Improved Fracture Permeability Evaluation Model for Granite Reservoirs in Marine Environments: A Case Study from the South China Sea

Abstract

1. Introduction

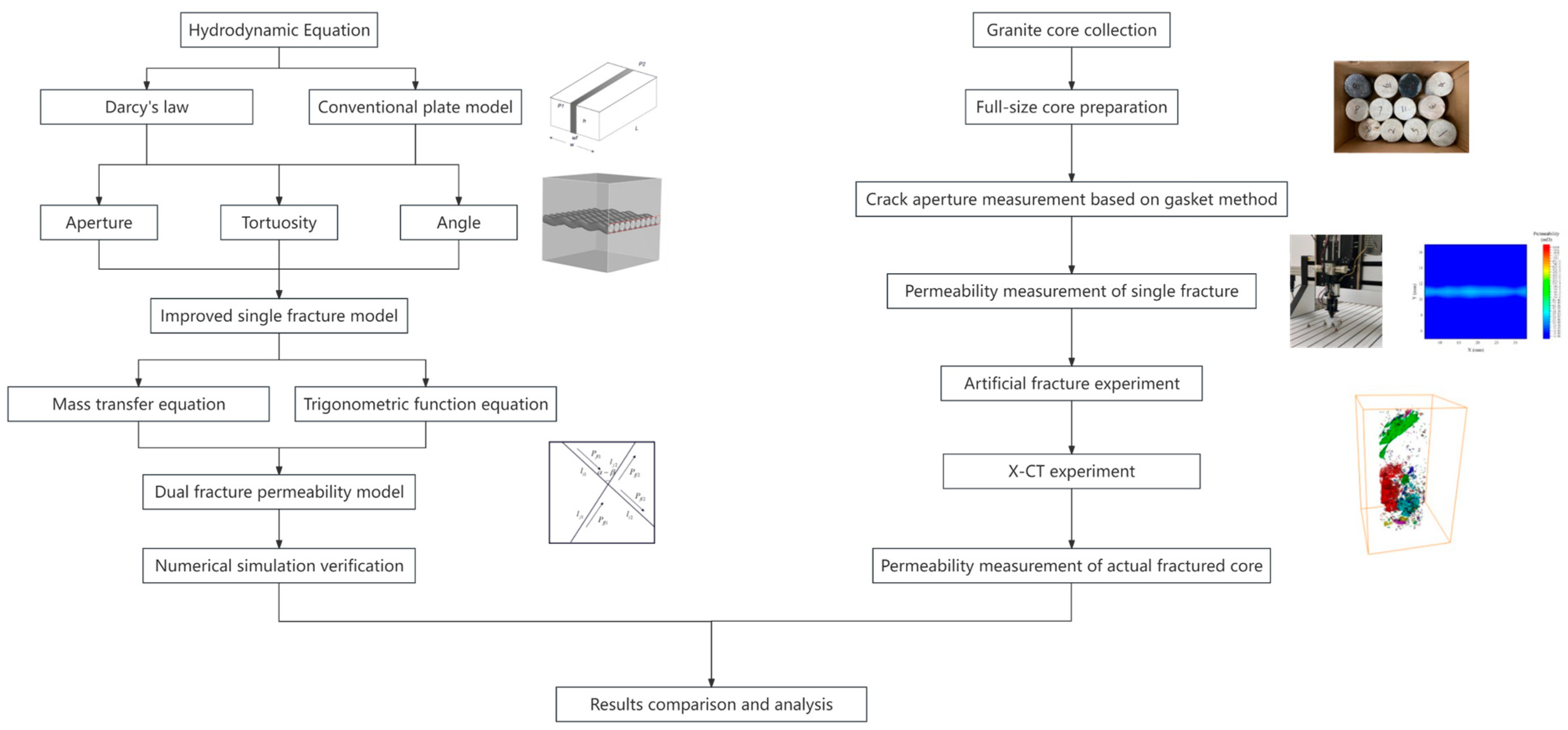

2. Formula Derivation and Simulation

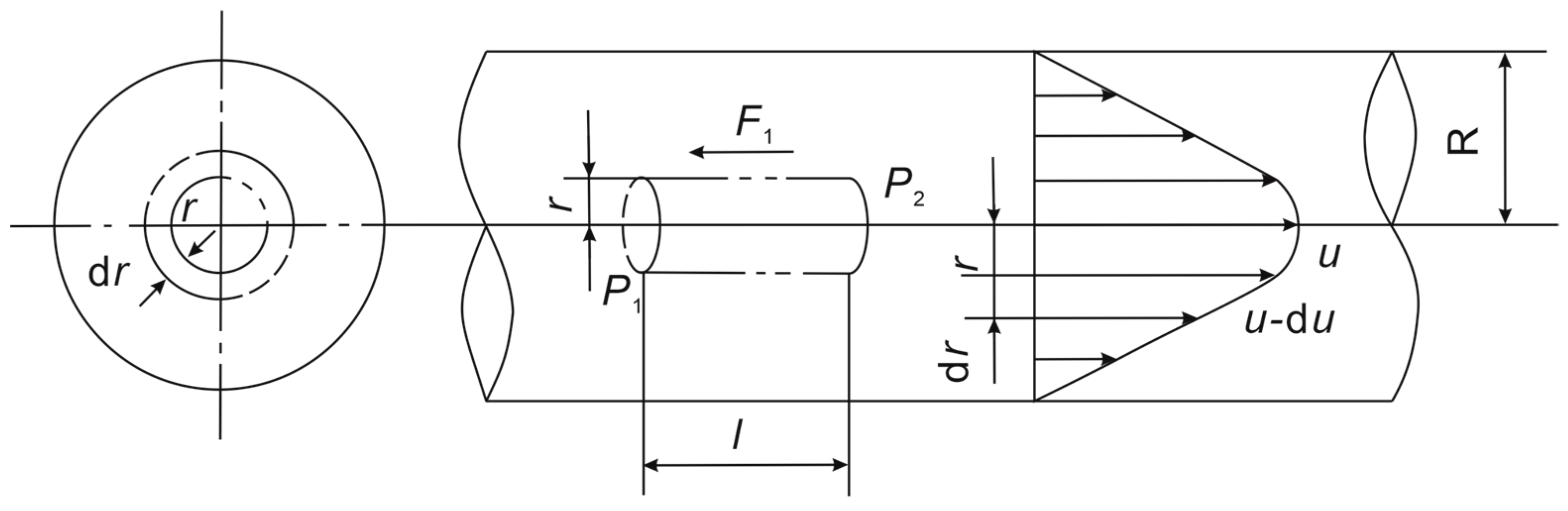

2.1. Conventional Flat Plate Model for Single Fracture

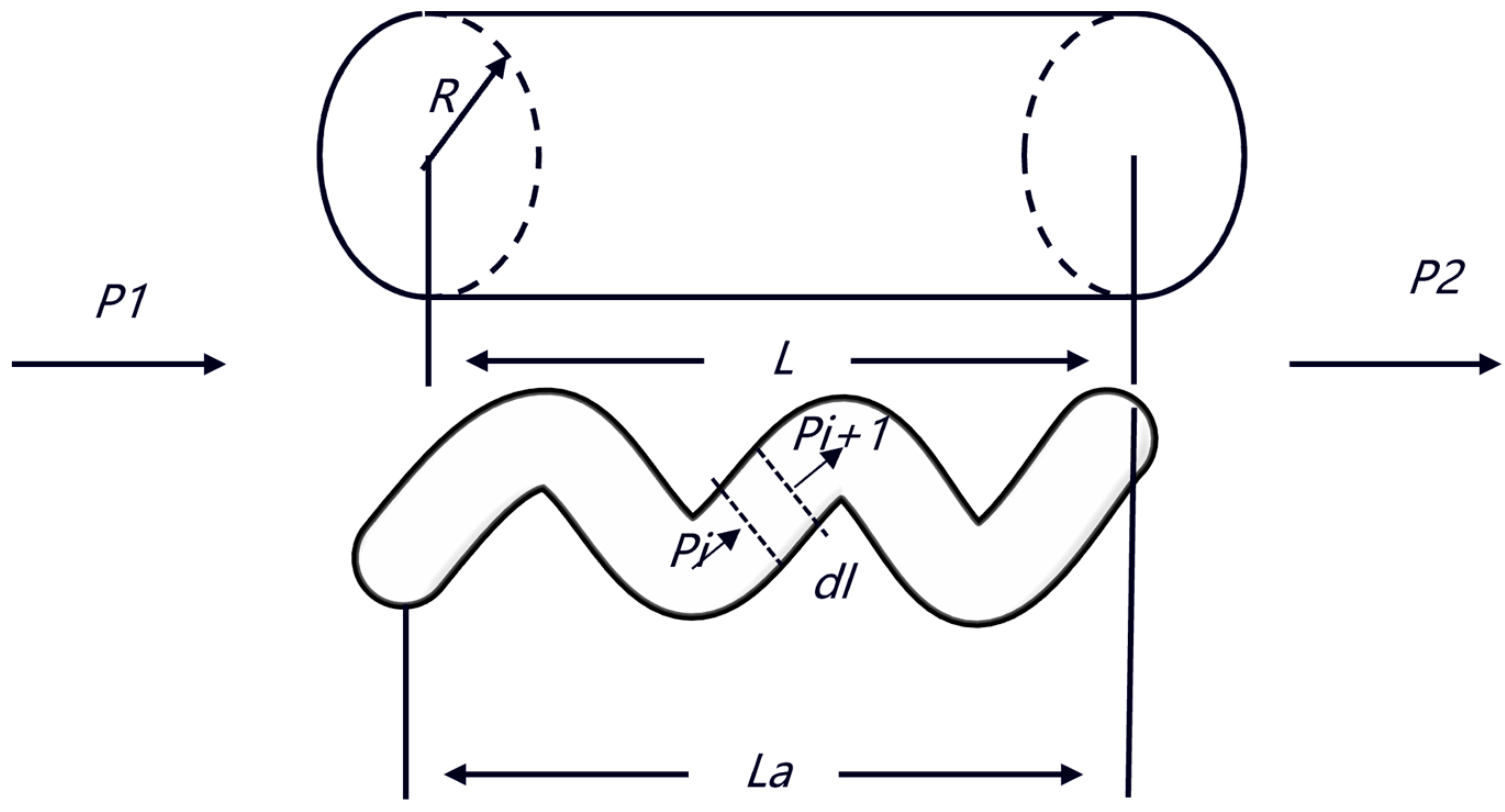

2.2. Improved Flat Plate Model for Single Fracture

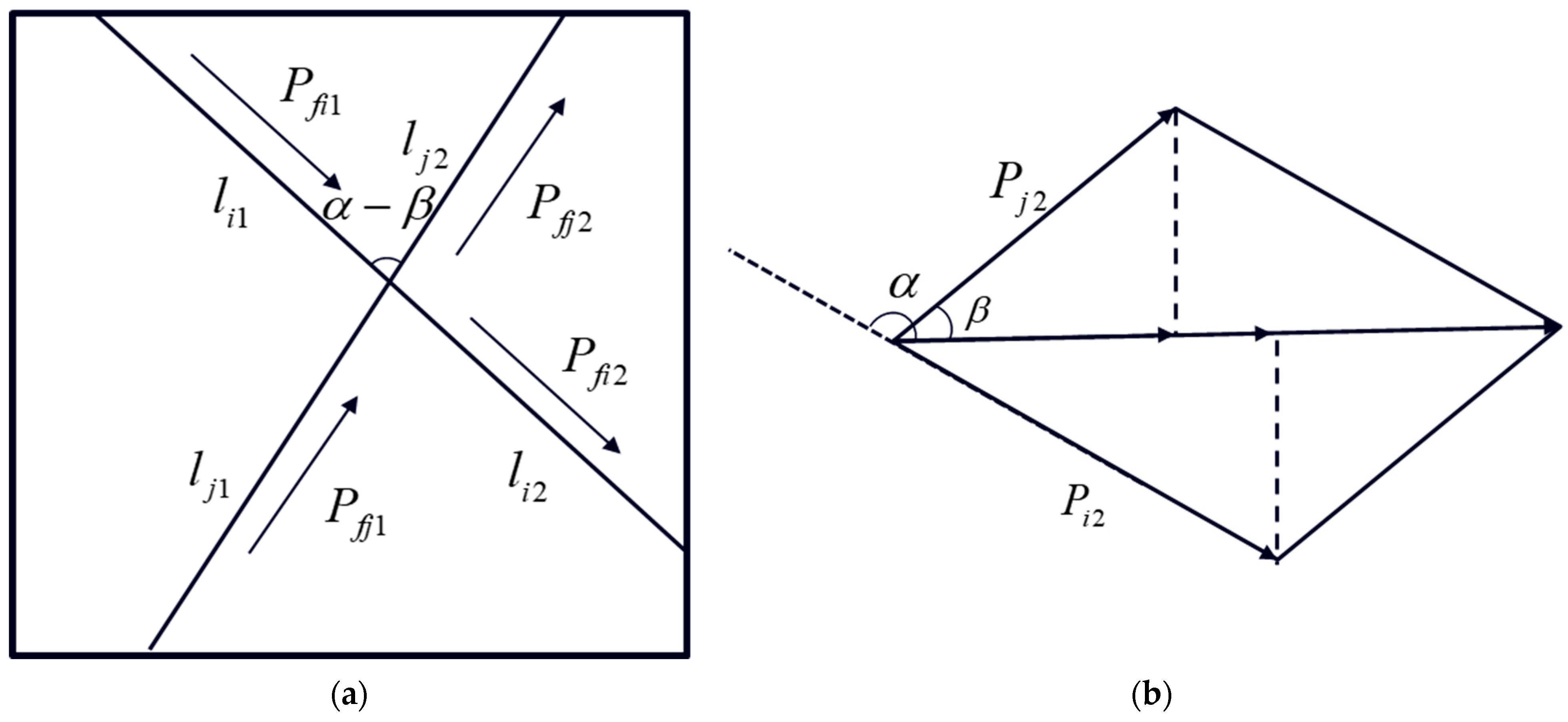

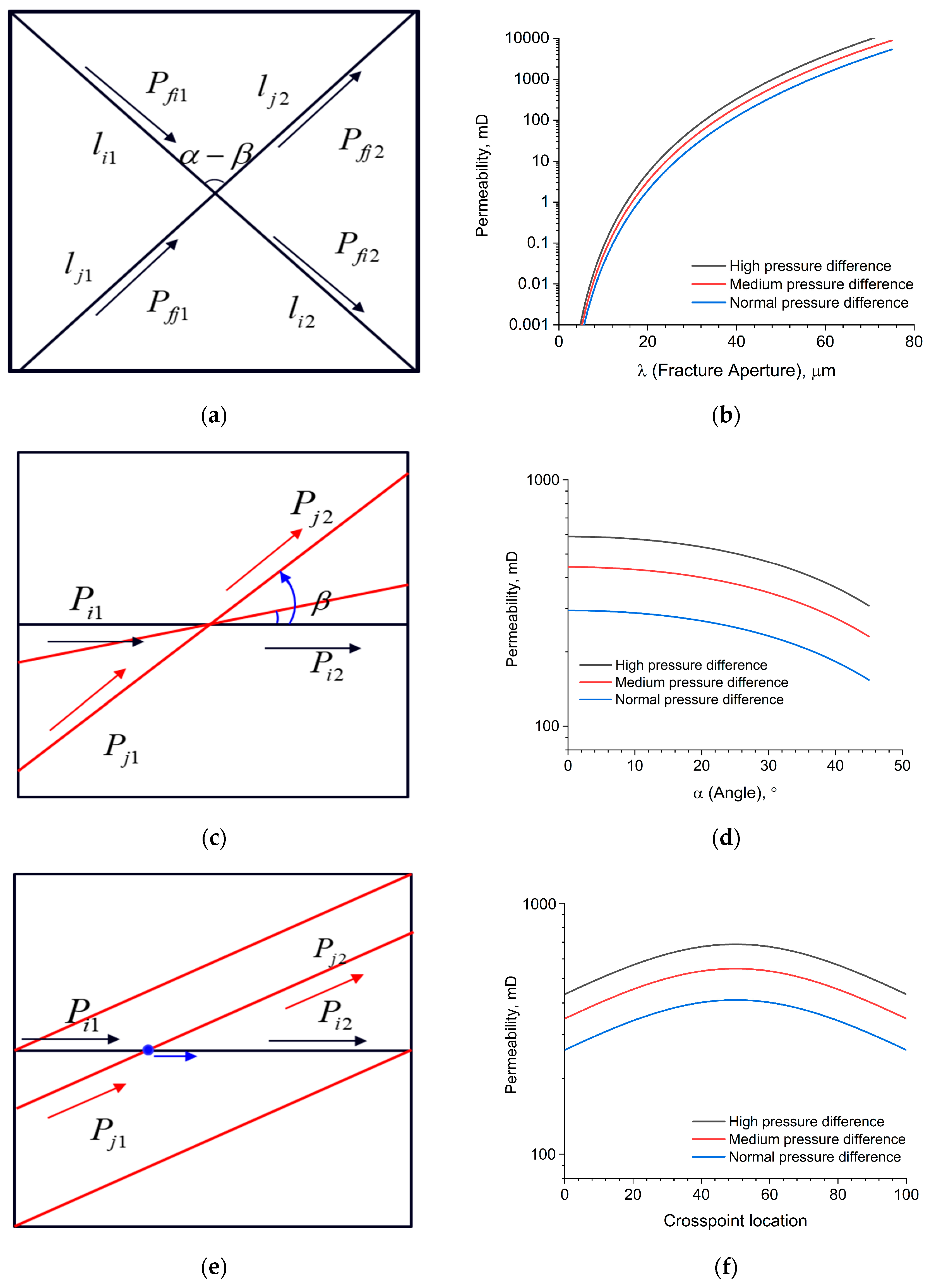

2.3. Derivation of Dual-Fracture Permeability Model

2.4. Numerical Simulation Results of the Equation

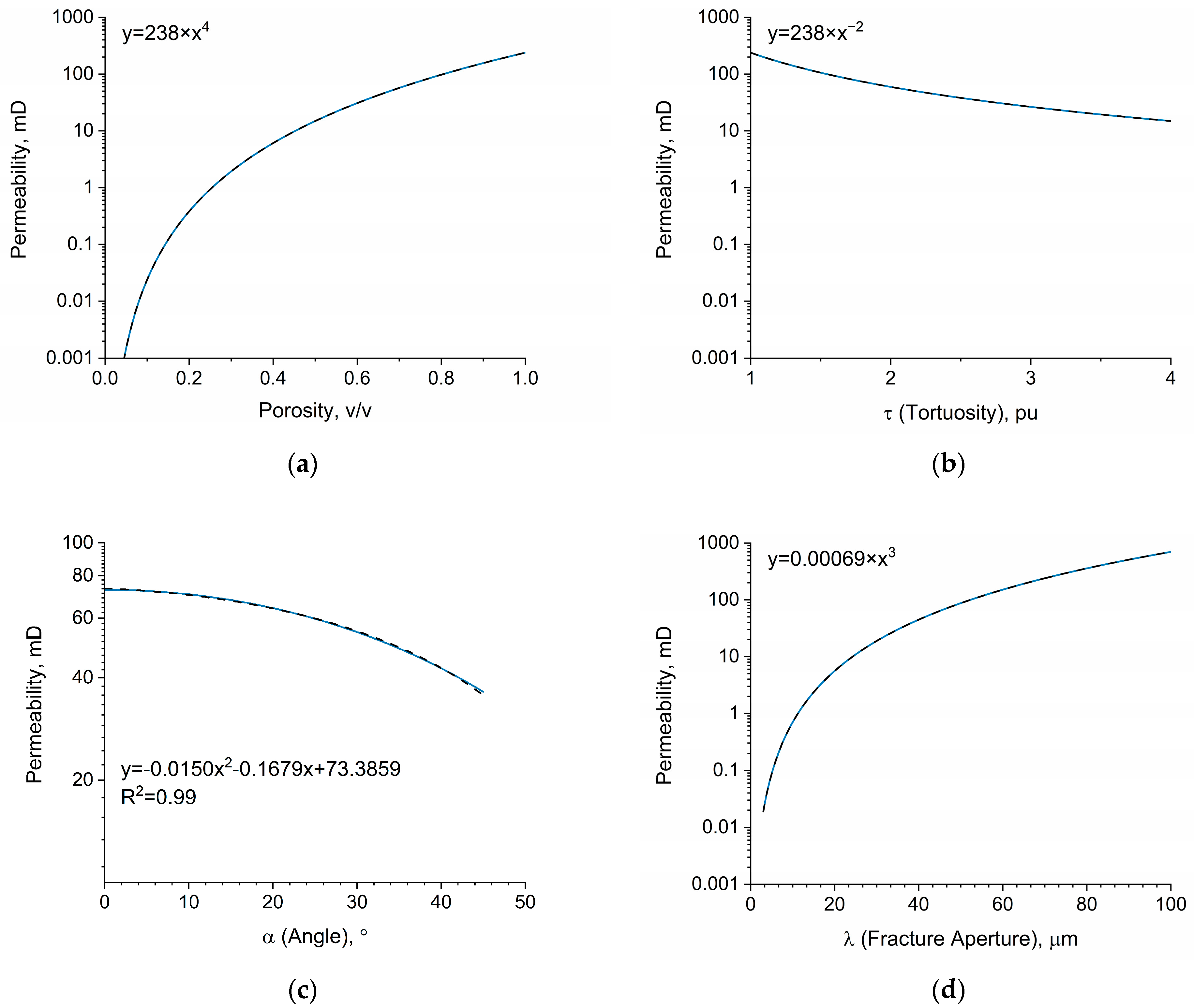

2.4.1. Improved Single-Fracture Model

2.4.2. Dual-Fracture Permeability Model

3. Experimental Materials and Methods

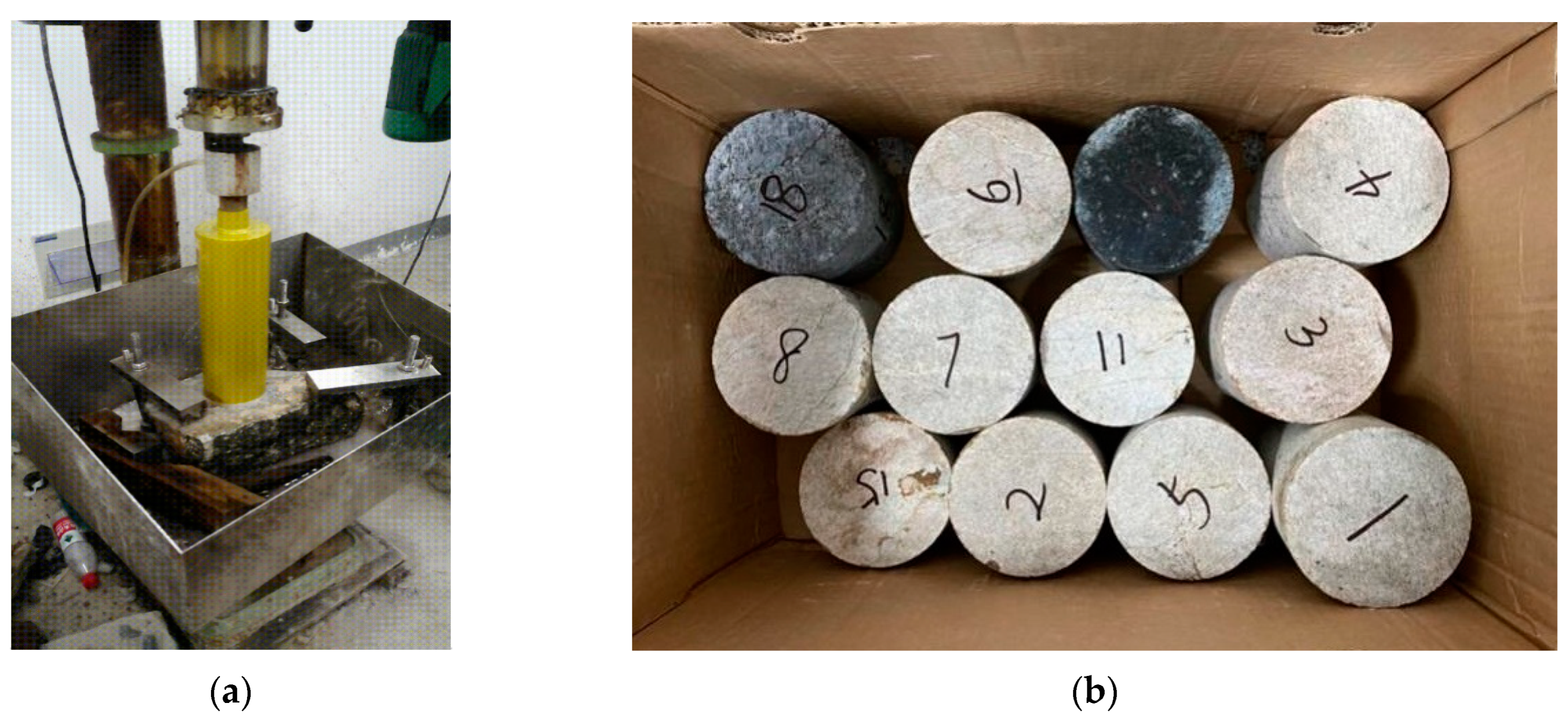

3.1. Acquisition of Experimental Materials

3.2. Flat Plate Fracture Permeability Measurement

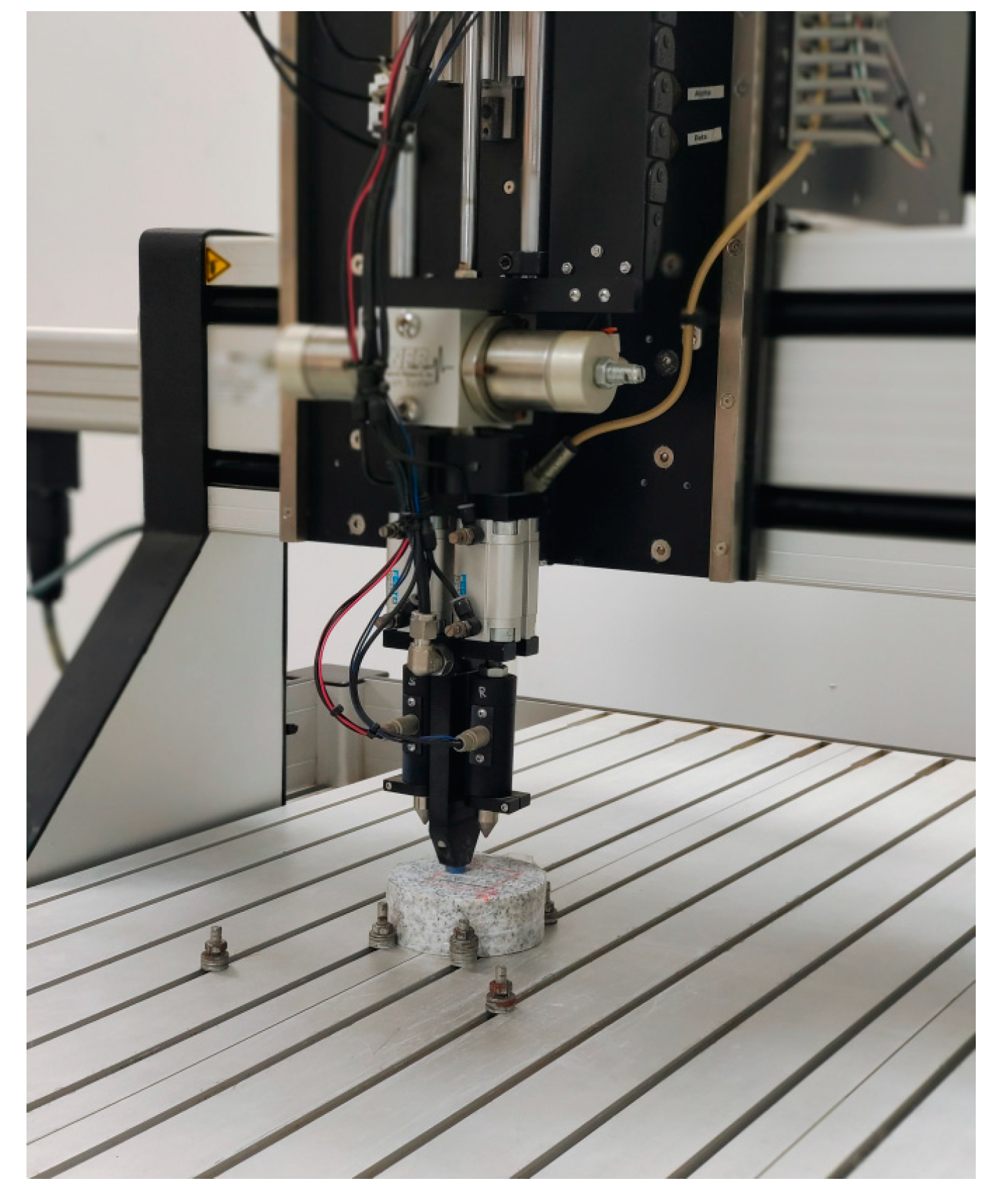

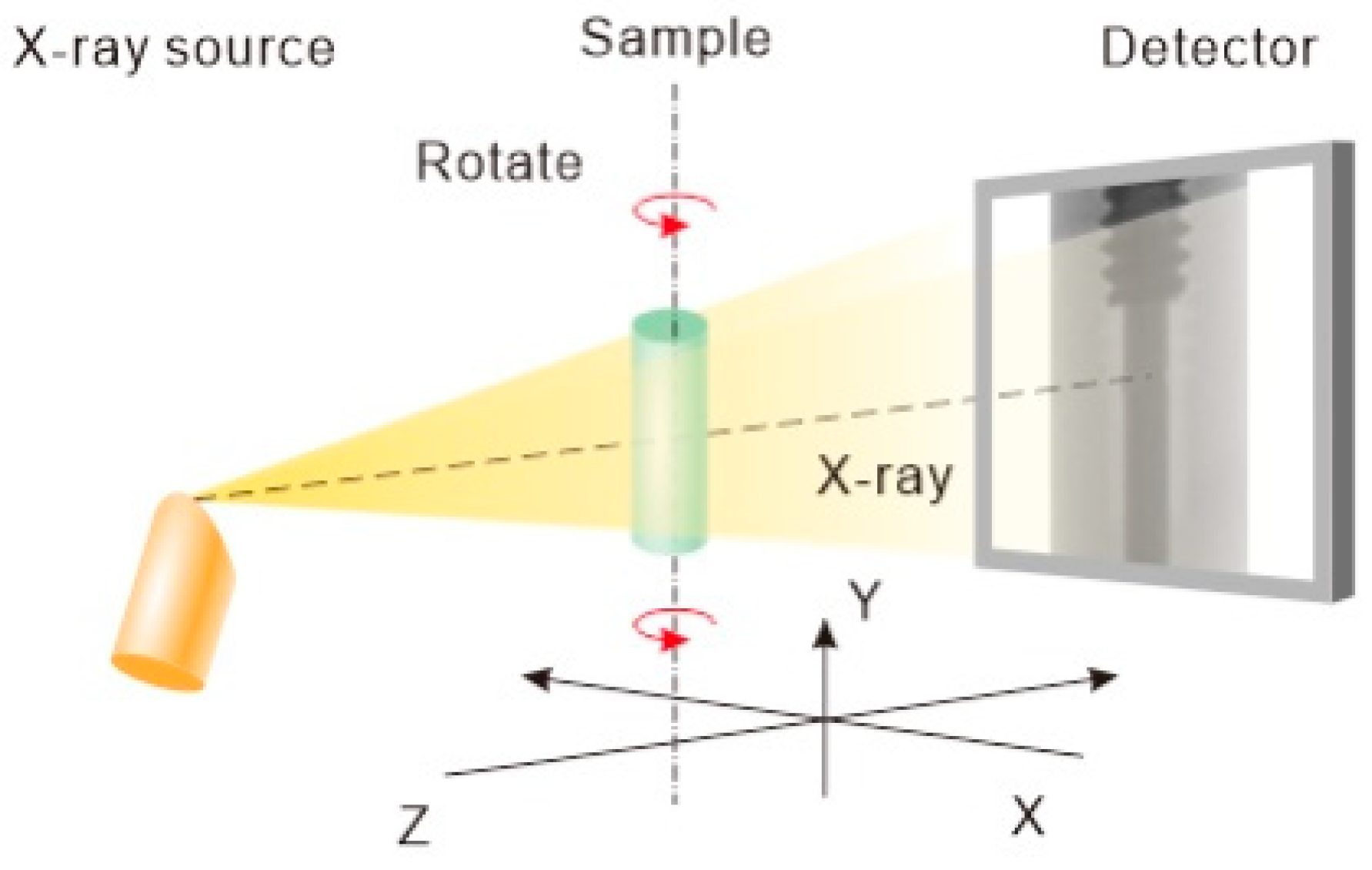

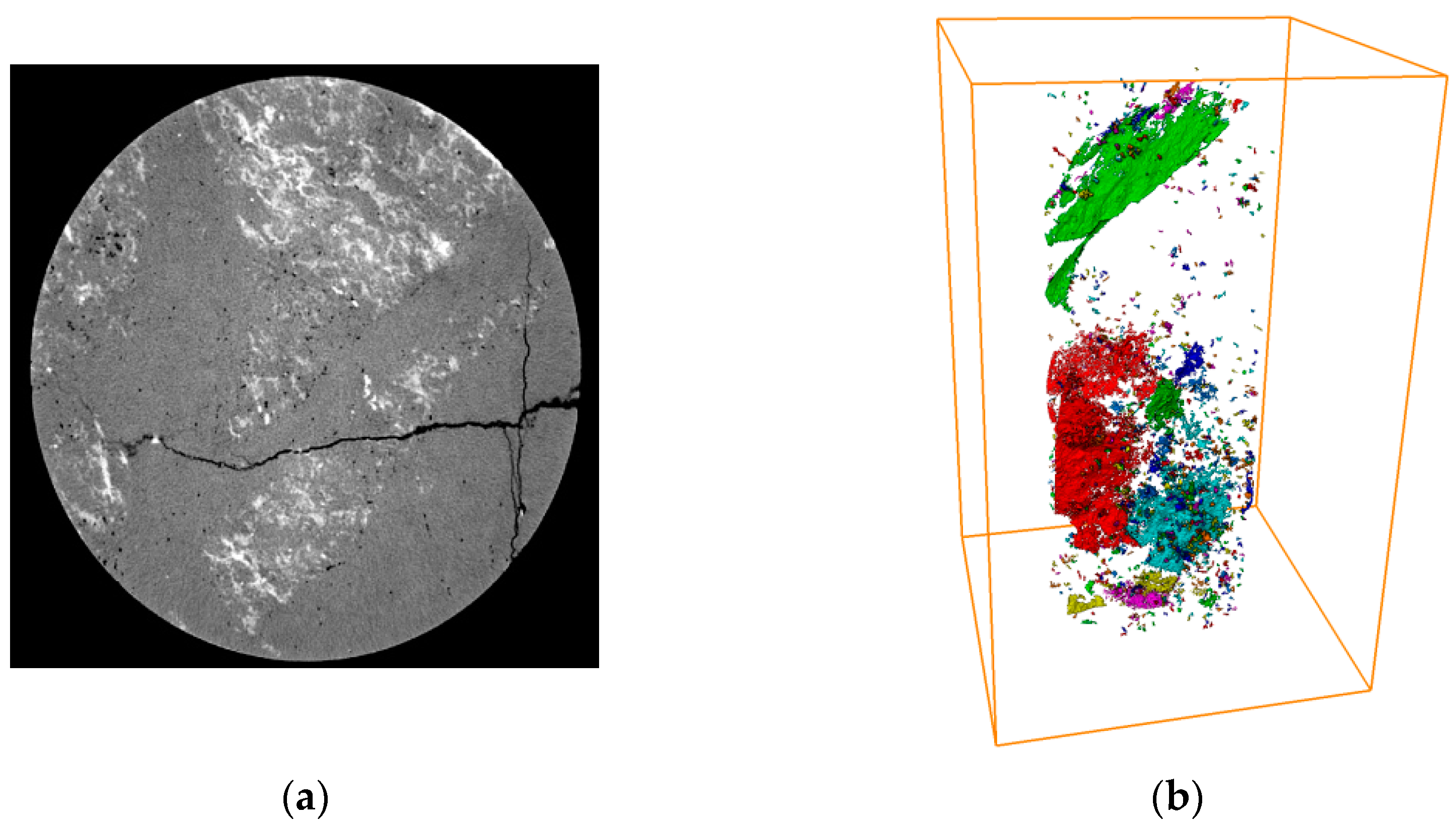

3.3. Core Fracturing Methods and X-CT Scanning

4. Results

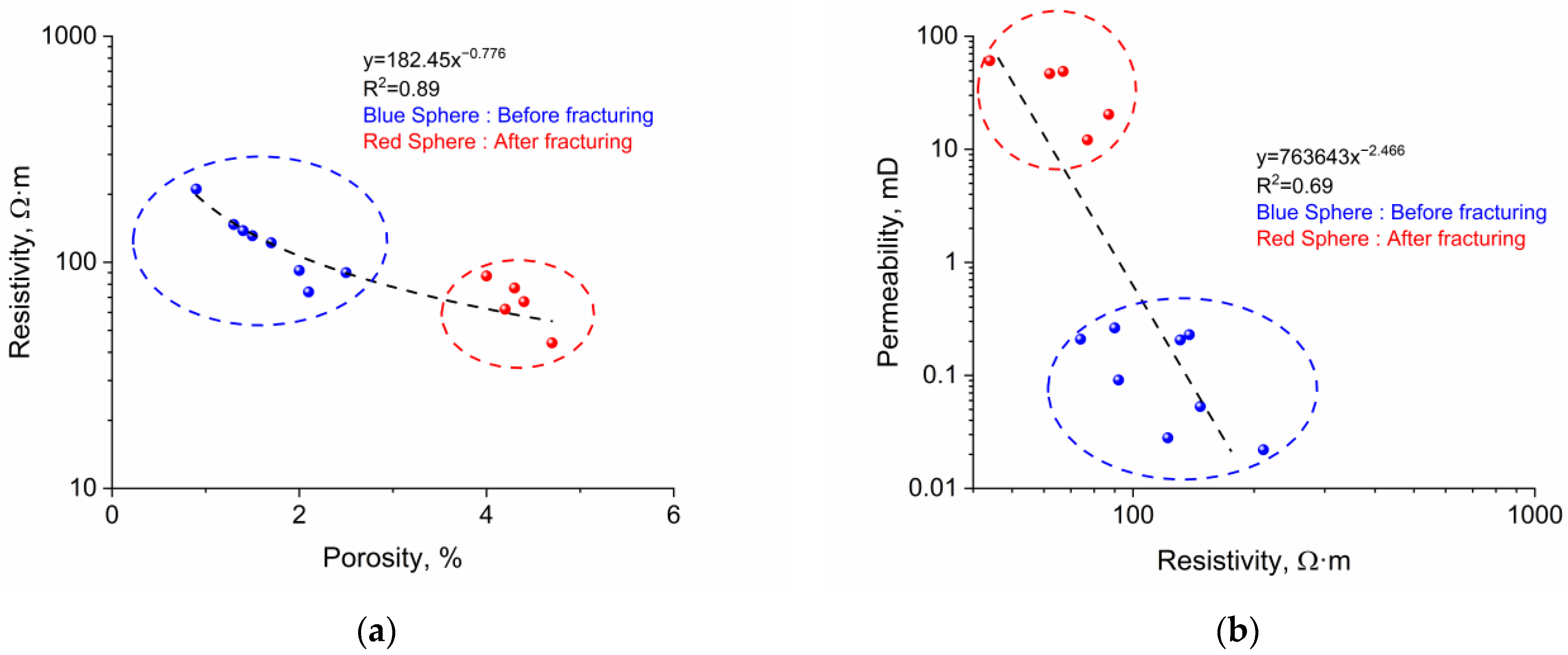

4.1. Core Permeability Test Results

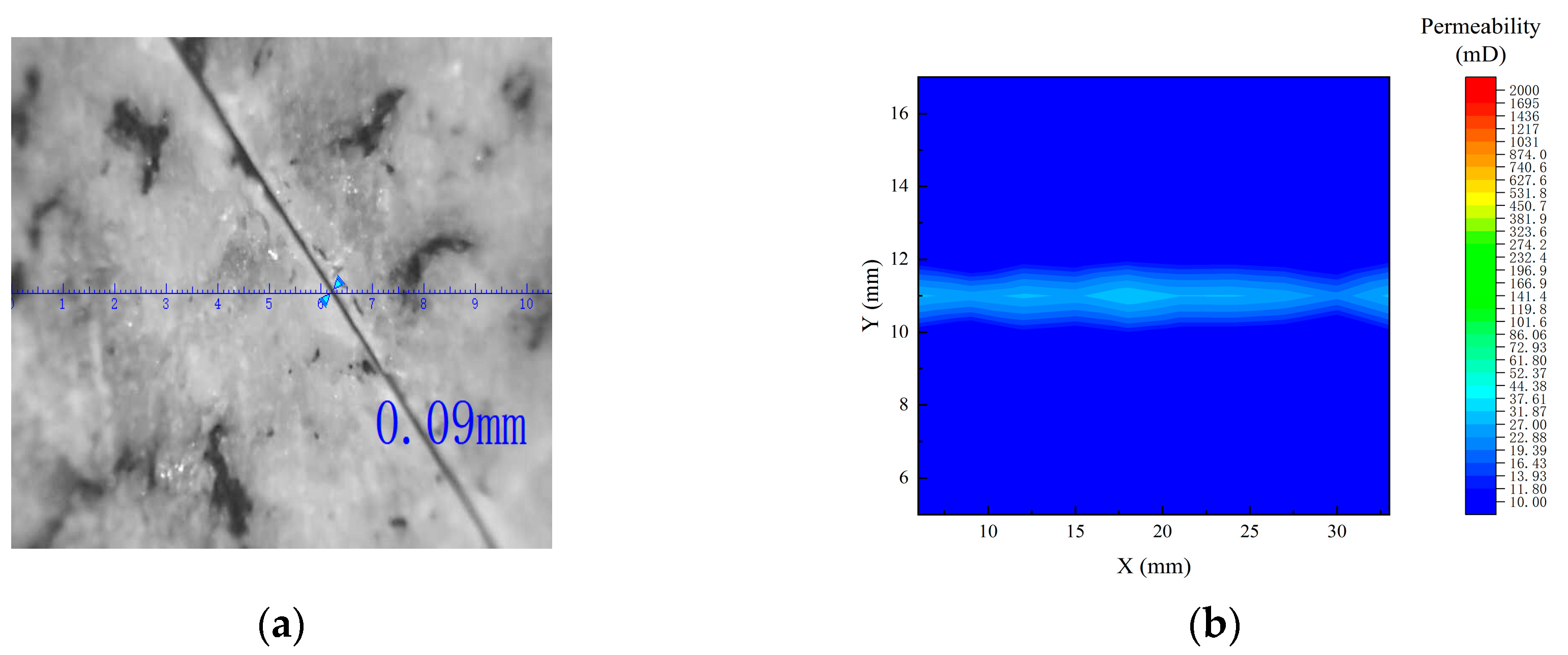

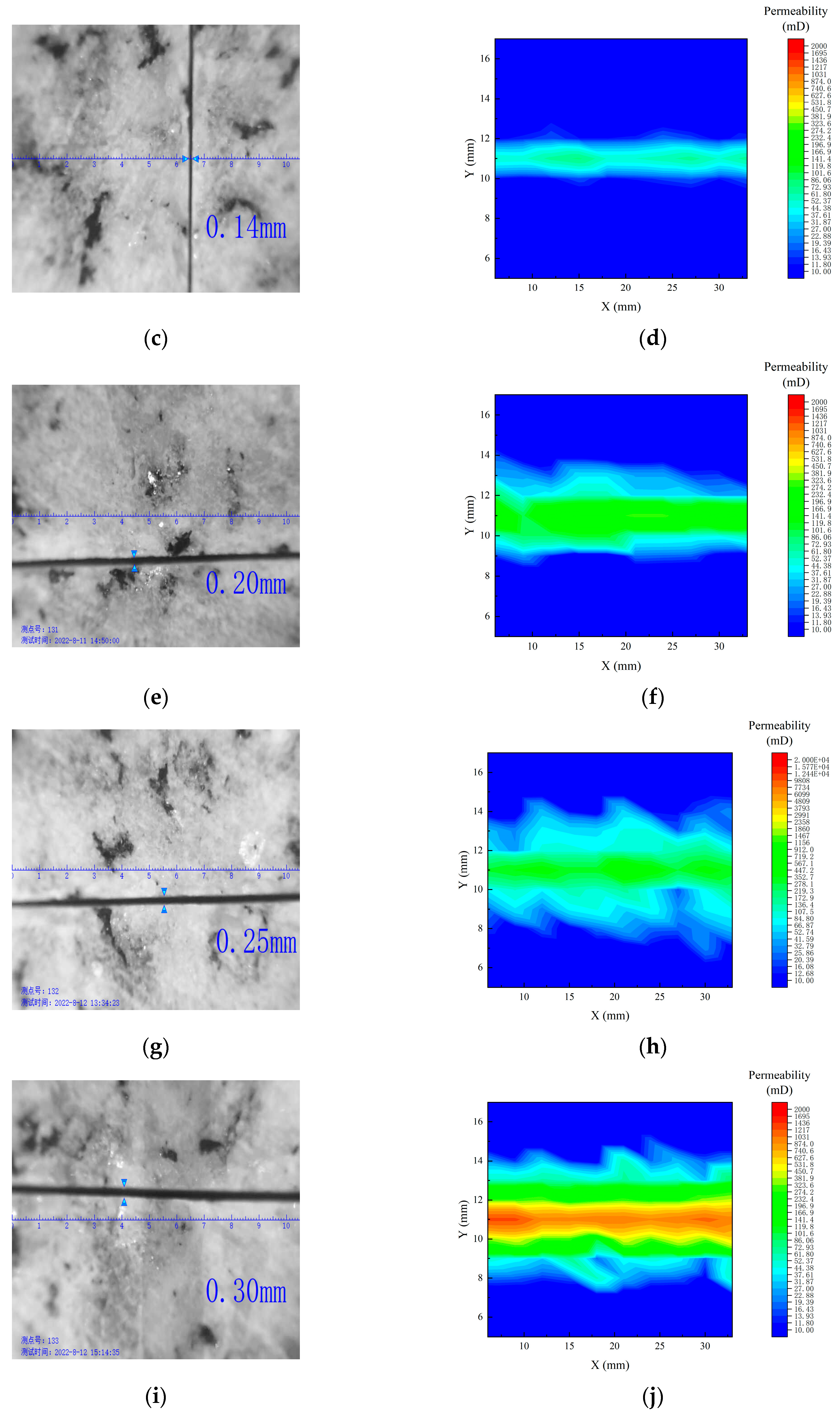

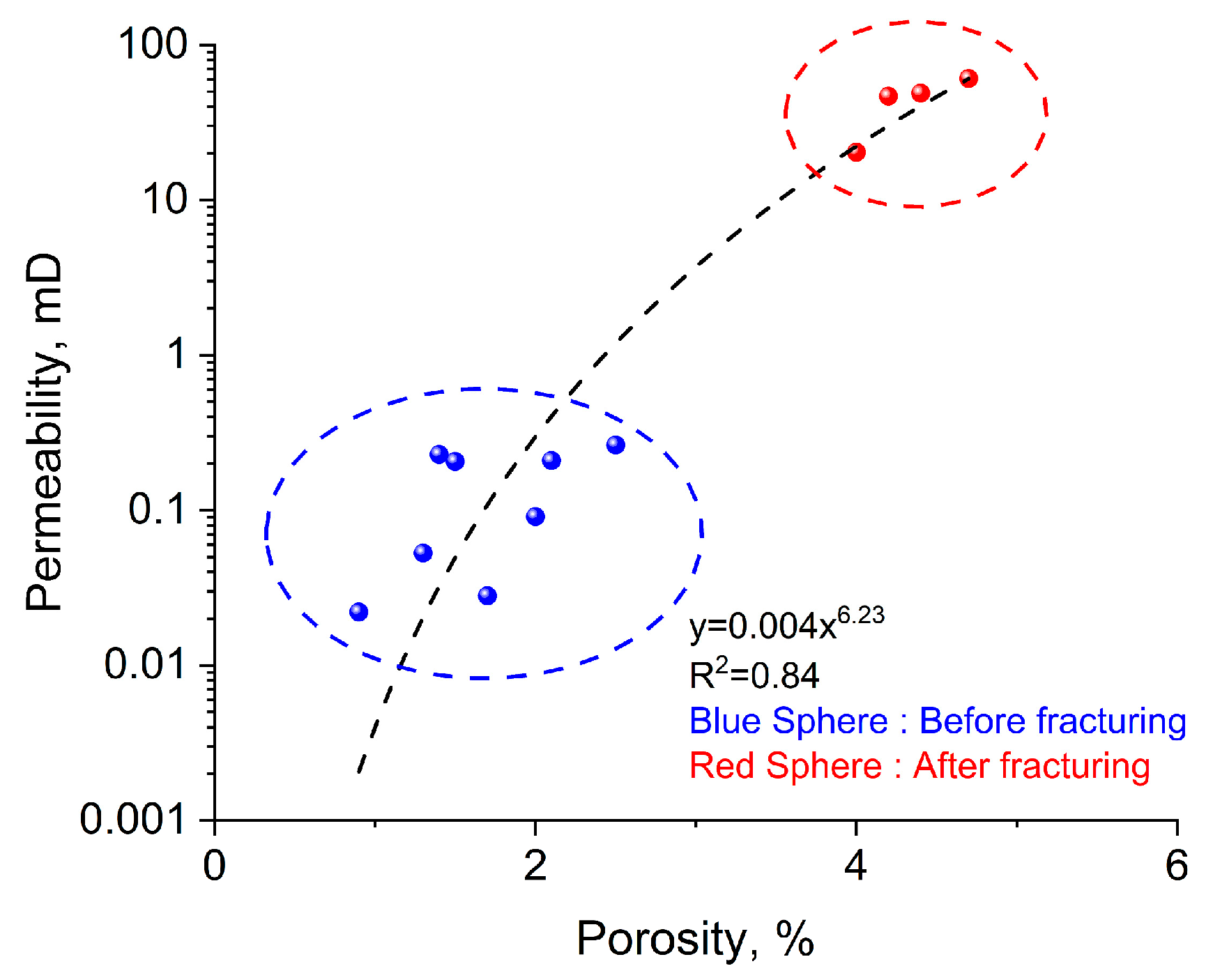

4.2. X-CT Scanning Results and Permeability Test Results of Cores before and after Fracturing

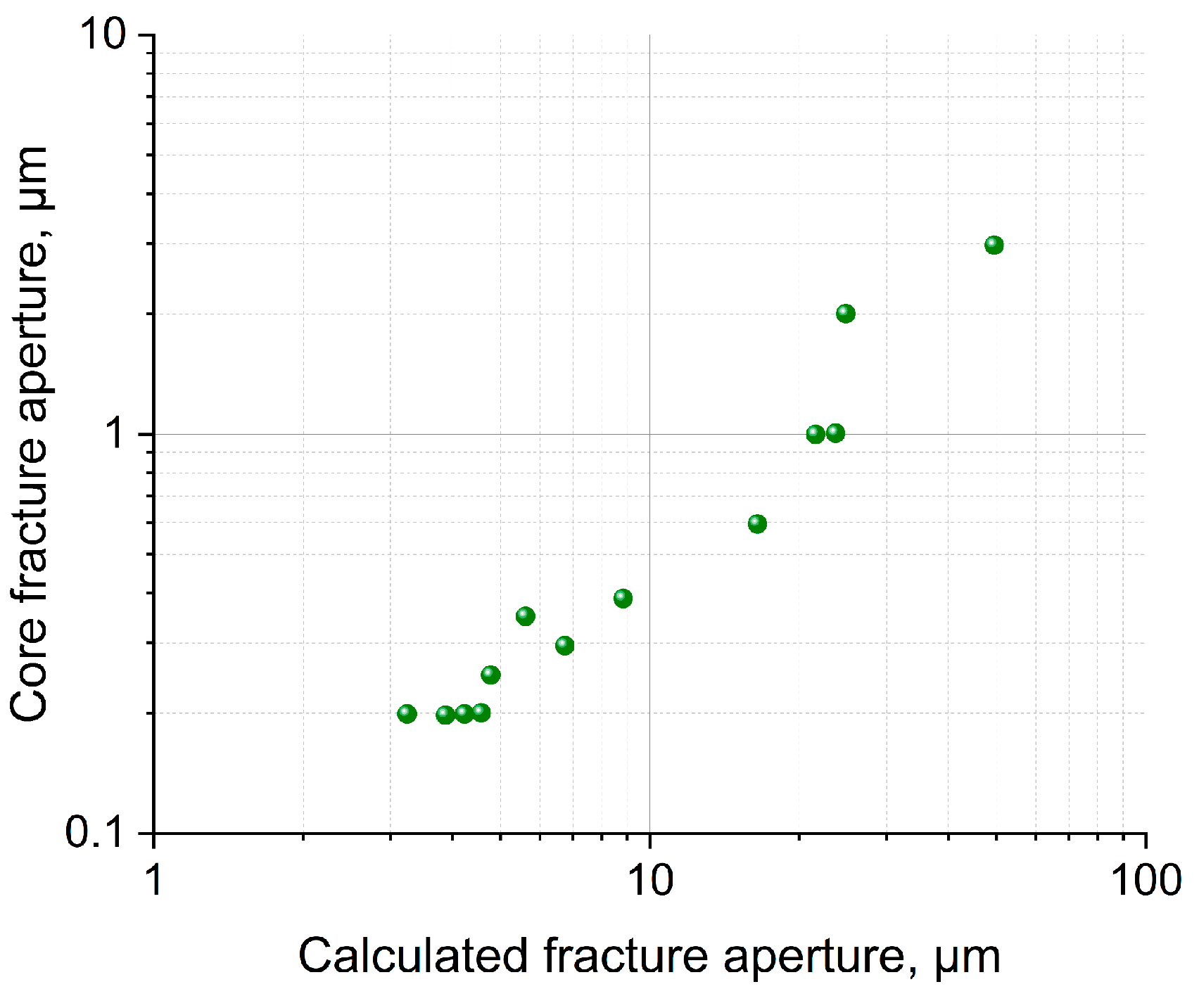

4.3. Comparative Analysis of Simulation and Experiment Results

5. Discussion

5.1. Error Analysis of Single-Fracture Model

5.2. Limitations of the Dual-Fracture Model

5.2.1. Limitations of the Suture Experiment

5.2.2. Differences between the Ideal Fracture Model and Actual Core Characteristics

5.2.3. Limitations of Logging Methods in Evaluating Cross-Fracture Permeability

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dong, Z.; Aifen, L.; Qiang, S.; Yangqing, F. Measuring oil and water relative permeability in a single fracture and researching its impacting factors. Petrol. Sci. Technol. 2013, 31, 2191–2201. [Google Scholar] [CrossRef]

- Chen, H.; Li, H.; Li, Z.; Li, S.; Wang, Y.; Wang, J.; Li, B. Effects of matrix permeability and fracture on production characteristics and residual oil distribution during flue gas flooding in low permeability/tight reservoirs. J. Petrol. Sci. Eng. 2020, 195, 107813. [Google Scholar] [CrossRef]

- Huang, X.; Kang, Z.; Zhao, J.; Wang, G.; Zhang, H.; Yang, D. Experimental investigation on micro-fracture evolution and fracture permeability of oil shale heated by water vapor. Energy 2023, 277, 127677. [Google Scholar] [CrossRef]

- Zhang, Y.; Hou, S.; Mei, S.; Zhao, T.; Li, D. Experimental study of permeability-hydraulic fracturing characteristics of tight rocks. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 182. [Google Scholar] [CrossRef]

- Li, X.; Yang, Z.; Li, S.; Huang, W.; Zhan, J.; Lin, W. Reservoir characteristics and effective development technology in typical low-permeability to ultralow-permeability reservoirs of China National Petroleum Corporation. Energy Explor. Exploit. 2021, 39, 1713–1726. [Google Scholar] [CrossRef]

- Gale, J.F.W.; Laubach, S.E.; Olson, J.E.; Eichhubl, P.; Fall, A. Natural fractures in shale: A review and new observations. AAPG Bull. 2014, 98, 2165–2216. [Google Scholar] [CrossRef]

- Wang, S.; Elsworth, D.; Liu, J. Permeability evolution in fractured coal: The roles of fracture geometry and water-content. Int. J. Coal Geol. 2011, 87, 13–25. [Google Scholar] [CrossRef]

- Ghanizadeh, A.; Clarkson, C.R.; Aquino, S.; Ardakani, O.H.; Sanei, H. Petrophysical and geomechanical characteristics of Canadian tight oil and liquid-rich gas reservoirs: II. Geomechanical property estimation. Fuel 2015, 153, 682–691. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, Z.; Xiao, H.; Zhang, C.; Zhu, L.; Wang, C. Quantitative interpretation of coal industrial components using a gray system and geophysical logging data: A case study from the Qinshui Basin, China. Front. Earth Sci. 2023, 10, 1031218. [Google Scholar] [CrossRef]

- Zhang, H.; Ait Abderrahmane, H.; Arif, M.; Al Kobaisi, M.; Sassi, M. Influence of heterogeneity on carbonate permeability upscaling: A renormalization approach coupled with the pore network model. Energy Fuels 2022, 36, 3003–3015. [Google Scholar] [CrossRef]

- Nabawy, B.S.; Géraud, Y.; Rochette, P.; Bur, N. Pore-throat characterization in highly porous and permeable sandstones. AAPG Bull. 2009, 93, 719–739. [Google Scholar] [CrossRef]

- Taghipour, S.A.; Hoseinpour, S.A.; Soltani, B.; Bahadori, A. Accurate estimation of formation permeability by means of petrophysical logs. Petrol. Sci. Technol. 2017, 35, 718–725. [Google Scholar] [CrossRef]

- Aghli, G.; Moussavi-Harami, R.; Mohammadian, R. Reservoir heterogeneity and fracture parameter determination using electrical image logs and petrophysical data (a case study, carbonate Asmari Formation, Zagros Basin, SW Iran). Petrol. Sci. 2020, 17, 51–69. [Google Scholar] [CrossRef]

- Kozeny, J. Ueber kapillare leitung des wassers im boden. Sitzungsberichte Akad. Wiss. Wien 1927, 136, 271–306. [Google Scholar]

- Wu, F.; Fan, Q.; Huang, D.; Ma, L.; Liang, X.; Sima, L. Predicting gas–water relative permeability using nuclear magnetic resonance and mercury injection capillary pressure measurements. J. Nat. Gas Sci. Eng. 2016, 32, 35–47. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, C.; Wei, Y.; Zhang, C. Permeability prediction of the tight sandstone reservoirs using hybrid intelligent algorithm and nuclear magnetic resonance logging data. Arab. J. Sci. Eng. 2017, 42, 1643–1654. [Google Scholar] [CrossRef]

- Piscopo, V.; Baiocchi, A.; Lotti, F.; Ayan, E.A.; Biler, A.R.; Ceyhan, A.H.; Cüylan, M.; Dişli, E.; Kahraman, S.; Taşkın, M. Estimation of rock mass permeability using variation in hydraulic conductivity with depth: Experiences in hard rocks of western Turkey. Bull. Eng. Geol. Environ. 2018, 77, 1663–1671. [Google Scholar] [CrossRef]

- Jiang, X.; Wang, X.; Wan, L. Semi-empirical equations for the systematic decrease in permeability with depth in porous and fractured media. Hydrogeol. J. 2010, 18, 839–850. [Google Scholar] [CrossRef]

- Achtziger-Zupančič, P.; Loew, S.; Mariethoz, G. A new global database to improve predictions of permeability distribution in crystalline rocks at site scale. J. Geophys. Res. Solid Earth 2017, 122, 3513–3539. [Google Scholar] [CrossRef]

- Tang, X.; Zhou, W.; Yang, W.; Zhang, C.; Zhang, C. An improved method in petrophysical rock typing based on mercury-injection capillary pressure data. Energy Sources Part A 2020, 2020, 1–16. [Google Scholar] [CrossRef]

- Chen, L.; Jiang, Z.; Liu, Q.; Jiang, S.; Liu, K.; Tan, J.; Gao, F. Mechanism of shale gas occurrence: Insights from comparative study on pore structures of marine and lacustrine shales. Mar. Pet. Geol. 2019, 104, 200–216. [Google Scholar] [CrossRef]

- Kenyon, W.E.; Day, P.I.; Straley, C.; Willemsen, J.F. A three-part study of NMR longitudinal relaxation properties of water-saturated sandstones. SPE Form. Eval. 1988, 3, 622–636. [Google Scholar] [CrossRef]

- Morriss, C.E.; Maclnnis, J.; Freedman, R.; Smaardyk, J.; Straley, C.; Kenyon, W.E.; Vinegar, H.S.; Tutunjian, P.N. Field test of an experimental pulsed nuclear magnetism tool. In Proceedings of the SPWLA Annual Logging Symposium, Calgary, AB, Canada, 13 June 1993. Paper ID. SPWLA-1993-GGG. [Google Scholar]

- Timur, A. An investigation of permeability, porosity, and residual water saturation relationships. In Proceedings of the SPWLA Annual Logging Symposium, New Orleans, LA, USA, 23 June 1968. Paper ID. SPWLA-1968-J. [Google Scholar]

- Coates, G.R.; Xiao, L.; Prammer, M.G. NMR Logging. Principles and Interpretation; Halliburton Energy Service: Huston, TX, USA, 1999. [Google Scholar]

- Prince, C.M.; Steele, D.D.; Devier, C.A. Permeability estimation in tight gas sands and shales using NMR—A new interpretive methodology. In Proceedings of the 9th AAPG International Conference and Exhibition, Rio de Janeiro, Brazil, 15–18 November 2009. [Google Scholar]

- Rezaee, R.; Saeedi, A.; Clennell, B. Tight gas sands permeability estimation from mercury injection capillary pressure and nuclear magnetic resonance data. J. Petrol. Sci. Eng. 2012, 88, 92–99. [Google Scholar] [CrossRef]

- Hossain, Z.; Grattoni, C.A.; Solymar, M.; Fabricius, I.L. Petrophysical properties of greensand as predicted from NMR measurements. Petrol. Geosci. 2011, 17, 111–125. [Google Scholar] [CrossRef]

- Wu, F.; Li, Y.; Burnham, B.; Zhang, Z.; Yao, C.; Yuan, L.; Zhang, F.; Deng, H.; Xi, Y.; He, J. Fractal-based NMR permeability estimation in tight sandstone: A case study of the Jurassic rocks in the Sichuan Basin, China. J. Petrol. Sci. Eng. 2022, 218, 110940. [Google Scholar] [CrossRef]

- Xia, F.; Su, Y.; Tang, X. Stoneley wave reflection and transmission across permeable formations and fractured zones: Comparison of analytical and numerical modeling results. Chin. J. Geophys. 2022, 65, 1508–1518. [Google Scholar]

- Guo, J.; Zhang, Z.; Nie, X.; Zhao, Q.; Lv, H. Logging Evaluation of Irreducible Water Saturation: Fractal Theory and Data-Driven Approach—Case Study of Complex Porous Carbonate Reservoirs in Mishrif Formation. Fractal. Fract. 2024, 8, 487. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, G.; Li, H.; Huang, Y.; Zhao, F.; Guo, Y.; Gao, J.; Lai, J. A novel deep learning method based on 2-D CNNs and GRUs for permeability prediction of tight sandstone. Geoenergy Sci. Eng. 2024, 238, 212851. [Google Scholar] [CrossRef]

- Li, N.; Wang, K.; Lu, J.; Liu, P.; Xiao, C.; Wu, H.; Guo, Q.; Fan, H.; Men, B.; Feng, Z.; et al. First successful downhole testing of the permeability logging prototype. J. Geophys. Eng. 2024, 21, 1179–1182. [Google Scholar] [CrossRef]

- Moinfar, A.; Varavei, A.; Sepehrnoori, K.; Johns, R.T. Development of an efficient embedded discrete fracture model for 3D compositional reservoir simulation in fractured reservoirs. SPE J. 2014, 19, 289–303. [Google Scholar] [CrossRef]

- Zhang, H.; Hu, Y.; Li, X.; Du, K.; Zeng, T.; Li, C. Application of support vector machines and genetic algorithms to fluid identification in Offshore Granitic subduction hill reservoirs. Geoenergy Sci. Eng. 2024, 240, 213013. [Google Scholar] [CrossRef]

- Li, Z.; Guo, J.; Wu, S. Characteristics and Genetic Mechanism of Granite Weathering Crust of Songnan Low Uplift, Qiongdongnan Basin, South China Sea. Minerals 2024, 14, 512. [Google Scholar] [CrossRef]

- Bisdom, K.; Bertotti, G.; Nick, H.M. The impact of different aperture distribution models and critical stress criteria on equivalent permeability in fractured rocks. J. Geophys. Res. Solid Earth 2016, 121, 4045–4063. [Google Scholar] [CrossRef]

- Zhang, B.; Deng, Z.; Fu, X.; Yu, K.; Zeng, F.B. An experimental study on the effects of acidization on coal permeability: Implications for the enhancement of coalbed methane production. Energy 2023, 280, 128145. [Google Scholar] [CrossRef]

- Nakagawa, S.; Nakashima, S.; Korneev, V.A. Laboratory measurements of guided-wave propagation within a fluid-saturated fracture. Geophys. Prospect. 2015, 64, 143–156. [Google Scholar] [CrossRef]

- Jiao, Y.; Wang, Y.; Feng, D.; Gong, J.; Niu, Y.; Hu, S.; Ren, J. Laboratory study on fluid-induced fracture slip and permeability evolution in marble fractures. Rock Mech. Rock Eng. 2023, 56, 2497–2513. [Google Scholar] [CrossRef]

- Aziz, A. A similarity solution for laminar thermal boundary layer over a flat plate with a convective surface boundary condition. Commun. Nonlinear Sci. 2009, 14, 1064–1068. [Google Scholar] [CrossRef]

- Niessner, J.; Berg, S.; Hassanizadeh, S.M. Comparison of two-phase Darcy’s law with a thermodynamically consistent approach. Transport. Porous. Med. 2011, 88, 133–148. [Google Scholar] [CrossRef]

- Pouya, A.; Vu, M.N. Fluid flow and effective permeability of an infinite matrix containing disc-shaped cracks. Adv. Water Resour. 2012, 42, 37–46. [Google Scholar] [CrossRef][Green Version]

- Su, H.; Zhang, Y.; Xiao, B.; Huang, X.; Yu, B. A fractal-monte carlo approach to model oil and water two-phase seepage in low-permeability reservoirs with rough surfaces. Fractals 2021, 29, 2150003. [Google Scholar] [CrossRef]

- Teruel, F.E. Characterization of a porous medium employing numerical tools: Permeability and pressure-drop from Darcy to turbulence. Int. J. Heat Mass Tran. 2009, 52, 5878–5888. [Google Scholar] [CrossRef]

- Ahmia, A.C.; Idouhar, M.; Wongwailikit, K.; Dietrich, N.; Hébrard, G. Impact of cellulose and surfactants on mass transfer of bubble columns. Chem. Eng. Technol. 2019, 42, 2465–2475. [Google Scholar] [CrossRef]

- Li, X.; Qin, R.; Wei, D.; Cao, J.; Wang, P.; Ye, X.; Yin, Z. Research progress in logging evaluation of offshore buried-hill fractured reservoirs in China. China Offshore Oil Gas 2023, 35, 69–82. [Google Scholar]

- Li, X.; Qin, R.; Cao, J.; Wang, P.; Liu, X.; Ping, H. Method of connected porosity evaluation and quantitative permeability calculation for complex reservoirs. Oil Geophys. Prospect. 2022, 57, 377–385. [Google Scholar]

- Li, B.; Nie, X.; Cai, J.; Zhou, X.; Wang, C.; Han, D. U-Net model for multi-component digital rock modeling of shales based on CT and QEMSCAN images. J. Petrol. Sci. Eng. 2022, 216, 110734. [Google Scholar] [CrossRef]

- Plumb, R.A.; Luthl, S.M. Analysis of borehole images and their application to geologic modeling of an eolian reservoir. SPE Form. Eval. 1989, 4, 505–514. [Google Scholar] [CrossRef]

- Li, X.; Qin, R.; Cao, J.; Wang, P.; Ye, X.; Yin, Z. Dolomite reservoir characteristics and permeability evaluation methods: An example from the Paleogene, Mesopotamian basin, Iraq. China Offshore Oil Gas 2024, 36, 81–94. [Google Scholar]

- Qin, Z.; Wu, J.; Wang, C.; Luo, S.; Yang, H.; Su, K.; Luo, Y.; Liu, L.; Zhu, Y.; Wei, K.; et al. A novel calculation model, characteristics and applications of Archie’s cementation exponent in dual porosity reservoirs with intersecting dual fractures. Geoenergy Sci. Eng. 2023, 231, 212390. [Google Scholar] [CrossRef]

- Zhu, Z.; Cui, L.; Dong, Y.; Sheng, Q.; Tian, K.; Guo, Z. A Novel Deformation Analytical Solution and Constitutive Model for Fractured Rock Masses. J. Mar. Sci. Eng. 2023, 11, 2351. [Google Scholar] [CrossRef]

- Zheng, H.; Zhang, Z.; Guo, J.; Fang, S.; Wang, C. Numerical Simulation Study on the Influence of Cracks in a Full-Size Core on the Resistivity Measurement Response. Energies 2024, 17, 1386. [Google Scholar] [CrossRef]

| Core No. | Fracture Information | Before Fracturing | After Fracturing | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Fracture No. | Angle | Aperture (μm) | Angle | Aperture (μm) | Porosity (%) | Permeability (mD) | Porosity (%) | Permeability (mD) | |

| X1 | ① | 73° | 324 | 68.26° | 34 | 2.5 | 0.263 | — | — |

| ② | 129° | 205 | 20.88 | 8.43 | |||||

| ③ | 74° | 172 | 15.54 | 31.75 | |||||

| ④ | 28° | 99 | 3.13 | 6.71 | |||||

| X2 | ① | 58° | 309 | — | — | 2 | 0.091 | 4.3 | 12.09 |

| X3 | ① | 84° | 324 | 99.32° | 109 | 1.5 | 0.206 | 4.4 | 48.841 |

| ② | 98° | 162 | |||||||

| ③ | 9° | 182 | |||||||

| X4 | ① | 91° | 359 | 99.348° | 80 | 1.4 | 0.229 | — | — |

| ② | 98° | 72 | |||||||

| X5 | ① | 84° | 354 | — | — | 1.7 | 0.028 | 4.7 | 60.743 |

| ② | 83° | 297 | |||||||

| X6 | ① | 74° | 159 | 116.68° | 79 | 2.1 | 0.209 | 4.2 | 46.649 |

| X7 | ① | 118° | 284 | — | — | 0.9 | 0.022 | 4 | 20.323 |

| X8 | ① | 80° | 255 | 80.57° | 121 | 1.3 | 0.053 | — | — |

| ② | 93° | 76 | |||||||

| ③ | 179° | 303 | |||||||

| Validation Sample Number | Fracture Aperture (μm) | Fracture Angle (°) | Core Fracture Permeability (mD) | Calculated Fracture Permeability (mD) | Absolute Error (mD) | Relative Error (%) |

|---|---|---|---|---|---|---|

| V1 | 94.9 | 0 | 61.58 | 59.57 | 2.01 | 3.26 |

| V2 | 173.6 | 0 | 247.63 | 268.51 | 20.88 | 8.43 |

| V3 | 109 | 40 | 48.94 | 64.48 | 15.54 | 31.75 |

| V4 | 89 | 31 | 46.65 | 43.52 | 3.13 | 6.71 |

| V5 | 99 | 58 | 20.32 | 36.11 | 15.79 | 77.71 |

| 94.9 | 0 | 61.58 | 59.57 | 2.01 | 3.26 | |

| Average Error | 11.47 | 25.57 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Gu, B.; Lv, H.; Zhu, Z.; Zhang, Z. Improved Fracture Permeability Evaluation Model for Granite Reservoirs in Marine Environments: A Case Study from the South China Sea. J. Mar. Sci. Eng. 2024, 12, 1868. https://doi.org/10.3390/jmse12101868

Guo J, Gu B, Lv H, Zhu Z, Zhang Z. Improved Fracture Permeability Evaluation Model for Granite Reservoirs in Marine Environments: A Case Study from the South China Sea. Journal of Marine Science and Engineering. 2024; 12(10):1868. https://doi.org/10.3390/jmse12101868

Chicago/Turabian StyleGuo, Jianhong, Baoxiang Gu, Hengyang Lv, Zuomin Zhu, and Zhansong Zhang. 2024. "Improved Fracture Permeability Evaluation Model for Granite Reservoirs in Marine Environments: A Case Study from the South China Sea" Journal of Marine Science and Engineering 12, no. 10: 1868. https://doi.org/10.3390/jmse12101868

APA StyleGuo, J., Gu, B., Lv, H., Zhu, Z., & Zhang, Z. (2024). Improved Fracture Permeability Evaluation Model for Granite Reservoirs in Marine Environments: A Case Study from the South China Sea. Journal of Marine Science and Engineering, 12(10), 1868. https://doi.org/10.3390/jmse12101868