Abstract

The term “sea waste” generally refers to any solid, liquid, or gaseous material or substance that is discarded, disposed of, or abandoned in the ocean, sea, or any other body of salty water, such as a lagoon, etc. This includes waste generated by human activities on land that makes its way into the ocean, as well as waste generated by ships and other vessels at sea. Examples of sea waste include plastic debris, chemicals and toxic substances, oil spills, sewage, and other forms of pollution. These pollutants can harm marine ecosystems, endanger marine life, and impact human health and wellbeing. Efforts are being made by governments, organizations, researchers, and individuals to reduce the amount of sea waste generated, and to clean up existing waste in the ocean. Less attention is usually paid to waste materials of natural origin as they are considered (sometimes wrongly) to be less critical; an example is the tons of organic and inorganic material of natural origin that wash up on the beaches daily and must be landfilled or incinerated. The present paper intends to provide an updated review of research experiences and engineering solutions that are able to offer a second life to natural (biological) sea waste by incorporating it into the creation of new, more sustainable materials, and especially composites.

1. Introduction

In the field of maritime activities, a variety of sources of refuse are present. These need attention in relation to the management of planetary resources towards a circular economy and include, e.g., waste originating from the extensive use of composites in the fabrication of ships and boats. These composites remain at sea after dismantling or are very sparsely and randomly managed, and have been brought to the attention of researchers in the field [1]. Marine pollution caused by the presence of sea-dispersed materials is a serious issue that receives significant attention; particularly regarding microplastics, whose detection is increasingly perfected through qualitative and quantitative methods [2]. A recent review clarified the potential for, and the technical perspectives of, the mitigation of microplastics’ environmental impact [3]. These materials primarily result from the degradation of products from specific industries such as packaging [4] and textiles [5]. However, human activities at sea also contribute to the problem, for example, just to name one activity directly connected to the sea, the progressive deterioration of fishing nets capable of incorporating within themselves large quantities of various refuse [6].

Generally, it can be said that it should be possible to reuse sea waste in various ways, thereby turning a problem into an opportunity. One of the most effective ways is through recycling [7]. This involves collecting and processing materials such as plastics, metals, and glass from the ocean to create new products. Recycling can help reduce the amount of waste in the ocean, prevent further pollution, and preserve natural resources.

Other ways to reuse sea waste include using it in energy recovery through incineration [8], or to produce energy directly. For example, ocean currents can be employed to generate electricity through the use of underwater turbines [9]. Additionally, some forms of sea waste, such as organic matter, can be converted into biofuels [10] or used as a source of biogas through the process of anaerobic digestion; especially when rich in polysaccharides, as is the case with algae [11].

In recent years, there has been increasing interest in recycling ocean plastics to create new products such as clothing [12], furniture complements and stuffing [13], and building materials [14]. This can help to reduce the amount of virgin materials needed for production and create a circular economy for ocean waste.

Furthermore, some organizations are developing technologies to capture and utilize carbon dioxide from the ocean to reduce greenhouse gas emissions. These technologies involve the use of seaweed or other types of marine biomass to capture and store carbon dioxide from the atmosphere [15].

Overall, there are many potential ways to reuse sea waste, and ongoing research and development in this area will help to uncover new opportunities for sustainable utilization of ocean resources.

While the above issues are well known, the relevance of natural waste as a source of marine pollution, on which the present work focuses, is often overlooked. Biological waste from sea-related activities can take various forms: ceramics, such as mollusk shells made of calcium carbonate [16]; fish scales, a hydroxyapatite-collagen composite [17]; polysaccharides, such as chitin from crustacean exoskeletons [18]; or cellulose from excess algae resulting from eutrophication [19]. Some types of waste that are considered in the present review are shown in Figure 1 as examples of sea-derived biological waste.

Figure 1.

Some of the sea-derived biological waste proposed for use in materials’ development.

Unfortunately, there are currently no established solutions for reusing these materials. This is still true, despite the fact that some high-profile applications have been attempted. For example, the addition of seashell powder to active carbons magnetized with ferrous-ferric oxide (Fe3O4) assists the removal of chemicals, such as methylene blue, from water solutions [20]. The production of nanocomposites based on zinc oxide and biochar has also been carried out using extracts of sea lettuce (Ulva lactuca) waste from the Black Sea [21]. Regarding biologically active carbons, a proposal has been made to obtain a novel cathode for lithium-sulfur batteries with good initial capacity, quite easily retained thereinafter, from Posidonia oceanica sea waste [22]. In the case of chitin-based shrimp exoskeletons, a possible application in a soil bioremediation process has also been suggested [23].

However, in the most common case, they become waste that needs to be managed. In natural fiber composites, cellulose in the form of short fibers or disorganized fabrics can serve as reinforcement, while pulverized ceramic can be used as a filler, to enhance the tensile strength and hardness of polymeric matrices. However, managing the inherent variability of these materials’ chemical and mechanical properties is crucial for their effective use. When using natural waste as a functional material, managing its chemical and mechanical variability is even more critical. Non-compostable marine waste, in particular, contains high levels of cellulose, lignin, carbonates, or silicates which must be characterized precisely for their purity. Additionally, they are difficult to process as they are often contaminated by human-made waste or through their use in manufacturing chains, such as food production or fishing. A short and introductory review has been published already, yet it mostly concentrated on the use of calcium carbonate from seashells in concrete, a straightforward and limited risk application [24].

The present work aims at more generally elucidating recent advancements in the use of sea waste to produce advanced materials, with special attention to reinforced composites that may represent the most promising destination of use for such waste. Materials produced from waste become more sustainable in terms of environmental impact, even if they introduce non-marginal challenges in terms of development, production, and use. This paper is focused on such unusual topics, proposing itself as a basis for further insights.

2. Methodological Approach

The present analysis is based on a few methodological concepts.

In terms of data source and consistency:

- -

- Apart from exceptions, which are introduced to provide an historical framework, only very recent investigations and case studies were considered (typically within the last 5 years). In this period, the subject investigated has experienced very significant developments.

- -

- Only investigations and case studies from already-published scientific studies are considered here. No references to activity carried out for industrial and/or commercial purposes are provided outside scientifically based research.

In terms of data information analysis, with the scope of providing a better classification of information, investigations were distinguished based on the element of the composite materials that were substituted by biological sea waste, between:

- reinforcement/filler (e.g., fibers or particles);

- matrix (e.g., biopolymers)

3. Reinforcements

3.1. Ceramic Fillers

The high purity of calcium carbonate content (95–97%) of mussel shells makes this filler, when powdered, a suitable component in cement, and in particular as the replacement for aggregate. In this sense, mussel shells represent one of the so-called “aquaculture modifiers”, together with, e.g., oyster shells or scallop shells, which are globally presented in [25]. In the case of polymers, calcium carbonate is frequently used to reduce their cost, improve their properties (in particular hardness), and better control their rheology during molding. As a substitute for extracted limestone, mussel shells are lately in competition with eggshell powder (ESP), which also has around 95% calcium carbonate content [26]. The two fillers have their origin as food industry waste in common. However, it can also be observed that calcium carbonate is prevalently formed by aragonite crystals, a high-density and -hardness material; thence it is very adapted as a bio-filler for polymer matrices [27]. Some uncertainty remains about whether the few percentages of proteinaceous matter present in both of them would effectively link with the polymer or should be removed, possibly by thermal degradation, as they might harm the performance of the manufactured materials [28].

The use of seashells in thermoplastic polymers requires more sophisticated methods, such as directly blending in polymer pellets before twin-screw extrusion, such as in [29] where proportions of seashells (SS) of up to 18% were introduced in a nylon-6 matrix. Seashell content of up to 15% increases the composite crystallinity, leading to higher storage modulus, and at 18% content, SS leads to a more pronounced elastic behavior, as indicated by the lower loss modulus, though the temperature for degradation onset is lower for higher oxidative stability.

Another possibility regarding the use of calcium carbonate from seashells is its introduction in a bio-based polymer, as is the case for bio-epoxy. The work from Fombuena et al. evidenced as two main points the significant increase in flexural properties, up to 50%, achievable through the introduction of 30 wt.% seashell calcium carbonate, and, once again, the higher thermal stability subsequently reached, with an increase in glass transition temperature from 80.6 °C to 91 °C [30]. A similar work, though focusing on bio-polyurethane with 25% castor oil resin content, was carried out in [31] to improve the sound absorption characteristics of polyurethane foam, namely below 500 Hz, and at the same time to enhance its compression strength. To try to standardize test results, especially in regards to thermal characterization, it is essential to offer indications about the exact species from which the shells are obtained, as was the case for one of the first studies in the sector, concerning Rapana Thomasiana, a type of sea-snail [32]. To continue with the specific uses of seashell powder from certain species, the use of cowrie shell powder in polypropylene-acrylonitrile injection-molded composites has also been reported [33].

In Table 1, the characteristics and main achievements of some studies on seashell-filled composites are reported. The first studies [34,35,36,37,38,39,40,41] specifically concern mechanical properties, whereas the following ones [42,43,44,45] are described in the parts regarding other properties, such as biological, optical, etc.

Table 1.

Studies on ceramic sea waste in polymer matrices.

In particular, the introduction of clamshell powder has been investigated as an improvement for providing a more regular drilling performance of glass fiber-reinforced plastics [46]. Most recent studies also involved the study of biodegradable matrices, such as polycaprolactone (PCL), when added to different kinds of calcium carbonate shells, and considered that those of agricultural origin are mainly based on calcite, while seashells are conversely constituted of aragonite [47,48].

The above considerations open the field to the possible comparison of seashell calcium carbonate as a filler for polymers, even a bio-based polymer such as poly(lactic acid) (PLA) when compared to other types of food waste of different origins [49]. The main requirement in this case is to increase as much as possible the amount of filler introduced into the polymer with limited detriment to its structural properties: a comparative indication of the different percentages introduced over 100 parts of polymer is offered in Figure 2. From the reported information, it is clear that powdered mussel shell represents one of the wastes most adapted for matrix-filling, as demonstrated by the high quantity it is possible to introduce. Even more recently, the introduction of seashell powder, combined with various ligno-cellulosic wastes, also led to the potential prototyping of more structural products, such as in the case of a centrifugal clutch lining for a motorcycle [50]. The synergistic effect of different sea-derived wastes proved to be of interest for achieving enhanced properties with different aspects, such as obtaining flame retardancy together with antimicrobial effects [51].

Figure 2.

Amounts of powdered food wastes capable of being introduced into a poly(lactic acid) (PLA) matrix (elaborated from preliminary tests for [45]).

3.2. Cellulosic Fillers

The function of filler in polymer matrices of different origins and nature can also be exerted by fibers obtained from prevalently cellulosic sea-derived waste—namely algae and other plants such as Posidonia oceanica—growing at sea, yet extirpated from particular areas, typically due to weather-related events or to specific activities, such as trawl fishing [52]. These materials would become refuse unless economic opportunities for recycling are offered. In the case of Posidonia, an over-abundant waste in the Mediterranean context, and a refuse produced in quantities which can be only partially used for seashore protection, a proposal has been made for it to become a raw material for the wood chipboard industry [53]. A further possibility, given the high amount and crystallinity of cellulose present, e.g., in algae cells, is the extraction of microcrystalline cellulose (MCC) from this waste [54,55]. This bears some interest, though it might be chemically intensive due to the substantial use of acids required, and is also strongly dependent on the algal species for MCC yield.

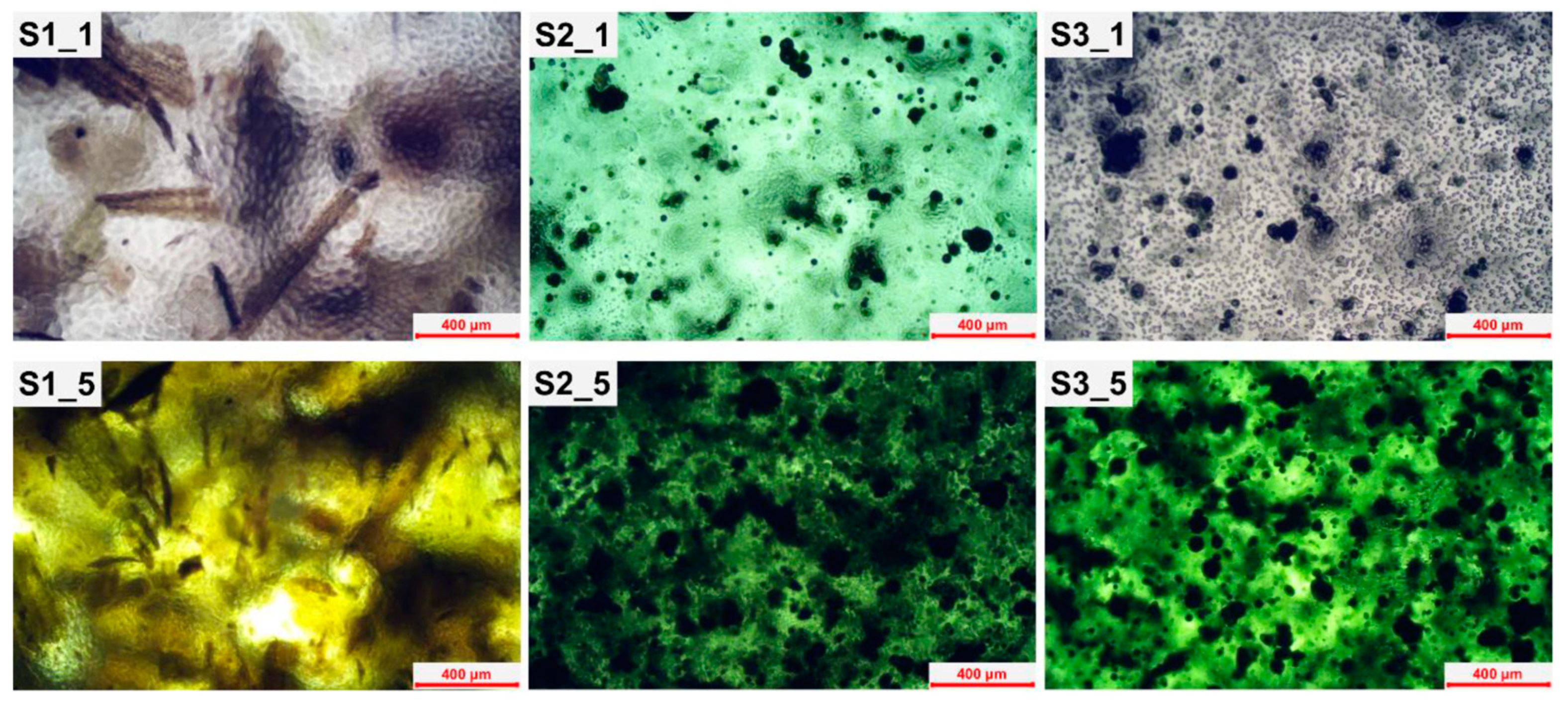

For the possible use of cellulosic marine waste in composites, the same issue reported above for ceramic fillers appears substantial. In practice, the limited knowledge of engineers about the botanical nature, properties, and origin of cellulosic biomass results in an equally incomplete development of possible biocomposites from their use, as reported in [56]. This suggests that a multidisciplinary approach is increasingly needed in this respect, especially for the large and gradually growing number of species involved in experimentation with natural fiber composites. In a waste management approach, it is often the case that biomass from various species is available, so that it can be introduced in a polymer matrix. This occurred, e.g., with Chlorella vulgaris, from algal oil extraction, when mixed biomass from two further species, such as Enteromorpha and Zostera marina, were introduced in a polyurethane elastomer matrix [57]. The morphological differences between the species were not negligible, as shown in Figure 3; however, they were not prevented from being applied as the reinforcement of the same matrix.

Figure 3.

Optical micrograph of algae-thermoplastic polyurethane composites. S1 was filled with an Enteromorpha–Zostera marina blend, S2 with Chlorella vulgaris after oil extraction, and S3 with Chlorella vulgaris before oil extraction [57]. (Figures marked with 1 do represent samples with 1 wt.% algae, while those marked with 5 do represent samples with 5 wt.% algae) Distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

In Table 2, a selected number of works are described which include sea-derived cellulosic biomass as the filler for polymer matrices. In another sense, it is also possible to directly extract the polysaccharides from algae waste by removing the possible presence of lipids, proteins, or ash from the waste [58]. However, Table 2 concentrates on those studies that have strived to use the biomass as received, which is deemed to be a more sustainable practice. As per Table 2, in some cases the type of algae used is declared, while in others it is only generically indicated as such. After presenting some works on algae, these are followed by specific works using seagrass waste, such as Posidonia oceanica. The objective of these studies is generally the use of bio-based matrices, such as poly(lactic acid) (PLA), which showed promising applications in other sectors in combination with red and brown algae waste, e.g., for collagen replacement [59]. However, limitations encountered in their performance often recommend carrying out studies using well-tested, and often more reliable traditional thermosetting matrices, such as epoxy. In particular, reviews exist which investigate a particular species’ algae biomass, such as Sargassum, with a view to creating a productive system based on it, which would include the production of epoxy composites for the construction industry in a prominent role [60].

Table 2.

Studies on prevalently cellulosic sea waste in polymer matrices.

The interest in mixing different types of cellulose biomass, including marine waste such as Posidonia oceanica, in a modern concept of composite production based, e.g., on additive manufacturing, namely using fused deposition mode (FDM) with poly(lactic acid) (PLA) matrix, was proposed in [71]. As shown in Figure 4, the blending of Posidonia short fibers was performed with the reinforcement obtained from Opuntia ficus indica biomass, which was also studied elsewhere as a prospective filler for thermoplastic starch (TPS) composites [72].

Figure 4.

Posidonia oceanica leaves (POL), (a): before washing, (b) after washing, (c) after being chopped [71]. Distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

4. Sea Waste Polymer Matrices

An additional possibility is linked to the extraction of polymers from sea waste in order to provide added functionalities as a matrix in composites for various uses. An example of this prospect is given by the mixing of chitosan, extracted from refuse shrimp shells, with Ulva lactuca fibers in a biocomposite; this proved effective for the biosorption of cadmium ions (Cd II), most effectively at pH = 5.5 [73]. The aforementioned work is capable of possible extension, since a similar mixture also worked for the removal of mercury from aqueous solutions at a more acidic pH = 4 [74]. It is normally considered more straightforward to proceed to the deacetylation of waste sea shrimps’ chitin into chitosan to improve water retention properties; therefore, to provide possible interfaces for hydrophilic fillers, such as lignocellulosic fibers [75]. Despite this, the reduction into powder of chitin from seashell waste for the prospective preparation of pellets for injection molding has been considered [76].

Beyond the chitin/chitosan system of crustaceans, such as sea shrimps, products from excess algae biomass have also been considered in the production of biopolymers and, prospectively, biocomposite matrices: this is the case for alginates [77], alginic acid [78], and carrageenan, used more specifically for drug delivery purposes [79]. The blending of the two biomasses of the wastes, chitosan, and Cladophora algae also showed some promising properties for the removal of heavy metals ions, such as Cr(III), Cu(II), and Ni(II), from water solutions [80].

5. Conclusions

Marine waste, such as mollusk shells, algae, and other plants, e.g., Posidonia oceanica, and crustaceans’ exoskeletons, can be considered as a mine for useful raw materials; namely ceramics (calcium carbonate) and biopolymers (cellulose, chitin). Composites are a suitable “container” for this waste, especially as particle fillers in the case of ceramics, or fibrous reinforcements in the case of biopolymers. This presents an advantage in terms of sustainability by effectively extracting calcium carbonate and cellulose from purposely cropped plants, therefore contributing to a reduction in raw material consumption.

The evolution of this trend, which is supposed to be constantly growing as an effect of eutrophication and of sea-related activities, will be the development of composites entirely based on sea waste, and possibly combining biological and man-made waste (e.g., polyester or nylon end-of-life fishing nets, or even microplastics). This would contribute further to both cleaning the sea of waste and reducing the raw materials required for a composites’ fabrication.

Author Contributions

Conceptualization, C.F.; methodology, C.S., A.P. and C.F.; investigation, C.S. and C.F.; resources, C.S., D.N. and C.F.; data curation, A.P.; writing—original draft preparation, C.S. and C.F.; writing—review and editing, A.P. and D.N.; visualization, C.S. and C.F.; supervision, D.N.; project administration, C.S.; funding acquisition, C.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was co-funded by the Ministry of Foreign Affairs and International Cooperation of Italy, and by the Ministry of Education, Science, Culture and Sports of Montenegro, inside the bilateral Science and Technology Cooperation Programme 2022–2024 entitled ‘SEA-COMP, Sea Waste from Adriatic to Enhance Marine Composites’ project activity.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Senavirathna, G.R.U.; Galappaththi, U.I.K.; Ranjan, M.T.T. A review of end-life management options for marine structures: State of the art, industrial voids, research gaps and strategies for sustainability. Clean Eng. Technol. 2022, 8, 100489. [Google Scholar] [CrossRef]

- Wang, D.; Su, L.; Ruan, H.D.; Chen, J.; Lu, J.; Lee, C.H.; Jiang, S.Y. Quantitative and qualitative determination of microplastics in oyster, seawater and sediment from the coastal areas in Zhuhai, China. Mar. Poll Bull 2021, 164, 112000. [Google Scholar] [CrossRef] [PubMed]

- Watt, E.; Picard, M.; Maldonado, B.; Abdelwahab, M.A.; Mielewski, D.F.; Drzal, L.T.; Misra, M.; Mohanty, A.K. Ocean plastics: Environmental implications and potential routes for mitigation—A perspective. RSC Adv. 2021, 11, 21447–21462. [Google Scholar] [CrossRef] [PubMed]

- Bonifazi, G.; Fiore, L.; Pelosi, C.; Serranti, S. Evaluation of plastic packaging waste degradation in seawater and simulated solar radiation by spectroscopic techniques. Polym. Degrad. Stab. 2023, 207, 110215. [Google Scholar] [CrossRef]

- Sait, S.T.; Sørensen, L.; Kubowicz, S.; Vike-Jonas, K.; Gonzalez, S.V.; Asimakopoulos, A.G.; Booth, A.M. Microplastic fibres from synthetic textiles: Environmental degradation and additive chemical content. Environ. Pollut. 2021, 268, 115745. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, P.P.; Singh, S.; Rout, P.K.; Mishra, S.; Das, A.P. Microbial remediation of plastic pollutants generated from discarded and abandoned marine fishing nets. Biotechnol. Genet. Eng. Rev. 2022, 1–16. [Google Scholar] [CrossRef]

- Kumartasli, S.; Avinc, O. Recycling of marine litter and ocean plastics: A vital sustainable solution for increasing ecology and health problem. In Sustainability in the Textile and Apparel Industries: Sourcing Synthetic and Novel Alternative Raw Materials; Muthu, S.S., Gardetti, M.A., Eds.; Springer Link: Cham, Switzerland, 2020; pp. 117–137. [Google Scholar]

- Kristiansen, N.R.; Snyder, G.J.; Nielsen, H.K.; Rosendahl, L. Waste heat recovery from a marine waste incinerator using a thermoelectric generator. J. Electron. Mater. 2009, 41, 1024–1029. [Google Scholar] [CrossRef]

- Drake, C. Hydro: Current thinking is just like wind, but underwater. Ecogeneration 2019, 113, 62–63. [Google Scholar]

- Yahyaee, R.; Ghobadian, B.; Najafi, G. Waste fish oil biodiesel as a source of renewable fuel in Iran. Renew Sust. Energ. Rev. 2013, 17, 312–319. [Google Scholar] [CrossRef]

- Yildirim, O.; Ozkaya, B.; Demir, A. Evaluation of the biogas potential of mucilage formed in the Marmara Sea. Int. J. Hydrogen Energy 2022, 47, 15456–15463. [Google Scholar] [CrossRef]

- Moorhouse, D.; Moorhouse, D. Sustainable design: Circular economy in fashion and textiles. Des. J. 2017, 20 (suppl. 1), S1948–S1959. [Google Scholar] [CrossRef]

- Bhuyan, M.S.; Venkatramanan, S.; Selvam, S.; Szabo, S.; Hossain, M.M.; Rashed-Un-Nabi, M.; Islam, M.S. Plastics in marine ecosystem: A review of their sources and pollution conduits. Reg. Stud. Mar. Sci. 2021, 41, 101539. [Google Scholar]

- Abdel Tawab, O.F.; Amin, M.R.; Ibrahim, M.M.; Abdel Wahab, M.; Abd El Rahman, E.N.; Hassanien, R.H.; Ghaly, A.E. Recycling waste plastic bags as a replacement for cement in production of building bricks and concrete blocks. J. Waste Res. Recycl. 2020, 1, 202. [Google Scholar]

- Packer, M. Algal capture of carbon dioxide; biomass generation as a tool for greenhouse gas mitigation with reference to New Zealand energy strategy and policy. Energy Policy 2009, 37, 3428–3437. [Google Scholar] [CrossRef]

- Ab Manan, W.N.A.; Ab Aziz, N.A. Optimization of soil pH by using calcium carbonate (CaCO3) obtained from seashell waste. Gading. J. Sci. Technol. 2018, 1, 81–86. [Google Scholar]

- Yaseen, A.A.; Waqar, T.; Khan, M.A.A.; Asad, M.; Djavanroodi, F. Fish Scales and Their Biomimetic Applications. Front. Mater 2021, 8, 649456. [Google Scholar] [CrossRef]

- Hamed, I.; Özogul, F.; Regenstein, J.M. Industrial applications of crustacean by-products (chitin, chitosan, and chitooligosaccharides): A review. Trends Food Sci. Technol. 2016, 48, 40–50. [Google Scholar] [CrossRef]

- Annam Renita, A.; Senthil Kumar, P. Valorization of waste algal boom for value-added products. In Bioprocess Engineering for Bioremediation: Valorization and Management Techniques; Jerold, M., Arockiasamy, S., Sivasubramanian, V., Eds.; Springer: Cham, Switzerland, 2020; pp. 129–137. [Google Scholar]

- Stel’makh, S.A.; Shcherban, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Tashpulatov, S.S.; Chernil’nik, A.; Shcherban, N.; Tyutina, A. Composition, technological, and microstructural aspects of concrete modified with finely ground mussel shell powder. Materials 2023, 16, 82. [Google Scholar] [CrossRef]

- Dumbrava, A.; Matei, C.; Diacon, A.; Moscalu, F.; Berger, D. Novel ZnO-biochar nanocomposites obtained by hydrothermal method in extracts of Ulva lactuca collected from Black Sea. Ceram. Int. 2023, 49, 10003–10013. [Google Scholar] [CrossRef]

- Spyrou, A.V.; Tantis, I.; Baikousi, M.; Bourlinos, A.B.; Salmas, C.E.; Zboril, R.; Karakassides, M.A. The use of activated bio-carbon derived from “Posidonia oceanica” sea-waste for Lithium-Sulfur batteries development. Sustain. Eng. Technol. Assess 2022, 53, 102748. [Google Scholar] [CrossRef]

- Nirmal, N.P.; Santivarangkna, C.; Rajput, M.S.; Benjakul, S. Trends in shrimp processing waste utilization: An industrial prospective. Trends Food Sci. Technol. 2020, 103, 20–35. [Google Scholar] [CrossRef]

- Ramnath, B.V.; Jeykrishnan, J.; Ramakrishnan, G.; Barath, B.; Ejoelavendhan, E. Sea shells and natural fibres composites: A review. Mater. Today Proc. 2018, 5, 1846–1851. [Google Scholar] [CrossRef]

- Bordbar, M.; Negahdar, N.; Khodadadi, B. Magnetized Nanocomposite of Sea Shell and Walnut Shell-waste as Adsorbent for Efficient Removal of Methylene Blue. J. Nanostruct. 2022, 12, 262–278. [Google Scholar]

- Parsons, A.H. Structure of the eggshell. Poult. Sci 1982, 61, 2013–2021. [Google Scholar] [CrossRef]

- Sasaki, K.; Yamashita, T.; Tsunekawa, M. Synthesis of aragonite from calcined scallop shells at ambient temperatures and their morphological characterization by FE-SEM. J. Min. Mater. Process. Inst. Jpn. 2002, 118, 553–558. [Google Scholar] [CrossRef]

- Owuamanam, S.; Cree, D. Progress of bio-calcium carbonate waste eggshell and seashell fillers in polymer composites: A review. J. Compos. Sci. 2020, 4, 70. [Google Scholar] [CrossRef]

- Vasanthkumar, P.; Balasundaram, R.; Senthilkumar, N.; Palanikumar, K.; Lenin, K.; Deepanraj, B. Thermal and thermo-mechanical studies on seashell incorporated Nylon-6 polymer composites. J. Mater. Res. Technol. 2022, 21, 3154–3168. [Google Scholar] [CrossRef]

- Fombuena, V.; Bernardi, L.; Fenollar, O.; Boronat, T.; Balart, R. Characterization of green composites from biobased epoxy matrices and bio-fillers derived from seashell wastes. Mater. Des. 2014, 57, 168–174. [Google Scholar] [CrossRef]

- Maamoun, A.A.; El-Wakil, A.A.; El-Basheer, T.M. Enhancement of the mechanical and acoustical properties of flexible polyurethane foam/waste seashell composites for industrial applications. J. Cell Plast. 2022, 58, 645–672. [Google Scholar] [CrossRef]

- Mustata, F.; Tudorachi, N.; Rosu, D. Thermal behavior of some organic/inorganic composites based on epoxy resin and calcium carbonate obtained from conch shell of Rapana thomasiana. Compos. B Eng. 2012, 43, 702–710. [Google Scholar] [CrossRef]

- Karanjikar, S.R.; Lakade, S.S. Evaluation of mechanical properties of polypropylene–Acrylonitrile butadiene styrene blend reinforced with cowrie shell [Cypraeidae] powder. Mater. Today Proc. 2022, 50, 1644–1652. [Google Scholar] [CrossRef]

- Balan, G.S.; Kumar, V.S.; Rajaram, S.; Ravichandran, M. Investigation on water absorption and wear characteristics of waste plastics and seashell powder reinforced polymer composite. J. Tribol. 2020, 27, 57–70. [Google Scholar]

- Karthick, R.; Sirisha, P.; Sankar, M.R. Mechanical and tribological properties of PMMA-sea shell based biocomposite for dental application. Procedia Mater. Sci. 2014, 6, 1989–2000. [Google Scholar] [CrossRef]

- Krishna, U.G.; Srinivasa, C.S.; Amara, N.S.; Gudoor, S. Processing, characterization and property evaluation of seashell and glass fibre added epoxy based polymer matrix composite. Mater. Today Proc. 2021, 35, 417–422. [Google Scholar] [CrossRef]

- Hamester, M.R.R.; Balzer, P.S.; Becker, D. Characterization of calcium carbonate obtained from oyster and mussel shells and incorporation in polypropylene. Mater. Res. 2012, 15, 204–208. [Google Scholar] [CrossRef]

- Yao, Z.T.; Chen, T.; Li, H.Y.; Xia, M.S.; Ye, Y.; Zheng, H. Mechanical and thermal properties of polypropylene (PP) composites filled with modified shell waste. J. Hazard. Mater. 2013, 262, 212–217. [Google Scholar] [CrossRef]

- Panigrahi, A.; Jena, H.; Surekha, B. Effect of clams shell in impact properties of jute epoxy composite. Mater. Today Proc. 2018, 5, 19997–20001. [Google Scholar] [CrossRef]

- Jena, H.; Panigrahi, A.; Jena, M. Mechanical property of jute fibre reinforced polymer composite filled with clam shell filler: A marine waste. Adv. Mater Proc. Technol. 2022, 1–17. [Google Scholar] [CrossRef]

- Zhang, P.; Weng, F.; Koranteng, E.; Guo, D.; Cao, P.; Wu, Q. Effect of special structure of clam shell powder on structure and properties of castor oil-based composites. J. Appl. Polym. Sci. 2021, 138, 49963. [Google Scholar] [CrossRef]

- Ayyanar, C.B.; Marimuthu, K.; Gayathri, B.; Sankarrajan. Characterization and in vitro cytotoxicity evaluation of fish scale and seashell derived nano-hydroxyapatite high-density polyethylene composite. Polym. Polym. Compos. 2021, 29, 1534–1542. [Google Scholar] [CrossRef]

- Moustafa, H.; Duquesne, S.; Darwish, N.A.; Youssef, A.M. Highly flame retardant green composites using seashells. Soc. Plast. Eng. 2016, 1–3. [Google Scholar] [CrossRef]

- Cangiotti, J.; Scatto, M.; Araya-Hermosilla, E.; Micheletti, C.; Crivellari, D.; Balloni, A.; Pucci, A.; Benedetti, A. Valorization of seashell waste in polypropylene composites: An accessible solution to overcome marine landfilling. Eur. Polym. J. 2022, 162, 110877. [Google Scholar] [CrossRef]

- Jena, H.; Panigrahi, A. The effect of clam shell powder on kinetics of water absorption of jute epoxy composite. World J. Eng. 2021, 18, 684–691. [Google Scholar] [CrossRef]

- Jena, H.; Kumar, M. Study of influence of process parameters in drilling of glass fibre reinforced polymer composite with clam shell filler. Mater. Today Proc. 2019, 19, 392–396. [Google Scholar] [CrossRef]

- Weng, F.; Zhang, P.; Koranteng, E.; Ma, N.; Wu, Z.; Wu, Q. Effects of the special structure of bio-based shell powder on the properties of shell-polycaprolactone composite. J. Appl. Polym. Sci. 2020, 137, 48768. [Google Scholar] [CrossRef]

- Jian, K.; Weng, F.; Zhang, P.; Gao, S.; Zhao, W.; Hong, L.; Zhuang, K.; Wu, Q. Effects of different kinds of shell powder on the structure and properties of polycaprolactone-based composites. J. Thermoplast. Compos. Mater. 2023, 8927057231154424. [Google Scholar] [CrossRef]

- Cecchi, T.; Giuliani, A.; Iacopini, F.; Santulli, C.; Sarasini, F.; Tirillò, J. Unprecedented high percentage of food waste powder filler in poly lactic acid green composites: Synthesis, characterization, and volatile profile. Environ. Sci. Pollut. Res. 2019, 26, 7263–7271. [Google Scholar] [CrossRef]

- Kholil, A.; Dwiyati, S.T.; Randika, H.P. Performance Testing of Motorcycle Centrifugal Clutch Lining Made from Composite Wood Powder, Coconut Fibre, and Green Mussel Shell. J. Phys. Conf. Ser. 2021, 2019, 12065. [Google Scholar] [CrossRef]

- Echeverria, C.A.; Ozkan, J.; Pahlevani, F.; Willcox, M.; Sahajwalla, V. Multifunctional marine bio-additive with synergistic effect for non-toxic flame-retardancy and anti-microbial performance. Sustain. Mater. Technol. 2020, 25, e00199. [Google Scholar] [CrossRef]

- Ruiz, J.M.; Marco-Méndez, C.; Sánchez-Lizaso, J.L. Remote influence of off-shore fish farm waste on Mediterranean seagrass (Posidonia oceanica) meadows. Mar. Environ. Res. 2010, 69, 118–126. [Google Scholar] [CrossRef]

- Rammou, E.; Mitani, A.; Ntalos, G.; Koutsianitis, D.; Taghiyari, H.R.; Papadopoulos, A.N. The potential use of seaweed (Posidonia oceanica) as an alternative lignocellulosic raw material for wood composites manufacture. Coatings 2021, 11, 69. [Google Scholar] [CrossRef]

- Jmel, M.A.; Anders, N.; Messaoud, G.B.; Marzouki, M.N.; Spiess, A.; Smaali, I. The stranded macroalga Ulva lactuca as a new alternative source of cellulose: Extraction, physicochemical and rheological characterization. J. Clea. Prod. 2019, 234, 1421–1427. [Google Scholar] [CrossRef]

- Strømme, M.; Mihranyan, A.; Ek, R. What to do with all these algae? Mater Lett. 2002, 57, 569–572. [Google Scholar] [CrossRef]

- Summerscales, J.; Grove, S. Manufacturing methods for natural fibre composites. In Natural Fibre Composites; Hodzic, A., Shanks, R., Eds.; Woodhead Publishing: Cambridge, UK, 2014; pp. 176–215. ISBN 978-0-85709-524-4. [Google Scholar]

- Głowińska, E.; Gotkiewicz, O.; Kosmela, P. Sustainable strategy for algae biomass waste management via development of novel bio-based thermoplastic polyurethane elastomers composites. Molecules 2023, 28, 436. [Google Scholar] [CrossRef]

- Tahreen, A.; Adli, S.A.; Anuar, H.; Jamaluddin, J.; Mohan, R.; Ali, F. Algae materials for food and food packaging. In Algae Materials; Arunkumar, K., Arun, A., Raja, R., Palaniappan, R., Eds.; Academic Press: Cambridge, MA, USA, 2023; pp. 85–91. [Google Scholar]

- Sayin, S.; Kohlhaas, T.; Veziroglu, S.; Okudan, E.; Naz, M.; Schröder, S.; Saygili, E.; Açil, Y.; Faupel, F.; Wiltfang, J.; et al. Marine Algae-PLA composites as de novo alternative to porcine derived collagen membranes. Mater. Today Chem. 2020, 17, 100276. [Google Scholar] [CrossRef]

- Rossignolo, J.A.; Duran, A.J.F.P.; Bueno, C.; Martinelli Filho, J.E.; Junior, H.S.; Tonin, F.G. Algae application in civil construction: A review with focus on the potential uses of the pelagic Sargassum spp. biomass. J. Environ. Manag. 2022, 303, 114258. [Google Scholar] [CrossRef]

- Constante, A.; Pillay, S. Compression molding of algae fiber and epoxy composites: Modeling of elastic modulus. J. Reinf. Plast. Compos. 2018, 37, 1202–1216. [Google Scholar] [CrossRef]

- dos Santos Silva, G.; Capela, C.; Gaspar, M. Developing sustainable materials for marine environments: Algae as natural fibers n polymer composites. In Progress in Digital and Physical Manufacturing: Proceedings of ProDPM’19, Leiria, Portugal, 2–4 October 2019; Springer International Publishing: New York, NY, USA, 2020; pp. 198–205. [Google Scholar]

- Wu, C.S. Preparation, characterisation, and controlled-release of biodegradable polyester and marine-algae composite. J. Polym. Environ. 2015, 23, 356–366. [Google Scholar] [CrossRef]

- Chiellini, E.; Cinelli, P.; Ilieva, V.I.; Martera, M. Biodegradable thermoplastic composites based on polyvinyl alcohol and algae. Biomacromolecules 2008, 9, 1007–1013. [Google Scholar] [CrossRef]

- Bulota, M.; Budtova, T. PLA/algae composites: Morphology and mechanical properties. Compos. A Appl. Sci. Manuf. 2015, 73, 109–115. [Google Scholar] [CrossRef]

- Iannace, S.; Nocilla, G.; Nicolais, L. Biocomposites based on sea algae fibers and biodegradable thermoplastic matrices. J. Appl. Polym. Sci. 1999, 73, 583–592. [Google Scholar] [CrossRef]

- Ferrero, B.; Boronat, T.; Moriana, R.; Fenollar, O.; Balart, R. Green composites based on wheat gluten matrix and posidonia oceanica waste fibers as reinforcements. Polym. Compos. 2013, 34, 1663–1669. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Lopresti, F. Physical properties of green composites based on poly-lactic acid or Mater-Bi® filled with Posidonia Oceanica leaves. Compos. Part. A Appl. Sci. Manufact. 2018, 112, 315–327. [Google Scholar] [CrossRef]

- Khiari, R.; Marrakchi, Z.; Belgacem, M.N.; Mauret, E.; Mhenni, F. New lignocellulosic fibres-reinforced composite materials: A stepforward in the valorisation of the Posidonia oceanica balls. Compos. Sci. Technol. 2011, 71, 1867–1872. [Google Scholar] [CrossRef]

- Haddar, M.; Elloumi, A.; Koubaa, A.; Bradai, C.; Migneault, S.; Elhalouani, F. Synergetic effect of Posidonia oceanica fibres and deinking paper sludge on the thermo-mechanical properties of high density polyethylene composites. Ind. Crop. Prod. 2018, 121, 26–35. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Gulino, E.F.; Alaimo, G.; Morreale, M. Green composites based on PLA and agricultural or marine waste prepared by FDM. Polymers 2021, 13, 1361. [Google Scholar] [CrossRef]

- Scognamiglio, F.; Mirabile Gattia, D.; Roselli, G.; Persia, F.; De Angelis, U.; Santulli, C. Thermoplastic starch films added with dry nopal (opuntia Ficus Indica) fibers. Fibers 2019, 7, 99. [Google Scholar] [CrossRef]

- Saad, E.M.; Elshaarawy, R.F.; Mahmoud, S.A.; El-Moselhy, K.M. New ulva lactuca algae based chitosan bio-composites for bioremediation of Cd (II) ions. J. Bioresour. Bioprod. 2021, 6, 223–242. [Google Scholar] [CrossRef]

- Allouche, F.N. A user-friendly Ulva lactuca/chitosan composite bead for mercury removal. Inorg. Chem. Commun. 2021, 130, 108747. [Google Scholar] [CrossRef]

- Rasweefali, M.K.; Sabu, S.; Sunooj, K.V.; Sasidharan, A.; Xavier, K.M. Consequences of chemical deacetylation on physicochemical, structural and functional characteristics of chitosan extracted from deep-sea mud shrimp. Carbohydr. Polym. Technol. Appl. 2021, 2, 100032. [Google Scholar] [CrossRef]

- Alabaraoye, E.; Achilonu, M.; Hester, R. Biopolymer (Chitin) from various marine seashell wastes: Isolation and characterization. J. Polym. Environ. 2018, 26, 2207–2218. [Google Scholar] [CrossRef]

- Novak, U.; Bajić, M.; Kõrge, K.; Oberlintner, A.; Murn, J.; Lokar, K.; Triler, K.V.; Likozar, B. From waste/residual marine biomass to active biopolymer-based packaging film materials for food industry applications–A review. Phys. Sci. Rev. 2019, 5, 20190099. [Google Scholar] [CrossRef]

- Sreekumar, K.; Bindhu, B. Alginic acid: A potential biopolymer from brown algae. Mater. Int. 2020, 2, 433–438. [Google Scholar]

- Qureshi, D.; Nayak, S.K.; Maji, S.; Kim, D.; Banerjee, I.; Pal, K. Carrageenan: A wonder polymer from marine algae for potential drug delivery applications. Curr. Pharm. Des. 2019, 25, 1172–1186. [Google Scholar] [CrossRef] [PubMed]

- Sargın, İ.; Arslan, G.; Kaya, M. Efficiency of chitosan–algal biomass composite microbeads at heavy metal removal. React. Funct. Polym. 2016, 98, 38–47. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).