1. Introduction

As critical nodes in the global supply chain, container terminals play a significant role in international trade. As technology advances and operational equipment is upgraded, ports are gradually transitioning toward constructing automated or semiautomated container terminals (ACTs). Horizontal transportation equipment used for the delivery of containers between the seaside and the landside is a key component in the operation of container terminals. Among these, automated guided vehicles (AGVs) constitute the transportation equipment with the largest market share in the global container port business.

In recent years, to achieve high throughput and storage density in ACTs, yards equipped with unilateral cantilever rail-mounted gantry cranes combine the advantages of conventional and general automated container yards and have been adopted in newly constructed automated terminals, such as the Tuas Port in Singapore and the Haifa Port in Israel. In this new yard layout, AGVs can enter the interior of blocks arranged perpendicularly to the shoreline for interaction with the yard cranes (YCs). This approach has resulted in the development of long-range AGVs operating in more complex environments, requiring more maneuvering and under more complex scheduling requirements.

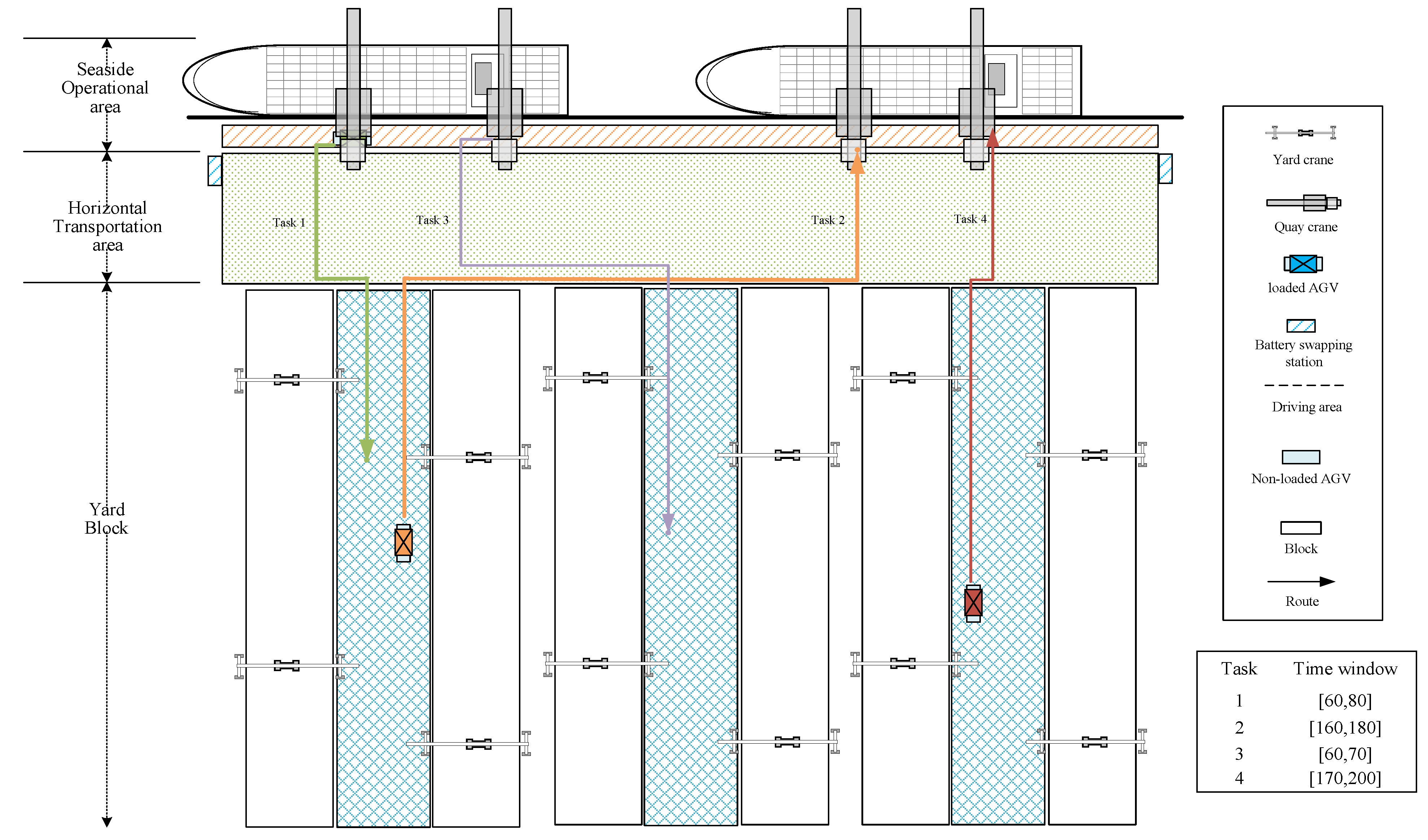

Figure 1 shows a typical layout of a new ACT. The terminal is divided into three parts: the seaside operation area, the horizontal transportation area, and the yard blocks. In addition, a battery-swapping station providing battery recovery for AGVs is arranged within the horizontal transportation area. In addition, the AGV-drivable area is divided into three parts: the apron area, the horizontal transportation area, and the block area. Among them, AGVs in the apron area need to handle containers in cooperation with quay cranes (QCs), while in the block area of the yard, AGVs need to interact with YCs to handle containers. Because of the lack of space allowing wide movement, as in the horizontal transportation area, interaction with YCs is more challenging. The roads inside the yard block are narrow and crowded, the traffic environment is more complex, and the speed control requirements are high.

In the conventional container terminal truck scheduling, vehicles are often controlled by drivers. With the advancement of Industry 4.0, the terminal’s transportation system has been updated to automation and digital intelligent technology, posing additional operational challenges. Unoccupied vehicles have to rely on control systems for scheduling. In addition to completing container transportation tasks, it is also necessary to control the vehicle’s driving speed and monitor the vehicle’s electricity level. Because of the limited capacity of their battery packs, AGVs often need to return to the battery stations for battery swapping during the yard operations. However, the handling capacity of the battery-swapping stations is limited, and too many AGVs entering at the same time may cause congestion. In addition, the traffic environment in different areas of the terminal can also have an impact on the movement speed of AGVs, thereby affecting their energy consumption and, by extension, the CO2 emissions associated with replenishing the batteries.

Unlike the conventional AGV scheduling [

1,

2,

3,

4,

5], when studying the AGV scheduling problem in a new type of automated container terminal, it is necessary to pay attention to its battery consumption, ensuring that the depleted AGVs can be restored in a timely manner while completing their task, thereby ensuring the smooth completion of container transportation. At the same time, it is necessary to consider the charging capacity of the terminal to avoid congestion of AGVs with depleted batteries at the battery-swapping station and consider factors that affect the energy consumption of AGVs, such as their driving speed, often influenced by the traffic environment in different areas of the terminal. Therefore, this paper schedules AGV operations to determine the task and sequence of AGV operations while also exploring the impact of AGV speed variability on carbon emissions and task completion.

With the construction of smart terminals, intelligent equipment and technologies have also been widely applied, and low-carbon environmental protection is receiving increasing attention. Therefore, this paper studies the scheduling problem of AGVs in new terminals from the perspective of energy conservation and emission reduction, ensuring that AGVs complete their tasks while reducing carbon emissions. It also provides an academic reference for the operation of smart terminals and the intelligent upgrading of traditional ones.

This paper studies the AGV scheduling problem in a new type of automated container terminal, taking into account the battery swapping and speed control of AGVs and optimizing their task assignment and operation sequence while avoiding congestion at the battery-swapping station, thereby minimizing the operation delay and carbon emission costs of AGVs. The contributions of this paper mainly lie in the consideration of the following:

- (1)

A speed control strategy considering the traffic environment of new ACTs is proposed, and a mixed integer programming (MIP) model is established with the goal of minimizing CO2 emissions and delays due to AGV operations. The new model takes into account the battery recovery of AGVs and the impact of traffic conditions on speed in different areas of new ACTs;

- (2)

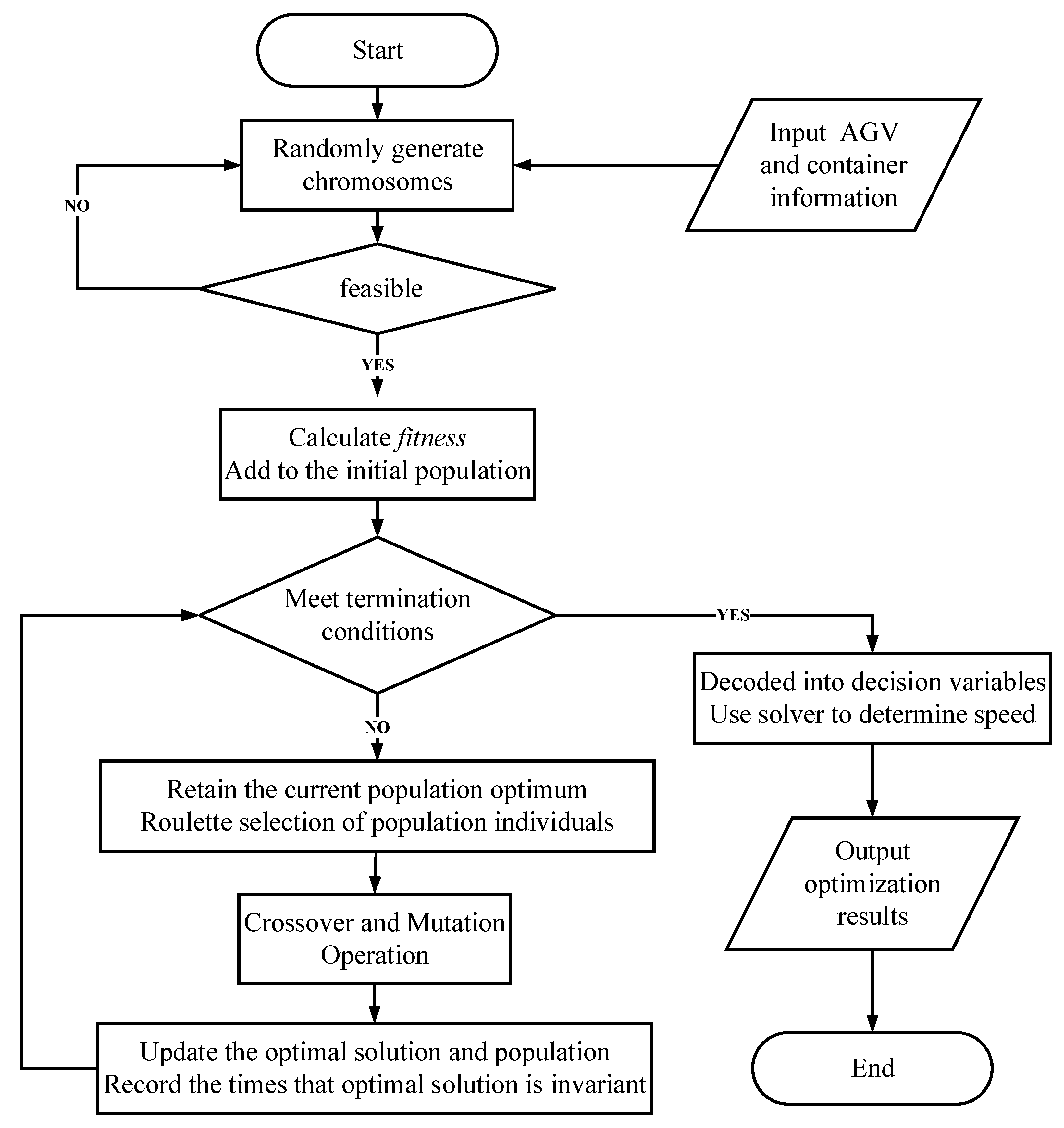

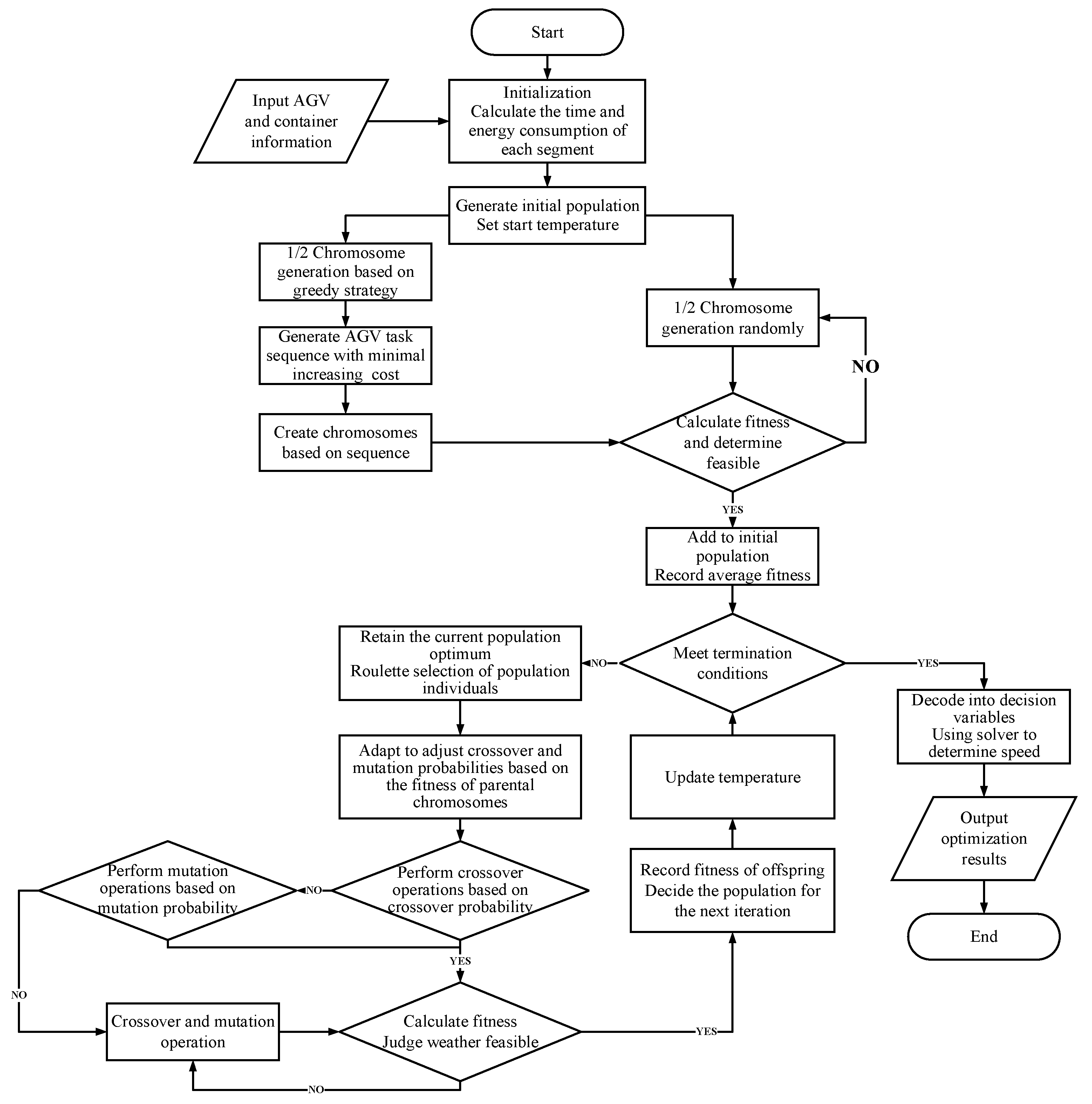

Because of the complexity of the proposed model, an improved genetic algorithm (GA)-based solution is developed. A greedy strategy is used to generate a better initial solution. A simulated annealing (SA)-based population selection approach and an adaptive crossover and mutation probability calculation prevent the algorithm from falling into local optima while increasing the rate of convergence, thus improving the solution efficiency.

In the rest of this paper,

Section 2 offers a brief review of the AGV scheduling problem. This problem in new ACTs is defined in

Section 3, and a MIP model is established. The proposed approach is introduced in

Section 4. The results of simulation experiments are presented in

Section 5. Finally, the study’s conclusion is discussed, and future directions for this field are put forward in

Section 6.

2. Literature Review

In this section, the relevant literature on the AGV scheduling problem is reviewed, and the following aspects are considered: AGV scheduling in ACTs, AGV scheduling considering battery recovery, and AGV scheduling considering speed control.

Scholars have conducted extensive research on the AGV scheduling problem in ACTs. Sun et al. (2022) provided a comprehensive review of AGV-based transportation systems of ACTs and summarized the literature presented in the past 25 years from different research perspectives [

6]. Grunow et al. (2005) studied the multi-load AGV dispatching problem. On this foundation [

1], Grunow et al. (2006) further considered the uncertain handling time of cranes and release times of orders [

7]. Yang et al. (2018) established a bi-level programming model to study AGV scheduling in ACTs and proposed an improved GA to solve the proposed model [

2]. Zhong et al. (2020) integrated the AGV scheduling problem and AGV conflict-free path-planning problem into a hybrid genetic algorithm-particle swarm optimization designed to solve the proposed mixed integer programming model [

3]. Wang et al. (2022) investigated the AGV scheduling problem considering bidirectional paths in ACTs and designed a branch-and-bound algorithm to generate conflict-free routes and minimize the total completion time [

4]. Duan et al. (2023) studied the AGV scheduling problem considering the interaction with QC, and a mixed integrated programming model was established with the goal of minimizing the completion time of ships and the idle time of AGVs [

5]. Yang et al. (2023) studied the AGV scheduling problem under the sea rail intermodal transportation model and established a mixed integer programming model to minimize equipment energy consumption [

8]. Hu et al. (2023) investigated AGV path planning in conflict situations, and the multiagent deep deterministic policy gradient (MADDPG) method was proposed to obtain the shortest path [

9].

There is also relevant research on yard vehicle assignment and scheduling. Dotoli et al. (2014) developed a Petri nets-based framework for intermodal freight transport terminals that can evaluate the operational performance of transportation systems and the terminals’ efficiency [

10]. Subsequently, Cavone et al. (2016a) proposed two further control policies to optimize the terminal performance [

11], and Cavone et al. (2016b) used timed Petri nets to solve the strategic planning and the capacity/frequency of the transportation equipment [

12]. Iris et al. (2018) integrated the management of loading operations, planning, and scheduling of the transport vehicles and established a mixed integer programming model to minimize tardiness and vessel service time [

13].

With the construction of green ports, electric vehicle scheduling has gradually attracted the attention of several scholars. Iris and Lam (2019) and Zhou et al. (2022) provided a comprehensive review of energy efficiency and application of AGV in green ports, respectively [

14,

15]. Schmidt et al. (2015) evaluated the cost efficiency of electric AGVs in ACTs from a revenue perspective and proposed strategies to further enhance their profitability [

16]. Ma et al. (2020) studied the planning of charging station facilities and operational strategies of electric AGVs in ACTs and proposed two layout designs and two charging strategies for deploying charging stations and controlling electric AGV charging [

17].

In addition, scholars have conducted in-depth research on the issue of battery power in AGV scheduling. Xiang et al. (2021) established an ACT-nested semi-open queuing network model, which evaluates the ACT performance under different plug-in charging and battery-swapping strategies [

18]. Singh et al. (2022) studied AGV scheduling in ACTs considering battery charging to minimize the tardiness and travel costs of AGVs and developed an adaptive large-neighborhood search algorithm to solve the proposed MIP model [

19]. Sun et al. (2023) investigated AGV scheduling focusing on battery charging and established a collaborative scheduling optimization model that trades off terminal operational efficiency and energy savings [

20].

Other scholars have studied the energy recovery of electric vehicles in other application scenarios. Keskin et al. (2019) studied electric vehicle routing with time windows, taking into account the queuing time of vehicles at charging stations [

21]. Hosseini et al. (2020) proposed a novel, fully distributed control strategy for large-scale electric vehicles, minimizing total charging costs and battery degradation while achieving optimal charging [

22]. Dang et al. (2021) studied the scheduling problem of heterogeneous AGVs in factories, considering limited battery capacities and partial charging at critical battery thresholds [

23]. Jamshidi et al. (2021) studied the scheduling problem of electric taxis and developed a charging algorithm that considers movement distance, charging facility capacity, and charging time [

24]. In order to explore the relationship between AGV scheduling, charging threshold, and power consumption, Li et al. (2022) studied AGV scheduling in a manufacturing factory [

25]. Lam et al. (2022) studied electric vehicle routing considering time windows and charging constraints, but in this case, the energy recovery was modeled as a piecewise linear function of charging time [

26]. Boccia et al. (2023) studied AGV scheduling with battery constraints in manufacturing workshops and determined the optimal scheduling of transportation and charging operations for AGV fleets [

27].

Some scholars’ focus on AGV speed control in AGV scheduling is also worth noting. Nishi et al. (2014) studied the optimization of collision-free paths for AGVs with acceleration and deceleration. By discretizing the transportation area into several regions, a continuous time model was established to represent the dynamic changes in the vehicle’s state [

28]. Adamo et al. (2018) determined the AGV path and speed on each arc to prevent conflicts, focusing on time windows and minimizing the total energy consumption [

29]. Chen et al. (2021) studied automatic truck scheduling and established a mixed integer second-order cone programming model based on fuel consumption functions related to movement speed and fleet formation to minimize the total operating costs [

30]. Considering the impact of speed on AGV travel time and energy consumption, Xing et al. (2023) studied AGV scheduling in ACTs and established an MIP model to minimize the total operation time of cranes and the energy consumption of the AGVs [

31].

The literature related to automated vehicle scheduling is classified in

Table 1 on the basis of the following six main consideration parameters: (1) charging demand, (2) limited charging capacity, (3) speed, (4) types of constraints, (5) types of models, and (6) solution approach. Overall, only a few papers have considered a speed factor in vehicle scheduling problems. Additionally, only a few works have considered both AGV speed control and energy consumption in ACT settings. Moreover, these studies did not simultaneously consider the charging demand of AGVs. In the AGV scheduling of urban roads and factory workshops, only a few scholars have considered the charging demand while addressing the limited charging capacity.

Therefore, from the perspective of green port construction, in this paper, AGV scheduling is studied in the context of container transportation operations in ACTs, taking into account the charging demands of AGVs and the limited charging capacity of the terminal. The traffic environment in different areas is also analyzed to determine the optimal AGV speed and the CO2 emissions incurred during AGV transportation.

5. Numerical Experiments

This section presents a series of experiments to verify the effectiveness and efficiency of the proposed MIP model and solution method. The proposed mathematical model was implemented and solved using the popular commercial solver GUROBI. The proposed solution method was implemented in C#, and the model was solved using GUROBI 10.0. All experiments were conducted on a computer with a 3.80 GHz CPU and 64 GB RAM.

5.1. Parameter Settings

The planning horizon in this paper is one hour, and the QC and YC operation time and sequence of each container are assumed to have been determined at a higher level of planning, which is beyond the scope of this paper. The processing time of the QC and the YC follow a uniform distribution of U (40, 200) s, and the initial cumulative power consumption of the AGVs follows a uniform distribution of U (0, 100) kw/h.

The length of the shoreline was assumed to be 2350 m, and the width of the horizontal transportation area was set to 120 m. The battery-swapping station was assumed to be equipped with three swapping robots, and the AGV stay time at the battery-swapping station was set to 5 min. The maximum speed of the AGVs was set to 6 m/s, which led to a discrete set of velocities

. Considering the environmental traffic limitations in different areas of the yard, the maximum speed in different segments was set as

when the AGVs were in a no-load state, and the maximum speeds in different segments were set as

when the AGVs were loaded. The settings of the other parameters are shown in

Table 2.

The feasibility and effectiveness of the model and algorithm were verified in small, medium, and large-scale cases. Detailed information on all cases is shown in

Table 3.

5.2. Numerical Experiment Results

5.2.1. Analysis of Results for Different Scale Cases

This section presents the results of numerical experiments to evaluate the effectiveness of the proposed model and solution approach. The results of the standard GA, a GA based on SA (SAGA), an adaptive genetic algorithm based on SA (SAAGA), a greedy algorithm (Greedy), and the proposed GSAAGA were compared with the results of the GUROBI solver. Because of the randomness of the heuristic algorithms (HAs), each case was run 10 times, and the average values are reported as the results. The numerical experimental results of all cases are shown in

Table 4.

Because of the complexity of the problem, GUROBI could only solve the small-scale cases within the specified time. For those, GUROBI obtained the optimal solution in most cases, and the GAP (defined as GAP (%) = (OBJheuristics − OBJ)/OBJ ⋅ 100%) between the HA-based solution methods and the optimal solution was 0, verifying the effectiveness of the HA-based solution methods. In addition, all HA-based solution methods obtained the optimal solution within about 1 s on average, while GUROBI’s solution time was, on average, more than 30 times slower.

It is worth noting that for cases S3 and S5, GUROBI could not find the optimal solution within the specified time, while the GAP between the solution obtained using the HA-based method and the approximate solution was about 15% and 45%, respectively, further verifying the effectiveness of the HA-based solution methods. In addition, although the greedy algorithm-based methods could obtain a solution in a short time, the quality of the solution was not guaranteed because of the limited number of iterations allowed. In cases S5 and S6, the greedy algorithm-based methods obtained the worst solution.

5.2.2. Comparison of Algorithm Convergence

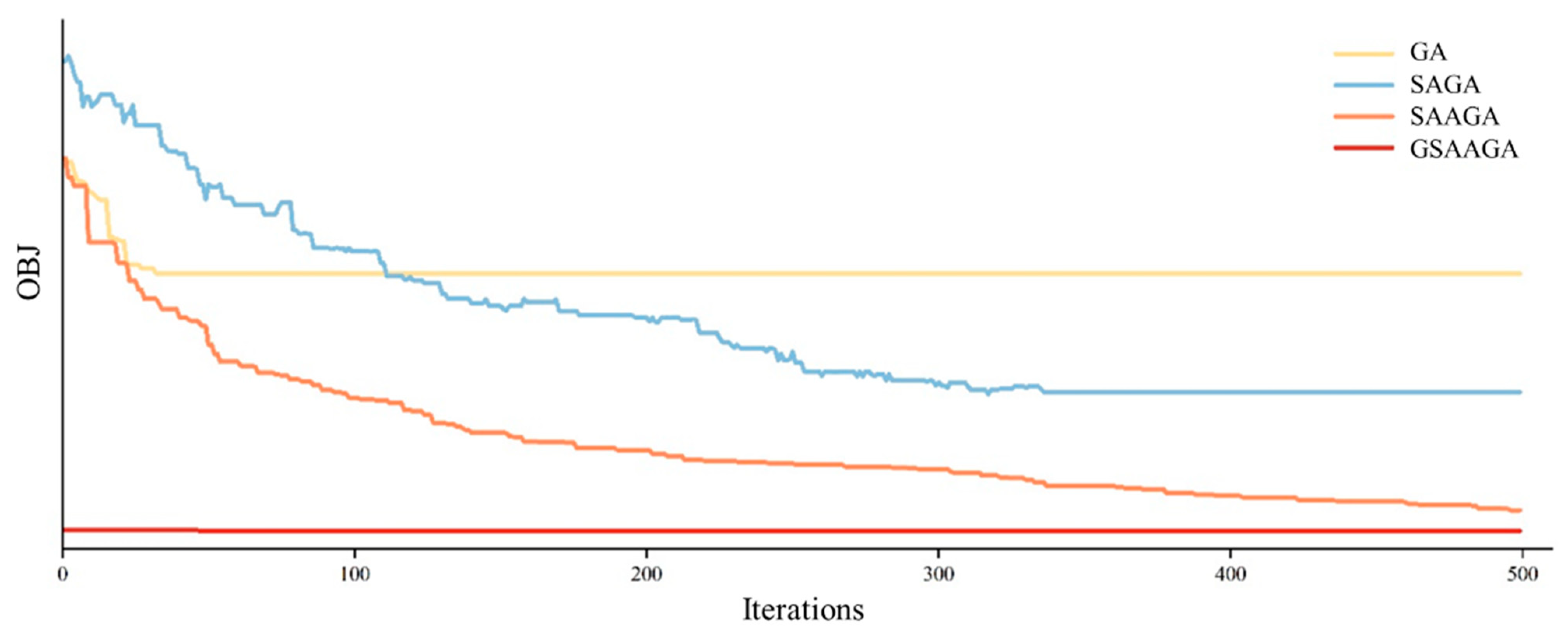

To further demonstrate the advantages of the solution approach proposed in this paper, the convergence of GA, SAGA, SAAGA, and GSAAGA in solving case L7 is shown in

Figure 9. The population of the algorithm was set to 50, and the number of iterations was 500. The termination criterion was the absence of improvement in 20 generations. It can be seen from

Figure 9 that the GA was easily trapped in local optima, and the population selection strategy based on SA helped the algorithm overcome these local optima effectively. The rate of convergence of SAAGA was faster than that of SAGA; that is, the adaptive crossover and mutation probabilities accelerated the rate of convergence of the algorithm. It is worth noting that half of the initial population in GAASGA adopts the greedy algorithm, which has a good initial solution from the beginning, allowing for a significant improvement in the quality of the solution.

5.2.3. Scheduling Scheme

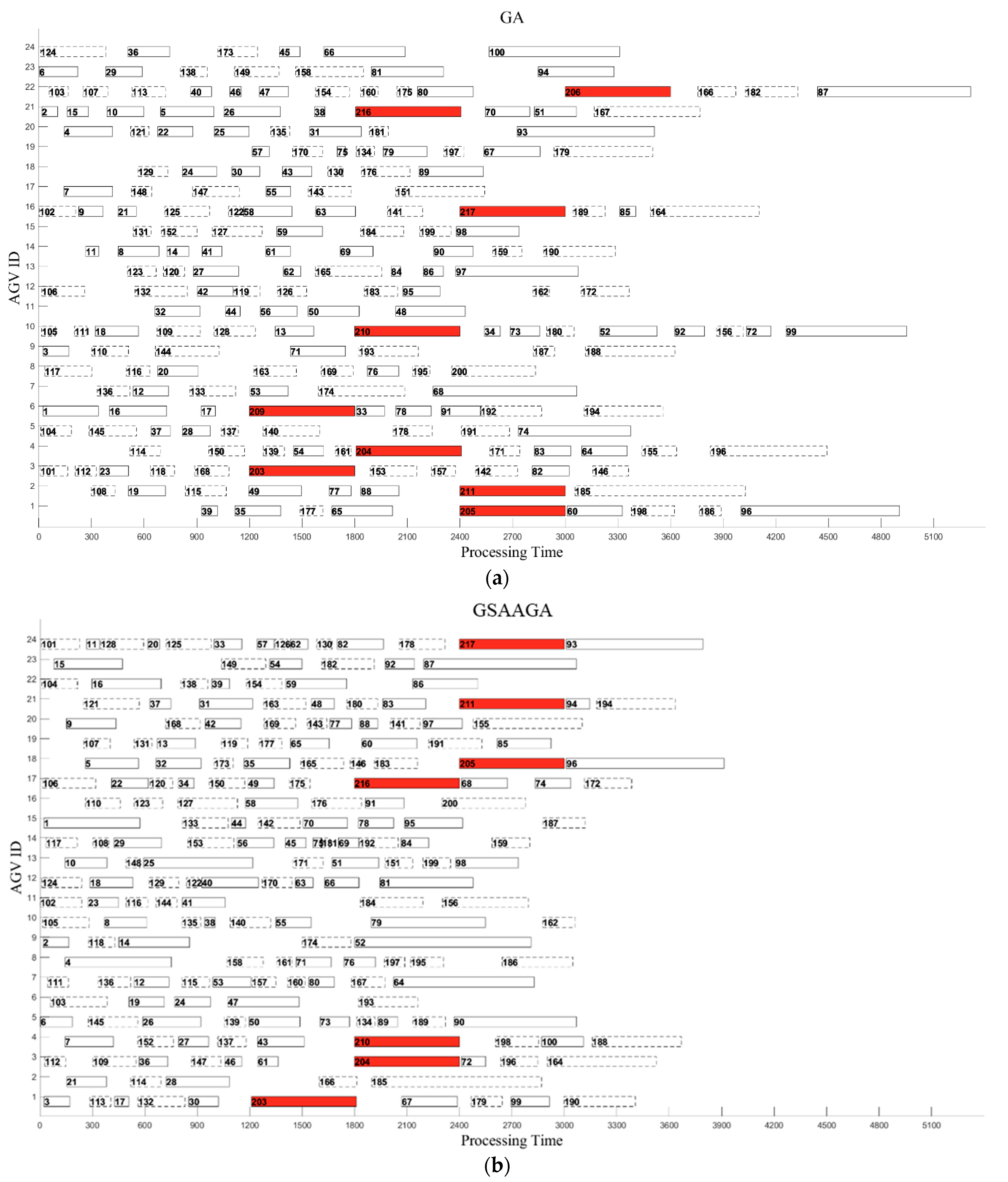

The scheduling results of the L7 large-scale case are shown in

Figure 10. This case included 200 container tasks and 24 AGVs. The rectangles in the figure represent container and battery-swapping tasks for the AGVs. Solid rectangles represent inbound container tasks, dashed rectangles represent outbound container tasks, and red rectangles represent the battery-swapping tasks. The width of each rectangle represents the duration of the task, and the number in the rectangle represents the task number.

The scheduling scheme of the GA-based solution approach is shown in

Figure 10a, while the scheduling scheme of GSAAGA is shown in

Figure 10b. It can be seen that in the scheduling plan obtained using the GA-based solution approach, 9 AGVs had their batteries swapped, while in the case of GSAAGA, only 7 AGVs required battery swapping, which resulted in reduced cost of CO

2 emission generated through idle movement. It is worth noting that the GSAAGA-based solution approach resulted in the faster completion of container tasks and the effective reduction in the delay cost.

5.3. Sensitivity Analysis

This section presents a sensitivity analysis conducted using different numbers of AGVs and battery-swapping station capacities to analyze these parameters’ impact on scheduling results, CO2 emission cost, and delay costs.

5.3.1. Sensitivity Analysis on the Number of Automated Guided Vehicles

In order to observe the impact of the number of AGVs on CO

2 emission cost and delay costs, a sensitivity analysis was conducted for ACT configurations with different numbers of AGVs. The number of container tasks was set to 20, 80, and 160, and the number of AGVs varied from 2 to 21. The specific settings and experimental results are shown in

Table 5.

In order to demonstrate the impact of the number of AGVs on cost, for this experiment, Constraint (6) was relaxed, so not all AGVs were required to complete the tasks. Constraint (6) in the original model was replaced with Constraint (47)

The experimental results indicate that energy consumption decreased as the number of AGVs increased. This is because an increase in the number of AGVs will lower the average number of tasks performed by each AGV, reducing the demand that AGVs return to the battery-swapping stations for energy recovery, thereby reducing the overall CO2 emission cost of the operation. In addition, when the number of container tasks is small, adding AGVs can bring more significant cost reductions. As the scale of container tasks expands, the cost improvement brought about through an increased investment in AGVs will gradually decrease.

5.3.2. Sensitivity Analysis on the Capacity of Battery-Swapping Stations

In this section, a sensitivity analysis is presented on the handling capacity of the battery-swapping stations, which was conducted by changing the number of swapping robots. The number of container tasks was set to 160, and three scenarios with different AGV numbers were considered, while the number of battery-swapping robots ranged from 1 to 5. The specific settings and experimental results are shown in

Table 6.

When the handling capacity of the battery-swapping station was low, some tasks could not be completed, resulting in the inability to honor the schedule. The experimental results indicate that when the handling capacity of the battery-swapping station is low, the total costs will gradually decrease as the number of battery-swapping robots increases because AGVs that require battery swapping have more options. In contrast, when the handling capacity of the battery-swapping stations is already sufficient, the overall cost reduction will decrease as the number of robots further increases. At that point, AGVs do not require additional swapping tasks. In addition, when the number of AGVs has already met the operational requirements of the container tasks, meaning there are no delay costs, a further increase in the number of robots will not result in a cost reduction. It is worth noting that increasing the number of robots leads to a significant improvement in delay costs, while its impact on CO2 emission is relatively small.

5.3.3. Sensitivity Analysis on Speed Variability

To reflect the impact of speed on carbon emission costs, sensitivity analysis was conducted by changing the deriving speed of AGVs. Considering that the fixed driving speeds of AGV were 3, 4, 5, and 6, respectively, and the number of container tasks was set to 20, 80, and 160, the various costs were compared between fixed speed and variable speed strategies. The specific settings and experimental results are shown in

Table 7.

It can be seen that compared with the fixed speed strategy, the variable speed has a greater impact on the calculation results. There is a 43.31% difference in the calculation results in small-scale cases, and this difference gradually increases as the scale of the cases increases. Therefore, considering the speed variability significantly impacts the calculation of carbon emissions and time for AGV operations.

In most cases, compared with a fixed speed, the total cost of variable speed was greater. However, the increase in total costs and the decrease in carbon emission costs were not necessarily related. Indeed, an increase in total costs did not necessarily mean an increase in carbon emission costs. The total cost included carbon emission and delay costs, which were conflicting, with the latter playing a more important role in reducing the total cost. In addition, considering the traffic conditions of different driving environments in the actual operation of the terminal, the variable speed could more accurately depict the carbon emissions and B-AGV operation time.

5.4. Discussion

In terms of solving efficiency, comparing different solution methods shows that the greedy strategy has advantages in generating initial solutions but also has limitations as it is very unstable in solving results. In addition, the SA strategy and adaptive cross-mutation strategy can effectively address the drawbacks of GA being prone to local optima and slow convergence speed [

20]. Therefore, compared with the standard GA-based method, the proposed method has significantly better solution and scheduling results. This means reducing the carbon emissions of AGVs while reducing task delays.

Moreover, as an important factor affecting the completion time and energy consumption of AGV tasks, speed has a significant impact on the actual operation of AGV. The experimental results also demonstrate the importance of variable speed considering the actual production environment of the terminal, which will more accurately depict the actual operation process of AGV.

In addition, to reduce the delay and carbon emission costs of AGVs in the actual operation of the terminal, terminal operators could increase the number of AGVs used while also increasing the difficulty of system scheduling. In addition, further improvements can be made to the infrastructure of the terminal, thereby enhancing its battery-swapping capacity.

6. Conclusions

In this paper, ACTs with limited charging capacity are analyzed using a model that considers a discrete handling capacity of battery-swapping stations. To reduce the CO2 emission cost of horizontal transportation, an AGV scheduling plan based on speed control is proposed. In addition, an MIP model considering the charging demand and speed control is established to ensure that AGVs complete their tasks while the CO2 emissions generated by transportation are minimized.

Because of the complexity of the problem, an improved GA-based solution approach is proposed to solve the established model effectively. The feasibility and effectiveness of the model and algorithm are verified through a series of numerical experiments. A greedy strategy is adopted to obtain a better initial solution for the algorithm in solving large-scale cases, while adaptive and SA strategies are used to improve the quality of the solution in small-scale and medium-scale cases.

At the same time, the impact of the number of AGVs and the handling capacity of battery-swapping stations on CO2 emission cost and delay costs are analyzed. The experimental results indicate that although an increase in the number of AGVs can lead to reduced CO2 emission cost and delay costs, this improvement will be less pronounced once the number of AGVs exceeds a certain point. Therefore, a reasonable number of AGVs can reduce CO2 emission and delay costs effectively.

Moreover, the number of battery-swapping robots also has a significant impact on CO2 emission cost and delay costs. A shortage of battery-swapping robots can lead to the inability to complete tasks, while more swapping robots can help reduce CO2 emission costs and delay costs during AGV operations. Therefore, equipping a reasonable number of battery-swapping robots can ensure the smooth operation of the terminal.

With respect to the charging demand and speed control, the AGV scheduling model established in this paper applies not only to newly constructed automated terminals but also to traditional terminals undergoing automation upgrades. The research results not only expand the theoretical research on port resource scheduling but also provide terminal managers with references for decision making and the operation of green ports.

This paper only focuses on the short-term scheduling problem of AGV. In the future, scholars can further consider the conflict and congestion issues during AGV operation. In addition, with continuous equipment upgrading, different energy recovery methods have emerged at container terminals [

15]. In addition to the widely used overall battery-swapping method, they also include plug-in charging methods. Researchers can further consider the AGV scheduling problem of combining different charging methods.