Theoretical Analysis of Plastic Behavior of Sandwich Beam with Metal Foam under Repeated Impacts

Abstract

:1. Introduction

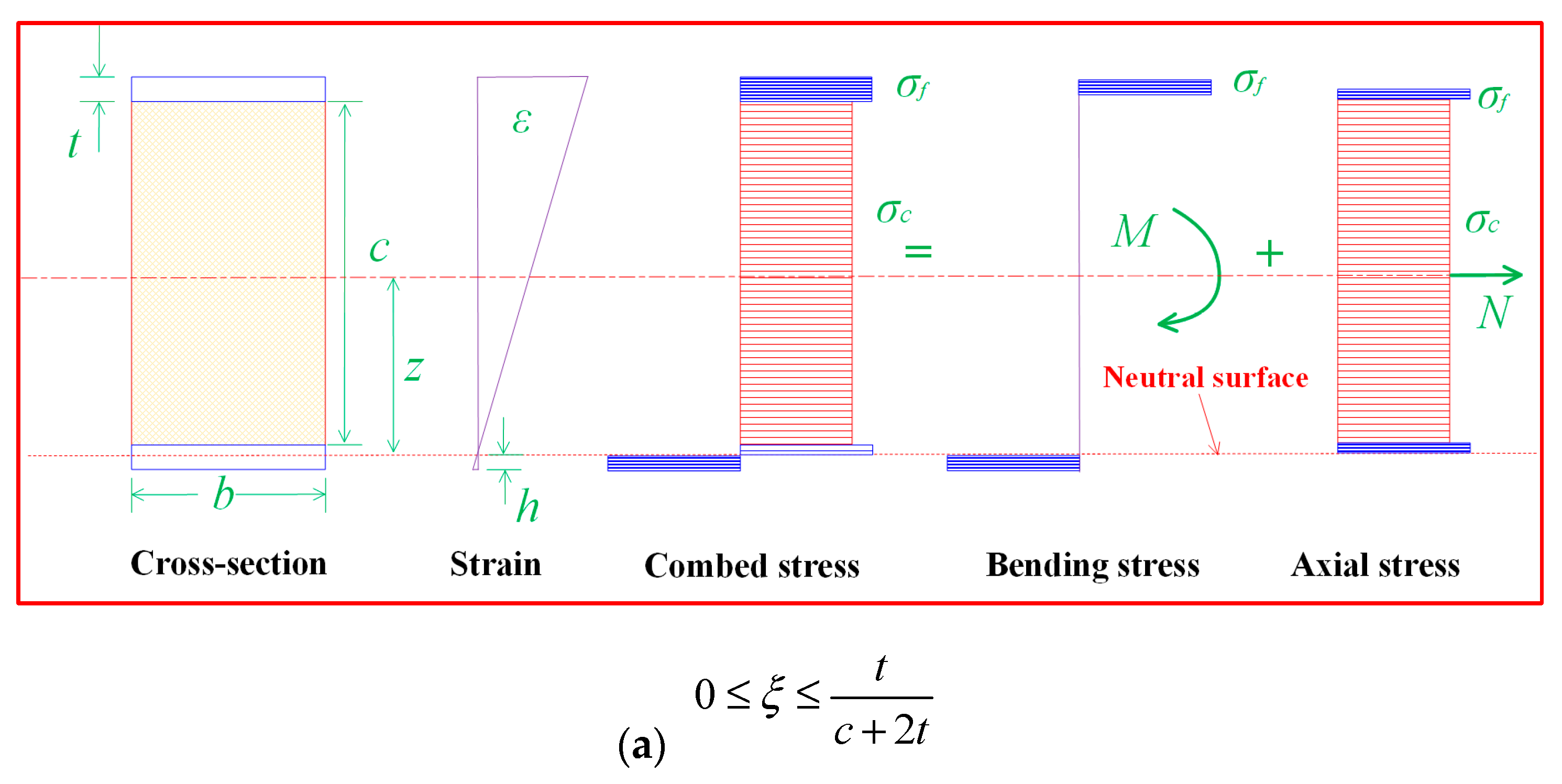

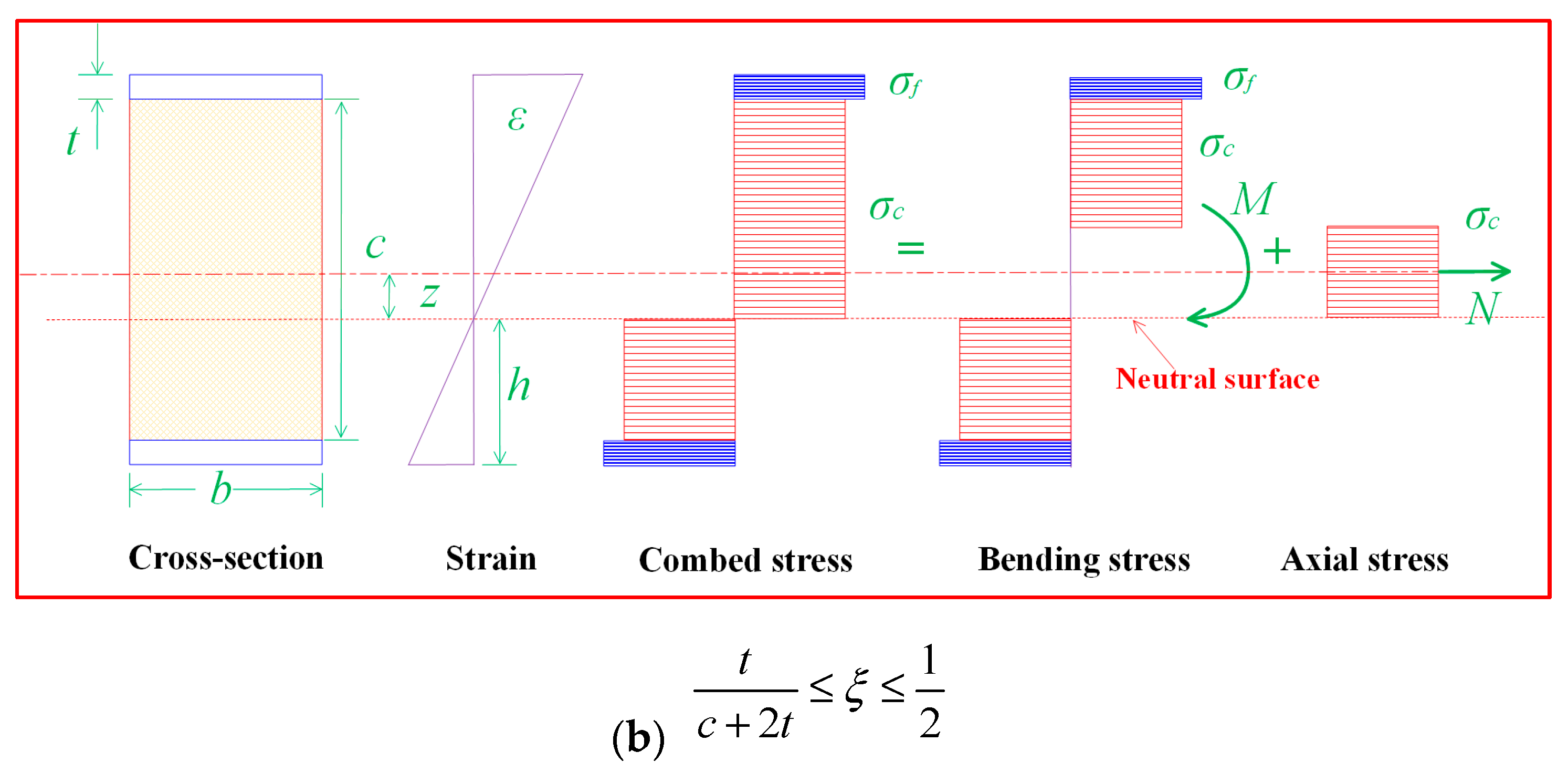

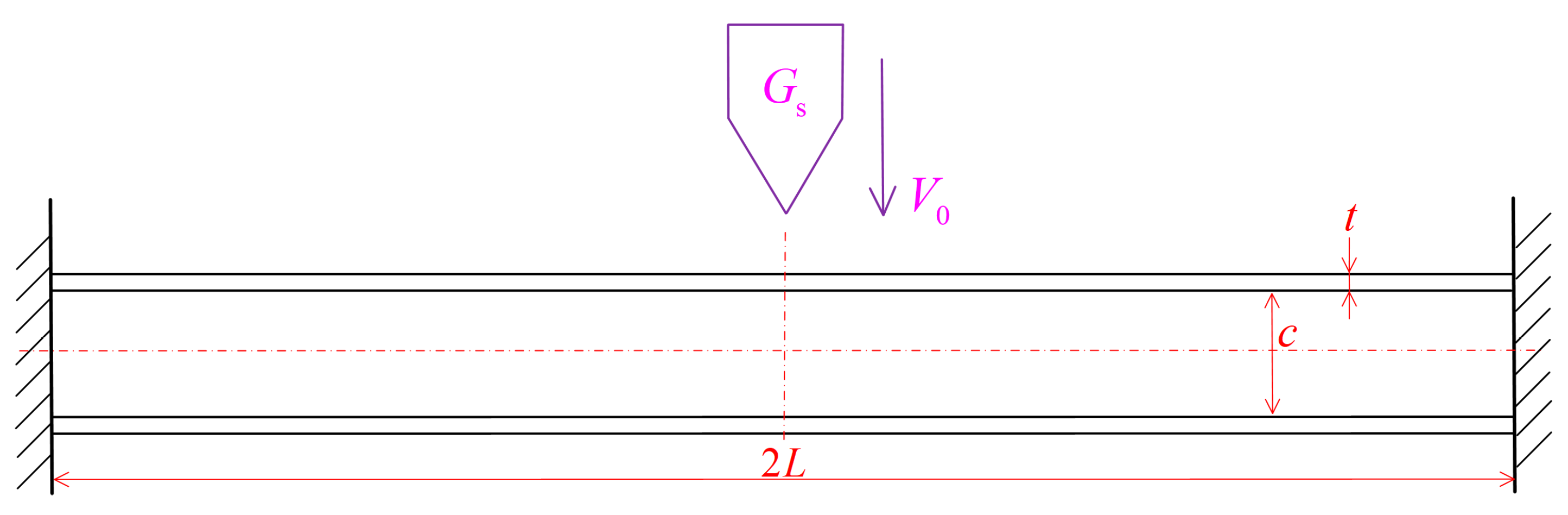

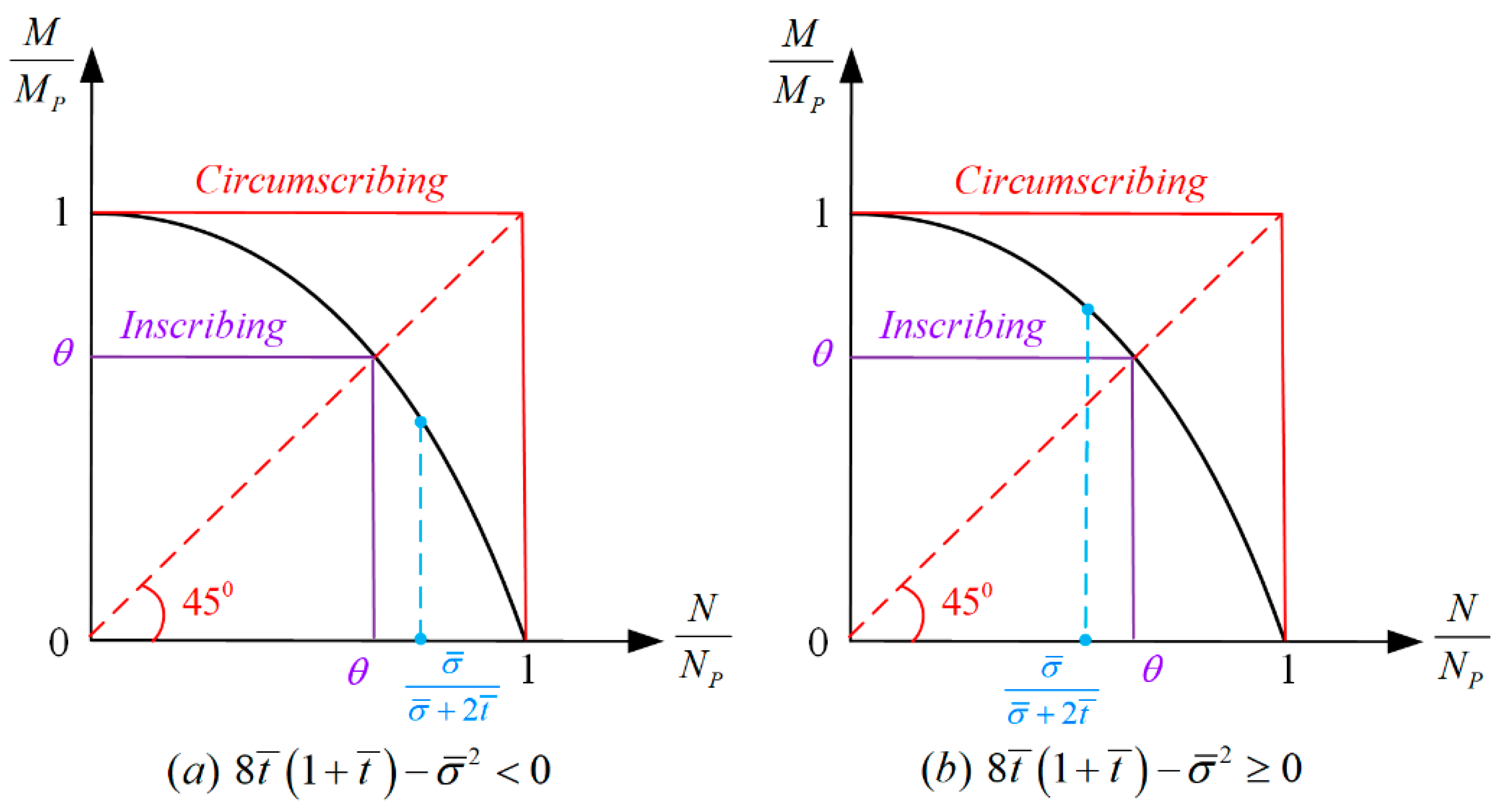

2. A Unified Yield Criterion for Sandwich Structures

3. Analytical Solutions

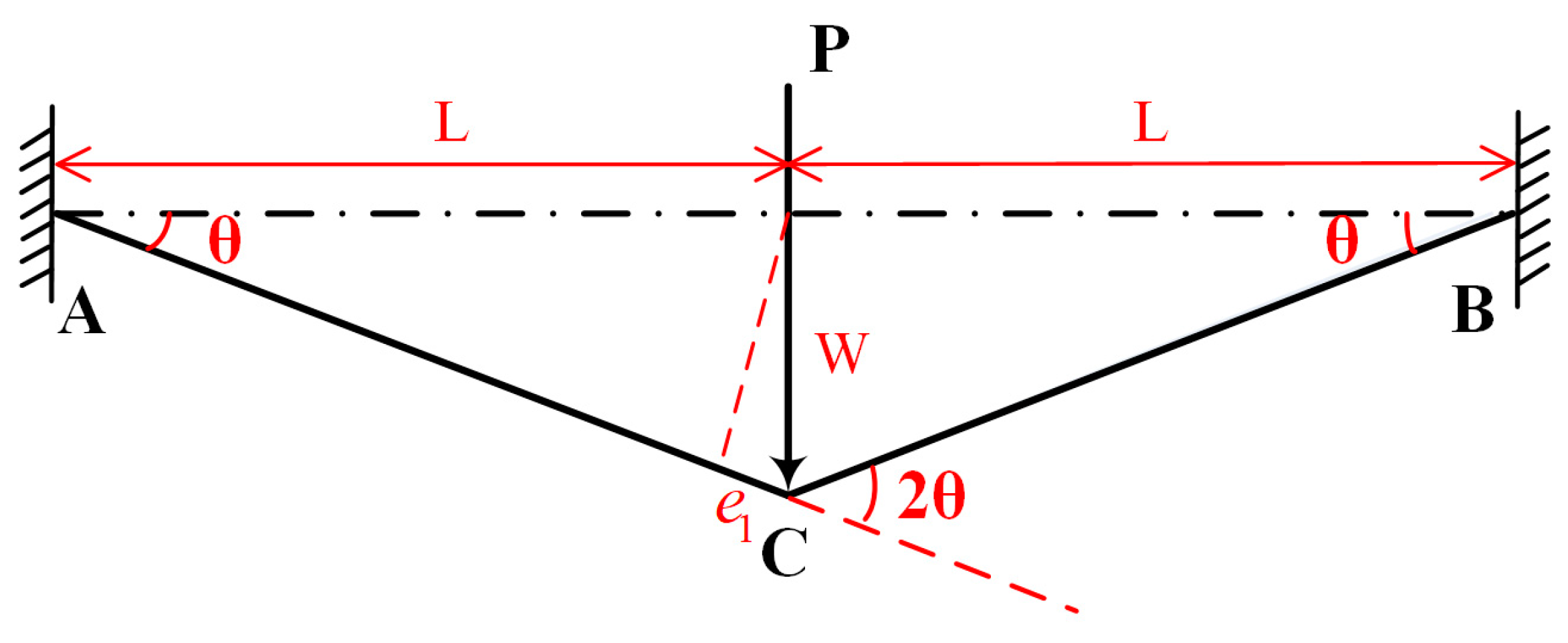

3.1. Solutions Based on the Membrane Factor Method

3.2. Solutions Based on Square Yield Surface

4. Results and Discussion

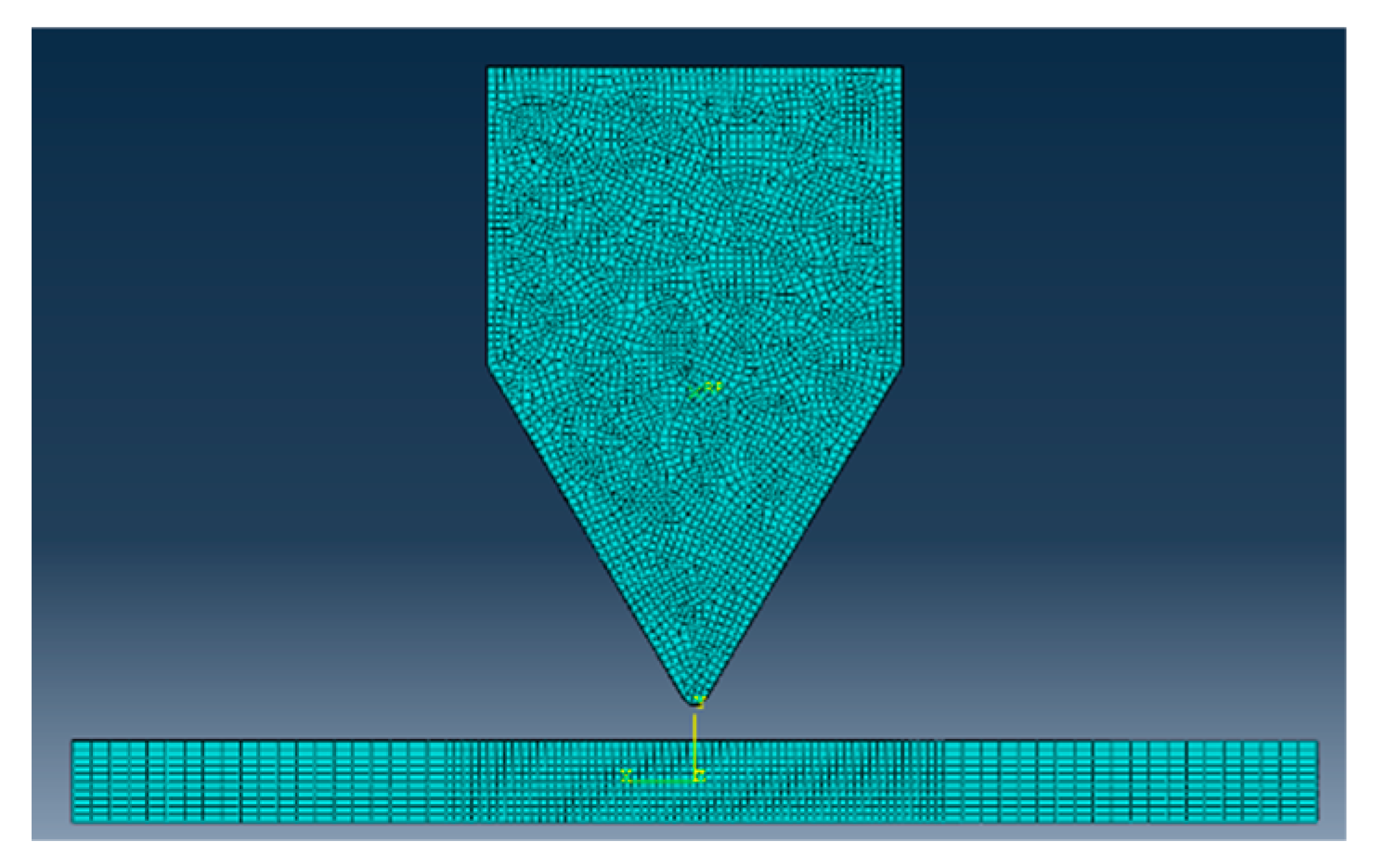

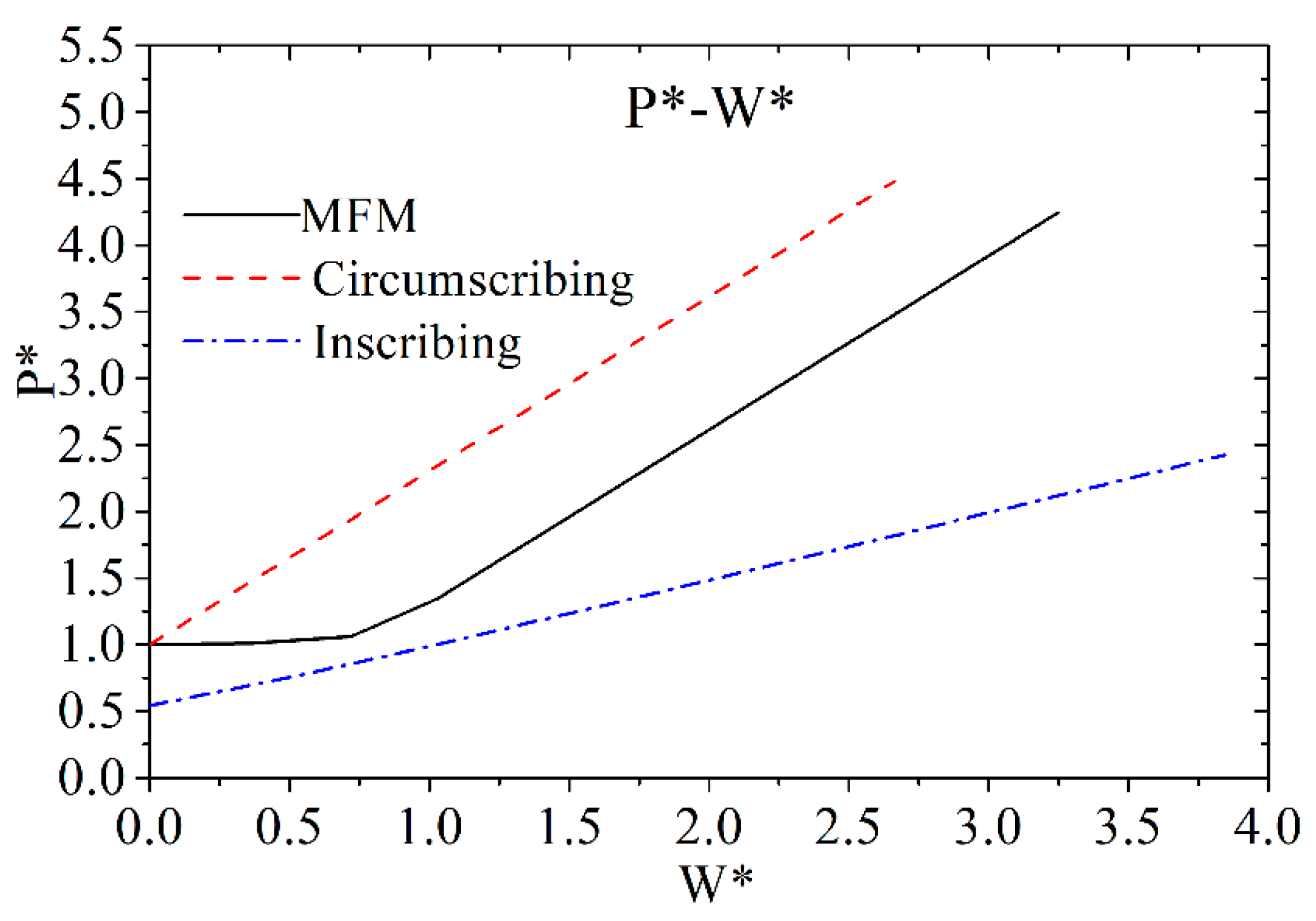

4.1. Validation of Theoretical Model

4.2. Dynamic Responses of MFSBs

4.3. Effect of Core Strength

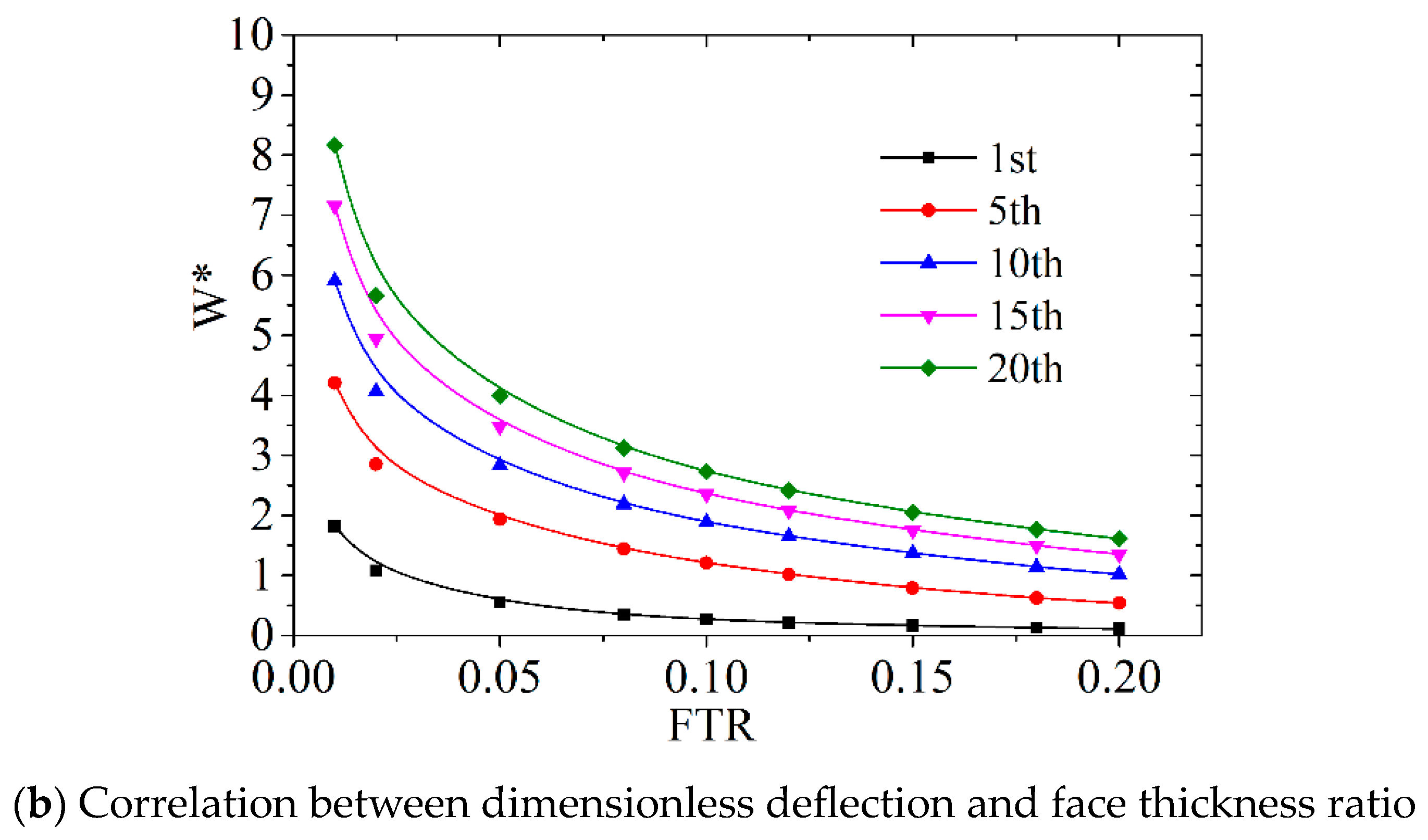

4.4. Effect of Face Thickness

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, L.; Faulkner, D. Damage estimate for plating of ships and platforms under repeated impacts. Mar. Struct. 1996, 9, 697–720. [Google Scholar] [CrossRef]

- Truong, D.D.; Jung, H.J.; Shin, H.K.; Cho, S.R. Response of low-temperature steel beams subjected to single and repeated lateral impacts. Int. J. Nav. Arch. Ocean 2018, 10, 670–682. [Google Scholar] [CrossRef]

- Truong, D.D.; Shin, H.K.; Cho, S.R. Repeated lateral impacts on steel grillage structures at room and sub-zero temperatures. Int. J. Impact Eng. 2018, 113, 40–53. [Google Scholar] [CrossRef]

- Zhu, L.; Shi, S.; Jones, N. Dynamic response of stiffened plates under repeated impacts. Int. J. Impact Eng. 2018, 117, 113–122. [Google Scholar] [CrossRef]

- Zeng, Y.; Chen, H.; Yu, R.; Shen, Z.; Yu, Z.; Liu, J. Experimental research on dynamic behavior of circular mild steel plates with surface cracks subjected to repeated impacts in low temperature. Shock Vib. 2020, 2020, 3713709. [Google Scholar] [CrossRef]

- Jones, N. Pseudo-shakedown phenomenon for the mass impact loading of plating. Int. J. Impact Eng. 2014, 65, 33–39. [Google Scholar] [CrossRef]

- He, X.; Soares, C.G. Experimental study on the dynamic behavior of beams under repeated impacts. Int. J. Impact Eng. 2021, 147, 103724. [Google Scholar] [CrossRef]

- He, X.; Soares, C.G. Numerical study on the pseudo-shakedown of beams under repeated impacts. Ocean Eng. 2021, 242, 110137. [Google Scholar] [CrossRef]

- He, X.; Garbatov, Y.; Soares, C.G. Analysis of pseudo-shakedown of rectangular plates under repeated impacts. Ocean Eng. 2022, 265, 112609. [Google Scholar] [CrossRef]

- He, X.; Garbatov, Y.; Soares, C.G. Pseudo-shakedown of rectangular plates under repeated impacts. Mar. Struct. 2022, 85, 103258. [Google Scholar] [CrossRef]

- Cai, W.; Zhu, L.; Qian, X. Dynamic responses of steel plates under repeated ice impacts. Int. J. Impact Eng. 2022, 162, 104129. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.G.; Guo, K.L.; Zhu, L. Dynamic mechanical behaviour and energy absorption of aluminium honeycomb sandwich panels under repeated impact loads. Ocean Eng. 2021, 209, 108344. [Google Scholar] [CrossRef]

- Zeng, Y.; Liu, J.X.; Zhao, Y.J. Experimental research on the repeated impacts behavior of aluminium corrugated-core sandwich structures. Shock Vib. 2022, 2022, 4644029. [Google Scholar]

- Palomba, G.; Epasto, G.; Sutherland, L.; Crupi, V. Aluminium honeycomb sandwich as a design alternative for lightweight marine structures. Ships Offshore Struct. 2022, 17, 2355–2366. [Google Scholar] [CrossRef]

- Mozafari, H.; Distefano, F.; Epasto, G.; Gu, L.; Linul, E.; Crupi, V. Design of an Innovative Hybrid Sandwich Protective Device for Offshore Structures. J. Mar. Sci. Eng. 2022, 10, 1385. [Google Scholar] [CrossRef]

- Lin, H.; Han, C.; Yang, L.; Karampour, H.; Luan, H.; Han, P.; Xu, H.; Zhang, S. Dynamic Performance and Crashworthiness Assessment of Honeycomb Reinforced Tubular Pipe in the Jacket Platform under Ship Collision. J. Mar. Sci. Eng. 2022, 10, 1194. [Google Scholar] [CrossRef]

- Corigliano, P.; Palomba, G.; Crupi, V.; Garbatov, Y. Stress–Strain Assessment of Honeycomb Sandwich Panel Subjected to Uniaxial Compressive Load. J. Mar. Sci. Eng. 2023, 11, 365. [Google Scholar] [CrossRef]

- Guo, H.Y.; Zhang, J.X. Expansion of sandwich tubes with metal foam core under axial compression. J. Appl. Mech. 2023, 90, 051008. [Google Scholar] [CrossRef]

- Jing, L.; Wang, Z.; Ning, J.; Zhao, L.M. The dynamic response of sandwich beams with open-cell metal foam cores. Compos. Part B-Eng. 2011, 42, 1–10. [Google Scholar] [CrossRef]

- Qin, Q.H.; Wang, T.J. A theoretical analysis of the dynamic response of metallic sandwich beam under impulsive loading. Eur. J. Mech. A-Solid 2009, 28, 1014–1025. [Google Scholar] [CrossRef]

- Qin, Q.H.; Wang, T.J. Low-velocity heavy-mass impact response of slender metal foam core sandwich beam. Compos. Struct. 2011, 93, 1526–1537. [Google Scholar] [CrossRef]

- Qin, Q.H.; Wang, T.J. Plastic Analysis of Metal Foam Core Sandwich Beam Transversely Loaded by a Flat Punch: Combined Local Denting and Overall Deformation. Int. J. Appl. Mech. 2012, 79, 041010. [Google Scholar] [CrossRef]

- Qin, Q.H.; Wang, T.J. Low-velocity impact response of fully clamped metal foam core sandwich beam incorporating local denting effect. Compos. Struct. 2013, 96, 346–356. [Google Scholar] [CrossRef]

- Asemi, K.; Salami, S.J. A study on low velocity impact response of FGM rectangular plates with 3D elasticity based graded finite element modeling. J. Theor. Appl. Mech. 2015, 53, 859–872. [Google Scholar] [CrossRef]

- Zafarmand, H.; Salehi, M.; Asemi, K. Three dimensional free vibration and transient analysis of two directional functionally graded thick cylindrical panels under impact loading. Lat. Am. J. Solids Struct. 2015, 12, 205–225. [Google Scholar] [CrossRef]

- Khatounabadia, M.; Jafariaand, M.; Asemi, K. Low-velocity impact analysis of functionally graded porous circular plate reinforced with graphene platelets. Wave Random Complex Media 2022, 6, 2091182. [Google Scholar] [CrossRef]

- Zhang, W.; Qin, Q.H.; Li, K.; Li, J.F.; Wang, Q. Effect of stepwise gradient on dynamic failure of composite sandwich beams with metal foam core subject to low-velocity impact. Int. J. Solids Struct. 2021, 228, 111125. [Google Scholar] [CrossRef]

- Fang, B.; Huang, W.; Xu, H.; Jiang, C.; Liu, J. High-velocity impact resistance of stepwise gradient sandwich beams with metal foam cores. Thin Wall Struct. 2022, 181, 110054. [Google Scholar] [CrossRef]

- Zhou, X.F.; Jing, L. Large deflection response of sandwich beams with layered-gradient foam cores subjected to low-velocity impact. Int. J. Impact Eng. 2023, 172, 104429. [Google Scholar] [CrossRef]

- Guo, K.L.; Mu, M.Y.; Zhou, S. Investigation on the dynamic behaviors of aluminum foam sandwich beams subjected to repeated low-velocity impacts. Metals 2023, 13, 1115. [Google Scholar] [CrossRef]

- Guo, K.L.; Mu, M.Y.; Zhou, S.; Zhang, Y.J. Dynamic responses of metal foam sandwich beam under repeated impacts considering impact location and face thickness distribution. Compos. Part C-Open 2023, 11, 100372. [Google Scholar] [CrossRef]

- Qin, Q.H.; Wang, T.J. An analytical solution for the large deflections of a slender sandwich beam with a metallic foam core under transverse loading by a flat punch. Compos. Struct. 2009, 88, 509–518. [Google Scholar] [CrossRef]

- Yu, T.X.; Stronge, W.J. Large deflections of a rigid-plastic beam-on-foundation from impact. Int. J. Impact Eng. 1990, 9, 115–126. [Google Scholar] [CrossRef]

- Yu, T.X.; Chen, F.L. Analysis of large deflection dynamic response of rigid-plastic beams. J. Eng. Mech. 1993, 119, 1293–1301. [Google Scholar]

- Zhu, L.; Tian, L.R.; Chen, F.L.; Yu, T.X. A new equivalent method for complex- shaped pulse loading based on saturation analysis and membrane factor method. Int. J. Impact Eng. 2021, 158, 104018. [Google Scholar] [CrossRef]

| Impact Number | Permanent Deflection (mm) | Rebound Energy (J) | Absorbed Energy (J) |

|---|---|---|---|

| 1 | 3.85 | 0.41 | 17.39 |

| 2 | 6.86 | 0.53 | 17.27 |

| 3 | 9.46 | 0.68 | 17.12 |

| 4 | 11.78 | 1.03 | 16.77 |

| 5 | 13.85 | 1.41 | 16.39 |

| 6 | 15.61 | 1.50 | 16.30 |

| 7 | 17.04 | 1.69 | 16.11 |

| 8 | 18.35 | 2.12 | 15.68 |

| 9 | 19.30 | 2.28 | 15.52 |

| 10 | 20.05 | 2.60 | 15.20 |

| Parameter | Symbol | Unit | Value | |

|---|---|---|---|---|

| Geometric Parameters | Beam Length | 2L | mm | 150 |

| Face Thickness | t | mm | 1 | |

| Core Thickness | c | mm | 10 | |

| Beam Width | B | mm | 30 | |

| Material Properties | Face Density | u1 | kg/mm3 | 7.8 × 10−6 |

| Core Density | u2 | kg/mm3 | 5.0 × 10−7 | |

| Line Density of the Beam | u | kg/mm | 2.06 × 10−6 | |

| Face Yield Stress | σf | GPa | 0.25 | |

| Core Yield Stress | σc | GPa | 0.01 | |

| Face Young’s Moduli | Ef | GPa | 201 | |

| Core Young’s Moduli | Ec | GPa | 0.42 | |

| Fully Plastic Moment | MP | kg.mm2/ms2 | 3.00 | |

| Fully Plastic Axial Force | NP | kg.mm/ms2 | 0.60 | |

| Energy | Beam Mass | GB | kg | 9.27 × 10−3 |

| Impactor Mass | GS | kg | 7.884 | |

| Mass Ratio | G* = GS/GS | / | 850 | |

| Impact Velocity | V | m/s | 2.12 | |

| Impact Energy | EK0 | J | 17.8 | |

| Dimensionless parameters | Yield Stress | / | 0.04 | |

| Thickness | / | 0.10 | ||

| Thickness to length | / | 0.133 | ||

| Kinetic energy | EK0* | / | 0.25664 |

| Impact Number | MFM | Circumscribing | Inscribing | Numerical [31] | Test [30] |

|---|---|---|---|---|---|

| 1 | 0.268 | 0.236 | 0.405 | 0.332 | 0.321 |

| 2 | 0.530 | 0.425 | 0.703 | 0.613 | 0.572 |

| 3 | 0.781 | 0.586 | 0.947 | 0.845 | 0.788 |

| 4 | 1.014 | 0.728 | 1.157 | 1.035 | 0.982 |

| 5 | 1.208 | 0.856 | 1.344 | 1.195 | 1.154 |

| 6 | 1.374 | 0.972 | 1.513 | 1.333 | 1.301 |

| 7 | 1.520 | 1.080 | 1.667 | 1.456 | 1.420 |

| 8 | 1.652 | 1.179 | 1.809 | 1.567 | 1.529 |

| 9 | 1.773 | 1.272 | 1.941 | 1.669 | 1.608 |

| 10 | 1.886 | 1.359 | 2.065 | 1.765 | 1.671 |

| Case | σc | σf | CSR |

|---|---|---|---|

| CSR-0.01 | 0.0025 | 0.25 | 0.01 |

| CSR-0.05 | 0.0125 | 0.25 | 0.05 |

| CSR-0.1 | 0.025 | 0.25 | 0.1 |

| CSR-0.2 | 0.050 | 0.25 | 0.2 |

| CSR-0.3 | 0.075 | 0.25 | 0.3 |

| CSR-0.5 | 0.125 | 0.25 | 0.5 |

| CSR-1 | 0.250 | 0.25 | 1 |

| Case | t | c | CSR |

|---|---|---|---|

| FTR-0.01 | 0.1 | 10 | 0.01 |

| FTR-0.02 | 0.2 | 10 | 0.02 |

| FTR-0.05 | 0.5 | 10 | 0.05 |

| FTR-0.08 | 0.8 | 10 | 0.08 |

| FTR-0.1 | 1.0 | 10 | 0.1 |

| FTR-0.12 | 1.2 | 10 | 0.12 |

| FTR-0.15 | 1.5 | 10 | 0.15 |

| FTR-0.18 | 1.8 | 10 | 0.18 |

| FTR-0.2 | 2.0 | 10 | 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, K.; Mu, M.; Cai, W.; Xu, B.; Zhu, L. Theoretical Analysis of Plastic Behavior of Sandwich Beam with Metal Foam under Repeated Impacts. J. Mar. Sci. Eng. 2023, 11, 1974. https://doi.org/10.3390/jmse11101974

Guo K, Mu M, Cai W, Xu B, Zhu L. Theoretical Analysis of Plastic Behavior of Sandwich Beam with Metal Foam under Repeated Impacts. Journal of Marine Science and Engineering. 2023; 11(10):1974. https://doi.org/10.3390/jmse11101974

Chicago/Turabian StyleGuo, Kailing, Mengying Mu, Wei Cai, Bofang Xu, and Ling Zhu. 2023. "Theoretical Analysis of Plastic Behavior of Sandwich Beam with Metal Foam under Repeated Impacts" Journal of Marine Science and Engineering 11, no. 10: 1974. https://doi.org/10.3390/jmse11101974

APA StyleGuo, K., Mu, M., Cai, W., Xu, B., & Zhu, L. (2023). Theoretical Analysis of Plastic Behavior of Sandwich Beam with Metal Foam under Repeated Impacts. Journal of Marine Science and Engineering, 11(10), 1974. https://doi.org/10.3390/jmse11101974