ShipGen: A Diffusion Model for Parametric Ship Hull Generation with Multiple Objectives and Constraints

Abstract

:1. Introduction

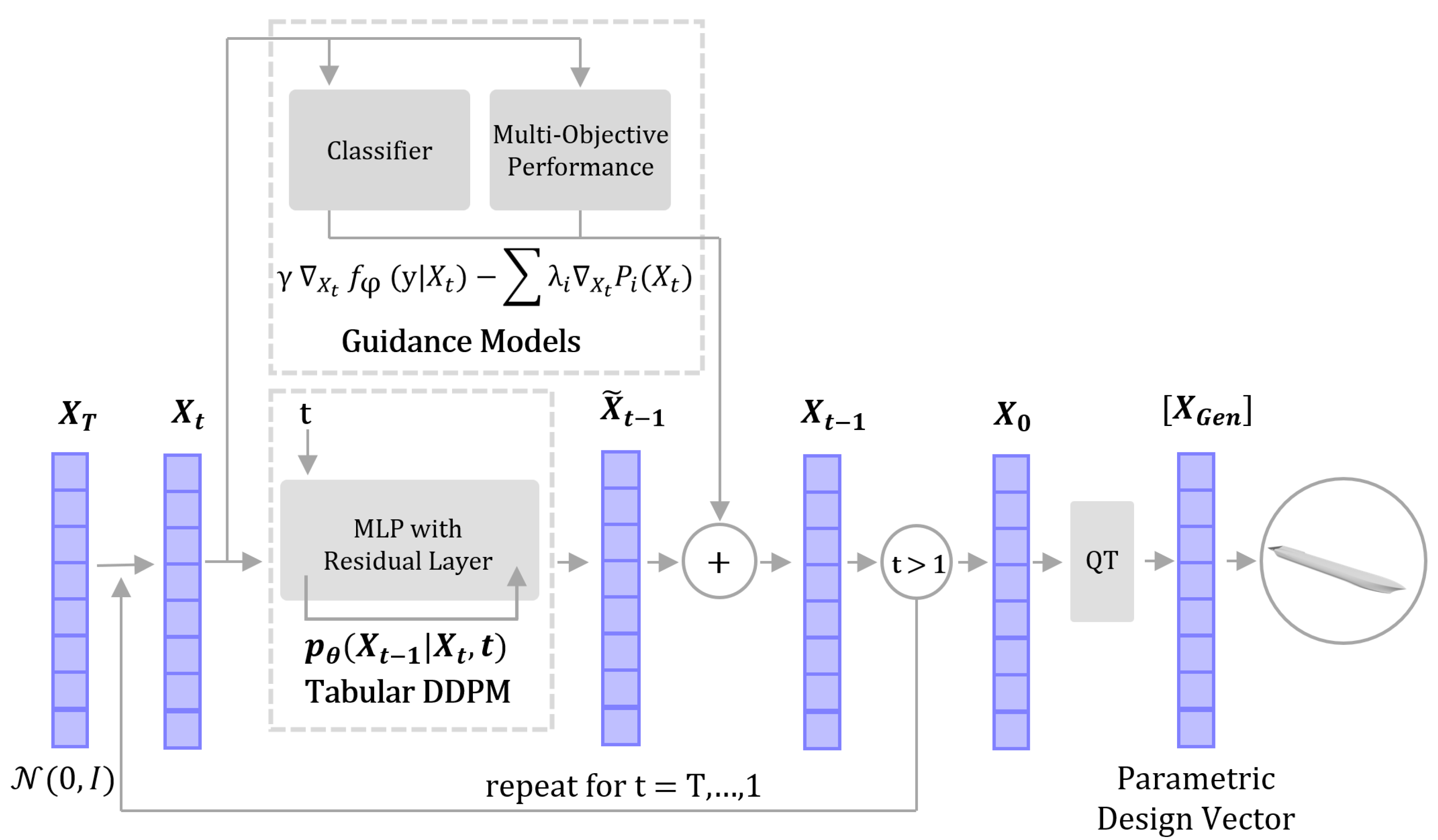

- The first known use of denoising diffusion probabilistic models for generating parametric tabular data for an engineering performance-focused design application;

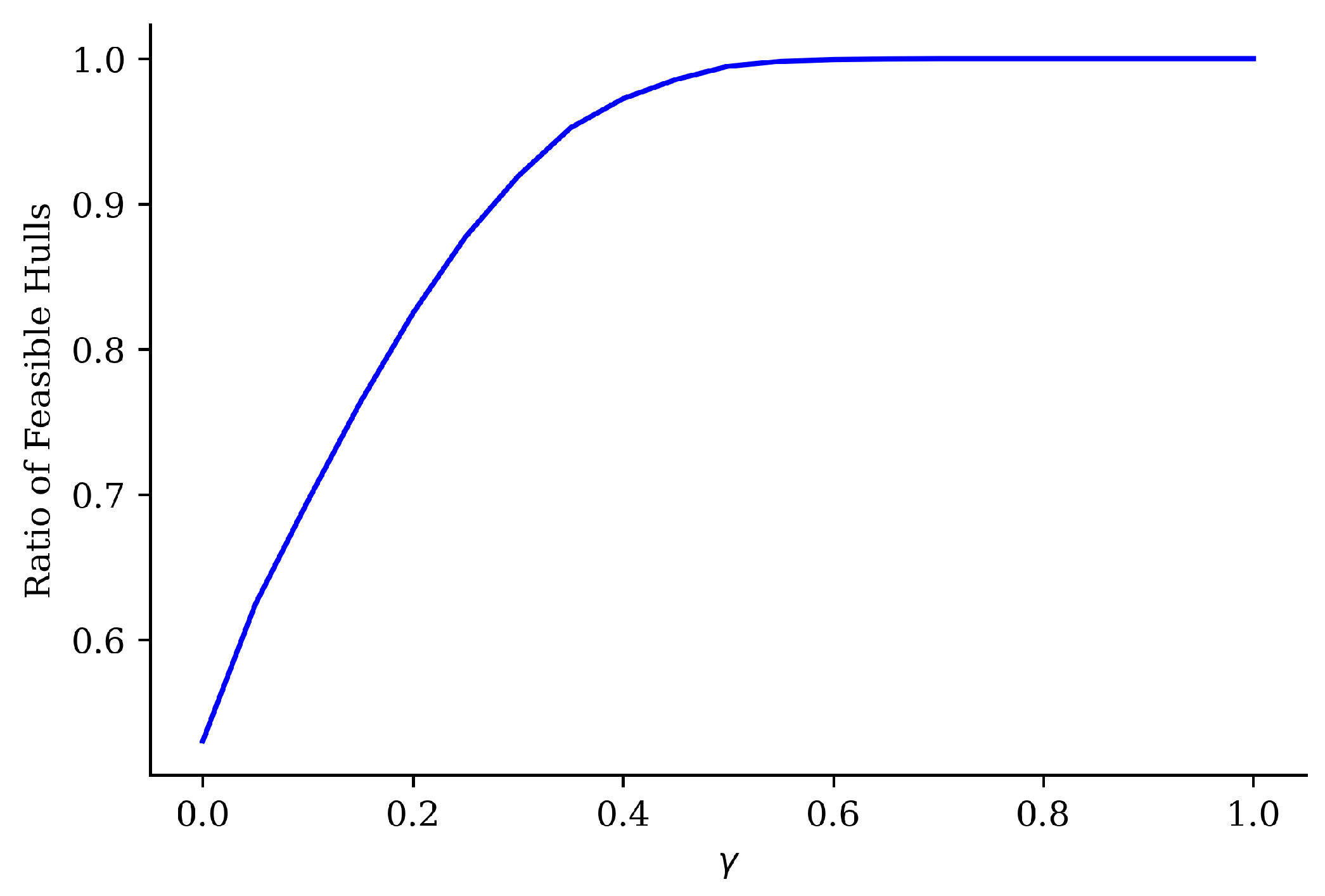

- Showcasing that classifier guidance in the DDPM navigates complex design feasibility constraints to generate feasible samples with over 99% success, while maintaining dataset design coverage;

- Use of guidance to improve ship hull performance, with samples having an average 91.4% reduction in wave drag coefficient and 47.9× more displaced volume compared to the mean performance of the hulls in the dataset.

2. Prior Work

2.1. Computational Ship Design

2.2. Generative Design with Diffusion Models

| Algorithm 1 This is the training algorithm for a standard DDPM. The DDPM is represented by the function in step 5. |

|

| Algorithm 2 This is the sampling algorithm for a standard DDPM. The DDPM is represented by the function in step 4. |

|

3. Methods

3.1. Ship-D Dataset and Hull Parameterization

- Principal dimensions (e.g., overall length, beam at main deck);

- Cross-section of the parallel midbody (e.g., deadrise angle, chine radius);

- Geometry of bow and stern taper;

- Geometry of bulbs at bow and stern

3.1.1. Feasibility Constraints for Hull Geometry

- The hull is watertight, meaning that there are no holes on its surface;

- The hull surface is not self-intersecting.

3.1.2. Hull Performance Measures

- Height of draftmark;

- Length of the waterline;

- Area of the waterplane;

- Surface area of the hull below the specified draftmark (wetted surface);

- Longitudinal centers of flotation (waterplane centroid);

- Second moment of area about the longitudinal axis of the waterplane;

- Second moment of area about the transverse axis of the waterplane;

- Displaced volume below the draftmark;

- Longitudinal center of buoyancy;

- Vertical center of buoyancy.

- Aggregated sum of wave drag coefficients;

- Surface area of the hull up to 50% of its total depth;

- Total surface area of the hull;

- Displaced volume of the hull up to 50% of its total depth;

- Total displaced volume of the hull;

- Volume of the MaxBox;

- Gaussian curvature.

3.2. Dataset Coverage and Generated Sample Evaluation

- Coverage is quantified as the mean Chamfer distance of each dataset instance from its nearest neighbor among the generated samples;

- Realism, on the other hand, measures the mean Chamfer distance of each generated sample instance from its closest match within the dataset [49].

3.3. Denoising Diffusion Probabilistic Models

3.3.1. Standard Diffusion Model

3.3.2. Classifier Guidance for Diffusion Models

3.3.3. Performance Guidance for Diffusion Models

4. Results

4.1. Benchmark Feasibility Constraint Satisfaction Studies

4.2. Feasibility Constraint Satisfaction with Tabular Denoising Diffusion Probabilistic Models

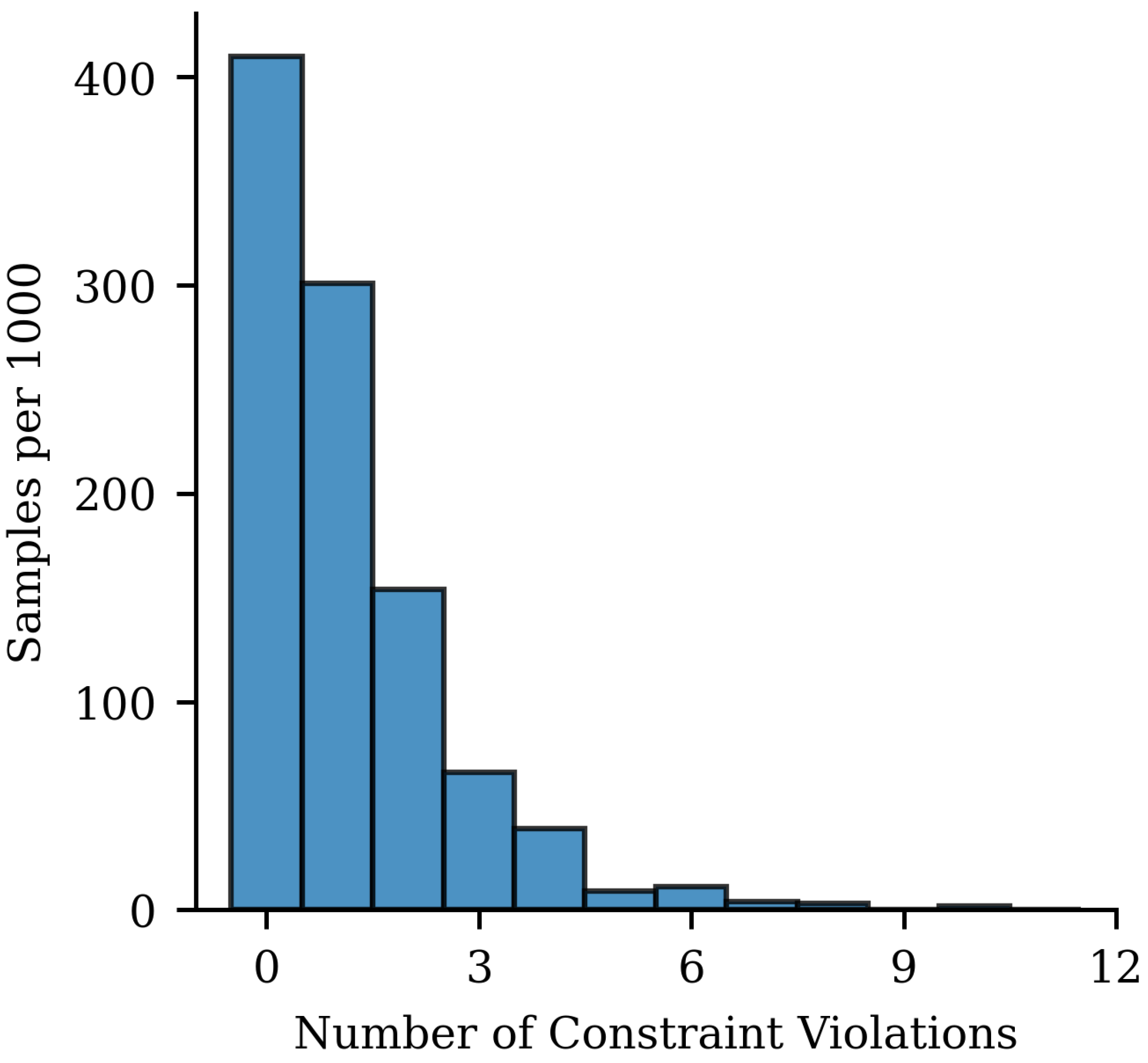

4.2.1. Standard DDPM Leads to Good Feasibility and Coverage

4.2.2. Guided Denoising Diffusion Probabilistic Model for Enhanced Feasibility

4.3. Hull Generation with Performance Guided Denoising Diffusion Probabilistic Model

4.3.1. Performance Prediction Training

4.3.2. Multi-Objective Guided Performance Hull Generation

5. Discussion

5.1. Feasibility Constraint Satisfaction

5.2. Dataset Coverage

5.3. Performance Guidance

6. Conclusions

6.1. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| DDPM | Denoising Diffusion Probabilistic Model, aka Diffusion Model |

| TabDDPM | Tabular Denoising Diffusion Probabilistic Model |

| GAN | Generative Adversarial Network |

| CTGAN | Conditional Tabular GAN |

| PCA | Principal Component Analysis |

| LOA | Length Overall |

| FFD | Free Form Deformation |

| CFD | Computational Fluid Dynamics |

Appendix A. Conditional Diffusion Models

Appendix A.1. Methods

Appendix A.2. Results

Appendix A.3. Discussion

Appendix B. Parametric Hull Design: Parameters and Constraints

- The hull is watertight, meaning that there are no holes on its surface;

- The hull surface is not self-intersecting.

References

- Bagazinski, N.J.; Ahmed, F. Ship-D: Ship Hull Dataset for Design Optimization using Machine Learning. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 20–23 August 2023; American Society of Mechanical Engineers: New York, NY, USA, 2023. [Google Scholar]

- Lin, C.K.; Shaw, H.J. Feature-based estimation of preliminary costs in shipbuilding. Ocean Eng. 2017, 144, 305–319. [Google Scholar] [CrossRef]

- Evans, J.H. Basic design concepts. J. Am. Soc. Nav. Eng. 1959, 71, 671–678. [Google Scholar] [CrossRef]

- Brown, A.; Salcedo, J. Multiple-objective optimization in naval ship design. Nav. Eng. J. 2003, 115, 49–62. [Google Scholar] [CrossRef]

- Feng, Y.; el Moctar, O.; Schellin, T. Parametric Hull Form Optimization of Containerships for Minimum Resistance in Calm Water and in Waves. J. Mar. Sci. Appl. 2022, 20, 670–693. [Google Scholar] [CrossRef]

- Read, D. A Drag Estimate for Concept-Stage Ship Design Optimization; The University of Maine: Orono, ME, USA, 2009. [Google Scholar]

- Zhang, Y.; Kim, D.J.; Bahatmaka, A. Parametric Method Using Grasshopper for Bulbous Bow Generation. In Proceedings of the 2018 International Conference on Computing, Electronics & Communications Engineering (iCCECE), Southend, UK, 16–17 August 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 307–310. [Google Scholar]

- Chrismianto, D.; Kim, D.J. Parametric bulbous bow design using the cubic Bezier curve and curve-plane intersection method for the minimization of ship resistance in CFD. J. Mar. Sci. Technol. 2014, 19, 479–492. [Google Scholar] [CrossRef]

- Lu, Y.; Chang, X.; Hu, A.k. A hydrodynamic optimization design methodology for a ship bulbous bow under multiple operating conditions. Eng. Appl. Comput. Fluid Mech. 2016, 10, 330–345. [Google Scholar] [CrossRef]

- Knight, J.T.; Zahradka, F.T.; Singer, D.J.; Collette, M.D. Multiobjective Particle Swarm Optimization of a Planing Craft with Uncertainty. J. Ship Prod. Des. 2014, 30, 194–200. [Google Scholar] [CrossRef]

- Knight, J.T.; Singer, D.J.; Collette, M.D. Testing of a spreading mechanism to promote diversity in multi-objective particle swarm optimization. Optim. Eng. 2015, 16, 279–302. [Google Scholar] [CrossRef]

- Hodges, J.; Wheeler, M.; Belhocine, M.; Henry, J. AI/ML applications for ship design. In Proceedings of the ICCAS 2022, Yokohama, Japan, 13–15 September 2022. [Google Scholar] [CrossRef]

- Wang, Y.; Joseph, J.; Aniruddhan Unni, T.; Yamakawa, S.; Barati Farimani, A.; Shimada, K. Three-dimensional ship hull encoding and optimization via deep neural networks. J. Mech. Des. 2022, 144, 101701. [Google Scholar] [CrossRef]

- Ao, Y.; Li, Y.; Gong, J.; Li, S. An artificial intelligence-aided design (AIAD) of ship hull structures. J. Ocean. Eng. Sci. 2021, 8, 15–32. [Google Scholar] [CrossRef]

- Ao, Y.; Li, Y.; Gong, J.; Li, S. Artificial Intelligence Design for Ship Structures: A Variant Multiple-Input Neural Network-Based Ship Resistance Prediction. J. Mech. Des. 2022, 144, 091707. [Google Scholar] [CrossRef]

- Peri, D.; Rossetti, M.; Campana, E.F. Design optimization of ship hulls via CFD techniques. J. Ship Res. 2001, 45, 140–149. [Google Scholar] [CrossRef]

- Demo, N.; Tezzele, M.; Mola, A.; Rozza, G. Hull shape design optimization with parameter space and model reductions, and self-learning mesh morphing. J. Mar. Sci. Eng. 2021, 9, 185. [Google Scholar] [CrossRef]

- Abbas, A.; Rafiee, A.; Haase, M. DeepMorpher: Deep learning-based design space dimensionality reduction for shape optimisation. J. Eng. Des. 2023, 34, 254–270. [Google Scholar] [CrossRef]

- Khan, S.; Kaklis, P.; Serani, A.; Diez, M.; Kostas, K. Shape-supervised dimension reduction: Extracting geometry and physics associated features with geometric moments. Comput.-Aided Des. 2022, 150, 103327. [Google Scholar] [CrossRef]

- Khan, S.; Kaklis, P.; Serani, A.; Diez, M. Geometric moment-dependent global sensitivity analysis without simulation data: Application to ship hull form optimisation. Comput.-Aided Des. 2022, 151, 103339. [Google Scholar] [CrossRef]

- Khan, S.; Goucher-Lambert, K.; Kostas, K.; Kaklis, P. ShipHullGAN: A generic parametric modeller for ship hull design using deep convolutional generative model. Comput. Methods Appl. Mech. Eng. 2023, 411, 116051. [Google Scholar] [CrossRef]

- Shaeffer, A. Application of Artificial Neural Networks to Early-Stage Hull Form Design. Ph.D. Thesis, George Mason University, Fairfax, VA, USA, 2023. [Google Scholar]

- Shaeffer, A.K.; Wilson, W.; Yang, C. Application of Machine Learning to Early-Stage Hull Form Design. In Proceedings of the SNAME Maritime Convention, SNAME, Virtual, 29 September–1 October 2020; p. D043S019R002. [Google Scholar]

- Hollenbach, K.U. Estimating resistance and propulsion for single-screw and twin-screw ships-ship technology research 45 (1998). Schiffstechnik 1998, 45, 72. [Google Scholar]

- Hollenbach, U.; Friesch, J. Efficient hull forms–What can be gained. In Proceedings of the 1st International Conference on Ship Efficiency, Hamburg, Germany, 8–9 October 2007; pp. 8–9. [Google Scholar]

- Savitsky, D. Hydrodynamic Design of Planing Hulls. Mar. Technol. SNAME News 1964, 1, 71–95. [Google Scholar] [CrossRef]

- Michell, J.H., XI. The wave-resistance of a ship. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1898, 45, 106–123. [Google Scholar] [CrossRef]

- Tuck, E.O. The wave resistance formula of JH Michell (1898) and its significance to recent research in ship hydrodynamics. ANZIAM J. 1989, 30, 365–377. [Google Scholar]

- Mantzaris, D.A. A Rankine Panel Method as a Tool for the Hydrodynamic Design of Complex Marine Vehicles. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1998. [Google Scholar]

- Dawson, C. A practical computer method for solving ship-wave problems. In Proceedings of the Second International Conference on Numerical Ship Hydrodynamics, Berkeley, CA, USA, 19–21 September 1977; pp. 30–38. [Google Scholar]

- Noblesse, F.; Huang, F.; Yang, C. The Neumann–Michell theory of ship waves. J. Eng. Math. 2013, 79, 51–71. [Google Scholar] [CrossRef]

- Yang, C.; Huang, F.; Noblesse, F. Practical evaluation of the drag of a ship for design and optimization. J. Hydrodyn. 2013, 25, 645–654. [Google Scholar] [CrossRef]

- Huang, F.; Yang, C.; Noblesse, F. Numerical implementation and validation of the Neumann–Michell theory of ship waves. Eur. J. Mech.-B/Fluids 2013, 42, 47–68. [Google Scholar] [CrossRef]

- Marlantes, K.; Maki, K. Modeling Vertical Planing Boat Motions using a Neural-Corrector Method. In Proceedings of the SNAME International Conference on Fast Sea Transportation, Providence, RI, USA, 26 October 2021. [Google Scholar] [CrossRef]

- Silva, K.M.; Maki, K.J. Implementation of the Critical Wave Groups Method with Computational Fluid Dynamics and Neural Networks. arXiv 2023, arXiv:2301.09834. [Google Scholar]

- Dhariwal, P.; Nichol, A. Diffusion models beat gans on image synthesis. Adv. Neural Inf. Process. Syst. 2021, 34, 8780–8794. [Google Scholar]

- Ho, J.; Jain, A.; Abbeel, P. Denoising diffusion probabilistic models. Adv. Neural Inf. Process. Syst. 2020, 33, 6840–6851. [Google Scholar]

- Ramesh, A.; Dhariwal, P.; Nichol, A.; Chu, C.; Chen, M. Hierarchical text-conditional image generation with clip latents. arXiv 2022, arXiv:2204.06125. [Google Scholar]

- Rombach, R.; Blattmann, A.; Lorenz, D.; Esser, P.; Ommer, B. High-Resolution Image Synthesis with Latent Diffusion Models. In Proceedings of the 2022 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), New Orleans, LA, USA, 18–24 June 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 10674–10685. [Google Scholar]

- Liu, R.; Wu, R.; Van Hoorick, B.; Tokmakov, P.; Zakharov, S.; Vondrick, C. Zero-1-to-3: Zero-shot one image to 3d object. In Proceedings of the IEEE/CVF International Conference on Computer Vision, Paris, France, 4–6 October 2023. [Google Scholar]

- Mazé, F.; Ahmed, F. Diffusion Models Beat GANs on Topology Optimization. In Proceedings of the AAAI Conference on Artificial Intelligence (AAAI), Washington, DC, USA, 7–14 February 2023; Volume 37, pp. 9108–9116. [Google Scholar] [CrossRef]

- Giannone, G.; Srivastava, A.; Winther, O.; Ahmed, F. Aligning Optimization Trajectories with Diffusion Models for Constrained Design Generation. arXiv 2023, arXiv:2305.18470. [Google Scholar]

- Giannone, G.; Regenwetter, L.; Srivastava, A.; Gutfreund, D.; Ahmed, F. Learning from Invalid Data: On Constraint Satisfaction in Generative Models. arXiv 2023, arXiv:2306.15166. [Google Scholar]

- Arechiga, N.; Permenter, F.; Song, B.; Yuan, C. Drag-guided diffusion models for vehicle image generation. arXiv 2023, arXiv:2306.09935. [Google Scholar]

- Zubaly, R. Applied Naval Architecture; Cornell Maritime Press: Centreville, MD, USA, 1996. [Google Scholar]

- Newman, J.N. Marine Hydrodynamics; The MIT Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Dalle, D. Comparison of numerical techniques for Euclidean curvature. Rose-Hulman Undergrad. Math. J. 2006, 7, 12. [Google Scholar]

- Nelder, J.A.; Mead, R. A simplex method for function minimization. Comput. J. 1965, 7, 308–313. [Google Scholar] [CrossRef]

- Regenwetter, L.; Srivastava, A.; Gutfreund, D.; Ahmed, F. Beyond Statistical Similarity: Rethinking Metrics for Deep Generative Models in Engineering Design. Comput.-Aided Des. 2023, 165, 103609. [Google Scholar] [CrossRef]

- Xu, L.; Skoularidou, M.; Cuesta-Infante, A.; Veeramachaneni, K. Modeling Tabular data using Conditional GAN. In Proceedings of the Advances in Neural Information Processing Systems, Vancouver, BC, Canada, 8–14 December 2019. [Google Scholar]

- Kotelnikov, A.; Baranchuk, D.; Rubachev, I.; Babenko, A. Tabddpm: Modelling tabular data with diffusion models. In Proceedings of the International Conference on Machine Learning, PMLR, Honolulu, HI, USA, 23–29 July 2023; pp. 17564–17579. [Google Scholar]

- Reuther, A.; Kepner, J.; Byun, C.; Samsi, S.; Arcand, W.; Bestor, D.; Bergeron, B.; Gadepally, V.; Houle, M.; Hubbell, M.; et al. Interactive Supercomputing on 40,000 Cores for Machine Learning and Data Analysis. In Proceedings of the 2018 IEEE High Performance Extreme Computing Conference (HPEC), Waltham, MA USA, 25–27 September 2018; pp. 1–6. [Google Scholar] [CrossRef]

| Generation Method | Chamfer Distance (Lower Is Better) | Normalized Coverage (Higher Is Better) |

|---|---|---|

| Random Dataset Sample | 4.315 | (Baseline) 1.000 |

| Interpolation Study 1 | 5.099 | 0.965 |

| Interpolation Study 2 | 2.976 | 1.059 |

| CTGAN Standard DDPM | 5.660 4.672 | 0.940 0.984 |

| Guidance: | 4.731 | 0.982 |

| Guidance: | 5.067 | 0.967 |

| Guidance: | 6.002 | 0.925 |

| Guidance: | 8.453 | 0.817 |

| Guidance: | 13.611 | 0.589 |

| Guidance: | 27.054 |

| Generation Method | Feasibility Rate |

|---|---|

| Interpolation Study 1 | 0.931 |

| Interpolation Study 2 | 0.938 |

| CTGAN Standard DDPM | 0.007 0.511 |

| Guidance: | 0.839 |

| Guidance: | 0.962 |

| Guidance: | 0.995 |

| Guidance: | 1.000 |

| Guidance: | 1.000 |

| Guidance: | 1.000 |

| Performance Objective | Training Fit: [] |

|---|---|

| Wave Drag | 0.973 |

| Surface Area | 0.983 |

| Surface Area | 0.982 |

| Volume | 0.988 |

| Volume | 0.986 |

| Volume | 0.784 |

| Gaussian Curvature | 0.765 |

| Performance Objective | Ship-D Dataset | Generated Samples | Scaled Factor | ||

|---|---|---|---|---|---|

| () | () | () | |||

| Mean | Std. | Mean | Std. | ||

| Wave Drag | 17.38 | 23.90 | 0.086 | ||

| Surface Area | 0.53 | 0.19 | 4.365 | ||

| Surface Area | 0.45 | 0.19 | 2.138 | ||

| Volume | 4.78 | 0.81 | 2.72 | 0.59 | 114.815 |

| Volume | 3.80 | 0.62 | 2.12 | 0.43 | 47.863 |

| Volume | 0.010 | 0.072 | 0.948 | ||

| Gaussian Curvature | 2.43 | 0.529 | 2.61 | 0.24 | 1.514 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bagazinski, N.J.; Ahmed, F. ShipGen: A Diffusion Model for Parametric Ship Hull Generation with Multiple Objectives and Constraints. J. Mar. Sci. Eng. 2023, 11, 2215. https://doi.org/10.3390/jmse11122215

Bagazinski NJ, Ahmed F. ShipGen: A Diffusion Model for Parametric Ship Hull Generation with Multiple Objectives and Constraints. Journal of Marine Science and Engineering. 2023; 11(12):2215. https://doi.org/10.3390/jmse11122215

Chicago/Turabian StyleBagazinski, Noah J., and Faez Ahmed. 2023. "ShipGen: A Diffusion Model for Parametric Ship Hull Generation with Multiple Objectives and Constraints" Journal of Marine Science and Engineering 11, no. 12: 2215. https://doi.org/10.3390/jmse11122215

APA StyleBagazinski, N. J., & Ahmed, F. (2023). ShipGen: A Diffusion Model for Parametric Ship Hull Generation with Multiple Objectives and Constraints. Journal of Marine Science and Engineering, 11(12), 2215. https://doi.org/10.3390/jmse11122215