A Novel Time–Frequency Feature Fusion Approach for Robust Fault Detection in a Marine Main Engine

Abstract

1. Introduction

1.1. Background

1.2. Literature Review

1.2.1. Acoustic Signal Source-Based Fault Detection and Diagnosis

1.2.2. Vibration Signal Source-Based Fault Detection and Diagnosis

1.2.3. Other Data-Oriented Approaches for Fault Detection and Diagnosis

1.3. Contribution

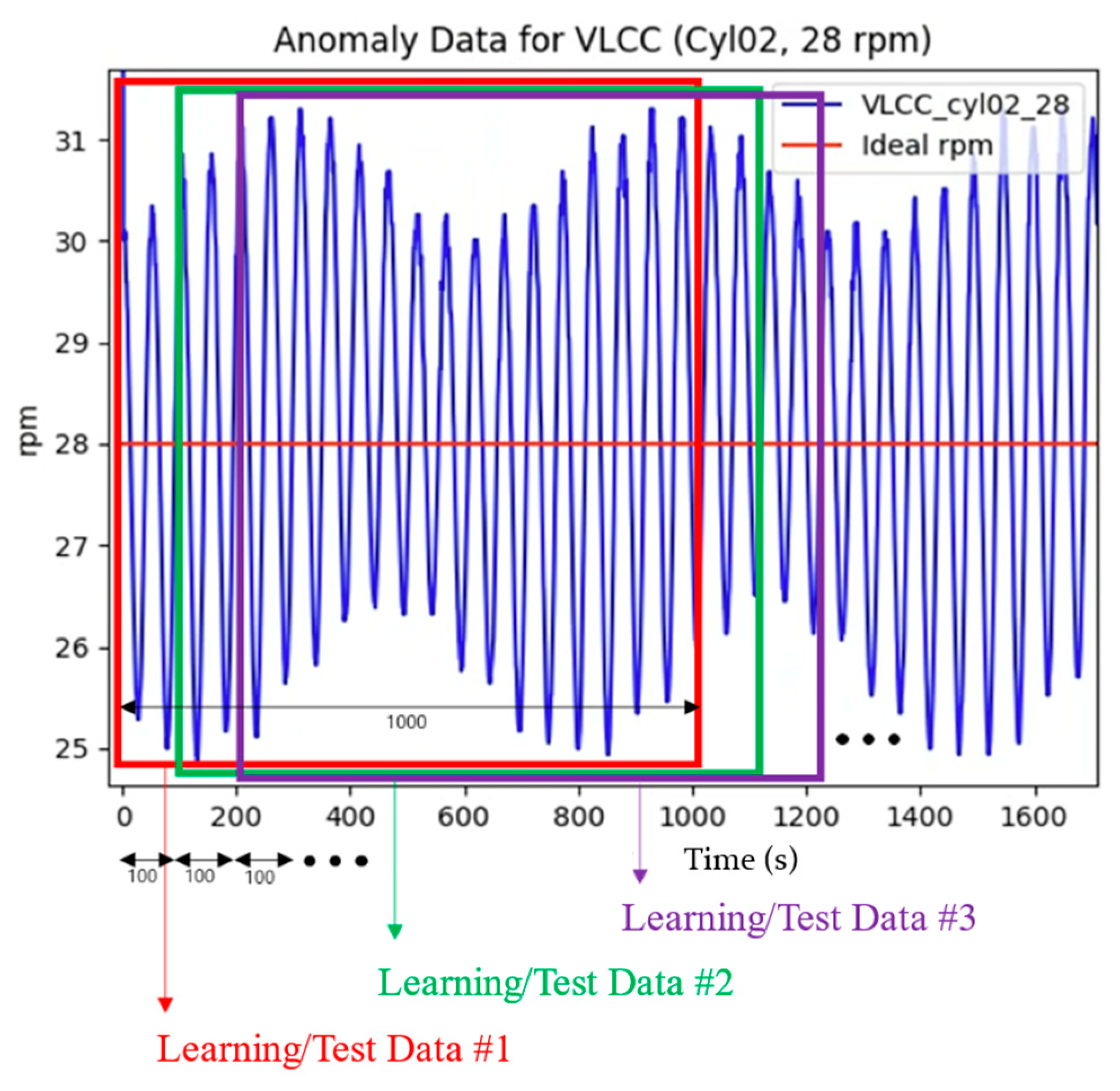

2. Problem Definition

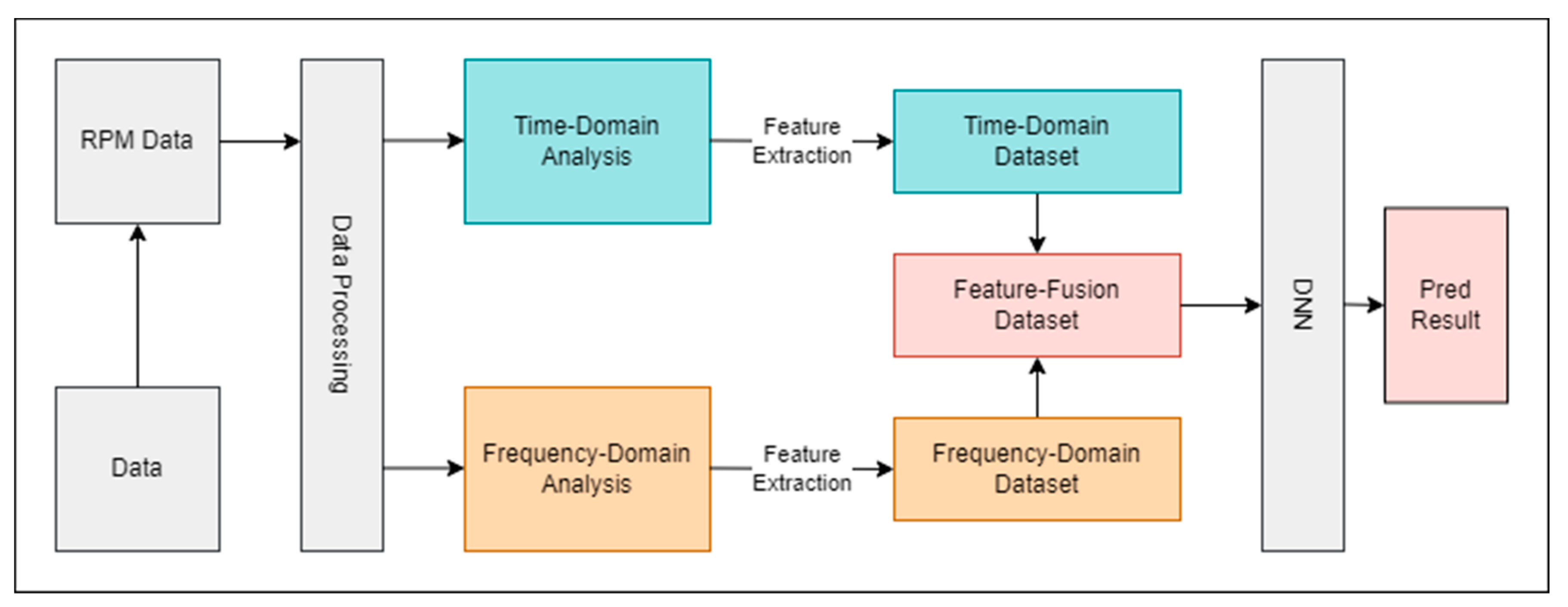

3. Methodology for Performance Evaluation

3.1. Deep Neural Network (DNN)

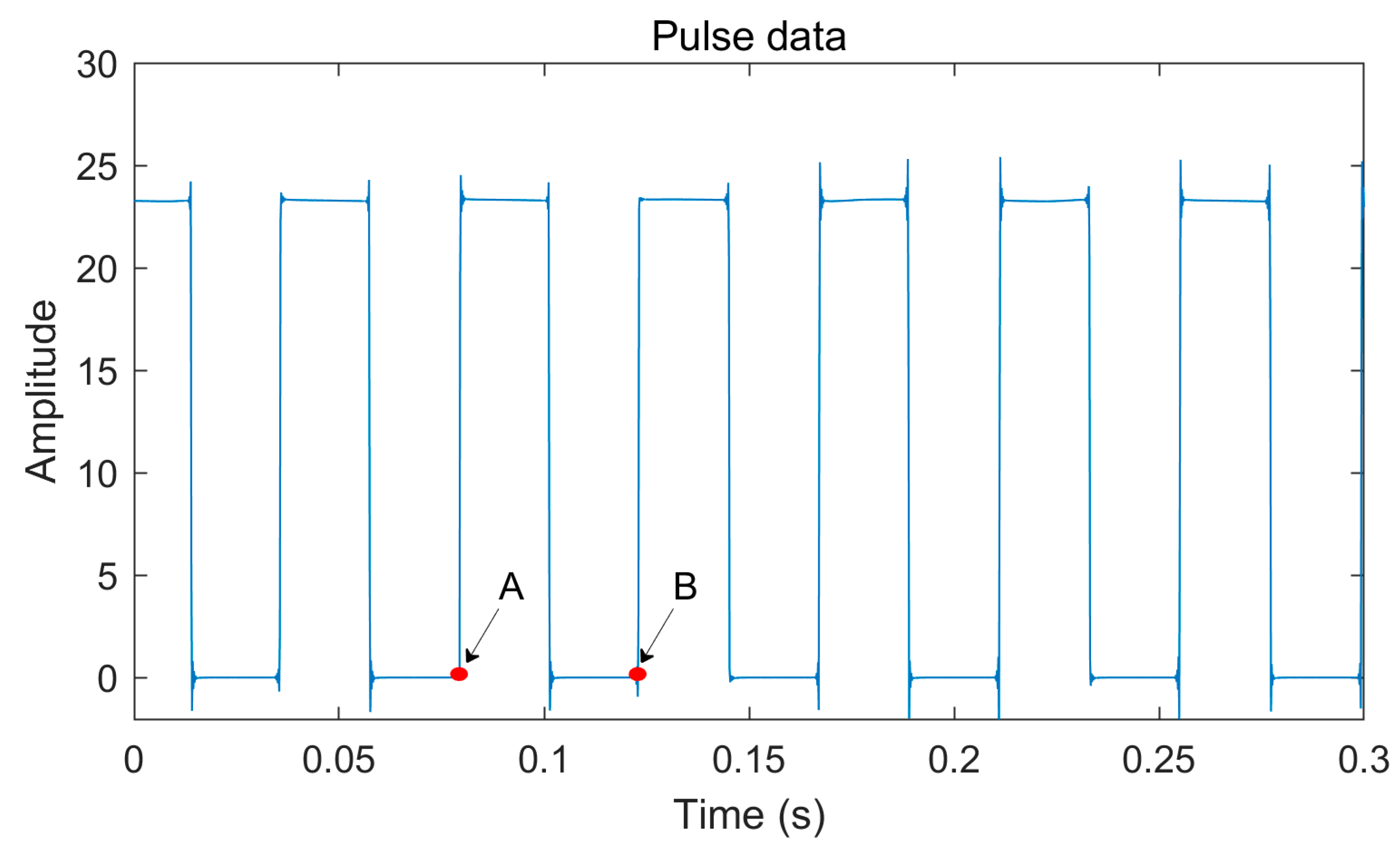

3.2. Data Processing

3.3. Performance Evaluation Metrics

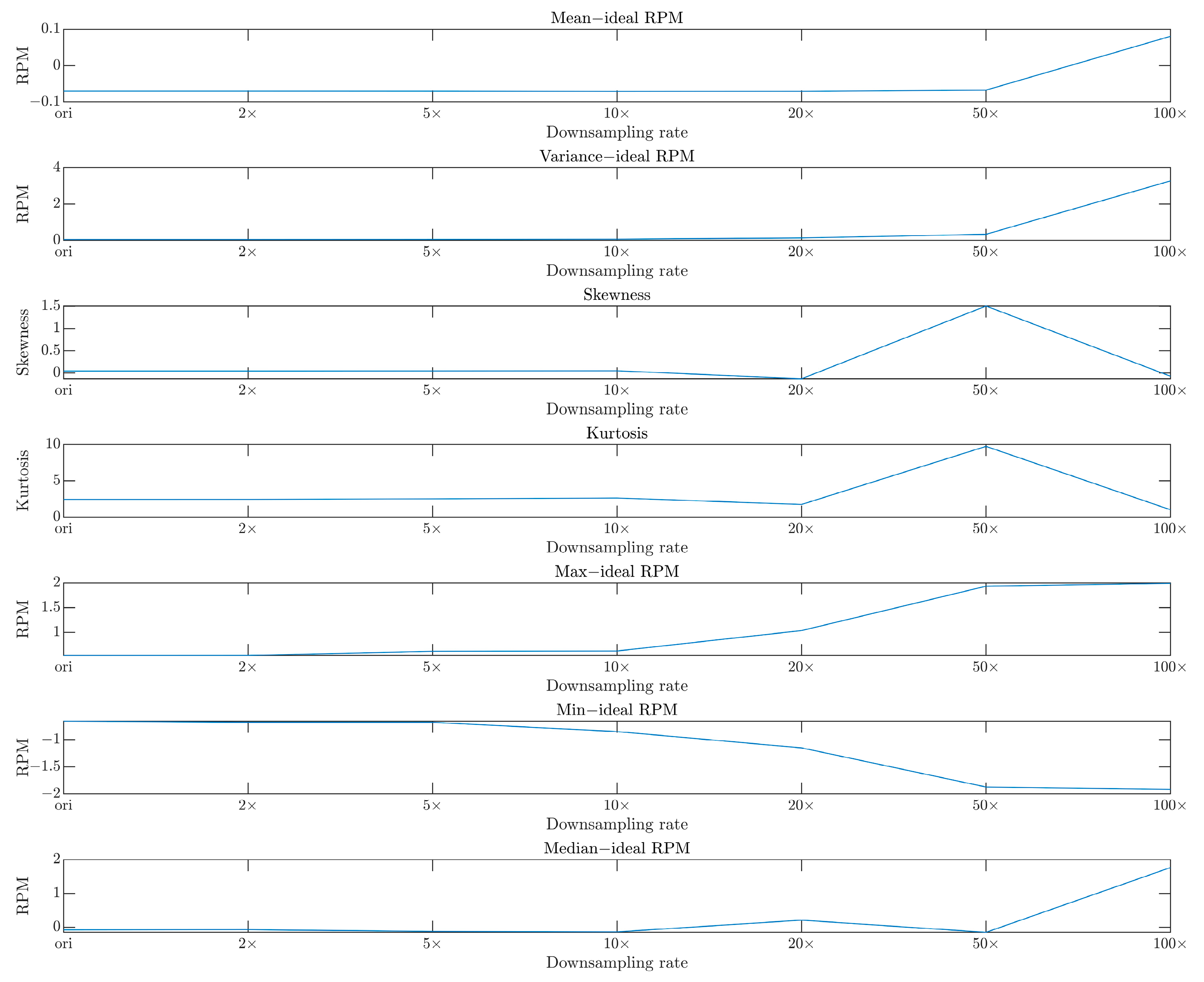

4. Time Domain

4.1. Time-Domain Feature Extraction

4.2. Time-Domain Analysis

5. Frequency-Domain Analysis

5.1. Data Preprocessing in the Frequency Domain

5.2. Frequency-Domain Analysis Method

5.3. Frequency-Domain Feature Extraction

5.4. Analysis in the Frequency Domain

6. Results

6.1. Dataset Configuration

6.2. Experiment Results

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Unctad. Review of Maritime Transport 2021; UN: New York, NY, USA, 2021. [Google Scholar]

- International Maritime Organization. IMO MASS Guide (Autonomous Shipping). 2021. Available online: https://www.imo.org/en/MediaCentre/HotTopics/Pages/Autonomous-shipping.aspx (accessed on 21 June 2023).

- Felski, A.; Zwolak, K. The ocean-going autonomous ship—Challenges and threats. J. Mar. Sci. Eng. 2020, 8, 41. [Google Scholar] [CrossRef]

- Jimenez, V.J.; Bouhmala, N.; Gausdal, A.H. Developing a predictive maintenance model for vessel machinery. J. Ocean Eng. Sci. 2020, 5, 358–386. [Google Scholar] [CrossRef]

- Albarbar, A.; Gu, F.; Ball, A. Diesel engine fuel injection monitoring using acoustic measurements and independent component analysis. Measurement 2010, 43, 1376–1386. [Google Scholar] [CrossRef]

- Glowacz, A.; Glowacz, W.; Glowacz, Z.; Kozik, J. Early fault diagnosis of bearing and stator faults of the single-phase induction motor using acoustic signals. Measurement 2018, 113, 1–9. [Google Scholar] [CrossRef]

- Yao, J.; Xiang, Y.; Qian, S.; Wang, S.; Wu, S. Noise source identification of diesel engine based on variational mode decomposition and robust independent component analysis. Appl. Acoust. 2017, 116, 184–194. [Google Scholar] [CrossRef]

- Yao, J.; Xiang, Y.; Qian, S.; Li, S.; Wu, S. Noise source separation of diesel engine by combining binaural sound localization method and blind source separation method. Mech. Syst. Signal Process. 2017, 96, 303–320. [Google Scholar] [CrossRef]

- Alharbi, F.; Luo, S.; Zhang, H.; Shaukat, K.; Yang, G.; Wheeler, C.A.; Chen, Z. A Brief Review of Acoustic and Vibration Signal-Based Fault Detection for Belt Conveyor Idlers Using Machine Learning Models. Sensors 2023, 23, 1902. [Google Scholar] [CrossRef] [PubMed]

- Xiaoqin, L.; Xing, W.; Chang, L. A comparison of acoustic emission and vibration on bearing fault detection. In Proceedings of the 2011 International Conference on Transportation, Mechanical, and Electrical Engineering (TMEE), Changchun, China, 16–18 December 2011; pp. 922–926. [Google Scholar]

- Li, Z.; Yan, X.; Guo, Z.; Liu, P.; Yuan, C.; Peng, Z. A new intelligent fusion method of multi-dimensional sensors and its application to tribo-system fault diagnosis of marine diesel engines. Tribol. Lett. 2012, 47, 1–15. [Google Scholar] [CrossRef]

- Xi, W.; Li, Z.; Tian, Z.; Duan, Z. A feature extraction and visualization method for fault detection of marine diesel engines. Measurement 2018, 116, 429–437. [Google Scholar] [CrossRef]

- Yan, G.; Hu, Y.; Jiang, J. A novel fault diagnosis method for marine blower with vibration signals. Pol. Marit. Res. 2022, 29, 77–86. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, Z.; Chen, B.; Zhang, W.; Huang, G. An improved complementary ensemble empirical mode decomposition with adaptive noise and its application to rolling element bearing fault diagnosis. ISA Trans. 2019, 91, 218–234. [Google Scholar] [CrossRef] [PubMed]

- Wang, F. Pulsation signals analysis of turbocharger turbine blades based on optimal EEMD and TEO. Pol. Marit. Res. 2019, 26, 78–86. [Google Scholar] [CrossRef]

- Liu, X.; Randall, R. Blind source separation of internal combustion engine piston slap from other measured vibration signals. Mech. Syst. Signal Process. 2005, 19, 1196–1208. [Google Scholar] [CrossRef]

- Li, Z.; Yan, X.; Guo, Z.; Zhang, Y.; Yuan, C.; Peng, Z. Condition monitoring and fault diagnosis for marine diesel engines using information fusion techniques. Elektron. Ir Elektrotechnika 2012, 123, 109–112. [Google Scholar] [CrossRef]

- Jing, Y.-B.; Liu, C.-W.; Bi, F.-R.; Bi, X.-Y.; Wang, X.; Shao, K. Diesel engine valve clearance fault diagnosis based on features extraction techniques and FastICA-SVM. Chin. J. Mech. Eng. 2017, 30, 991–1007. [Google Scholar] [CrossRef]

- Li, Z.; He, Y.; Chu, F.; Han, J.; Hao, W. Fault recognition method for speed-up and speed-down process of rotating machinery based on independent component analysis and Factorial Hidden Markov Model. J. Sound Vib. 2006, 291, 60–71. [Google Scholar] [CrossRef]

- Wang, Z.; Yao, L.; Chen, G.; Ding, J. Modified multiscale weighted permutation entropy and optimized support vector machine method for rolling bearing fault diagnosis with complex signals. ISA Trans. 2021, 114, 470–484. [Google Scholar] [CrossRef]

- Qu, C.; Zhou, Z.; Liu, Z.; Jia, S. Predictive anomaly detection for marine diesel engine based on echo state network and autoencoder. Energy Rep. 2022, 8, 998–1003. [Google Scholar] [CrossRef]

- Lee, S.-M.; Choi, Y.-S. Fault diagnosis of partial rub and looseness in rotating machinery using Hilbert-Huang transform. J. Mech. Sci. Technol. 2008, 22, 2151–2162. [Google Scholar] [CrossRef]

- Berredjem, T.; Benidir, M. Bearing faults diagnosis using fuzzy expert system relying on an improved range overlaps and similarity method. Expert Syst. Appl. 2018, 108, 134–142. [Google Scholar] [CrossRef]

- Sun, W.; Chen, J.; Li, J. Decision tree and PCA-based fault diagnosis of rotating machinery. Mech. Syst. Signal Process. 2007, 21, 1300–1317. [Google Scholar] [CrossRef]

- Jana, D.; Patil, J.; Herkal, S.; Nagarajaiah, S.; Duenas-Osorio, L. CNN and Convolutional Autoencoder (CAE) based real-time sensor fault detection, localization, and correction. Mech. Syst. Signal Process. 2022, 169, 108723. [Google Scholar] [CrossRef]

- Silva, K.; Souza, B.A.; Brito, N.S. Fault detection and classification in transmission lines based on wavelet transform and ANN. IEEE Trans. Power Deliv. 2006, 21, 2058–2063. [Google Scholar] [CrossRef]

- Khelil, Y.; Graton, G.; Djeziri, M.; Ouladsine, M.; Outbib, R. Fault detection and isolation in marine diesel engines: A generic methodology. IFAC Proc. Vol. 2012, 45, 964–969. [Google Scholar] [CrossRef]

- Kowalski, J.; Krawczyk, B.; Woźniak, M. Fault diagnosis of marine 4-stroke diesel engines using a one-vs-one extreme learning ensemble. Eng. Appl. Artif. Intell. 2017, 57, 134–141. [Google Scholar] [CrossRef]

- Lima, E.M.; dos Santos Junqueira, C.M.; Brito, N.S.D.; de Souza, B.A.; de Almeida Coelho, R.; Gayoso Meira Suassuna de Medeiros, H. High impedance fault detection method based on the short-time Fourier transform. IET Gener. Transm. Distrib. 2018, 12, 2577–2584. [Google Scholar] [CrossRef]

- Moschopoulos, M.; Rossopoulos, G.N.; Papadopoulos, C.I. Journal bearing performance prediction using machine learning and octave-band signal analysis of sound and vibration measurements. Pol. Marit. Res. 2021, 28, 137–149. [Google Scholar] [CrossRef]

- Brandsæter, A.; Vanem, E.; Glad, I.K. Efficient on-line anomaly detection for ship systems in operation. Expert Syst. Appl. 2019, 121, 418–437. [Google Scholar] [CrossRef]

- Kim, D.; Antariksa, G.; Handayani, M.P.; Lee, S.; Lee, J. Explainable anomaly detection framework for maritime main engine sensor data. Sensors 2021, 21, 5200. [Google Scholar] [CrossRef]

- Lazakis, I.; Gkerekos, C.; Theotokatos, G. Investigating an SVM-driven, one-class approach to estimating ship systems condition. Ships Offshore Struct. 2019, 14, 432–441. [Google Scholar] [CrossRef]

- Lazakis, I.; Raptodimos, Y.; Varelas, T. Predicting ship machinery system condition through analytical reliability tools and artificial neural networks. Ocean Eng. 2018, 152, 404–415. [Google Scholar] [CrossRef]

- Ou, S.; Yu, Y.; Yang, J. Identification and reconstruction of anomalous sensing data for combustion analysis of marine diesel engines. Measurement 2022, 193, 110960. [Google Scholar] [CrossRef]

- Li, Z.; Yan, X.; Yuan, C.; Peng, Z. Intelligent fault diagnosis method for marine diesel engines using instantaneous angular speed. J. Mech. Sci. Technol. 2012, 26, 2413–2423. [Google Scholar] [CrossRef]

- Lee, T.-W. Independent Component Analysis. In Independent Component Analysis: Theory and Applications; Lee, T.-W., Ed.; Springer US: Boston, MA, USA, 1998; pp. 27–66. [Google Scholar]

- Kim Eung, S.; Lee You, J. Analysis of Nonlinear Time Series by Bispectrum Methods and its Applications. KIPS Trans. 1999, 6, 1312–1322. [Google Scholar]

- Yu, H. Classification Performance Comparison of Feature Vectors Based on Summation Scheme and Maximization Scheme. Int. J. Mach. Learn. Comput. 2011, 1, 73. [Google Scholar] [CrossRef]

| Main Engine Model Type | Max Power (kW) | Number of Cylinders | Normal Continuous Rating (NCR) |

|---|---|---|---|

| Doosan Engine G70ME-C9.2 TII (MAN B&W Licensed) | 29,120 kW | 8 | 83 RPM |

| Layer | Details |

|---|---|

| Input layer | N nodes |

| First hidden layer | 50 nodes/ReLU |

| Second hidden layer | 80 nodes/ReLU |

| Third hidden layer | 120 nodes/ReLU |

| Fourth hidden layer | 120 nodes/ReLU |

| Fifth hidden layer | 120 nodes/ReLU |

| Sixth hidden layer | 80 nodes/ReLU |

| Seventh hidden layer | 50 nodes/ReLU |

| Output layer | 2 nodes/sigmoid |

| Loss Function | Optimizer | Epoch |

|---|---|---|

| Cross entropy | Adam (learning rate = 1 × 104) | 4000 |

| Feature | Formulas |

|---|---|

| (Mean-ideal RPM) | |

| (Variance-ideal RPM) | |

| Skewness | |

| Kurtosis | |

| (Max-ideal RPM) | |

| (Min-ideal RPM) | |

| (Median-ideal RPM) |

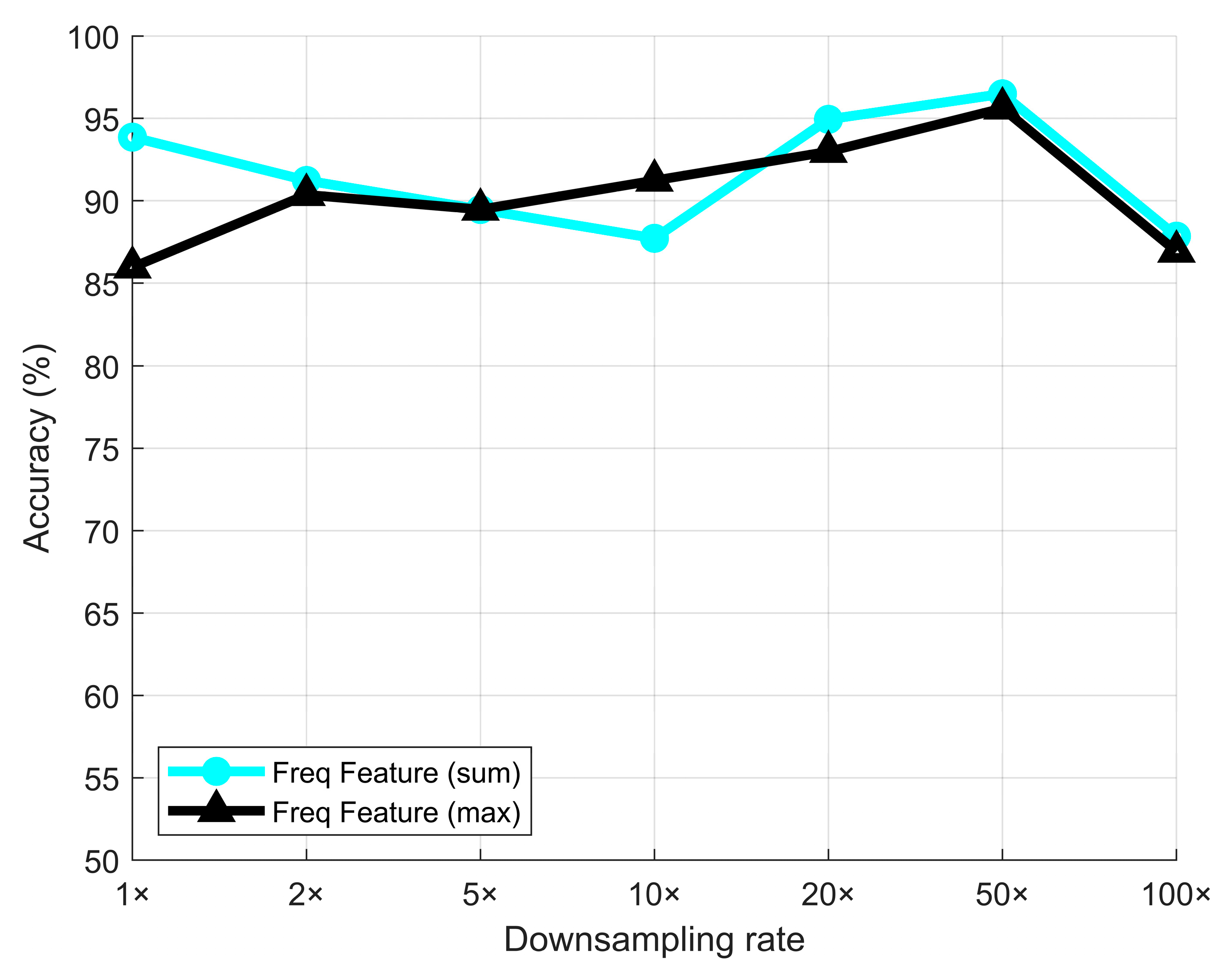

| Acc. (%)\DS Rate | 1× | 2× | 5× | 10× | 20× | 50× | 100× |

| Time | 98.99 | 96.49 | 97.37 | 96.49 | 97.37 | 61.4 | 53.48 |

| Freq (max) | 85.96 | 90.36 | 89.47 | 91.23 | 92.98 | 95.61 | 86.92 |

| Freq (sum) | 93.86 | 91.23 | 89.47 | 87.72 | 94.94 | 96.49 | 87.85 |

| Acc. (%)\DS Rate | 1× | 2× | 5× | 10× | 20× | 50× | 100× |

| Time | 98.99 | 96.49 | 97.37 | 96.49 | 97.37 | 61.4 | 53.48 |

| Freq (max) | 85.96 | 90.36 | 89.47 | 91.23 | 92.98 | 95.61 | 86.92 |

| Freq (sum) | 93.86 | 91.23 | 89.47 | 87.72 | 94.94 | 96.49 | 87.85 |

| Time-Freq (sum) | 100.00 | 100.00 | 100.00 | 100.00 | 99.12 | 99.12 | 96.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Je-Gal, H.; Lee, S.-J.; Yoon, J.-H.; Lee, H.-S.; Yang, J.-H.; Kim, S. A Novel Time–Frequency Feature Fusion Approach for Robust Fault Detection in a Marine Main Engine. J. Mar. Sci. Eng. 2023, 11, 1577. https://doi.org/10.3390/jmse11081577

Je-Gal H, Lee S-J, Yoon J-H, Lee H-S, Yang J-H, Kim S. A Novel Time–Frequency Feature Fusion Approach for Robust Fault Detection in a Marine Main Engine. Journal of Marine Science and Engineering. 2023; 11(8):1577. https://doi.org/10.3390/jmse11081577

Chicago/Turabian StyleJe-Gal, Hong, Seung-Jin Lee, Jeong-Hyun Yoon, Hyun-Suk Lee, Jung-Hee Yang, and Sewon Kim. 2023. "A Novel Time–Frequency Feature Fusion Approach for Robust Fault Detection in a Marine Main Engine" Journal of Marine Science and Engineering 11, no. 8: 1577. https://doi.org/10.3390/jmse11081577

APA StyleJe-Gal, H., Lee, S.-J., Yoon, J.-H., Lee, H.-S., Yang, J.-H., & Kim, S. (2023). A Novel Time–Frequency Feature Fusion Approach for Robust Fault Detection in a Marine Main Engine. Journal of Marine Science and Engineering, 11(8), 1577. https://doi.org/10.3390/jmse11081577