Study on the Influence of Tip Clearance on Cavitation Performance and Entropy Production of an Axial Flow Pump

Abstract

1. Introduction

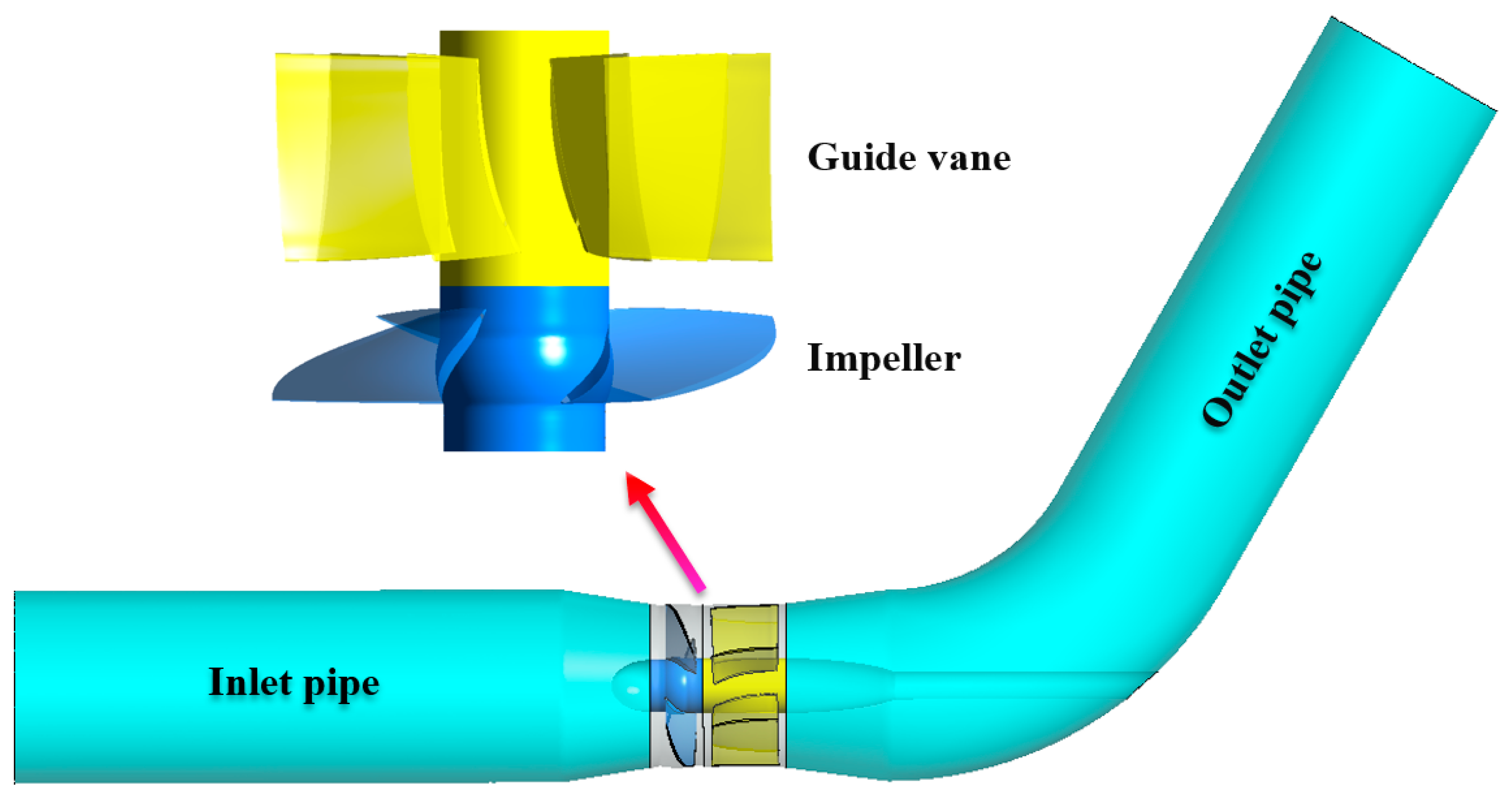

2. Calculation Model and Scheme Parameters

2.1. Geometric Model

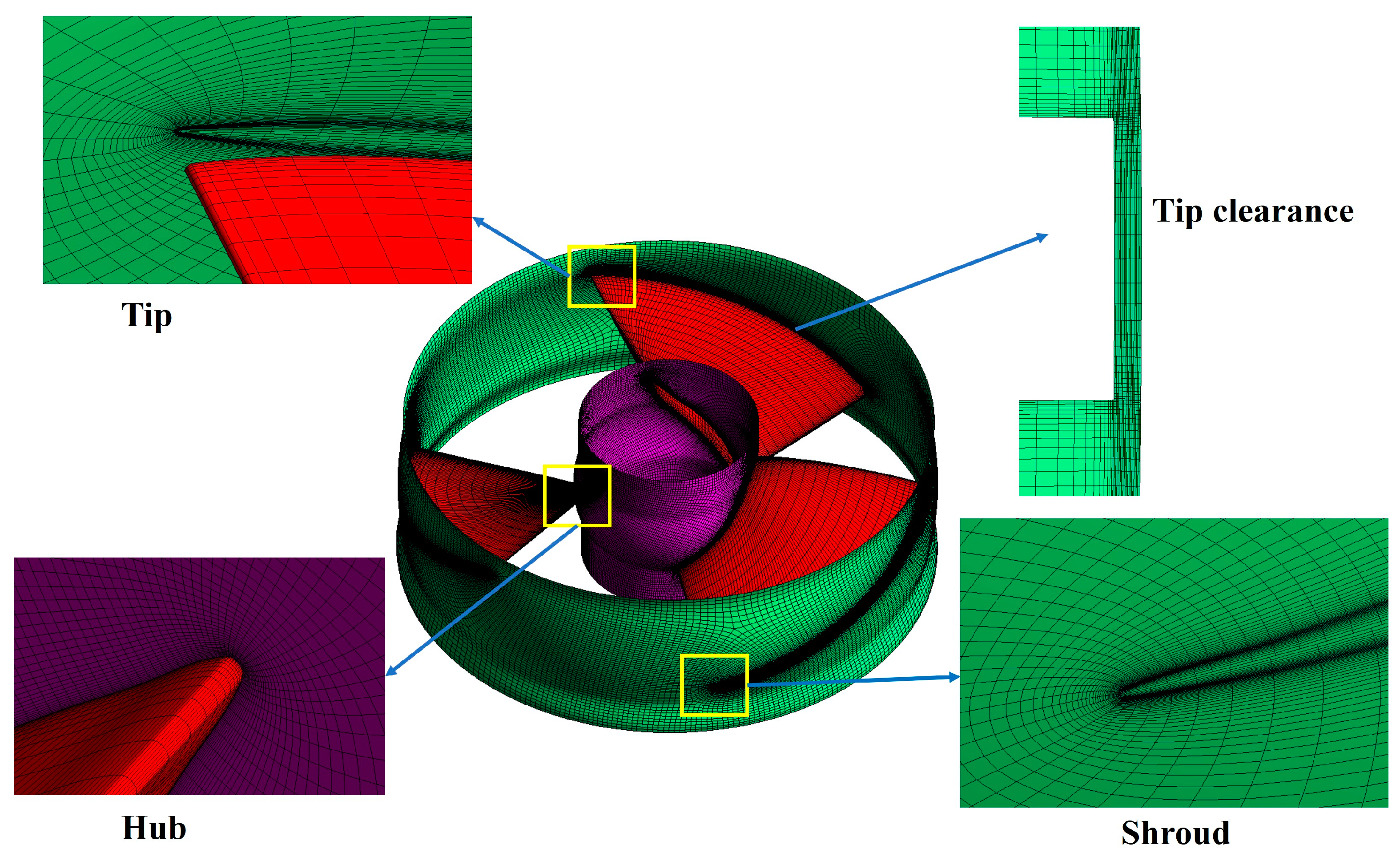

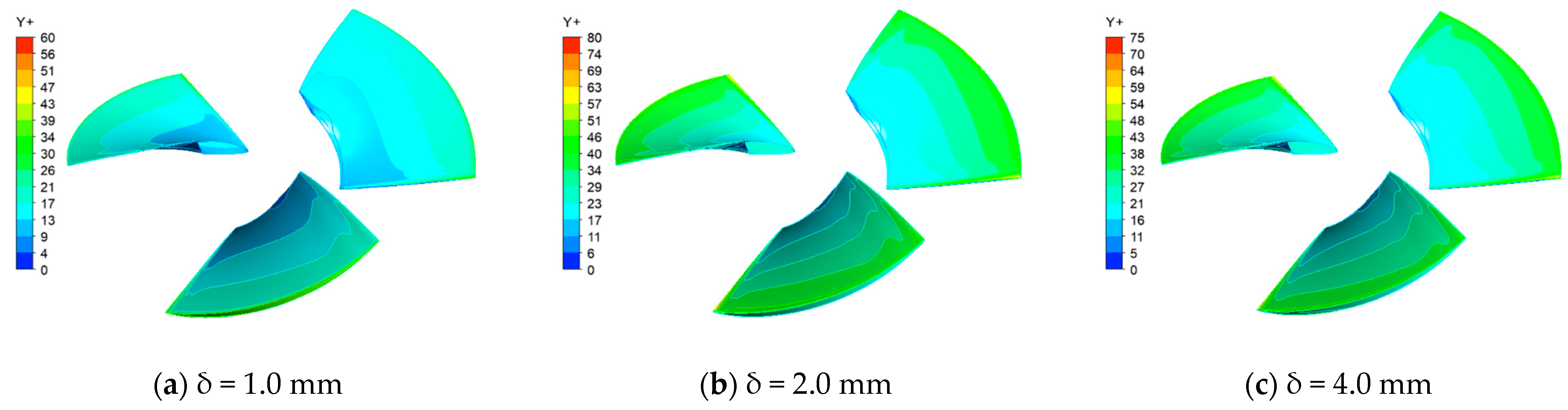

2.2. Grid Division

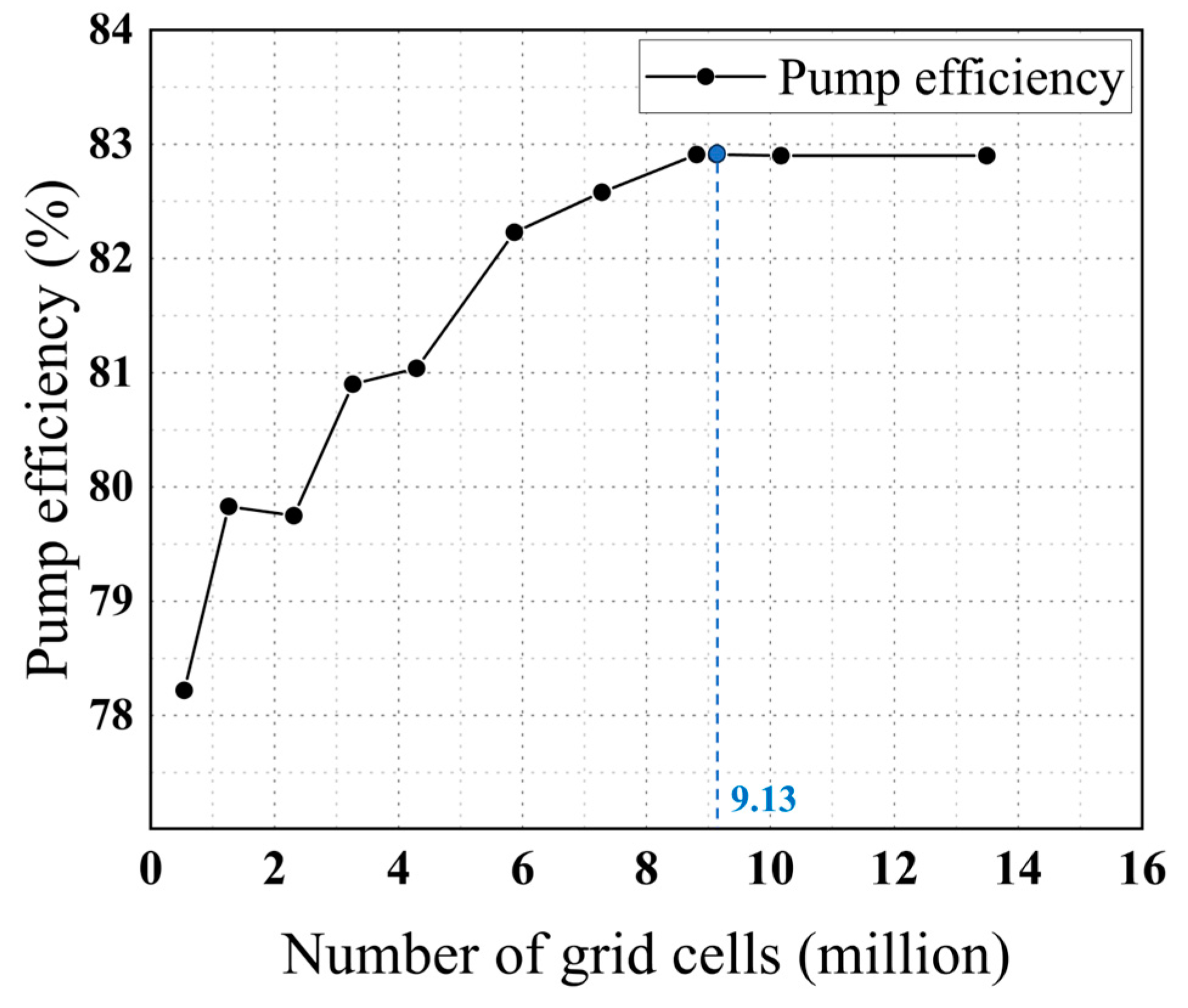

2.3. Grid Independence Verification

3. Numerical Simulation and Boundary Conditions

3.1. Entropy Production Theory

3.2. Turbulence Model

3.3. Cavitation Model

3.4. Boundary Conditions

4. Results and Analysis

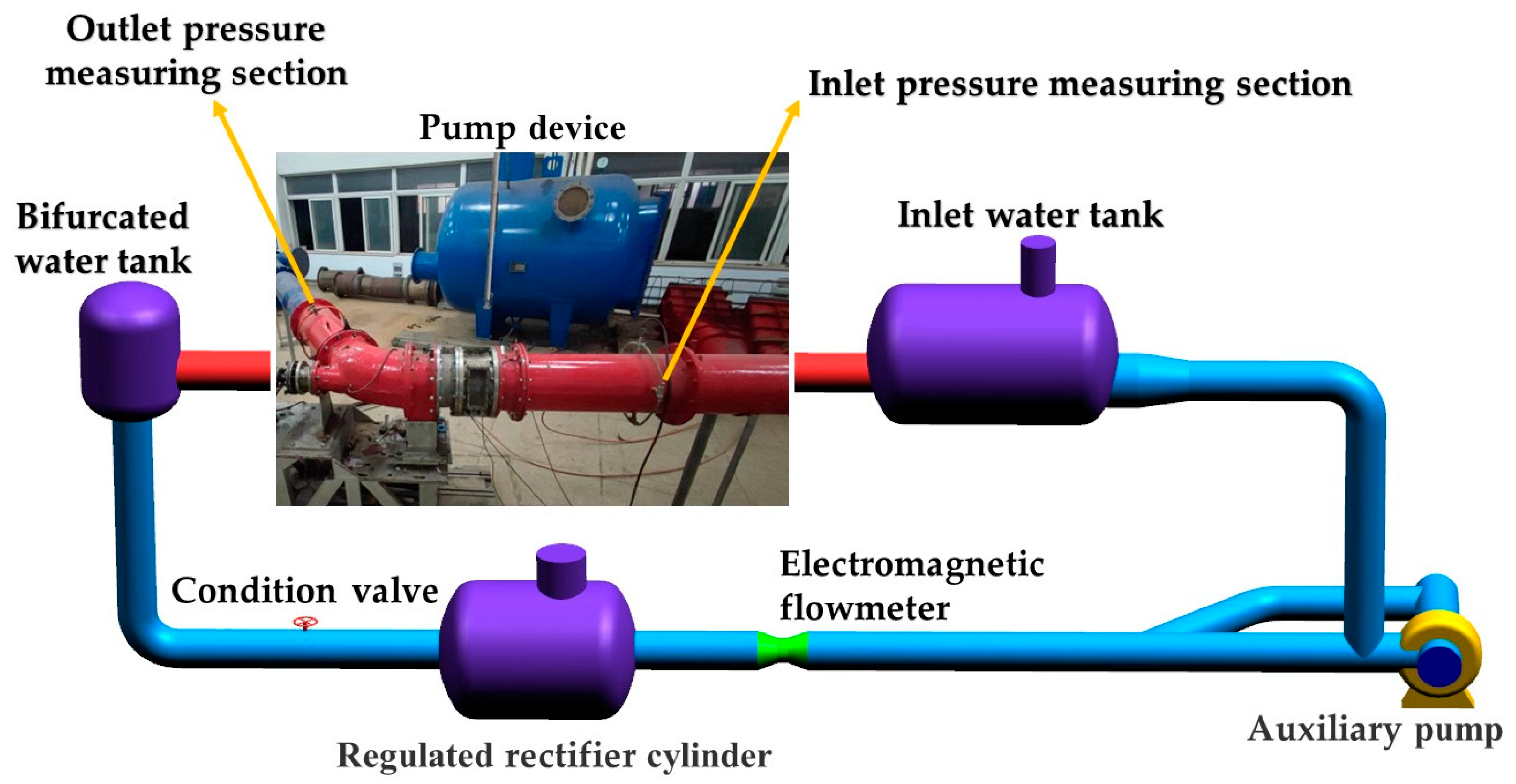

4.1. Experimental Device

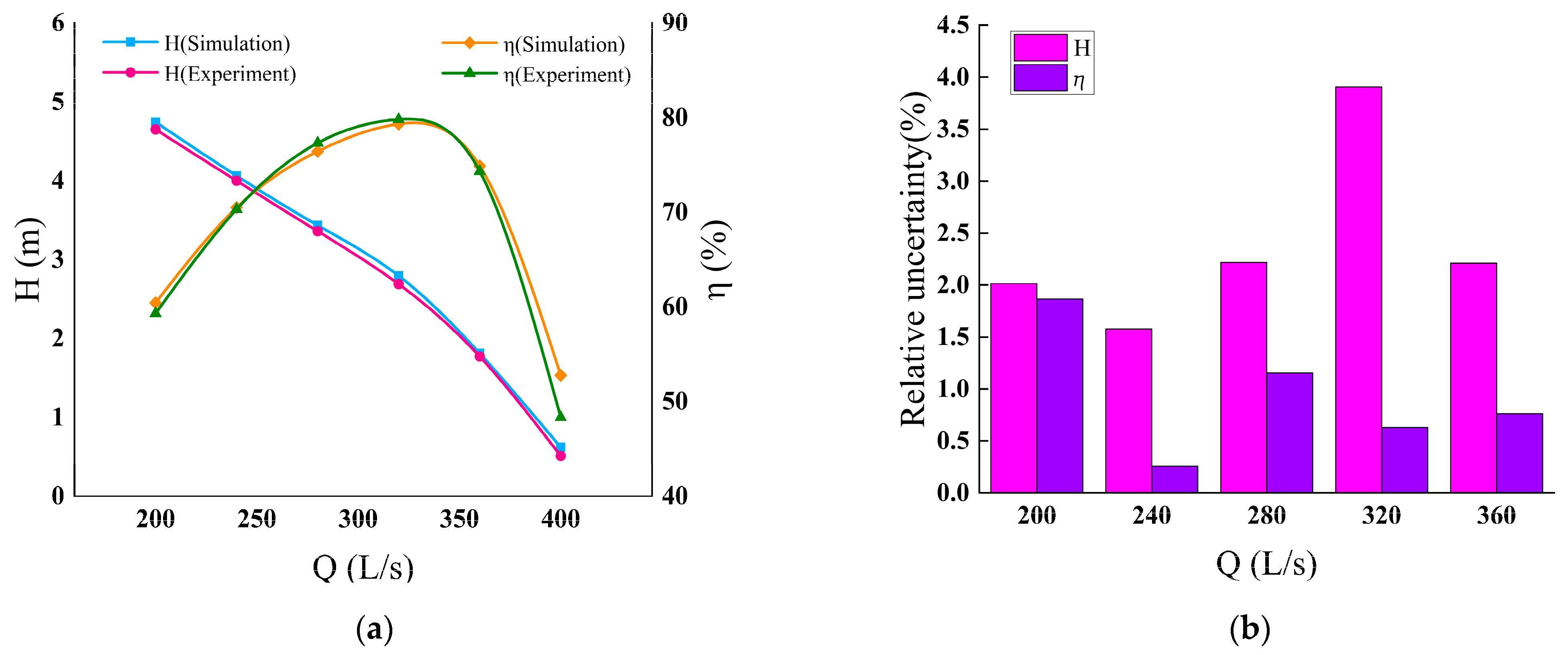

4.2. Comparison of External Characteristics

4.3. Comparison of Cavitation Characteristics

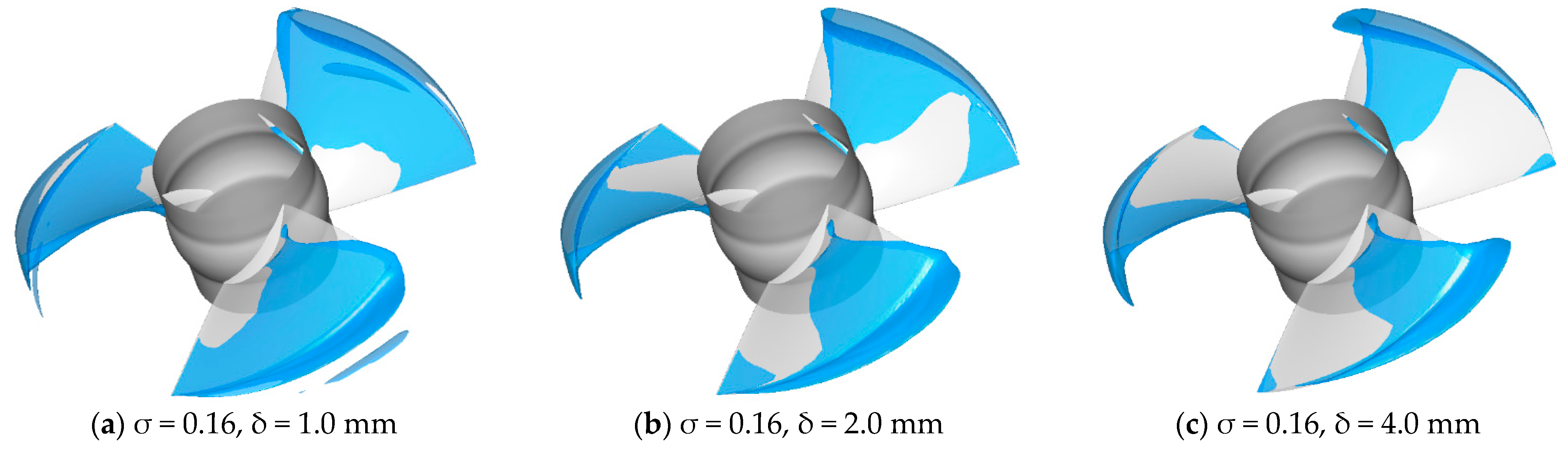

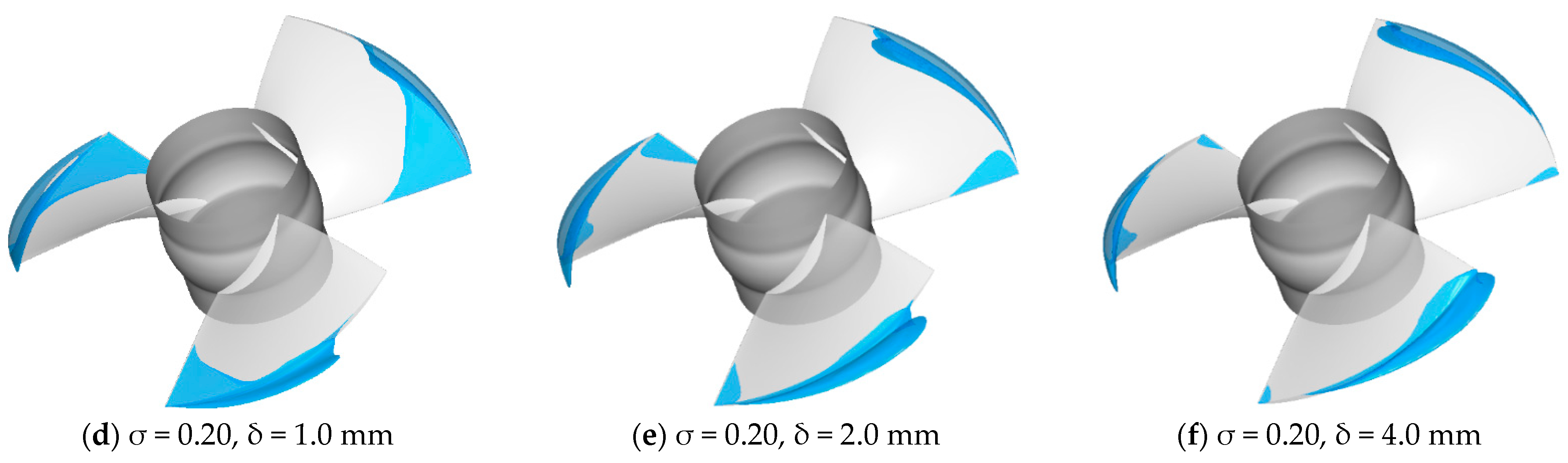

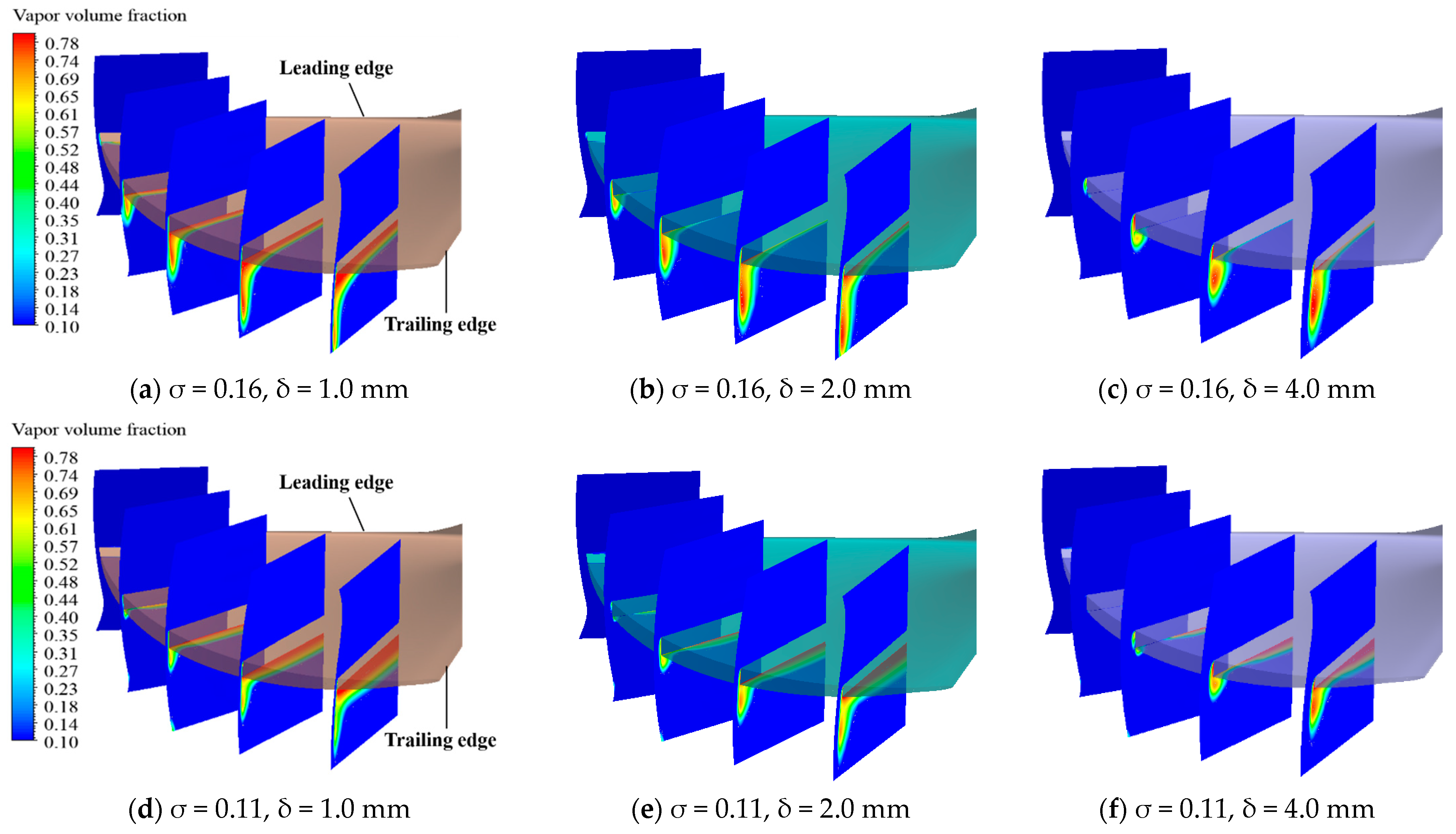

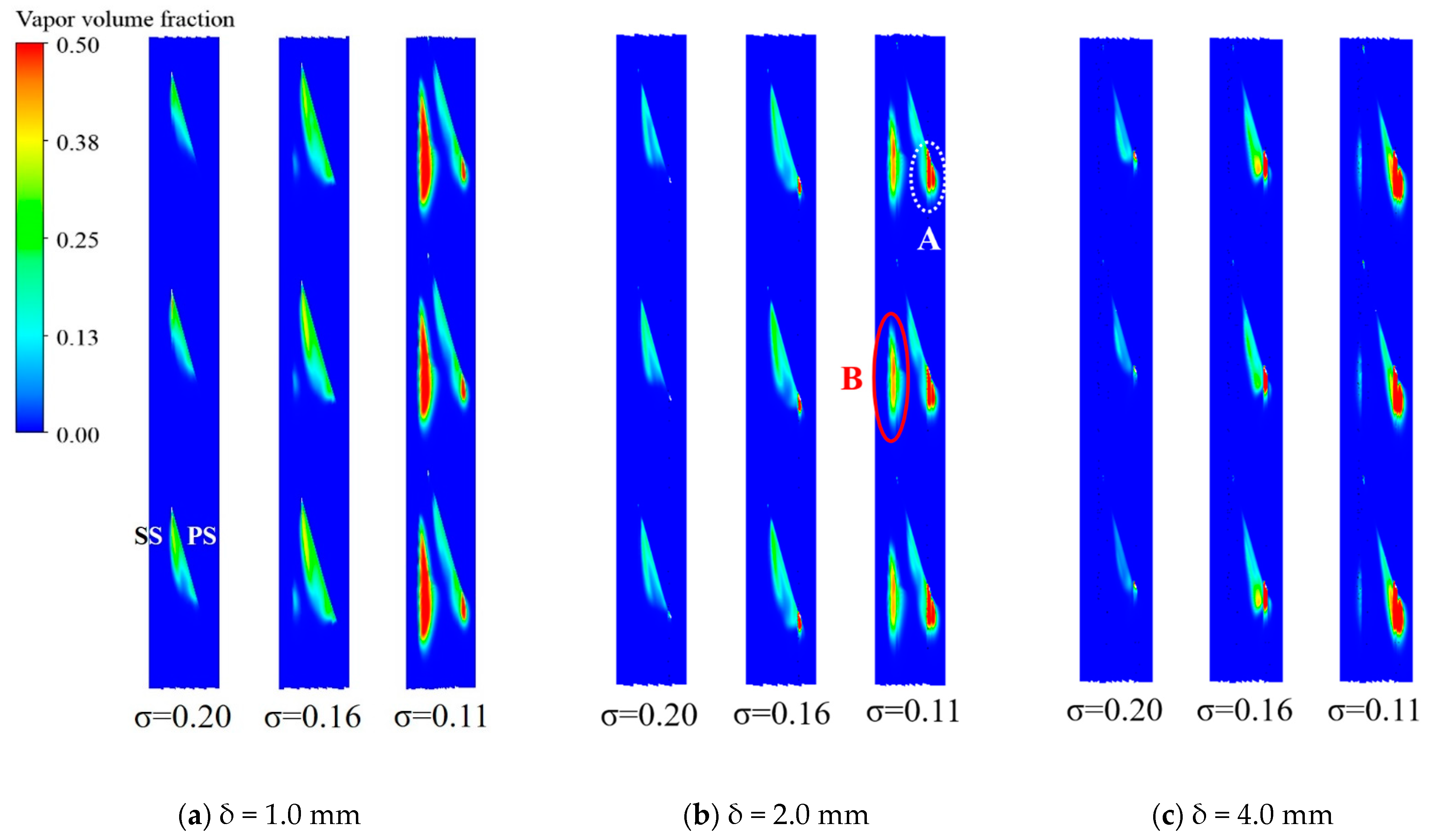

4.4. Distribution of Vapor Volume Fraction

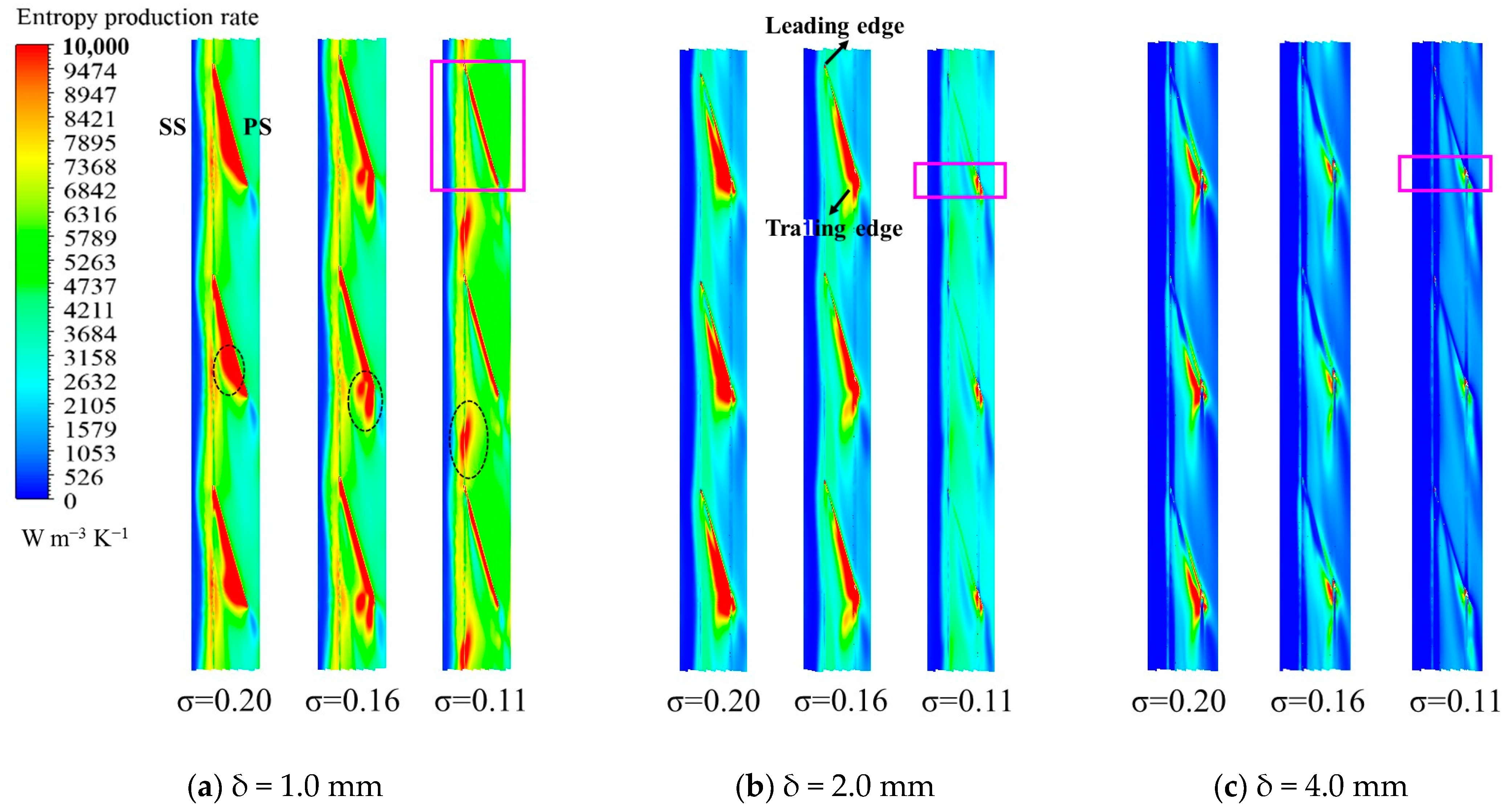

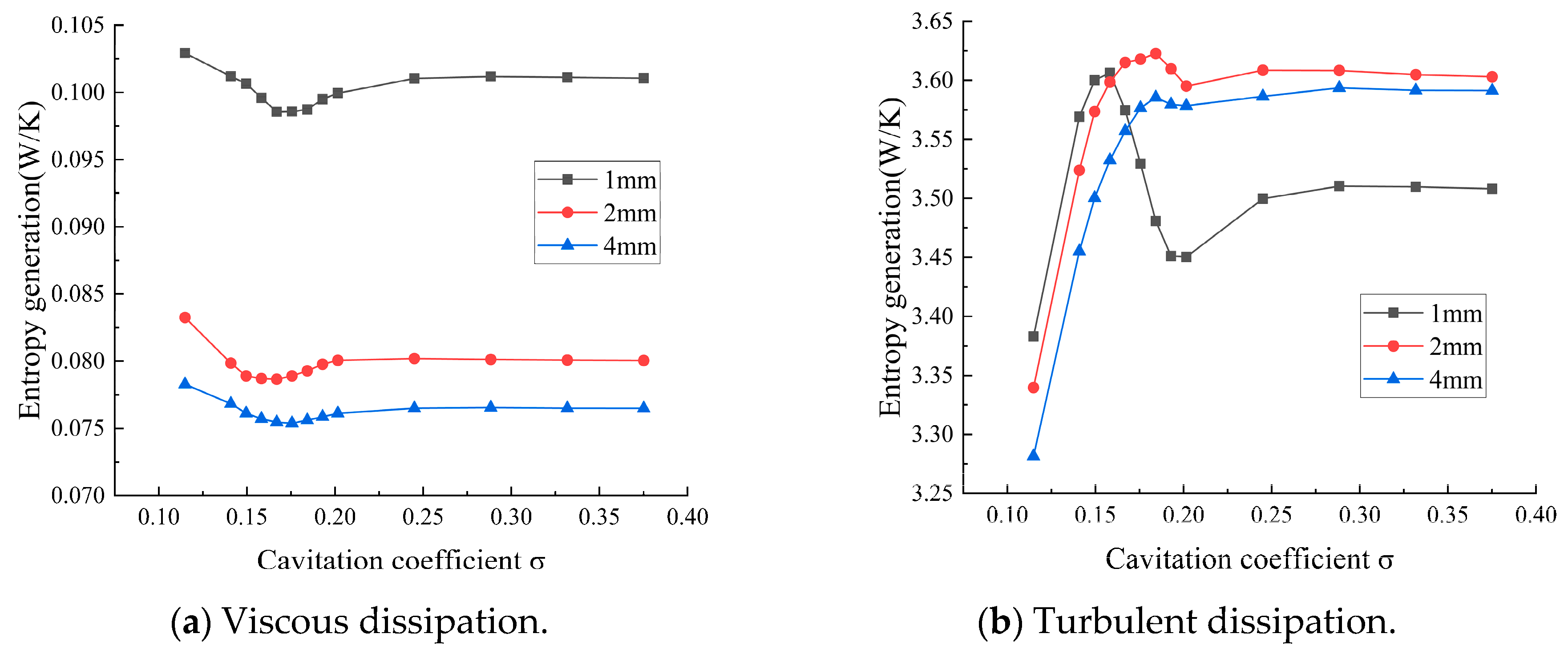

4.5. Distribution of Entropy Production

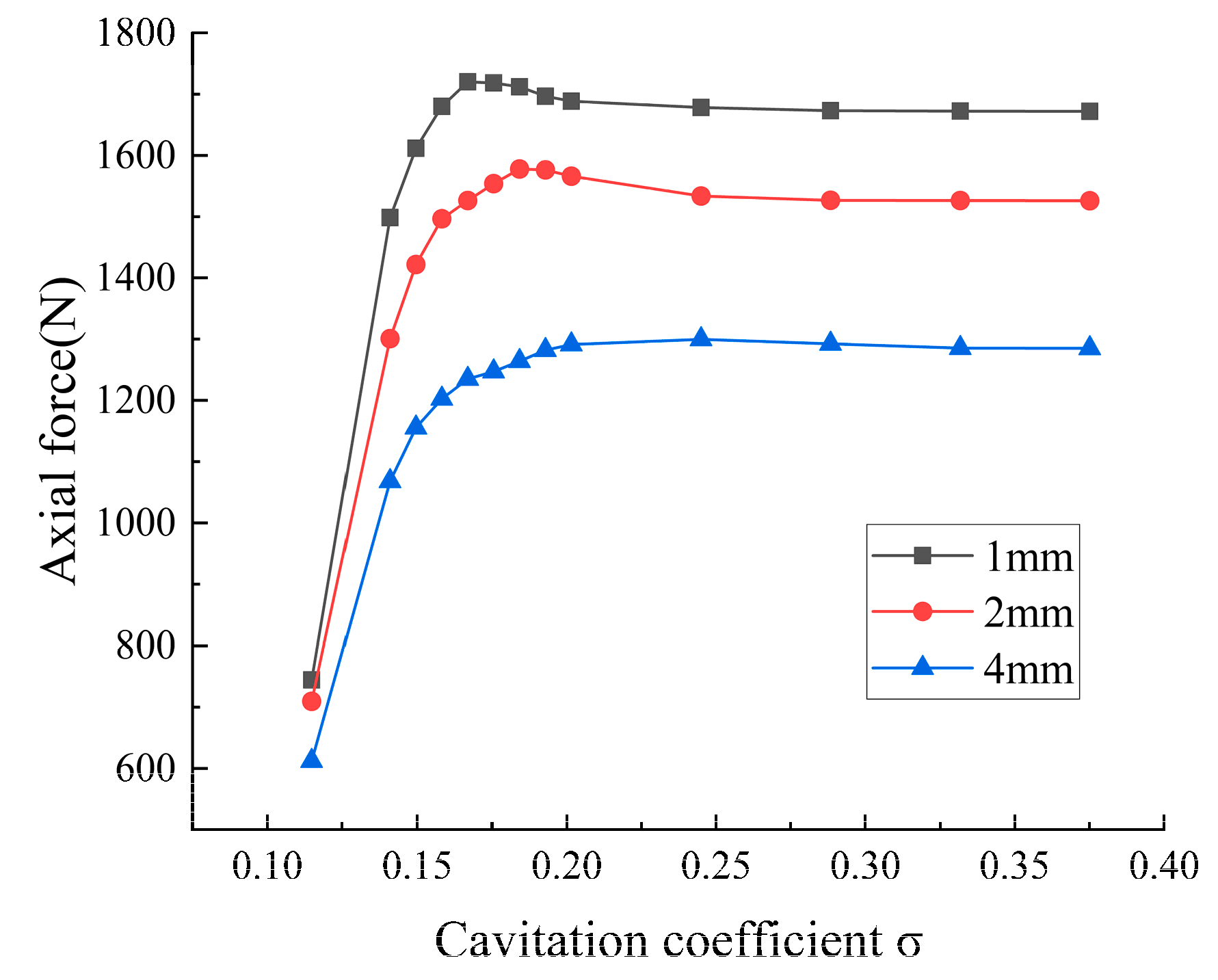

4.6. Axial Force Analysis

5. Conclusions

- (1)

- Under the same cavitation coefficient, with the broadening of tip clearance, the TLV cavitation accumulates toward the trailing edge and approaches the suction surface. The vapor volume fraction within the TLV cavitation region experiences an escalation, concurrent with a reduction in the thickness of sheet cavitation on the suction surface.

- (2)

- When cavitation occurs in an axial flow pump, the high-value region of the entropy production rate at the tip of the blade section expands from the leading to the trailing edge. The magnitude of tip clearance directly influences the leakage amount, with larger tip clearances resulting in increased leakage. On the contrary, the smaller the turbulence trend at the tip clearance, the smaller the turbulence dissipation caused by the water flow through the tip clearance. Therefore, there is a low-value region of the entropy production rate between the tip and the pump shell.

- (3)

- The larger the blade tip clearance, the greater the distribution area of vapor volume fraction below the tip on the cross-section of the blade. Moreover, the region of vapor volume fraction distribution near the trailing edge of the tip increases with the size of the tip clearance. The shedding phenomenon of TLV cavitation can be more clearly observed through the entropy production rate distribution on the cascade surface.

- (4)

- As the cavitation deepens within the pump, the entropy production resulting from turbulent dissipation is much higher than that caused by viscous dissipation. As the tip clearance increases, there is a decrease in viscous entropy production. Meanwhile, the relationship between the turbulent entropy production and the tip clearance is not obvious.

- (5)

- In the cavitation process of the axial flow pump, the larger the tip clearance is, the smaller the axial force on the impeller is. Increasing the tip clearance can alleviate the axial force on the bearing. In practical application, the size of the tip clearance should be determined by considering the axial force, the head loss attributed to tip leakage, the impact of tip clearance on cavitation performance, and the friction between the casing and the tip resulting from the oscillation of the pump shaft. For the axial flow pump used in this study, a blade tip clearance of 1 mm is recommended.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geng, L.L.; Zhang, D.S.; Chen, J.; Escaler, X. Large-Eddy simulation of cavitating TLV structures and dynamics around a NACA0009 hydrofoil. J. Mar. Sci. Eng. 2021, 9, 1198. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, J.; Zhang, D.S.; Shi, W.D.; Zang, J.B. Numerical analysis of the effect of cavitation on the TLV in an axial-flow pump. J. Mar. Sci. Eng. 2021, 9, 775. [Google Scholar] [CrossRef]

- Ma, Y.; Qian, B.; Feng, Z.G.; Wang, X.; Shi, G.T.; Liu, Z.K.; Liu, X.B. Flow behaviors in a Kaplan turbine runner with different tip clearances. Adv. Mech. Eng. 2021, 13, 16878140211015879. [Google Scholar] [CrossRef]

- Song, M.R.; Xie, H.; Yang, B.; Shi, W.D.; Zhang, S.Y. Influence of tip clearance on flow characteristics of axial compressor. Processes 2020, 8, 1445. [Google Scholar] [CrossRef]

- Han, C.Z.; Xu, S.; Cheng, H.Y.; Ji, B.; Zhang, Z.Y. LES method of the tip clearance vortex cavitation in a propelling pump with special emphasis on the cavitation-vortex interaction. J. Hydrodyn. 2020, 32, 1212–1216. [Google Scholar] [CrossRef]

- Han, C.Z.; Long, Y.; Xu, M.H.; Ji, B. Verification and validation of large eddy simulation for tip clearance vortex cavitating flow in a waterjet pump. Energies 2021, 14, 7635. [Google Scholar] [CrossRef]

- Liu, H.Y.; Tang, F.P.; Shi, L.J.; Dai, L.; Shen, J.; Liu, J. The analysis of cavitation flow and pressure pulsation of bi-directional pump. J. Mar. Sci. Eng. 2023, 11, 268. [Google Scholar] [CrossRef]

- Zhang, X.D.; Liu, Z.H.; Cao, L.S.; Wan, D.C. Tip clearance effect on the TLV evolution and wake instability of a ducted propeller. J. Mar. Sci. Eng. 2022, 10, 1007. [Google Scholar] [CrossRef]

- Zhang, M.J.; Qi, M.X.; Zhang, H. Influence of uneven blade tip clearances on aeroacoustic characteristics of centrifugal compressors. J. Glob. Power Propuls. Soc. 2022, 6, 254–265. [Google Scholar] [CrossRef]

- Jahani, Z.; Khaleghi, H.; Tabejamaat, S. Tip injection effects on a transonic centrifugal impeller with various tip clearances in the presence of inlet distortion. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 397. [Google Scholar] [CrossRef]

- Chung, J.; Baek, S.; Hwang, W. Experimental investigation of aerodynamic performance due to blade tip clearance in a gas turbine rotor cascade. J. Therm. Sci. 2022, 31, 173–178. [Google Scholar] [CrossRef]

- Xiang, L.; Tan, Y.H.; Chen, H.; Xu, K.F. Experimental investigation of cavitation instabilities in inducer with different tip clearances. Chin. J. Aeronaut. 2021, 34, 168–177. [Google Scholar] [CrossRef]

- Guo, X.M.; Jiang, C.Y.; Qian, H.; Zhu, Z.C.; Zhou, C.Q. Effect of tip clearance on the cavitation flow in a shunt blade inducer. Energies 2022, 15, 6330. [Google Scholar] [CrossRef]

- Guo, X.M.; Yang, S.D.; Li, X.J.; Shi, L.; Hua, E.R.; Zhu, Z.C. The tip clearance cavitation mechanism of a high-speed centrifugal pump with a splitter-bladed inducer. Processes 2021, 9, 1576. [Google Scholar] [CrossRef]

- Zhang, H.; Zang, J.B.; Shi, W.D.; Zhang, D.S. Analysis of the formation mechanism and evolution of the perpendicular cavitation vortex of tip leakage flow in an axial-flow pump for off-design conditions. J. Mar. Sci. Eng. 2021, 9, 1045. [Google Scholar] [CrossRef]

- Sun, T.Z.; Xie, Q.M.; Zou, L.; Wang, H.; Xu, C. Numerical investigation of unsteady cavitation dynamics over a naca66 hydrofoil near a free surface. J. Mar. Sci. Eng. 2020, 8, 341. [Google Scholar] [CrossRef]

- Wu, Y.Z.; Wang, X.H.; Yang, X.L.; Ding, J.F.; Zhu, D.; Tao, R.; Wang, H.M.; Xiao, R.F. Prediction of the influence of runner tip clearance on the performance of tubular turbine. J. Mar. Sci. Eng. 2022, 10, 136. [Google Scholar] [CrossRef]

- Wang, X.L.; Zhang, J.S.; Huang, Z.W.; Wang, L.C.; Li, W.; Lan, G.H. Large eddy simulation on the cavitation flow and noise characteristics of a naca0009 hydrofoil with different tip clearance sizes. J. Fluids Eng.-Trans. ASME 2022, 145, 011204. [Google Scholar] [CrossRef]

- Karakas, E.S.; Watanabe, H.; Aureli, M.; Evrensel, C.A. Cavitation performance of constant and variable pitch helical inducers for centrifugal pumps: Effect of inducer tip clearance. J. Fluids Eng.-Trans. ASME 2020, 142, 021211. [Google Scholar] [CrossRef]

- Shen, X.; Zhang, D.S.; Xu, B.; Wu, H.R.; Wang, P.; Shi, W.D. Comparative study of TLV trajectory and cavitation in an axial flow pump with various tip clearances. J. Mech. Sci. Technol. 2022, 36, 1289–1302. [Google Scholar] [CrossRef]

- Nichik, M.Y.; Timoshevskiy, M.V.; Pervunin, K.S. Effect of an end-clearance width on the gap cavitation structure: Experiments on a wall-bounded axis-equipped hydrofoil. Ocean. Eng. 2022, 254, 111387. [Google Scholar] [CrossRef]

- Wang, L.; Tang, F.P.; Chen, Y.; Liu, H.Y. Evolution characteristics of suction-side-perpendicular cavitating vortex in axial flow pump under low flow condition. J. Mar. Sci. Eng. 2021, 9, 1058. [Google Scholar] [CrossRef]

- Mousmoulis, G.; Kassanos, I.; Aggidis, G.; Anagnostopoulos, I. Numerical simulation of the performance of a centrifugal pump with a semi-open impeller under normal and cavitating conditions. Appl. Math. Model. 2020, 89, 1814–1834. [Google Scholar] [CrossRef]

- Shen, S.M.; Huang, B.S.; Huang, S.; Xu, S.; Liu, S.F. Research on cavitation flow dynamics and entropy generation analysis in an axial flow pump. J. Sens. 2023, 2022, 7087679. [Google Scholar] [CrossRef]

- Shu, Z.K.; Shi, G.T.; Dan, Y.; Wang, B.X.; Tan, X. Enstrophy dissipation of the TLV in a multiphase pump. Phys. Fluids 2022, 34, 033310. [Google Scholar] [CrossRef]

- Lai, F.; Huang, M.L.; Wu, X.F.; Nie, C.H.; Li, G.J. Local entropy generation analysis for cavitation flow within a centrifugal pump. J. Fluids Eng.-Trans. ASME 2022, 144, 101206. [Google Scholar] [CrossRef]

- Yu, A.; Wang, Y.F.; Song, F.; Li, Z.L.; Tang, Q.H. Numerical study of the entropy production characteristics in cryogenic liquid nitrogen cavitating flow. Int. Commun. Heat Mass Transf. 2022, 133, 105963. [Google Scholar] [CrossRef]

- Li, W.G.; Yu, Z.B. Cavitating flows of organic fluid with thermodynamic effect in a diaphragm pump for organic rankine cycle systems. Energy 2021, 237, 121495. [Google Scholar] [CrossRef]

- Fei, Z.D.; Zhang, R.; Xu, H.; Feng, J.G.; Mu, T.; Chen, Y.H. Energy performance and flow characteristics of a slanted axial-flow pump under cavitation conditions. Phys. Fluids 2022, 34, 035121. [Google Scholar] [CrossRef]

- Yang, F.; Li, Z.B.; Hu, W.Z.; Liu, C.; Jiang, D.J.; Liu, D.S.; Nasr, A. Analysis of flow loss characteristics of slanted axial-flow pump device based on entropy production theory. R. Soc. Open Sci. 2022, 9, 211208. [Google Scholar] [CrossRef]

- Kan, K.; Zhao, F.; Xu, H.; Feng, J.G.; Chen, H.X.; Liu, W.D. Energy performance evaluation of an axial-flow pump as turbine under conventional and reverse operating modes based on an energy loss intensity model. Phys. Fluids 2023, 35, 015125. [Google Scholar] [CrossRef]

- Chen, J.; Wang, C.C.; Wang, G.Y.; Huang, B. Numerical investigation of the cavitating flow structure with special emphasis on the vortex identification method. Mod. Phys. Lett. B 2020, 34, 2050058. [Google Scholar] [CrossRef]

| Measuring Instrument | Measurement Interval | Uncertainty |

|---|---|---|

| Differential pressure transmitter | 0~200 kPa | |

| Electromagnetic flowmeter | DN400 mm | |

| Torque meter | 500 N·m | |

| Absolute pressure transmitter | 0~130 kPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, L.; Cheng, L.; Xu, W.; Lei, S. Study on the Influence of Tip Clearance on Cavitation Performance and Entropy Production of an Axial Flow Pump. J. Mar. Sci. Eng. 2024, 12, 101. https://doi.org/10.3390/jmse12010101

Yu L, Cheng L, Xu W, Lei S. Study on the Influence of Tip Clearance on Cavitation Performance and Entropy Production of an Axial Flow Pump. Journal of Marine Science and Engineering. 2024; 12(1):101. https://doi.org/10.3390/jmse12010101

Chicago/Turabian StyleYu, Lei, Li Cheng, Wentao Xu, and Shuaihao Lei. 2024. "Study on the Influence of Tip Clearance on Cavitation Performance and Entropy Production of an Axial Flow Pump" Journal of Marine Science and Engineering 12, no. 1: 101. https://doi.org/10.3390/jmse12010101

APA StyleYu, L., Cheng, L., Xu, W., & Lei, S. (2024). Study on the Influence of Tip Clearance on Cavitation Performance and Entropy Production of an Axial Flow Pump. Journal of Marine Science and Engineering, 12(1), 101. https://doi.org/10.3390/jmse12010101