Effects of Laying Depth and Pipe Arc Length on the Mechanical Performance of Large-Diameter Cold-Water Pipes during Float-and-Sink Installation

Abstract

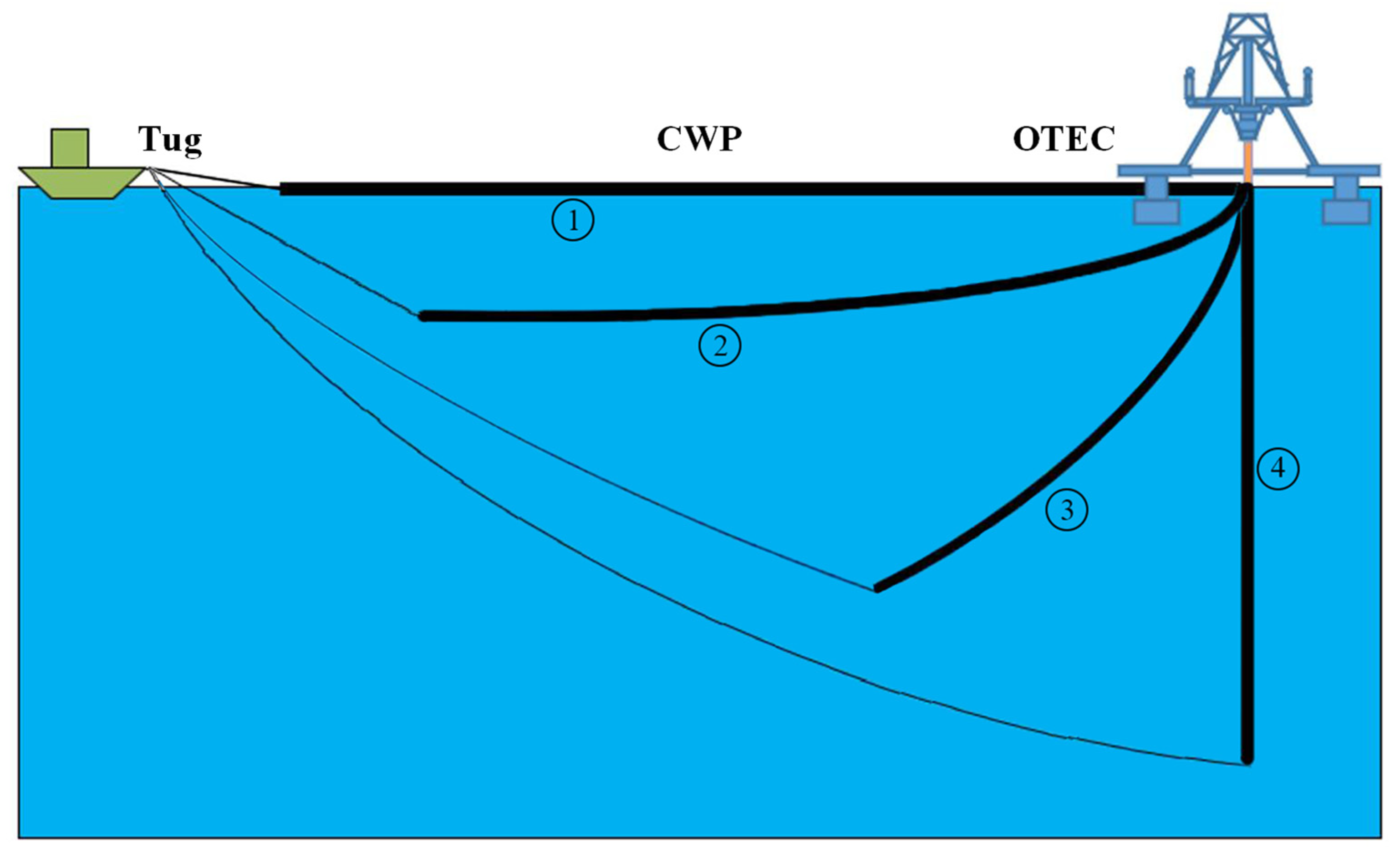

1. Introduction

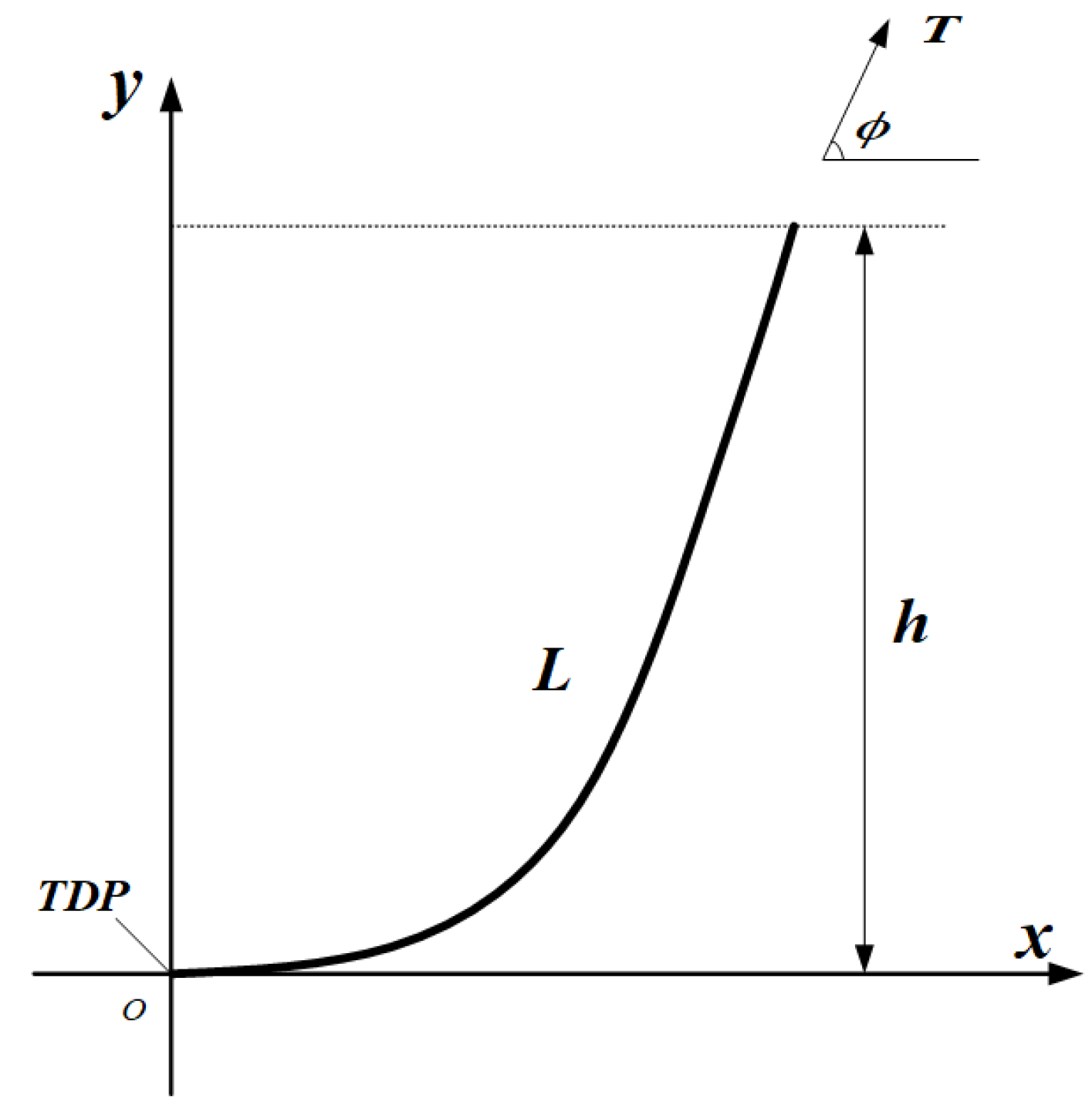

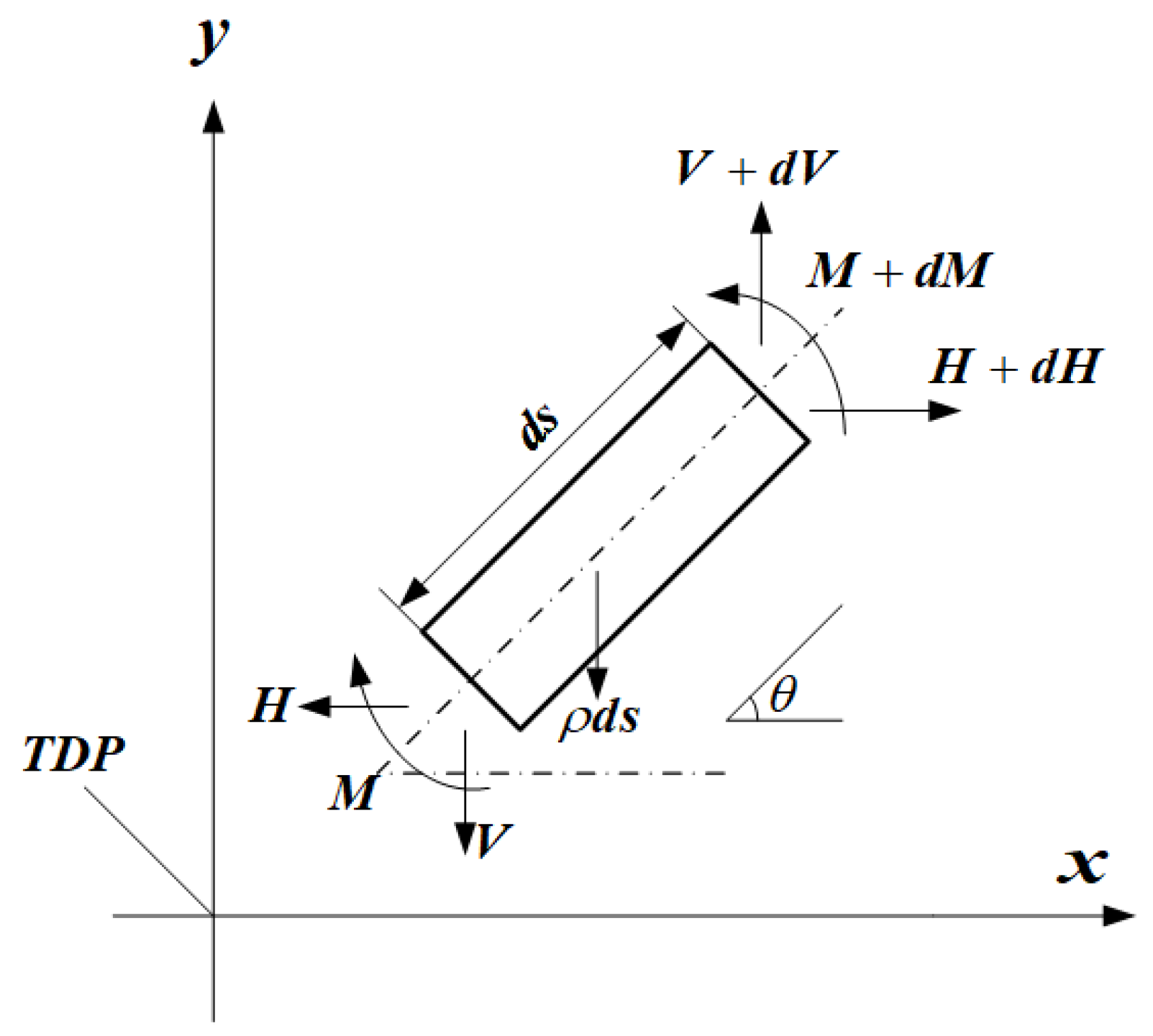

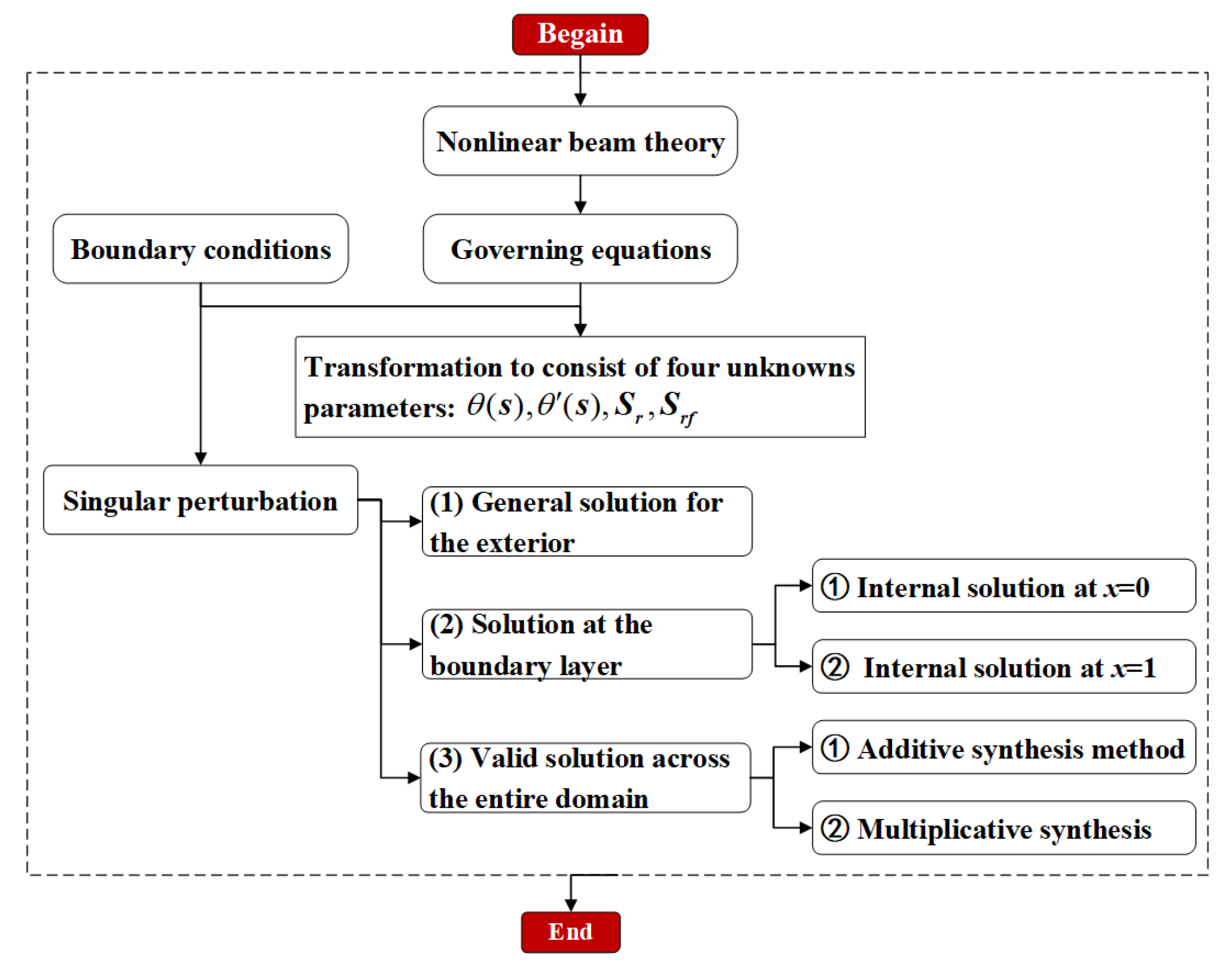

2. Theoretical Model and Solution

2.1. Nonlinear Beam Theory

2.2. Boundary Conditions

2.3. Singular Perturbation

2.3.1. General Solution for the Exterior

2.3.2. Solution at the Boundary Layer

- (1)

- Internal solution around x = 0

- (2)

- Internal solution around x = 1

2.3.3. Valid Solution across the Entire Domain

- (1)

- Additive synthesis method

- (2)

- Multiplicative synthesis

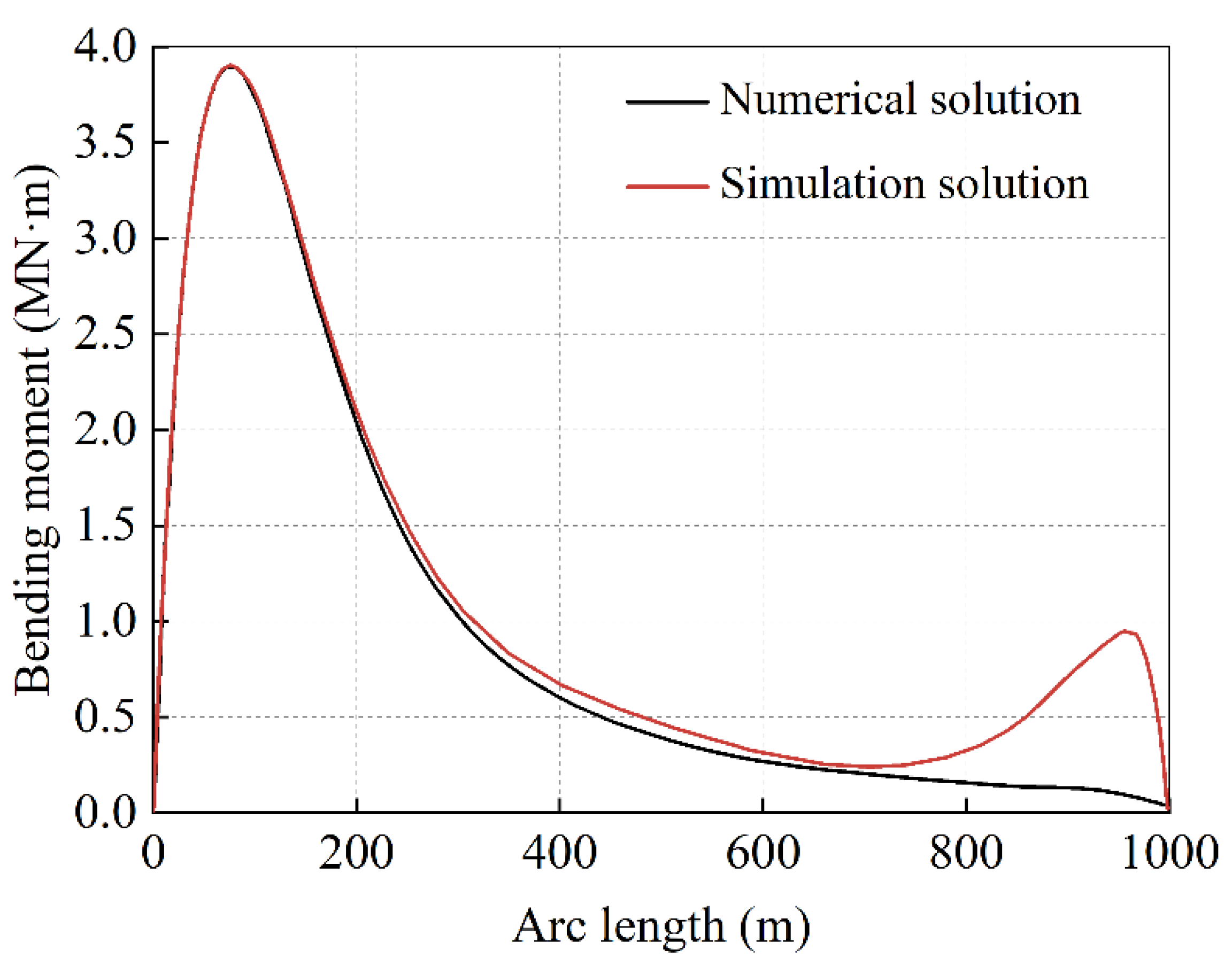

3. Solution Correctness and Validity

4. Results and Discussion

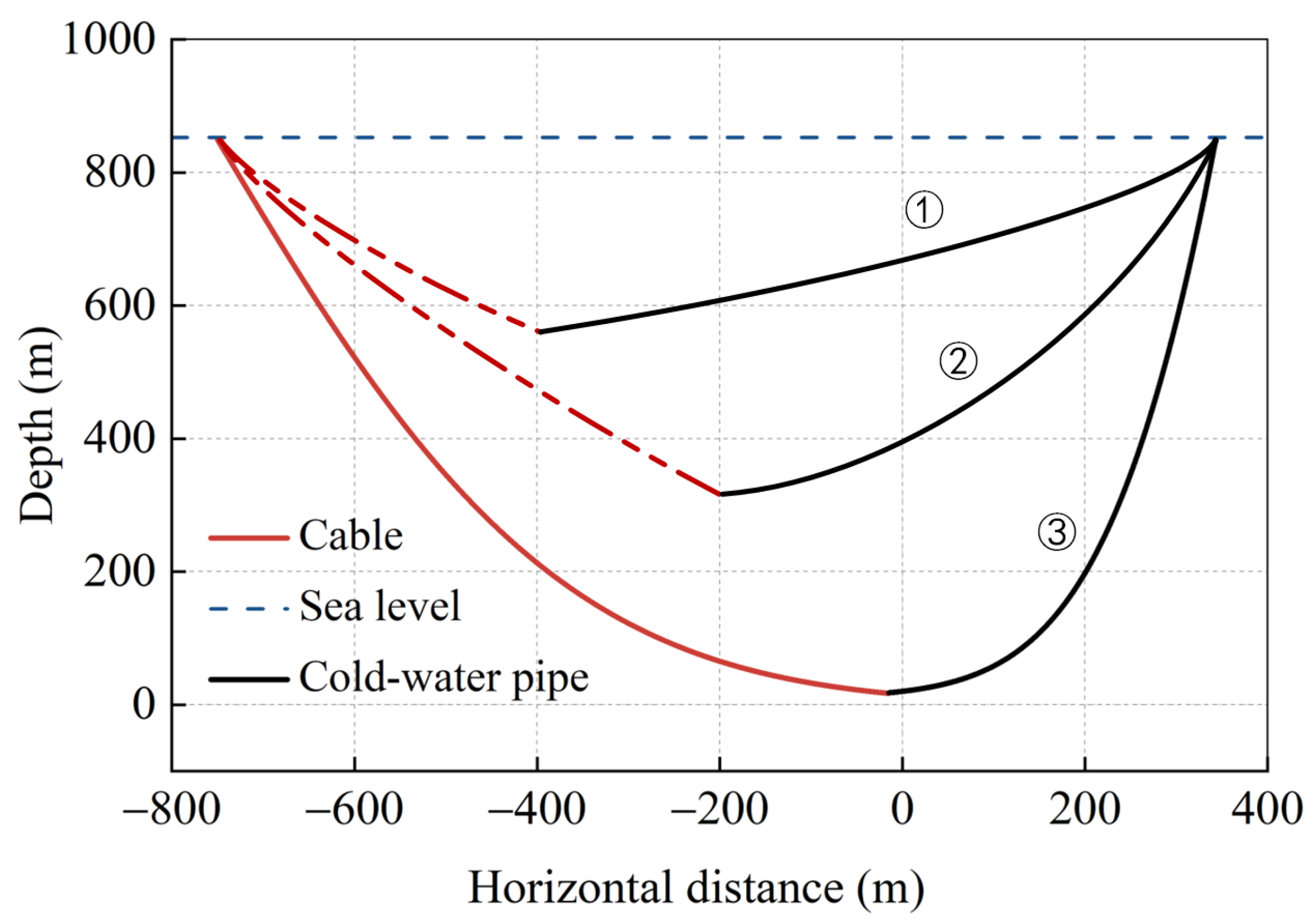

4.1. Influence of Laying Depth on Pipeline Form

4.2. Parameter Analysis

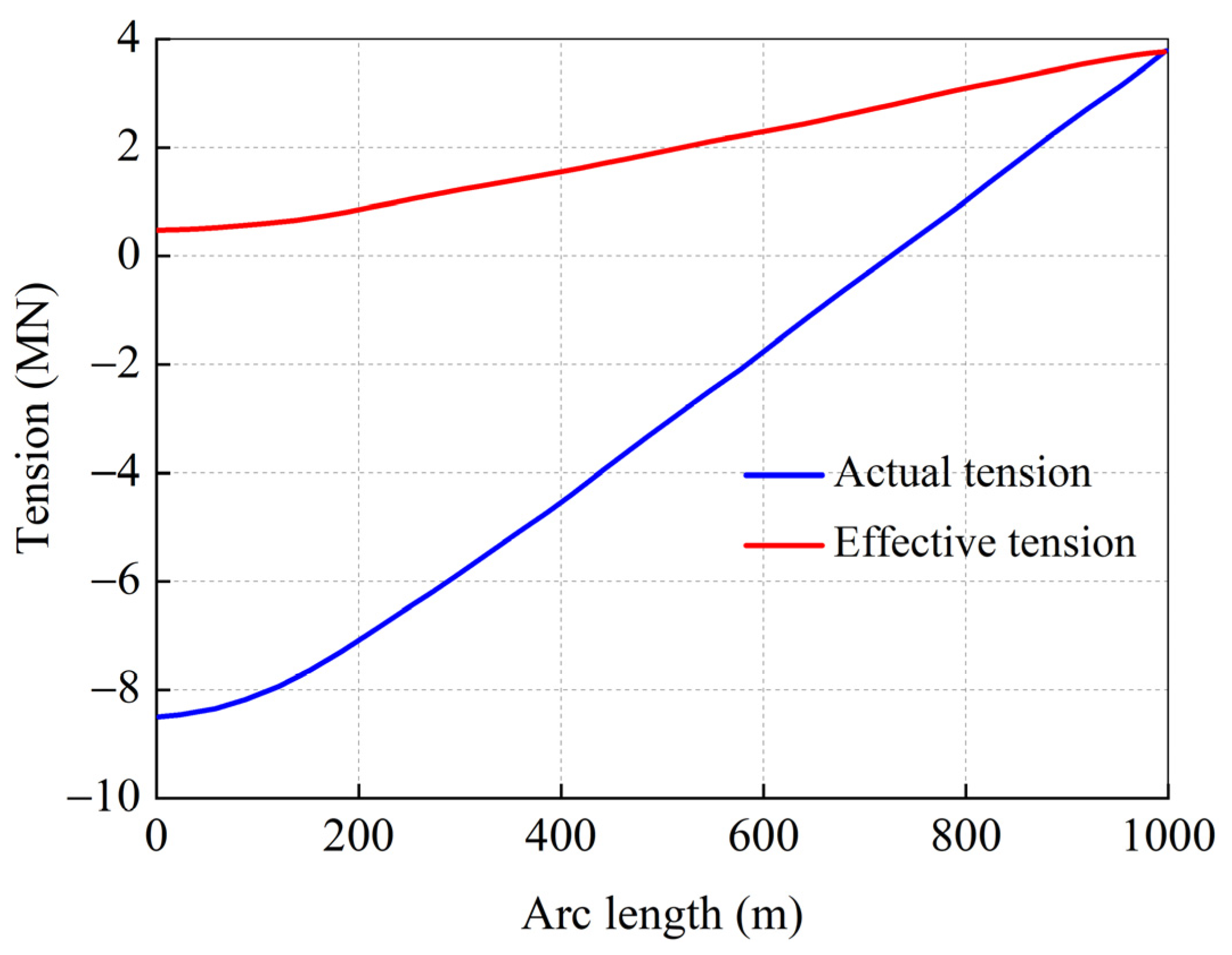

4.2.1. Effect of Pipe Arc Length Tension

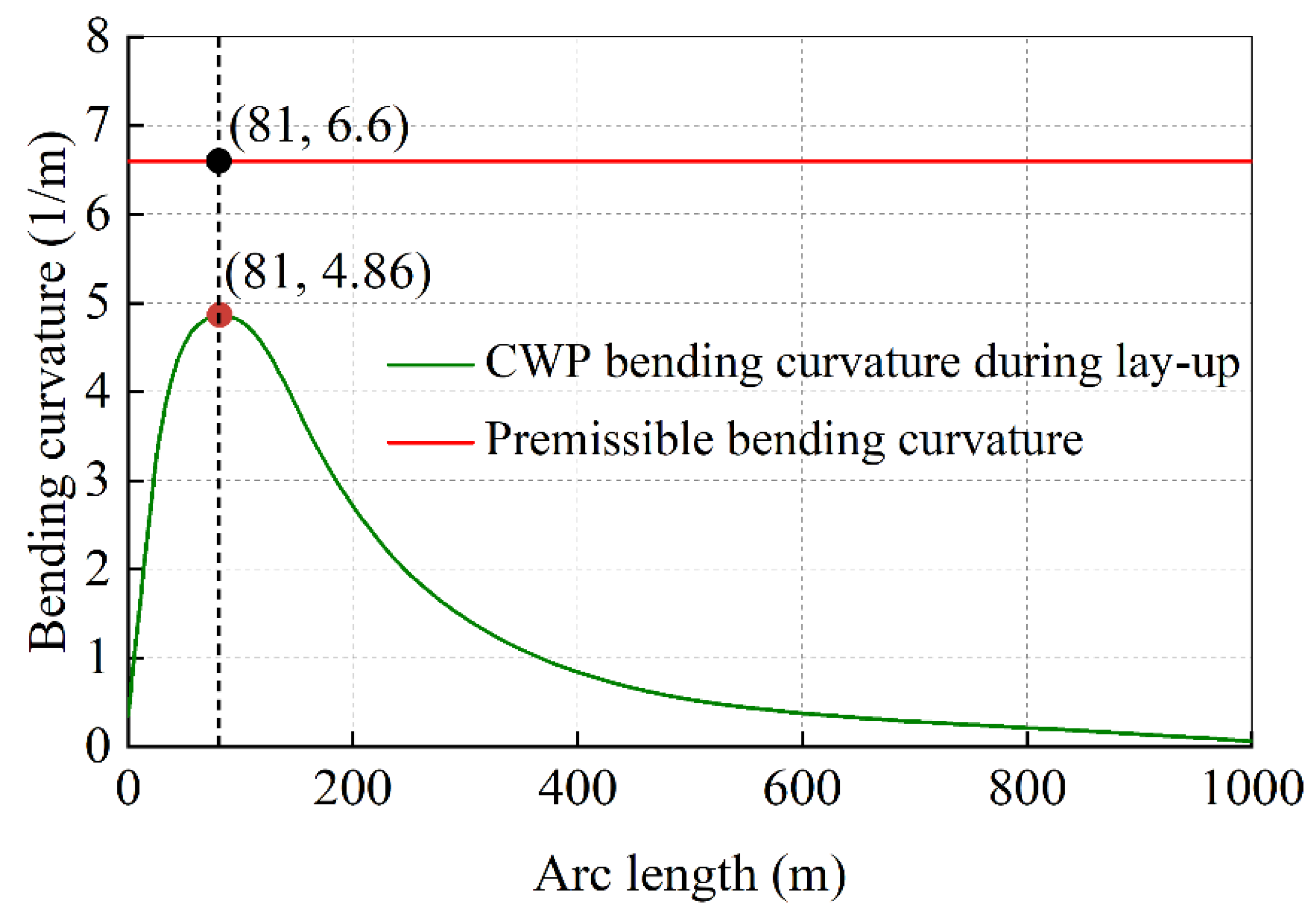

4.2.2. Effect of Pipe Arc Length on the Curvature

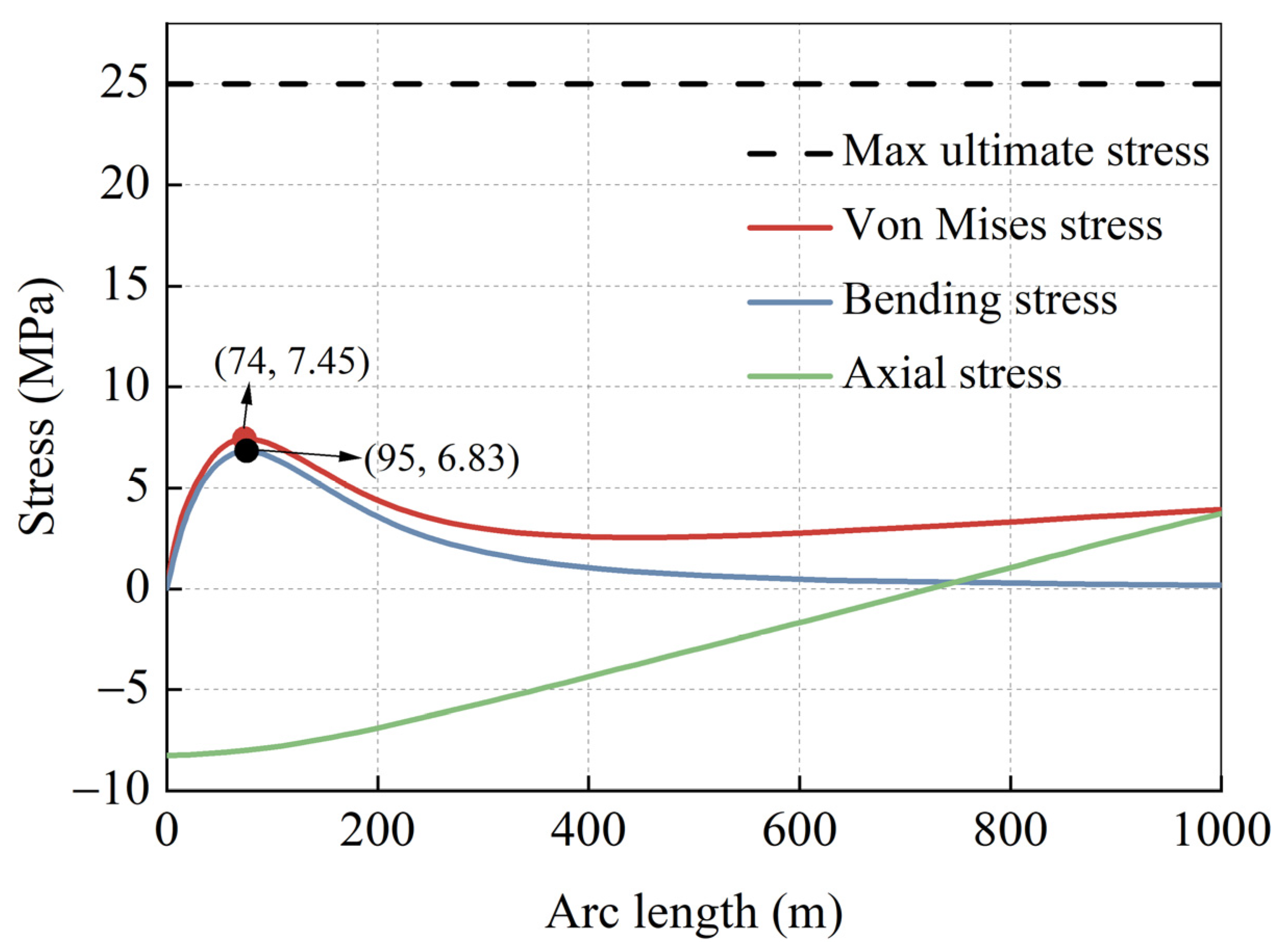

4.2.3. Effect of Pipe Arc Length on Stress

5. Conclusions

- (1)

- A novel semi-analytical solution had been developed for the nonlinear differential Equation of the cold-water pipe, which can accurately and efficiently capture the pipeline form and stress state during the installation process. The solution has been validated by comparing it with numerical simulations using OrcaFlex software, showing good agreement and reasonable differences.

- (2)

- The laying depth significantly impacts the final form of the pipeline, which transitions from gentle to increasingly bent, exhibiting significant bending near the bottom of the pipeline. This confirms the likelihood of substantial deformation of large-diameter cold water pipes during the installation process and suggests the need for careful monitoring and control of the laying depth.

- (3)

- The pipeline’s arc length substantially influences the pipeline’s tension, curvature, bending moment, and stress. We have found that the bending curvature, Von Mises stress, and bending stress of the pipeline all first increase and then decrease as the arc length of the pipeline increases, peaking at about 80 m along the pipeline. We have also found that both actual and axial tension decrease and then increase with the increase in the pipeline arc length. These findings indicate that special attention should be given to the section of the pipeline at 50~100 m during the actual installation process to ensure the safe and smooth installation of the pipeline.

- (4)

- This study has some limitations that should be acknowledged and addressed in future research. First, we have assumed that the cold-water pipe is a uniform beam with constant cross-section and material properties, which may not be realistic for practical applications. Second, we have neglected some external load conditions such as wave-induced forces, soil-pipe interaction, and thermal effects, which may have significant effects on the dynamic behavior of the cold-water pipe. Third, we have only considered one installation method (the float-and-sink method), which may not be suitable for all scenarios and environments. Future research should aim to relax these assumptions and incorporate more realistic factors into the theoretical model, as well as explore other installation methods such as J-lay or S-lay.

- (5)

- The findings of this study provide valuable insights for practical cold-water pipe installation and laying, as well as for theoretical analysis and numerical simulation of large-diameter marine risers. The proposed semi-analytical solution can serve as a useful tool for designing and optimizing cold-water pipe systems for ocean thermal energy conversion projects. The results can also help to identify the critical parameters and regions that affect the mechanical performance of cold-water pipes and to develop effective strategies for mitigating potential risks and challenges during installation and operation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adiputra, R.; Utsunomiya, T. Stability based approach to design cold-water pipe (CWP) for ocean thermal energy conversion (OTEC). Appl. Ocean Res. 2019, 92, 101921. [Google Scholar] [CrossRef]

- Li, Z.; Wang, C.; He, N.; Zhao, D.Y. An Overview of Deepwater Pipeline Laying Technology. China Ocean Eng. 2008, 22, 521–532. [Google Scholar]

- Zan, Y.; Yuan, L.; Huang, K.; Ding, S.; Wu, Z. Numerical Simulations of Dynamic Pipeline-Vessel Response on a Deepwater S-Laying Vessel. Processes 2018, 6, 261. [Google Scholar] [CrossRef]

- Keesmaat, K. Installation Limits of Large Diameter Cold Water Pipes in Deep Water for Land-Based OTEC Plants; TU Delft: Delft, The Netherlands, 2015. [Google Scholar]

- Miroslav, S. (Pipe-Life) Email Conversation with Pipe-Life; Large Diameter OTEC Pipe Installation Thesis Bluerise. 2015. [Google Scholar]

- Senthil, B.; Selvam, R.P. Dynamic Analysis of a J-lay Pipeline. Procedia Eng. 2015, 116, 730–737. [Google Scholar] [CrossRef]

- Konuk, I. Higher Order Approximations in Stress Analysis of Submarine Pipelines. J. Energy Resour. Technol. 1980, 102, 190–196. [Google Scholar] [CrossRef]

- Lenci, S.; Callegari, M. Simple analytical models for the J-lay problem. Acta Mechanica 2005, 178, 23–39. [Google Scholar] [CrossRef]

- Brown, R.J.; Palmer, A. Developing Innovative Deep Water Pipeline Construction Techniques with Physical Models. J. Offshore Mech. Arct. Eng. 2004, 129, 56–60. [Google Scholar] [CrossRef]

- Gong, S.; Chen, K.; Chen, Y.; Jin, W.; Li, Z.; Zhao, D. Configuration analysis of deepwater S-lay pipeline. China Ocean Eng. 2011, 25, 519–530. [Google Scholar] [CrossRef]

- Winget, J.M.; Huston, R.L. Cable dynamics—A finite segment approach. Comput. Struct. 1976, 6, 475–480. [Google Scholar]

- Santillan, S.T.; Virgin, L.N. Numerical and experimental analysis of the static behavior of highly deformed risers. Ocean Eng. 2011, 38, 1397–1402. [Google Scholar] [CrossRef]

- Wang, L.; Ju, M.; Xing, X.; Yun, F.; Wang, X. Dynamic Behavior of the Deepwater Flexible Pipeline during Pipe Laying Process. J. Mar. Sci. Eng. 2020, 8, 286. [Google Scholar] [CrossRef]

- Xu, P.; Du, Z.; Gong, S. Numerical Investigation into Freak Wave Effects on Deepwater Pipeline Installation. J. Mar. Sci. Eng. 2020, 8, 119. [Google Scholar] [CrossRef]

- Ghafouri, M.; Ghassabi, M.; Zarastvand, M.R.; Talebitooti, R. Sound propagation of three-dimensional sandwich panels: Influence of three-dimensional re-entrant auxetic core. AIAA J. 2022, 60, 6374–6384. [Google Scholar] [CrossRef]

- Zarastvand, M.R.; Asadijafari, M.H.; Talebitooti, R. Acoustic wave transmission characteristics of stiffened composite shell systems with double curvature. Compos. Struct. 2022, 292, 115688. [Google Scholar] [CrossRef]

- Alanazi, M.J.; Qinghua, Y.; Al-Bukhaiti, K. Performance Study of Buried Pipelines under Static Loads. Civ. Eng. J. 2022, 8, 1–23. [Google Scholar] [CrossRef]

- Yamini, O.A.; Movahedi, A.; Mousavi, S.H.; Kavianpour, M.R.; Kyriakopoulos, G.L. Hydraulic Performance of Seawater Intake System Using CFD Modeling. J. Mar. Sci. Eng. 2022, 10, 988. [Google Scholar] [CrossRef]

- Nogmov, M.K.; Lianov, I.M.; Lysenko, V.R.; Dmitrichenko, N.V. Development of a Flow-Measuring Hydropneumatic Bench for Testing Pipeline Valves. Civ. Eng. J. 2023, 9, 166–182. [Google Scholar] [CrossRef]

- Fraenkel, L.E. Perturbation Methods; Academic Press: Cambridge, MA, USA, 1980. [Google Scholar]

- Lange, C.G.; Miura, R.M. Singular perturbation analysis of boundary value problems for differential-difference equations. V. Small shifts with layer behavior. SIAM J. Appl. Math. 1994, 54, 249–272. [Google Scholar] [CrossRef]

| Parameters | Description |

|---|---|

| L | Pipe length |

| EI | Pipe bending stiffness |

| Qcw | Pipeline cold seawater flow rate |

| LTOP | The horizontal distance between tug and OTEC |

| H | Laying water depth |

| Sr | Cable arc length |

| The angle between CWP and the horizontal plane | |

| The curvature of the bend along the CWP pipeline | |

| Surf | Cable extension arc length |

| Cold seawater flow rate | |

| ac | Cable section suspension chain line scale factor |

| Gravity per unit length of cable | |

| T | The tensioning force of the pipe |

| LP | The horizontal projection of CWP |

| Lr | Horizontal projection of the cable |

| Vr | Vertical projection of the cable |

| Vp | Vertical projection of CWP |

| DS | Equivalent single-layer pipe outer diameter |

| Unknown | Description |

|---|---|

| Angle between CWP and horizontal plane | |

| Bending curvature along the CWP line | |

| Cable arc length | |

| Cable extension arc length |

| Parameter | Values |

|---|---|

| Pipe length (m) | 1000 |

| Pipe outside diameter (m) | 1.564 |

| Pipe inner diameter (m) | 1.5 |

| Unit length dry weight (kg/m) | 235 |

| Pipe density (kg/m3) | 960 |

| Modulus of elasticity (Gpa) | 0.9 |

| Wave height (m) | 4.8 |

| Wave phase angle (o) | 180 |

| Water depth (m) | 1200 |

| Seawater density (kg/m3) | 1025 |

| Wave period (s) | 7.8 |

| Sea surface current velocity (m/s) | 0.99 |

| Sea current subsea current velocity (m/s) | 0 |

| Ship—platform maximum distance (m) | 2250 |

| Ship movement speed (m/s) | 3.5 |

| Cable length (m) | 1250 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Zheng, M.; Zhang, L.; Mao, Z.; Tan, J.; Zhang, Y.; Duan, M. Effects of Laying Depth and Pipe Arc Length on the Mechanical Performance of Large-Diameter Cold-Water Pipes during Float-and-Sink Installation. J. Mar. Sci. Eng. 2023, 11, 1520. https://doi.org/10.3390/jmse11081520

Wang D, Zheng M, Zhang L, Mao Z, Tan J, Zhang Y, Duan M. Effects of Laying Depth and Pipe Arc Length on the Mechanical Performance of Large-Diameter Cold-Water Pipes during Float-and-Sink Installation. Journal of Marine Science and Engineering. 2023; 11(8):1520. https://doi.org/10.3390/jmse11081520

Chicago/Turabian StyleWang, Dongshi, Miaozi Zheng, Li Zhang, Zhenyu Mao, Jian Tan, Yulong Zhang, and Menglan Duan. 2023. "Effects of Laying Depth and Pipe Arc Length on the Mechanical Performance of Large-Diameter Cold-Water Pipes during Float-and-Sink Installation" Journal of Marine Science and Engineering 11, no. 8: 1520. https://doi.org/10.3390/jmse11081520

APA StyleWang, D., Zheng, M., Zhang, L., Mao, Z., Tan, J., Zhang, Y., & Duan, M. (2023). Effects of Laying Depth and Pipe Arc Length on the Mechanical Performance of Large-Diameter Cold-Water Pipes during Float-and-Sink Installation. Journal of Marine Science and Engineering, 11(8), 1520. https://doi.org/10.3390/jmse11081520