Micro/Bubble Drag Reduction Focused on New Applications

Abstract

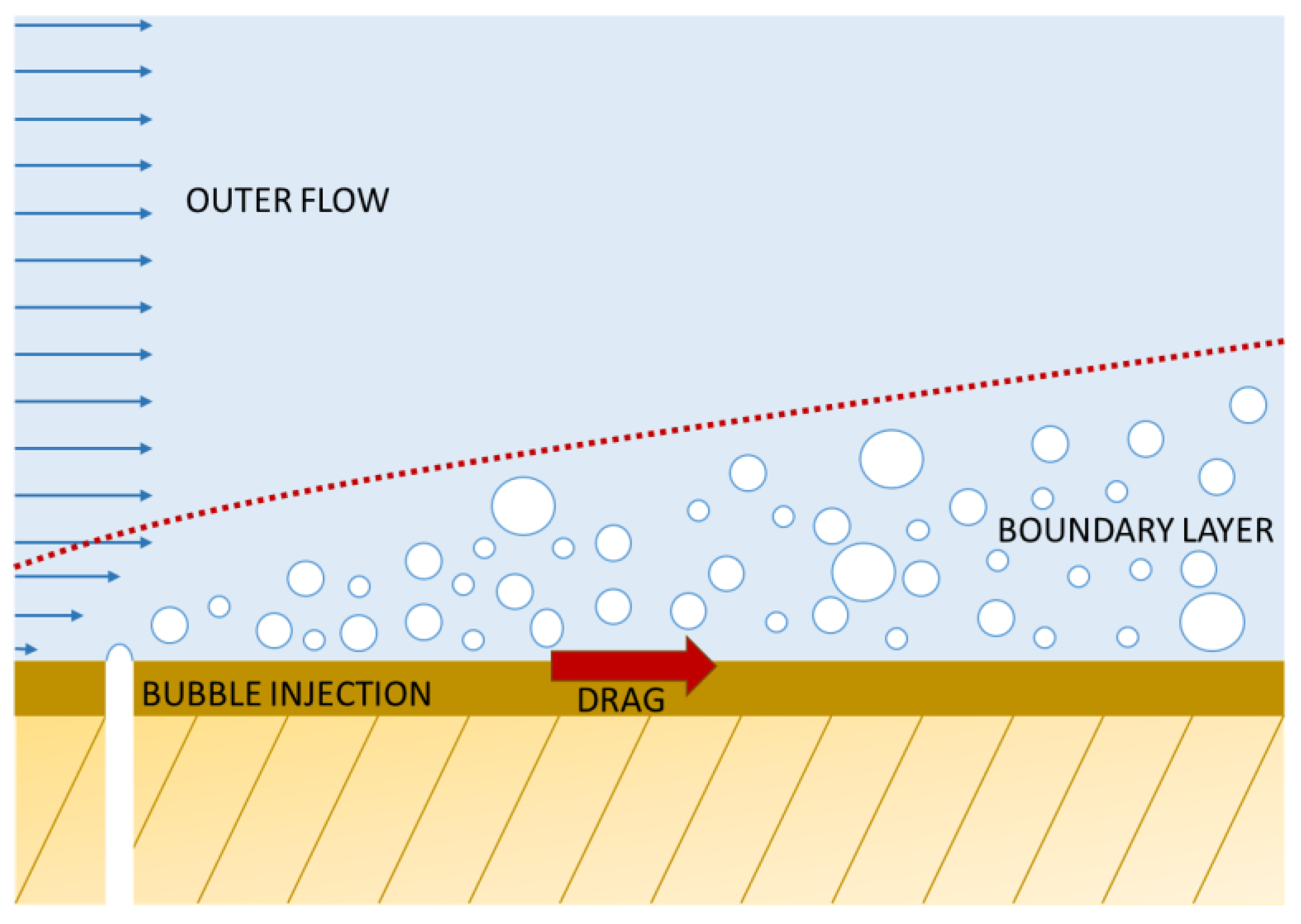

1. Introduction

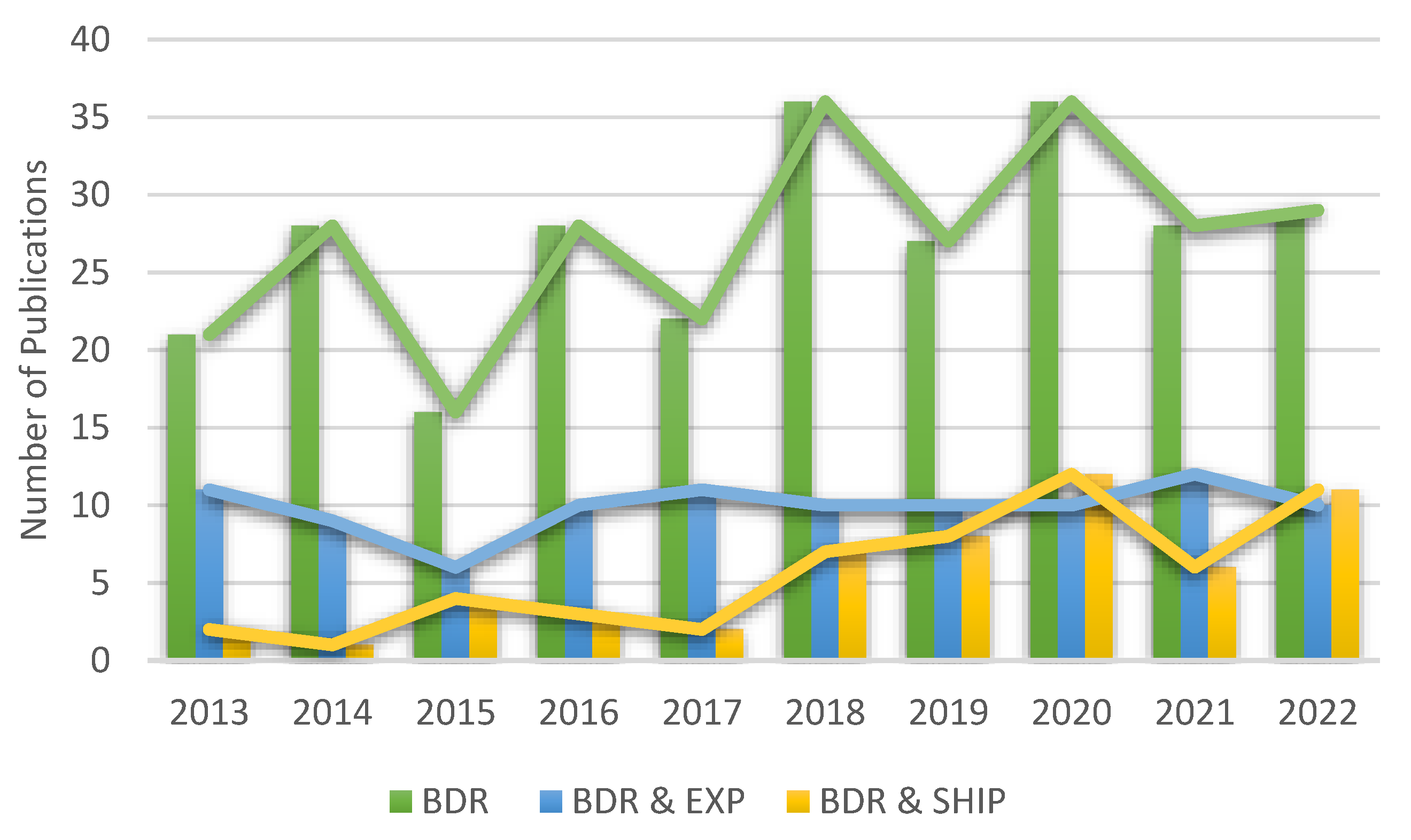

2. Methodology

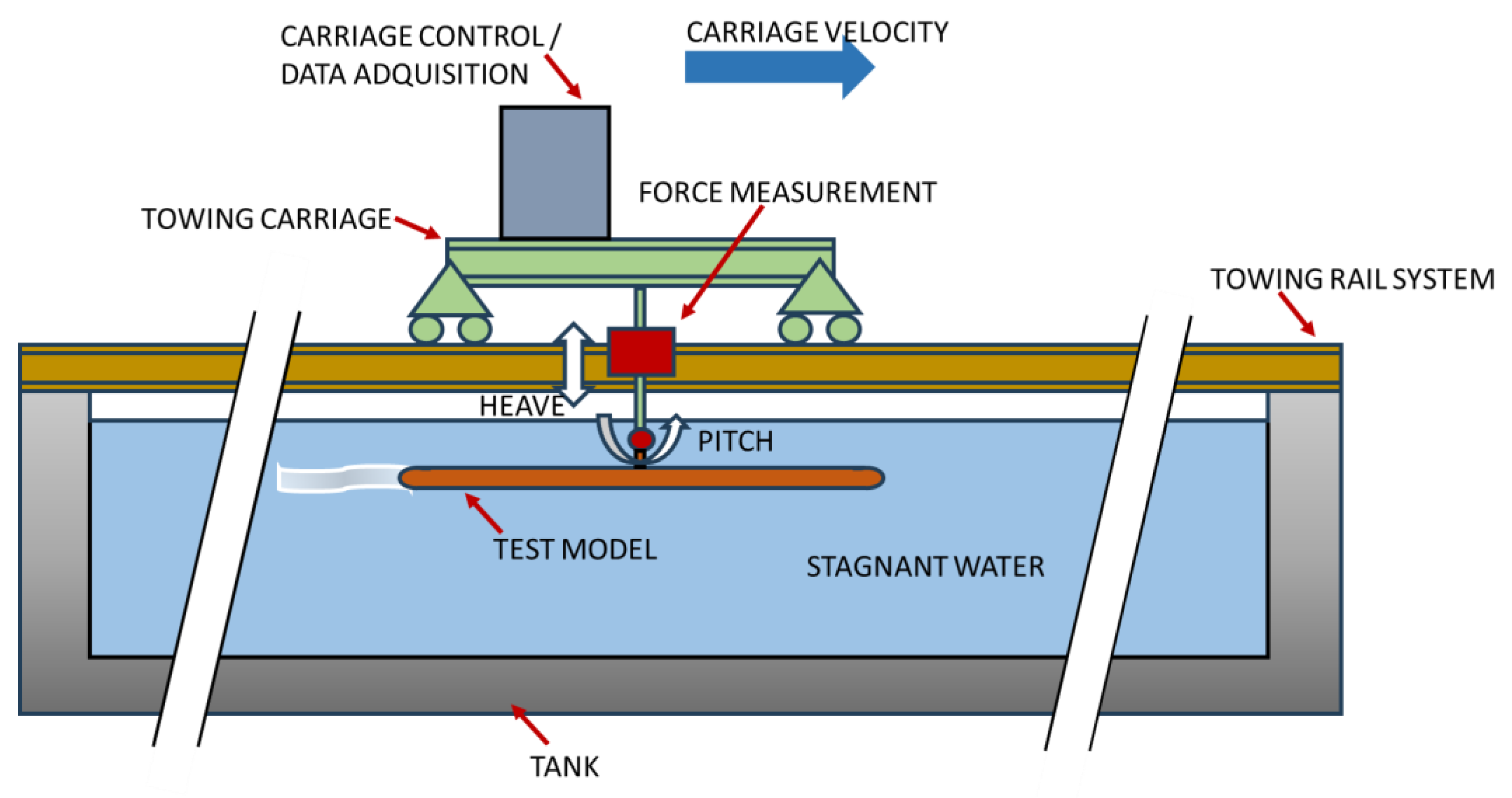

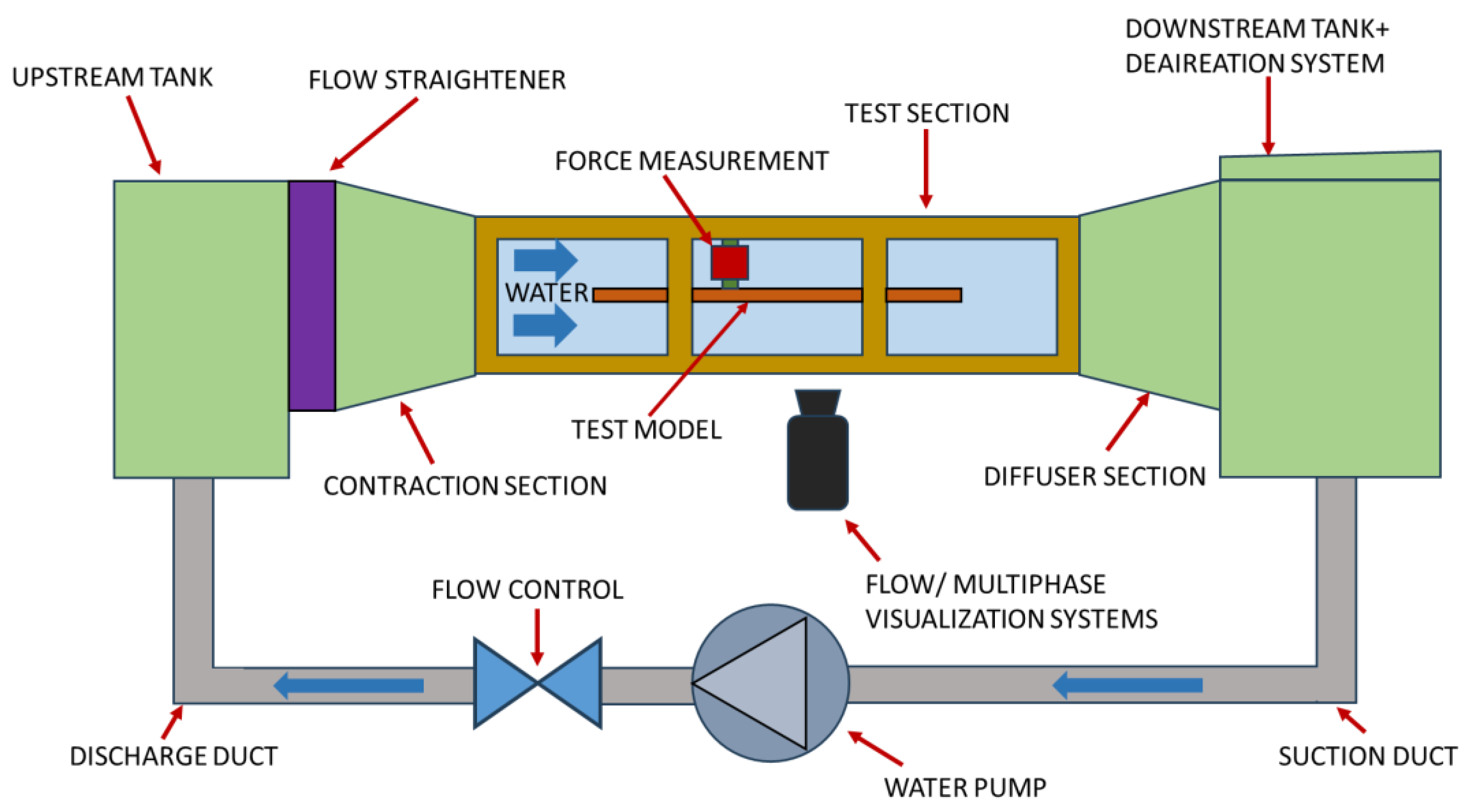

3. Towing Tank Experiments Applied to Ships

4. Fundamental Experimental Studies

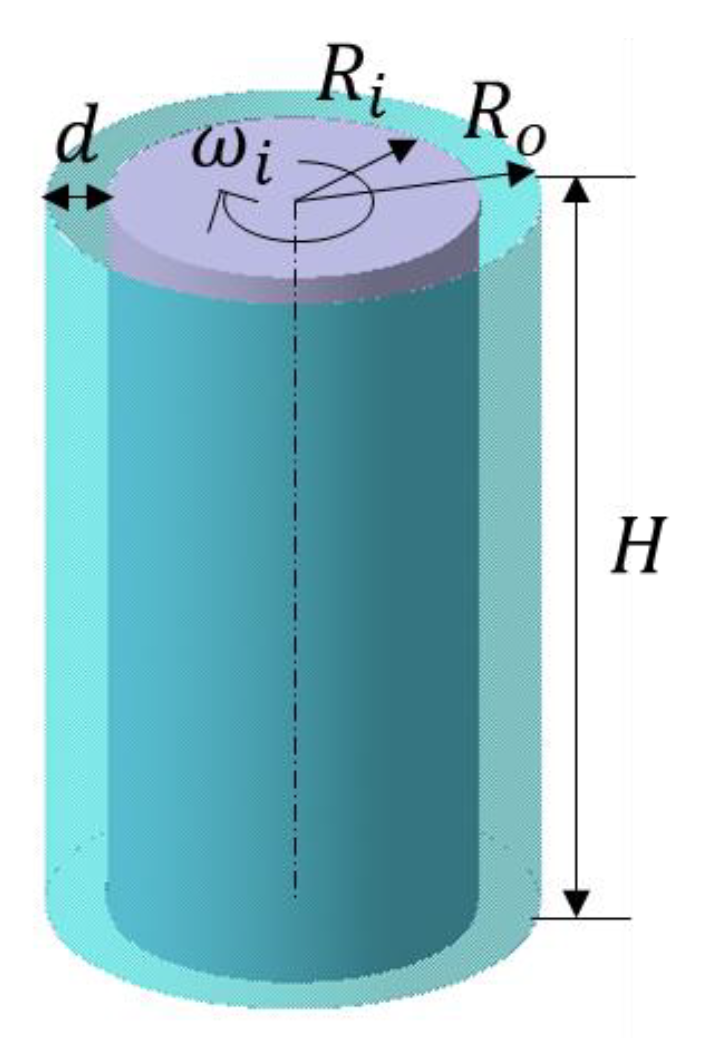

4.1. Taylor–Couette Experiments

- Inner layer of constant shear stress (linear evolution of the azimuthal velocity):

- Logarithmic azimuthal velocity law (farther from the wall).

4.2. Cavitation Tunnel/Water Tunnel Channel Experiments

- Decrease in the density in the buffer layer.

- Increase in the effective viscosity.

- Turbulence modification in the near-wall zone of the boundary layer (by bubble interaction with the vortex sheet).

- Coalescence or breakup of bubbles.

- Buoyancy Dominant Regime (at 2 m/s): Bubbles are sliding along the wall. At small void fraction, there is an increase in friction, while for higher void fractions there is a friction reduction. Friction reduction in this case is considered to be due to inversion of the wakes of bubbles (from jet-like flow to wake-like flow). The effect of deformation of bubbles is considered to be the cause of wall-normal oscillating motion of the bubbles.

- Turbulent Dispersion Dominant Regime (at higher velocities): The reduction in the liquid turbulence stress (which reduces the frictional drag) is governed by the correlation between the fluctuations of the gas volume fraction and the wall-normal fluctuating velocity of the liquid. The waves of the void fraction are generated by repetitive bubble accumulation near the wall in liquid sweeping events.

4.3. Other Experimental Setups

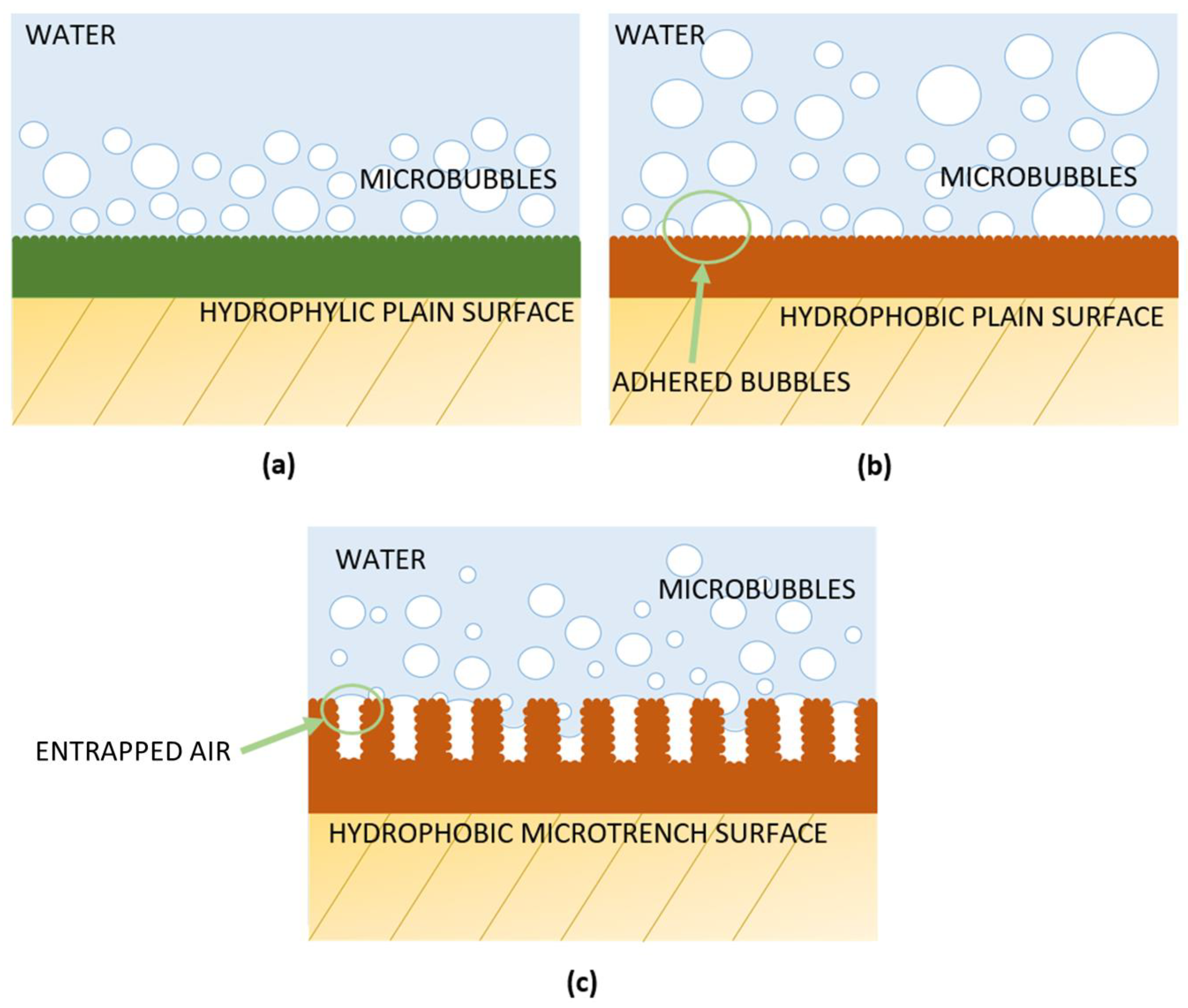

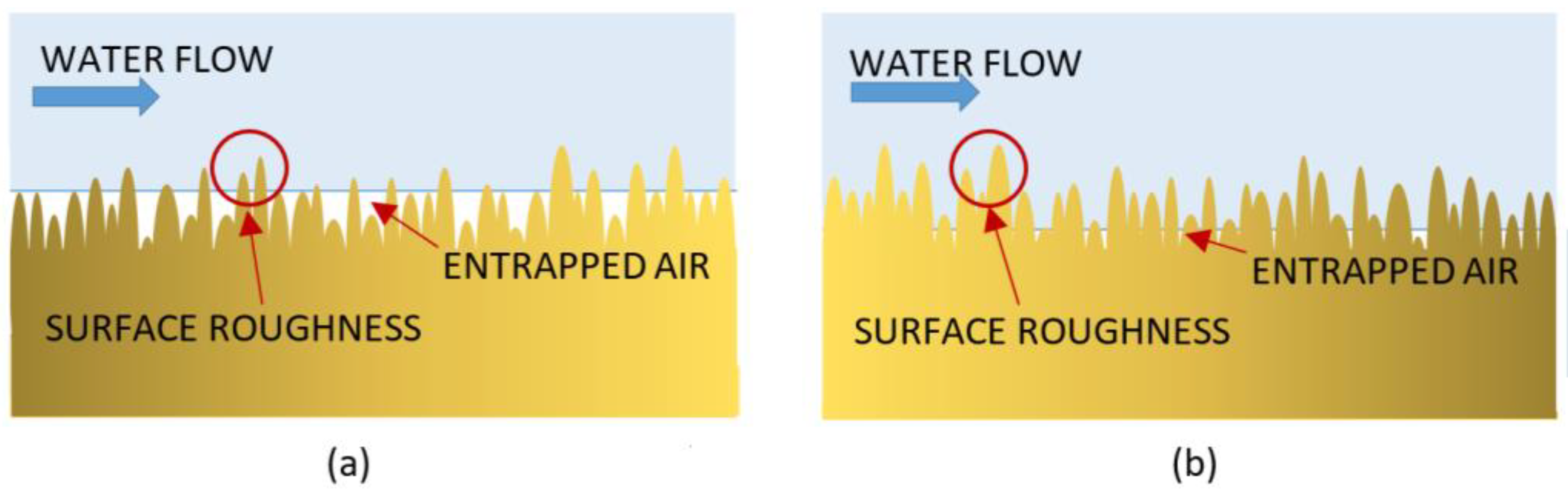

5. Surface Wettability and Microbubble Drag Reduction

6. Summary and Conclusions

- The main facilities/setups used for studying BDR are towing tanks, the cavitation tunnel, water channels and Taylor–Couette setups. Among them, special attention has to be paid to testing in a cavitation tunnel where the pressure could be increased due to the bubble injection.

- The main way used to inject bubbles in the last decade for the experiments in BDR is through a porous plate with an array of holes connected to a reservoir and a pump.

- There is still much work to be done regarding the way to measure the bubbles inside the boundary layer and their interaction with it.

- First, it has recently been discovered that introducing intermittent waves of swarms of bubbles could be beneficial, rather than a continuous injection of bubbles. This is now being investigated, and seems to be promising in order to achieve greater drag reduction. However, there is still much work to be done to elucidate all the physics involved.

- Secondly, there are still contradictions all over the literature regarding the effects of bubble size and air injection flow. Therefore, fundamental studies are still necessary to shed light on the problem, which seems to be due to different complex mechanisms. In any case, bubble size has been shown to be a key parameter.

- Finally, and regarding the way to control bubble size, a new trend in the research has been identified for studying the relation of the wettability to the bubble size of the air injected. In this context, hydrophobic and hydrophilic surfaces have been investigated in relation to BDR. Further studies in this direction are also necessary.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sindagi, S.; Vijayakumar, R. Succinct review of MBDR/BDR technique in reducing ship’s drag. Ships Off-Shore Struct. 2021, 16, 968–979. [Google Scholar] [CrossRef]

- Kumar, S.; Pandey, K.M.; Sharma, K.K. Advances in drag-reduction methods related with boundary layer control—A review. Mater. Today Proc. 2021, 45, 6694–6701. [Google Scholar] [CrossRef]

- Ceccio, S.L. Friction drag reduction of external flows with bubble and gas injection. Annu. Rev. Fluid Mech. 2010, 42, 183–203. [Google Scholar] [CrossRef]

- Murai, Y. Frictional drag reduction by bubble injection. Exp. Fluids 2014, 55, 1773. [Google Scholar] [CrossRef]

- Legner, H.H. A simple model for gas bubble drag reduction. Phys. Fluids 1984, 27, 2788–2790. [Google Scholar] [CrossRef]

- Kim, S.Y.; Cleaver, J.W. The persistence of drag reduction following the injection of microbubbles into a turbulent boundary layer. Int. Commun. Heat Mass Transf. 1995, 22, 353–357. [Google Scholar] [CrossRef]

- Murai, Y.; Oishi, Y.; Sasaki, T.; Kodama, T.; Yamamoto, F. Turbulent shear stress profile in horizontal bubbly channel flow. In Proceedings of the 6th International Symposium on Smart Control of Turbulence, Tokyo, Japan, 6–9 March 2005; pp. 289–295. [Google Scholar]

- Hassan, Y.A.; Gutierrez-Torres, C.C. Investigation of drag reduction mechanism by microbubble injection within a channel boundary layer using particle tracking velocimetry. Nucl. Eng. Technol. 2006, 38, 763–778. [Google Scholar]

- Paik, B.G.; Yim, G.T.; Kim, K.Y.; Kim, K.S. The effects of microbubbles on skin friction in a turbulent boundary layer flow. Int. J. Multiph. Flow 2016, 80, 164–175. [Google Scholar] [CrossRef]

- Park, H.J.; Saito, D.; Tasaka, Y.; Murai, Y. Color-coded visualization of microbubble clouds interacting with eddies in a spatially developing turbulent boundary layer. Exp. Therm. Fluid Sci. 2019, 109, 109919. [Google Scholar] [CrossRef]

- Feng, Y.Y.; Hu, H.; Peng, G.Y.; Zhou, Y. Microbubble effect on friction drag reduction in a turbulent boundary layer. Ocean Eng. 2020, 211, 107583. [Google Scholar] [CrossRef]

- Park, H.J.; Tasaka, Y.; Murai, Y. Bubbly drag reduction accompanied by void wave generation inside turbulent boundary layers. Exp. Fluids 2018, 59, 166. [Google Scholar] [CrossRef]

- Tanaka, T.; Oishi, Y.; Park, H.J.; Tasaka, Y.; Murai, Y.; Kawakita, C. Repetitive bubble injection promoting frictional drag reduction in high-speed horizontal turbulent channel flows. Ocean Eng. 2021, 239, 109909. [Google Scholar] [CrossRef]

- An, H.; Pan, H.; Yang, P. Research Progress of Air Lubrication Drag Reduction Technology for Ships. Fluids 2022, 7, 319. [Google Scholar] [CrossRef]

- Zhang, J.; Gabillet, C.; Billard, J.-Y. Experimental study of the bubbly drag reduction in the recovery region of a separated turbulent boundary layer. Int. J. Multiph. Flow 2021, 142, 103697. [Google Scholar] [CrossRef]

- Wang, H.; Wang, K.; Liu, G. Drag reduction by gas lubrication with bubbles. Ocean Eng. 2022, 258, 111833. [Google Scholar] [CrossRef]

- Zhao, L.; Mo, Z.; Sun, L.; Xie, G.; Liu, H.; Du, M.; Tang, J. A visualized study of the motion of individual bubbles in a venturi-type bubble generator. Prog. Nucl. Energy 2017, 97, 74–89. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, S.; Liu, J. Numerical investigation of a novel device for bubble generation to reduce ship drag. Int. J. Nav. Archit. Ocean Eng. 2018, 10, 629–643. [Google Scholar] [CrossRef]

- Murai, Y.; Sakamaki, H.; Kumagai, I.; Park, H.J.; Tasaka, Y. Mechanism and performance of a hydrofoil bubble generator utilized for bubbly drag reduction ships. Ocean Eng. 2020, 216, 108085. [Google Scholar] [CrossRef]

- Rodríguez-Rodríguez, J.; Sevilla, A.; Martínez-Bazán, C.; Gordillo, J.M. Generation of microbubbles with applications to industry and medicine. Annu. Rev. Fluid Mech. 2015, 47, 405–429. [Google Scholar] [CrossRef]

- Mccormick, M.E.; Bhattacharyya, R. Drag reduction of a submersible hull by electrolysis. Nav. Eng. J. 1973, 85, 11–16. [Google Scholar] [CrossRef]

- Dominguez-Ontiveros, E.E.; Estrada-Perez, C.E.; Hassan, Y.A. Wall Shear Stress Measurements in Two-phase Flow using PIV, an Optical Sensor and Wall Pressure Transducer. In Proceedings of the 6th International Symposium on Particle Image Velocimetry Pasadena, Pasadena, CA, USA, 21–23 September 2005. [Google Scholar]

- Zhu, R.; Zhang, H.; Wen, W.; He, X.; Zhao, C.; Liu, Y.; Zhuang, Q.; Liu, Z. Flow-drag reduction performance of a resident electrolytic microbubble array and its mechanisms. Ocean Eng. 2023, 268, 113496. [Google Scholar] [CrossRef]

- Velasco, L.J.; Venturi, D.N.; Fontes, D.H.; de Souza, F.J. Numerical simulation of drag reduction by microbubbles in a vertical channel. Eur. J. Mech.-B/Fluids 2022, 92, 215–225. [Google Scholar] [CrossRef]

- Lyu, X.; Tang, H.; Sun, J.; Wu, X.; Chen, X. Simulation of microbubble resistance reduction on a suboff model. Brodogr. Teor. I Praksa Brodogr. I Pomor. Teh. 2014, 65, 23–32. [Google Scholar]

- Cihonski, A.J.; Finn, J.R.; Apte, S.V. Volume displacement effects during bubble entrainment in a travelling vortex ring. J. Fluid Mech. 2013, 721, 225–267. [Google Scholar] [CrossRef]

- Li, Z.P.; Sun, L.Q.; Xiao, W.; Yao, X.L. Three-dimensional numerical analysis of near-wall single-orifice ventilated bubble dynamics. Ocean Eng. 2019, 186, 106066. [Google Scholar] [CrossRef]

- Zhang, G.Q.; Schlüter, J.; Hu, X. Parametric investigation of drag reduction for marine vessels using air-filled dimpled surfaces. Ships Offshore Struct. 2018, 13, 244–255. [Google Scholar] [CrossRef]

- Zhao, X.; Zong, Z.; Jiang, Y.; Sun, T. A numerical investigation of the mechanism of air-injection drag reduction. Appl. Ocean Res. 2020, 94, 101978. [Google Scholar] [CrossRef]

- Wu, T.; Li, Y.; Jiang, D.; Zhang, Y. Numerical Research of Dynamical Behavior in Engineering Applications by Using E–E Method. Mathematics 2022, 10, 3150. [Google Scholar] [CrossRef]

- Liu, T.; Huang, B.; Wang, G.; Zhang, M.; Gao, D. Experimental investigation of the flow pattern for ventilated partial cavitating flows with effect of Froude number and gas entrainment. Ocean Eng. 2017, 129, 343–351. [Google Scholar] [CrossRef]

- Liu, T.; Huang, B.; Wang, G.; Zhang, M. Experimental investigation of ventilated partial cavitating flows with special emphasis on flow pattern regime and unsteady shedding behavior around an axisymmetric body at different angles of attack. Ocean Eng. 2018, 147, 289–303. [Google Scholar] [CrossRef]

- Maiga, M.A.; Coutier-Delgosha, O. Analysis of the re-entrant jet to twin vortex flow regimes transition in ventilated cavitation. Eur. J. Mech.-B/Fluids 2022, 94, 375–384. [Google Scholar] [CrossRef]

- Qin, S.; Sun, S.; Fang, H.; Wang, L.; Chen, Y.; Wu, D. Experimental and numerical investigation on the cavity regime and drag reduction of ventilated partial cavity. Ocean Eng. 2021, 234, 109257. [Google Scholar] [CrossRef]

- Yu, D.; Wei, Y.; Wang, C.; Lu, J.; Li, Y.; Zhang, W. Experimental investigation of two ventilated cavities with effect of Froude number and gas entrainment. Ocean Eng. 2022, 261, 112109. [Google Scholar] [CrossRef]

- Qin, S.; Sun, S.; Yoon, K.; Fang, H.; Chen, Y.; Wu, D. Investigation on the internal flow of ventilated partial cavity. Phys. Fluids 2021, 33, 083303. [Google Scholar] [CrossRef]

- Sun, S.; Qin, S.; Fang, H.; Wu, D.; Huang, B. Effects of lateral space and angle of attack on ventilated partial cavity. Appl. Ocean Res. 2021, 106, 102479. [Google Scholar] [CrossRef]

- Wang, L.; Huang, B.; Qin, S.; Cao, L.; Fang, H.; Wu, D.; Li, C. Experimental investigation on ventilated cavity flow of a model ship. Ocean Eng. 2020, 214, 107546. [Google Scholar] [CrossRef]

- Xiang, M.; Li, K.; Tu, J.Y.; Zhang, H.W. Numerical investigation on the gas entrainment of ventilated partial cavity based on a multiscale modelling approach. Appl. Ocean Res. 2016, 60, 84–93. [Google Scholar] [CrossRef]

- Xu, C.; Huang, J.; Wang, Y.; Wu, X.; Huang, C.; Wu, X. Supercavitating flow around high-speed underwater projectile near free surface induced by air entrainment. AIP Adv. 2018, 8, 035016. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, X.J.; Dai, Y.J.; Wu, G.Q.; Cao, Y.; Huang, D.G. Numerical investigation of drag reduction by heat-enhanced cavitation. Appl. Therm. Eng. 2015, 75, 193–202. [Google Scholar] [CrossRef]

- Karn, A.; Rosiejka, B. Air entrainment characteristics of artificial supercavities for free and constrained closure models. Exp. Therm. Fluid Sci. 2017, 81, 364–369. [Google Scholar] [CrossRef]

- Erfanian, M.-R.; Anbarsooz, M. Numerical investigation of body and hole effects on the cavitating flow behind a disk cavitator at extremely low cavitation numbers. Appl. Math. Model. 2018, 62, 163–180. [Google Scholar] [CrossRef]

- Sun, T.; Ding, Y.; Liu, Y.; Zou, L. Numerical modeling and investigation of the effect of internal waves on the dynamic behavior of an asymmetric ventilated supercavity. Ocean Eng. 2021, 233, 109193. [Google Scholar] [CrossRef]

- Azad, S.; Lotfi, H.; Riasi, A. The effects of viscoelastic fluid on the cavitation inception and development within a centrifugal pump: An experimental study. Int. Commun. Heat Mass Transf. 2019, 107, 106–113. [Google Scholar] [CrossRef]

- Vakarelski, I.U.; Klaseboer, E.; Jetly, A.; Mansoor, M.M.; Aguirre-Pablo, A.A.; Chan, D.Y.; Thoroddsen, S.T. Self-determined shapes and velocities of giant near-zero drag gas cavities. Sci. Adv. 2017, 3, e1701558. [Google Scholar] [CrossRef]

- Kadivar, E.; el Moctar, O.; Skoda, R.; Löschner, U. Experimental study of the control of cavitation-induced erosion created by collapse of single bubbles using a micro structured riblet. Wear 2021, 486, 204087. [Google Scholar] [CrossRef]

- Chanson, H. Hydraulics of aerated flows: Qui pro quo? J. Hydraul. Res. 2013, 51, 223–243. [Google Scholar] [CrossRef]

- Basovich, A. The effect of contaminant drag reduction on the onset and evolution of Langmuir circulations. J. Phys. Oceanogr. 2014, 44, 2739–2752. [Google Scholar] [CrossRef]

- Elbing, B.R.; Perlin, M.; Dowling, D.R.; Ceccio, S.L. Modification of the mean near-wall velocity profile of a high-Reynolds number turbulent boundary layer with the injection of drag-reducing polymer solutions. Phys. Fluids 2013, 25, 085103. [Google Scholar] [CrossRef]

- Han, X.; Krajnović, S. Very large eddy simulation of passive drag control for a D-shaped cylinder. J. Fluids Eng. 2013, 135, 101102. [Google Scholar] [CrossRef]

- Kwon, B.H.; Kim, H.H.; Jeon, H.J.; Kim, M.C.; Lee, I.; Chun, S.; Go, J.S. Experimental study on the reduction of skin frictional drag in pipe flow by using convex air bubbles. Exp. Fluids 2014, 55, 1722. [Google Scholar] [CrossRef]

- Lorite-Díez, M.; Jiménez-González, J.I.; Pastur, L.; Martínez-Bazán, C.; Cadot, O. Experimental analysis of the effect of local base blowing on three-dimensional wake modes. J. Fluid Mech. 2020, 883, A53. [Google Scholar] [CrossRef]

- Wang, G.-H.; Du, Y.; Xiao, Z.-J.; Huang, J.; Wng, Z.-Y.; Li, H.-C.; Wang, J.-Z.; Wang, Y.-W. Numerical study on formation of a splash sheet induced by an oscillating bubble in extreme vicinity to a water surface. J. Hydrodyn. 2022, 34, 1021–1031. [Google Scholar] [CrossRef]

- Yang, H.; Guo, Z.; Li, Y.; Wang, H.; Dou, Y. Experimental study on microbubble drag reduction on soil-steel interface. Appl. Ocean Res. 2021, 116, 102891. [Google Scholar] [CrossRef]

- Yang, H.; Guo, Z.; Li, Y.; Wang, H.; Dou, Y. Unsteady dynamic analysis for the cavitating hydrofoils based on OpenFOAM. Exp. Comput. Multiph. Flow 2019, 1, 101–108. [Google Scholar]

- Yanuar; Waskito, K.T.; Pratama, S.Y.; Candra, B.D.; Rahmat, B.A. Comparison of microbubble and air layer injection with porous media for drag reduction on a self-propelled barge ship model. J. Mar. Sci. Appl. 2018, 17, 165–172. [Google Scholar] [CrossRef]

- Gunawan; Yanuar; Waskito, K.T. Determination the optimum location for microbubble drag reduction method in self propelled barge model; an experimental approach. Energy Rep. 2020, 6, 774–783. [Google Scholar] [CrossRef]

- Hao, W.U.; Yongpeng, O.; Qing, Y.E. Experimental study of air layer drag reduction on a flat plate and bottom hull of a ship with cavity. Ocean Eng. 2019, 183, 236–248. [Google Scholar] [CrossRef]

- Sindagi, S.; Vijayakumar, R.; Saxena, B.K. Experimental parametric investigation to reduce drag of a scaled model of bulk carrier using BDR/ALS technique. J. Ship Res. 2021, 65, 257–265. [Google Scholar] [CrossRef]

- Zhao, X.; Zong, Z. Experimental and numerical studies on the air-injection drag reduction of the ship model. Ocean Eng. 2022, 251, 111032. [Google Scholar] [CrossRef]

- Sayyaadi, H.; Nematollahi, M. Determination of optimum injection flow rate to achieve maximum micro bubble drag reduction in ships; an experimental approach. Sci. Iran. 2013, 20, 535–541. [Google Scholar]

- Schlichting, H.; Gersten, K. Boundary-Layer Theory; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Park, H.J.; Oishi, Y.; Tasaka, Y.; Murai, Y. Void waves propagating in the bubbly two-phase turbulent boundary layer beneath a flat-bottom model ship during drag reduction. Exp. Fluids 2016, 57, 178. [Google Scholar] [CrossRef]

- Mäkiharju, S.A.; Lee, I.H.R.; Filip, G.P.; Maki, K.J.; Ceccio, S.L. The topology of gas jets injected beneath a surface and subject to liquid cross-flow. J. Fluid Mech. 2017, 818, 141–183. [Google Scholar] [CrossRef]

- Sanders, W.C.; Winkel, E.S.; Dowling, D.R.; Perlin, M.; Ceccio, S.L. Bubble friction drag reduction in a high-Reynolds-number flat-plate turbulent boundary layer. J. Fluid Mech. 2006, 552, 353–380. [Google Scholar] [CrossRef]

- Fokoua, G.N.; Gabillet, C.; Aubert, A.; Colin, C. Effect of bubble’s arrangement on the viscous torque in bubbly Taylor-Couette flow. Phys. Fluids 2015, 27, 034105. [Google Scholar] [CrossRef]

- Maryami, R.; Javadpoor, M.; Farahat, S. Experimental investigation of head resistance reduction in bubbly Couette–Taylor flow. Heat Mass Transf. 2016, 52, 2593–2608. [Google Scholar] [CrossRef]

- Sun, C.; Zhou, Q. Experimental techniques for turbulent Taylor–Couette flow and Rayleigh–Bénard convection. Nonlinearity 2014, 27, R89. [Google Scholar] [CrossRef]

- Gao, X.; Kong, B.; Vigil, R. Dennis. CFD simulation of bubbly turbulent Tayor–Couette flow. Chin. J. Chem. Eng. 2016, 24, 719–727. [Google Scholar] [CrossRef]

- Lavrenteva, O.; Prakash, J.; Nir, A. Effect of added mass on the interaction of bubbles in a low-Reynolds-number shear flow. Phys. Rev. E 2016, 93, 023105. [Google Scholar] [CrossRef]

- Spandan, V.; Ostilla-Mónico, R.; Verzicco, R.; Lohse, D. Drag reduction in numerical two-phase Taylor–Couette turbulence using an Euler–Lagrange approach. J. Fluid Mech. 2016, 798, 411–435. [Google Scholar] [CrossRef]

- Elbing, B.R.; Mäkiharju, S.; Wiggins, A.; Perlin, M.; Dowling, D.R.; Ceccio, S.L. On the scaling of air layer drag reduction. J. Fluid Mech. 2013, 717, 484–513. [Google Scholar] [CrossRef]

- Qin, S.; Chu, N.; Yao, Y.; Liu, J.; Huang, B.; Wu, D. Stream-wise distribution of skin-friction drag reduction on a flat plate with bubble injection. Phys. Fluids 2017, 29, 037103. [Google Scholar] [CrossRef]

- Wu, H.; Ou, Y. Analysis of air layer shape formed by air injection at the bottom of flat plate. Ocean Eng. 2020, 216, 108091. [Google Scholar] [CrossRef]

- Evseev, A.R.; Mal’tsev, L.I. Effect of Microbubble Gas Saturation on Near-Wall Turbulence and Drag Reduction. J. Eng. Thermophys. 2018, 27, 155–172. [Google Scholar] [CrossRef]

- Hazuku, T.; Ihara, T.; Hibiki, T. Reduction of skin friction and two-phase flow structure beneath wall in horizontal rectangular channel. Ocean Eng. 2022, 248, 110846. [Google Scholar] [CrossRef]

- Ushida, A.; Hasegawa, T.; Narumi, T.; Nakajima, T. Flow properties of nanobubble mixtures passing through micro-orifices. Int. J. Heat Fluid Flow 2013, 40, 106–115. [Google Scholar] [CrossRef]

- Ushida, A. Anomalous Phenomena of Complex Fluids in Small-Sized Flow Fields and Effect of Fine Bubble Mixtures. Nihon Reoroji Gakkaishi 2016, 44, 237–243. [Google Scholar] [CrossRef]

- Saffari, H.; Moosavi, R.; Gholami, E.; Nouri, N.M. The effect of bubble on pressure drop reduction in helical coil. Exp. Therm. Fluid Sci. 2013, 51, 251–256. [Google Scholar] [CrossRef]

- Dinsmore, C.; Aminfar, A.; Princevac, M. Dissipative effects of bubbles and particles in shear flows. J. Fluids Eng. 2017, 139, 061302. [Google Scholar] [CrossRef]

- Gvozdić, B.; Alméras, E.; Mathai, V.; Zhu, X.; Van Gils, D.; Verzicco, R.; Huisman, S.-G.; Sun, C.; Lohse, D. Experimental investigation of heat transport in homogeneous bubbly flow. J. Fluid Mech. 2018, 845, 226–244. [Google Scholar] [CrossRef]

- Gan, N.; Yao, X.; Cheng, S.; Chen, Y.; Ma, G. Experimental investigation on dynamic characteristics of ventilation bubbles on the surface of a vertical moving body. Ocean Eng. 2022, 246, 110641. [Google Scholar] [CrossRef]

- Yun, H.; Lyu, X.; Wei, Z. Experimental study on vertical water entry of two tandem spheres. Ocean Eng. 2020, 201, 107143. [Google Scholar] [CrossRef]

- Kitagawa, A.; Denissenko, P.; Murai, Y. Effect of wall surface wettability on collective behavior of hydrogen microbubbles rising along a wall. Exp. Therm. Fluid Sci. 2017, 80, 126–138. [Google Scholar] [CrossRef]

- Kitagawa, A.; Denissenko, P.; Murai, Y. Behavior of bubbles moving along horizontal flat plates with different surface wettability. Exp. Therm. Fluid Sci. 2019, 104, 141–152. [Google Scholar] [CrossRef]

- Bullee, P.A.; Verschoof, R.A.; Bakhuis, D.; Huisman, S.G.; Sun, C.; Lammertink, R.G.; Lohse, D. Bubbly drag reduction using a hydrophobic inner cylinder in Taylor–Couette turbulence. J. Fluid Mech. 2020, 883, A61. [Google Scholar] [CrossRef]

- Hu, H.; Wen, J.; Bao, L.; Jia, L.; Song, D.; Song, B.; Pan, G.; Scaraggi, M.; Dini, D.; Xue, Q.; et al. Significant and stable drag reduction with air rings confined by alternated superhydrophobic and hydrophilic strips. Sci. Adv. 2017, 3, e1603288. [Google Scholar] [CrossRef]

- Mail, M.; Moosmann, M.; Häger, P.; Barthlott, W. Air retaining grids—A novel technology to maintain stable air layers under water for drag reduction. Philos. Trans. R. Soc. A 2019, 377, 20190126. [Google Scholar] [CrossRef]

- Xu, M.; Grabowski, A.; Yu, N.; Kerezyte, G.; Lee, J.W.; Pfeifer, B.R. Superhydrophobic drag reduction for turbulent flows in open water. Phys. Rev. Appl. 2020, 13, 034056. [Google Scholar] [CrossRef]

- Karatay, E.; Haase, A.S.; Visser, C.W.; Sun, C.; Lohse, D.; Tsai, P.A.; Lammertink, R.G. Control of slippage with tunable bubble mattresses. Proc. Natl. Acad. Sci. USA 2013, 110, 8422–8426. [Google Scholar] [CrossRef]

- Yin, L.; Zhang, H.F.; Shi, S.Y.; Lu, Y.; Wang, Y.; Liu, X.W. Numerical investigation of relationship between water contact angle and drag reduction ratio of superhydrophobic surfaces. Front. Phys. 2016, 11, 114701. [Google Scholar] [CrossRef]

- Bidkar, R.A.; Leblanc, L.; Kulkarni, A.J.; Bahadur, V.; Ceccio, S.L.; Perlin, M. Skin-friction drag reduction in the turbulent regime using random-textured hydrophobic surfaces. Phys. Fluids 2014, 26, 085108. [Google Scholar] [CrossRef]

- Lv, X.; Wu, W.T.; Lv, J.; Mao, K.; Gao, L.; Li, Y. Study on the law of pseudo-cavitation on superhydrophobic surface in turbulent flow field of backward-facing step. Fluids 2021, 6, 200. [Google Scholar] [CrossRef]

- Park, H.; Choi, C.-H.; Kim, C.-J. Superhydrophobic drag reduction in turbulent flows: A critical review. Exp. Fluids 2021, 62, 229. [Google Scholar] [CrossRef]

| Search Name | Search Parameters |

|---|---|

| BDR | (TS or TI or AB) = BDR and NRB |

| BDR & EXP | (TS or TI or AB) = BDR and EXP and NRB |

| BDR & SHIP | (TS or TI or AB) = BDR and SHIP and NRB |

| BDR & SHIP & EXP | (TS or TI or AB) = BDR and SHIP and EXP and NRB |

| BDR & BL | (TS or TI or AB) = BDR and BL and NRB |

| BDR & BL & EXP | (TS or TI or AB) = BDR and BL and EXP and NRB |

| Search Parameter | Search Name | Proposed Definition |

|---|---|---|

| BDR | Bubble Drag Reduction | (((“Microbubble” or “Bubble”) and (“Drag Reduction”)) or (“Bubbly Drag”)) |

| EXP | Experimental | (“Experimental”) |

| NRB | No Recirculation Bubble | (not (“Separation Bubble” or “Recirculation Bubble”) not (“Aerodynamics”)) |

| SHIP | Ships | (“Ship” or “Vessel” or “Boat” or “Frigate” or “Barge”) |

| BL | Boundary Layer | (“Boundary Layer”) |

| Search Name | Total Publications | Total Publications Last 10 Years | Mean Number of Publications | Percentage Publications Last 10 Years |

|---|---|---|---|---|

| BDR | 459 | 271 | 27.1 | 59% |

| BDR & EXP | 148 | 99 | 9.9 | 67% |

| BDR & SHIP | 84 | 56 | 5.6 | 67% |

| BDR & SHIP & EXP | 29 | 26 | 2.6 | 90% |

| BDR & BL | 171 | 83 | 8.3 | 48% |

| BDR & BL & EXP | 54 | 31 | 3 | 57% |

| Search Name | Number of Publications per Year | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | |

| BDR | 21 | 28 | 16 | 28 | 22 | 36 | 27 | 36 | 28 | 29 |

| BDR & EXP | 11 | 9 | 6 | 10 | 11 | 10 | 10 | 10 | 12 | 10 |

| BDR & SHIP | 2 | 1 | 4 | 3 | 2 | 7 | 8 | 12 | 6 | 11 |

| BDR & SHIP & EXP | 1 | 1 | 1 | 1 | 2 | 2 | 5 | 4 | 4 | 5 |

| BDR & BL | 5 | 9 | 5 | 8 | 7 | 12 | 12 | 10 | 5 | 10 |

| BDR & BL & EXP | 3 | 4 | 1 | 2 | 5 | 5 | 3 | 2 | 3 | 3 |

| Authors and Year of the Publication | Towing Tank Institution | Towing Tank Dimensions | Fr | Model | Air Injection | Specific Instrumentation | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Length (m) | Width (m) | Depth (m) | Type | Length (m) | Beam (m) | Height (m) | Draft T(m) | Scale | Bubble Generation/ Air Injection | Injection Location | Air Injected | Shear Stress | |||

| Sayyadi et al., 2013 [62] | Sharif University of Technology | 25 | 2.5 | 1.2 | 0.36–1.34 | Catamaran | 0.707 | 0.072 | 0.031 | - | Array of holes (porous plate) of diameter around 1 mm | three positions: fore, midship and stern regions | injection coefficient: 0.1–1 | - | |

| Park et al., 2016 [64] | Hiroshima University | 100 | 8 | 3.5 | 0.32–0.48 | Ship with Flat Plate Bottom | 4 | 0.5 | 0.6 | 0.09 | - | Array of holes (porous plate) of diameter around 5 mm | at 0.7 m after bow | flow rate: 1.5–9 m3/h | ultrasonic bubble measurement system, wall shear stress sensors and optical-bubble imaging system |

| Park et al., 2018 [12] | - | Array of holes (porous plate) of diameter around 100 μm | flow rate: 4.5–9 m3/h | ||||||||||||

| Mäkiharju 2017 [65] | University of Michigan | 109.7 | 6.7 | 3.2 | 1.3–7.2 | Barge | 4.3 | 0.7 | 0.3 | 0.08 | - | gas-injection tubes (orifice diameter: 6 and 10 mm) | at the fore of the flat part with different injection angle (22.5°–157.5°) | flow rate: 0.36–43 m3/h | - |

| Barge | 6.5 | 1.5 | 0.5 | 0.08 | - | gas-injection tubes (orifice diameter: 5, 10, and 20 mm) | |||||||||

| Yanuar et al., 2018 [57] | Indonesia Hydrodynamic Laboratory | 234.5 | 11 | 5.5 | 0.11–0.31 | Barge | 2 | 0.52 | 0.12 | 0.05 | 1:28 | Porous medium with holes of diameter of 100 µm | at 0.35 L after midship | injection coefficient: 0.2–0.6 | Load cell located at 0.35 L after midship |

| Gunawan et al., 2019 [58] | Indonesia Hydrodynamic Laboratory | 234.5 | 11 | 5.5 | 0.1–0.35 | Barge | 0.200 | 0.052 | 0.012 | 0.09 | 1:45 | Porous media connected to air compressor by 1/4-inch pipe. | 100 mm after bow (location 1) and 50 mm after mid-ship (location 2) | injection coefficient: 0.2–0.6 | Load cell located at 0.35 L |

| Hao et al., 2019 [59] | Chinese Special Vehicle Research | 550 | 6.5 | 5 | 0.12–0.27 | Flat Plate | 5.016 | 1 | 0.12 | - | - | with and without cavity | at the front of the bottom surface | ideal air thickness: 0–35 mm | four floating-plate-type friction sensors |

| 0.11–0.18 | Bulk Carrier | 6.079 | 1 | - | - | 1:38 | arc air injection device and hole-shaped air injection device (11 through-holes 10 mm in diameter) | in the arc-shape bottom cavity (4.32 m × 0.82 m × 25 mm): arc device at the fore-step position of the cavity; hole-shaped on the rear’s of the cavity front step | ideal air thickness: 0–6 mm | - | |||||

| Sindagi et al., 2021 [60] | Indian Institute of Technology Madras | 85 | 3.2 | 2.8 | 0.09–0.15 | Bulk Carrier | 5.09 | 0.87 | 0.31 | 0.21 | 1:23 | air chamber with an array of holes of 1 mm and air chamber with array of holes of 2 mm | in the front of the ship | flow rate: 0.85–5.1 m3/h | 50 Kg load cell |

| Zhao et al., 2022 [61] | Dalian University of Technology | 170 | 7 | 3.7 | 0.08–0.2 | Ship | 3 | 0.6 | 0.3 | 0.048 | Porous medium plate with pore diameter of 50 µm | air injection chamber installed at 0.75 m away from the bow | flow rate: 0.25–10 m3/h | Seaworthiness instrument | |

| Author and Year of Publication | Inner Cylinder | Gap | Radius Ratio | Reynolds Number | Void Fraction | Bubble Diameter | |

|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | Re | (%) | D (mm) | ||

| Maryami et al. [68] (2016) | 630 | 120 | 10 | 0.92 | 7·103–7·104 | 0–10 | 0.8–1.7 |

| Fokoua et al. [67] (2015) | 886 | 200 | 20 | 0.91 | 632–2·104 | 0.002–0.02 | 1–2.5 |

| Author and Year of Publication | Type of Facility | Test Section Dimension | Water Velocity (m/s) | Model/Wall | Model Dimensions/Injection Distance in Test Section (m) | Air injection | Specific Instrumentation | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Length (m) | Width (m) | Height (m) | Bubble Generation/Air Injection | Bubble Size (mm) | Air Injected (Flow Rate) | ||||||

| Elbing et al., 2013 [73] | Cavitation Tunnel | 13 | 3.5 | 3.05 | 6.3 | Flat plate | 12.9 × 3.5 × 0.18 | Backward Facing Step (13 mm) at injection location | - | 0–66 L/min | Floating-plate-type, three probe’s traversing system (pitot-static, electrical impedance and time of flight) |

| Qin et al., 2017 [74] | Cavitation Tunnel | 2.6 | 0.6 | 0.6 | 4–8 | Flat plate | 1.6 × 0.3 × 0.05 | Line of 25 solenoid-valve actuated air compressed injectors | 0.1–1 | 23.5–118 L/min | 6 force transducers 100 N capacity and high speed camera for |

| Wu et al., 2020 [75] | Low Turbulence Water Tunnel | 6.0 | 0.4 | 0.4 | 0.1–1.3 | Flat plate | 1.2 × 0.38 × 0.01 | Multiple air holes of diameter 0.2 mm | - | 0.84–206 L/min | High performance camera |

| Zhang et al., 2021 [15] | Recirculation Closed Water Tunnel | 0.76 | 0.192 | 0.192 | 2–8 | Upper wall thickened by mounting a 2D Obstacle | 0.134 | Grid of 57 needles of 180 µm in diameter | 0.4–1.3 | 0.083–1.33 L/min | Time resolved, low spatial resolution, particle image velocimetry, shadowgraphy, low frequency |

| Evseev et al., 2018 [76] | Horizontal Water Channel | 2.2 | 0.3 | 0.1 | 2–11 | Top and bottom wall | 0.615 (top wall) and 0.429 (bottom wall) | Air injection 20 µm porous medium | 0.2–1.5 | 0–420 L/min | Floating element transducer, fiber-optic sensor (void fraction) |

| Hazuku et al., 2022 [77] | Horizontal Water Channel | 3 | 0.2 | 0.05 | 1–3 | Upper wall | 0.8 | Air injection 1 mm holes | 1–6 | 18–600 L/min | Double conductivity electrical probe |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Magariño, A.; Lopez-Gavilan, P.; Sor, S.; Terroba, F. Micro/Bubble Drag Reduction Focused on New Applications. J. Mar. Sci. Eng. 2023, 11, 1315. https://doi.org/10.3390/jmse11071315

García-Magariño A, Lopez-Gavilan P, Sor S, Terroba F. Micro/Bubble Drag Reduction Focused on New Applications. Journal of Marine Science and Engineering. 2023; 11(7):1315. https://doi.org/10.3390/jmse11071315

Chicago/Turabian StyleGarcía-Magariño, Adelaida, Pablo Lopez-Gavilan, Suthyvann Sor, and Félix Terroba. 2023. "Micro/Bubble Drag Reduction Focused on New Applications" Journal of Marine Science and Engineering 11, no. 7: 1315. https://doi.org/10.3390/jmse11071315

APA StyleGarcía-Magariño, A., Lopez-Gavilan, P., Sor, S., & Terroba, F. (2023). Micro/Bubble Drag Reduction Focused on New Applications. Journal of Marine Science and Engineering, 11(7), 1315. https://doi.org/10.3390/jmse11071315