blasques, J.P.A.A.; Gaunaa, M.; Natarajan, A. The DTU 10-MW Reference Wind Turbine. Available online: https://backend.orbit.dtu.dk/ws/portalfiles/portal/55645274/The_DTU_10MW_Reference_Turbine_Christian_Bak.pdf#:~:text=%E2%80%A2%20The%20DTU%2010%20MW%20RWT%20has%20been%20released%20to (accessed on 20 September 2024).

- Vsetas. MHI Vestas Launches the First 10 MW Wind Turbine in History. Available online: https://www.vestas.com/en/media/mwow-press-releases/2018/mhi-vestas-launches-the-first-10-mw-wind-turbine-in-history#:~:text=MHI%20Vestas%20Offshore%20Wind,%20in%20a%20stunning%20announcement%20at%20the (accessed on 20 September 2024).

- Chen, M.; Jiang, J.; Zhang, W.; Li, C.B.; Zhou, H.; Jiang, Y.; Sun, X. Study on mooring design of 15 MW floating wind turbines in South China Sea. J. Mar. Sci. Eng. 2024, 12, 33. [Google Scholar] [CrossRef]

- 2020ATB_NREL_Reference_18MW_263. Available online: https://nrel.github.io/turbine-models/2020ATB_NREL_Reference_18MW_263.html (accessed on 20 September 2024).

- Zahle, F.; Barlas, A.; Lønbæk, K.; Bortolotti, P.; Zalkind, D.; Wang, L.; Labuschagne, C.; Sethuraman, L.; Barter, G. Definition of the IEA Wind 22-Megawatt Offshore Reference Wind Turbine. Available online: https://backend.orbit.dtu.dk/ws/files/357327260/iea-22-280-rwt-report.pdf (accessed on 20 September 2024).

- Ahn, D.; Shin, S.-C.; Kim, S.-Y.; Kharoufi, H.; Kim, H.-C. Comparative evaluation of different offshore wind turbine installation vessels for Korean west–south wind farm. Int. J. Nav. Archit. Ocean. Eng. 2017, 9, 45–54. [Google Scholar] [CrossRef]

- Uraz, E. Offshore Wind Turbine Transportation & Installation Analyses Planning Optimal Marine Operations for Offshore Wind Projects. Master’s Thesis, Gotland University, Visby, Sweden, 2011. [Google Scholar]

- Kuijken, L. Single Blade Installation for Large Wind Turbines in Extreme Wind Conditions: A Quasi-Steady Aeroelastic Study in High Wind Speeds under Different Inflow Angles. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2015. [Google Scholar]

- Gaunaa, M.; Heinz, J.; Skrzypiński, W. Toward an Engineering Model for the Aerodynamic Forces Acting on Wind Turbine Blades in Quasisteady Standstill and Blade Installation Situations. J. Phys. Conf. Ser. 2016, 753, 022007. [Google Scholar] [CrossRef]

- Gaunaa, M.; Bergami, L.; Guntur, S.; Zahle, F. First-order aerodynamic and aeroelastic behavior of a single-blade installation setup. J. Phys. Conf. Ser. 2014, 524, 012073. [Google Scholar] [CrossRef]

- Larsen, T.J.; Hansen, A.M. How 2 HAWC2, the User’s Manual; Risø National Laboratory: Roskilde, Denmark, 2007. Available online: https://backend.orbit.dtu.dk/ws/portalfiles/portal/7703110/ris_r_1597.pdf (accessed on 18 September 2024).

- Larsen, T.J.; Hansen, A.M. How 2 HAWC2, the User’s Manual. 2014. Available online: https://backend.orbit.dtu.dk/ws/portalfiles/portal/103754900/Pdap_Manual_rev.pdf (accessed on 18 September 2024).

- Yin, L.; Qiao, D.; Tang, G.; Yan, J.; Lu, L.; Ou, J. Dynamic responses analysis of crane-blade coupling system for the single blade installation of offshore wind turbine considering the wind effect. Mar. Struct. 2024, 94, 103570. [Google Scholar] [CrossRef]

- Zhao, Y.; Cheng, Z.; Sandvik, P.C.; Gao, Z.; Moan, T. An integrated dynamic analysis method for simulating installation of single blades for wind turbines. Ocean Eng. 2018, 152, 72–88. [Google Scholar] [CrossRef]

- Ren, Z.; Jiang, Z.; Skjetne, R.; Gao, Z. Development and application of a simulator for offshore wind turbine blades installation. Ocean Eng. 2018, 166, 380–395. [Google Scholar] [CrossRef]

- Idres, M.; Youssef, K.; Mook, D.; Nayfeh, A. A nonlinear 8-DOF coupled crane-ship dynamic model. In Proceedings of the 44th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Norfolk, VA, USA, 7–10 April 2003; p. 1855. [Google Scholar]

- Jiang, Z.; Gao, Z.; Ren, Z.; Li, Y.; Duan, L. A parametric study on the final blade installation process for monopile wind turbines under rough environmental conditions. Eng. Struct. 2018, 172, 1042–1056. [Google Scholar] [CrossRef]

- Verma, A.S.; Jiang, Z.; Vedvik, N.P.; Gao, Z.; Ren, Z. Impact assessment of a wind turbine blade root during an offshore mating process. Eng. Struct. 2019, 180, 205–222. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, P.; Sun, N.; Zhang, Y. Dynamics analysis and nonlinear control of an offshore boom crane. IEEE Trans. Ind. Electron. 2013, 61, 414–427. [Google Scholar] [CrossRef]

- Masoud, Z.; Nayfeh, A.; Mook, D. Cargo pendulation reduction of ship-mounted cranes. Nonlinear Dyn. 2004, 35, 299–311. [Google Scholar] [CrossRef]

- Ren, Z.; Jiang, Z.; Gao, Z.; Skjetne, R. Active tugger line force control for single blade installation. Wind Energy 2018, 21, 1344–1358. [Google Scholar] [CrossRef]

- Sander, A.; Meinhardt, C.; Thoben, K.-D. Monitoring of offshore wind turbines under wave and wind loading during installation. In Proceedings of the EURODYN 2020 XI International Conference on Structural Dynamics, Athens, Greece, 23–26 November 2020; pp. 22–24. [Google Scholar]

- Brodersen, M.L.; Bjørke, A.S.; Høgsberg, J. Active tuned mass damper for damping of offshore wind turbine vibrations. Wind Energy 2017, 20, 783–796. [Google Scholar] [CrossRef]

- Jiang, Z. The impact of a passive tuned mass damper on offshore single-blade installation. J. Wind. Eng. Ind. Aerodyn. 2018, 176, 65–77. [Google Scholar] [CrossRef]

- Chen, M.; Zou, M.; Zhu, L.; Sun, L. Numerical analysis of GBS float-over deck installation at docking and undocking stages based on a coupled heave-roll-pitch impact model. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Scotland UK, 8–11 October 2019; p. V009T012A010. [Google Scholar]

- Hofmann, M.; Sperstad, I.B. Will 10 MW wind turbines bring down the operation and maintenance cost of offshore wind farms? Energy Procedia 2014, 53, 231–238. [Google Scholar] [CrossRef]

- Wang, C.; Utsunomiya, T.; Wee, S.; Choo, Y. Research on floating wind turbines: A literature survey. IES J. Part A Civ. Struct. Eng. 2010, 3, 267–277. [Google Scholar] [CrossRef]

- Luengo, M.; Kolios, A. Failure mode identification and end of life scenarios of offshore wind turbines: A review. Energies 2015, 8, 8339–8354. [Google Scholar] [CrossRef]

- Jenny, N.; Ronny, R.; Thien, T. Mass and aerodynamic imbalance estimates of wind turbines. Energies 2010, 3, 696–710. [Google Scholar] [CrossRef]

- Dong, W.; Moan, T.; Gao, Z. Fatigue reliability analysis of the jacket support structure for offshore wind turbine considering the effect of corrosion and inspection. Reliab. Eng. Syst. Saf. 2012, 106, 11–27. [Google Scholar] [CrossRef]

- Wen, B.; Li, Z.; Jiang, Z.; Tian, X.; Dong, X.; Peng, Z. Blade loading performance of a floating wind turbine in wave basin model tests. Ocean Eng. 2020, 199, 107061. [Google Scholar] [CrossRef]

- Bhardwaj, U.; Teixeira, A.; Soares, C.G. Reliability prediction of an offshore wind turbine gearbox. Renew. Energy 2019, 141, 693–706. [Google Scholar] [CrossRef]

- Shipurkar, U.; Ma, K.; Polinder, H.; Blaabjerg, F.; Ferreira, J.A. A review of failure mechanisms in wind turbine generator systems. In Proceedings of the 2015 17th European Conference on Power Electronics and Applications (EPE’15 ECCE-Europe), Geneva, Switzerland, 8–10 September 2015; pp. 1–10. [Google Scholar]

- Sun, W.; Lin, W.-C.; You, F.; Shu, C.-M.; Qin, S.-H. Prevention of green energy loss: Estimation of fire hazard potential in wind turbines. Renew. Energy 2019, 140, 62–69. [Google Scholar] [CrossRef]

- Price, S.J.; Figueira, R.B. Corrosion protection systems and fatigue corrosion in offshore wind structures: Current status and future perspectives. Coatings 2017, 7, 25. [Google Scholar] [CrossRef]

- Kang, J.; Sun, L.; Sun, H.; Wu, C. Risk assessment of floating offshore wind turbine based on correlation-FMEA. Ocean Eng. 2017, 129, 382–388. [Google Scholar] [CrossRef]

- Dong, X.; Lian, J.; Wang, H.; Yu, T.; Zhao, Y. Structural vibration monitoring and operational modal analysis of offshore wind turbine structure. Ocean Eng. 2018, 150, 280–297. [Google Scholar] [CrossRef]

- Karyotakis, A.; Bucknall, R. Planned intervention as a maintenance and repair strategy for offshore wind turbines. J. Mar. Eng. Technol. 2010, 9, 27–35. [Google Scholar] [CrossRef]

- Peng, J. Maintenance of wind turbine. Electr. Equip. 2011, 28, 68–71. [Google Scholar]

- Zhang, C.; Gao, W.; Guo, S.; Li, Y.; Yang, T. Opportunistic maintenance for wind turbines considering imperfect, reliability-based maintenance. Renew. Energy 2017, 103, 606–612. [Google Scholar] [CrossRef]

- Garcia, M.C.; Sanz-Bobi, M.A.; Del Pico, J. SIMAP: Intelligent System for Predictive Maintenance: Application to the health condition monitoring of a windturbine gearbox. Comput. Ind. 2006, 57, 552–568. [Google Scholar] [CrossRef]

- Ryan, W.; Mark, B. Wind Technologies Market Report; US Department of Energy: Washington, DC, USA, 2011. [Google Scholar]

- Staffell, I.; Green, R. How does wind farm performance decline with age? Renew. Energy 2014, 66, 775–786. [Google Scholar] [CrossRef]

- Faulstich, S.; Hahn, B.; Tavner, P.J. Wind turbine downtime and its importance for offshore deployment. Wind Energy 2011, 14, 327–337. [Google Scholar] [CrossRef]

- Karyotakis, A. On the Optimisation of Operation and Maintenance Strategies for Offshore Wind Farms. Ph.D. Thesis, University College London, London, UK, 2011. [Google Scholar]

- Santos, F.; Teixeira, A.; Guedes Soares, C. An age-based preventive maintenance for offshore wind turbines. In Safety and reliability: Methodology and Applications; CRC Press: Boca Raton, FL, USA, 2015; pp. 1147–1155. [Google Scholar]

- Dui, H.; Si, S.; Yam, R.C. A cost-based integrated importance measure of system components for preventive maintenance. Reliab. Eng. Syst. Saf. 2017, 168, 98–104. [Google Scholar] [CrossRef]

- Ma, H.; Zhang, H.; Ma, L.; Ren, C.; Wang, Z.; Gao, X.; Fang, H.; He, X. None-Watering and Tube-Protecting Planting Technique for Haloxylon ammodendron under Desert and Its Extension. Sci. Sin. Vitae 2014, 44, 248–256. [Google Scholar] [CrossRef]

- Chen, L.; Cheng, C.; Dui, H.; Xing, L. Maintenance cost-based importance analysis under different maintenance strategies. Reliab. Eng. Syst. Saf. 2022, 222, 108435. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Y.; Dui, H.; Wang, S.; Tomovic, M.M. Importance measure-based maintenance strategy considering maintenance costs. Eksploat. Niezawodn.-Maint. Reliab. 2022, 24, 15–24. [Google Scholar] [CrossRef]

- Dui, H.; Xu, H.; Zhang, L.; Wang, J. Cost-based preventive maintenance of industrial robot system. Reliab. Eng. Syst. Saf. 2023, 240, 109595. [Google Scholar] [CrossRef]

- Thomas, É.; Levrat, É.; Iung, B. Overview on opportunistic maintenance. IFAC Proc. Vol. 2008, 41, 245–250. [Google Scholar] [CrossRef]

- Radner, R.; Jorgenson, D.W. Opportunistic replacement of a single part in the presence of several monitored parts. Manag. Sci. 1963, 10, 70–84. [Google Scholar] [CrossRef]

- Dai, L.; Stålhane, M.; Utne, I.B. Routing and scheduling of maintenance fleet for offshore wind farms. Wind Eng. 2015, 39, 15–30. [Google Scholar] [CrossRef]

- Sarker, B.R.; Faiz, T.I. Minimizing maintenance cost for offshore wind turbines following multi-level opportunistic preventive strategy. Renew. Energy 2016, 85, 104–113. [Google Scholar] [CrossRef]

- Abdollahzadeh, H.; Atashgar, K.; Abbasi, M. Multi-objective opportunistic maintenance optimization of a wind farm considering limited number of maintenance groups. Renew. Energy 2016, 88, 247–261. [Google Scholar] [CrossRef]

- Zhang, C.; Gao, W.; Yang, T.; Guo, S. Opportunistic maintenance strategy for wind turbines considering weather conditions and spare parts inventory management. Renew. Energy 2019, 133, 703–711. [Google Scholar] [CrossRef]

- Besnard, F.; Patriksson, M.; Strömberg, A.-B.; Wojciechowski, A.; Bertling, L. An optimization framework for opportunistic maintenance of offshore wind power system. In Proceedings of the 2009 IEEE Bucharest Powertech, Bucharest, Romania, 28 June–2 July 2009; pp. 1–7. [Google Scholar]

- Zhao, H.; Xu, F.; Liang, B.; Zhang, J.; Song, P. A condition-based opportunistic maintenance strategy for multi-component system. Struct. Health Monit. 2019, 18, 270–283. [Google Scholar] [CrossRef]

- Li, M.; Wang, M.; Kang, J.; Sun, L.; Jin, P. An opportunistic maintenance strategy for offshore wind turbine system considering optimal maintenance intervals of subsystems. Ocean Eng. 2020, 216, 108067. [Google Scholar] [CrossRef]

- Tao, Z.; Liu, H.; Si, Y.; Wang, C.; Zhu, R. An opportunistic joint maintenance strategy for two offshore wind farms. Ocean Eng. 2024, 304, 117890. [Google Scholar] [CrossRef]

- Su, C.; Wu, L. Opportunistic maintenance optimisation for offshore wind farm with considering random wind speed. Int. J. Prod. Res. 2024, 62, 1862–1878. [Google Scholar] [CrossRef]

- Su, H.; Cao, Q.; Li, Y. Condition-based opportunistic maintenance strategy for multi-component wind turbines by using stochastic differential equations. Sci. Rep. 2024, 14, 2390. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Xia, Y.; Qin, Y.; Zhang, X. Optimal external opportunistic maintenance for wind turbines considering wind speed. Int. J. Green Energy 2024, 21, 2022–2041. [Google Scholar] [CrossRef]

- Hui, C.; Qinming, L.; Chunming, Y.; Xiaoyan, Y. An opportunistic maintenance strategy for wind turbines under external environment shocks. Ind. Eng. J. 2023, 26, 159. [Google Scholar]

- Papadopoulos, P.; Coit, D.W.; Aziz Ezzat, A. STOCHOS: Stochastic opportunistic maintenance scheduling for offshore wind farms. IISE Trans. 2024, 56, 1–15. [Google Scholar] [CrossRef]

- de Azevedo, H.D.M.; Araújo, A.M.; Bouchonneau, N. A review of wind turbine bearing condition monitoring: State of the art and challenges. Renew. Sustain. Energy Rev. 2016, 56, 368–379. [Google Scholar] [CrossRef]

- Salameh, J.P.; Cauet, S.; Etien, E.; Sakout, A.; Rambault, L. Gearbox condition monitoring in wind turbines: A review. Mech. Syst. Signal Process. 2018, 111, 251–264. [Google Scholar] [CrossRef]

- Daneshi-Far, Z.; Capolino, G.-A.; Henao, H. Review of failures and condition monitoring in wind turbine generators. In Proceedings of the XIX International Conference on Electrical Machines-ICEM 2010, Rome, Italy, 6–8 September 2010; pp. 1–6. [Google Scholar]

- Amirat, Y.; Benbouzid, M.E.; Bensaker, B.; Wamkeue, R. Condition monitoring and ault diagnosis in wind energy conversion systems: A review. In Proceedings of the 2007 IEEE International Electric Machines & Drives Conference, Antalya, Turkey, 3–5 May 2007; pp. 1434–1439. [Google Scholar]

- Maheswari, R.U.; Umamaheswari, R. Trends in non-stationary signal processing techniques applied to vibration analysis of wind turbine drive train–A contemporary survey. Mech. Syst. Signal Process. 2017, 85, 296–311. [Google Scholar] [CrossRef]

- Tchakoua, P.; Wamkeue, R.; Ouhrouche, M.; Slaoui-Hasnaoui, F.; Tameghe, T.A.; Ekemb, G. Wind turbine condition monitoring: State-of-the-art review, new trends, and future challenges. Energies 2014, 7, 2595–2630. [Google Scholar] [CrossRef]

- Yang, W.; Tavner, P.J.; Crabtree, C.J.; Feng, Y.; Qiu, Y. Wind turbine condition monitoring: Technical and commercial challenges. Wind Energy 2014, 17, 673–693. [Google Scholar] [CrossRef]

- Liu, W.; Tang, B.; Han, J.; Lu, X.; Hu, N.; He, Z. The structure healthy condition monitoring and fault diagnosis methods in wind turbines: A review. Renew. Sustain. Energy Rev. 2015, 44, 466–472. [Google Scholar] [CrossRef]

- Segura Asensio, E.; Pinar Pérez, J.M.; García Márquez, F.P. Economic viability study for offshore wind turbines maintenance management. In Proceedings of the Ninth International Conference on Management Science and Engineering Management, Karlsruhe, Germany, 21–23 July 2015; pp. 235–244. [Google Scholar]

- Walgern, J.; Peters, L.; Madlener, R. Economic Evaluation of Maintenance Strategies for Offshore Wind Turbines Based on Condition Monitoring Systems. 2017. Available online: https://www.fcn.eonerc.rwth-aachen.de/global/show_document.asp?id=aaaaaaaaabbjfly (accessed on 14 August 2024).

- Kang, J.; Wang, Z.; Guedes Soares, C. Condition-based maintenance for offshore wind turbines based on support vector machine. Energies 2020, 13, 3518. [Google Scholar] [CrossRef]

- Bayati, I.; Efthimiou, L. Challenges and Opportunities of Major Maintenance for Floating Offshore Wind; World Forum Offshore Wind e.V.: Hamburg, Germany, 2021; Available online: https://www.researchgate.net/publication/357151329_Challenges_and_Opportunities_of_Major_Maintenance_for_Floating_Offshore_Wind_-_World_Forum_Offshore_Wind_WFO (accessed on 15 August 2024).

- Searenergy. ‘World’s First’ In-Situ Generator Swap on Floating Wind Turbine Completed Offshore Scotland. Available online: https://www.offshorewind.biz/2024/09/20/worlds-first-in-situ-generator-swap-on-floating-wind-turbine-completed-offshore-scotland/ (accessed on 26 September 2024).

- Brons-Illing, C. Analysis of Operation and Maintenance Strategies for Floating Offshore Wind Farms. Master’s Thesis, University of Stavanger, Stavanger, Norway, 2015. [Google Scholar]

- Li, B. Operability study of walk-to-work for floating wind turbine and service operation vessel in the time domain. Ocean Eng. 2021, 220, 108397. [Google Scholar] [CrossRef]

- Li, B. Effect of hydrodynamic coupling of floating offshore wind turbine and offshore support vessel. Appl. Ocean Res. 2021, 114, 102707. [Google Scholar] [CrossRef]

- Yin, L.; Qiao, D.; Li, B.; Liang, H.; Yan, J.; Tang, G.; Ou, J. Modeling and controller design of an offshore wind service operation vessel with parallel active motion compensated gangway. Ocean Eng. 2022, 266, 112999. [Google Scholar] [CrossRef]

- Halvorsen-Weare, E.E.; Gundegjerde, C.; Halvorsen, I.B.; Hvattum, L.M.; Nonås, L.M. Vessel fleet analysis for maintenance operations at offshore wind farms. Energy Procedia 2013, 35, 167–176. [Google Scholar] [CrossRef]

- Han, X.; Leira, B.J.; Sævik, S. Vessel hydrodynamic model tuning by discrete Bayesian updating using simulated onboard sensor data. Ocean Eng. 2021, 220, 108407. [Google Scholar] [CrossRef]

- Catterson, V.; McMillan, D.; Dinwoodie, I.; Revie, M.; Dowell, J.; Quigley, J.; Wilson, K. An economic impact metric for evaluating wave height forecasters for offshore wind maintenance access. Wind Energy 2016, 19, 199–212. [Google Scholar] [CrossRef]

- James, E.P.; Benjamin, S.G.; Marquis, M. Offshore wind speed estimates from a high-resolution rapidly updating numerical weather prediction model forecast dataset. Wind Energy 2018, 21, 264–284. [Google Scholar] [CrossRef]

- Taylor, J.W.; Jeon, J. Probabilistic forecasting of wave height for offshore wind turbine maintenance. Eur. J. Oper. Res. 2018, 267, 877–890. [Google Scholar] [CrossRef]

- Shi, J.; Hu, M.; Zhang, Y.; Chen, X.; Yang, S.; Hallak, T.S.; Chen, M. Dynamic Analysis of Crane Vessel and Floating Wind Turbine during Temporary Berthing for Offshore On-Site Maintenance Operations. J. Mar. Sci. Eng. 2024, 12, 1393. [Google Scholar] [CrossRef]

- van Dun, L. Maintenance Offshore Wind: Feasibility Study into Alternative Lifting Systems for Offshore Wind Turbine Maintenance Operations. Master’s Thesis, Delft University of Technology (TU Delft), Delft, The Netherlands, 2018. [Google Scholar]

- Gao, Z.; Verma, A.; Zhao, Y.; Jiang, Z.; Ren, Z. A summary of the recent work at NTNU on marine operations related to installation of offshore wind turbines. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Madrid, Spain, 17–22 June 2018; p. V11AT12A044. [Google Scholar]

- Verma, A.S.; Haselbach, P.U.; Vedvik, N.P.; Gao, Z. A global-local damage assessment methodology for impact damage on offshore wind turbine blades during lifting operations. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Madrid, Spain, 17–22 June 2018; p. V010T009A064. [Google Scholar]

- Carroll, J.; McDonald, A.; Dinwoodie, I.; McMillan, D.; Revie, M.; Lazakis, I. Availability, operation and maintenance costs of offshore wind turbines with different drive train configurations. Wind Energy 2017, 20, 361–378. [Google Scholar] [CrossRef]

- Li, Y.; Wang, R.; Yang, Z. Optimal scheduling of isolated microgrids using automated reinforcement learning-based multi-period forecasting. IEEE Trans. Sustain. Energy 2021, 13, 159–169. [Google Scholar] [CrossRef]

- Anaya-Lara, O.; Jenkins, N.; McDonald, J. Communications requirements and technology for wind farm operation and maintenance. In Proceedings of the First International Conference on Industrial and Information Systems, Peradeniya, Sri Lanka, 8–11 August 2006; pp. 173–178. [Google Scholar]

- Helsen, J.; Peeters, C.; Doro, P.; Ververs, E.; Jordaens, P.J. Wind farm operation and maintenance optimization using big data. In Proceedings of the 2017 IEEE Third International Conference on Big Data Computing Service and Applications (BigDataService), San Francisco, CA, USA, 6–9 April 2017; pp. 179–184. [Google Scholar]

- Wu, Y.-K.; Lee, C.-Y.; Chen, C.-R.; Hsu, K.-W.; Tseng, H.-T. Optimization of the wind turbine layout and transmission system planning for a large-scale offshore windfarm by AI technology. IEEE Trans. Ind. Appl. 2013, 50, 2071–2080. [Google Scholar] [CrossRef]

- Lin, Z.; Liu, X. Wind power forecasting of an offshore wind turbine based on high-frequency SCADA data and deep learning neural network. Energy 2020, 201, 117693. [Google Scholar] [CrossRef]

- Yin, X.; Zhao, X. Deep neural learning based distributed predictive control for offshore wind farm using high-fidelity LES data. IEEE Trans. Ind. Electron. 2020, 68, 3251–3261. [Google Scholar] [CrossRef]

- Trombe, P.J.; Pinson, P.; Vincent, C.; Bøvith, T.; Cutululis, N.A.; Draxl, C.; Giebel, G.; Hahmann, A.N.; Jensen, N.E.; Jensen, B.P. Weather radars–the new eyes for offshore wind farms? Wind Energy 2014, 17, 1767–1787. [Google Scholar] [CrossRef]

- Cutululis, N.A.; Detlefsen, N.K.; Sørensen, P.E. Offshore wind power prediction in critical weather conditions. In Proceedings of the 10th International Workshop on Large-Scale Integration of Wind Power into Power Systems As Well As on Transmission Networks for Offshore Wind Farms, Aarhus, Denmark, 23–28 October 2011. [Google Scholar]

- Japar, F.; Mathew, S.; Narayanaswamy, B.; Lim, C.M.; Hazra, J. Estimating the wake losses in large wind farms: A machine learning approach. In Proceedings of the ISGT 2014, Washington, DC, USA, 19–22 February 2014; pp. 1–5. [Google Scholar]

- Chao, H.; Hu, B.; Xie, K.; Tai, H.-M.; Yan, J.; Li, Y. A sequential MCMC model for reliability evaluation of offshore wind farms considering severe weather conditions. IEEE Access 2019, 7, 132552–132562. [Google Scholar] [CrossRef]

- Brusch, S.; Lehner, S.; Schulz-Stellenfleth, J. Synergetic use of radar and optical satellite images to support severe storm prediction for offshore wind farming. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2008, 1, 57–66. [Google Scholar] [CrossRef]

- Halvorsen-Weare, E.E.; Norstad, I.; Stålhane, M.; Nonås, L.M. A metaheuristic solution method for optimizing vessel fleet size and mix for maintenance operations at offshore wind farms under uncertainty. Energy Procedia 2017, 137, 531–538. [Google Scholar] [CrossRef]

- Domínguez-Navarro, J.A.; Dinwoodie, I.; McMillan, D. Statistical forecasting for offshore wind helicopter operations. In Proceedings of the 2014 International Conference on Probabilistic Methods Applied to Power Systems (PMAPS), Durham, UK, 7–10 July 2014; pp. 1–6. [Google Scholar]

- Gundegjerde, C.; Halvorsen, I.B.; Halvorsen-Weare, E.E.; Hvattum, L.M.; Nonås, L.M. A stochastic fleet size and mix model for maintenance operations at offshore wind farms. Transp. Res. Part C Emerg. Technol. 2015, 52, 74–92. [Google Scholar] [CrossRef]

- Stålhane, M.; Halvorsen-Weare, E.E.; Nonås, L.M.; Pantuso, G. Optimizing vessel fleet size and mix to support maintenance operations at offshore wind farms. Eur. J. Oper. Res. 2019, 276, 495–509. [Google Scholar] [CrossRef]

- Li, M.; Bijvoet, B.; Wu, K.; Jiang, X.; Negenborn, R.R. Optimal chartering decisions for vessel fleet to support offshore wind farm maintenance operations. Ocean Eng. 2024, 298, 117202. [Google Scholar] [CrossRef]

- Gutierrez-Alcoba, A.; Hendrix, E.M.; Ortega, G.; Halvorsen-Weare, E.E.; Haugland, D. On offshore wind farm maintenance scheduling for decision support on vessel fleet composition. Eur. J. Oper. Res. 2019, 279, 124–131. [Google Scholar] [CrossRef]

- Group, S. Self Elevating Platform SEA JACK. Available online: https://www.spanopoulos-group.com/equipment/self-elevating-platforms/self-elevating-platform-sea-jack (accessed on 15 September 2024).

- Damen Shipyards Group. ASD Tug 3212. Available online: https://www.damen.com/vessels/tugs/asd-tugs/asd-tug-3212 (accessed on 15 September 2024).

- Group, D.S. CSOV 9020 Hybrid. Available online: https://www.damen.com/vessels/offshore/service-operation-vessels/csov-9020-walk-to-work-vessel (accessed on 15 September 2024).

- Huisman, B. Equipped for Impact. Available online: https://www.huismanequipment.com/en/products/cranes/offshore_cranes?_gl=1*f1edgn*_up*MQ..&gclid=EAIaIQobChMI6MqG-bXYiAMVUwZ7Bx1AEBHlEAAYASAAEgI8wvD_BwE#photos (accessed on 15 September 2024).

- Skjetne, R.; Ren, Z. A survey on modeling and control of thruster-assisted position mooring systems. Mar. Struct. 2020, 74, 102830. [Google Scholar] [CrossRef]

- Van Bussel, G.; Henderson, A. State of the art and technology trends for offshore wind energy: Operation and maintenance issues. In Proceedings of the Offshore Wind Energy Special Topic Conference, Brussels, Belgium, 10–12 December 2001; pp. 1–4. [Google Scholar]

- Chen, M.; Yuan, G.; Li, B.; Li, C.B.; Ouyang, M.; Li, L.; Shi, W.; Han, Z.; Zhang, W.; Chen, Z. Dynamic analysis of lift-off operation of offshore wind turbine jacket foundation from the transportation barge. Ocean Eng. 2024, 301, 117443. [Google Scholar] [CrossRef]

- van Suijlen, Q. Floating to Floating Installation of a Full 15 MW Wind Turbine on a Tension Leg Platform with a Semi-Submersible Crane Vessel: A Parametric Sensitivity Study. Master’s Thesis, Delft University of Technology (TU Delft), Delft, The Netherlands, 2023. [Google Scholar]

- Zaayer, M.; van den Broek, W.; van Bussel, G. Toward selection of concepts for offshore support structures for large scale wind turbine. In Proceedings of the International Conference on Marine Renewable Energies, Newcastle, UK, 27 March 2001; pp. 7–14. [Google Scholar]

- Dewan, A.; Asgarpour, M. Reference O & M Concepts for Near and Far Offshore Wind Farms; ECN: Petten, The Netherlands, 2016. [Google Scholar]

- Bjerkseter, C.; Ågotnes, A. Levelised Costs of Energy for Offshore Floating Wind Turbine Concepts; Norwegian University of Life Sciences: Ås, Norway, 2013. [Google Scholar]

- Maienza, C.; Avossa, A.; Ricciardelli, F.; Coiro, D.; Troise, G.; Georgakis, C.T. A life cycle cost model for floating offshore wind farms. Appl. Energy 2020, 266, 114716. [Google Scholar] [CrossRef]

- Harrison, J.; Garrad, A.; Warren, T.; Powell, J. Floating Offshore Wind: Installation, Operation & Maintenance Challenges. 2020. Available online: https://www.sciencedirect.com/science/article/pii/S0029801824011314 (accessed on 23 August 2024).

- Laura, C.-S.; Vicente, D.-C. Life-cycle cost analysis of floating offshore wind farms. Renew. Energy 2014, 66, 41–48. [Google Scholar] [CrossRef]

- Kim, B.; Kim, T.-w. Scheduling and cost estimation simulation for transport and installation of floating hybrid generator platform. Renew. Energy 2017, 111, 131–146. [Google Scholar] [CrossRef]

- Correia da Fonseca, F.X.; Amaral, L.; Chainho, P. A decision support tool for long-term planning of marine operations in ocean energy projects. J. Mar. Sci. Eng. 2021, 9, 810. [Google Scholar] [CrossRef]

- Nordic Heavy Lift ASA. General Presentation–First Mover in the Heavy Lift Installation Market; Nordic Heavy Lift ASA: Oslo, Norway, 2019. Available online: https://www.yumpu.com/en/document/read/5218692/nordic-heavy-lift-asa-general-presentation-24-october-netfonds (accessed on 23 August 2024).

- Robinson, R. Missing The Mark-Why We Will Not Meet Our Offshore Renewable Energy Goals and How to Fix it. In Proceedings of the SNAME Offshore Symposium, Houston, TX, USA, 4 March 2023; p. D011S003R003. [Google Scholar]

- Jiang, Z. Installation of offshore wind turbines: A technical review. Renew. Sustain. Energy Rev. 2021, 139, 110576. [Google Scholar] [CrossRef]

- ENABL. Offshore Blade-Lifting Yoke for B75 Blades. Available online: https://enabl-wind.com/cases/offshore-blade-lifting-yoke-for-b75-blades/ (accessed on 15 August 2024).

- Liftra. LT975 Blade Dragon. Available online: https://liftra.com/products/lt975-blade-dragon-cn (accessed on 15 August 2024).

- Group, E. Simple C-yoke-Basic. Available online: https://catalog.eltronic.dk/yoke-for-lifting-of-single-blades/?Page=5 (accessed on 15 August 2024).

- Siemens. Janett Lifting Yoke. Available online: https://enabl-wind.com/proficient-assembly-team-for-the-assembly-of-a-gigantic-blade-lifting-yoke/ (accessed on 15 August 2024).

- Leimeister, M.; Balaam, T.; Causon, P.; Cevasco, D.; Richmond, M.; Kolios, A.; Brennan, F. Human-free offshore lifting solutions. In Proceedings of the Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2018; p. 012030. [Google Scholar]

- Liftra. Blade Hawk. Available online: https://liftra.com/products/blade-hawk (accessed on 15 August 2024).

- Liftra. LT5061 Blade Eagle II. Available online: https://liftra.com/products/lt5061-blade-eagle (accessed on 15 August 2024).

- Eltronic. Yoke-SC. Available online: https://cmigearusa.com/products/yoke-sc (accessed on 15 August 2024).

- ematech. Rotor Blade Clamp. Available online: https://www.ematec.com/en/rbc/ (accessed on 15 August 2024).

- BladeBUG. Available online: http://bladebug.co.uk/ (accessed on 15 August 2024).

- Sonardyne. Uncrewed Surface Vehicles. Available online: https://www.sonardyne.com/applications/unmanned-surface-vehicles/ (accessed on 15 August 2024).

- Fahrni, L.; Thies, P.; Johanning, L.; Cowles, J. Scope and Feasibility of Autonomous Robotic Subsea Intervention Systems for Offshore Inspection, Maintenance and Repair; University of Exeter: Exeter, UK, 2018. [Google Scholar]

- CEIT. Watereye Project. 2020. Available online: https://watereye-project.eu/ (accessed on 15 August 2024).

- MIMRee. Multi-Platform Inspection, Maintenance and Repair in Extreme Environments (MIMRee). 2019. Available online: https://ore.catapult.org.uk/resource-hub/projects/mimree (accessed on 15 August 2024).

- ISO I. 19901-1: 2005; Petroleum and Natural Gas Industries-Specific Requirements for Offshore Structures-Part 1: Metocean Design and Operating Conditions. British Standards Institute: London, UK, 2005.

- DNV-RP-C205; Environmental Conditions and Environmental Loads. DNV: Bærum, Norway, 2010; p. 10.

- DNV GL. DNV-RP-H103; Recommended Practice for Modelling and Analysis of Marine Operations. DNV: Bærum, Norway, 2014.

- DNVGL-ST-0437; Loads and Site Conditions for Wind Turbines. DNV: Bærum, Norway, 2016.

- DNVGL-ST-0119; Floating Wind Turbine Structures. DNV: Bærum, Norway, 2018.

- IEC61400-3; Wind Turbine Generator System Part 3: Design Requirements for Offshore Wind Turbines. IEC: Geneva, Switzerland, 2009.

- Veritas, D.N. Available online: https://rules.dnv.com/docs/pdf/DNVPM/codes/docs/2011-10/Os-H101.pdf (accessed on 15 August 2024).

- Veritas, D.N. Modelling and analysis of marine operations. Offshore Stand. 2011, 80, 1–150. [Google Scholar]

- DNVGL-ST-N001; Planning and Executation of Marine Operations. DNV: Bærum, Norway, 2016.

- DNV-OS-H101; Marine Operations. DNV: Bærum, Norway, 2014.

- DNV-OS-H202; Sea Transport Operations. DNV: Bærum, Norway, 2015.

- DNVGL.ST-001; Marine Operations and Marine Warranty. DNV: Bærum, Norway, 2016; p. 6.

- DNVGL.OS-H205; Lifting Operations(VMO Standard-Part 2-5). DNV: Bærum, Norway, 2014; p. 4.

- Denton, N. Available online: https://www.heavyliftspecialist.com/FreeDownloadArticles/Noble%20Denton%20Guidelines%20for%20Lifting%20Operations%20by%20Floating%20Crane.pdf (accessed on 15 August 2024).

- DNV-RP-H201; Lifting Appliances Used in Subsea Operations. DNV: Bærum, Norway, 2014; p. 11.

- DNV-OS-H204; Offshore Installation Operations(VMO Standard Part 2-4). DNV: Bærum, Norway, 2013; p. 11.

- ISO 29400; Ships and Marine Technology—Offshore Wind Energy—Port and Marine Operations. ISO: Geneva, Switzerland, 2015.

- DNVGL-ST-0054; Transportation and Installation of Wind Power Plants. DNV: Bærum, Norway, 2017.

- Magazine, O.E. Floating Production Riding the Bull Run. Available online: https://offshoreengineer.oedigital.com/magazines/OffshoreEngineer/202401/pdf/ (accessed on 15 July 2024).

- Collu, M.; Maggi, A.; Gualeni, P.; Rizzo, C.M.; Brennan, F. Stability requirements for floating offshore wind turbine (FOWT) during assembly and temporary phases: Overview and application. Ocean Eng. 2014, 84, 164–175. [Google Scholar] [CrossRef]

- Wang, X.-G.; Ying, Z.-Q.; Chen, Z.-C. The analysis of the joint limitation condition of wave height-period on the floating crane lifting operation. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Glasgow, UK, 9–14 June 2019; p. V009T013A046. [Google Scholar]

- Mouhandiz, A.-A.; Bokhorst, J. Analysis and Offshore Support for the Float-Over of a 24,250 mT Topsides on the North West Shelf. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Nantes, France, 9–14 June 2013; p. V001T001A021. [Google Scholar]

- Chen, M.; Yuan, G.; Li, C.B.; Zhang, X.; Li, L. Dynamic analysis and extreme response evaluation of lifting operation of the offshore wind turbine jacket foundation using a floating crane vessel. J. Mar. Sci. Eng. 2022, 10, 2023. [Google Scholar] [CrossRef]

- Acero, W.G.; Li, L.; Gao, Z.; Moan, T. Methodology for assessment of the operational limits and operability of marine operations. Ocean Eng. 2016, 125, 308–327. [Google Scholar] [CrossRef]

- Li, L.; Guachamin Acero, W.; Gao, Z.; Moan, T. Assessment of allowable sea states during installation of offshore wind turbine monopiles with shallow penetration in the seabed. J. Offshore Mech. Arct. Eng. 2016, 138, 041902. [Google Scholar] [CrossRef]

- Acero, W.G.; Gao, Z.; Moan, T. Methodology for assessment of the allowable sea states during installation of an offshore wind turbine transition piece structure onto a monopile foundation. J. Offshore Mech. Arct. Eng. 2017, 139, 061901. [Google Scholar] [CrossRef]

- Li, L.; Parra, C.; Zhu, X.; Ong, M.C. Splash zone lowering analysis of a large subsea spool piece. Mar. Struct. 2020, 70, 102664. [Google Scholar] [CrossRef]

- Verma, A.S.; Jiang, Z.; Ren, Z.; Gao, Z.; Vedvik, N.P. Response-based assessment of operational limits for mating blades on monopile-type offshore wind turbines. Energies 2019, 12, 1867. [Google Scholar] [CrossRef]

- Li, B.; Qiao, D.; Zhao, W.; Hu, Z.; Li, S. Operability analysis of SWATH as a service vessel for offshore wind turbine in the southeastern coast of China. Ocean Eng. 2022, 251, 111017. [Google Scholar] [CrossRef]

| Barge | Semi-Submersible | Spar | TLP | |

|---|---|---|---|---|

| Stability | Hydrostatic | Hydrostatic | Ballast | Mooring tension |

| Towability | Great | Excellent | Good | Poor |

| Installation | Simple | Simple | Simple restricted | Complex |

| Water depth | >~30 m | >~30–60 m | >~50–100 m | >~40–60 m |

| Application | Some | Widely | Widely | A few |

| Project Name | Country | Water Depth | Distance to Shore | Capacity | Commission | Decommission |

|---|---|---|---|---|---|---|

| Hywind Demo [27] | Norway | 220 m | 12 km | 1 × 2.3 MW | 2009 | - |

| Hywind Scotland [28] | UK | 95–120 m | 25 km | 5 × 6 MW | 2017 | - |

| Hywind Tampen [35] | Norway | 260–300 m | 140 km | 11 × 8 MW | 2022 | - |

| Haenkaza/ Sakiyama [43] | Japan | 100 m | 5 km | 1 × 2 MW | 2013 | - |

| Goto floating wind farm [44] | Japan | - | - | 8 × 2.1 MW | 2026 | - |

| Fukushima Hamakaze [45] | Japan | 48 m | 23 km | 1 × 5 MW | 2016 | 2021 |

| Kabashima/ Sakiyama [46] | Japan | 76 m | 1 km | 1 × 2 MW | 2013 | - |

| TetraSpar demonstrator [47] | Norway | 200 m | 10 km | 1 × 3.6 MW | 2021 | - |

| Project Name | Country | Water Depth | Distance to Shore | Capacity | Commission | Decommission |

|---|---|---|---|---|---|---|

| WindFloat 1 [54] | Portugal | 45 m | 5 km | 1 × 2 MW | 2011 | 2016 |

| WindFloat Atlantic [54] | Portugal | 85–100 m | 20 km | 3 × 8.4 MW | 2019 | |

| Kincardine [54] | UK | 60–80 m | 15 km | 5 × 9.5 MW | 2021 | - |

| Les Éoliennes Flottantes du Golfe du Lion [54] | France | 70–100 m | 16 km | 3 × 10 MW | 2024 | - |

| Erebus [54] | UK | 70 m | 44 km | - | 2027 | - |

| Korea Floating Wind [54] | S Korea | 250 m | 80 km | - | 2028 | - |

| EOLINK demonstrator [55] | France | - | - | 1 × 5 MW | 2024 | - |

| BLOW project [56] | Bulgaria | - | - | 1 × 5 MW | 2025 | - |

| Fukushima Mirai [45] | Japan | 120 m | 23 km | 1 × 2 MW | 2013 | 2021 |

| Fukushima Shimpuu [45] | Japan | 32 m | 23 km | 1 × 7 MW | 2015 | 2020 |

| Yangxi Shapa III Demo [57] | China | 30 m | 28 km | 1 × 5.5 MW | 2021 | - |

| FuYao prototype [58] | China | 50–70 m | 13 km | 1 × 6.2 MW | 2022 | - |

| Haiyou Guanlan [59] | China | 100+ m | 136 km | 1 × 7.25 MW | 2023 | - |

| New England Aqua Ventus [60] | US | 60–110 m | 3 km | 2 × 6 MW | 2024 | - |

| Pentland FOWF [61] | UK | 60–102 m | 7.5 km | 7 × 15 MW | 2026 | - |

| TwinHub demo [62] | UK | 50–60 m | 16 km | 2 × 16 MW | 2026 | - |

| Project Name | Country | Water Depth | Distance to Shore | Capacity | Commission |

|---|---|---|---|---|---|

| Provence Grand Large [72] | France | 100 m | 17 km | 3 × 8.4 MW | 2023 |

| Bluewater TLP demonstrator [73] | Norway | 200 m | - | 1 × 6 MW | 2024 |

| PivotBuoy Project [74] | Spain | 50 m | 1 km | 1 × 225 kW | 2023 |

| NextFloat Project [75] | France | - | - | 1 × 6 MW | 2025 |

| Project Name | Country | Water Depth | Distance to Shore | Capacity | Commission |

|---|---|---|---|---|---|

| Floatgen [77] | France | 33 m | 22 km | 1 × 2 MW | 2018 |

| Hibiki [78] | Japan | 55 m | 15 km | 1 × 3 MW | 2018 |

| Eolmed [79] | France | 55 m | 16 km | 3 × 10 MW | 2024 |

| DemoSATH [80] | Spain | 85 m | 3 km | 1 × 2 MW | 2023 |

| Wind Turbine Model | Country | Year | Blade Length (m) | Hub Height (m) | Weight (Tons) |

|---|---|---|---|---|---|

| NREL 5 MW [95] | USA | 2009 | 61.5 | 90 | 17.3 |

| Sevion 5 MW [96] | Germany | 2010 | 61.5 | - | 20.8 |

| Siemens SWT 6 MW [97] | Germany | 2013 | 75 | - | - |

| FuYao prototype 6.2 MW [58] | China | 2022 | 74 | 96 | - |

| Haiyou Guanlan 7.25 MW [59] | China | 2023 | 76.6 | 102 | - |

| LEANWIND 8 MW [98] | Ireland | 2016 | 80 | 110 | 35 |

| DTU 10 MW [99] | Denmark | 2013 | 86.4 | 119 | 41.7 |

| MHI Vestas V164 10 MW [100] | France | 2022 | 80 | 105 | 35 |

| IEA 15 MW [101] | USA | 2020 | 117 | 150 | 65.3 |

| NREL 18 MW [102] | USA | 2020 | 125 | 156 | - |

| IEA 22 MW [103] | Denmark | 2024 | 137.8 | 170 | 82.301 |

| Brief Introduction | Advantages | Disadvantages | |

|---|---|---|---|

| Corrective maintenance | Repairs after a failure occurs | Targeted repairs, avoiding unnecessary maintenance | Can lead to longer downtime |

| Preventive maintenance | Regular inspections and part replacements before failure | Provides sufficient maintenance windows, reduces costs | May result in longer downtime |

| Opportunistic maintenance | Conducts preventive maintenance during corrective actions | Efficient scheduling, combining benefits of both types | Unable to predict specific turbine faults in advance |

| Predictive maintenance | Real-time monitoring of turbine status to detect potential faults | Minimizes downtime and reduces maintenance frequency | High technical difficulty |

| Type | Advantages | Disadvantages | Day Rate |

|---|---|---|---|

| Tugboat | High maneuverability, versatile | Slow speed, no lifting capability | USD 1000–5000 |

| Jack-up crane | Stability, reduced environment impact, self-elevating | Limited mobility, shallow operational depth, slow transfer speed | USD 100,000–250,000 |

| Heavy lift vessel | High mobility, flexibility, effective in various water depths | Weather sensitivity, limited stability | USD 80,000–100,000 |

| Semi-submersible crane vessel | Stability, heavy lifting capacity, versatility, dynamic positioning capability | High operational cost, limited mobility | USD 280,000–500,000 |

| Name | Manufacturer | Type | Rotation Range (°) | Max Wind Speed (m/s) | Features |

|---|---|---|---|---|---|

| LT1600 Blade Hawk [233] | Liftra | Horizontal | ±5 | 12 | Clamping structure; fine adjustment; weight 15 t, max load 30 t |

| LT975 Blade Dragon [229] | Liftra | Rotating | −215~35 | 12 | Clamping structure; single-point suspension; max load 65 t |

| LT5061 Blade Eagle II [234] | Liftra | Rotating | −60~30 | 12 | C-shaped; weight 160 t, max load 60 t |

| Simple C-yoke-Basic [230] | Eltronic | Horizontal | 0 | 15 | C-shaped; basic Eltronic C-series |

| SC-yoke [235] | Eltronic | Horizontal | ±6 | 15 | C-shaped; clamping; vertical lift with auxiliary crane |

| Janett lifting yoke [231] | Siemens | Horizontal | 0 | 14 | Clamping and sling; specific blades |

| Rotor Blade Clamp-D [236] | ema Tech | Rotating | ±35 | - | Hydraulic clamping pad; max load 50 t |

| Content | Standards | Title |

|---|---|---|

| Environmental conditions | DNVGL-RP-C205 | Environmental conditions and environmental loads |

| DNVGL-RP-H103 | Modeling and analysis of marine operations | |

| DNVGL-ST-0437 | Loads and site conditions for wind turbines | |

| Operation process | DNVGL-ST-N001 | Planning and execution of marine operations |

| DNV-OS-H204 | Offshore installation operations | |

| ISO 29400:2015 | Ships and marine technology, offshore wind energy, port and marine operations | |

| DNVGL-ST-0054 | Transportation and installation of wind power plants | |

| DNVGL-OS-H205 | Lifting operations | |

| Crane | DNVGL-ST-001 | Marine operations and marine warranty |

| Noble Denton-0027 | Guidelines for lifting operations by floating crane vessels | |

| DNVGL-RP-H201 | Lifting appliances used in subsea operations |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, M.; Shi, J.; Yang, S.; Chen, M.; Tang, Y.; Liu, S. Current Status and Future Trends in Installation, Operation and Maintenance of Offshore Floating Wind Turbines. J. Mar. Sci. Eng. 2024, 12, 2155. https://doi.org/10.3390/jmse12122155

Hu M, Shi J, Yang S, Chen M, Tang Y, Liu S. Current Status and Future Trends in Installation, Operation and Maintenance of Offshore Floating Wind Turbines. Journal of Marine Science and Engineering. 2024; 12(12):2155. https://doi.org/10.3390/jmse12122155

Chicago/Turabian StyleHu, Mingfeng, Jinkun Shi, Sheng Yang, Mingsheng Chen, Yichang Tang, and Suqian Liu. 2024. "Current Status and Future Trends in Installation, Operation and Maintenance of Offshore Floating Wind Turbines" Journal of Marine Science and Engineering 12, no. 12: 2155. https://doi.org/10.3390/jmse12122155

APA StyleHu, M., Shi, J., Yang, S., Chen, M., Tang, Y., & Liu, S. (2024). Current Status and Future Trends in Installation, Operation and Maintenance of Offshore Floating Wind Turbines. Journal of Marine Science and Engineering, 12(12), 2155. https://doi.org/10.3390/jmse12122155