A Novel Wellbore-Wall Heating Method without External Energy Injection for Natural Gas Hydrate Production—A Heat Transfer Device

Abstract

1. Introduction

2. Method Description

2.1. Thermal Pipe Technology

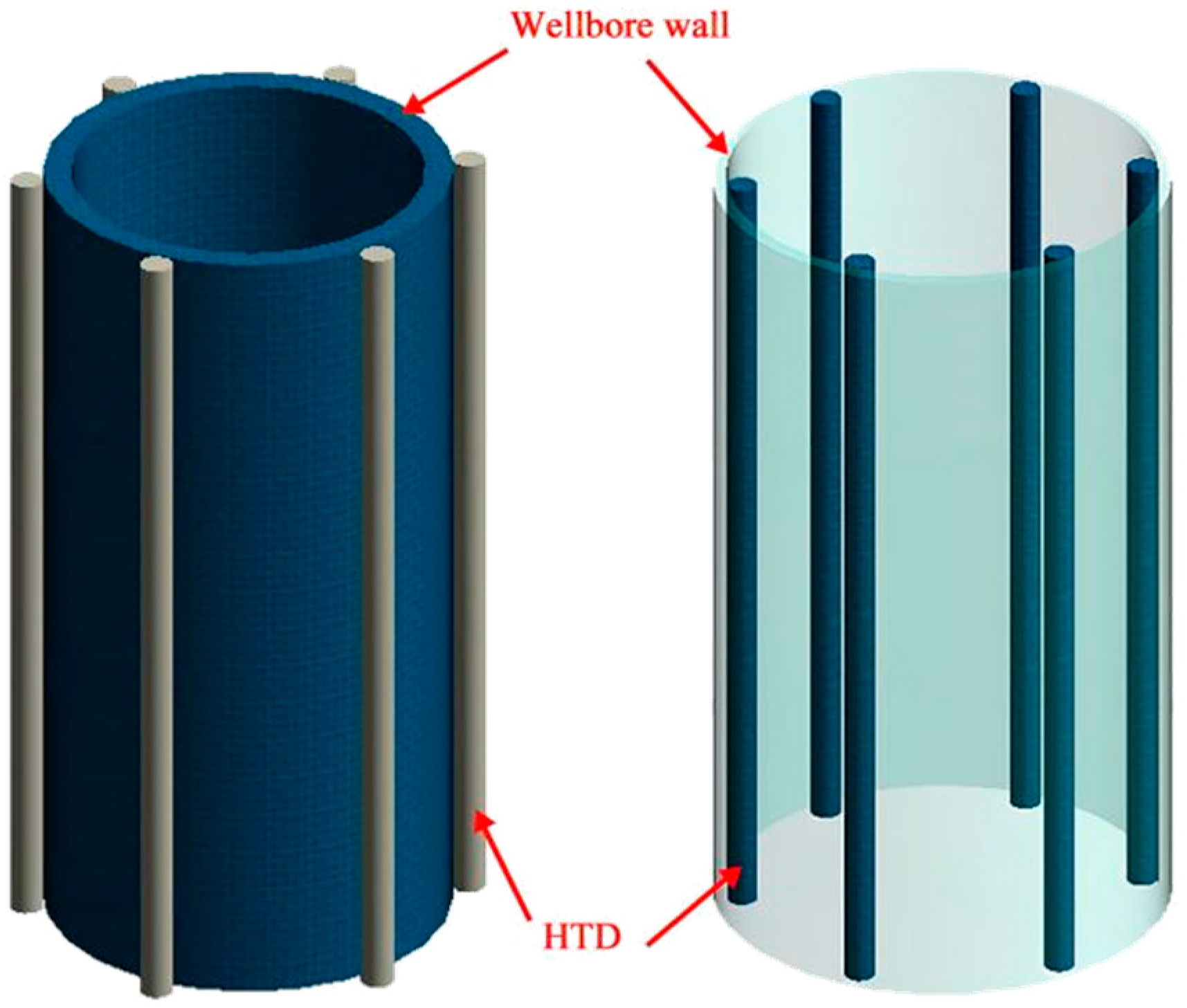

2.2. Application in Wellbore-Wall Heating

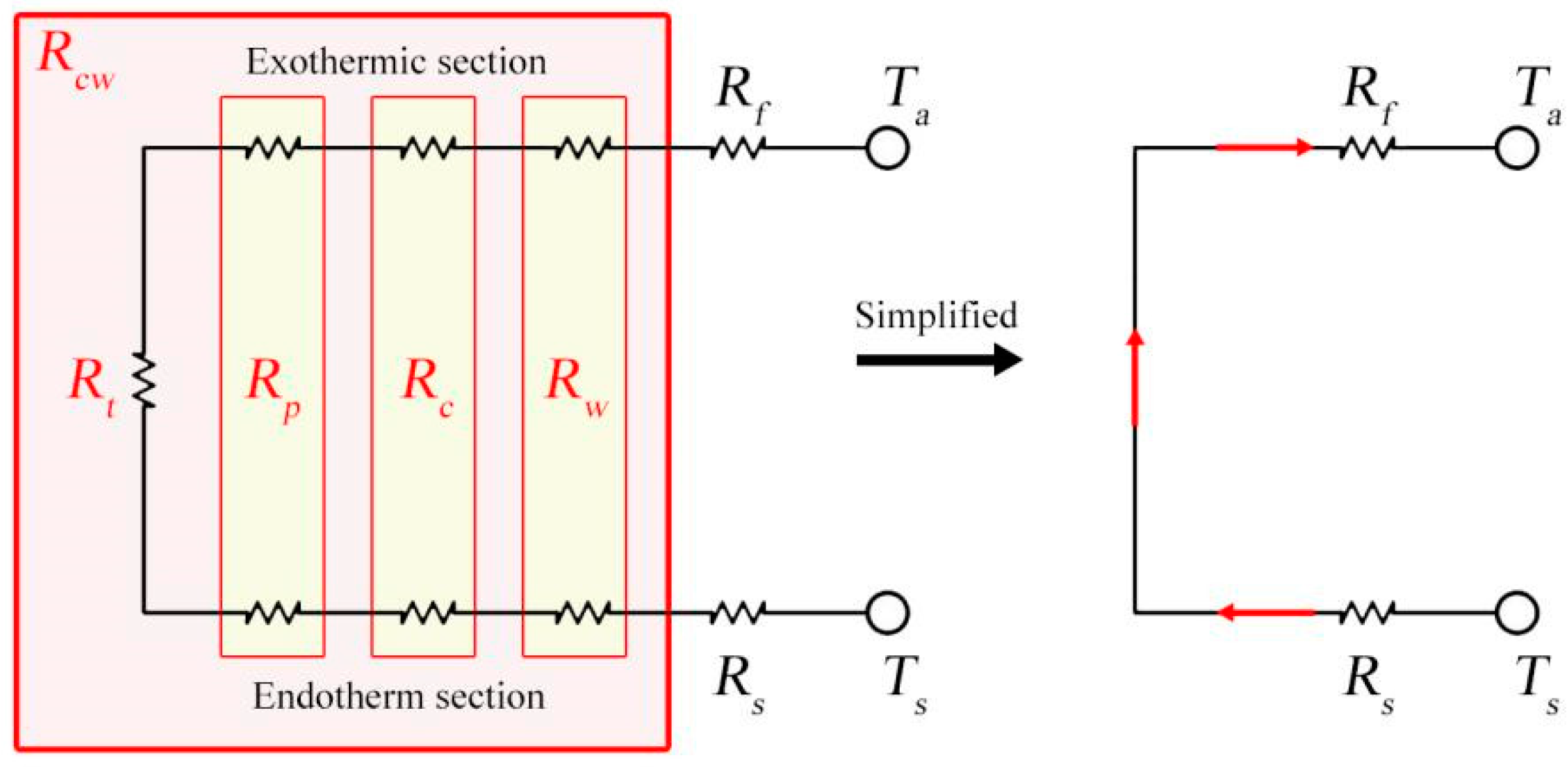

3. Heat Transfer Efficiency Analysis

3.1. Reaction Heat of Hydrate Dissociation

3.2. Heat Transfer Control Formula

3.3. Reservoir Condition

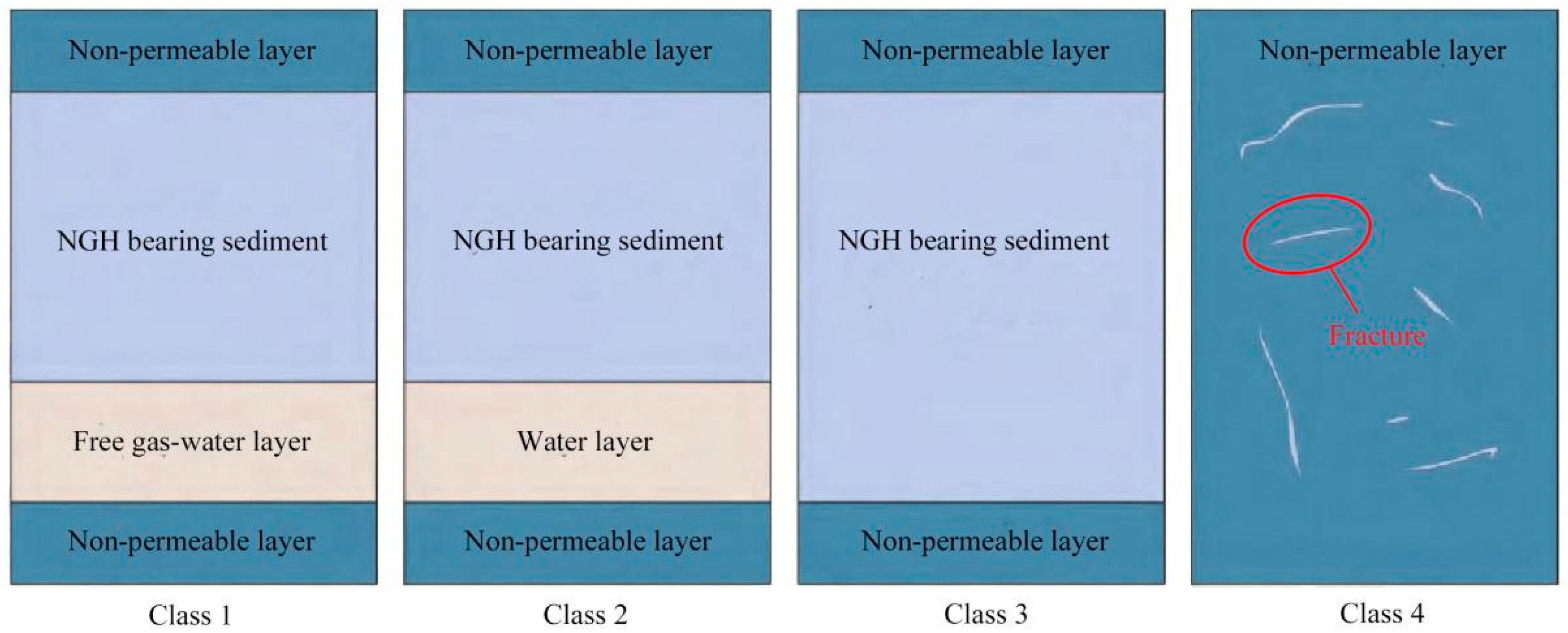

- (1)

- First category. The NBL, with an underlying two-phase fluid layer including free gas and water, makes up the Class 1 reservoir. Methane gas can be recovered directly before NGH dissociation in the Class 1 reservoir, which has excellent gas production potential to achieve commercial production, with distribution areas such as the Messoyakha gas field in Russia [40], North Slope tundra in the USA [20], Mallik area in Canada [16], the Black Sea in Turkey [41], and northern land slope of the South China Sea [42];

- (2)

- (3)

- (4)

- Fourth category. Low saturation and dispersed hydrate reservoirs are classified as the Class 4 reservoir, which is challenging to recover gas from, without commercial exploitation value [47].

4. Application Example Analysis

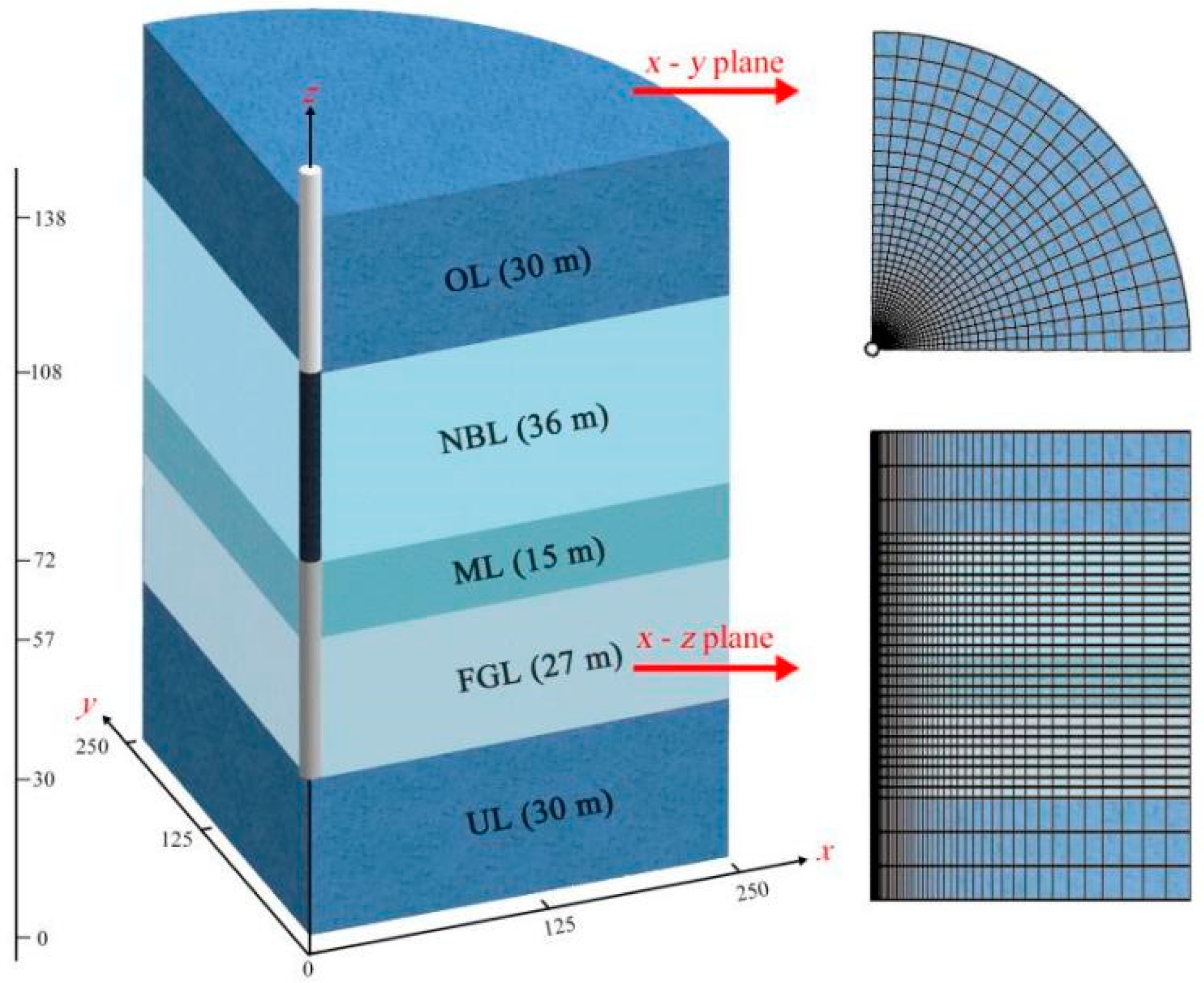

4.1. Model Construction

4.1.1. Geological Model

4.1.2. Numerical Simulator Code

4.1.3. Production Method and Case Design

4.2. Numerical Simulation Results

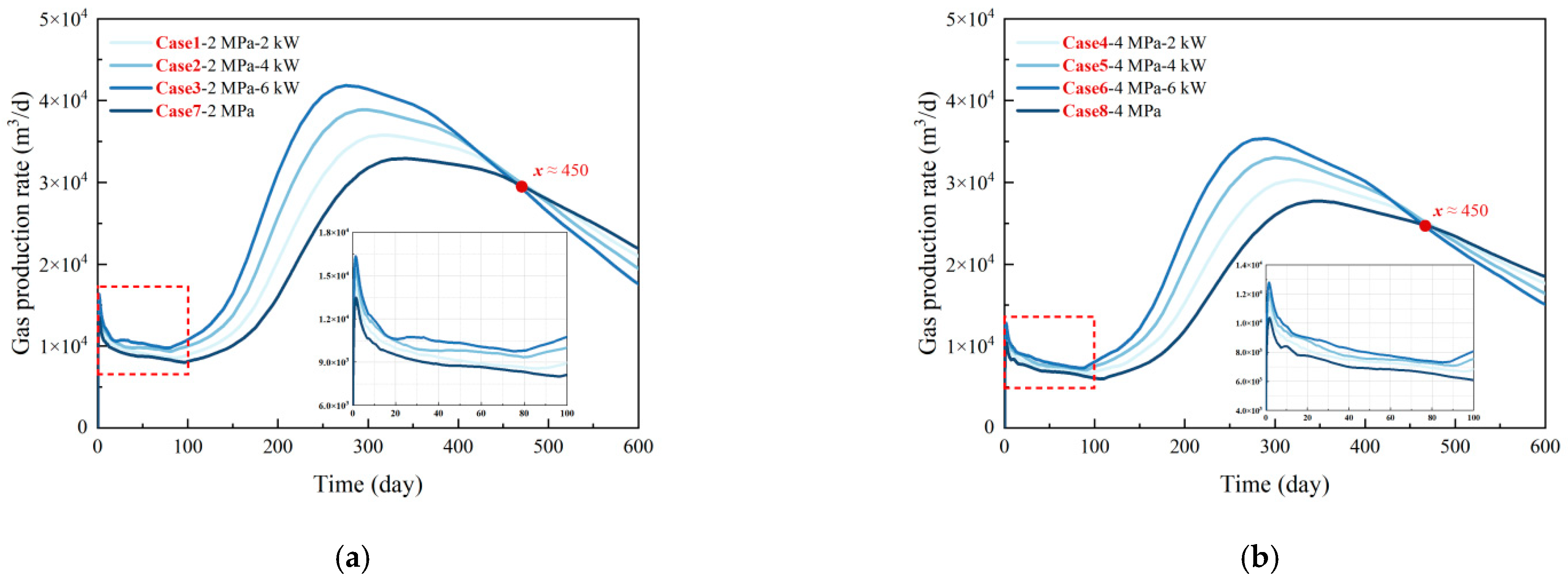

4.2.1. Gas Production

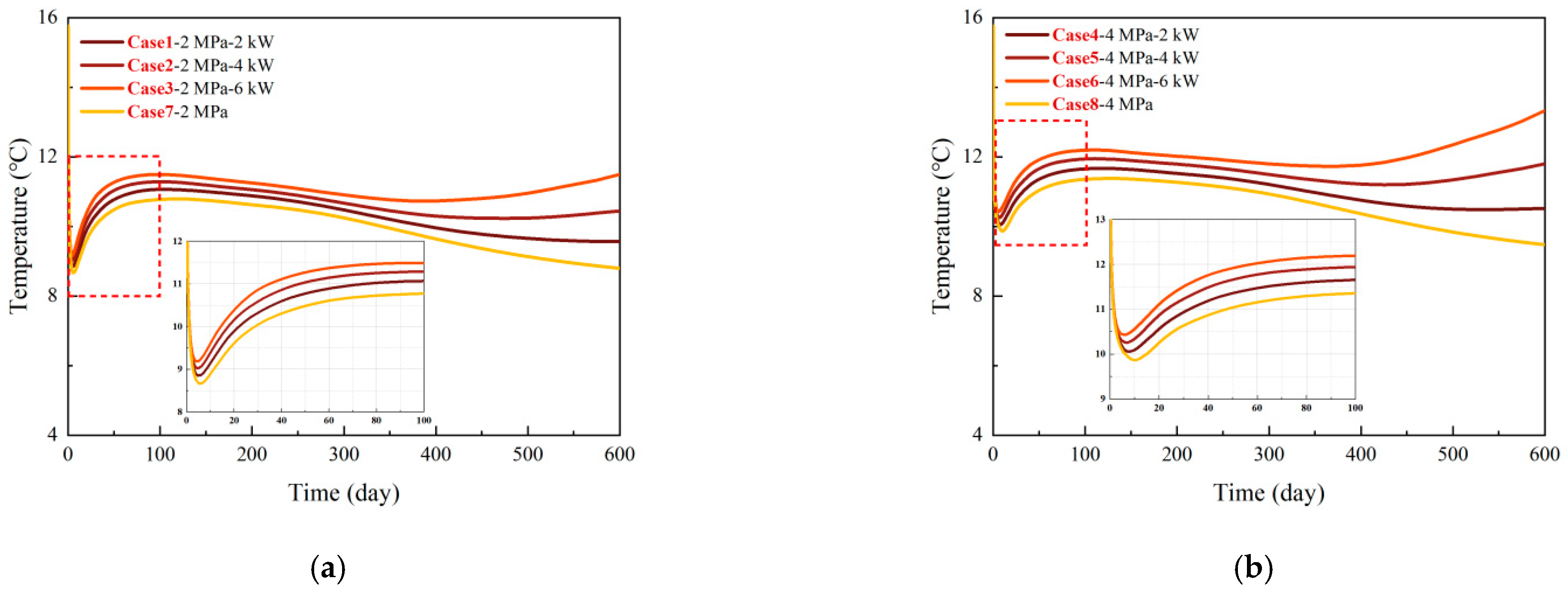

4.2.2. Temperature Evolution

4.2.3. Energy Efficiency

5. Conclusions

- (1)

- The HTD is a heat conduction pipe of gas-liquid two-phase flow circulation, attached circumferentially to the inside or outside of the wellbore wall. It can transfer heat from the lower part of the NGH reservoir to the open-hole section of the wellbore without external energy injection by using the temperature difference between the upper and lower ends during the pressure-reducing production process.

- (2)

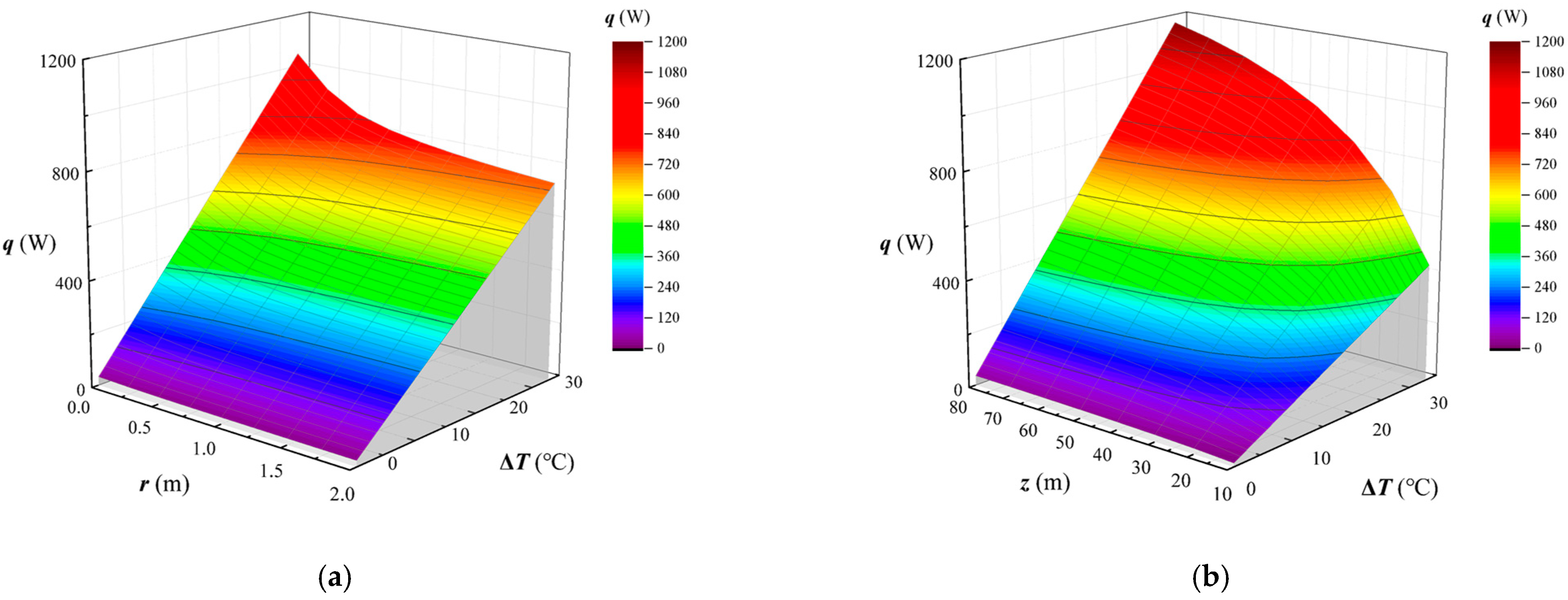

- The ΔT on the q is a linear increase. The increase of the r fails to strengthen the q due to the increased heat loss by extensive heat transfer. The enhancement in the z can increase q, especially at larger ΔT. However, an increase in z inevitably leads to an enlargement in thermal resistance, slowing down the promotion in q.

- (3)

- The HTD can be used in any NGH reservoir suitable for the depressurization method. The FGL for a Class 1 reservoir can increase gas production even when the contribution of NGH dissociation is small and will not intensify the water flow and inhibit gas production. Thus, it may be the best choice for meeting the working conditions of the HTD.

- (4)

- The power provided by the HTD is limited but sufficient to achieve the goal of preventing clogging of the wellbore wall at a low cost. In addition, wellbore-wall heating helps to improve gas production under the depressurization method, which is better than the pure depressurization exploitation scenario. However, from the simulation results, HTD may be more suitable for production in the short term (365 d).

- (5)

- Wellbore-wall heating in production wells can provide heat to the area and raise the temperature effectively. However, at the same time, its scope and effectiveness are minimal because of the low power of the HTD and the low thermal conductivity of the production well.

- (6)

- The energy efficiency of HTD is highly satisfactory because its heat transfer technique is designed to address the wellbore clogging problem. It can entirely take advantage of the depressurization method, requiring only the proper heat input, and eliminate the need for manual heat input.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zeng, H.; Zhang, Y.; Zhang, L.; Chen, Z.; Li, X. Effects of the NaCl Concentration and Montmorillonite Content on Formation Kinetics of Methane Hydrate. J. Mar. Sci. Eng. 2022, 10, 548. [Google Scholar] [CrossRef]

- Sloan, E.D. Fundamental principles and applications of natural gas hydrates. Nature 2003, 426, 353–359. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Zhan, L.; Lu, H. Mechanisms for Overpressure Development in Marine Sediments. J. Mar. Sci. Eng. 2022, 10, 490. [Google Scholar] [CrossRef]

- Kida, M.; Suzuki, K.; Kawamura, T.; Oyama, H.; Nagao, J.; Ebinuma, T.; Narita, H.; Suzuki, H.; Sakagami, H.; Takahashi, N. Characteristics of natural gas hydrates occurring in pore-spaces of marine sediments collected from the eastern Nankai trough, off Japan. Energy Fuels 2009, 23, 5580–5586. [Google Scholar] [CrossRef]

- Zhang, P.; Tian, S.; Zhang, Y.; Li, G.; Zhang, W.; Khan, W.A.; Ma, L. Numerical simulation of gas recovery from natural gas hydrate using multi-branch wells: A three-dimensional model. Energy 2021, 220, 119549. [Google Scholar] [CrossRef]

- Koh, C.A.; Sloan, E.D.; Sum, A.K.; Wu, D.T. Fundamentals and applications of gas hydrates. Annu. Rev. Chem. Biomol. Eng. 2011, 2, 237–257. [Google Scholar] [CrossRef]

- Kvenvolden, K.A. Methane hydrate—A major reservoir of carbon in the shallow geosphere? Chem. Geol. 1988, 71, 41–51. [Google Scholar] [CrossRef]

- Ye, H.; Wu, X.; Li, D. Numerical simulation of natural gas hydrate exploitation in complex structure wells: Productivity improvement analysis. Mathematics 2021, 9, 2184. [Google Scholar] [CrossRef]

- Aghajari, H.; Moghaddam, M.H.; Zallaghi, M. Study of effective parameters for enhancement of methane gas production from natural gas hydrate reservoirs. Green Energy Environ. 2019, 4, 453–469. [Google Scholar] [CrossRef]

- Yamamoto, K.; Wang, X.X.; Tamaki, M.; Suzuki, K. The second offshore production of methane hydrate in the Nankai Trough and gas production behavior from a heterogeneous methane hydrate reservoir. RSC Adv. 2019, 9, 25987–26013. [Google Scholar] [CrossRef]

- Yamamoto, K.; Terao, Y.; Fujii, T.; Ikawa, T.; Seki, M.; Matsuzawa, M.; Kanno, T. Operational overview of the first offshore production test of methane hydrates in the Eastern Nankai Trough. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 2014; Volume 3, pp. 1802–1812. [Google Scholar] [CrossRef]

- Li, J.F.; Ye, J.L.; Qin, X.W.; Qiu, H.J.; Wu, N.Y.; Lu, H.L.; Xie, W.W.; Lu, J.A.; Peng, F.; Xu, Z.Q.; et al. The first offshore natural gas hydrate production test in South China Sea. China Geol. 2018, 1, 5–16. [Google Scholar] [CrossRef]

- Ye, J.L.; Qin, X.W.; Xie, W.W.; Lu, H.L.; Ma, B.J.; Qiu, H.J.; Liang, J.Q.; Lu, J.A.; Kuang, Z.G.; Lu, C.; et al. The second natural gas hydrate production test in the South China Sea. China Geol. 2020, 3, 197–209. [Google Scholar] [CrossRef]

- Oldenburg, C.M. Joule-Thomson cooling due to CO2 injection into natural gas reservoirs. Energy Convers. Manag. 2007, 48, 1808–1815. [Google Scholar] [CrossRef]

- Liu, B.; Yuan, Q.; Su, K.H.; Yang, X.; Wu, B.C.; Sun, C.Y.; Chen, G.J. Experimental simulation of the exploitation of natural gas hydrate. Energies 2012, 5, 466–493. [Google Scholar] [CrossRef]

- Moridis, G.J.; Collett, T.S.; Dallimore, S.R.; Satoh, T.; Hancock, S.; Weatherill, B. Numerical studies of gas production from several CH4 hydrate zones at the Mallik site, Mackenzie Delta, Canada. J. Pet. Sci. Eng. 2004, 43, 219–238. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, P.; Pang, S.; Zhang, S.; Xiao, R. A Review of the Resource and Test Production of Natural Gas Hydrates in China. Energy Fuels 2021, 35, 9137–9150. [Google Scholar] [CrossRef]

- Wu, N.; Li, Y.; Wan, Y.; Sun, J.; Huang, L.; Mao, P. Prospect of marine natural gas hydrate stimulation theory and technology system. Nat. Gas Ind. 2020, 40, 100–115. [Google Scholar] [CrossRef]

- Collett, T.S. Gas hydrate production testing—Knowledge gained. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2019. [Google Scholar] [CrossRef]

- Kurihara, M.; Sato, A.; Funatsu, K.; Ouchi, H.; Masuda, Y.; Narita, H.; Collett, T.S. Analysis of formation pressure test results in the Mount Elbert methane hydrate reservoir through numerical simulation. Mar. Pet. Geol. 2011, 28, 502–516. [Google Scholar] [CrossRef]

- Loh, M.; Too, J.L.; Falser, S.; Linga, P.; Khoo, B.C.; Palmer, A. Gas production from methane hydrates in a dual wellbore system. Energy Fuels 2015, 29, 35–42. [Google Scholar] [CrossRef]

- Liang, Y.P.; Liu, S.; Wan, Q.C.; Li, B.; Liu, H.; Han, X. Comparison and optimization of methane hydrate production process using different methods in a single verticalwell. Energies 2019, 12, 124. [Google Scholar] [CrossRef]

- Falser, S.; Uchida, S.; Palmer, A.C.; Soga, K.; Tan, T.S. Increased gas production from hydrates by combining depressurization with heating of the wellbore. Energy Fuels 2012, 26, 6259–6267. [Google Scholar] [CrossRef]

- Ning, F.; Wu, N.; Jiang, G.; Zhang, L.; Guan, J.; Yu, Y.; Tang, F. A method to use solar energy for the production of gas from marine hydrate-bearing sediments: A case study on the Shenhu Area. Energies 2010, 3, 1861–1879. [Google Scholar] [CrossRef]

- Zhao, J.; Fan, Z.; Wang, B.; Dong, H.; Liu, Y.; Song, Y. Simulation of microwave stimulation for the production of gas from methane hydrate sediment. Appl. Energy 2016, 168, 25–37. [Google Scholar] [CrossRef]

- Li, D.L.; Liang, D.Q.; Fan, S.S.; Li, X.S.; Tang, L.G.; Huang, N.S. In situ hydrate dissociation using microwave heating: Preliminary study. Energy Convers. Manag. 2008, 49, 2207–2213. [Google Scholar] [CrossRef]

- Islam, M.R. A new recovery technique for gas production from Alaskan gas hydrates. J. Pet. Sci. Eng. 1994, 11, 267–281. [Google Scholar] [CrossRef]

- Liu, Y.; Hou, J.; Zhao, H.; Liu, X.; Xia, Z. A method to recover natural gas hydrates with geothermal energy conveyed by CO2. Energy 2018, 144, 265–278. [Google Scholar] [CrossRef]

- Liu, Y.; Hou, J.; Chen, Z.; Su, H.; Zhao, E.; Li, G. A novel natural gas hydrate recovery approach by delivering geothermal energy through dumpflooding. Energy Convers. Manag. 2020, 209, 112623. [Google Scholar] [CrossRef]

- Grover, G.; Cotter, T.; Erickson, G. Erratum: Structures of very high thermal conductance. J. Appl. Phys. 1964, 35, 3072. [Google Scholar] [CrossRef]

- Yue, C.; Zhang, Q.; Zhai, Z.; Wang, J.; Ling, L. Numerical study on flow and thermal characteristics of a micro-channel separated heat pipe under various surface wettability. Case Stud. Therm. Eng. 2021, 28, 101345. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Cui, Y.; Guo, W.; Lv, J. Numerical simulation of soil freezing and associated pipe deformation in ground heat exchangers. Geothermics 2018, 74, 112–120. [Google Scholar] [CrossRef]

- Nikolaenko, Y.E.; Pekur, D.V.; Sorokin, V.M.; Kravets, V.Y.; Melnyk, R.S.; Lipnitskyi, L.V.; Solomakha, A.S. Experimental study on characteristics of gravity heat pipe with threaded evaporator. Therm. Sci. Eng. Prog. 2021, 26, 101107. [Google Scholar] [CrossRef]

- Cen, J.; Li, F.; Li, T.; Huang, W.; Chen, J.; Jiang, F. Experimental study of the heat-transfer performance of an extra-long gravity-assisted heat pipe aiming at geothermal heat exploitation. Sustainability 2021, 13, 12481. [Google Scholar] [CrossRef]

- Shafieian, A.; Khiadani, M.; Nosrati, A. Strategies to improve the thermal performance of heat pipe solar collectors in solar systems: A review. Energy Convers. Manag. 2019, 183, 307–331. [Google Scholar] [CrossRef]

- Wang, E.L.; Tian, Y.; Liu, X.; Ren, Z.; Hu, S. Thermosyphon Application in the Embankment Project in Permafrost Area. J. Water Resour. Archit. Eng. 2021, 19, 148–153159. [Google Scholar] [CrossRef]

- Cranganu, C. In-situ thermal stimulation of gas hydrates. J. Pet. Sci. Eng. 2009, 65, 76–80. [Google Scholar] [CrossRef]

- Rydzy, M.B.; Schicks, J.M.; Naumann, R.; Erzinger, J. Dissociation enthalpies of synthesized multicomponent gas hydrates with respect to the guest composition and cage occupancy. J. Phys. Chem. B 2007, 111, 9539–9545. [Google Scholar] [CrossRef]

- Moridis, G.J.; Collett, T.S.; Boswell, R.; Kurihara, M.; Reagan, M.T.; Koh, C.; Sloan, E.D. Toward production from gas hydrates: Current status, assessment of resources, and simulation-based evaluation of technology and potential. SPE Reserv. Eval. Eng. 2009, 12, 745–771. [Google Scholar] [CrossRef]

- Makogon, Y.F.; Omelchenko, R.Y. Commercial gas production from Messoyakha deposit in hydrate conditions. J. Nat. Gas Sci. Eng. 2013, 11, 1–6. [Google Scholar] [CrossRef]

- Merey, S.; Sinayuc, C. Investigation of gas hydrate potential of the Black Sea and modelling of gas production from a hypothetical Class 1 methane hydrate reservoir in the Black Sea conditions. J. Nat. Gas Sci. Eng. 2016, 29, 66–79. [Google Scholar] [CrossRef]

- Ning, F.; Liang, J.; Wu, N.; Zhu, Y.; Wu, S.; Liu, C.; Wei, C.; Wang, D.; Zhang, Z.; Xu, M.; et al. Reservoir characteristics of natural gas hydrates in China. Nat. Gas Ind. 2020, 40, 1–24. [Google Scholar] [CrossRef]

- Klapp, S.A.; Murshed, M.M.; Pape, T.; Klein, H.; Bohrmann, G.; Brewer, P.G.; Kuhs, W.F. Mixed gas hydrate structures at the Chapopote Knoll, southern Gulf of Mexico. Earth Planet. Sci. Lett. 2010, 299, 207–217. [Google Scholar] [CrossRef]

- Fujii, T.; Suzuki, K.; Takayama, T.; Tamaki, M.; Komatsu, Y.; Konno, Y.; Yoneda, J.; Yamamoto, K.; Nagao, J. Geological setting and characterization of a methane hydrate reservoir distributed at the first offshore production test site on the Daini- Atsumi Knoll in the eastern Nankai Trough, Japan. Mar. Pet. Geol. 2014, 66, 310–322. [Google Scholar] [CrossRef]

- Li, X.S.; Yang, B.; Li, G.; Li, B. Numerical simulation of gas production from natural gas hydrate using a single horizontal well by depressurization in Qilian mountain permafrost. Ind. Eng. Chem. Res. 2012, 51, 4424–4432. [Google Scholar] [CrossRef]

- Ryu, B.-J.; Riedel, M. Gas hydrates in the Ulleung Basin, East Sea of Korea. Terr. Atmos. Ocean. Sci. 2017, 28, 943–963. [Google Scholar] [CrossRef][Green Version]

- Le, A.N.; Huuse, M.; Redfern, J.; Gawthorpe, R.L.; Irving, D. Seismic characterization of a Bottom Simulating Reflection (BSR) and plumbing system of the Cameroon margin, offshore West Africa. Mar. Pet. Geol. 2015, 68, 629–647. [Google Scholar] [CrossRef]

- Sun, Y.; Ma, X.; Guo, W.; Jia, R.; Li, B. Numerical simulation of the short- and long-term production behavior of the first offshore gas hydrate production test in the South China Sea. J. Pet. Sci. Eng. 2019, 181, 106196. [Google Scholar] [CrossRef]

- Kim, H.C.; Bishnoi, P.R.; Heidemann, R.A.; Rizvi, S.S.H. Kinetics of methane hydrate decomposition. Chem. Eng. Sci. 1987, 42, 1645–1653. [Google Scholar] [CrossRef]

- Gaddipati, M. Code Comparison of Methane Hydrate Reservoir Simulators using CMG STARS Manohar. Master’s Thesis, West Virginia University, Morgantown, WV, USA, 2008. [Google Scholar]

- Genuchten, V.M. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- Carman, P.C. Permeability of saturated sands, soils and clays. J. Agric. Sci. 1939, 29, 262–273. [Google Scholar] [CrossRef]

- Wu, X.; Ye, H.; Jiang, Y.; Li, D.; Wang, G. Development of a novel self-entry exploitation device for marine natural gas hydrate and the feasibility studies. Ocean Eng. 2022, 254, 111365. [Google Scholar] [CrossRef]

- Ruan, X.; Li, X.; Xu, C.; Zhang, Y.; Yan, K. Numerical simulation of gas production from hydrate by depressurization combined with well-wall heating. Huagong Xuebao/CIESC J. 2015, 66, 1544–1550. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Thickness of OL and UL | 15 m | Initial saturation of OL and UL | Sh = 0, Sw = 1, Sg = 0 |

| Thickness of NBL | 36 m | Initial saturation of NBL | Sh = 0.34, Sw = 0.66, Sg = 0 |

| Thickness of ML | 15 m | Initial saturation of ML | Sh = 0.31, Sw = 0.526, Sg = 0.164 |

| Thickness of FGL | 27 m | Initial saturation of FGL | Sh = 0, Sw = 0.922, Sg = 0.078 |

| Porosity of OL and UL | 0.3 | NGH molar mass | 0.119543 kg/gmole |

| Porosity of NBL | 0.35 | NGH density | 919.7 kg/m3 |

| Porosity of ML | 0.33 | Seawater density | 1020 kg/m3 |

| Porosity of FGL | 0.32 | Thermal conductivity of rock | 2.7 W/m/K |

| Initial permeability of OL and UL | kox = koy = 2 mD, koz = 1 mD | Thermal conductivity of water | 0.69 W/m/K |

| Initial permeability of NBL | kox = koy = 2.9 mD, koz = 1.45 mD | Thermal conductivity of NGH | 0.5 W/m/K |

| Initial permeability of ML | kox = koy = 1.5 mD, koz = 0.75 mD | Formation temperature | T = 14.475 + 0.03z °C, z is the depth (m) |

| Initial permeability of FGL | kox = koy = 7.4 mD, koz = 3.7 mD | Formation pressure | P = 1.469 + 0.01z MPa, z is the depth (m) |

| Case | Production Pressure | Heat Transfer Power | Production Method |

|---|---|---|---|

| Case 1 | 2 MPa | 2 kW | DP + WH 1 |

| Case 2 | 2 MPa | 4 kW | DP + WH |

| Case 3 | 2 MPa | 6 kW | DP + WH |

| Case 4 | 4 MPa | 2 kW | DP + WH |

| Case 5 | 4 MPa | 4 kW | DP + WH |

| Case 6 | 4 MPa | 6 kW | DP + WH |

| Case 7 | 2 MPa | / | DP 2 |

| Case 8 | 4 MPa | / | DP |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, H.; Wu, X.; Guo, G.; Li, D.; Jiang, Y. A Novel Wellbore-Wall Heating Method without External Energy Injection for Natural Gas Hydrate Production—A Heat Transfer Device. J. Mar. Sci. Eng. 2022, 10, 799. https://doi.org/10.3390/jmse10060799

Ye H, Wu X, Guo G, Li D, Jiang Y. A Novel Wellbore-Wall Heating Method without External Energy Injection for Natural Gas Hydrate Production—A Heat Transfer Device. Journal of Marine Science and Engineering. 2022; 10(6):799. https://doi.org/10.3390/jmse10060799

Chicago/Turabian StyleYe, Hongyu, Xuezhen Wu, Gaoqiang Guo, Dayong Li, and Yujing Jiang. 2022. "A Novel Wellbore-Wall Heating Method without External Energy Injection for Natural Gas Hydrate Production—A Heat Transfer Device" Journal of Marine Science and Engineering 10, no. 6: 799. https://doi.org/10.3390/jmse10060799

APA StyleYe, H., Wu, X., Guo, G., Li, D., & Jiang, Y. (2022). A Novel Wellbore-Wall Heating Method without External Energy Injection for Natural Gas Hydrate Production—A Heat Transfer Device. Journal of Marine Science and Engineering, 10(6), 799. https://doi.org/10.3390/jmse10060799