Dynamic Modeling and Motion Control Strategy of Cable-Driven Cleaning Robot for Ship Cargo Hold

Abstract

1. Introduction

- This article proposes a cable-driven cleaning robot for ship cargo hold. It reduces the burden of workers’ work, ensures the safety of personnel and improves the efficiency of cleaning operation. Moreover, it provides a new idea for modern ship maintenance.

- In this article, the Lagrange method is used to establish a dynamic model considering the ship motion and external disturbance forces, in which the motor model is considered. Moreover, the minimum 2-norm method is used to optimize the cable tension, which will keep the cable tight at all times to ensure the stability of the end-effector.

- Based on the unidirectional force, redundant drive and high-speed maneuvering characteristics of the cable, a tracking control strategy of C-DCR based on the modified PD feedforward controller is proposed. The analysis of the dynamic model shows that the control strategy has stable and smooth trajectory tracking performance. It can solve the problem of trajectory tracking for C-DCR with high-speed motion under ship motion and external disturbance.

2. Description of the Working Principle of the C-DCR

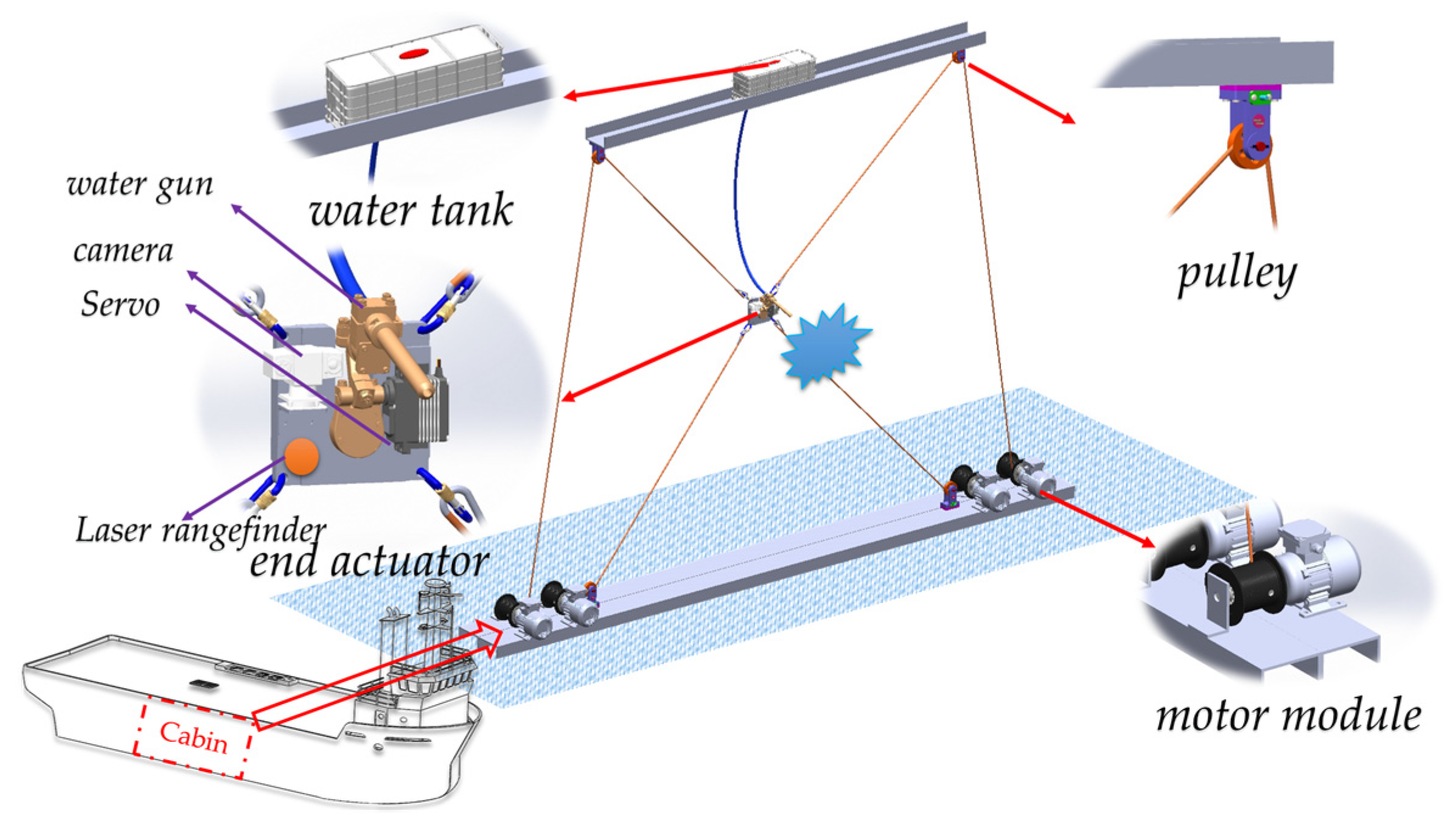

2.1. Mechanical Structure

2.2. Working Principle and Cost

3. Dynamic Model

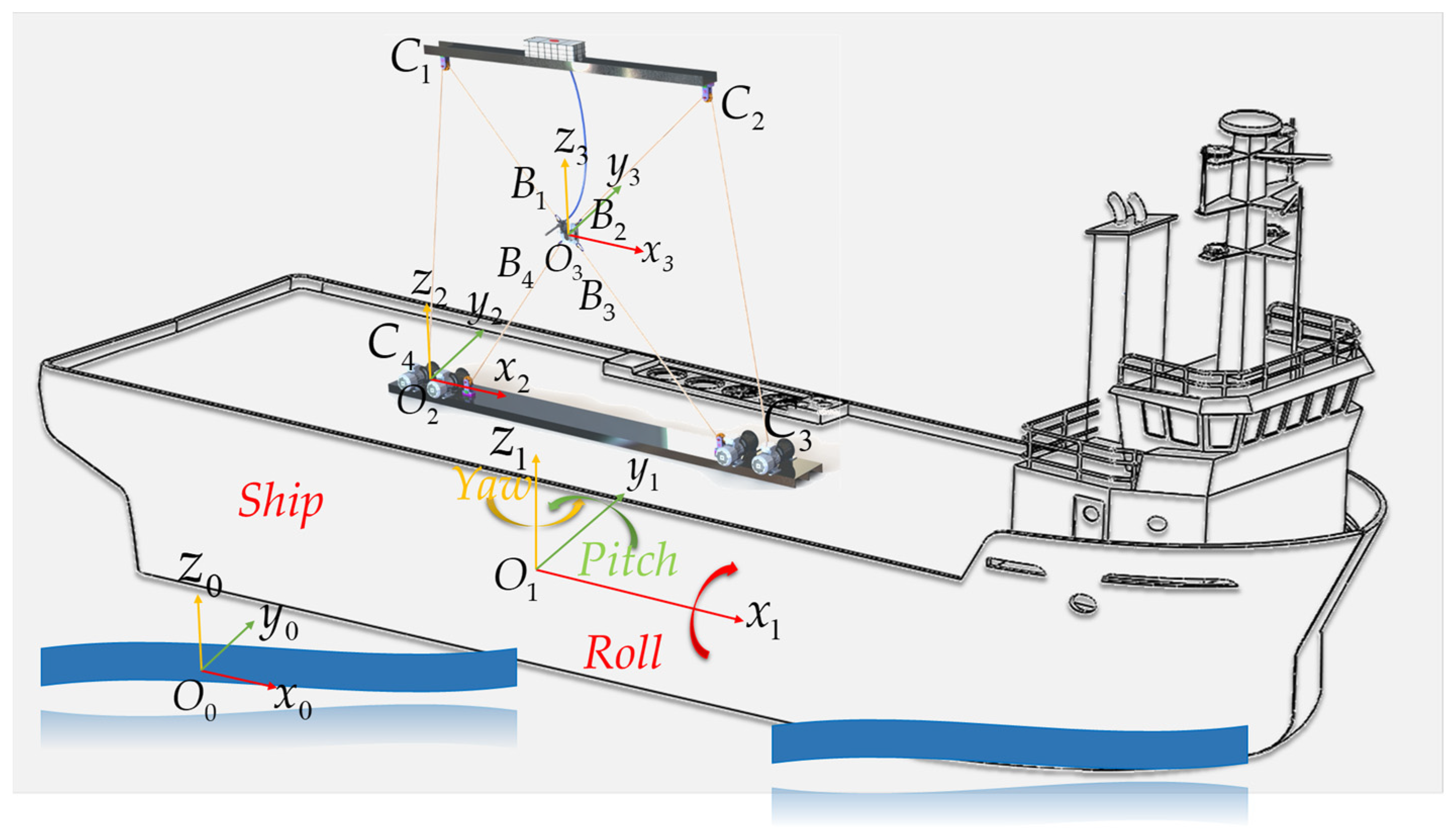

3.1. Frame Description

3.2. Frame Transformation

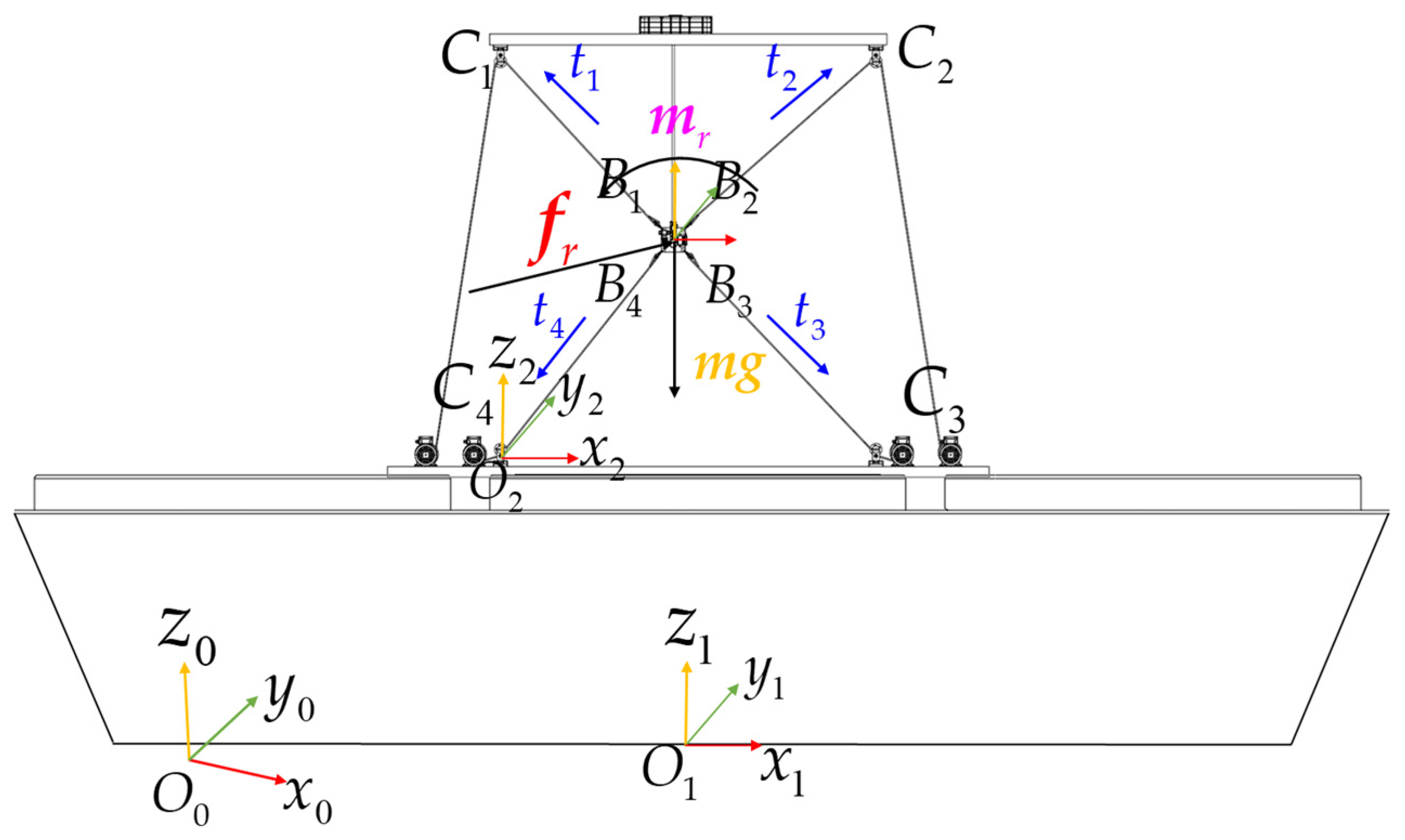

3.3. Dynamic Model of End-Effector

3.4. Dynamic Model of Driving Unit

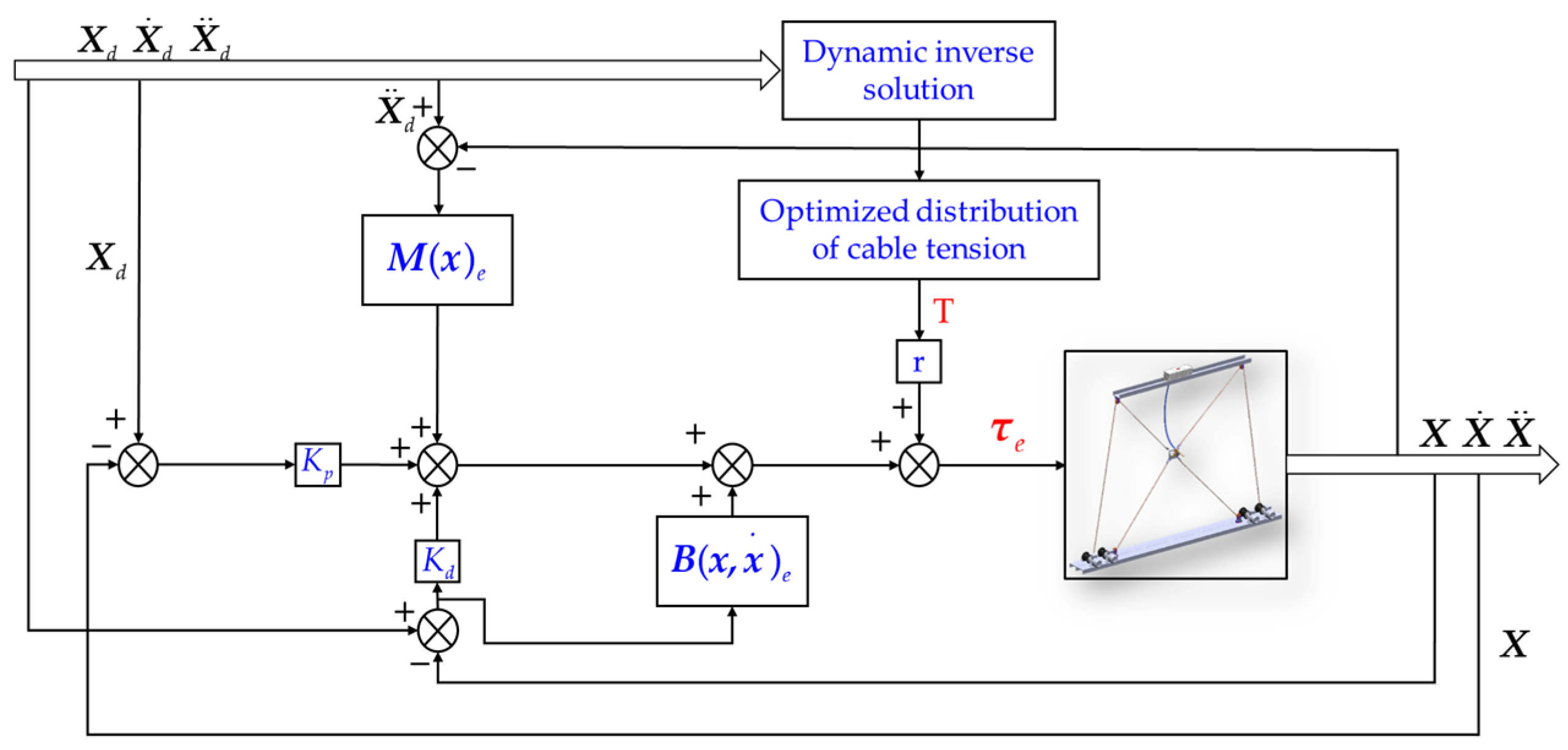

4. The Modified PD Feedforward Control Strategy

4.1. Controller Design

4.2. Stability Analysis of the System

5. Simulation Experiments

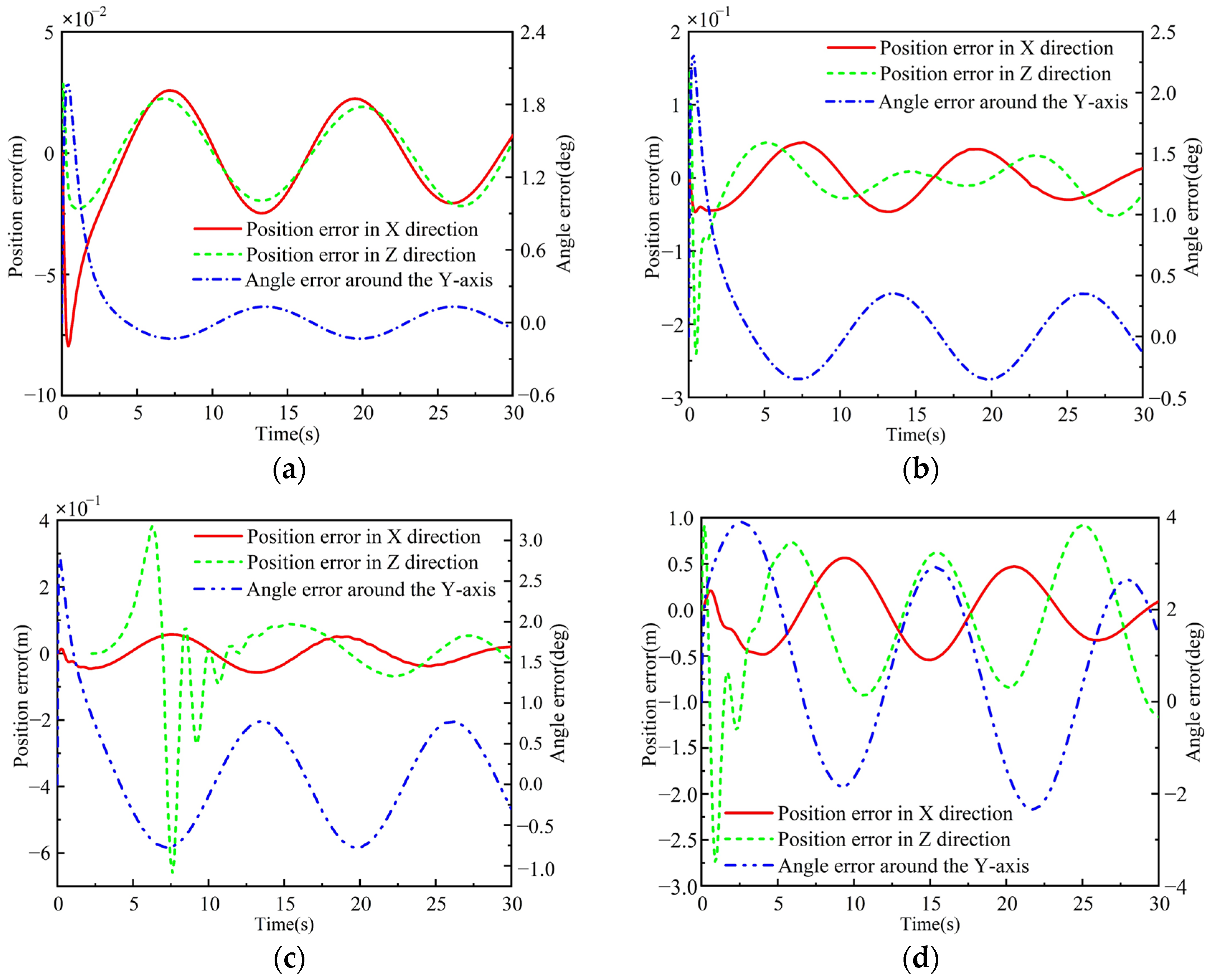

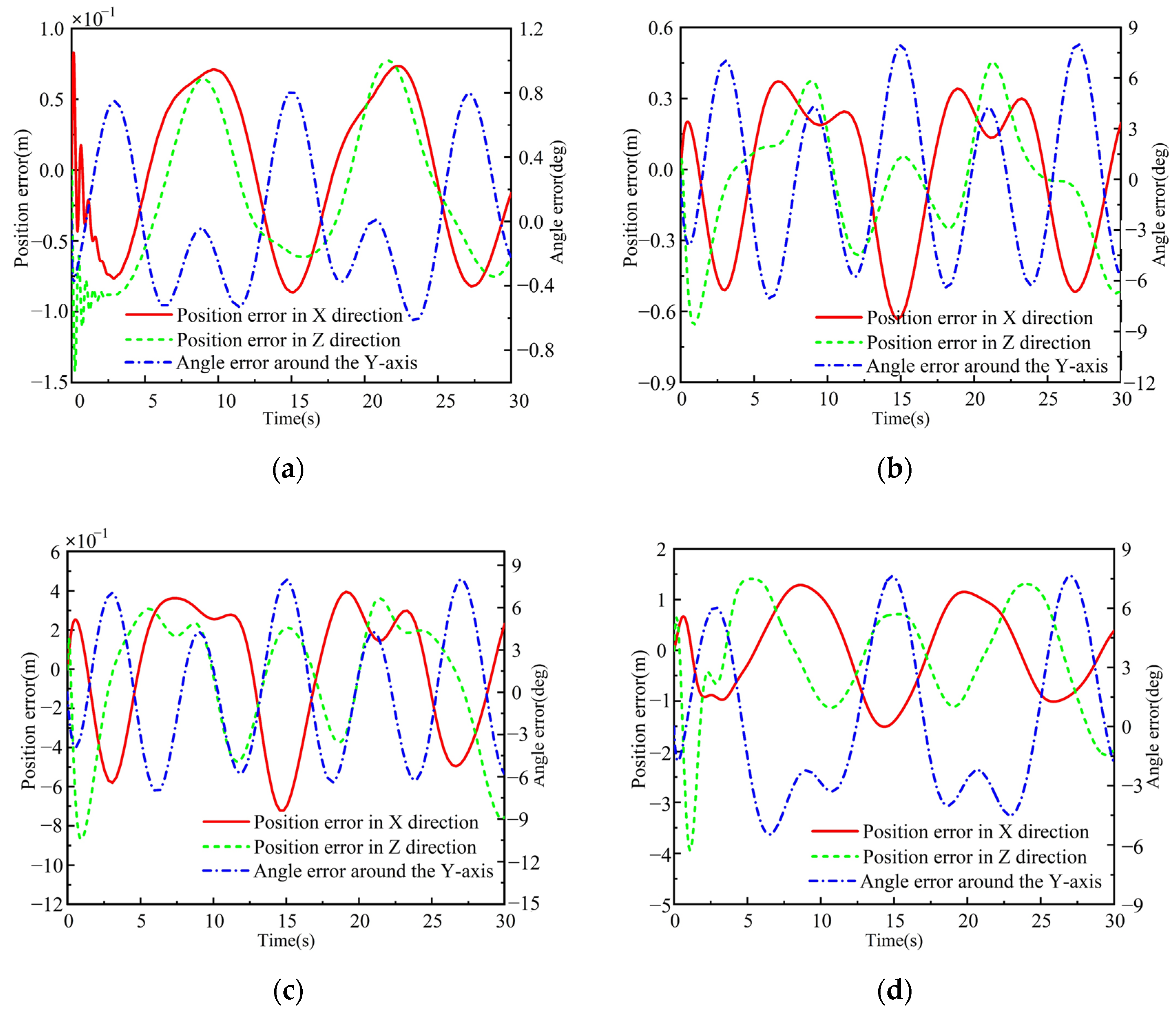

5.1. Simulation Verification

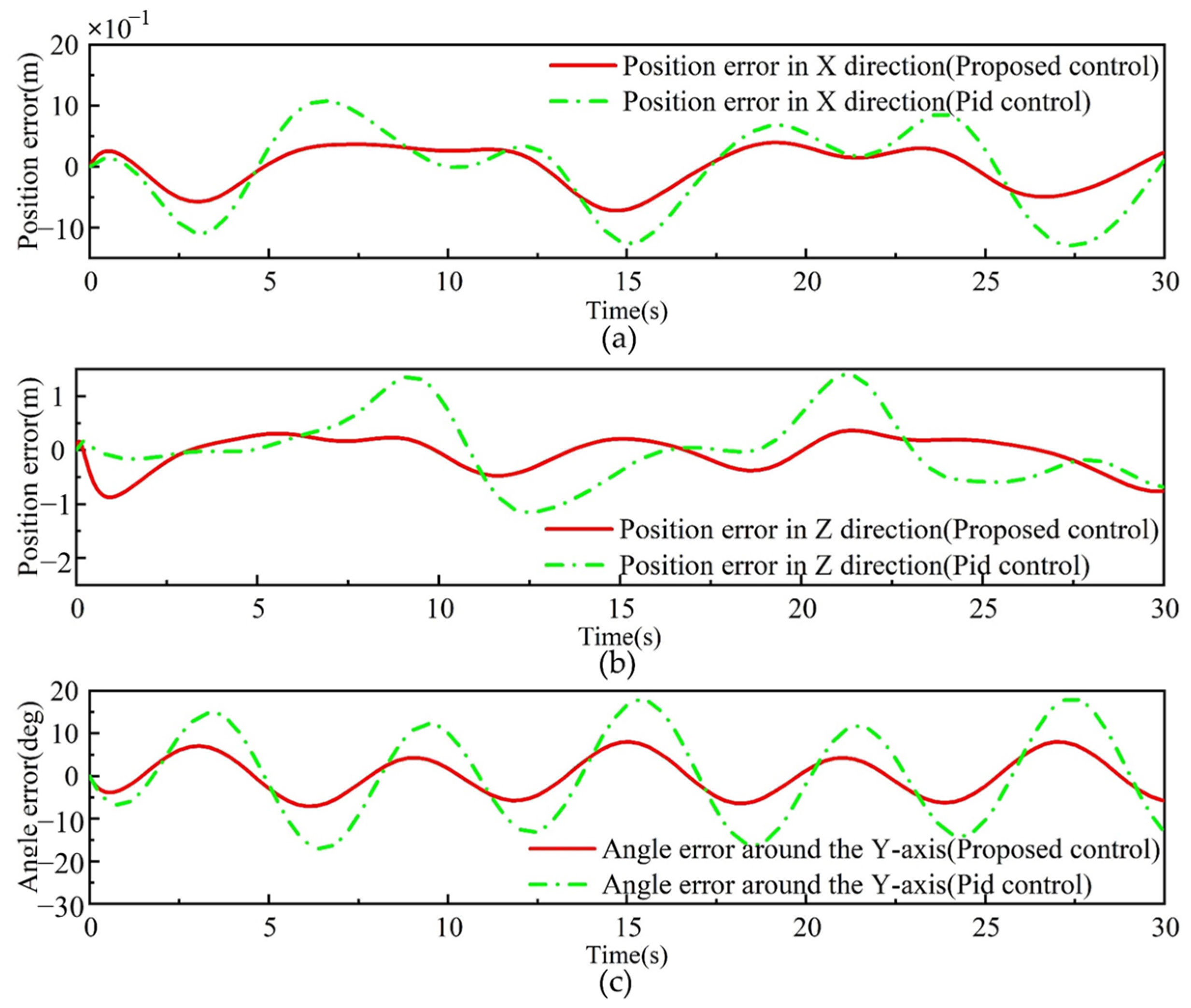

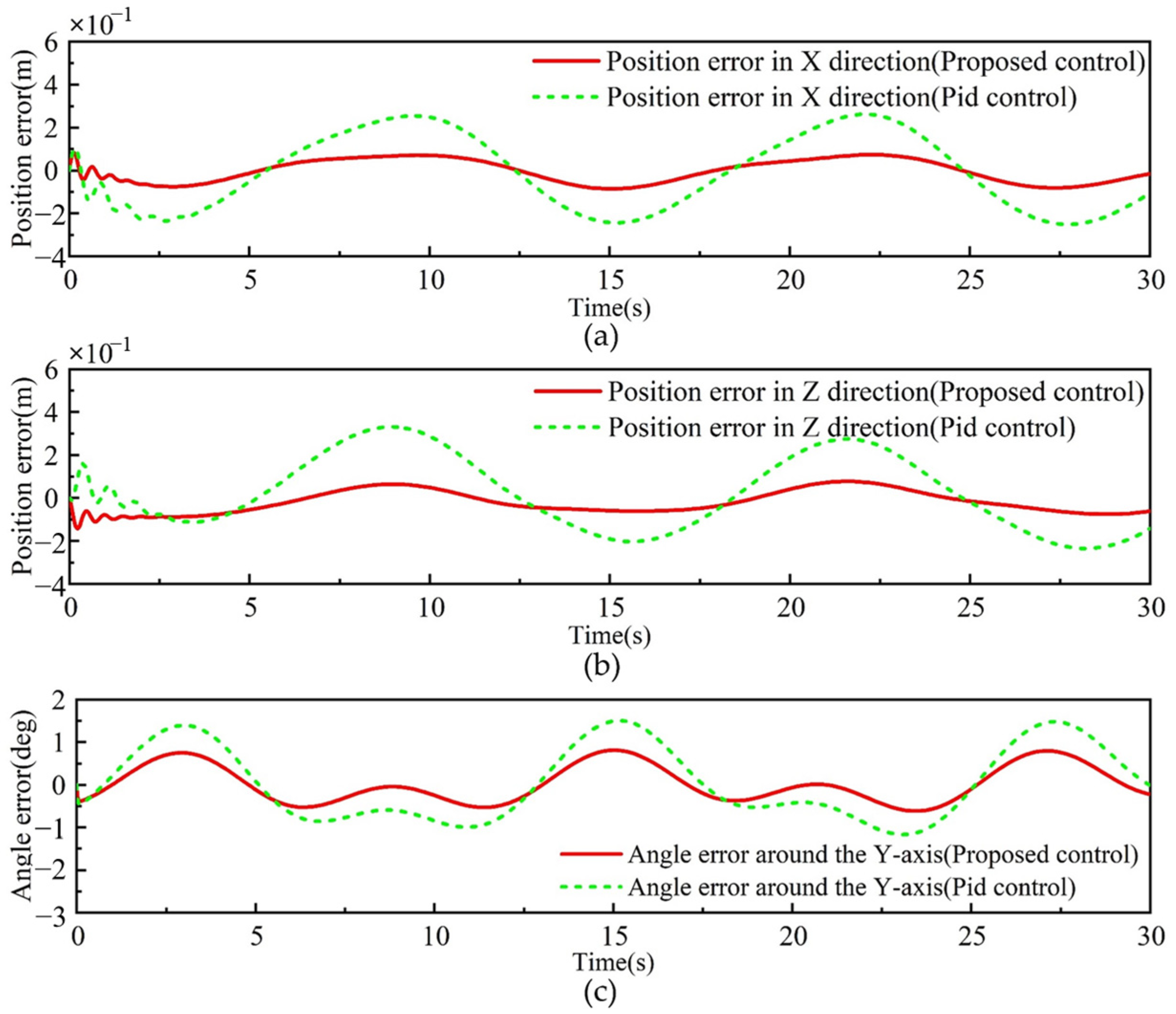

5.2. Discussion of Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Anh Vu, L.; Veerajagadheswar, P.; Kyaw, P.T.; Muthugala, M.A.V.J.; Elara, M.R.; Kuma, M.; Nguyen Huu Khanh, N. Towards optimal hydro-blasting in reconfigurable climbing system for corroded ship hull cleaning and maintenance. Expert Syst. Appl. 2020, 170, 114519. [Google Scholar] [CrossRef]

- Adland, R.; Cariou, P.; Jia, H.; Wolff, F.-C. The energy efficiency effects of periodic ship hull cleaning. J. Clean. Prod. 2018, 178, 1–13. [Google Scholar] [CrossRef]

- Eswaramoorthy, S.; John, F.G.P. Wheeled wall climbing robot with suction chamber: A study on forces and moments for stability. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; p. 012065. [Google Scholar]

- Li, H.; Sun, X.; Chen, Z.; Zhang, L.; Wang, H.; Wu, X. Design of a wheeled wall climbing robot based on the performance of bio-inspired dry adhesive material. Robotica 2022, 40, 611–624. [Google Scholar] [CrossRef]

- Akyuz, E.; Celik, M. A methodological extension to human reliability analysis for cargo tank cleaning operation on board chemical tanker ships. Saf. Sci. 2015, 75, 146–155. [Google Scholar] [CrossRef]

- Woods, C.M.C.; Floerl, O.; Jones, L. Biosecurity risks associated with in-water and shore-based marine vessel hull cleaning operations. Mar. Pollut. Bull. 2012, 64, 1392–1401. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.; Wang, S.; Han, G.; Sun, Y. Dynamic Modeling and Robust Adaptive Sliding Mode Controller for Marine Cable-Driven Parallel Derusting Robot. Appl. Sci. 2022, 12, 6137. [Google Scholar] [CrossRef]

- Bruckmann, T.; Boumann, R. Simulation and optimization of automated masonry construction using cable robots. Adv. Eng. Informatics 2021, 50, 101388. [Google Scholar] [CrossRef]

- Qin, Z.; Liu, Z.; Liu, Y.; Gao, H.; Sun, C.; Sun, G. Workspace analysis and optimal design of dual cable-suspended robots for construction. Mech. Mach. Theory 2022, 171, 104763. [Google Scholar] [CrossRef]

- Ueland, E.; Sauder, T.; Skjetne, R. Optimal Actuator Placement for Real-Time Hybrid Model Testing Using Cable-Driven Parallel Robots. J. Mar. Sci. Eng. 2021, 9, 191. [Google Scholar] [CrossRef]

- Chen, Q.; Zi, B.; Sun, Z.; Li, Y.; Xu, Q. Design and Development of a New Cable-Driven Parallel Robot for Waist Rehabilitation. IEEE/ASME Trans. Mechatron. 2019, 24, 1497–1507. [Google Scholar] [CrossRef]

- Tho, T.P.; Thinh, N.T. Using a Cable-Driven Parallel Robot with Applications in 3D Concrete Printing. Appl. Sci. 2021, 11, 563. [Google Scholar] [CrossRef]

- Iturralde, K.; Feucht, M.; Illner, D.; Hu, R.; Pan, W.; Linner, T.; Bock, T.; Eskudero, I.; Rodriguez, M.; Gorrotxategi, J.; et al. Cable-driven parallel robot for curtain wall module installation. Autom. Constr. 2022, 138, 104235. [Google Scholar] [CrossRef]

- Shao, Z.; Xie, G.; Zhang, Z.; Wang, L. Design and analysis of the cable-driven parallel robot for cleaning exterior wall of buildings. Int. J. Adv. Robot. Syst. 2021, 18, 172988142199031. [Google Scholar] [CrossRef]

- Liu, Z.; Qin, Z.; Gao, H.; Xiang, S.; Sun, G.; Sun, C.; Deng, Z. Mass design method considering force control errors for two-redundant cable-suspended parallel robots. Mech. Mach. Theory 2022, 177, 105043. [Google Scholar] [CrossRef]

- Mamidi, T.K.; Bandyopadhyay, S. Forward dynamic analyses of cable-driven parallel robots with constant input with applications to their kinetostatic problems. Mech. Mach. Theory 2021, 163, 104381. [Google Scholar] [CrossRef]

- Sun, G.; Liu, Z.; Gao, H.; Li, N.; Ding, L.; Deng, Z. Direct method for tension feasible region calculation in multi-redundant cable-driven parallel robots using computational geometry. Mech. Mach. Theory 2020, 158, 104225. [Google Scholar] [CrossRef]

- Wang, R.; Xie, Y.; Chen, X.; Li, Y. Kinematic and Dynamic Modeling and Workspace Analysis of a Suspended Cable-Driven Parallel Robot for Schonflies Motions. Machines 2022, 10, 451. [Google Scholar] [CrossRef]

- Kieu, V.N.D.; Huang, S.-C. Dynamic and Wrench-Feasible Workspace Analysis of a Cable-Driven Parallel Robot Considering a Nonlinear Cable Tension Model. Appl. Sci. 2021, 12, 244. [Google Scholar] [CrossRef]

- Goodarzi, R.; Korayem, M.H.; Tourajizadeh, H.; Nourizadeh, M. Nonlinear dynamic modeling of a mobile spatial cable-driven robot with flexible cables. Nonlinear Dyn. 2022, 108, 3219–3245. [Google Scholar] [CrossRef]

- Baklouti, S.; Courteille, E.; Lemoine, P.; Caro, S. Vibration reduction of Cable-Driven Parallel Robots through elasto-dynamic model-based control. Mech. Mach. Theory 2019, 139, 329–345. [Google Scholar] [CrossRef]

- Zhou, Z.; Zheng, X.; Chen, Z.; Wang, X.; Liang, B.; Wang, Q. Dynamics modeling and analysis of cable-driven segmented manipulator considering friction effects. Mech. Mach. Theory 2021, 169, 104633. [Google Scholar] [CrossRef]

- Choi, S.-H.; Park, K.-S. Integrated and nonlinear dynamic model of a polymer cable for low-speed cable-driven parallel robots. Microsyst. Technol. 2018, 24, 4677–4687. [Google Scholar] [CrossRef]

- Carpio, M.; Saltaren, R.; Viola, J.; Calderon, C.; Guerra, J. Proposal of a Decoupled Structure of Fuzzy-PID Controllers Applied to the Position Control in a Planar CDPR. Electronics 2021, 10, 745. [Google Scholar] [CrossRef]

- Yang, J.; Su, H.; Li, Z.; Ao, D.; Song, R. Adaptive Control with a Fuzzy Tuner for Cable-based Rehabilitation Robot. Int. J. Control. Autom. Syst. 2016, 14, 865–875. [Google Scholar] [CrossRef]

- Kawamura, S.; Kino, H.; Won, C. High-speed manipulation by using parallel wire-driven robots. Robotica 2000, 18, 13–21. [Google Scholar] [CrossRef]

- Xie, F.; Shang, W.; Zhang, B.; Cong, S.; Li, Z. High-Precision Trajectory Tracking Control of Cable-Driven Parallel Robots Using Robust Synchronization. IEEE Trans. Ind. Inform. 2020, 17, 2488–2499. [Google Scholar] [CrossRef]

- Kumar, A.A.; Antoine, J.-F.; Abba, G. Input-Output Feedback Linearization for the Control of a 4 Cable-Driven Parallel Robot. In Proceedings of the 9th IFAC/IFIP/IFORS/IISE/INFORMS Conference on Manufacturing Modelling, Management and Control (IFAC MIM), Berlin, Germany, 28–30 August 2019; pp. 707–712. [Google Scholar]

- Kino, H.; Yahiro, T.; Takemura, F.; Morizono, T. Robust PD control using adaptive compensation for completely restrained parallel-wire driven robots: Translational systems using the minimum number of wires under zero-gravity condition. IEEE Trans. Robot. 2007, 23, 803–812. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, L.; Nan, H.; Wang, B. System Modeling and Motion Control of a Cable-Driven Parallel Platform for Underwater Camera Stabilization. IEEE Access 2021, 9, 132954–132966. [Google Scholar] [CrossRef]

- Babaghasabha, R.; Khosravi, M.A.; Taghirad, H.D. Adaptive robust control of fully-constrained cable driven parallel robots. Mechatronics 2015, 25, 27–36. [Google Scholar] [CrossRef]

- Lyapunov, A.M. The general problem of the stability of motion. Int. J. Control 1992, 55, 531–534. [Google Scholar] [CrossRef]

| Components and Parts | Parameters | Number | Amount of Money |

|---|---|---|---|

| Winch | Radius is 0.5 m. | 4 | 3000 CNY |

| Motor | Torque is 500 Nm (no reducer). | 4 | 20,000 CNY |

| Mechanical structure | Pulleys, end-effectors, etc. | None | 50,000 CNY |

| Electric control equipment | Siemens PLC 1500. | None | 30,000 CNY |

| Tension sensor | The value ranges from 0–1000 N. | 4 | 10,000 CNY |

| Encoder | Optical encoder | 4 | 10,000 CNY |

| Single operating costs | Lifting and electricity charges | None | 5000 CNY |

| Parameter Name | Parameter Value | Parameter Name | Parameter Value |

|---|---|---|---|

| m | 5 kg | diag(0.03, 0.03, 0.06) kg/m2 | |

| 0.25 m | 0.25 m | ||

| 40 m | 35 m | ||

| (−1, 0, 2.5)T m | −9.8 kg/m2 | ||

| 10 N | 1000 N |

| Values | Low-Speed | Medium Speed | High-Speed | Ultra-High-Speed |

|---|---|---|---|---|

| Radius of motion trajectory | 1 m | 5 m | 10 m | 15 m |

| X-direction error mean increment | 0.0250 m | 0.1722 m | 0.1771 m | 0.5405 m |

| Z-direction error mean increment | 0.0347 m | 0.1381 m | 0.1449 m | 0.3140 m |

| Y-axis error mean increment | 0.0095 deg | 2.6117 deg | 2.1010 deg | 1.8673 deg |

| Controller | X-Direction Error Mean | Z-Direction Error Mean | Y-Axis Error Mean |

|---|---|---|---|

| MPD-FFC | 0.2021 m | 0.2206 m | 2.8023 deg |

| PD | 0.4494 m | 0.3989 m | 7.4965 deg |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, G.; Li, J.; Chen, Y.; Wang, S.; Chen, H. Dynamic Modeling and Motion Control Strategy of Cable-Driven Cleaning Robot for Ship Cargo Hold. J. Mar. Sci. Eng. 2023, 11, 87. https://doi.org/10.3390/jmse11010087

Han G, Li J, Chen Y, Wang S, Chen H. Dynamic Modeling and Motion Control Strategy of Cable-Driven Cleaning Robot for Ship Cargo Hold. Journal of Marine Science and Engineering. 2023; 11(1):87. https://doi.org/10.3390/jmse11010087

Chicago/Turabian StyleHan, Guangdong, Jian Li, Yizong Chen, Shenghai Wang, and Haiquan Chen. 2023. "Dynamic Modeling and Motion Control Strategy of Cable-Driven Cleaning Robot for Ship Cargo Hold" Journal of Marine Science and Engineering 11, no. 1: 87. https://doi.org/10.3390/jmse11010087

APA StyleHan, G., Li, J., Chen, Y., Wang, S., & Chen, H. (2023). Dynamic Modeling and Motion Control Strategy of Cable-Driven Cleaning Robot for Ship Cargo Hold. Journal of Marine Science and Engineering, 11(1), 87. https://doi.org/10.3390/jmse11010087