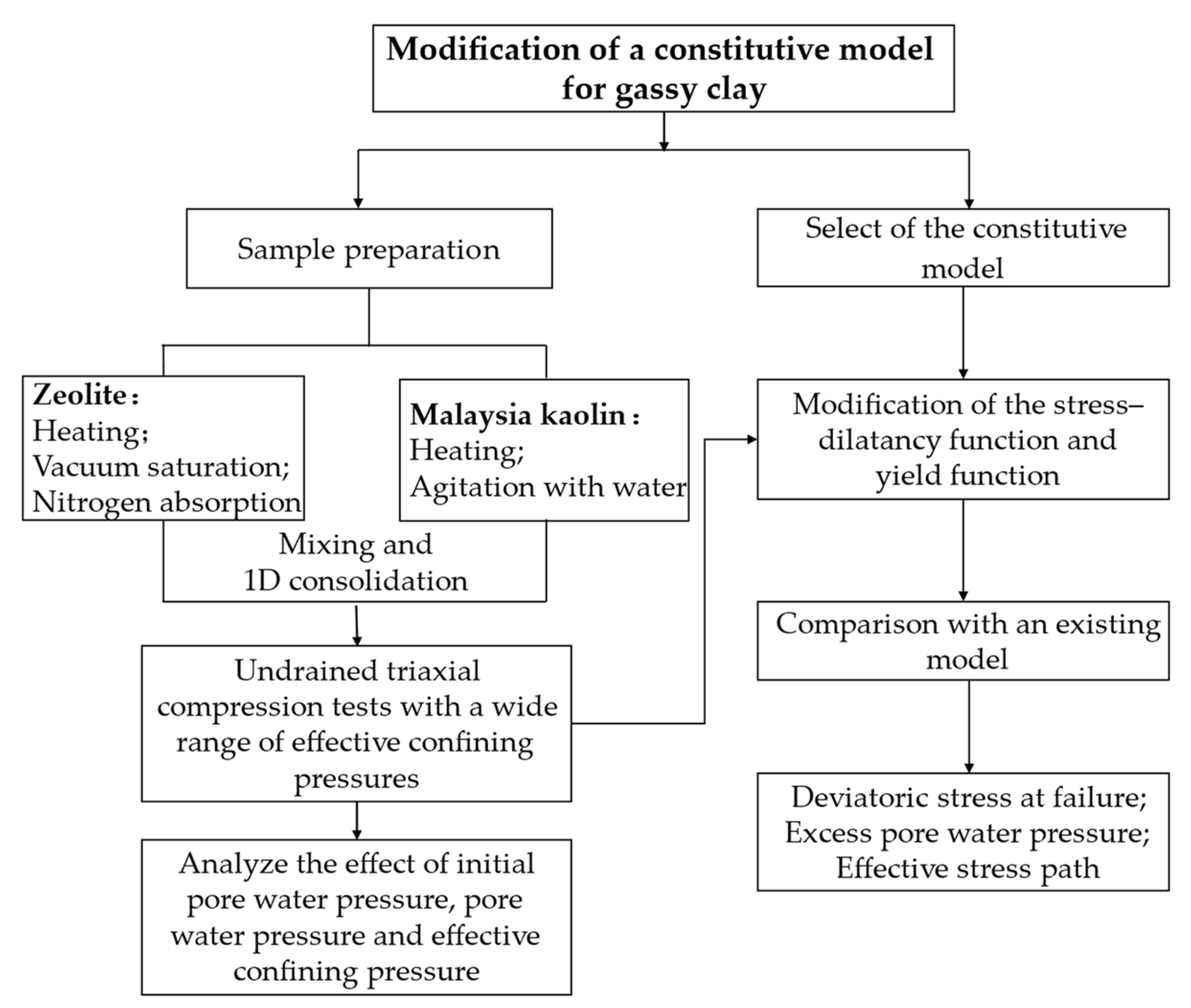

Modification of a Constitutive Model for Gassy Clay

Abstract

1. Introduction

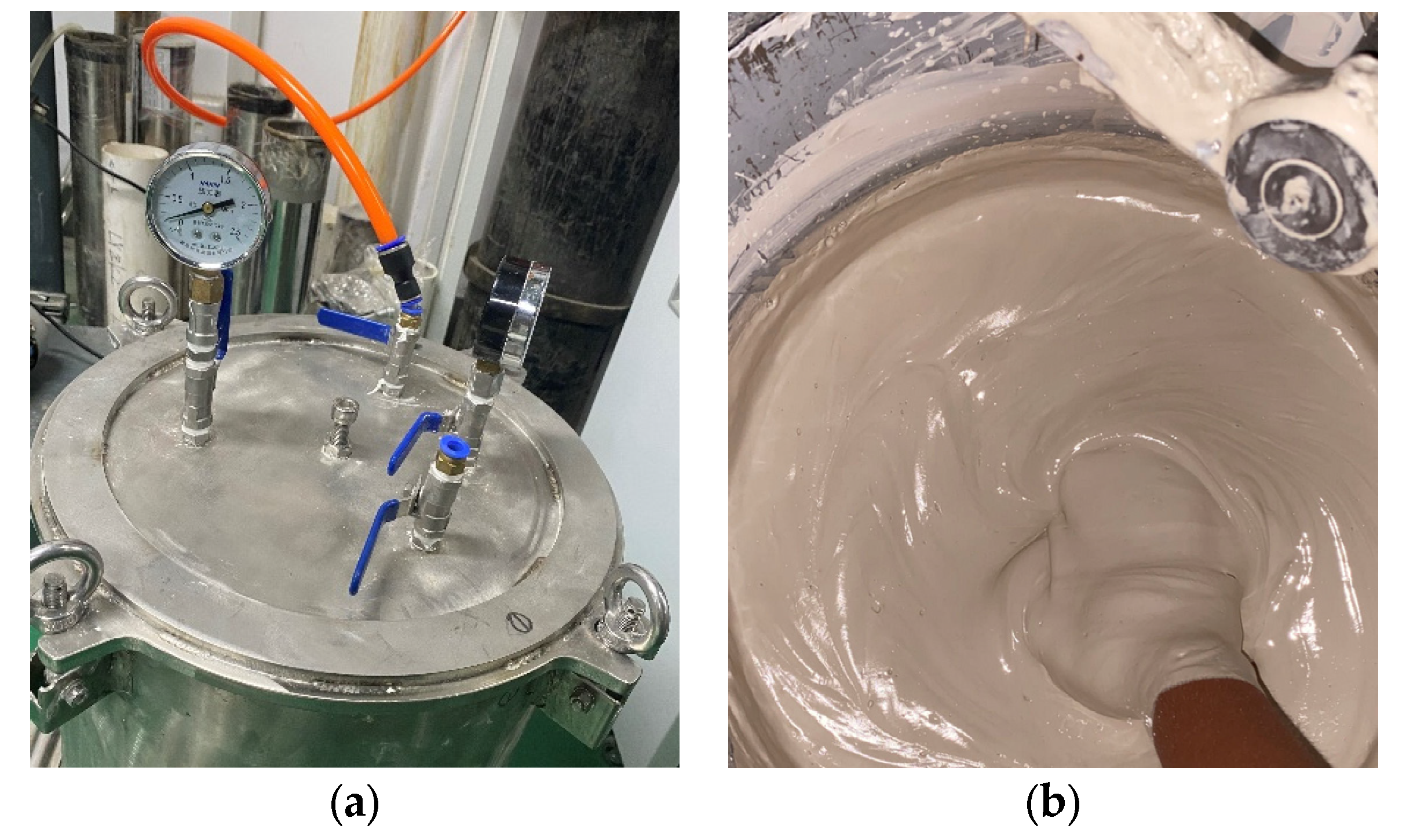

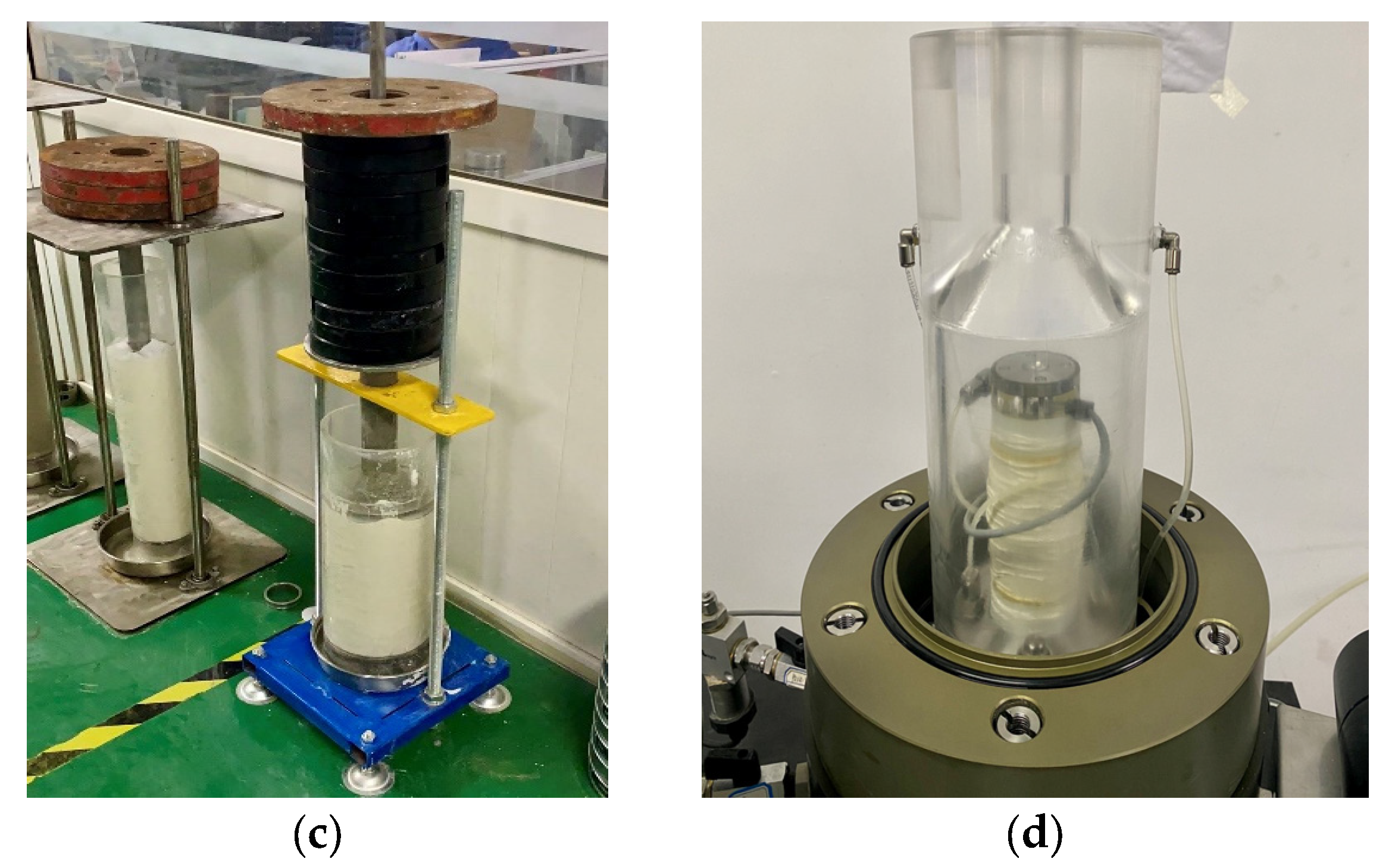

2. Testing Procedures

3. The Established Constitutive Model

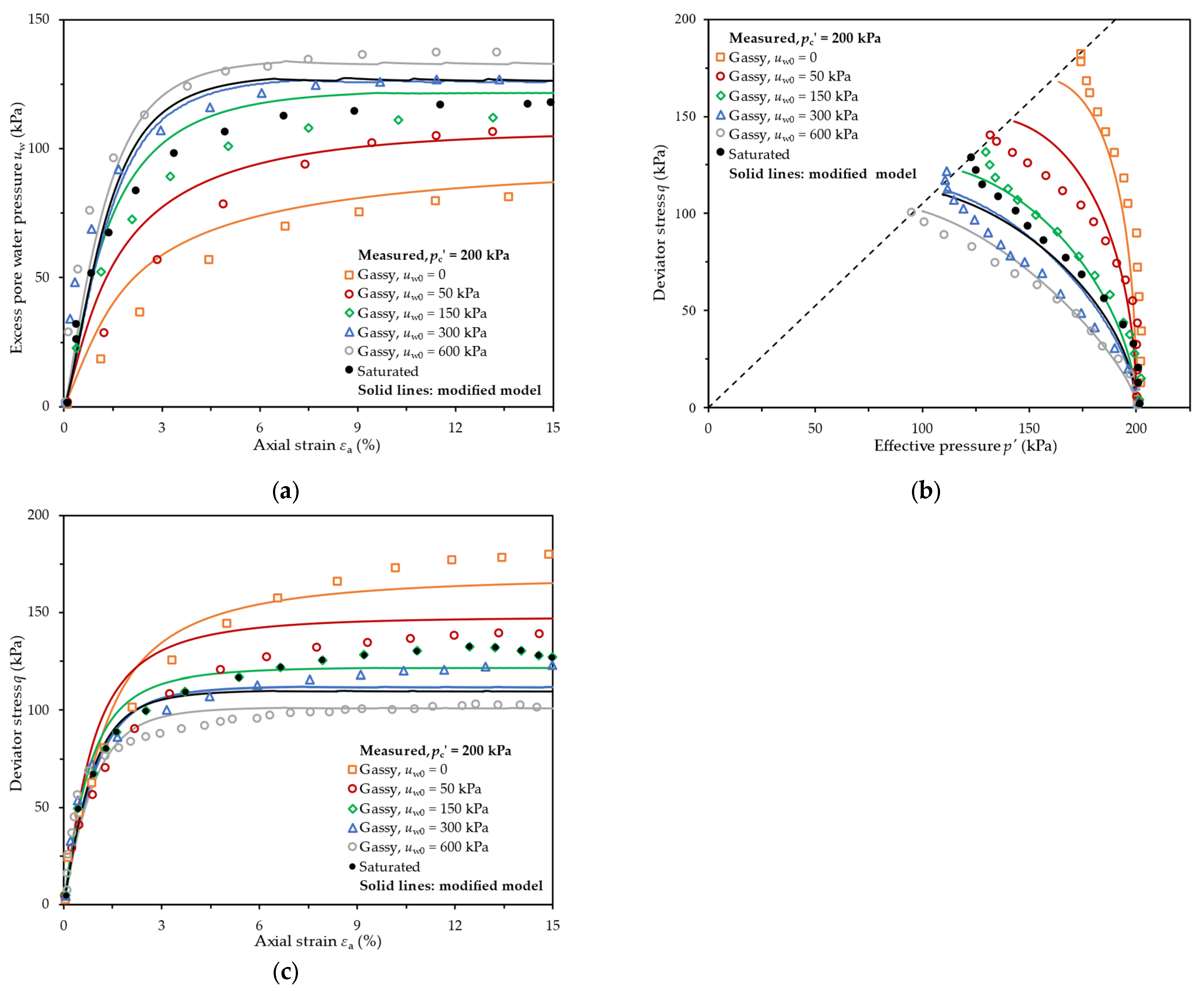

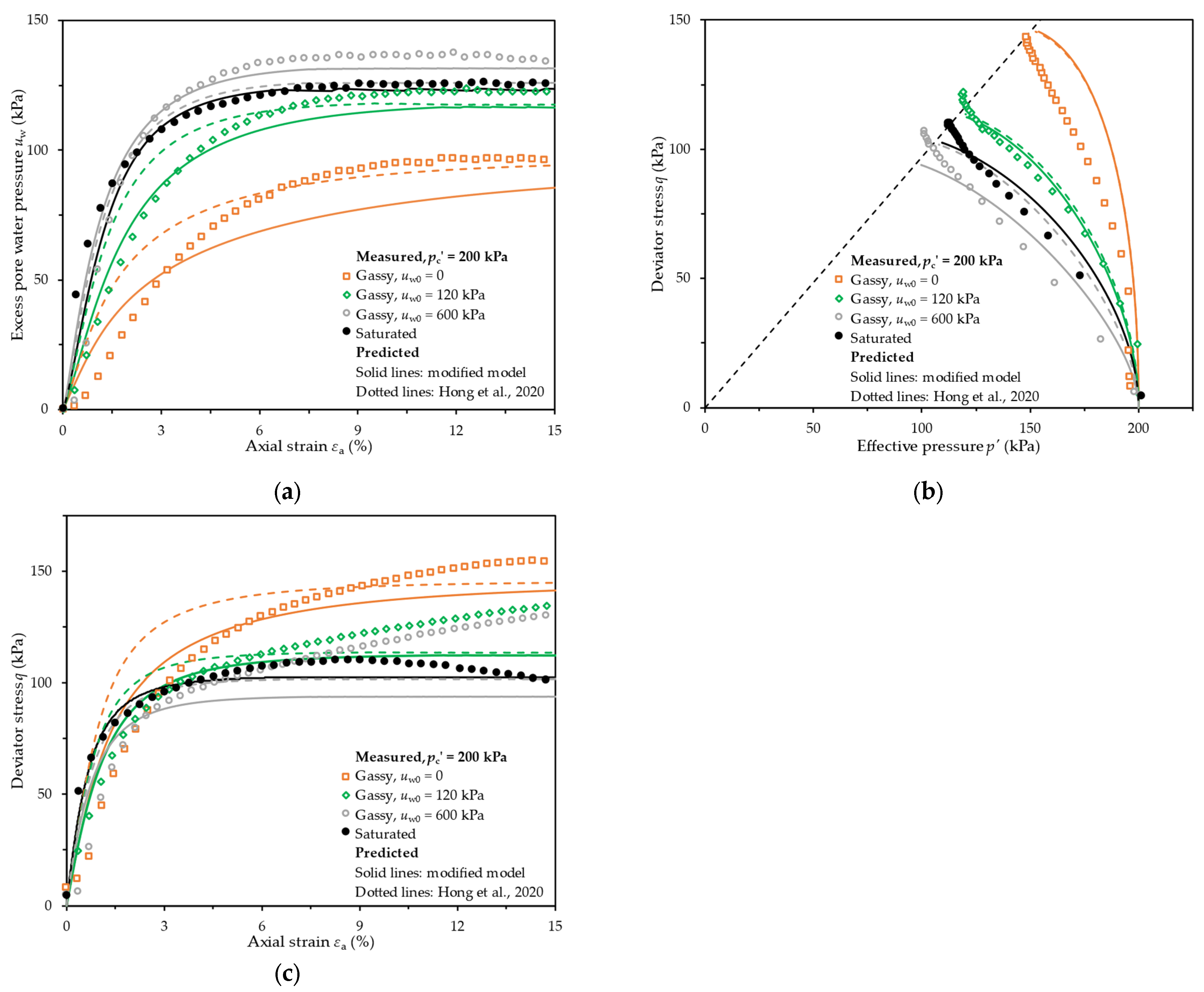

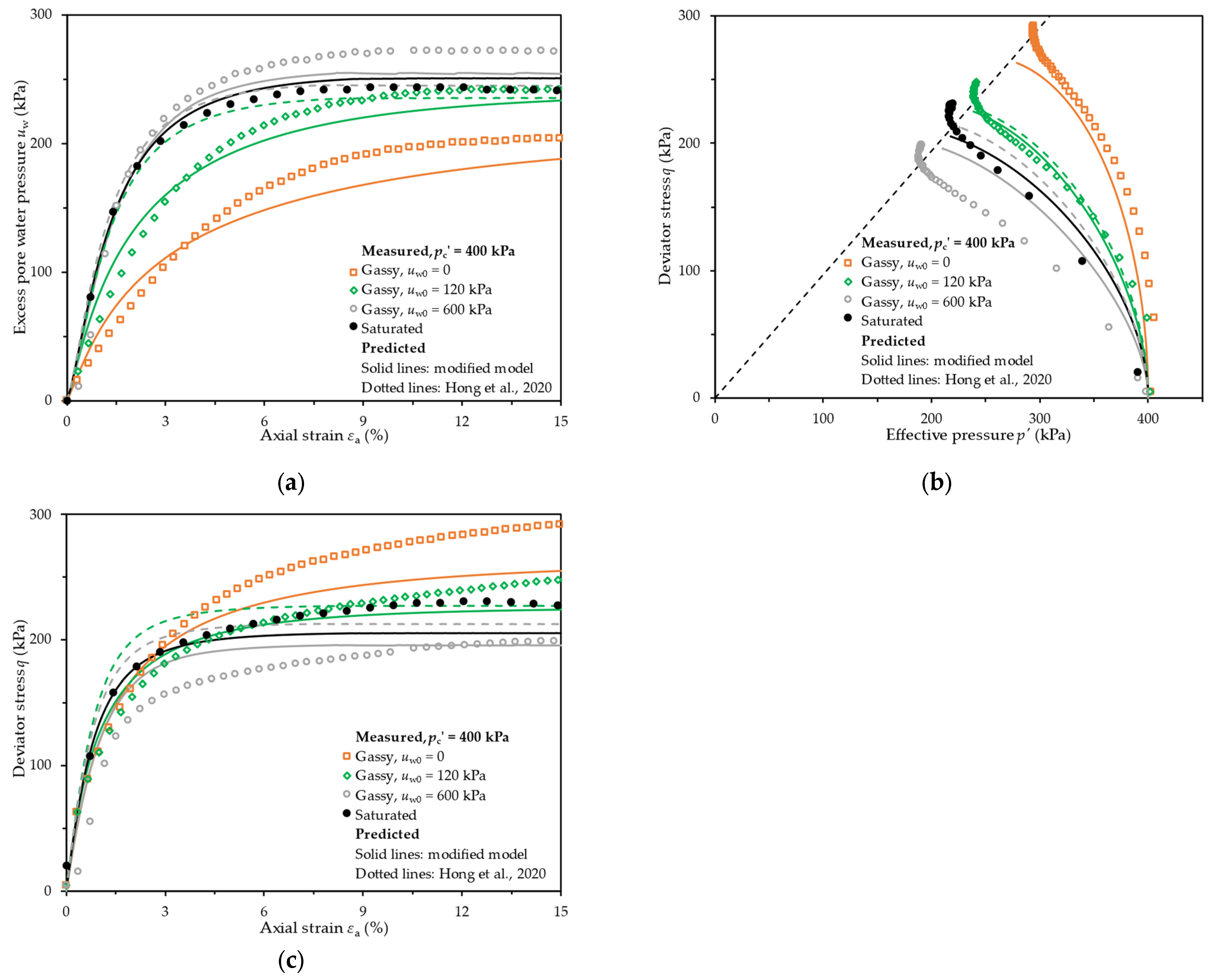

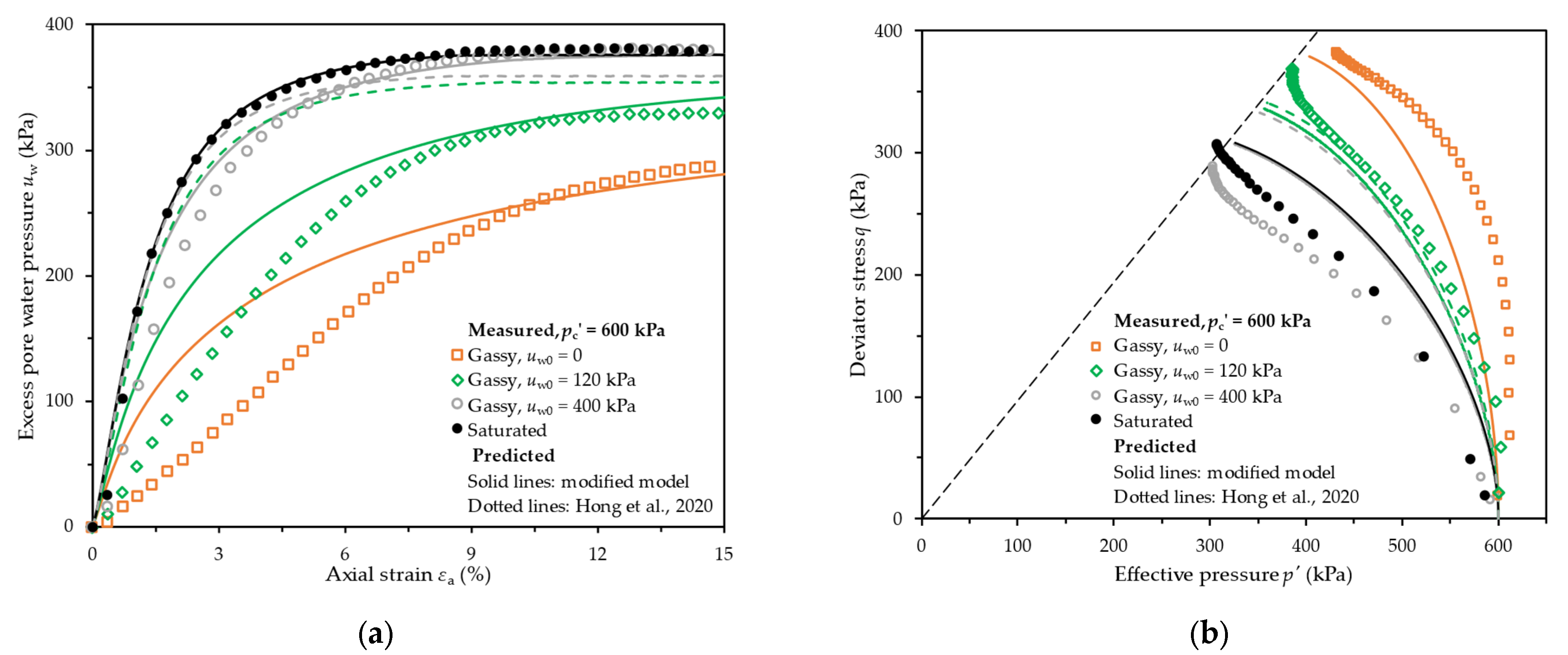

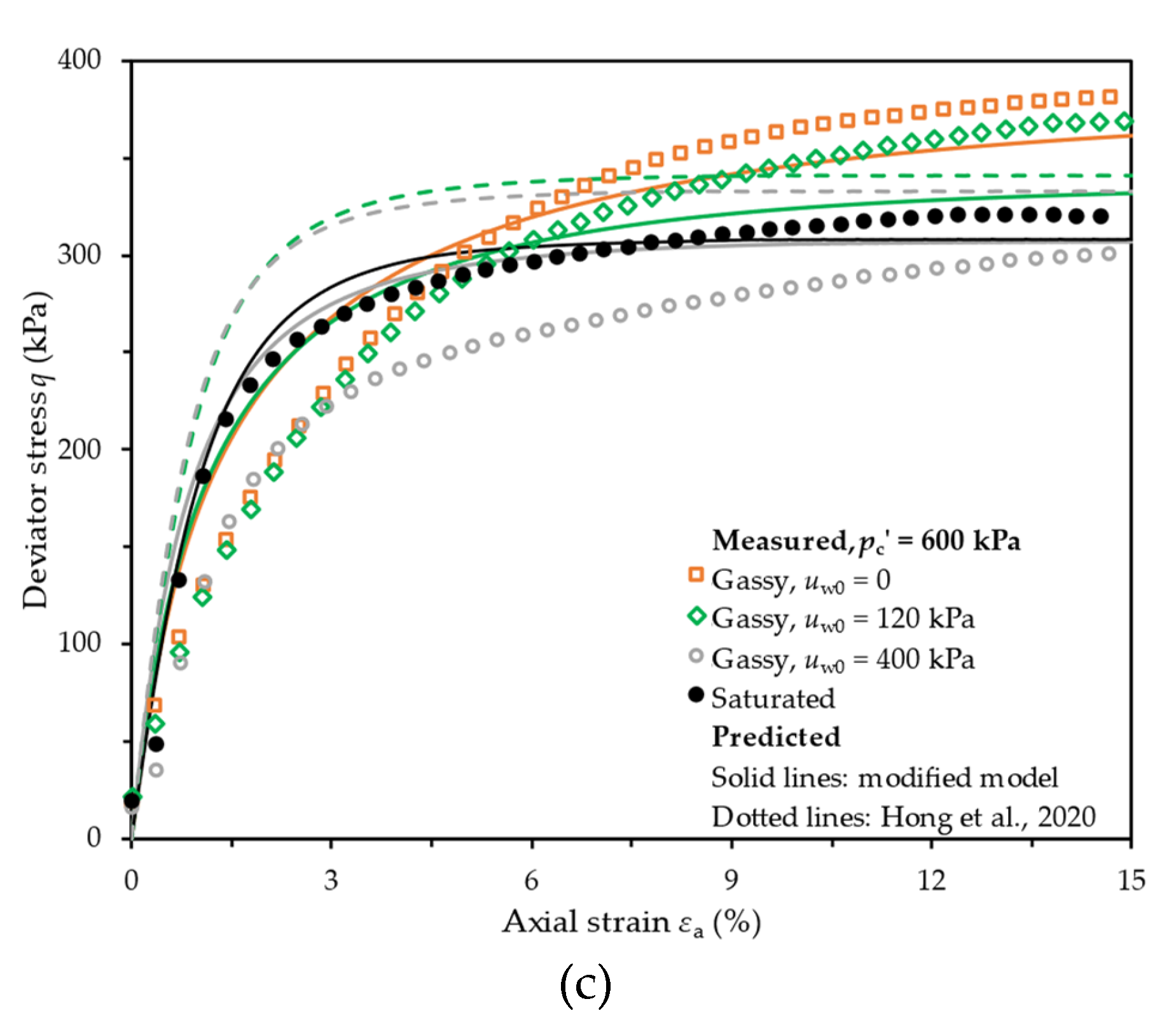

4. Improvements to a Critical State Model for Gassy Clay

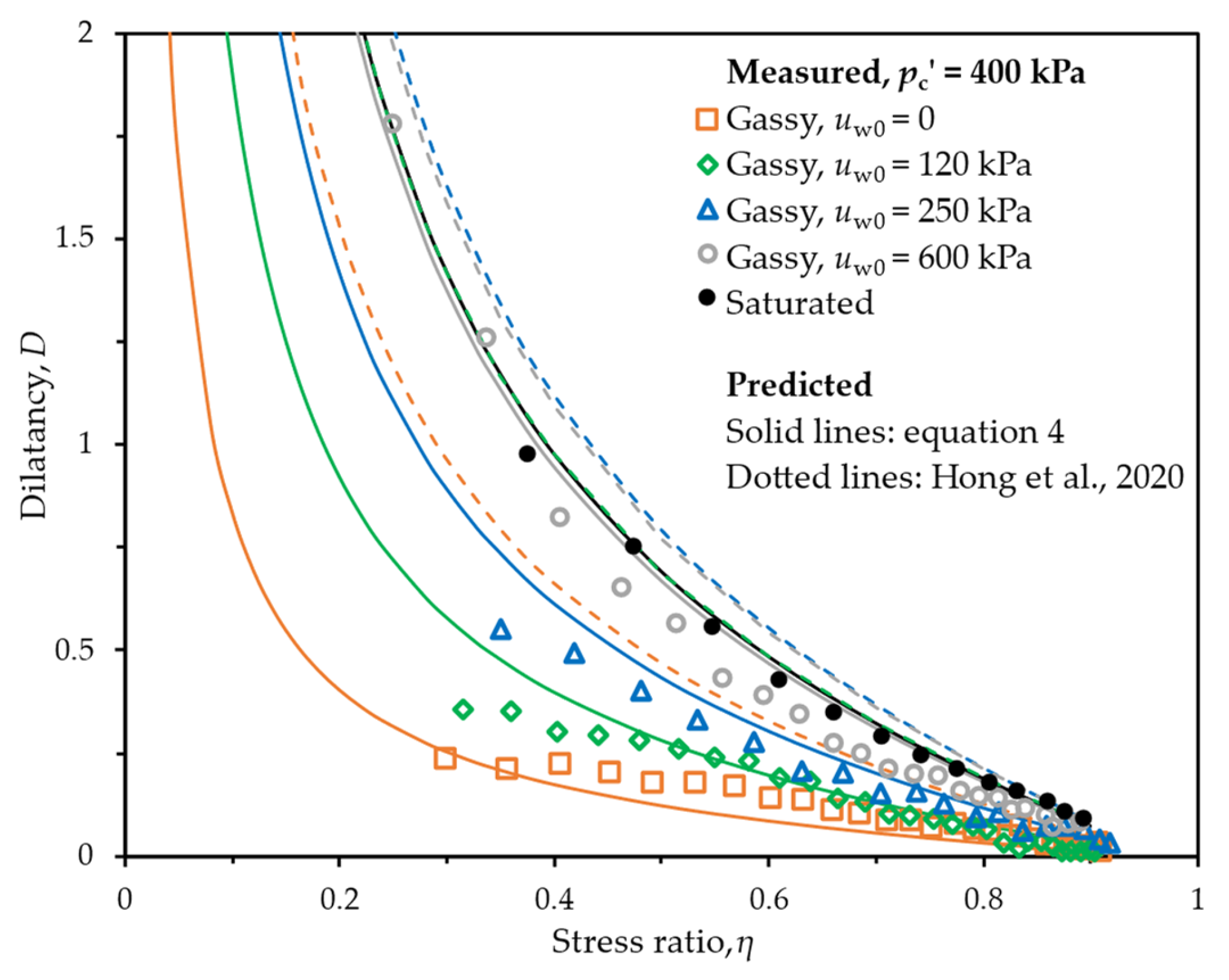

4.1. Stress-Dilatancy Function

4.2. Yield Function

5. Verification of the Model Developed

6. Results and Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Definition |

| Sr | Water saturation |

| ew | Water void ratio |

| e | Total void ratio |

| A | Gas volume fraction |

| A0 | Initial gas volume fraction |

| uw0 | Initial pore water pressure |

| LL | Liquid limit |

| PL | Plastic limit |

| Gs | Specific gravity |

| cv | Coefficient of consolidation |

| pc′ | Effective confining pressure |

| p′ | Mean effective stress |

| q | Deviatoric stress |

| K, G | Elastic bulk and shear modulus of the soil matrix |

| α, μ | Shape parameters of the yield surface |

| a, b, c | Parameters controlling the yield surface |

| D | Dilatancy |

| ξ, χ, m1, β | Parameters governing the stress-dilatancy |

| η | Stress ratio |

| M | Stress ratio at critical state |

| λ | Slope of the virgin consolidation line |

| κ | Slope of the swelling line |

| Increment of total, elastic, and plastic deviatoric strain of the soil matrix, respectively. | |

| Increment of total elastic and plastic volumetric strain of the soil matrix, respectively. | |

| f | Yield function |

| K1, 2 | Constant of the yield function |

| uw0_ref | Reference pore water pressure |

| eN | Intercept of the virgin consolidation line |

| v | Poisson’s ratio |

| εa | Axial strain |

| uw | Excess pore water pressure |

References

- Floodgate, G.D.; Judd, A.G. The origins of shallow gas. Cont. Shelf Res. 1992, 12, 1145–1156. [Google Scholar] [CrossRef]

- Sultan, N.; De Gennaro, V.; Puech, A. Mechanical behaviour of gas–charged marine plastic sediments. Geotechnique 2012, 62, 751–766. [Google Scholar] [CrossRef]

- Claypool, G.E.; Kaplan, I.R. The origin and distribution of methane in marine sediments. In Natural Gases in Marine Sediments; I.R. Kaplan: New York, NY, USA, 1974; pp. 99–139. [Google Scholar]

- Grozic, J.L.; Robertson, P.K.; Morgenstern, N.R. Cyclic liquefaction of loose gassy sand. Can. Geotech. J. 2000, 37, 843–856. [Google Scholar] [CrossRef]

- Liu, T.; Yang, X.T.; Zhang, Y. A Review of Gassy Sediments: Mechanical Property, Disaster Simulation and In-Situ Test. Front. Earth Sci. 2022, 10, 915735. [Google Scholar] [CrossRef]

- Vega-Posada, C.A.; Finno, R.J.; Zapata-Medina, D.G. Effect of Gas on the Mechanical Behavior of Medium-Dense Sands. J. Geotech. Geoenviron. Eng. 2014, 140, 04014063. [Google Scholar] [CrossRef]

- Locat, J.; Lee, H.J. Submarine landslides: Advances and challenges. Can. Geotech. J. 2002, 39, 193–212. [Google Scholar] [CrossRef]

- Riboulot, V.; Cattaneo, A.; Sultan, N.; Garziglia, S.; Ker, S.; Imbert, P.; Voisset, M. Sea–level change and free gas occurrence influencing a submarine landslide and pockmark formation and distribution in deepwater Nigeria. Earth Planet Sci. Lett. 2013, 375, 78–91. [Google Scholar] [CrossRef]

- Jommi, C.; Muraro, S.; Trivellato, E.; Zwanenburg, C. Experimental results on the influence of gas on the mechanical response of peats. Geotechnique 2019, 69, 753–766. [Google Scholar] [CrossRef]

- Gao, Z.W.; Hong, Y.; Wang, L.Z. Constitutive modelling of fine-grained gassy soil: A composite approach. Int. J. Numer. Anal. Methods Geomech. 2020, 44, 1350–1368. [Google Scholar] [CrossRef]

- Hong, Y.; Wang, L.Z.; Ng, C.W.W.; Yang, B. Effect of initial pore pressure on undrained shear behaviour of fine–grained gassy soil. Can. Geotech. J. 2017, 54, 1592–1600. [Google Scholar] [CrossRef]

- Nageswaran, S. Effect of Gas Bubbles on the Seabed Behaviour. Ph.D. Thesis, St. Catherine’s College, Oxford University, Oxford, UK, 1983. [Google Scholar]

- Wheeler, S.J. The undrained shear strength of soils containing large gas bubbles. Geotechnique 1988, 38, 399–413. [Google Scholar] [CrossRef]

- Sills, G.C.; Wheeler, S.J.; Thomas, S.D.; Gardner, T.N. Behaviour of offshore soils containing gas bubbles. Geotechnique 1991, 41, 227–241. [Google Scholar] [CrossRef]

- Puzain, A.M.; Tront, J.; Schmid, A.; Hughes, J.B. Engineered use of microbial gas production to decrease primary consolidation settlement in clayey soils. Geotechnique 2011, 61, 785–794. [Google Scholar]

- Kaminski, P.; Urlaub, M.; Grabe, J.; Berndt, C. Geomechanical behaviour of gassy soils and implications for submarine slope stability: A literature analysis. Geol. Soc. Lond. Spec. Publ. 2020, 500, 277–288. [Google Scholar] [CrossRef]

- Pietruszczak, S.; Pande, G.N. Constitutive relations for partially saturated soils containing gas inclusions. Geotech. Eng. 1996, 122, 50–59. [Google Scholar] [CrossRef]

- Grozic, J.L.H.; Nadim, F.; Kvalstad, T.J. On the undrained shear strength of gassy clays. Comput Geotech. 2005, 32, 483–490. [Google Scholar] [CrossRef]

- Sultan, N.; Garziglia, S. Mechanical behaviour of gas–charged fine sediments: Model formulation and calibration. Geotechnique 2014, 64, 851–864. [Google Scholar] [CrossRef]

- Yang, G.; Bai, B. A thermodynamic model to simulate the thermo-mechanical behavior of fine-grained gassy soil. B Eng. Geol. Environ. 2020, 79, 2325–2339. [Google Scholar] [CrossRef]

- Hong, Y.; Wang, L.Z.; Zhang, J.F.; Gao, Z.W. 3D elastoplastic model for fine–grained gassy soil considering the gas–dependent yield surface shape and stress–dilatancy. J. Eng. Mech. 2020, 146, 04020037. [Google Scholar] [CrossRef]

- Best, A.I.; Tuffin, M.D.J.; Dix, J.K.; Bull, J.M. Tidal height and frequency dependence of acoustic velocity and attenuation in shallow gassy marine sediments. J. Geophys. Res. 2004, 109, B08101. [Google Scholar] [CrossRef]

- Yang, S.; Choi, J.C.; Vanneste, M.; Kvalstad, T. Effects of gas hydrates dissociation on clays and submarine slope stability. B Eng. Geol. Environ. 2018, 77, 941–952. [Google Scholar] [CrossRef]

- Ilyas, T.; Leung, C.F.; Chow, Y.K.; Budi, S.S. Centrifuge model study of laterally loaded pile groups in clay. J. Geotech. Geoenviron. 2004, 130, 274–283. [Google Scholar] [CrossRef]

- Wang, L.Z.; Lai, Y.Q.; Hong, Y.; Masin, D. A unified lateral soil reaction model for monopiles in soft clay considering various length–to–diameter (L/D) ratios. Ocean Eng. 2020, 212, 107492. [Google Scholar] [CrossRef]

- Xie, Y.; Leung, C.F.; Chow, Y.K. Centrifuge modelling of spudcan–pile interaction in soft clay. Geotechnique 2012, 62, 799–810. [Google Scholar] [CrossRef]

- BS 5930; Code of Practice for Site Investigations. British Standards Institution: London, UK, 2015.

- ASTM D2435-11; Standard Test Methods for One Dimensional Consolidation Properties of Soils Using Incremental Loading. ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM D4767-11; Standard Test Method for Consolidated Undrained Triaxial Compression Test for Cohesive Soils. ASTM International: West Conshohocken, PA, USA, 2011.

- Wilkens, R.H.; Richardson, M.D. The influence of gas bubbles on sediment acoustic properties: In situ, laboratory, and theoretical results from Eckernforde Bay, Baltic sea. Cont. Shelf Res. 1998, 18, 1859. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Zhan, L.T.; Cui, Y.J. A new simple system for measuring volume changes in unsaturated soils. Can. Geotech. J. 2002, 39, 757–764. [Google Scholar] [CrossRef]

- Rahman, M.A.; Shahin, H.M.; Nakai, T. Stress–strain–dilatancy relationships of normally consolidated dhaka clay. Int. J. Geomate. 2018, 15, 188–194. [Google Scholar] [CrossRef]

- Wheeler, S.J.; Näätänen, A.; Karstunen, M.; Lojander, M. An anisotropic elastoplastic model for soft clays. Can. Geotech J. 2003, 40, 403–418. [Google Scholar] [CrossRef]

- Wang, L.Z.; Yin, Z.Y. Stress dilatancy of natural soft clay under an undrained creep condition. Int. J. Geomech. 2015, 15, A4014002. [Google Scholar] [CrossRef]

- Sham, W.K. The Undrained Shear Strength of Soils Containing Large Gas Bubbles. Ph.D. Thesis, Department of Civil Engineering, Queen’s University, Belfast, UK, 1989. [Google Scholar]

- Lagioia, R.; Puzrin, A.M.; Potts, D.M. A new versatile expression for yield and plastic potential surfaces. Comput. Geotech. 1996, 19, 171–191. [Google Scholar] [CrossRef]

- Kaminski, P.; Sager, T.; Grabe, J.; Urlaub, M. A new methodology to assess the potential of conjectural trigger mechanisms of submarine landslides exemplified by marine gas occurrence on the Balearic Promontory. Eng. Geol. 2021, 295, 106446. [Google Scholar] [CrossRef]

- Weber, R.C.; Romero, E.; Lloret, A. Shear strength and yield surface of a partially saturated sandy silt under generalized stress states. Can. Geotech. J. 2022, 59, 1188–1204. [Google Scholar] [CrossRef]

- Oliynyk, K.; Ciantia, M.O.; Tamagnini, C. A finite deformation multiplicative plasticity model with non–local hardening for bonded geomaterials. Comput. Geotech. 2021, 137, 104209. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Liquid limit, LL: % | 80 |

| Plastic limit, PL: % | 35 |

| Specific gravity, Gs | 2.60 |

| Coefficient of consolidation (at 100 kPa), cv: m2/year | 40 |

| Effective Confining Pressure, pc’: kPa | Initial Pore Water Pressure, uw0: kPa | Initial Water Void Ratio, ew0 | Initial Degree of Saturation, Sr0: % | Initial Gas Volume Fraction, A0: % |

|---|---|---|---|---|

| 200 | 0 | 0.97 | 90.0 | 5.2 |

| 120 | 1.02 | 93.5 | 3.4 | |

| 250 | 1.13 | 98.1 | 1.0 | |

| 600 | 1.11 | 98.8 | 0.6 | |

| — | 1.43 | 100.0 | 0 | |

| 400 | 0 | 1.04 | 89.2 | 5.8 |

| 120 | 1.09 | 94.1 | 3.2 | |

| 250 | 1.04 | 96.7 | 1.7 | |

| 600 | 1.08 | 98.6 | 0.7 | |

| — | 0.93 | 100.0 | 0 | |

| 600 | 0 | 0.86 | 89.2 | 5.3 |

| 120 | 0.94 | 93.6 | 3.2 | |

| 250 | 1.02 | 95.1 | 2.5 | |

| 400 | 1.08 | 98.8 | 0.6 | |

| — | 0.94 | 100.0 | 0 |

| Description | Equations |

|---|---|

| Elastic behavior | |

| Yield function | |

| Dilatancy | |

| Flow rule | |

| Hardening |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, T.; Wang, D.; Yang, X. Modification of a Constitutive Model for Gassy Clay. J. Mar. Sci. Eng. 2023, 11, 1013. https://doi.org/10.3390/jmse11051013

An T, Wang D, Yang X. Modification of a Constitutive Model for Gassy Clay. Journal of Marine Science and Engineering. 2023; 11(5):1013. https://doi.org/10.3390/jmse11051013

Chicago/Turabian StyleAn, Tao, Dong Wang, and Xiurong Yang. 2023. "Modification of a Constitutive Model for Gassy Clay" Journal of Marine Science and Engineering 11, no. 5: 1013. https://doi.org/10.3390/jmse11051013

APA StyleAn, T., Wang, D., & Yang, X. (2023). Modification of a Constitutive Model for Gassy Clay. Journal of Marine Science and Engineering, 11(5), 1013. https://doi.org/10.3390/jmse11051013