1. Introduction

Underwater robots can replace or accompany human beings to complete underwater missions in unknown and complex marine environments efficiently, which have broad application prospects for scientific exploration, economic operations, and military fields.

Propulsion mode is the key factor to determine the underwater maneuverability, endurance, and concealment of the robot. Rotor and bionic propulsion are two mainstream propulsion modes.

Multi-rotor propulsion has the advantages of high maneuverability and stability, which is particularly important for underwater robots to perform submarine salvage, sampling, pipeline maintenance, and other operations. Pierrot discussed the distribution configuration of six rotors in several different underwater robots and obtained better distribution [

1]. Choi developed an eight-rotor spherical underwater robot called Odin, which has good maneuverability and hydrodynamic performance [

2]. These multi-thruster underwater vehicles often have six to ten thrusters, which are relatively redundant for basic motion. Drews proposed a hybrid unmanned aerial underwater vehicle and established its kinematic and dynamic model [

3], which was the first time quadrotors were used in underwater environments. Ranganathan designed a quad-rotor underwater vehicle and analyzed it by establishing its mathematical model based on the Newton–Euler method [

4]. In addition, quadrotor underwater vehicles can achieve flexible and stable motion with fewer thrusters. Bian designed an X-shaped quad-rotor underwater vehicle, modeled it, and analyzed its motion mode to show the benefits of setting the four thrusters as an X shape [

5].

Bionic design is an effective method to develop underwater robots [

6,

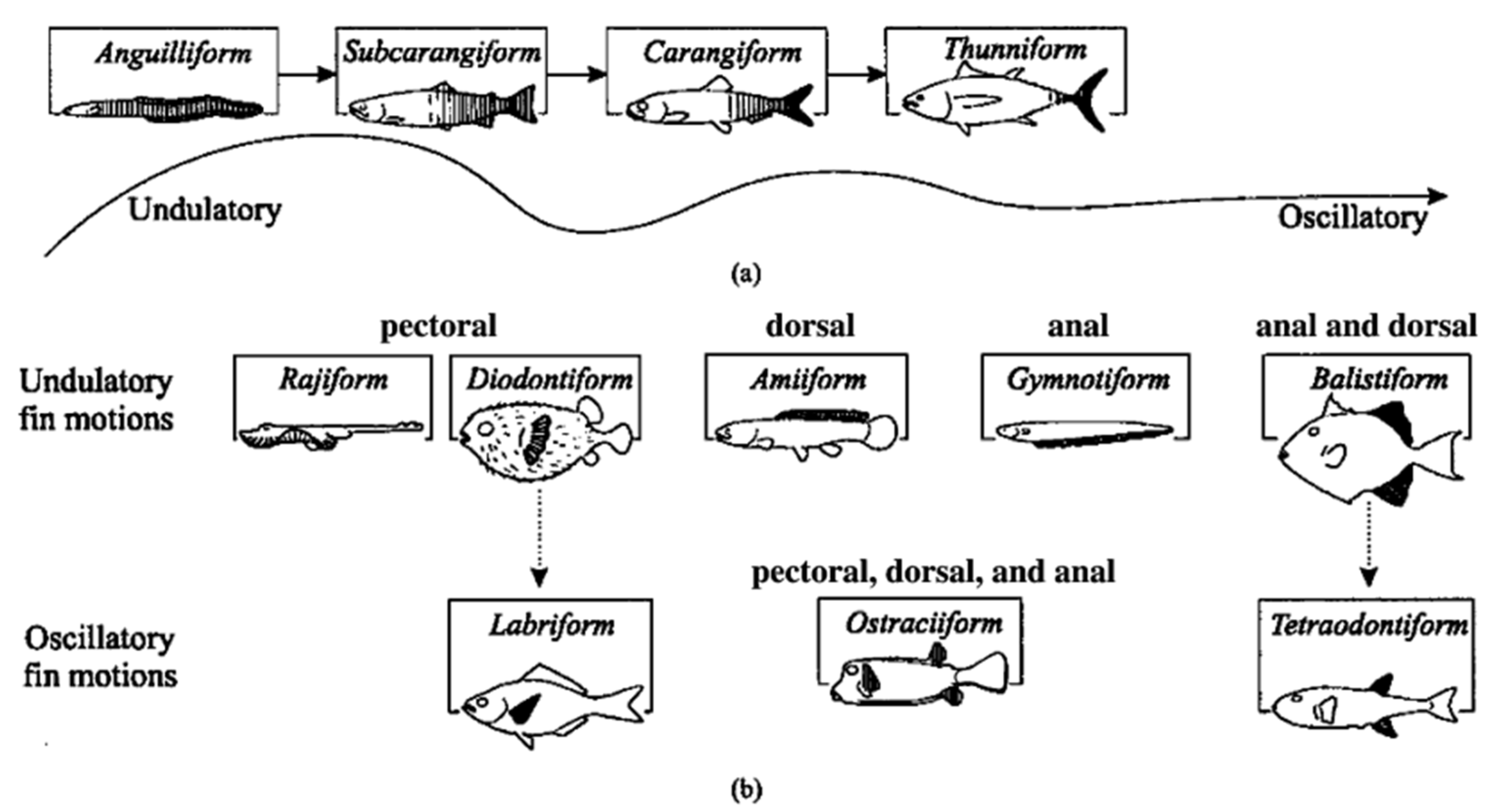

7]. Bionic propulsion is mainly divided into two types: the body/caudal fin (BCF) and median/paired fin (MPF) propulsions, which have the advantages of low noise and efficiency. As shown in

Figure 1a, the fish of the BCF mode bend their body into a backward-moving propulsive wave that extends to their caudal fin for producing the force of their forward propulsion. Cai developed a robot fish called Robo ray II with flexible swinging pectoral fins [

8]. They found that the thrust coefficient increases with the Strouhal number and reached 0.56 at maximum. The maximal linear swimming speed of Robo ray II is about 0.5 times that of body length per second (BL/s). Costa et al. [

9] designed a

Carangiform swimming robot and found that the average cruising speed has a linear dependency on the motor rotation frequency and the invariance of the Strouhal number with respect to the motor frequency. Samuel et al. [

10] investigated the

Carangiform fish body and proposed multi-segment fins for describing the kinematics and performance optimization. They suggested that five-segment models can approximate the undulatory movements of (sub-)

Carangiform swimmers during steady swimming, with at least 99% accuracy (model error < 0.01 L). Salazar et al. [

11] analyzed the piezoelectric energy of the aquatic unmanned vehicles under the

Thunniform condition of the fish’s motion. The simultaneous inclusion of geometric and piezoelectric nonlinearities in the analysis offers a unique solution of useable power scavenged from the

Anguilliform,

Subcarangiform,

Carangiform, and

Thunniform motions. Zhang et al. [

12] Samuel et al. invented a two-segment fin which imitates the

Ostraciidae fish for swimming underwater. The resonant frequency and the thrust force increased about three times and were 12% higher when compared with the one-segment fin.

Unlike the BCF fish swimming mode, the undulating fins of the MPF fish keep their body rigid and use their median and pectoral fins which can generate propulsion forces in different directions as shown in

Figure 1b. Although the propulsion velocity is lower compared with some BCF fish, the high efficiency and great maneuverability have made the MPF fish a good bionic sample for the design of the underwater propulsion devices. Zhou et al. [

13] established the coupled CFD model of the underwater robots propelled by bionic undulating fins and compared the simulation and experimental results. Their work has formed a meaningful basis and computational platform for future studies on the propulsion mechanism and control algorithm of bionic underwater robots. Rahman verified the braking ability of the double undulating fin robot by measuring the stopping time and swimming distance of the robot after the braking frequency was applied to linear and rotary motion [

14]. They confirmed that the undulating fin propulsion system can effectively perform braking even in complex underwater explorations. Wang et al. [

15] designed and modeled a biomimetic stingray-like robotic fish. After a year, he [

16] made a prototype and carried out underwater experiments to study the swimming performance of the robotic fish. The maximum velocity of the robotic fish is 4.3 cm/s (nearly 0.18 BL/s) at an oscillation frequency of 0.5 Hz. Scaradozzi et al. [

17] proposed a partially biomimetic underwater robot with a hybrid propulsion system and developed it to overcome the challenges involved in improving the thrust efficiency.

Especially,

Gymnarchus niloticus, as a kind of MPF fish, keep their body rigid and use their long fin to swim. Shahin et al. [

18] proposed numerical and experimental methods to investigate their counter-propagating propulsion in order to improve maneuverability and stability. Liu and Izaak et al. [

19,

20] measured 3D flow structure and fields during the forward and station-keeping of undulating swimming through particle image velocimetry (PIV). Zhang et al. [

21] proposed a modular mechanism with ten servomotors in order to drive the fin to undulate. They calculated the pressure distribution, the thrust force, and the efficiency of the undulating fins by numerical simulation and experimental measurements. Zhao et al. [

22] investigated the hydrodynamic performance of the undulating ribbon fin combined with the sinusoidal swing and the fish body’s undulating motion in a three-dimensional simulation. The effect of the phase-angle difference and angular amplitude were discussed to illustrate the thrust augmentation in the undulating fins with combined undulating motion. Low [

23,

24] developed the biomimetic robot NKF-II with two mechanisms of layouts with cranks and slider links. The robot could generate arbitrary undulating waveforms and kinematic analyses were also performed. Hu and his colleagues studied the locomotion mechanism of bio-inspired robotic undulating fins by carrying out biological measurements [

25], establishing kinematic equations, computational fluid dynamics (CFD) analyses [

26], trajectory tracking of the fin’s motion [

27], and experimental analyses of the robot propelled by undulating fins. These works showed that the undulating fins based on the

Gymnarchus niloticus could move forward, backward, or turn around underwater with good propulsive efficiency and high maneuverability.

In the field of marine search and rescue and marine exploration, it is hoped that marine robots will have the ability to move quietly and efficiently like fish, and have the ability to move in all directions like rotor robots to complete complex tasks and avoid disturbing other marine creatures, so as not to damage the environment.

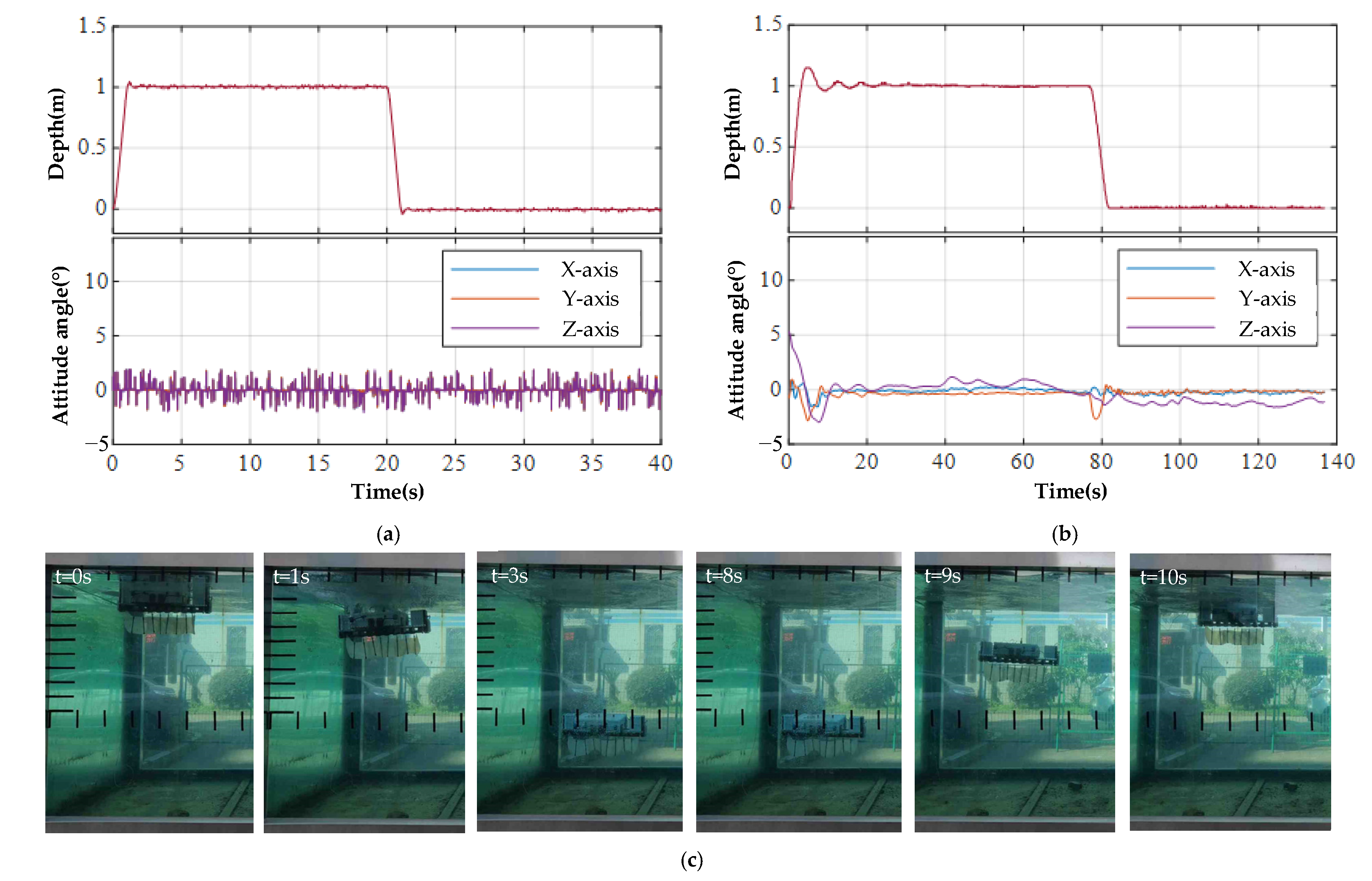

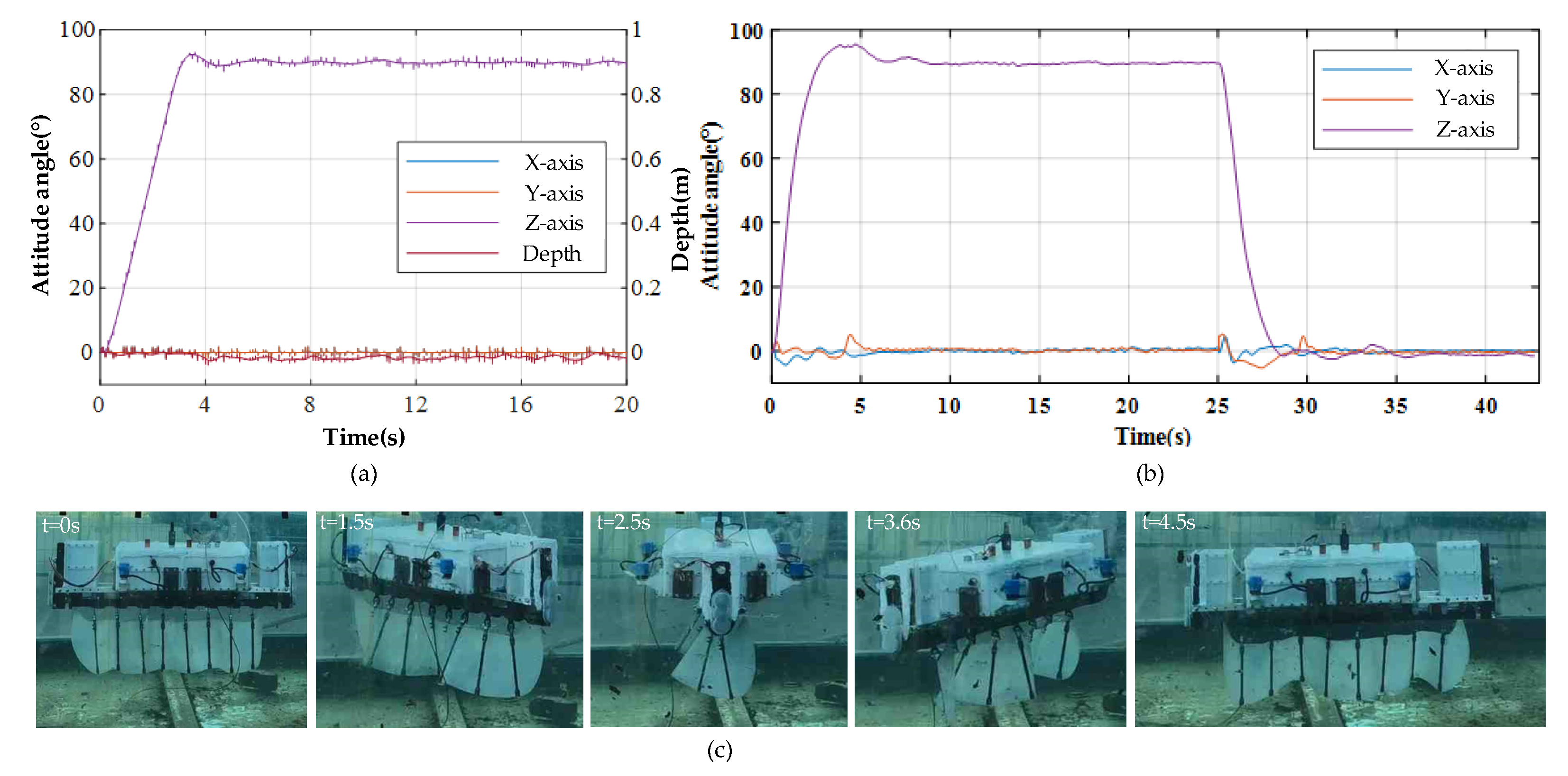

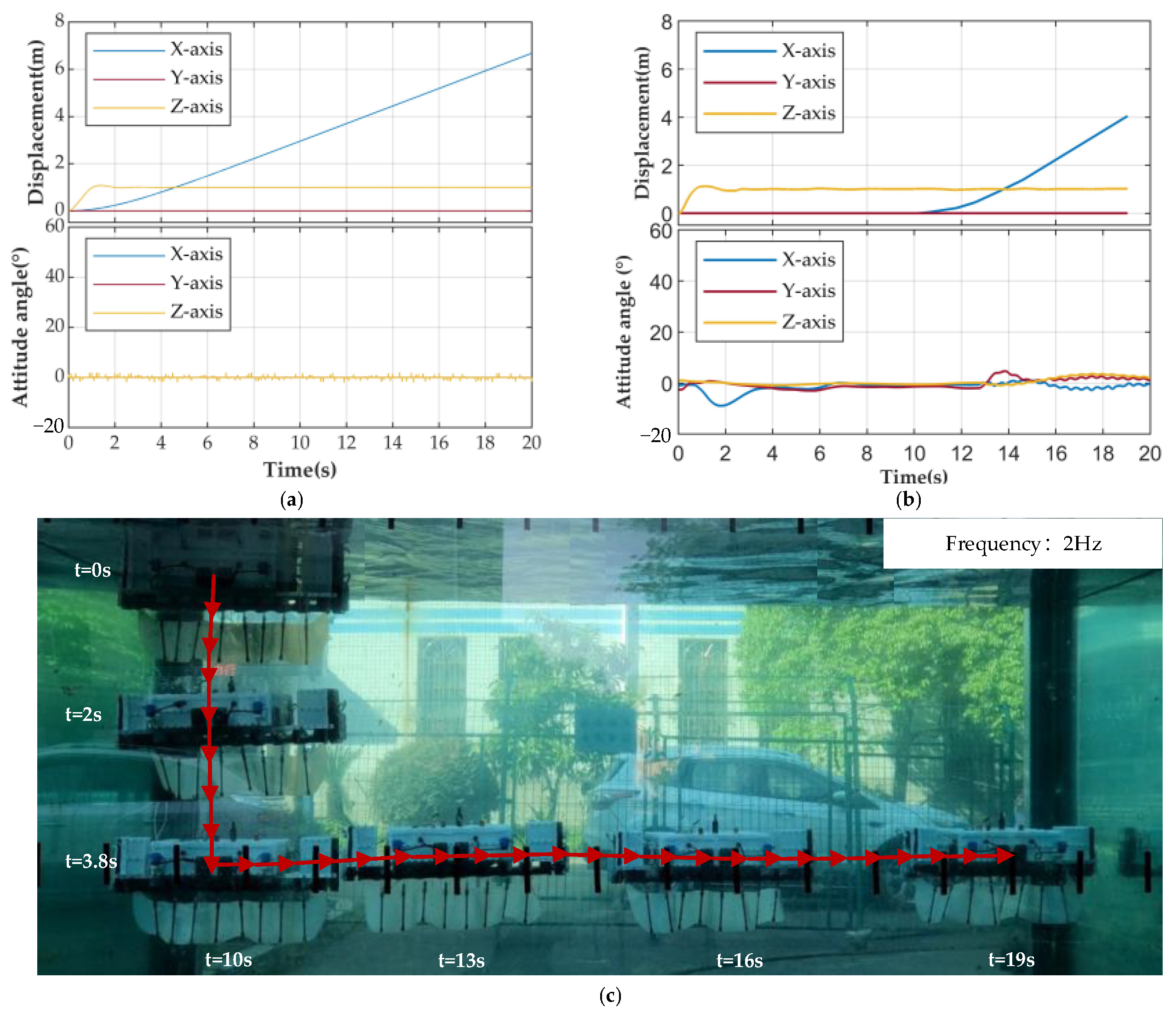

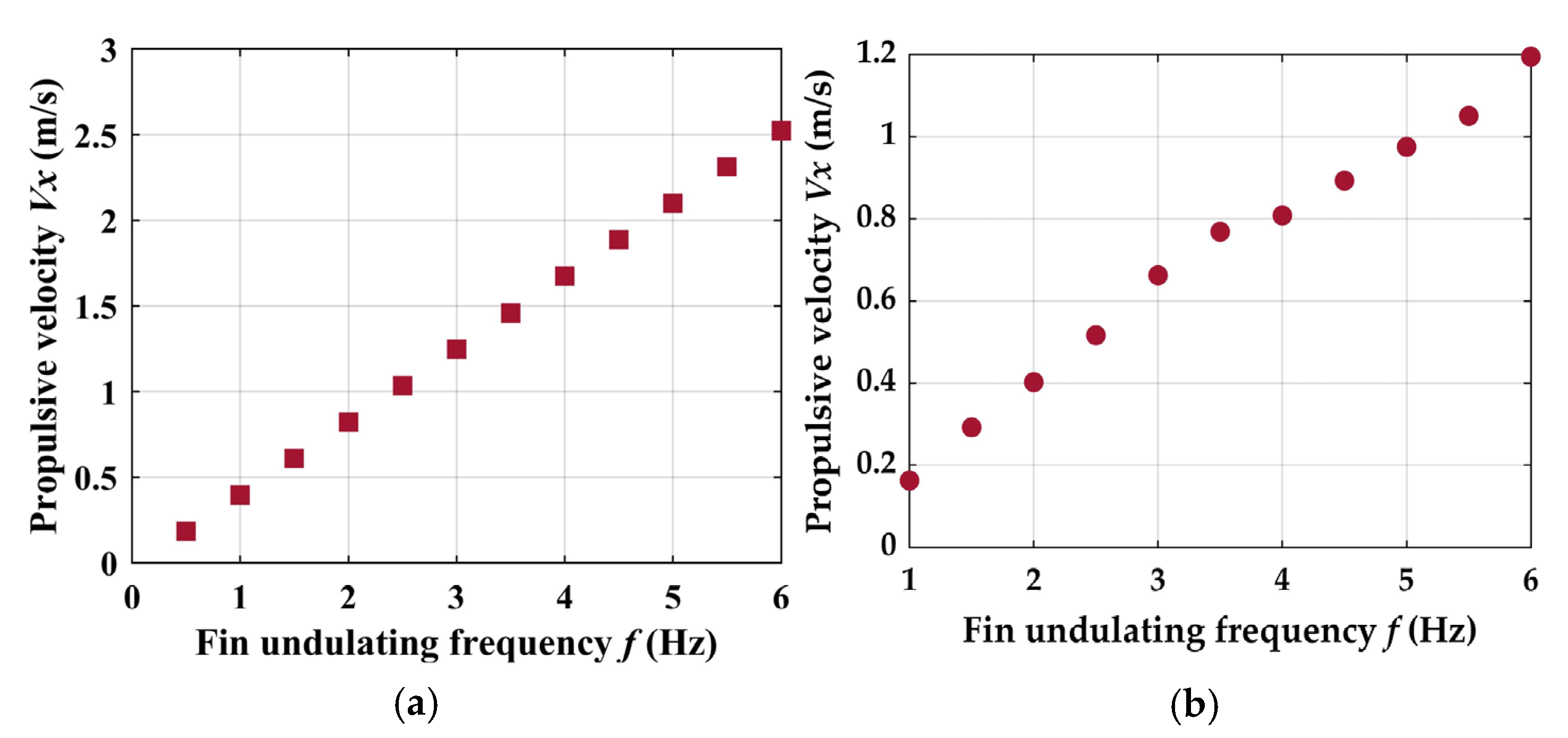

To achieve this goal, we designed a robot based on hybrid propulsion of quadrotor and bionic undulating fins. The robot mainly works in the undulating fin-propulsion mode to achieve quiet and efficient movement and when the robot needs to hover, such as when performing underwater pipe maintenance tasks, the robot will work in the rotor mode to achieve static hover. In this paper, the mechanical structure of the robot is described in

Section 2. The dynamic and control model of the robot is established and the motion control strategy is discussed in

Section 3. The simulation and experiments are conducted in

Section 4, which verify that the robot can realize five degrees of freedom motion, such as surge, heave, roll, pitch, and yaw. The experimental results show that the robot has good maneuverability and stability. When the undulating frequency is 6 Hz, the maximum propulsion speed of the robot can reach up to 1.2 m/s (1.5 BL/s). Finally, a conclusion is drawn in

Section 5.

Figure 1.

Swimming modes associated with (

a) BCF propulsion and (

b) MPF propulsion. Shaded areas contribute to thrust generation [

28]. Reproduced with permission from J.E. Colgate, IEEE Journal of Oceanic Engineering; published by IEEE, 2004.

Figure 1.

Swimming modes associated with (

a) BCF propulsion and (

b) MPF propulsion. Shaded areas contribute to thrust generation [

28]. Reproduced with permission from J.E. Colgate, IEEE Journal of Oceanic Engineering; published by IEEE, 2004.

2. Mechanical Structure

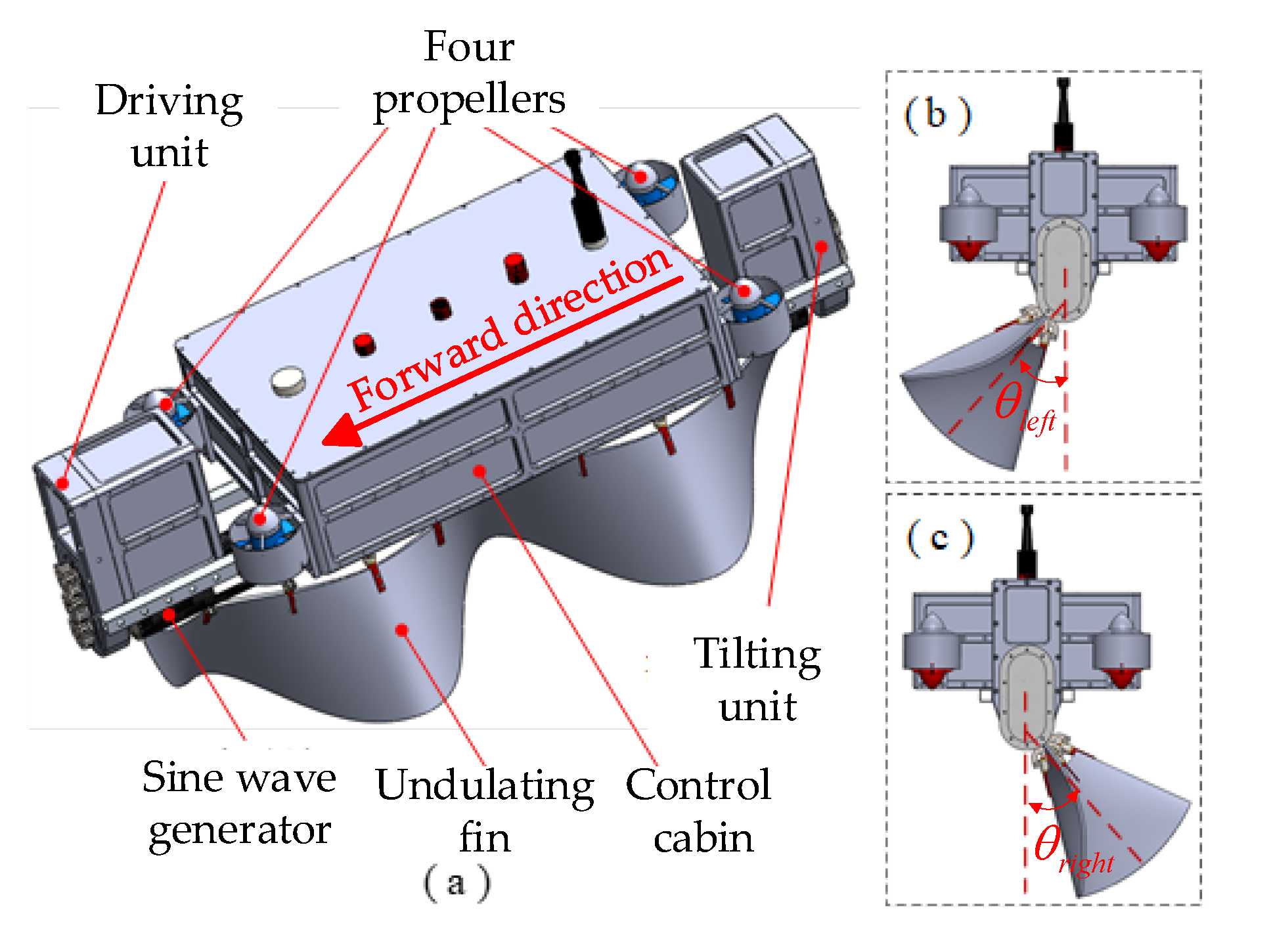

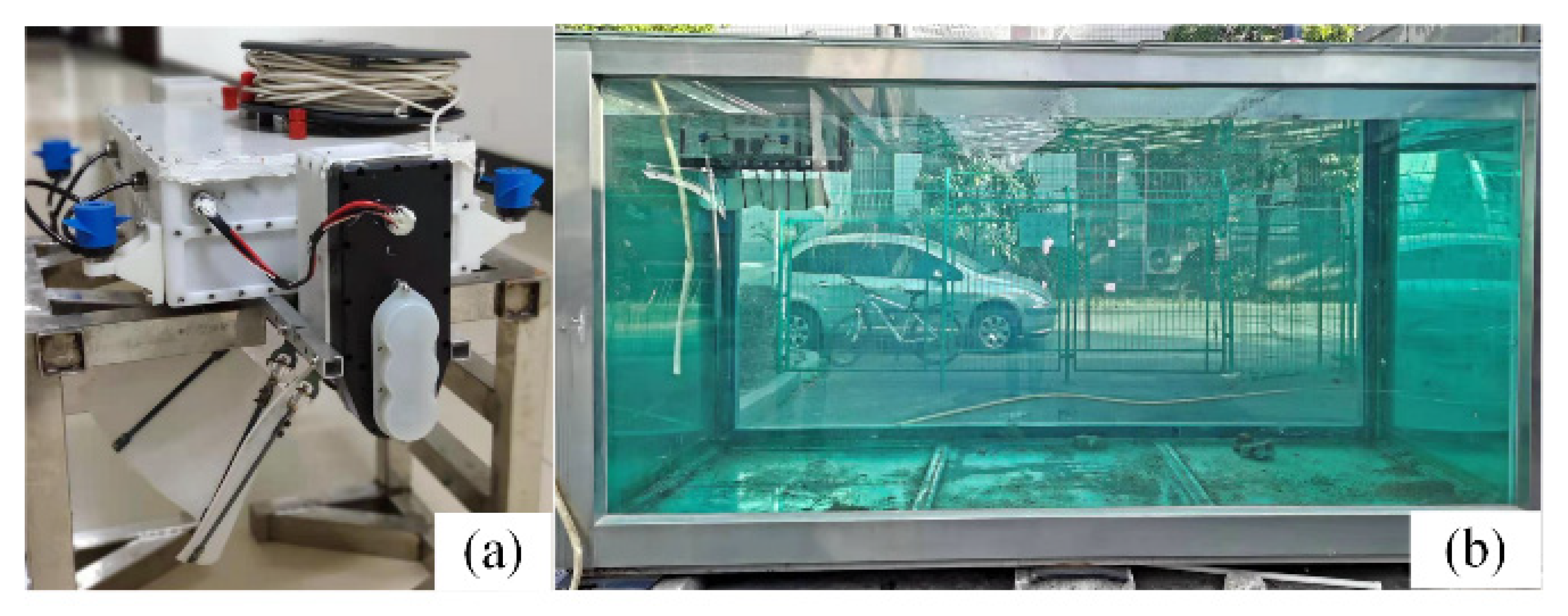

Our goal is to design an operating robot that can move quietly and efficiently to its destination like a fish and then hover like a quadrotor robot in order to perform a variety of tasks such as maritime search and rescue, hazard disposal, pipeline maintenance, etc. The design model of the underwater robot is shown in

Figure 2a. It is composed of one control cabin, four propellers, one undulating fin, one driving unit, one tilting unit, and one sine wave generator. The four propellers are configured as an X-type and installed vertically at the diagonal of the control cabin. The undulating fin is placed under the control cabin linking with the sine wave generator. As shown in

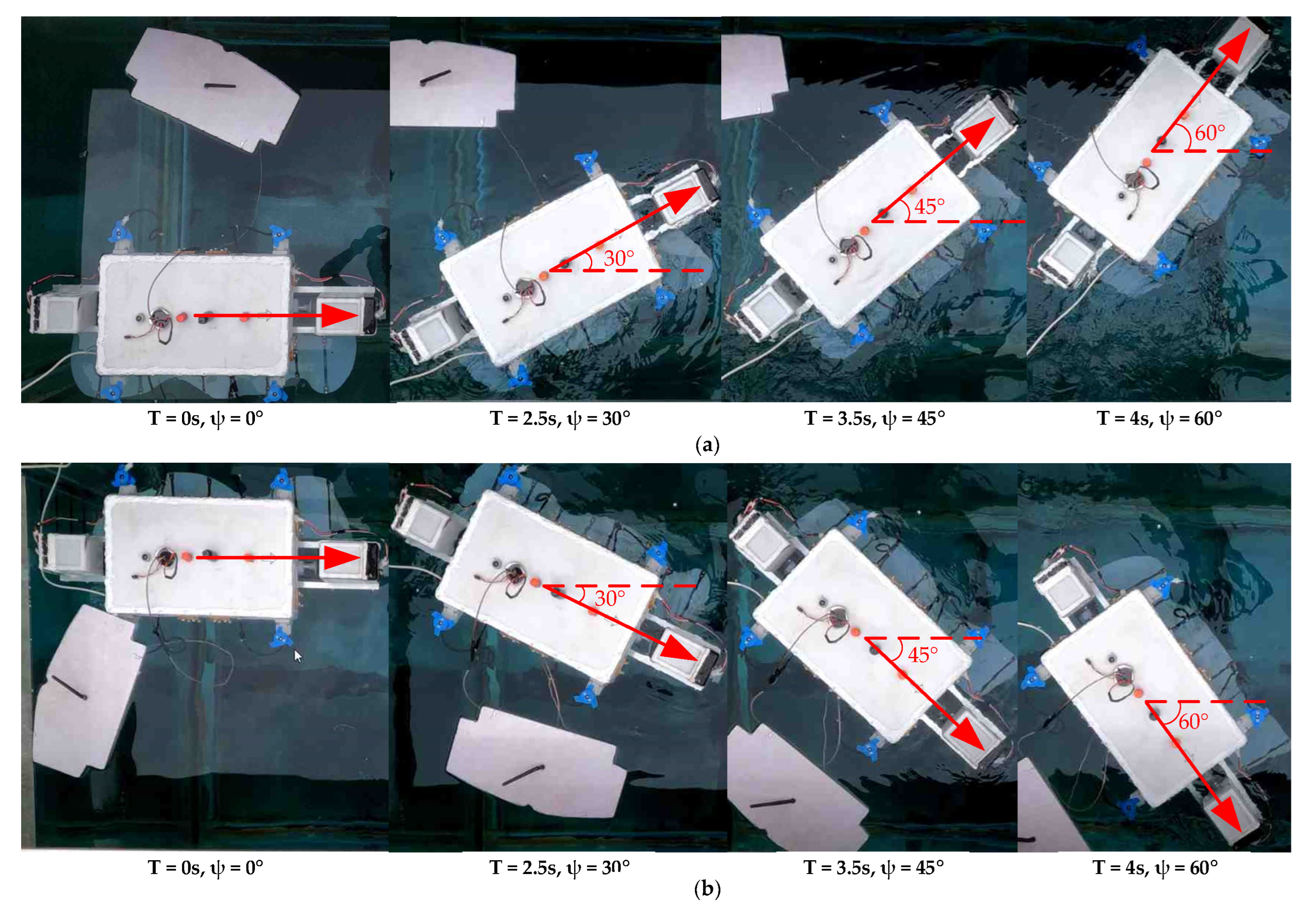

Figure 2b,c, the undulating fin can tilt left and right around the central axis to generate horizontal propulsion and yaw moment.

At present, the undulating fins generally use a set of servo motors as the driving components [

29], and each fin bar is driven by an electric motor. In this case, by coordinating and controlling the phase difference of each motor, the desired waveform can be formed. This kind of design is popular because of its simple transmission and multiple controllable parameters. However, too many motors bring some drawbacks, including the complexity of the mechanical structure, the increase in the difficulty of sealing, and the sacrifice of weight. Furthermore, system reliability will decrease significantly if one single motor fails which causes the failure of the entire waveform. Meanwhile, due to the limited response speed of the steering gear, the frequency of the undulating fin cannot reach a high level, and, generally, the maximum frequency is only 2–3 Hz [

30].

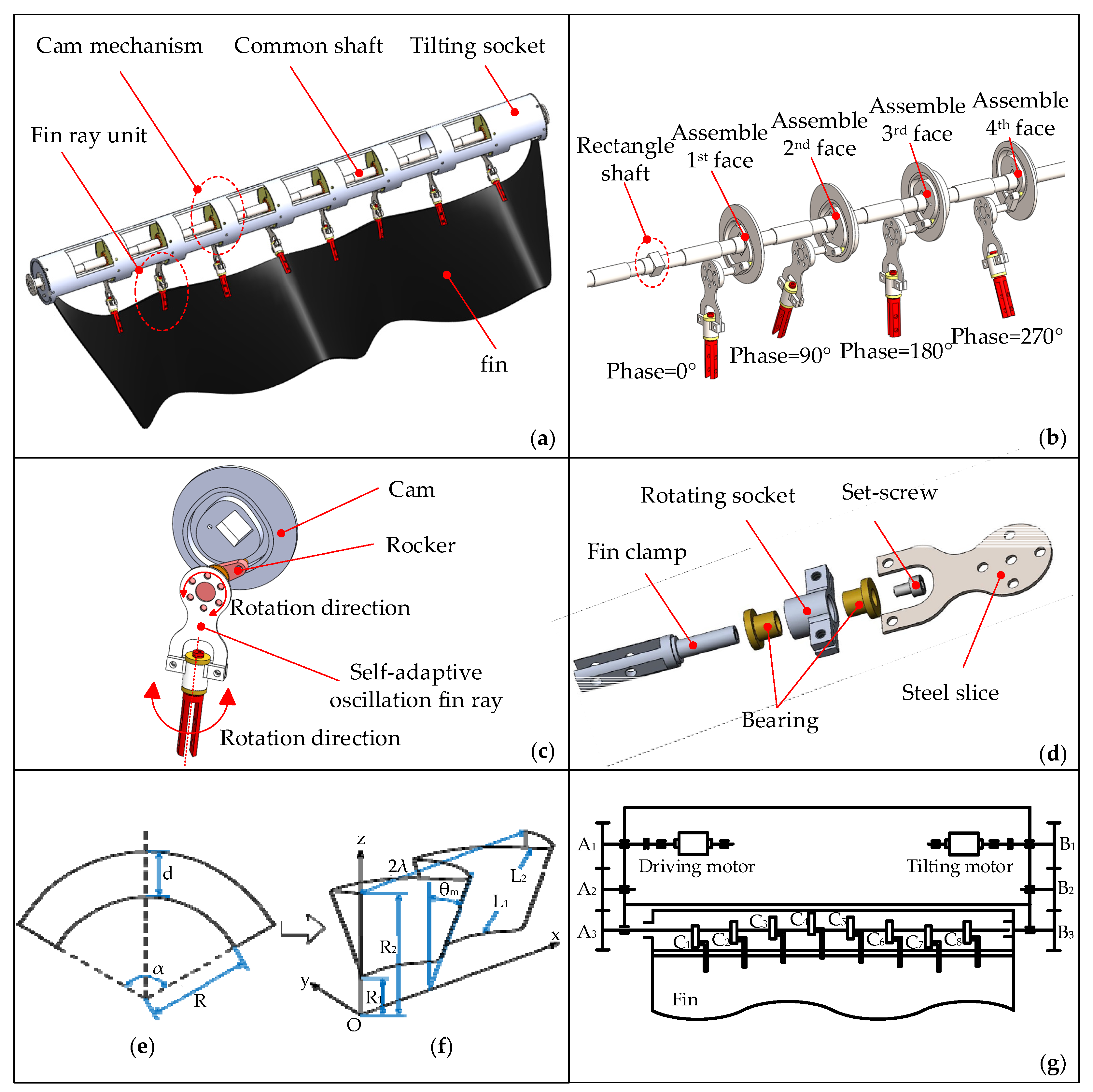

In order to realize the high-frequency-driven undulating fin to study the driving performance of the undulating fin under high-frequency characteristics and improve the above problems, a modular design of undulating fin based on a cam mechanism is proposed. As shown in

Figure 3a, the undulating fin is composed of a tilting socket, a common shaft, cam mechanisms, fin ray units, and a flexible fin.

The undulating fin is clamped on the corresponding cam by eight fin ray units. As shown in

Figure 3b, the phase interval between each cam is π/2 and is installed on the common shaft at an equal distance. As shown in

Figure 3c, the fin ray units swing back and forth according to the motion characteristics of the cam and drive the undulating fin to produce sinusoidal motion. If the flexible undulating fin is directly and rigidly connected with the cam, the water-facing angle of the undulating fin will be fixed and result in additional resistance. In order to solve this problem, we put a sliding bearing in the fin ray unit. As shown in

Figure 3d, the fin clamp has rotational freedom. When the long fin undulates, the fin surface can adaptively adjust the attack angle related to the local fluid velocity to reduce the additional resistance along the free stream velocity.

The initial geometry of the undulating fin is fan-shaped as shown in

Figure 3e. Due to the geometrical constraints of boundary conditions, the sector can form a sinusoidal-shaped conical-banded fin after straightening as shown in

Figure 3f. The geometric relationship of the design parameters of the undulating fin can be expressed by the following equations:

where

and

are the inner arc length and outer arc length of the undulating fin, respectively, which can be approximately calculated by the following formula:

where

is the undulating amplitude.

The driving and tilting transmission principle of the undulating fin is shown in

Figure 3g. The driving motor transmits the rotation to the common shaft through the gear train A1–A2–A3. By changing the motor rotation direction and speed, we can adjust the undulating direction and frequency. Likewise, the tilting motor transmits the rotation motion to the tilting socket through the gear train B1–B2–B3. By controlling the tilting motor, we can change the tilting angle of the undulating fin around the central axis to generate the yaw moment.

3. Control Model

3.1. Kinematic Model

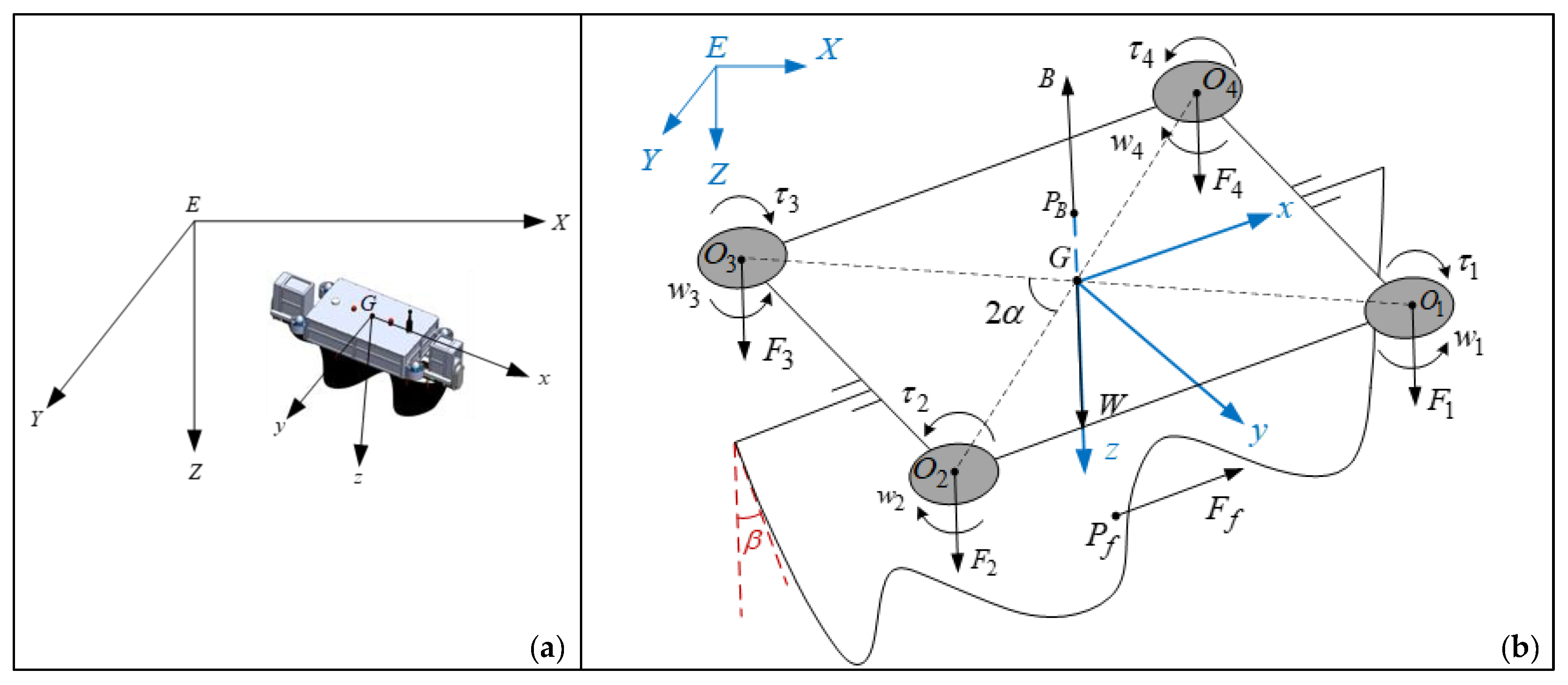

To describe the motion of the robot, the inertial coordinate system E-XYZ and the robot coordinate system G-XYZ as shown in

Figure 4a are established. E is any point, the EZ axis points to the center of the earth, and the EX and EY axes are arbitrarily selected according to the right-hand rule. G is the center of gravity of the robot, the GX axis points to the forward direction of the body, the GZ axis is vertical to the robot, and the GY axis is determined by the right-hand rule.

In the inertial coordinate system E-XYZ, the attitude of the robot is , where is the position of the robot, is the attitude angle of the robot. The velocity of the robot in the body coordinate system G-XYZ is , where is the linear velocity, is the angular velocity.

The kinematic model of the robot can be given by:

where

is the velocity rotation matrix from robot coordinate system to inertial coordinate system, which is defined as:

where

,

,

are the abbreviations of

,

,

, respectively.

3.2. Dynamic Model

The robot is subjected to the combined action of gravity, buoyancy, propulsion of propellers, and undulating fin and resistance. As shown in

Figure 4b, the weight force of the robot is

which acts on point

, the buoyancy is

, and the center of buoyancy is

. The thrust of propellers and counter torque are

,

(

i = 1, 2, 3, 4), respectively, and act on

(

i = 1, 2, 3, 4) which is the centroid of each propeller. The distance between the propellers and the center of the robot is

(

i = 1, 2, 3, 4) and the angle between the diagonal is

. The equivalent force of the undulating fin is

and acts on

.

3.2.1. Dynamic Model of Propellers

The velocity of the propeller is represented by

, the thrust and reverse torque are, respectively, represented by

,

(

i = 1, 2, 3, 4), and the distances between the thrusters are 2a, and 2b, respectively. The thrust and reverse torque of the propeller can be given by:

where

,

are thrust coefficient and reverse torque coefficient, respectively, which can be obtained through the regression polynomials of M’s 3 blades propeller open water thrust coefficient diagram [

31];

is a symbolic function;

is the directional coefficient, determined by the propeller installation direction. In order to counteract the reverse torque in hover, the rotation directions of adjacent propellers are opposite, so it leads to

,

.

3.2.2. Dynamic Model of Undulating Fin

The undulating fin can generate forward or backward thrust through sinusoidal motion, denoted as and the action point is taken at the center of the fin surface. The center of gravity of the robot is , , the tilting angle of the undulating fin is , so the coordinate of the action point of equivalent force is .

Previous studies have shown that the relationship between the thrust and frequency of undulating fin is a second-order equation:

where

is the frequency of the undulating fin and

is the thrust coefficient of the undulating fin, which can be obtained through simulation and experiment.

3.2.3. Model of Resilience

The buoyancy center of the robot is designed to be slightly higher than the center of gravity, so as to provide a certain restoring force and torque to assist the robot to maintain the balance of the body in an emergency. If the position of the center of buoyancy is marked as

, and the buoyancy and gravity are, respectively, represented by

B and

W, the resilience matrix acting on the center of gravity can be given by:

where

is the pitch angle of the robot and

is the roll angle of the robot.

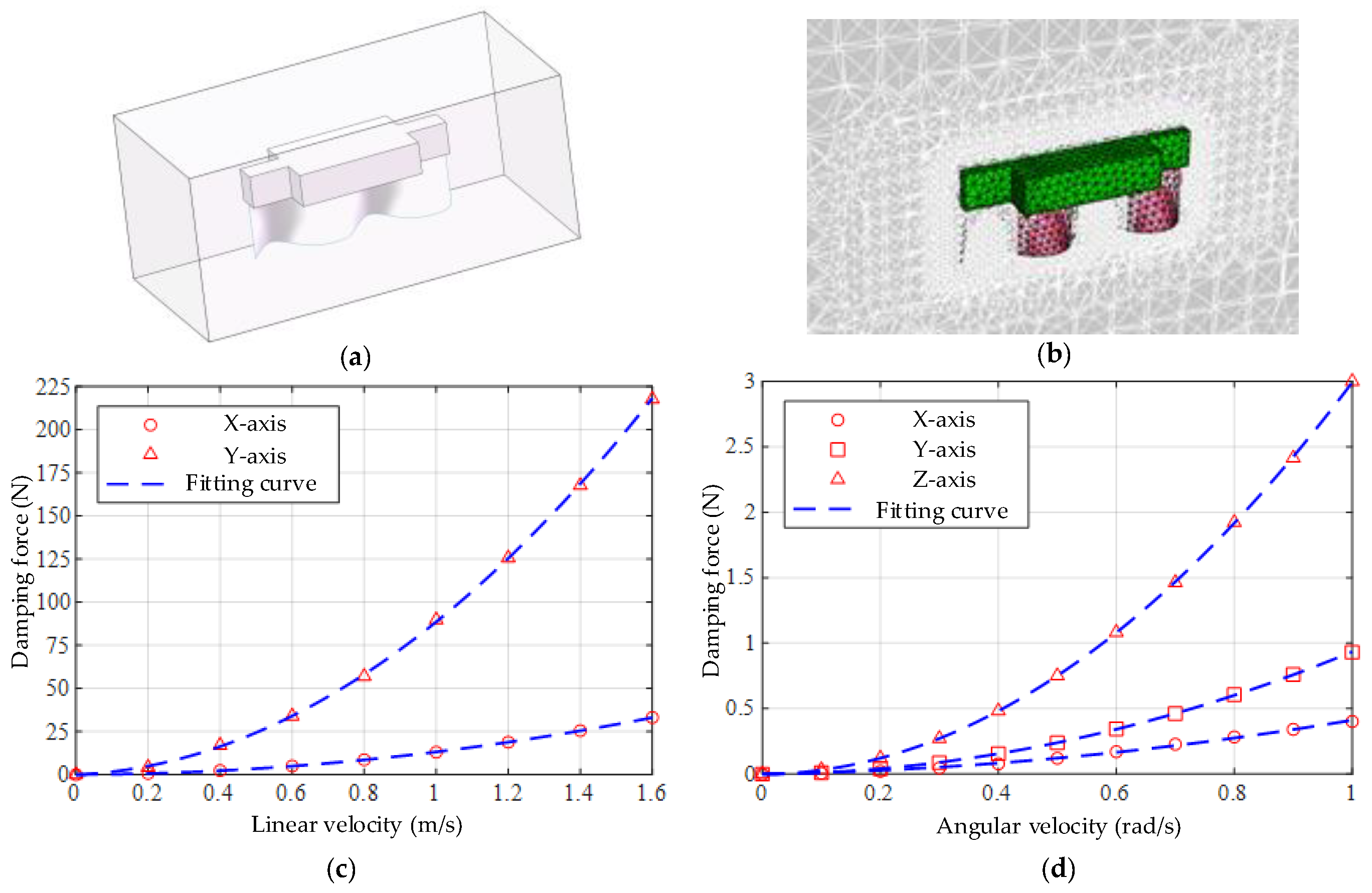

3.2.4. Model of Resistance

The resistance of underwater robots in the process of motion is very complex. At present, the commonly used method is to express the damping as the uncoupled superposition of primary damping and secondary damping. The damping force matrix can be given by:

where

,

,

,

,

,

are the primary damping coefficients in six directions of the body coordinate system, respectively,

,

,

,

,

,

are the secondary damping coefficients in six directions of the body coordinate system, respectively. The damping coefficient can be obtained by CFD.

3.3. Equation of Motion Control

We define the control force matrix and 6-DOF control force of the robot as:

We define

as the proportional coefficient of propellers thrust and reverse torque, the 6-DOF control force can be solved as given by:

Under the combined action of robot control force, resistance, and resilience, the dynamic mathematical model of the robot can be given by:

The meanings of physical quantities in the Equation (14) are as follows:

- control matrix represents the 6-DOF force and moment and the component expression is ;

- inertia matrix;

- resistance matrix;

- centrifugal force and Coriolis force matrix;

- resilience matrix;

- input force matrix represents the thrust of the propeller and undulating fin;

- control matrix represents the conversion relationship between the input force and the 6-DOF force of the robot.

As the robot navigates at low speed, the assumptions can be made as follows:

- 1.

Ignore the additional mass force [

32], i.e.,

;

- 2.

Assume that Coriolis force and centrifugal force have negligible influence on the motion [

32], i.e.,

;

- 3.

According to the dynamic analysis, the control component of the robot along the Y-axis direction is 0, so the sway motion along Y-axis is ignored.

Through the above analysis, the control force matrix, mass matrix, resistance matrix, and resilience matrix are substituted into Equation (12) and expanded. The motion is decomposed into independent channels, so the 6-DOF motion dynamics equation is:

Through the kinematic matrix conversion, the linear and angular acceleration of the robot in the geographical coordinate system can be given by:

3.4. Control Model and Strategy

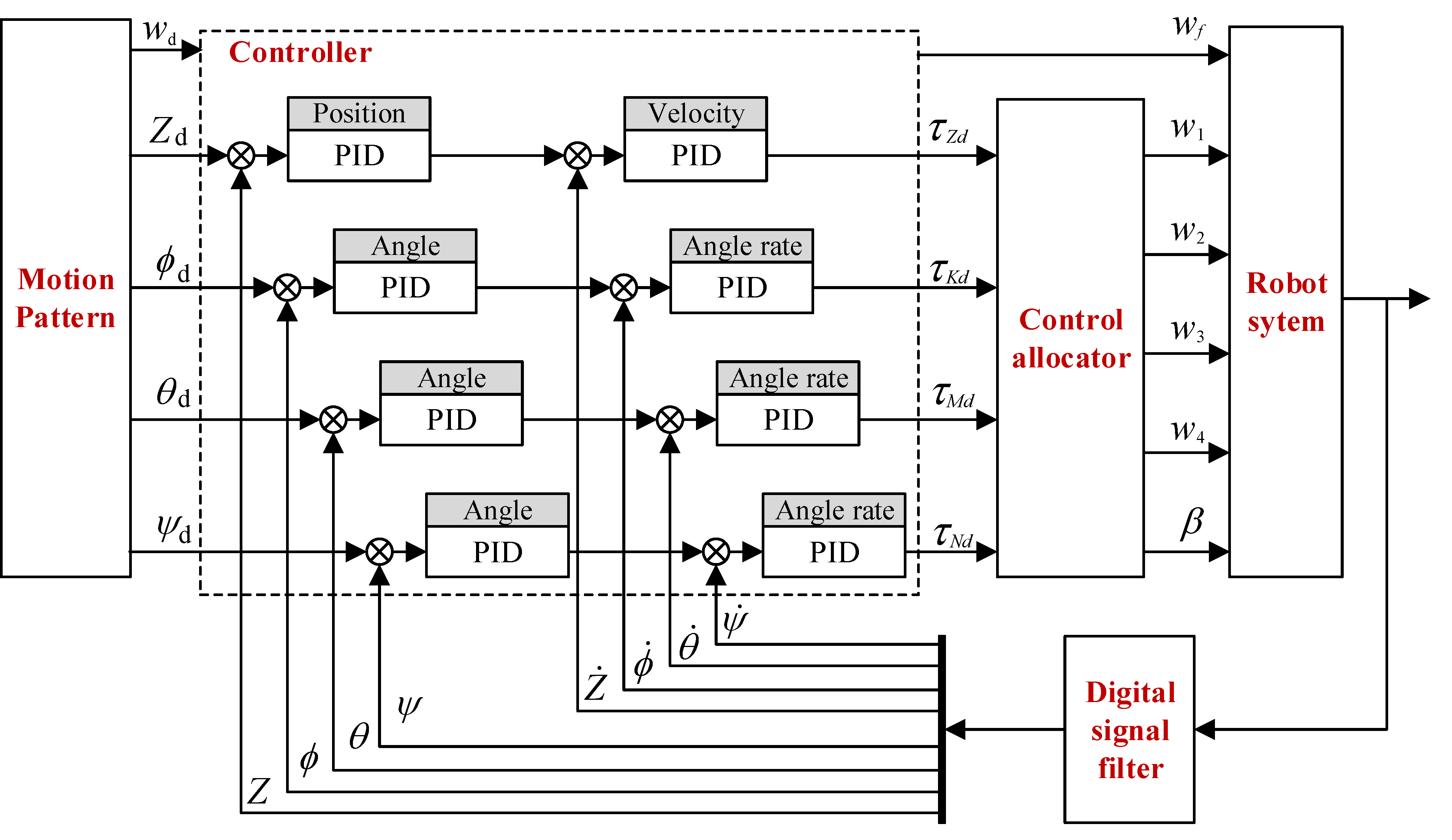

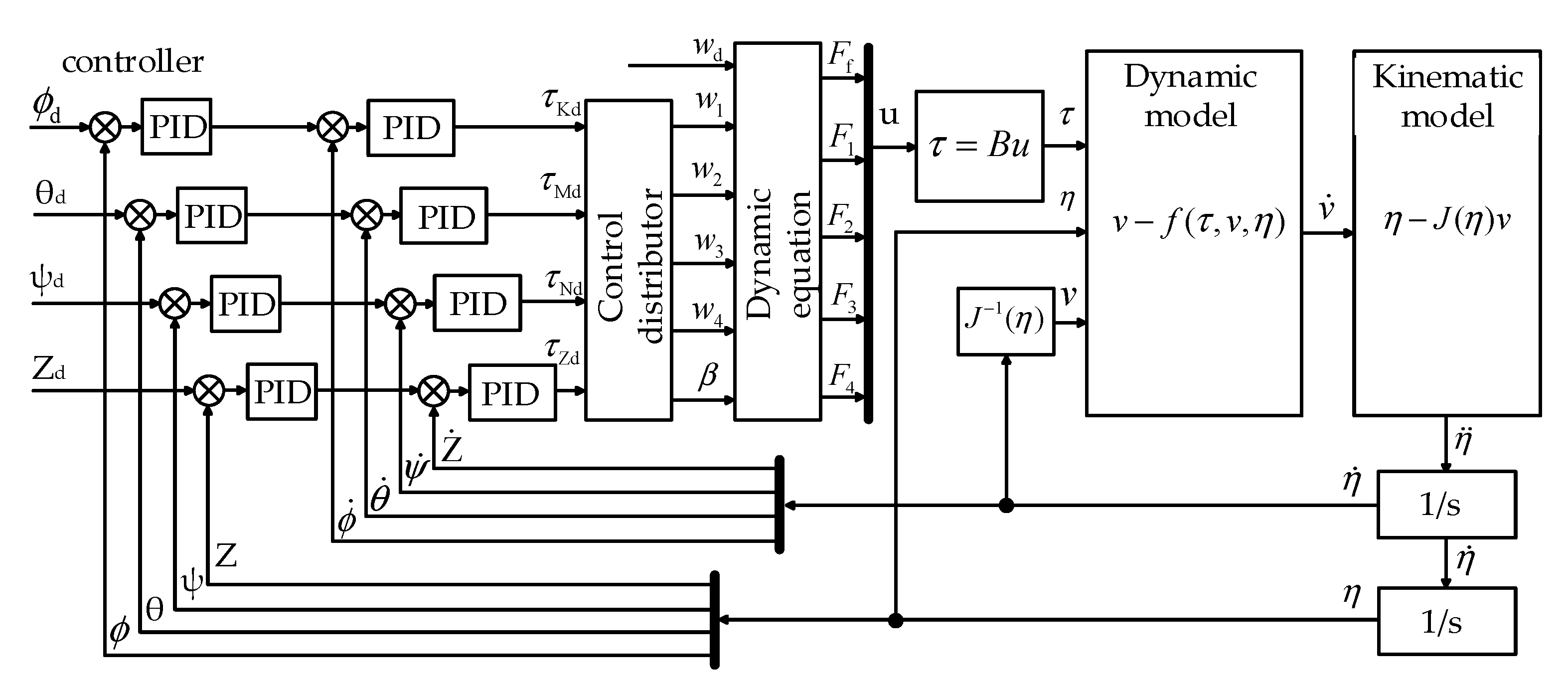

During the movement of the underwater robot, due to the nonlinear and time-varying characteristics of the external water flow disturbance, the system is prone to oscillation and even instability. So, it is difficult to establish an accurate hydrodynamic model of the robot. To solve the case, we propose a 4-DOF cascade PID controller. The control schematic diagram of the system is shown in

Figure 5. For the three-axis angle and

Z-axis position of the robot, an independent cascade PID closed-loop controller was designed, and speed feedback introduced to improve the response speed of the system. The speed open-loop control is adopted for the surge motion of the robot because we will conduct experimental research on the velocity of the robot with high-frequency undulation. The reference input of the control system is

, the components represent the expected value of depth and triaxial angle and the undulating frequency, respectively. The output of the controller is

, the components represent the expected vertical force, rolling torque, pitching torque, and yaw torque calculated by the four-channel controllers. To Define a control parameter matrix

, the components are the rotational speed of the four propellers, the undulating frequency, and the tilting angle, which are the final parameters directly controlled and the output through the motor.

In order to convert the expected force and torque calculated by the controller into direct control parameters, a control distributor is introduced. We quote a function to describe it, i.e., . It is too complicated to obtain the specific expression of the mapping relationship directly from the control force expression, so we use a decomposition strategy to decompose the system into the quadrotor subsystem and the undulating fin subsystem.

The quadrotor subsystem can be given by:

The inverse of the matrix can be obtained:

We know that the relationship between the thrust of the propeller and the rotation frequency is quadratic, and the thrust coefficient and the reverse torque coefficient can be obtained through experiments. Then, the specific expression of the propeller speed can be obtained, but this is not necessary because the PID controller can compensate for these unknown parameters. Using pseudo control quantity, the propeller speed can be obtained as:

The undulating fin subsystem can be given by:

Since the undulating frequency is directly given,

,

can be obtained. The problem is how to get the tilting angle of the undulating fin. In this case, we adopt a proportional control distribution strategy as shown in Equation (22):

where

λ can modify and determine the speed of steering.

5. Discussion

In this paper, we developed an underwater robot based on the hybrid propulsion of a quadrotor and a bionic undulating fin. In this section, the performance of the bionic robot is further discussed in terms of maneuverability, stability, control strategy, and applicability.

5.1. Performance of Maneuverability

The undulating fin inspired by

Gymnarchus niloticus plays an important role in enabling the underwater robot to realize the basic motion of heave, yaw, steering, and surge. As mentioned in

Section 2, the bionic fin has two features. First, driven by the cam mechanism, the long fin can undulate at a high frequency (about 6 Hz). The fact that the propulsive velocity of the robot can reach 1.2 m/s (1.5 BL/s) shows that the robot can swim fast (relative to other MPF underwater robots) even though the

Gymnarchus niloticus in nature cannot achieve this kind of speed. The second feature is that the long fin can tilt to the left/right side. The steering motion experiment shows that the yaw angle of the robot can be effectively adjusted only by tilting the angle of the undulating fin. From a design point of view, because the cam mechanism can theoretically achieve arbitrary regular oscillation, therefore, compared with the crank rocker mechanism [

23] and the crank slider mechanism [

39], the cam mechanism can provide more design possibilities, such as an undulating fin with a sine wave or cycloid wave.

5.2. Performance of Stability

Considering the excellent performance and mature control scheme of the quadrotor in attitude stability, we chose it for supplementary propulsion to achieve robot hover. So, the quadrotor is the other vital component of the underwater robot that hovers the robot and assists in maintaining its balance. The simulation and experiment results show that the attitude angle fluctuation range is less than ±5° in basic motion and hovering. This means that the robot can achieve attitude stability which fulfills our design purpose. The use of quadrotors sacrifices hydrodynamic performance in the direction of the robot’s wave-fin propulsion, but also increases the robot’s hovering function and maneuverability in other directions. In particular, when the wave fin fails, the quadrotor can help the robot to complete the task, thereby improving the robot’s motion reliability.

5.3. Control Strategy

In practical control, we must consider the disturbances within the environment. Even in the limited experimental tank, the robot may be rotated by some uncertain disturbances induced by itself. Taking the surge motion as an example, during the surge, the robot should move straight forward along the X-axis and the propellers should work for the attitude adjustment. If the error between the detected roll angle and the initial one is larger than 5°, which means an unnecessary rotation clockwise, then the propulsive force of the propellers at the right side of the surge orientation will be increased to a larger amplitude to generate an added resistance torque compensating the unnecessary rotation torque. This kind of force compensation and attitude adjustment are also working in the control process of pitch angle, yaw angle, and depth during the multi-mode locomotion. On the other hand, as the six-degree-of-freedom force generated by the four propellers is coupled, it is also a challenge to accurately allocate the thrust to the four propellers based on the calculation results of the controller. In this paper, a 4-DOF cascade PID controller and its control allocation algorithm were designed for this propulsive force adjusting. We conducted simulations and experiments to verify the effect of the controller and test the influence of PID parameters on stability control. The simulation and experimental results clearly show that the robot is able to realize heave motion, surge motion, steering motion, and maintain a stable hover.

5.4. Applicability

Owning to the aforementioned advantages, the novel underwater robot is suitable for a variety of tasks such as marine exploration, rescue, and operation. The most common example of such a task in the oil and gas industry is using the robot to make detailed maps of the seafloor before building a subsea infrastructure. In addition, the robot can carry the camera and robotic arm for underwater operations such as pipe maintenance and repair.

The present underwater robot prototype has successfully realized basic motion and high-frequency propulsion. However, compared to our design purpose and the simulation results, its swimming performance still has room for improvement. We summarized future work for the underwater robot as follows: first, the shape of the robot can be designed to be a fish-like shape to improve the hydrodynamic performance of the robot in the directions of moving forward, rising, and sinking; second, the cam mechanism can be optimized by replacing the rigid shaft with a flexible shaft and improving the structure of the fin with soft material to generate an ideal sine wave; and, last but not least, the control strategy can be improved to enhance stability and maneuverability.