Production Behavior of Hydrate-Bearing Sediments with Mixed Fracture- and Pore-Filling Hydrates

Abstract

1. Introduction

2. Model Setup

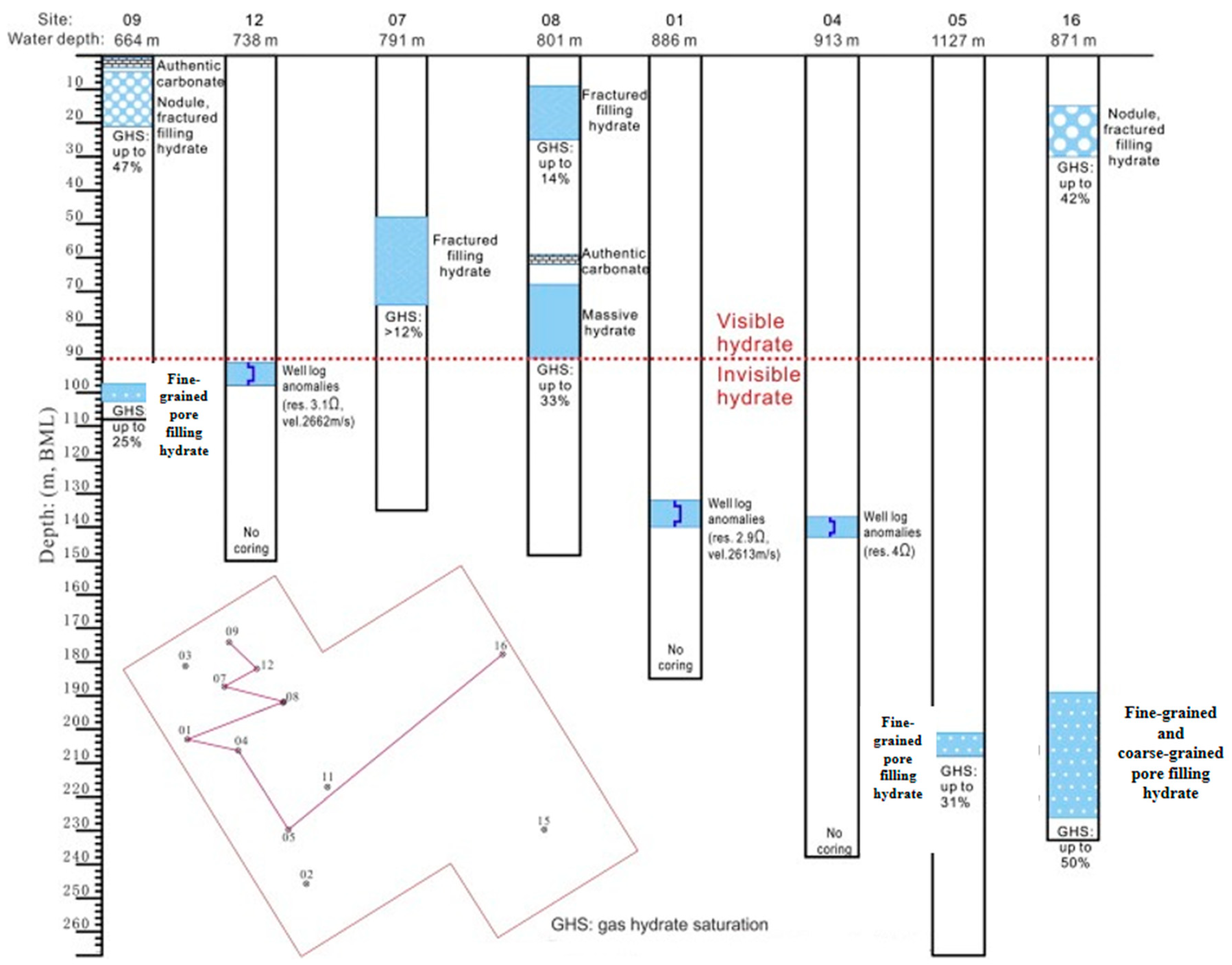

2.1. Geological Background in the Research Area

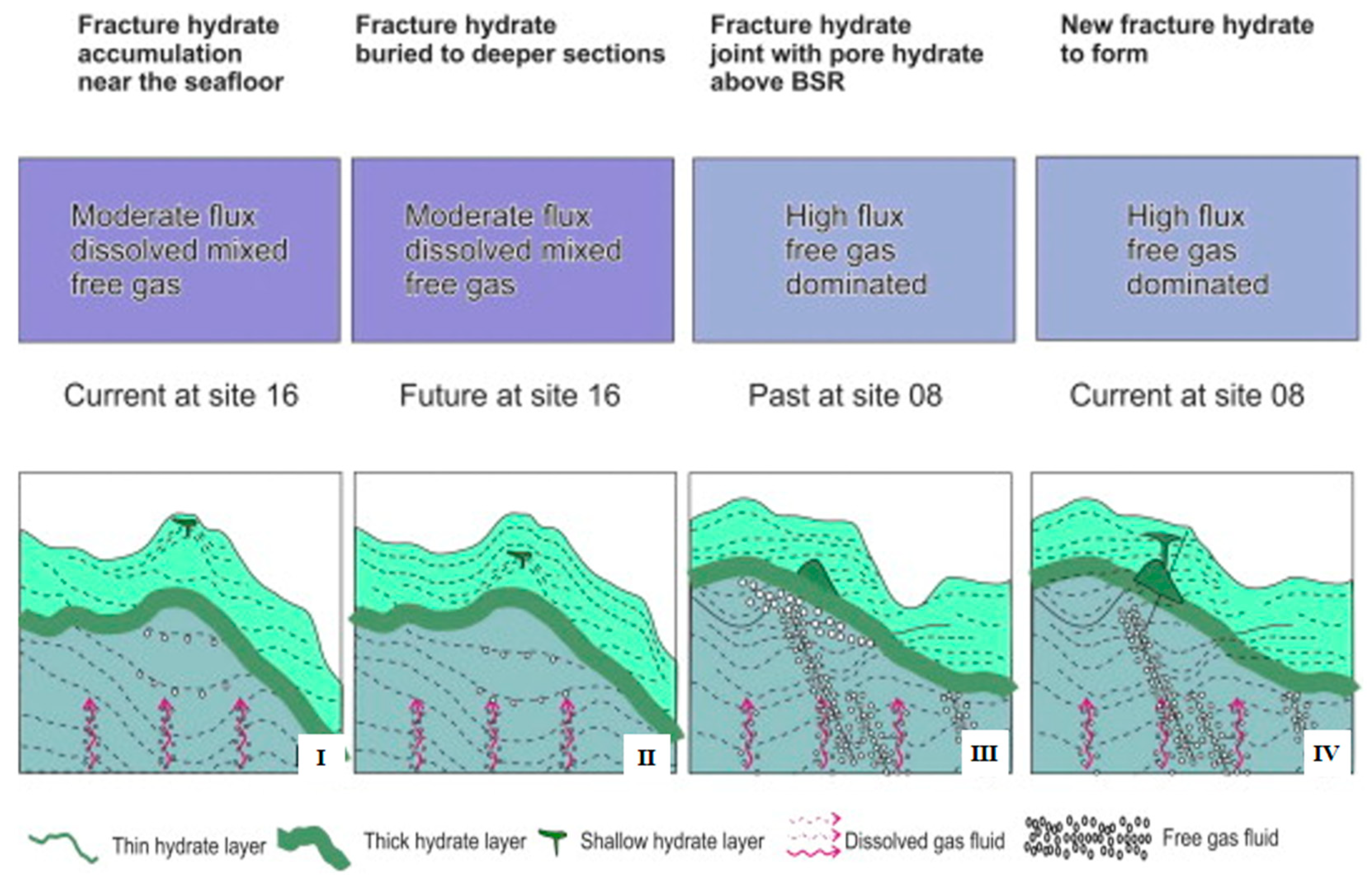

2.2. Formation and Development of Mixed-Type Hydrates in HBS

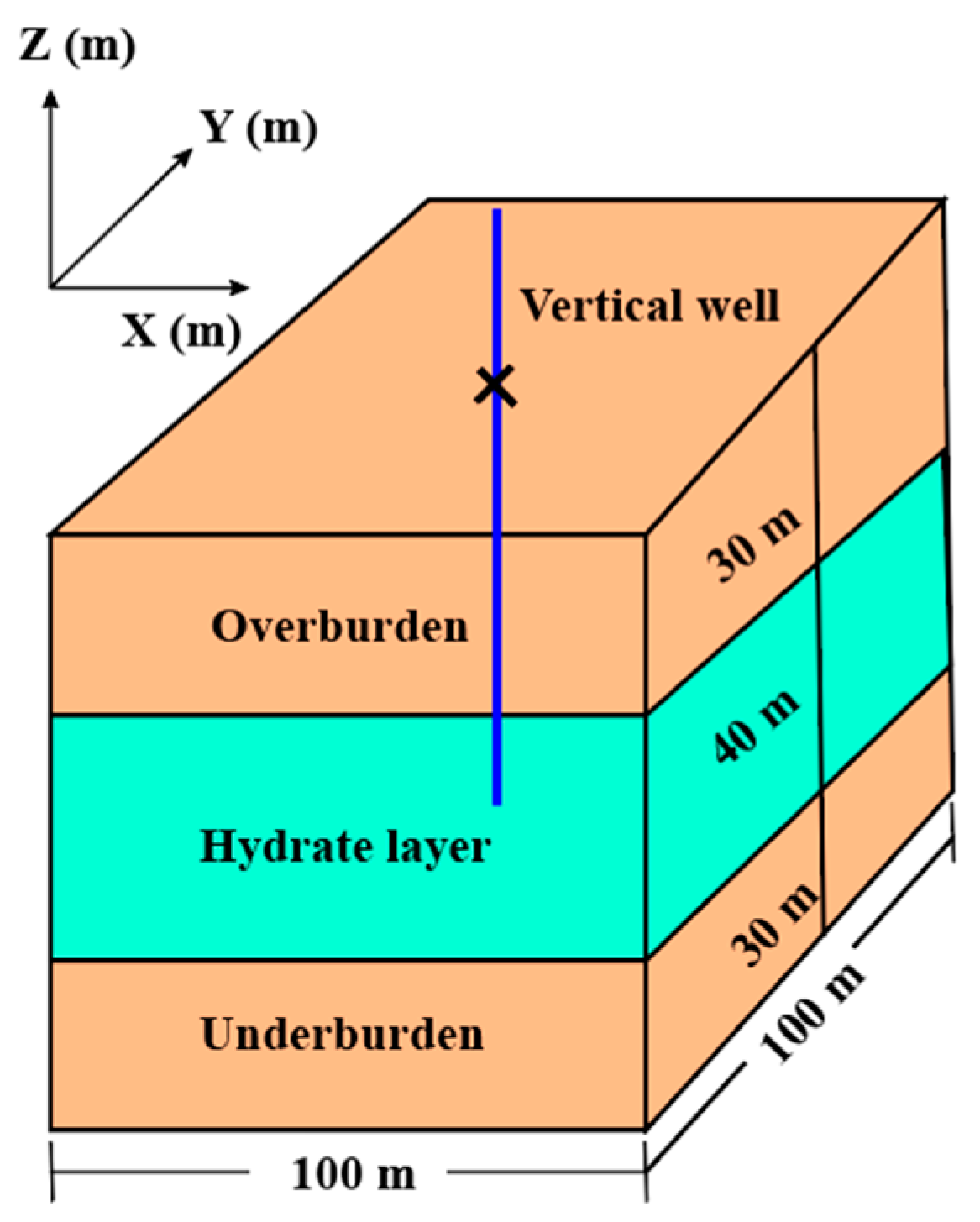

2.3. Model Geometry and Spatial Discretization

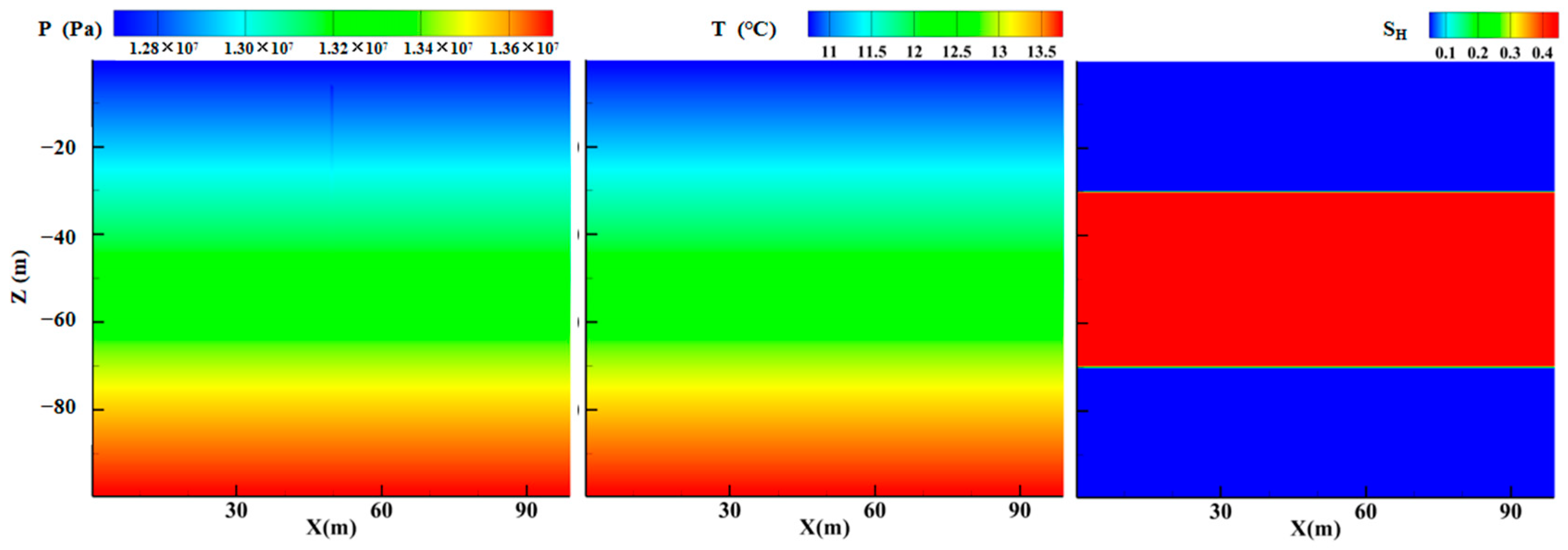

2.4. Initial and Boundary Conditions

2.5. Numerical Simulation Code

3. Results and Analysis

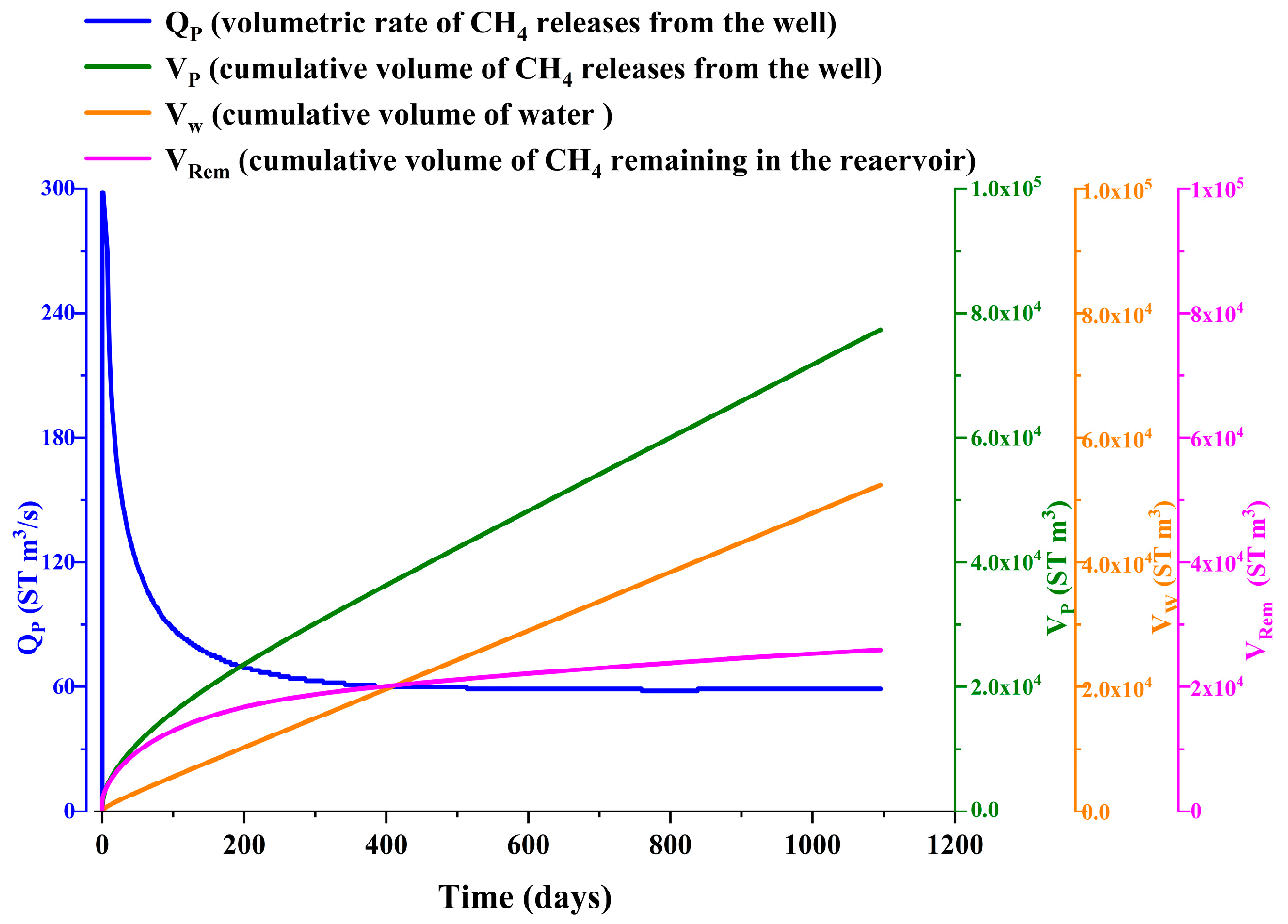

3.1. Production Behaviors of the HBS with Pore-Filling Hydrate Only

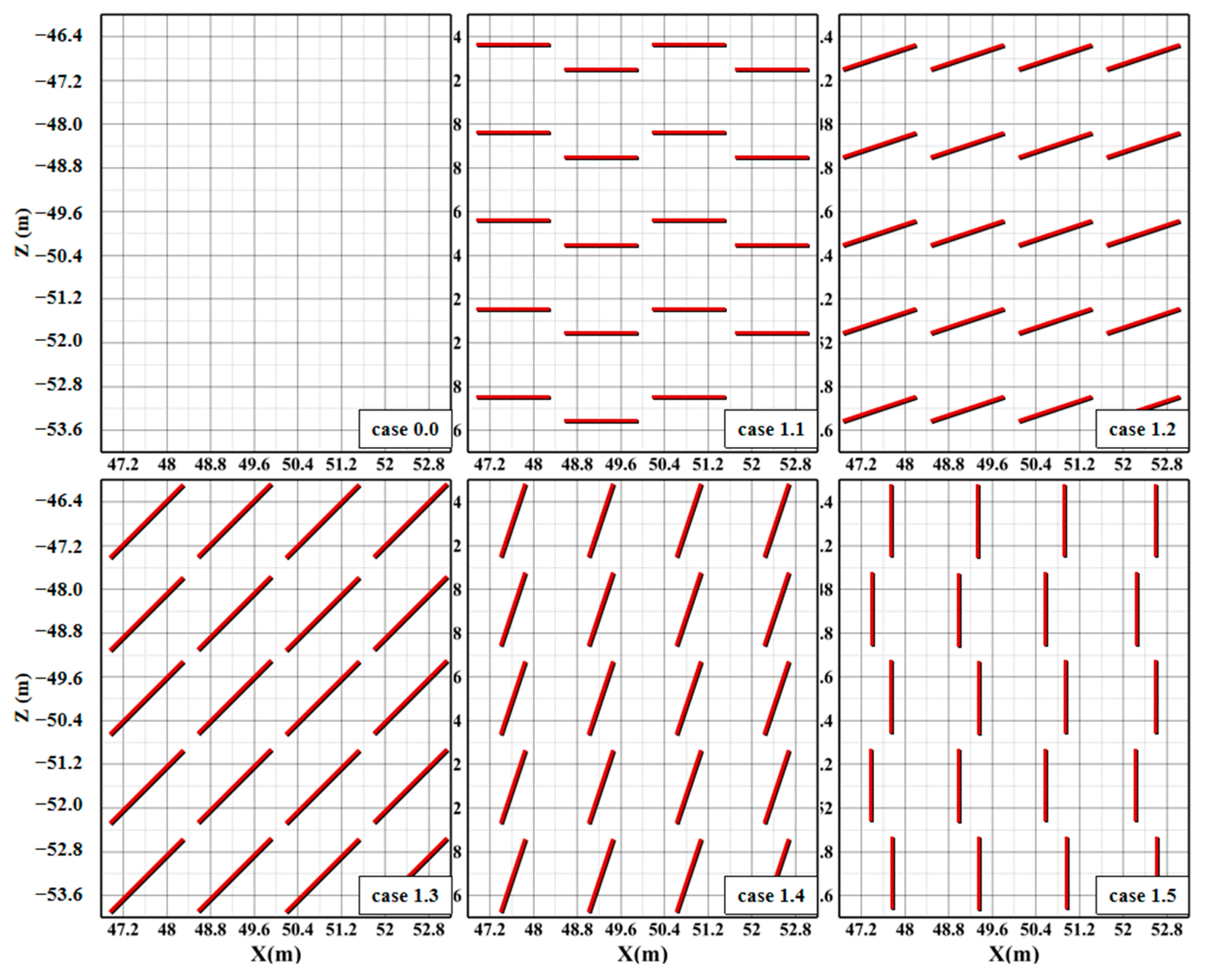

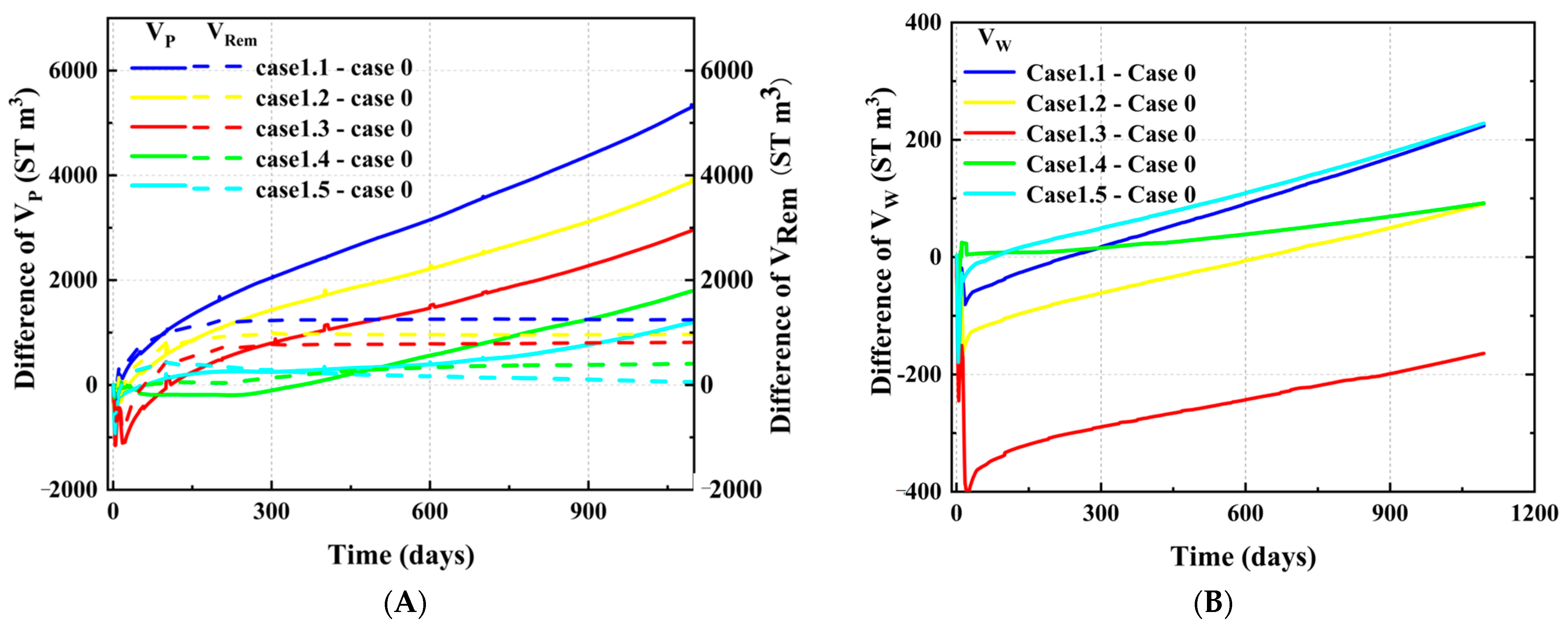

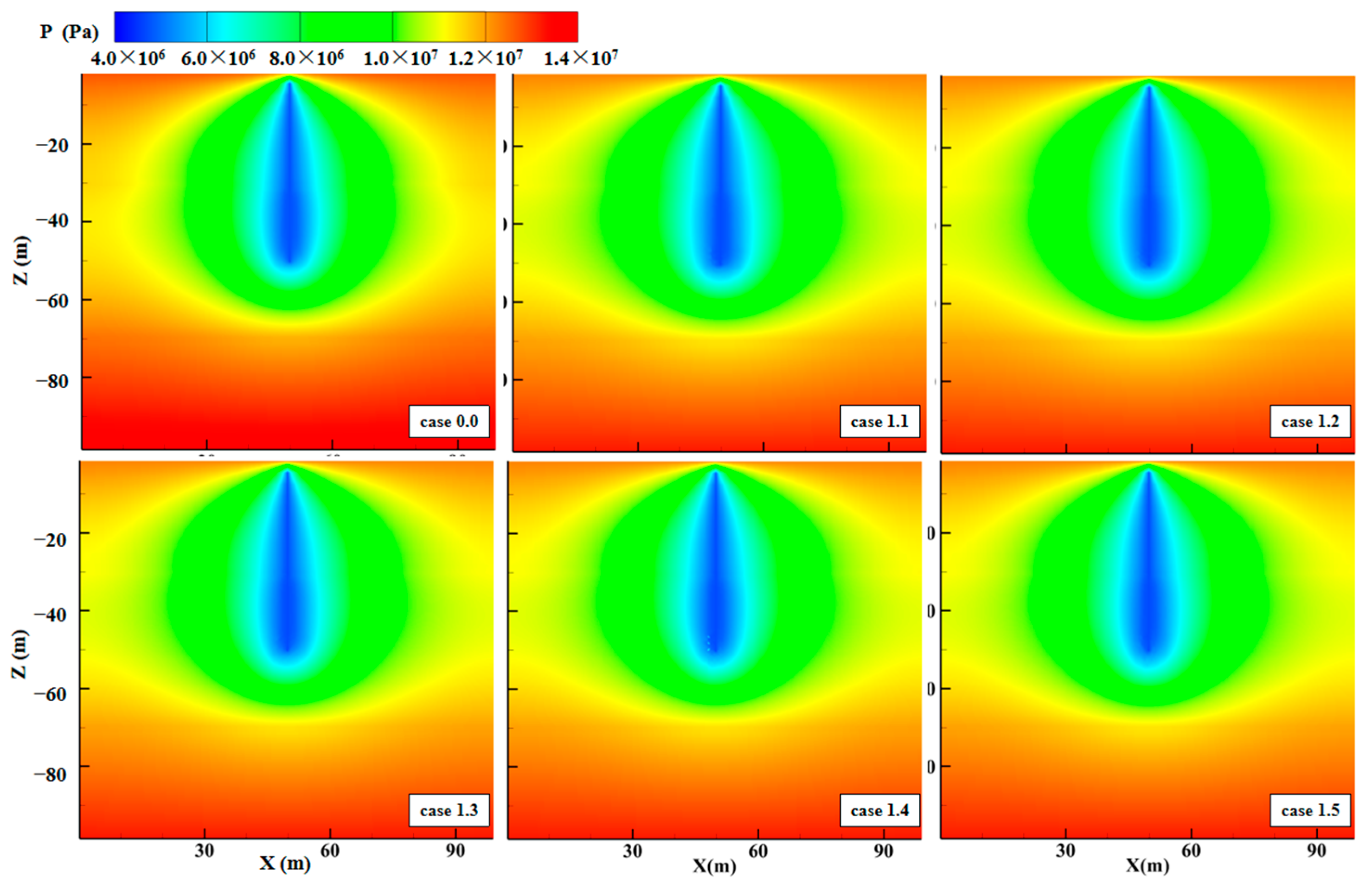

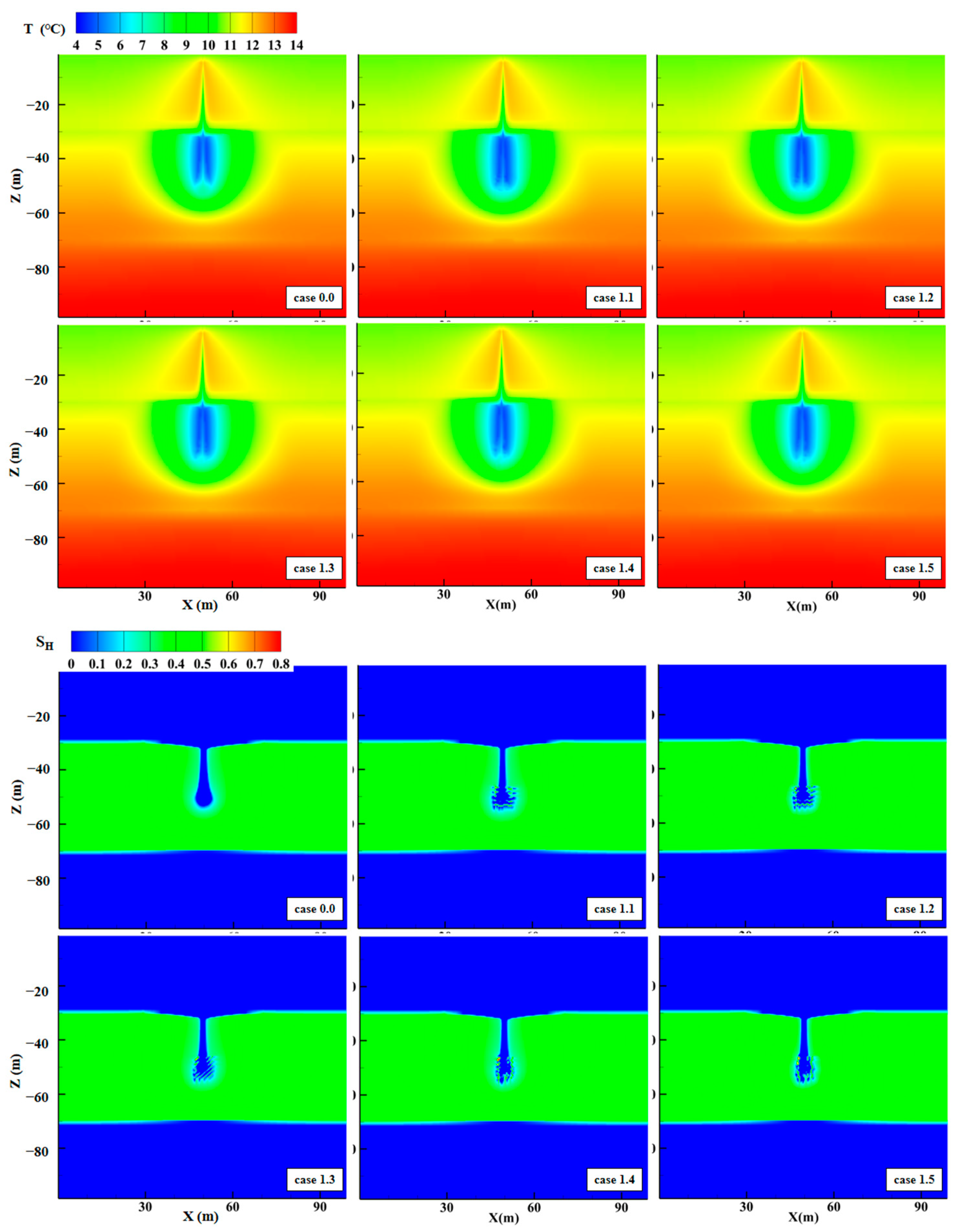

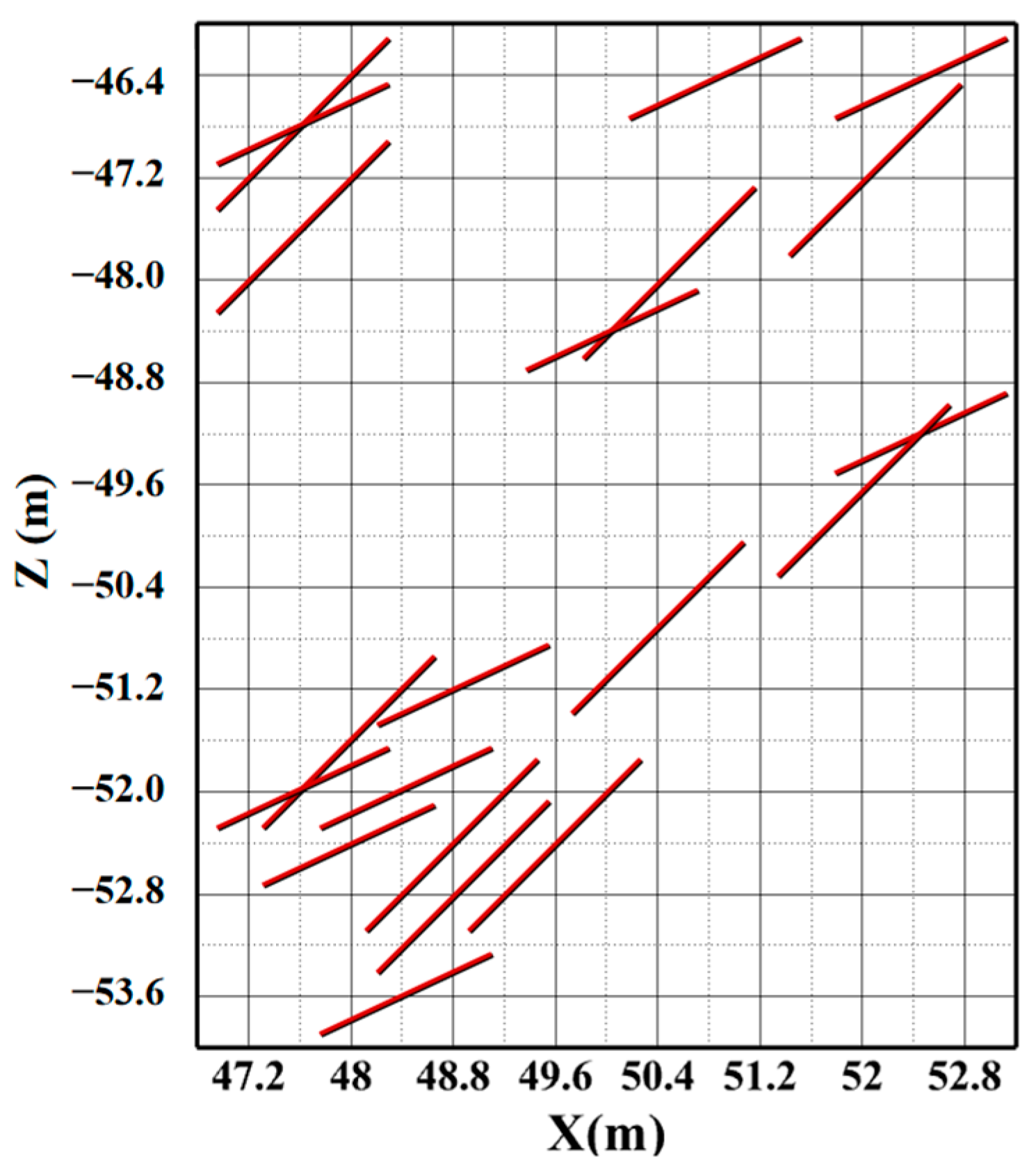

3.2. Impact of Fracture-Filling Hydrate on HBS Production

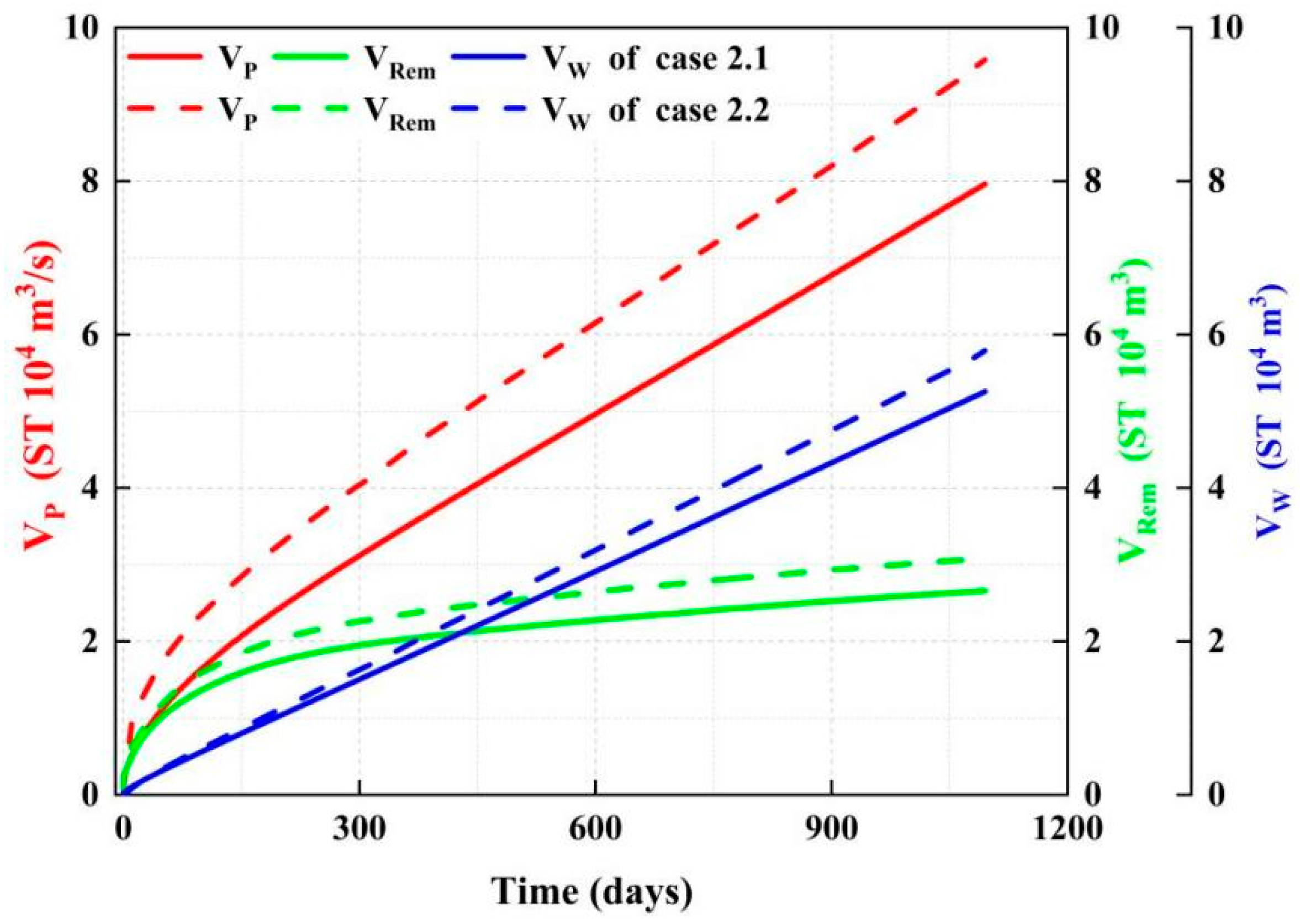

3.3. Optimization of Depressurization Production in HBSs with Mixed Fracture- and Pore-Filling Hydrates

4. Conclusions

- Due to the combined influence of temperature and pressure, gas source, the migration of gas-bearing fluid, and reservoir conditions, the fracture-filling hydrates formed in shallow fine-grained sediments and gradually migrated towards the pore-filling hydrate occurrence area. Finally, a stable occurrence area formed, containing both fracture- and pore-filling hydrates.

- The occurrence of fracture-filling hydrates could promote HBS production, compared with that containing pore-filling hydrates only. With the increase in the fracture dipping angle (cases 1.1–1.5), the gas productivity changed by +6.5%, +4.9%, +4.2%, +2.1%, and +1.3%, respectively. Therefore, the smaller the dipping angle of the fracture, the greater the promotion degree to the HBS production.

- During depressurization of the HBS with mixed pore- and fracture-filling hydrates, the problem of the low regional temperature and the formation of secondary hydrate caused by fracture-filling hydrate decomposition was significant, and the proper injection of hot water could solve these problems, promoting the depressurization production of HBS. Using the numerical simulation in this study, the gas productivity increased by 20.3% after using the heat-injection method to assist depressurization production.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, J.; Zhong, C.; Yao, Y.; Yan, P.; Wang, Y.; Wan, Z.; Guan, J.; Zhang, J. Progress and prospect of gas hydrate exploration and exploration in the northern South China Sea. Mar. Geol. Front. 2020, 36, 1–14. [Google Scholar] [CrossRef]

- Ning, F.; Liang, J.; Wu, N.; Zhu, Y.; Wu, S.; Liu, C.; Wei, C.; Wang, D.; Zhang, Z.; Xu, M.; et al. Reservoir characters of natural gas hydrates in China. Nat. Gas Ind. 2020, 40, 1–24. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Y.; Guo, X.; Wei, R.; Yu, T.; Xu, L.; Sun, L.; Yang, L. Gas production behavior from hydrate-bearing fine natural sediments through optimized step-wise depressurization. Appl. Energy 2020, 260, 114275. [Google Scholar] [CrossRef]

- Fan, D.; Li, F.; Wang, Z.; Miao, Q.; Bai, Y.; Liu, Q. Development status and prospects of China’s energy minerals under the target of carbon peak and carbon neutrality. China Min. Mag. 2021, 30, 1–8. [Google Scholar]

- Cheng, F.; Wu, Z.; Sun, X.; Shen, S.; Wu, P.; Liu, W.; Chen, B.; Liu, X.; Li, Y. Compression-induced dynamic change in effective permeability of hydrate-bearing sediments during hydrate dissociation by depressurization. Energy 2023, 264, 126137. [Google Scholar] [CrossRef]

- Li, J.; Ye, J.; Qin, X.; Qiu, H.; Wu, N.; Lu, H.; Xie, W.; Lu, J.; Peng, F.; Xu, Z.; et al. The first offshore natural gas hydrate production test in the South China Sea. China Geol. 2018, 1, 5–16. [Google Scholar] [CrossRef]

- Wang, H.; Wu, P.; Li, Y.; Liu, W.; Pan, X.; Li, Q.; He, Y.; Song, Y. Gas permeability variation during methane hydrate dissociation by depressurization in marine sediments. Energy 2022, 263, 125749. [Google Scholar] [CrossRef]

- Zhou, S.; Li, Q.; Lv, X.; Pang, W.; Fu, Q. Thinking and suggestions on research direction of natural gas hydrate development. China Offshore Oil Gas 2019, 31, 1–8. [Google Scholar] [CrossRef]

- Lu, J.; Lin, D.; Li, D.; Liang, D.; Zhang, Y.; Wu, S.; He, Y.; Shi, L. Research status on water controllina and sand controllina in horizontal well completion durina gas hydrate exploitation. Adv. New Renew. Energy 2022, 10, 447–455. [Google Scholar]

- Wu, P.; Li, Y.; Wang, L.; Sun, X.; Wu, D.; He, Y.; Li, Q.; Song, Y. Hydrate-bearing sediment of the South China Sea: Microstructure and mechanical characteristics. Eng. Geol. 2022, 307, 106782. [Google Scholar] [CrossRef]

- Zhang, G.; Liang, J.; Lu, J.; Yang, S.; Zhang, M.; Su, X.; Xu, H.; Fu, S.; Kuang, Z. Characteristics of natural gas hydrate reservoir on the northeastern slope of the South China Sea. Nat. Gas Ind. 2014, 34, 1–10. [Google Scholar] [CrossRef]

- Uddin, M.; Wright, F.; Dallimore, S.; Coombe, D. Gas hydrate dissociation in Mallik hydrate bearing zone A, B, and C by depressurization: Effect of salinity and hydration number in hydrate dissociation. J. Nat. Gas Sci. Eng. 2014, 21, 40–63. [Google Scholar] [CrossRef]

- Zhu, H. Numerical Study on Sand Production Processes during Natural Gas Hydrate Recovery and Its Impact on Gas Production. Ph.D. Thesis, Jilin University, Changchun, China, 2021. [Google Scholar]

- Yang, C.; Liu, J.; Yang, R.; Hu, X.; Yao, Y.; Wang, Z.; Li, X. Occurrence and resource potential of gas hydrate in the Alaska north slope basin of the Arctic. Chin. J. Polar Res. 2019, 31, 309–321. [Google Scholar] [CrossRef]

- Sha, Z.; Xu, Z.; Wang, P.; Liang, J.; Wan, X.; Wan, L.; Su, P. World progress in gas hydrate research and its enlightenment to accelerating industrialization in China. Mar. Geol. Front. 2019, 35, 1–10. [Google Scholar] [CrossRef]

- Li, Y.; Xin, X.; Xu, T.; Zhu, H.; Wang, H.; Chen, Q.; Yang, B. Comparative analysis on the evolution of seepage parameters in methane hydrate production under depressurization of clayey silt reservoir and sandy reservoir. J. Mar. Sci. Eng. 2022, 10, 653. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Y.; Fang, H.; Lu, Z.; Pang, S.; Zhang, S.; Xiao, R. Main progress of investigation and test production of natural gas hydrate in permafrost of China. Geol. Surv. China 2020, 7, 1–9. [Google Scholar] [CrossRef]

- Kuang, D.; He, B.; Wang, D. Logging evaluation of gas hydrate at leg 204 of ODP in hydrate ridge. Sci. Technol. Inf. 2013, 17, 1–2. [Google Scholar] [CrossRef]

- Zhao, E.; Hou, J.; Du, Q.; Liu, Y.; Ji, Y.; Bai, Y. Numerical modeling of gas production from methane hydrate deposits using low-frequency electrical heating assisted depressurization method. Fuel 2021, 290, 120075. [Google Scholar] [CrossRef]

- Wang, J.; Wu, S.; Yao, Y.; Li, B. Advances in geophysical research on gas hydrate reservoirs on the east continental margin of India. J. Trop. Oceanogr. 2017, 6, 90–99. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, W.; Liang, J.; Shang, J.; Meng, M.; Shan, C. Comparative study of gas hydrate accumulation system in the Qiongdongnan Basin of the South China Sea and the Ulleung Basin of Korea. J. China Univ. Min. Technol. 2021, 50, 363–380. [Google Scholar]

- Bei, K.; Xu, T.; Shang, S.; Wei, Z.; Yuan, Y.; Tian, H. Numerical modeling of gas migration and hydrate formation in heterogeneous marine sediments. J. Mar. Sci. Eng. 2019, 7, 348. [Google Scholar] [CrossRef]

- Zhao, K.; Sun, C.; Guo, J.; Wu, C. Enrichment characteristics and accumulation mechanism of natural gas hydrate in the Gulf of Mexico: Cases study of study area WR313 and GC955. Reserv. Eval. Dev. 2021, 11, 669–679. [Google Scholar] [CrossRef]

- Yu, T.; Guan, G.; Abudula, A.; Yoshida, A.; Wang, D.; Song, Y. Application of horizontal wells to the oceanic methane hydrate production in the Nankai Trough, Japan. J. Nat. Gas Sci. Eng. 2019, 62, 113–131. [Google Scholar] [CrossRef]

- Yin, Z.; Wan, Q.; Gao, Q.; Linga, P. Effect of pressure drawdown rate on the fluid production behavior from methane hydrate-bearing sediments. Appl. Energy 2020, 271, 115195. [Google Scholar] [CrossRef]

- Rita, G.; Alberto, G.; Andrea, R.; Beatrice, C.; Marco, M.; Marco, Z.; Andrea, N.; Federico, R. Thermodynamic assessment and microscale Raman spectroscopy of binary CO2/CH4 hydrates produced during replacement applications in natural reservoirs. J. Mol. Liq. 2022, 368, 120739. [Google Scholar] [CrossRef]

- Alberto, G.; Li, Y.; Federico, R. Influence of different proportion of CO2/N2 binary gas mixture on methane recovery through replacement processes in natural gas hydrates. Chem. Eng. Process. 2022, 175, 108932. [Google Scholar] [CrossRef]

- Wang, X.; Sain, K.; Satyavani, K.; Wang, J.; Ojha, M.; Wu, S. Gas hydrates saturation using geostatistical inversion in a fractured reservoir in the Krishna-Godavari basin, offshore eastern India. Mar. Pet. Geol. 2013, 45, 224–235. [Google Scholar] [CrossRef]

- Cai, J.; Xia, Y.; Xu, S.; Tian, H. Advances in multiphase seepage characteristics of natural gas hydrate sediments. Chin. J. Theor. Appl. Mech. 2020, 52, 208–223. [Google Scholar] [CrossRef]

- Zhu, H.; Xu, T.; Yuan, Y.; Xia, Y.; Xin, X. Numerical investigation of natural gas hydrate production tests in the Nankai Trough by incorporating sand migration. Appl. Energy 2020, 275, 115384. [Google Scholar] [CrossRef]

- Ghosh, R.; Ojha, M. Amount of gas hydrate estimated from rock physics analysis based on morphology and intrinsic anisotropy in area B, Krishna Godavari offshore basin, expedition NGHP-02. Mar. Pet. Geol. 2021, 124, 104856. [Google Scholar] [CrossRef]

- Yuan, Y. Numerical Simulation on Gas Production Potential and the Geomechanical Stability from Marine Natural Gas Hydrate through Depressurization. Ph.D. Thesis, Jilin University, Changchun, China, 2019. [Google Scholar]

- Xia, Y. Multi-scale joint study on dynamic evolution characteristics of reservoir seepage parameters during hydrate dissociation. Ph.D. Thesis, Jilin University, Changchun, China, 2022. [Google Scholar]

- Zhang, B.; Yu, Y.; Jin, K.; Wu, Q.; Gao, X.; Wu, Q.; Liu, C. Influence of depressurization amplitude and saturation in loose sediments on the dissociation process of natural gas hydrates. Nat. Gas Ind. 2020, 40, 133–140. [Google Scholar] [CrossRef]

- Peng, D.; Chen, C.; Pang, X.; Zhu, M.; Yang, F. Discovery of deep-water fan system in South China Sea. Acta Pet. Sin. 2004, 25, 17–23. [Google Scholar]

- Liang, J.; Zhang, G.; Lu, J.; Su, P.; Sha, Z.; Gong, Y.; Su, X. Accumulation characteristics and genetic models of natural gas hydrate reservoirs in the NE slope of the South China Sea. Nat. Gas Ind. 2016, 36, 157–162. [Google Scholar] [CrossRef]

- He, J.; Zhu, Y.; Wen, R.; Cui, S. Characters of north-west mud diapirs volcanoes in South China Sea and relationship between them and accumulation and migration of oil and gas. Earth Sci. 2010, 35, 75–86. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, J.; Cen, Y.; Su, P.; Lin, Q.; Liu, J. Authigenic minerals at site GMGS2-16 of northeastern South China Sea and its implications for gas hydrate evolution. Mar. Geol. Quat. Geol. 2018, 38, 144–155. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, J.; Stephen, C.; Liang, J.; Su, P.; Lin, Q.; Chen, C.; Liu, J. Non-evaporitic gypsum formed in marine sediments due to sulfate-methane transition zone fluctuations and mass transport deposits in the northern South China Sea. Mar. Chem. 2021, 233, 103988. [Google Scholar] [CrossRef]

- Sha, Z.; Liang, J.; Zhang, G.; Yang, S.; Lu, J.; Zhang, Z.; McConnell, D.; Humphrey, G. A seepage gas hydrate system in northern South China Sea: Seismic and well log interpretations. Mar. Geol. 2015, 366, 69–78. [Google Scholar] [CrossRef]

- Kuang, Z.; Fang, Y.; Liang, J.; Lu, J.; Wang, L. Geomorphological-geological-geophysical signatures of high-flux fluid flows in the Eastern Pearl River Mouth Basin and effects on gas hydrate accumulation. Sci. China Earth Sci. 2018, 48, 1033–1044. [Google Scholar] [CrossRef]

- Liu, T. Identification of marine gas hydrate morphology. Ph.D. Thesis, China University of Geosciences, Beijing, China, 2019. [Google Scholar]

- Jin, P.; Hu, G.; Bu, Q.; Chen, J.; Wan, Y.; Mao, X. Identification of pore-filling and fracture-filling hydrate by petrophysical simulation and acoustic experiment. Mar. Geol. Quat. Geol. 2020, 40, 208–218. [Google Scholar] [CrossRef]

- Xin, X.; Wang, H.; Luo, J.; Yu, H.; Yuan, Y.; Xia, Y.; Zhu, H.; Chen, Q. Simulation-optimization coupling model for the depressurization production of marine natural gas hydrate in horizontal wells based on machine learning method. Nat. Gas Ind. 2020, 40, 149–158. [Google Scholar] [CrossRef]

- Li, Y.; Xu, T.; Xin, X.; Wang, H.; Zhu, H. Study on gas hydrate reservoir reconstruction for enhanced gas production in Shenhu area of the South China Sea based on 3D heterogeneous geological model. Energy Fuels 2022, 36, 12695–12707. [Google Scholar] [CrossRef]

- Li, Y.; Xin, X.; Xu, T.; Zang, Y.; Yuan, Y.; Zhu, H.; Shan, Y. Study of Multibranch Wells for Productivity Increase in Hydrate Reservoirs Based on a 3D Heterogeneous Geological Model: A Case in the Shenhu Area, South China Sea. SPE J. 2023; SPE-215814-PA, in press. [Google Scholar] [CrossRef]

- Moridis, G.; Reagan, T.; Boyle, L.; Zhang, K. Evaluation of the gas production potential of some particularly challenging types of oceanic hydrate deposits. Transp. Porous Media 2011, 90, 269–299. [Google Scholar] [CrossRef]

| Type | Country | Area | Sediment Type | Type of Natural Gas Hydrate |

|---|---|---|---|---|

| Land areas | Canada | Mallik | Sandy mainly | Pore-filling hydrate mainly |

| USA | Alaska North Slope | Sandy | Pore-filling hydrate mainly | |

| China | Muli Basin | Siltstone and Clayey silt | Fractured-filling hydrate mainly, followed by fractured-filling and pore-filling mixed | |

| Marine areas | USA | Blake Ridge | Clayey silt mainly | Pore-filling hydrate: dispersed and nodular hydrate |

| Hydrate Ridge | Fine sandy mainly | Fractured-filling hydrate mainly | ||

| Gulf of Mexico | Fine sandy mainly | Fractured-filling hydrate with partial pore-filling hydrate | ||

| Japan | Nankai Trough | Sandy | Pore-filling hydrate mainly | |

| India | K-G Basin | Sandy and Clayey | Pore-filling and fractured-filling hydrate | |

| China | Shenhu area | Clayey silt | Dispersed, nodular, blocky, and thin-layered hydrate | |

| Pearl River Mouth Basin | Clayey silt | Pore-filling: dispersed hydrate | ||

| Qiongdongnan Basin | Clayey silt | Nodular, blocky, vein-like, layered, and dispersed hydrate | ||

| Korea | Ulleung Basin | Sandy | Pore-filling and fractured-filling hydrate |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Thickness of HBS (m) | 40 | Thickness of overburden/underburden (m) | 30 |

| Porosity of HBS | 0.53 | Porosity of overburden/underburden | 0.58 |

| Hydrate saturation of pore-filling hydrate | 0.42 | Hydrate saturation of fracture-filling hydrate | 0.50 [42] |

| Permeability of HBS (mD) | 10 | Permeability of overburden/underburden | 5 |

| Initial temperature at the base of HBS (°C) | 12.97 | Geothermal gradient (°C/100 m) | 3.47 |

| Initial pressure at the base of HBS (MPa) | 13.5 | Dry thermal conductivity (W/m/K) | 1.0 |

| Rock grain density (kg/m3) | 2600 | Wet thermal conductivity (W/m/K) | 3.1 |

| Specific heat capacity of hydrate (kJ/kg/K) | 2.1 | Water salinity | 3.05% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Xin, X.; Xu, T.; Zang, Y.; Yu, Z.; Zhu, H.; Yuan, Y. Production Behavior of Hydrate-Bearing Sediments with Mixed Fracture- and Pore-Filling Hydrates. J. Mar. Sci. Eng. 2023, 11, 1321. https://doi.org/10.3390/jmse11071321

Li Y, Xin X, Xu T, Zang Y, Yu Z, Zhu H, Yuan Y. Production Behavior of Hydrate-Bearing Sediments with Mixed Fracture- and Pore-Filling Hydrates. Journal of Marine Science and Engineering. 2023; 11(7):1321. https://doi.org/10.3390/jmse11071321

Chicago/Turabian StyleLi, Yaobin, Xin Xin, Tianfu Xu, Yingqi Zang, Zimeng Yu, Huixing Zhu, and Yilong Yuan. 2023. "Production Behavior of Hydrate-Bearing Sediments with Mixed Fracture- and Pore-Filling Hydrates" Journal of Marine Science and Engineering 11, no. 7: 1321. https://doi.org/10.3390/jmse11071321

APA StyleLi, Y., Xin, X., Xu, T., Zang, Y., Yu, Z., Zhu, H., & Yuan, Y. (2023). Production Behavior of Hydrate-Bearing Sediments with Mixed Fracture- and Pore-Filling Hydrates. Journal of Marine Science and Engineering, 11(7), 1321. https://doi.org/10.3390/jmse11071321