A Study on Mechanical Properties of Modified Soil–Cement Mixed with Ferronickel Slag Powder under Dry–Wet Cycles in Marine Environments

Abstract

:1. Introduction

2. Experimental Preparations

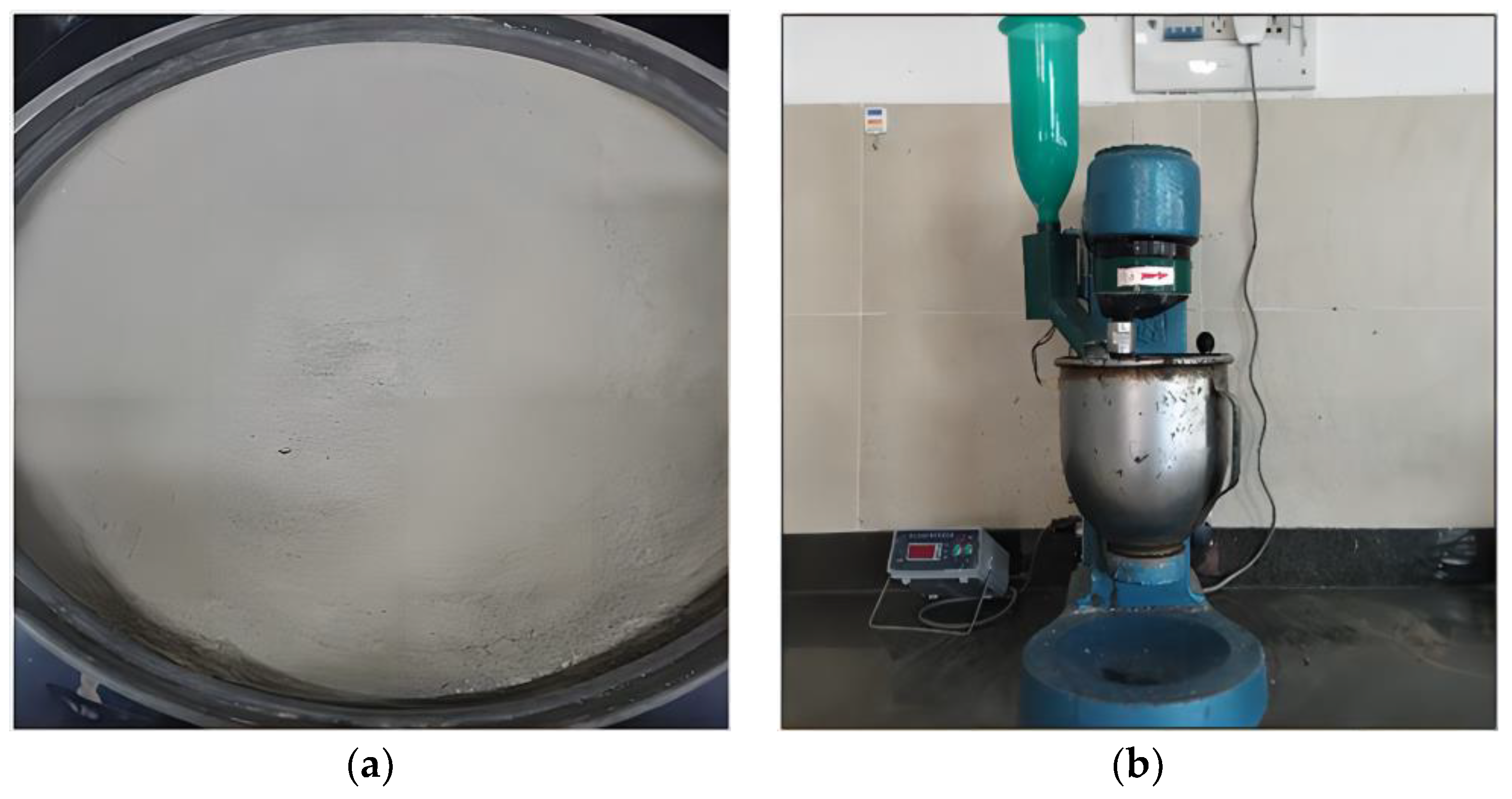

2.1. Experimental Materials

2.2. Sample Preparation

2.3. Experimental Scheme

2.4. Experimental Procedure

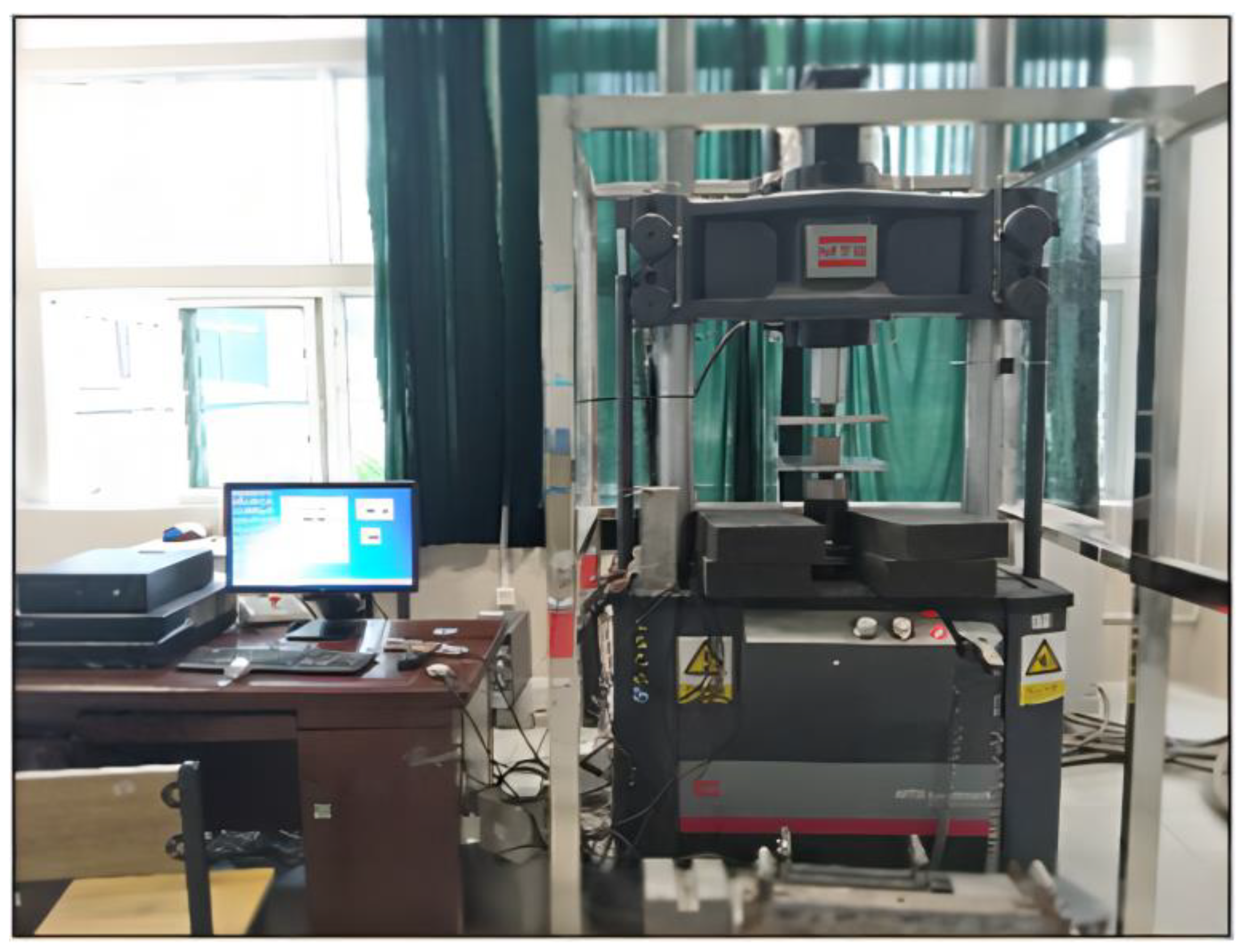

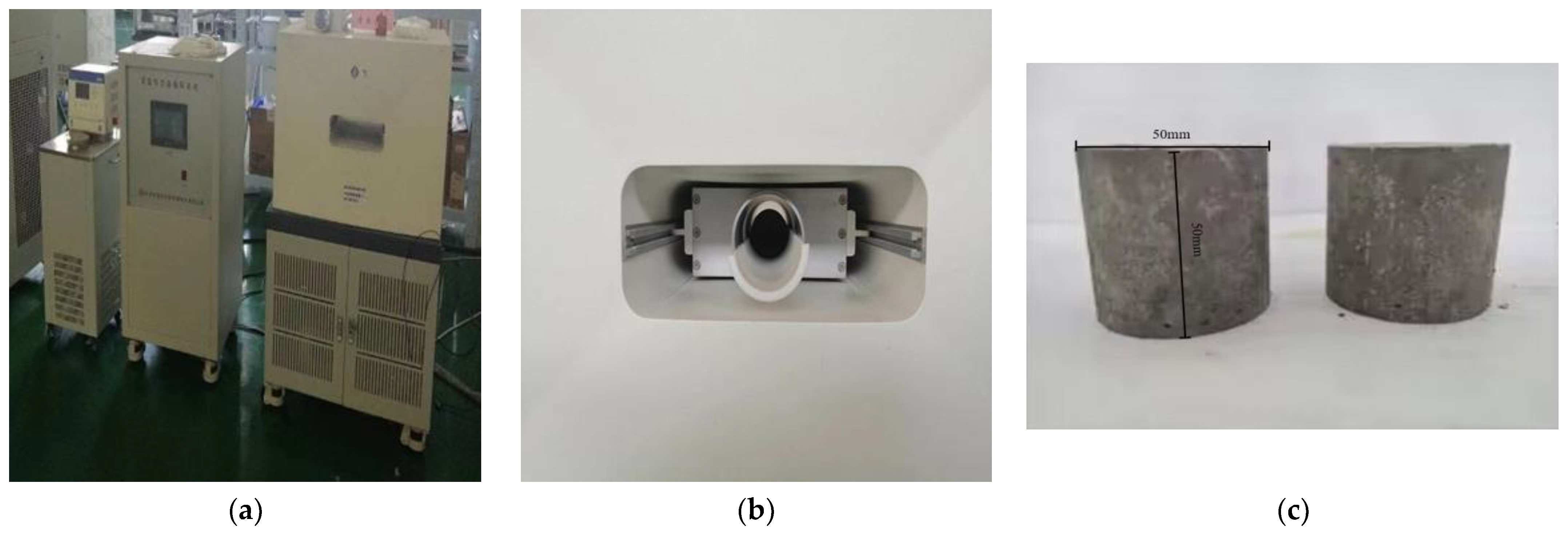

2.4.1. Dry–Wet Cycle

- Liquid inlet: The liquid inlet time was set to 15 min and the temperature to 25 °C.

- Soaking: Soaking was conducted after the end of liquid inlet. The soaking time started from the specimen being placed in the solution, with the soaking period being set to 10 h at a temperature of 25 °C.

- Drainage: Immediately after soaking, the liquid was drained, and the solution was emptied within 30 min before proceeding to the air-drying stage. The drainage time was 12 min, which is slightly shorter than the liquid inlet time, and the temperature was 25 °C.

- Air drying: The time from the solution drainage to the air drying of the samples was 1 h. The general air-drying time was set to 30 min, as in this experiment, at 25 °C.

- Heating and drying: Immediately after air drying, the heating temperature was set to 40 °C, and the heating time was completed within 30 min.

- Drying and insulation: After the temperature rose to 40 °C, the temperature was maintained at around 40 °C, and the samples were dried for 12 h.

- Cooling: Immediately after the drying process, the specimens were cooled at a temperature of 20 °C for 1 h.

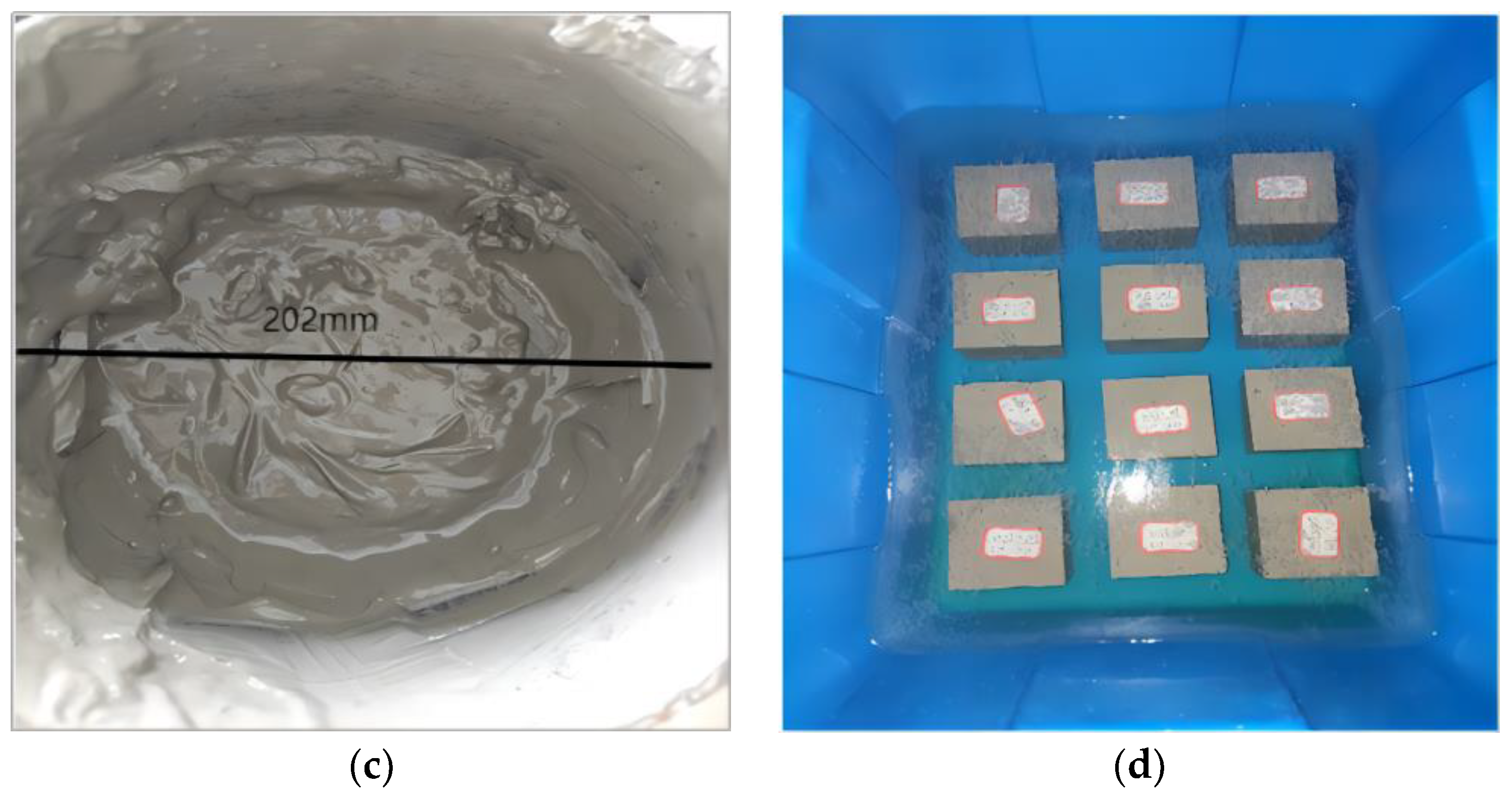

2.4.2. Unconfined Compression Test

- The soil–cement specimens that have been cured from the water tank were taken out in the standard curing room, and the surface was wiped clean.

- The specimen was immediately placed in the center of the test pressure table steel plate, and its geometric center was corrected.

- Pressure at a uniform speed of 100 N/s up to 1000 N was applied and held for 60 s. We continued to apply the pressure at a uniform speed of 100 N/s until the specimen failed, and the test data were recorded.

- After each test, the pressure table steel plate was cleaned to maintain its smooth and flat surface.

2.4.3. NWR Test

- Firstly, all specimens were dried for 24 h. After the drying was completed, the signal amplitude test was performed on the dried specimens to obtain the baseline signal amplitude value of the dried specimens.

- The specimens were subjected to negative pressure vacuum saturation treatment after drying. Since the strength of the soil–cement specimens of the silt material is small, saturation treatment is conducted under a negative pressure of −0.1 MPa for 24 h. After saturation, signal strength testing was performed to measure the signal amplitude value of the saturated specimen.

- The difference between the saturated signal strength value of the test specimen and the baseline signal strength value of the specimen after drying was obtained, and then the T2 distribution curve and pore nuclear magnetic imaging were obtained through data inversion.

3. Experimental Results

3.1. Impacts of Dry–Wet Cycles on Physical Properties of Specimens

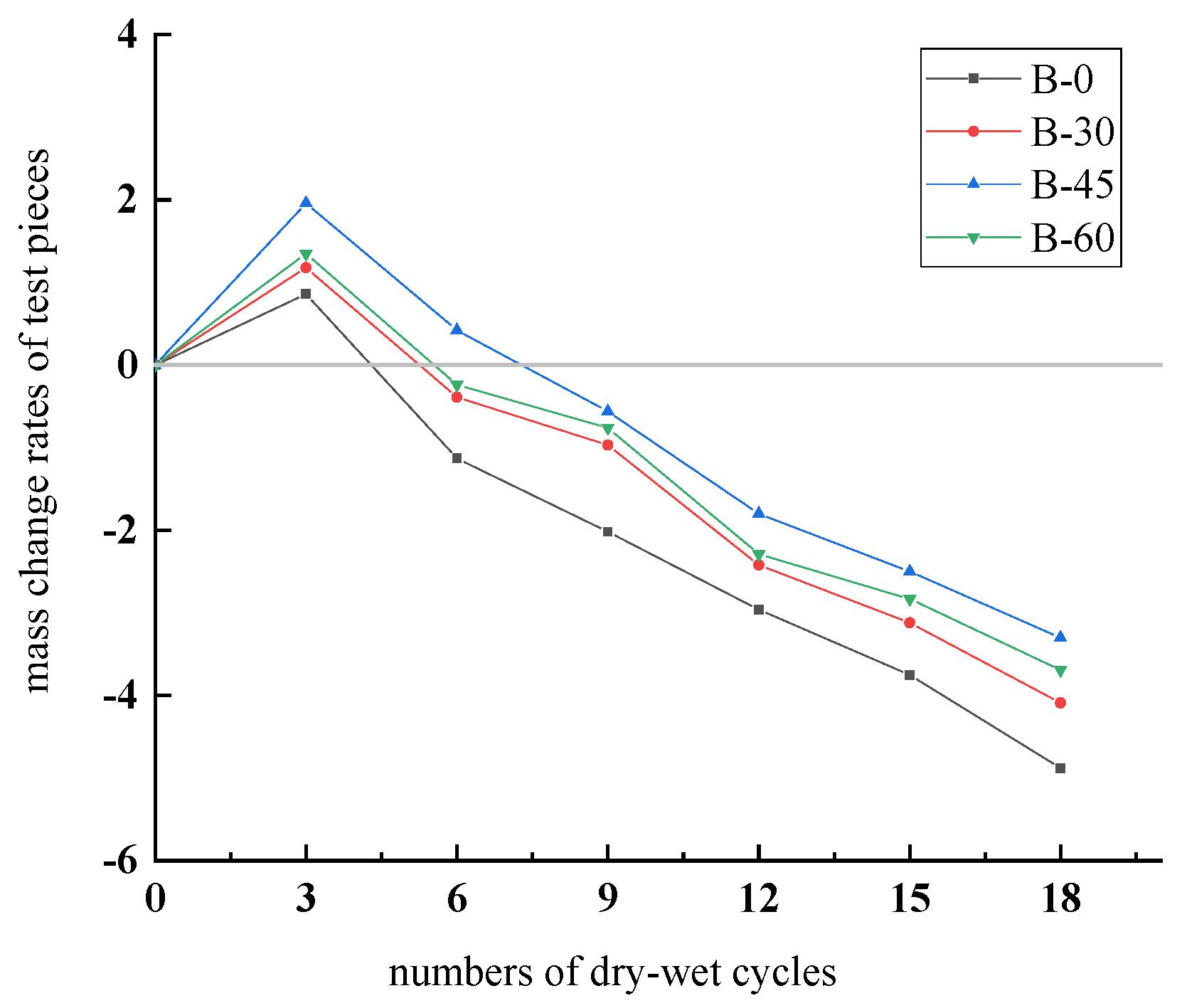

3.1.1. Mass Change Rate

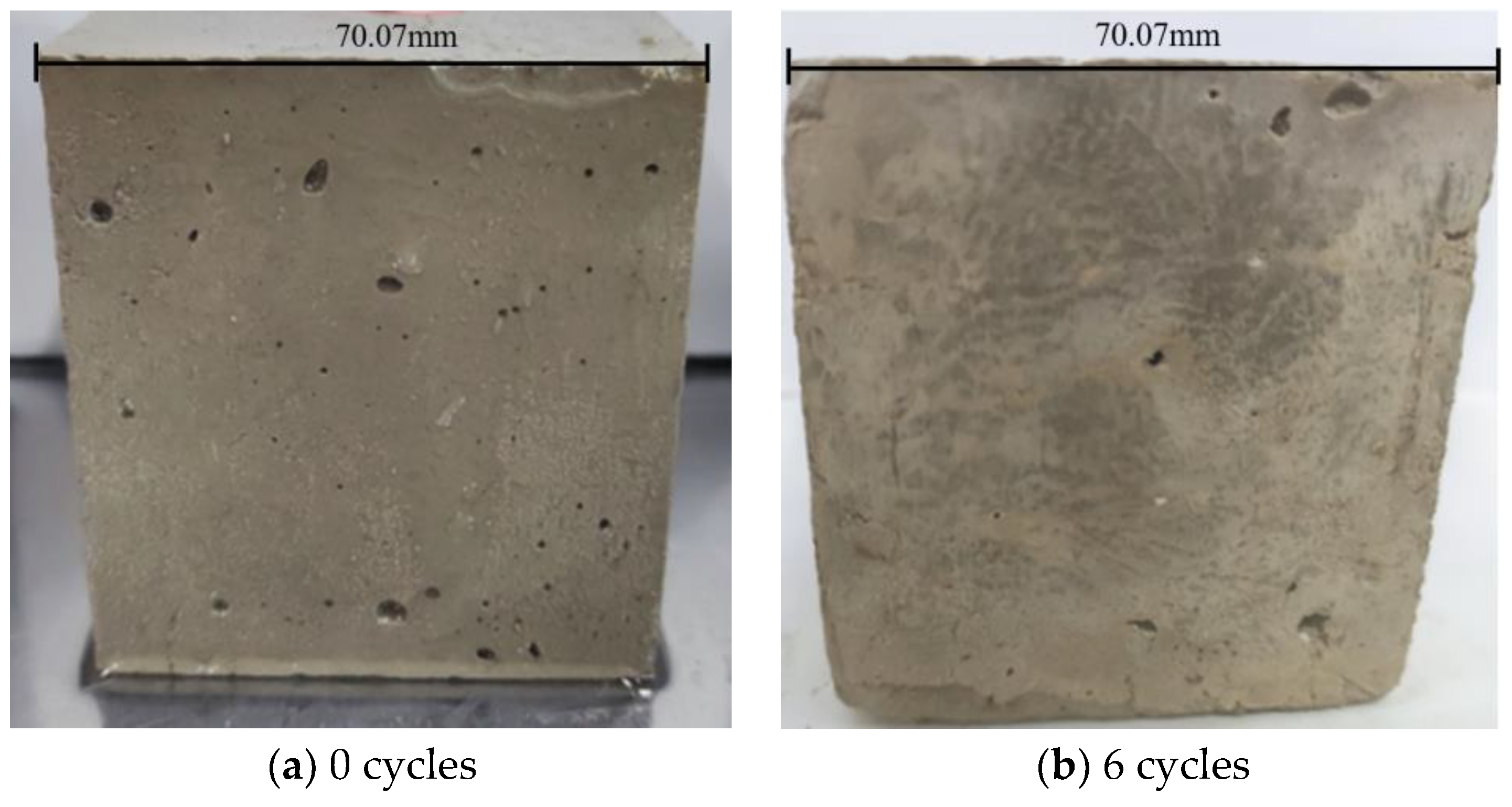

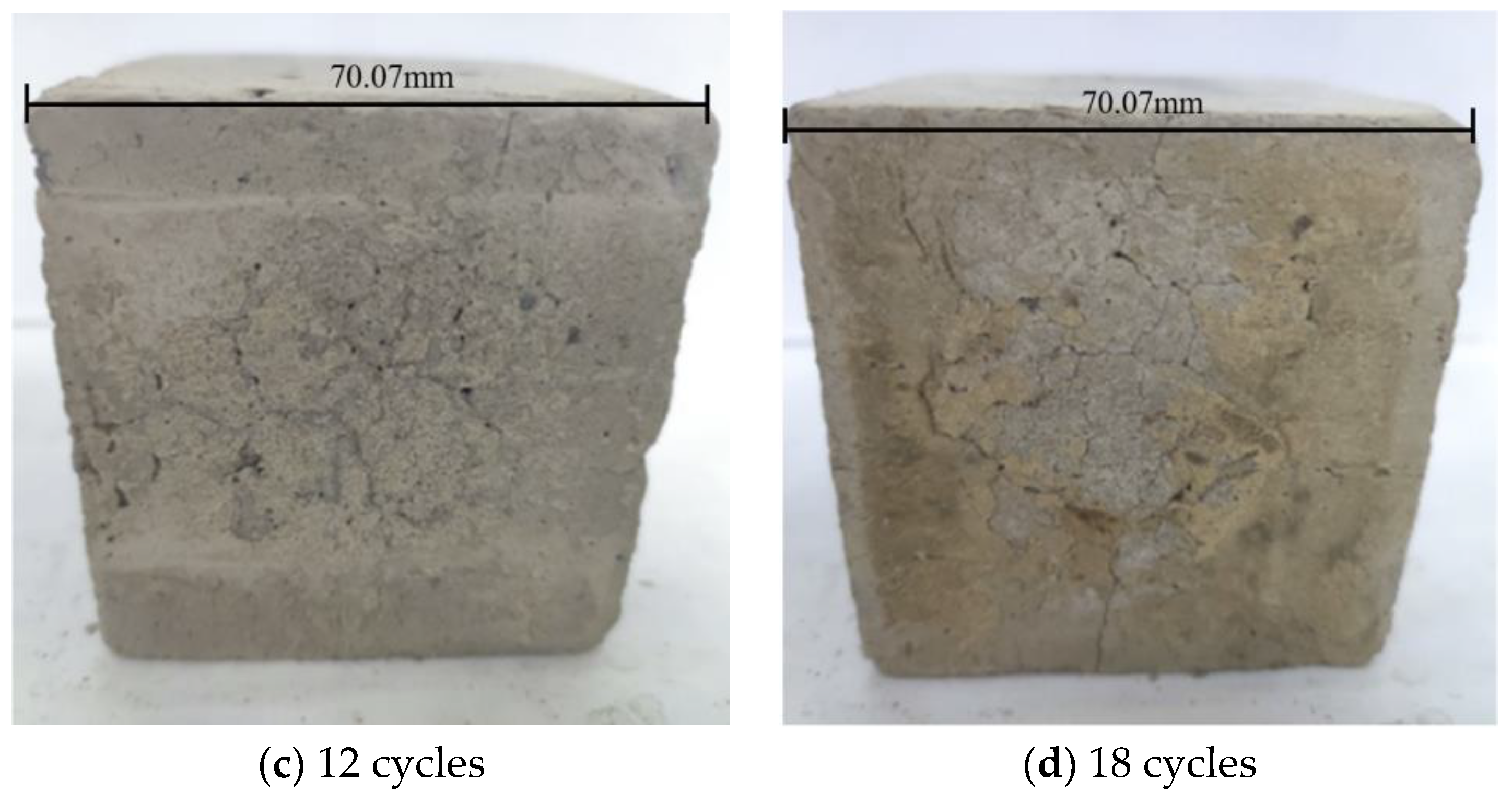

3.1.2. Apparent Erosion Characteristics

3.2. Impacts of Dry–Wet Cycles on Mechanical Properties of Specimens

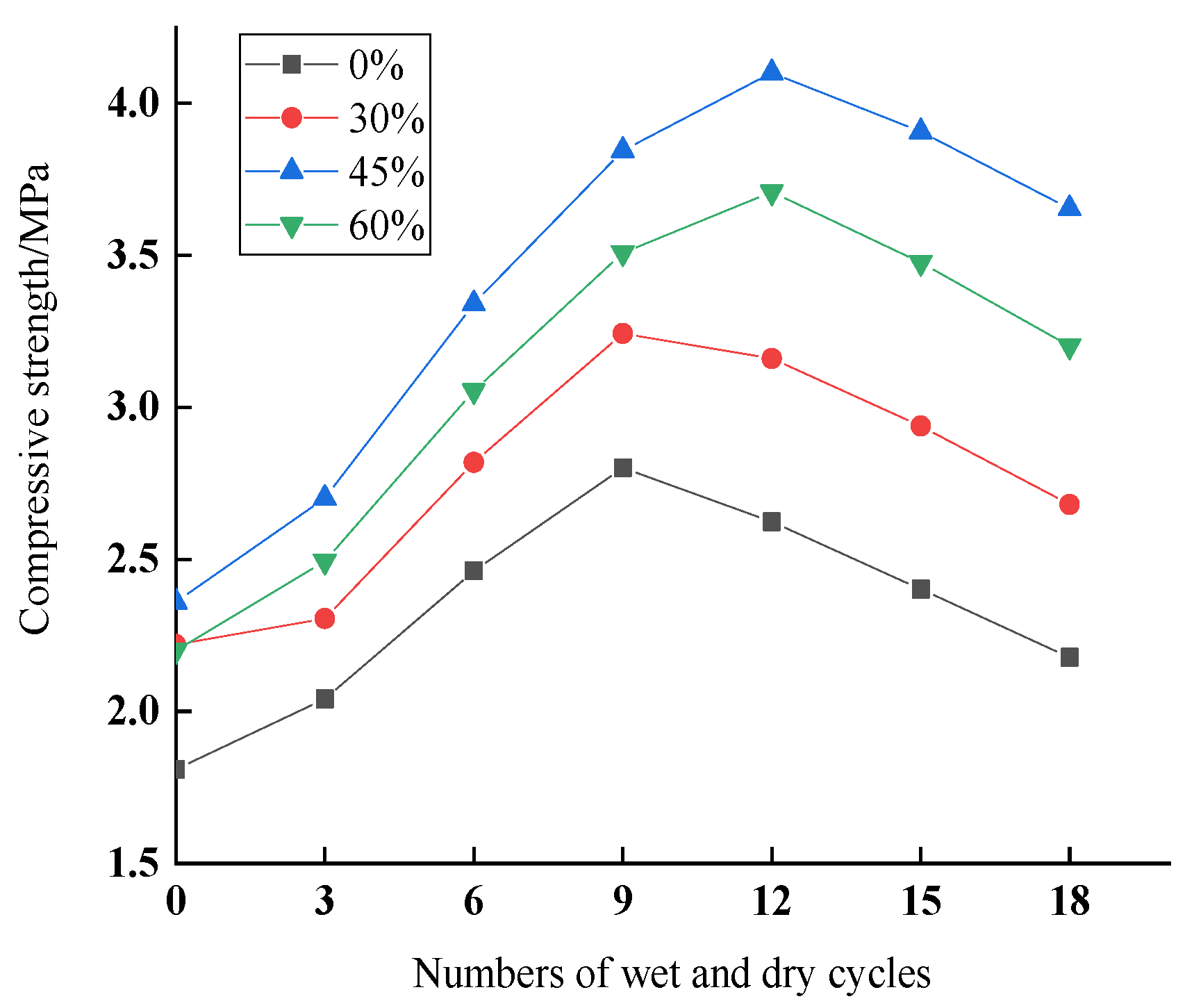

3.2.1. Unconfined Compressive Strength

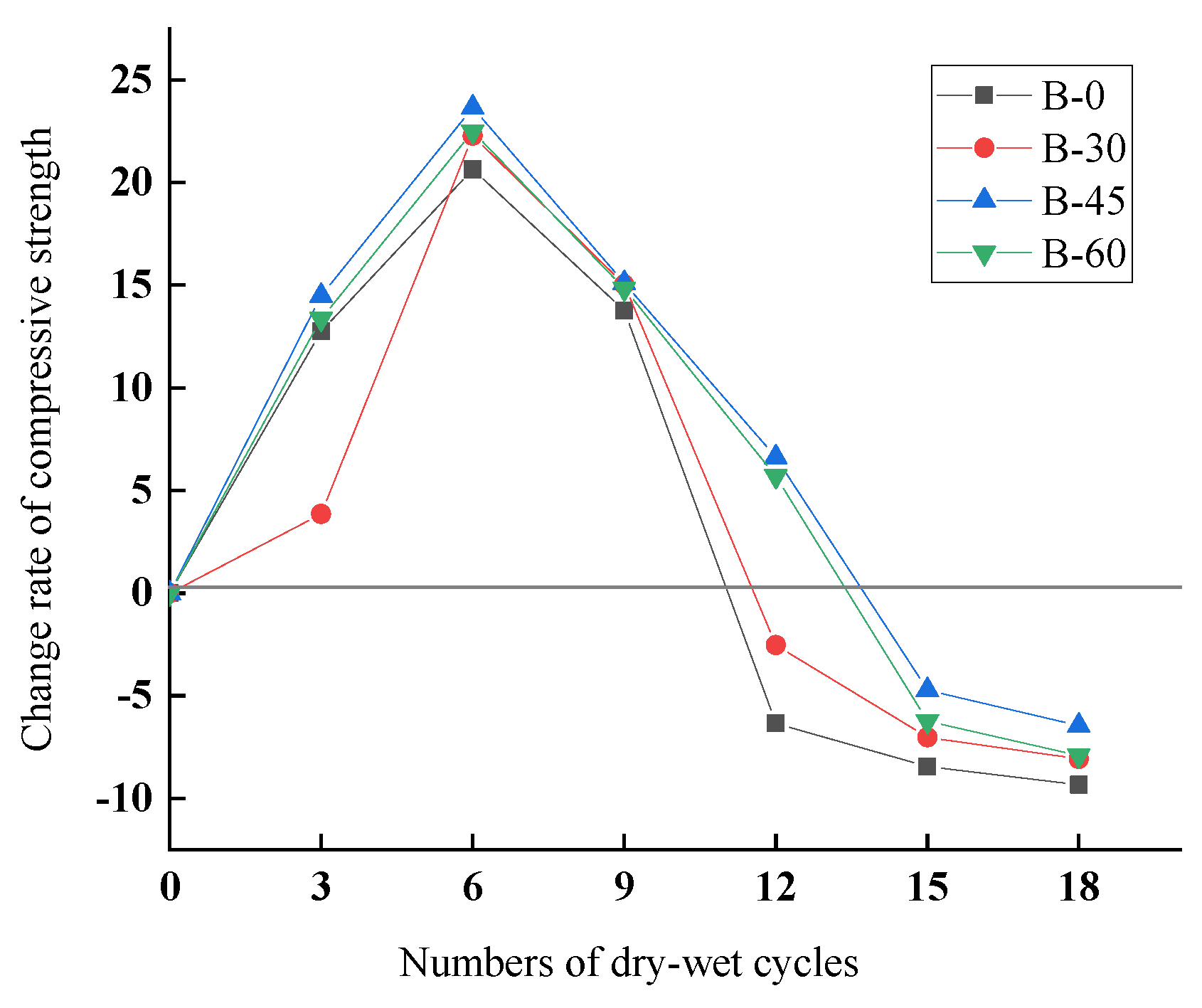

3.2.2. Compressive Strength Change Rates

3.3. NMR Test Analyses

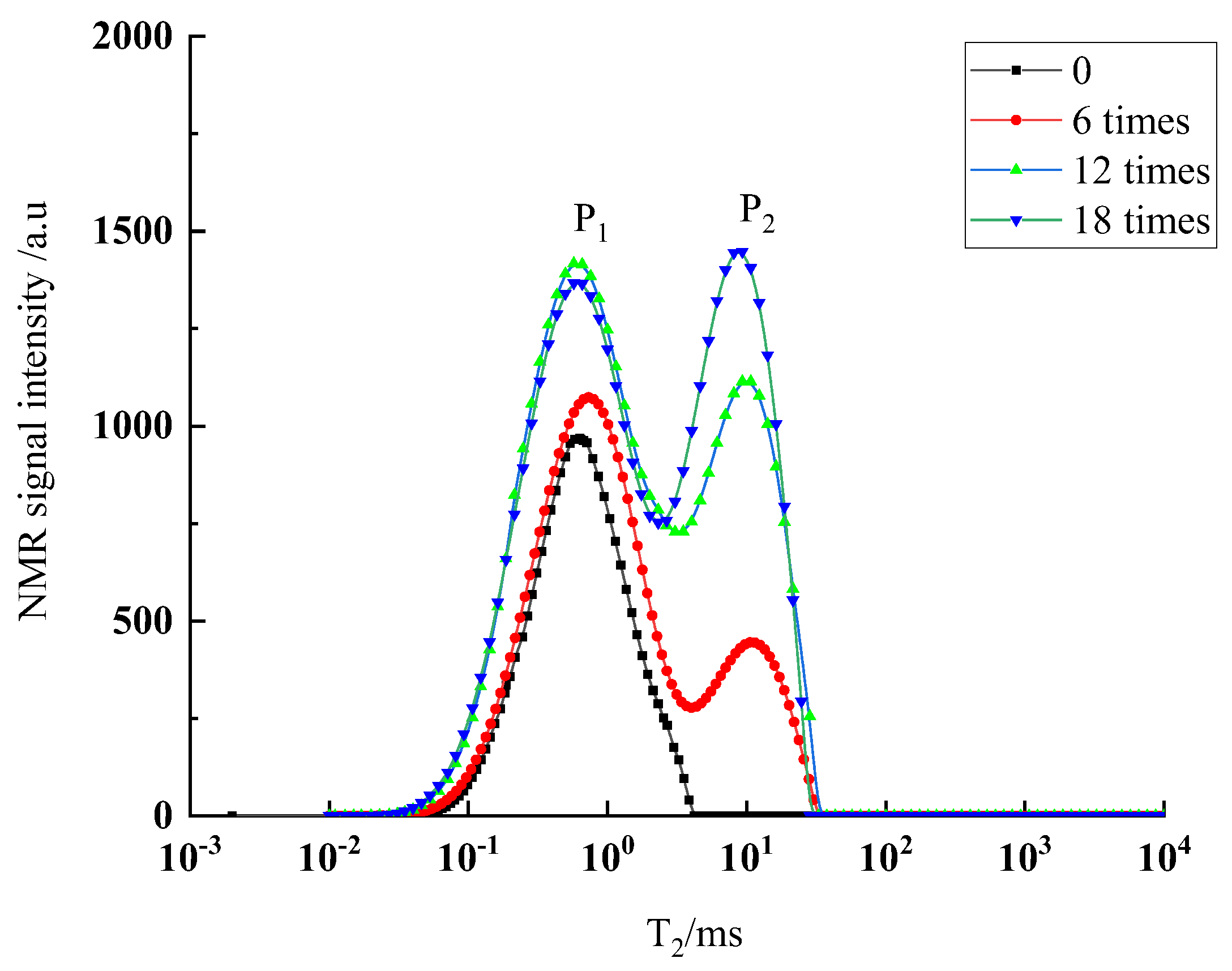

3.3.1. Analyses of Distribution Characteristics of T2 Curves

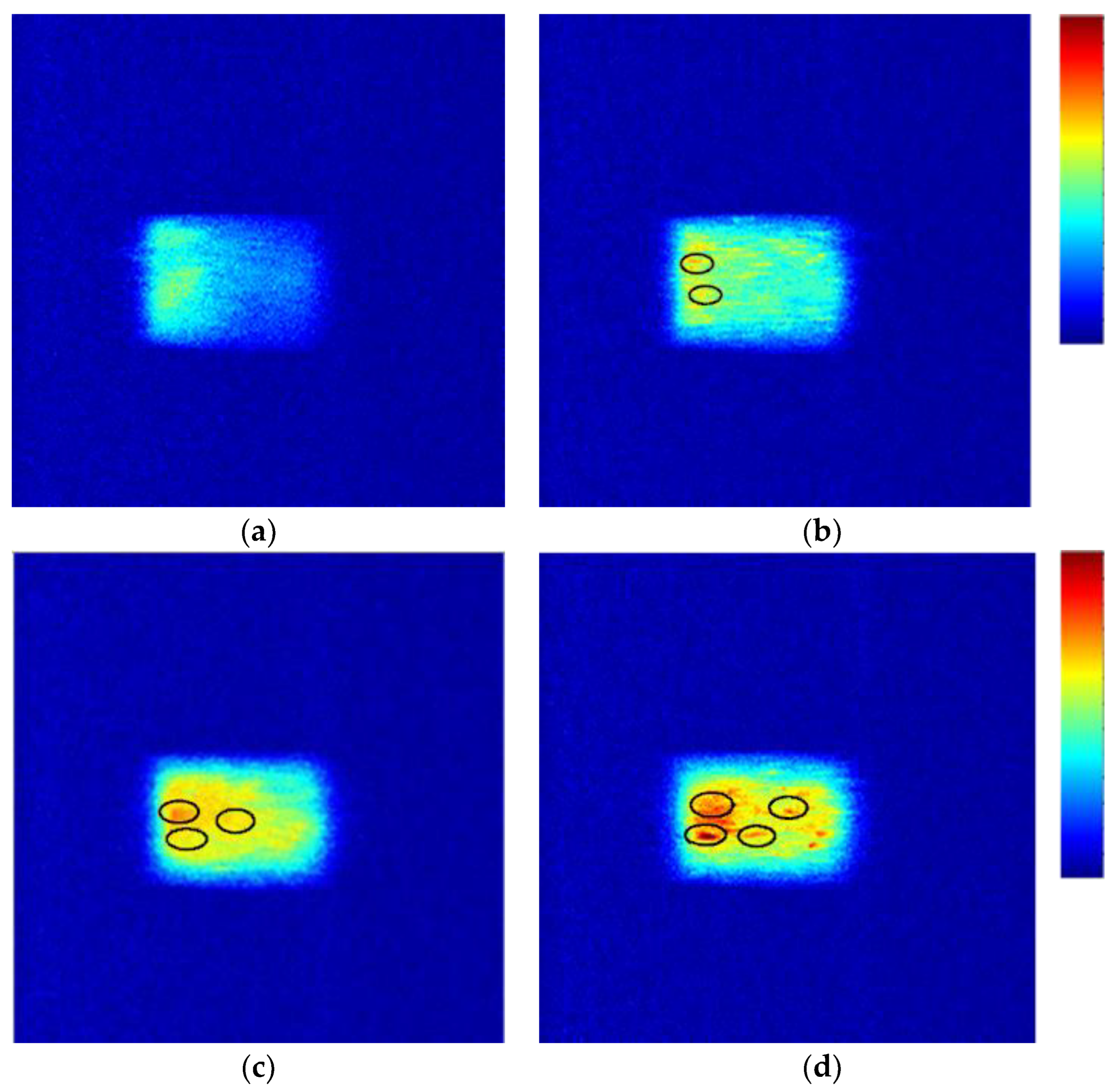

3.3.2. Imaging Analyses

4. Conclusions

- (1)

- As shown by compressive strength curves of soil–cement mixed with ferronickel slag powder under different numbers of dry–wet cycles, with the increase in the number of dry–wet cycles, the unconfined compressive strength first increases and then decreases. Subjected to the same number of dry–wet cycles, mixing with ferronickel slag powder has the potential to improve the strength of soil–cement. Strength change rates of soil–cement mixed with ferronickel slag powder are above those of soil–cement with no ferronickel slag powder doped. Therefore, soil–cement containing ferronickel slag powder performs better in resisting the actions of dry–wet cycles than that with no such powder added. As proved by relevant experimental results, the optimal mixing ratio of ferronickel slag powder is 45%.

- (2)

- According to mass change rate curves of soil–cement mixed with ferronickel slag powder, the mass of soil–cement first increases and then decreases as the number of dry–wet cycles increases. Subjected to the same number of dry–wet cycles, soil–cement mixed with ferronickel slag powder has a mass loss lower rate than that with no such powder mixed. It is concluded that adding ferronickel slag powder in soil–cement is capable of improving its moisture stability and durability.

- (3)

- Through analyses on apparent erosion characteristics of dry–wet cycles, it turns out that apparent erosion on soil–cement surfaces becomes increasingly serious after the sixth dry–wet cycle, which is embodied in the absence of edges and corners, deformed surfaces, spalling and cracking, etc. Provided that the number of dry–wet cycles remains unchanged, apparent erosion degrees of soil–cement with ferronickel slag powder are below those with no such powder mixed. Moreover, soil–cement mixed with ferronickel slag powder features higher compactness interiorly, better integrity, and stronger resistance to erosion caused by dry–wet cycles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiong, F.; Xing, H.; Li, H. Experimental study on the effects of multiple corrosive ion coexistence on soil-cement characteristics. Soils Found. 2019, 59, 398–406. [Google Scholar] [CrossRef]

- Pham, V.N.; Turner, B.; Huang, J.; Kelly, R. The long-term strength of soil-cement columns in coastal areas. Soils Found. 2017, 57, 645–654. [Google Scholar] [CrossRef]

- Li, N.; Zhao, W.Q.; Gu, J.H.; Zhao, S.W.; Wang, W.; Jiang, P. Study on mechanical properties of coastal soil-cement modified by fiber under dry-wet cycle. Yangtze River 2022, 53, 169–174. [Google Scholar]

- Wang, J.H.; Gao, Y.Q. Study on the strength degradation mechanism of cement-soils resulting from dry-wet cycles. China Railw. Sci. 2006, 05, 23–27. [Google Scholar]

- Zheng, J.; Yan, C.H.; Xia, W.J.; Zhang, Y.G.; Cui, D.W.; Zhou, X.; Zhang, R.; Chen, M.Z. Experimental study of influence of drying and wetting cycles on bearing capacity of improved soil by CMSC soil stabilized agent. Chin. J. Rock Mech. Eng. 2009, 28, 3051–3056. [Google Scholar]

- Liang, S.H.; Zeng, W.H. Experimental study on silt soil solidified by cement-fly ash mixture under dry-wet cycles in Nansha. Ind. Constr. 2018, 48, 83–86. [Google Scholar]

- Cuisinier, O.; Masrouri, F.; Mehenni, A. Alteration of the Hydromechanical Performances of a Stabilized Compacted Soil Exposed to Successive Wetting–Drying Cycles. J. Mater. Civ. Eng. 2020, 32. [Google Scholar] [CrossRef]

- Xu, L.N.; Deng, H.Y.; Niu, L.; Zheng, J.J.; Qian, Y.M. Experimental study on mechanical properties of fiber-reinforced cemented soil with the low temperature curing condition subjected to effect of salt and drying-wetting cycles. J. Civ. Environ. Eng. 2022, 44, 10–19. [Google Scholar]

- Li, Q.; Chen, J.; Shi, Q.; Zhao, S. Macroscopic and Microscopic Mechanisms of Cement-Stabilized Soft Clay Mixed with Seawater by Adding Ultrafine Silica Fume. Adv. Mater. Sci. Eng. 2014, 2014, 810652. [Google Scholar] [CrossRef]

- Akinyemi, B.A.; Omoniyi, T.E. Effect of experimental wet and dry cycles on bamboo fibre reinforced acrylic polymer modified cement composites. J. Mech. Behav. Mater. 2020, 29, 86–93. [Google Scholar] [CrossRef]

- Alazigha, D.; Vinod, J.S.; Indraratna, B.; Heitor, A. Potential Use of Lignosulfonate for Expansive Soil Stabilisation. Environ. Geotech. 2018, 6, 480–488. [Google Scholar] [CrossRef]

- Kampala, A.; Horpibulsuk, S.; Prongmanee, N.; Chinkulkijniwat, A. Influence of Wet-Dry Cycles on Compressive Strength of Calcium Carbide Residue–Fly Ash Stabilized Clay. J. Mater. Civ. Eng. 2013, 26, 633–643. [Google Scholar] [CrossRef]

- Wu, Y.K.; Shi, K.J.; Han, Y.; Han, T.; Yu, J.; Li, D. Experimental study on strength characteristics of expansive soil improved by steel slag powder and cement under dry-wet cycles. Iran. J. Sci. Technol. Trans. Civ. Eng. 2020, 45, 941–952. [Google Scholar] [CrossRef]

- Chen, J.H. Experimental study on solidification mechanism of nickel iron slag cement soil. J. Water Resour. Archit. Eng. 2020, 18, 122–127. [Google Scholar]

- Liu, F.; Chen, M.Z.; Li, F.Z.; Li, L.Q.; Wu, S.P.; Sang, Y. Effect of ground steel slag powder on cement properties. Mater. Res. Innov. 2015, 19, 150–153. [Google Scholar] [CrossRef]

- Ke, K.Z. Experimental Study on Early Age Strength of Nickel Iron Slag Powder Cement. J. Water Resour. Archit. Eng. 2018, 04, 192–195. [Google Scholar]

- Zhang, L.F.; Yang, L.; Fu, B.H.; Yue, Y. Research Progress on Carbonation Resistance of Alkali-Activated Slag Cement Concrete. Mater. Sci. Forum 2021, 1036, 347–357. [Google Scholar] [CrossRef]

- Chen, F.; Tong, S.H. Effect of Ferronickel Slag Powder on Strength of Soil in Marine Environment. Adv. Civ. Eng. 2020, 2020, 8856055. [Google Scholar] [CrossRef]

- Yang, Z.Q.; Gao, Q.; Wang, Y.Q.; Ni, W.; Chen, D.-x. Experimental study on new filling cementing material using water-hardening nickel slag tailings of Jinchuan Mine. Chin. J. Geotech. Eng. 2014, 36, 1498–1506. [Google Scholar]

- Shanmugasundar, G.; Krishnan, G.S.; Babu, L.G.; Kumar, S.; Makos, M. Investigation of Ferronickel Slag Powder for Marine Applications by Using MIP Method; IOP Publishing Ltd: Bristol, UK, 2022. [Google Scholar] [CrossRef]

- GB/T 50082-2009; Standard for Test Methods of Long-term Performance and Durability of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2009; pp. 36–37.

- Song, X.G.; Zhang, Z.M.; Chen, H.Y.; Guo, S.Z.; Dong, J.; Liu, J.L. Application of reinforced soil-cement mixed pile in strengthening existing heavy haul railway subgrade. Railw. Stand. Des. 2015, 59, 32–36. [Google Scholar]

| Soil Type | Moisture Content w (%) | Unit Weight r (kN/m3) | Porosity e - | Liquid Limit WL (%) | Plastic Limit Wp (%) | Plasticity Index Ip | Liquidity Index IL |

|---|---|---|---|---|---|---|---|

| Silt soil | 58.6 | 16.32 | 1.533 | 49 | 29.3 | 19.8 | 1.47 |

| Item | GB/T 175 | Measured Result |

|---|---|---|

| Specific surface area (m2·kg−1) | ≥300 | 381 |

| 80 μm sieve residue (%) | ≤10 | 0.63 |

| Standard consistency (%) | / | 25.8 |

| Loss on ignition (%) | ≤5.0 | 1.59 |

| Initial setting time (min) | ≥45 | 147 |

| Final setting time (min) | ≤600 | 212 |

| Composition | SO3 | MgO | CaO | SiO2 | Al2O3 | Fe2O3 | f-CaO | Others | LOI |

|---|---|---|---|---|---|---|---|---|---|

| Mass percent (%) | 2.89 | 2.05 | 62.55 | 21.69 | 4.38 | 3.34 | 0.57 | 0.84 | 1.59 |

| Composition | SiO2 | Al2O3 | CaO | MgO | TiO2 | MnO | Fe2O3 | SO3 | LOI |

|---|---|---|---|---|---|---|---|---|---|

| Ferronickel slag powder (%) | 35.82 | 21.46 | 29.22 | 9.46 | 0.78 | 0.57 | 1.33 | 0.16 | 2.43 |

| Mineral powder (%) | 32.00 | 16.81 | 36.12 | 10.59 | 0.93 | 0.9 | 2.29 | 0.14 | 0.16 |

| Composition | NaCl | MgCl2 | Na2SO4 | CaCl2 | KCl | NaHCO3 | KBr | H3BO3 | SrCl2 |

|---|---|---|---|---|---|---|---|---|---|

| Concentration (g/L) | 24.53 | 5.20 | 4.09 | 1.16 | 0.70 | 0.20 | 0.10 | 0.03 | 0.03 |

| Serial No. | Binder Material Ratio (%) | Water–Cement Ratio | Replacement Ratio (%) | Curing Condition | Number of Specimens | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 Cycle | 3 Cycles | 6 Cycles | 9 Cycles | 12 Cycles | 15 Cycles | 18 Cycles | |||||

| B-0 | 15 | 0.5 | 0 | Seawater | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| B-30 | 30 | Seawater | 3 | 3 | 3 | 3 | 3 | 3 | 3 | ||

| B-45 | 45 | Seawater | 3 | 3 | 3 | 3 | 3 | 3 | 3 | ||

| B-60 | 60 | Seawater | 3 | 3 | 3 | 3 | 3 | 3 | 3 | ||

| Serial No. | Mass | ||||||

|---|---|---|---|---|---|---|---|

| 0 Cycles (g) | 3 Cycles (g) | 6 Cycles (g) | 9 Cycles (g) | 12 Cycles (g) | 15 Cycles (g) | 18 Cycles (g) | |

| B-0 | 582.93 | 587.91 | 576.31 | 565.65 | 571.13 | 561.04 | 554.45 |

| B-30 | 584.64 | 591.54 | 582.36 | 578.97 | 570.49 | 566.60 | 560.73 |

| B-45 | 585.72 | 597.20 | 588.18 | 582.44 | 575.18 | 571.08 | 566.39 |

| B-60 | 584.86 | 592.76 | 583.46 | 580.42 | 571.47 | 568.31 | 563.28 |

| Serial No. | Change Rate | ||||||

|---|---|---|---|---|---|---|---|

| 0 Cycles (%) | 3 Cycles (%) | 6 Cycles (%) | 9 Cycles (%) | 12 Cycles (%) | 15 Cycles (%) | 18 Cycles (%) | |

| B-0 | 0 | 0.83 | −1.13 | −2.02 | −2.96 | −3.75 | −4.88 |

| B-30 | 0 | 1.88 | −0.39 | −0.97 | −2.42 | −3.12 | −4.09 |

| B-45 | 0 | 1.96 | 0.42 | −0.56 | −1.8 | −2.5 | −3.3 |

| B-60 | 0 | 1.35 | −0.24 | −0.76 | −2.29 | −2.83 | −3.69 |

| Number of Dry–Wet Cycles | 0 | 6 | 12 | 18 |

|---|---|---|---|---|

| Porosity (%) | 43.48 | 48.72 | 54.61 | 60.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Chen, F.; Chen, W.; Wang, H.; Yang, J. A Study on Mechanical Properties of Modified Soil–Cement Mixed with Ferronickel Slag Powder under Dry–Wet Cycles in Marine Environments. J. Mar. Sci. Eng. 2023, 11, 1684. https://doi.org/10.3390/jmse11091684

Chen S, Chen F, Chen W, Wang H, Yang J. A Study on Mechanical Properties of Modified Soil–Cement Mixed with Ferronickel Slag Powder under Dry–Wet Cycles in Marine Environments. Journal of Marine Science and Engineering. 2023; 11(9):1684. https://doi.org/10.3390/jmse11091684

Chicago/Turabian StyleChen, Sanshan, Feng Chen, Weizhen Chen, Hao Wang, and Jianxue Yang. 2023. "A Study on Mechanical Properties of Modified Soil–Cement Mixed with Ferronickel Slag Powder under Dry–Wet Cycles in Marine Environments" Journal of Marine Science and Engineering 11, no. 9: 1684. https://doi.org/10.3390/jmse11091684

APA StyleChen, S., Chen, F., Chen, W., Wang, H., & Yang, J. (2023). A Study on Mechanical Properties of Modified Soil–Cement Mixed with Ferronickel Slag Powder under Dry–Wet Cycles in Marine Environments. Journal of Marine Science and Engineering, 11(9), 1684. https://doi.org/10.3390/jmse11091684