Abstract

Real-time monitoring of the mooring safety of floating structures is of great significance to their production operations. A deep learning model is proposed here, based on the long short-term memory (LSTM) artificial neural network. Firstly, the numerical simulation is carried out with the single-point mooring system of a Floating Production Storage and Offloading (FPSO) as the training data of LSTM. Then the proposed LSTM is performed. Finally, taking the motion of FPSO which is not encountered by LSTM neural network model as input, we predict the mooring line tension with this model. Here, one FPSO in the South China Sea is taken as a research case, hydrodynamic and mooring models are established, and the network structure and hyper-parameters of the LSTM model are determined. The prediction results of the LSTM under different combinations of wind, wave, and current are compared with the calculation results of AQWA software. The model constructed here can well predict the mooring line tension of different combinations of wind, wave and current.

1. Introduction

Offshore oil production in medium-depth water is mainly performed through floating production systems in the South China Sea, such as semi-submersible platforms or FPSO. The marine environment served by these platforms is extremely complex and harsh. Once an accident occurs, it will cause serious economic losses and environmental pollution. A mooring system is a positioning device for a platform or a ship that can limit the platform to remain relatively static within a certain range under the action of external loads. Therefore, it is important to monitor the tension response of the mooring line to prevent potential damage. However, the marine environment in which the platform works is harsh, and monitoring equipment such as inclinometers and tensiometers are prone to failure; moreover, their long-term maintenance and service costs are also very expensive.

The purpose of designing the mooring system is to fix the floating body at a certain position and restrict the movement of the floating body. Therefore, we can calculate the tension of the mooring system based on the movement of the floating body. Compared with testing equipment such as dynamometers, GPS is mounted on a floating upper deck and is less exposed to seawater erosion. Thus, GPS is more reliable and stable and can obtain more accurate data [1]. Therefore, by taking the position of the floating body as the excitation condition and using finite element software to calculate the response of the mooring line, the nonlinear behavior of the mooring system can be accurately calculated. However, the finite-element calculation software is not only slow in calculation speed but also unable to calculate the tension of the mooring line in real time; therefore, the rapid monitoring of the mooring system is based on the movement of the floating body and has become a problem worthy of study [2].

With the rapid development of machine learning, artificial neural networks (ANNs) have been applied to research in the field of ocean engineering. Queau et al. [3] used the back propagation (BP) network to study the fatigue behavior of catenary riser in the case that only the static load is considered while the inertia or damping is ignored. A quadratic Volterra model with a finite nonlinear memory effect was introduced and applied to the time-series prediction of a slender marine structure exposed to the Morison load [4]. Mak et al. [5] used the machine learning approaches to estimate the relative wave direction based on the time histories of six-degrees-of-freedom ship motions. Chaves et al. [6] predicted the tension, curvature, and fatigue life of the flexible pipeline based on the combinations of dynamic finite element analyses and ANN. Guo et al. [7] developed an LSTM-based machine learning model to predict the heave and surge motions of a semi-submersible.

It can be seen that ANN not only can compute complex relationships but also predict future performance; therefore, some scholars apply ANN to the research of mooring lines. Lin and Liu [8] built a deep learning model to study the contributing factors of the maximum mooring tension of the floating wind turbine system in tensioned mooring and relaxation mooring. Li and Choung [9] analyzed and studied the fatigue damage of the mooring line of the OC4 floating wind turbine system based on the artificial neural network method of the multilayer feed-forward neural network and the BP learning scheme. Janas et al. [10] established a convolutional neural network (CNN) model and trained it through historical image data and numerical simulation results to recognize mooring line failures under non-extreme sea conditions.

LSTM is a special neural network that not only can deal with sequence problems but also solve problems such as gradient explosion during training [11]; it can predict time series accurately for many different tasks, such as weather conditions [12,13], ocean temperature [14], stock prices [15], and ship motion [16,17].

Obviously, with the continuous advancement of computer technology and algorithms, the LSTM network is used in the prediction of mooring line tension [18]. Chung et al. [19] studied a damage detection method of tension leg platform mooring line based on deep neural network. Sidarta et al. [20,21] built a neural network model and used the platform’s six degrees of freedom and platform mass to predict mooring line tension and identify mooring line damage. Guarize et al. [22] used a combination of neural network and finite element method to analyze the response of mooring line and riser. Saad et al. [23] used Multilayer Perceptron (MLP) and LSTM networks to build models, based on the comparison between measured motion and predicted motion, to predict mooring line failures and compared the performance of the two models. Qiao et al. [24] used the internal turret FPSO as the research object and constructed the LSTM model, taking the 6-DOF (degrees of freedom) motion of the ship as the input label, and the tension of the mooring line as the output label. The accuracy of the model’s prediction of mooring line tension under given sea conditions was studied. However, the study only considered the conditions of winds, waves, and currents in the same direction.

The inner turret FPSO has a wind vane effect, and the floating body will rotate 360° around the turret under the action of environmental loads. To remove the influence of the wind vane effect on the yaw motion, this paper takes the 5-DOF of the FPSO as the input and the mooring line tension as the output result and builds an LSTM model to study the prediction of the mooring line tension. At the same time, the paper also studies the working conditions of different wind, wave, and current directions.

The content here is arranged as follows: Section 2 describes the methods and formulas; Section 3 describes the main dimensions of FPSO, single point mooring system, and working conditions of the FPSO; Section 4 describes the verification of hydrodynamic and mooring models, the construction of LSTM models, and the parameters settings; and Section 5 describes the analysis of the LSTM model’s prediction results for multiple working conditions.

2. Methodology for the Tensions Evaluation of Single Point Mooring System

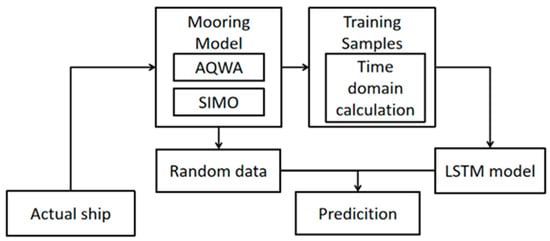

The hydrodynamic and mooring model is established based on the given FPSO. The LSTM model is trained and built according to the AQWA time-domain calculation results to achieve the purpose of calculating the mooring line tension based on the motion of the ship. The specific process is shown in Figure 1. Firstly, establish hydrodynamic and mooring models according to the actual ship. Then carry out the time-domain calculation with corresponding wind, wave, and current environmental conditions to provide samples for training the LSTM network. The next step is to train the data with the LSTM model. Finally, predict the mooring line tension with the random motion, which is not encountered by LSTM neural network model.

Figure 1.

General framework of mooring line tension prediction.

2.1. Theory of LSTM Neural Network

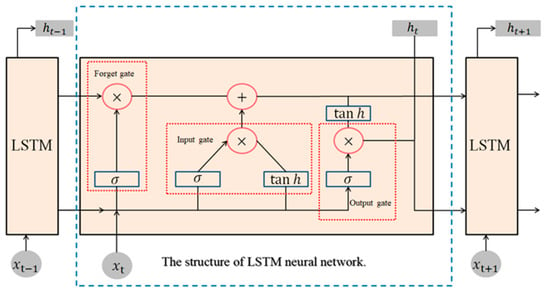

The LSTM neural network is a special recurrent neural network that learns long-term dependent information through repeated structure design. The LSTM neural network not only has the large loop of the external neural network but also the self-loop of the “cell state” of the LSTM itself. The self-loop is controlled by the gate structure processed by three sigmoid activation functions (as shown in Figure 2): The forget gate () determines which part of the memory needs to be forgotten according to the current input, the output at the previous moment, and the offset of the gate; the expression is shown in Equation (1). The input gate () supplements the latest memories; the expressions are shown in Equations (2) and (3). The output gate () determines the output of the moment according to the latest state of the current moment, the output of the previous moment, and the input of the current moment; the expressions are shown in Equations (5) and (6). Equation (4) is the cell state () at time t [11].

where , , is the activation function; is the output at t − 1 second; is the input at t second; and , , , and are their respective weights. When the LSTM model is applied to mooring line tension prediction, represents all predicted future mooring line tension.

Figure 2.

LSTM neural network inner cell structure.

2.2. Normalization of the Neural Network

The LSTM model built here takes the 5-DOF of the floating body as the input, and the mooring line tension as the output. The unit and magnitude of the input and output data are inconsistent; to make the LSTM model predict more accurately, the data need to be normalized. In the same way, the data calculated by LSTM must be denormalized to get the data we want. The normalization method used here is the Min–Max scaling normalization, and its expression is shown in Equation (7) where, x is the original data, is the minimum value of the data, and is the maximum value of the data.

2.3. Indicators of Calculation Accuracy

Here, three kinds of error evaluation indicators are used: root mean square error (RMSN), average absolute error (MAE), and average absolute error percentage (MAPE). As shown in Equations (8)–(10), n is the total number of samples, is the number i actual value, and is the number i predictive value.

The prediction precision can be judged by comparing the maximum, minimum, and average value of the LSTM predicted value data sets and the AQWA calculated value data sets.

2.4. Training Data of LSTM Neural Network

The training set, validation set, and test set of the LSTM neural network were calculated by AQWA software. Equation (11) was solved by this software in the time domain.

where i is in the range from 1 to 6; is the mass matrix of floating structure; is the added mass matrix; is the hysteresis function matrix; is the viscous damping matrix; is the static recovery stiffness matrix of the FPSO; and is the force on the FPSO, including mooring force, wind force, current force, wave force, riser force, and so on.

Here, only mooring force, wind force, current force, and wave force are considered. The wave forces on the FPSO are calculated by the boundary element method on the diffraction theory [25]. Because the FPSO ship structure is similar to VLCC (very large crude carrier), the wind forces and current forces on the FPSO are calculated by API (American Petroleum Institute) standard [26]. The mooring forces on the FPSO are calculated by lumped mass method [27]. The 5-DOF and nine mooring line tension, which were calculated by AQWA software, were selected as training data of the LSTM neural network.

3. FPSO and Single-Point Mooring System with the Environment

3.1. FPSO and Mooring System

An FPSO in the South China Sea was taken as the research object to verify the proposed LSTM network prediction mooring system. The specific parameters of the FPSO are shown in Table 1. The inner turret FPSO is a 150,000 DWT (dead weight ton) single bottom double-shell structure. The single-point permanent mooring mode is adopted, and the average water depth is 105 m.

Table 1.

Ship’s main dimensions.

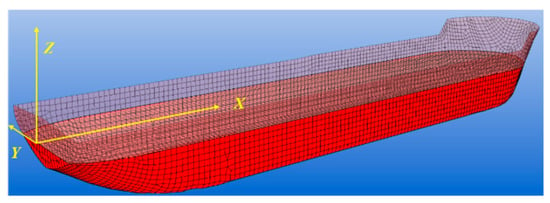

Modeling and meshing are built in AQWA software with the specific form in Figure 3. The FPSO model grid unit is 1 m with the total 10,344 elements. The coordinate origin is located at the water surface, between the stern vertical line length and draft line intersection point. The x-axis is along the length direction of the floating body to the bow, the y-axis is along the width direction of the floating body to the starboard, and the z-axis is vertical upward. In general, the mesh element covers the wet surface, and the size of the mesh element is less than 1/7 of the incident wavelength.

Figure 3.

Ship surface model.

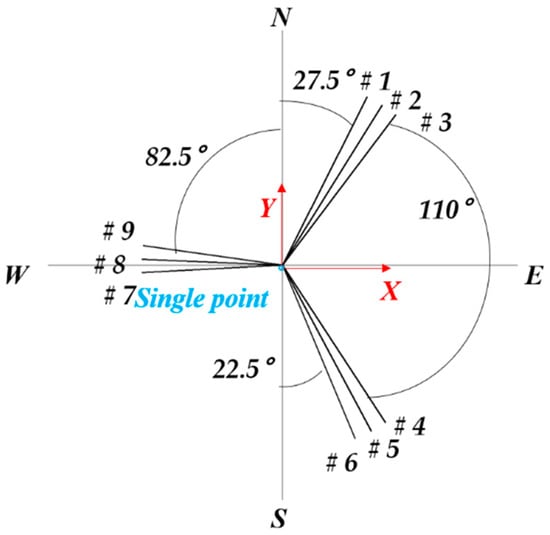

The mooring system consists of nine mooring lines grouped into three clusters with three mooring lines, as shown in Figure 4. The angle is 5 degrees between the mooring lines in each cluster. The angle is 120 degrees between clusters. The composition and physical properties of each mooring line are shown in Table 2 and Table 3. In the table, the LCS represents the lower chain section, the CE represents the connecting element, the LWS represents the lower wire rope section, the UWS represents the upper wire rope section, and the UCS represents the upper chain section. UCS1, UCS2, and UCS3 are made of the same material, and there are 17 weights on the UCS2. In Table 3, the UCS2 data are treated equivalently.

Figure 4.

Mooring system layout.

Table 2.

Mooring line components.

Table 3.

Properties of mooring line components.

3.2. Working Environment Conditions

The working conditions of numerical simulation data used here are described in the following cases. Single condition (Case 1): JONSWAP irregular wave with 2 m significate wave height, NPD wind spectrum. The angle is 15° between the wind direction and wave direction. The angle is 45° between the current direction and wave direction, as shown in Table 4. Working condition 10003 is the time domain tension data of the ship with 5-DOF and nine mooring lines for 3 h. The value interval is 1 s. The first 7000 are behavior training sets of the data, and the rest are the validation sets. The first five columns are the input data of the neural network, and the rest are the output data labels.

Table 4.

Description of Case 1.

Multiple working conditions (Case 2): significate wave height of 1 m, peak period of 11.2 s, peak factor of 3.3, wind speed of 3 m/s, and current velocity of 0.15 m/s, as shown in Table 5. The 35 working conditions were randomly selected as the training sets, with the remaining four used as prediction sets. In each environmental working condition, there are 10,000 s of hull 5-DOF movement and nine mooring line tension time history data. The value interval is 1 s, so there are 10,000 rows and 14 columns in total. Take the first 7000 rows of each working condition and stitch them together to obtain the training sets of the neural network; the remaining 3000 rows of data are stitched into the verification sets; and the first five columns (surge, sway, heave, roll, and pitch) are used as input data, and the mooring line tensions are used as output result labels. The splicing sequence is shown in Table 6, from the first row to the fifth row stitched together.

Table 5.

Description of Case 2.

Table 6.

Splicing of Case 2.

There are two conditions set: Case 1 is a single combination of wind, wave, and current that is used to study the hyperparameters of LSTM model and the accuracy of LSTM model in single condition; and Case 2 is the combination of the same wind, wave, and current with different directions that is used to study the generalization ability of LSTM model.

4. Preliminary Process for the Evaluations

4.1. Validation of the Mooring Model

To verify the accuracy of the initial layout of the entire system, we established FPSO mooring models in AQWA and SIMO software and performed static balance calculations; the calculation results are shown in Table 7. The SIMO results show that the pre-tension of every single mooring line is 260 kN, and the AQWA calculation results show that the pre-tension of Mooring Lines 1 to 6 is 256 kN, with an error of 1.56%; the pre-tension of Mooring Lines 7 to 9 is 258 kN, with an error of 0.78%. The difference between the AQWA calculation result and the SIMO calculation result is mainly caused by the equivalent treatment of the connectors. The deviation is within the ideal range, so the model is considered accurate.

Table 7.

Comparison of pre-tension.

4.2. LSTM Model Design

The Keras’ LSTM layer is used to construct a many-to-many LSTM model. By referring to previous research conclusions [24,28], we see that the deep learning model is built with a three-layer LSTM loop layer and a fully connected output layer. The training is carried out with the following data set: (the number of samples sent, the time step of the loop core expansion, the number of input features) as input, (the number of samples sent, the number of labels output) as the output.

Considering the time step as a sensitive factor, the hyperparameters, such as learning rate, number of training rounds, and batch size, are kept consistent in order to study the influences. The working condition 10003 is taken as an example for optimization. Its network layout is shown in Table 8.

Table 8.

Neural network parameters of working condition 10003.

The Case 1 data were transferred into the LSTM model for training. The errors were calculated corresponding to different time steps according to the input results of the working conditions.

As shown in Table 9, the root mean square error and average absolute error of number 1 are the smallest, indicating that the time-step model has acceptable performance. It can be found that 25 time steps are relative to the best performance from the error analysis results.

Table 9.

Error result statistics of working condition 10003.

Therefore, the hyperparameters of the network model are determined with the following parameters: number of training epochs is 20, batch size is 256, number of network layers is 5, discard rate is 0.3, learning rate is 0.01, loss function is MSE, activation function is tanh, optimizer is Adam.

5. Cases Study of Tension Prediction with LSTM

5.1. The Same Condition Verification

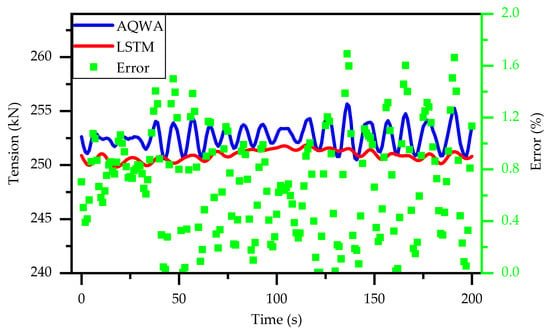

The prediction result of this case is compared with the time-domain calculation result of AQWA to further verify its accuracy. The tension comparison for Mooring Line 2 is shown in Figure 5 for the calculated and the predicted results. Within a wave period, the mooring force predicted by LSTM is in good agreement with that calculated by AQWA, except the amplitude points. The reason why the prediction accuracy of amplitude points is low is that there are less data for amplitude points in the training data, and the change characteristics were not learned by the neural network model completely. The calculation results of the LSTM model and the AQWA results are statistically analyzed in Table 10. The maximum values of the result predicted by LSTM neural network are smaller than those calculated by AQWA, the minimum values of the result predicted by the LSTM neural network are larger than those calculated by AQWA, and the average values are very close. This is because the LSTM neural network has a more accurate prediction value at general points than at amplitude points. In general, the maximum error of LSTM neural network prediction results is 5.25%, which is within the allowable range of engineering. Therefore, it proves that the proposed LSTM neural network model can predict a single short-term working condition.

Figure 5.

Mooring Line 2 tension comparison under Case 1.

Table 10.

Result statistics of mooring tensions in Case 1.

5.2. The Different Conditions Verification

5.2.1. Validation Sets Prediction

In Case 2, the prediction results are compared with the validation set obtained from AQWA, as shown in Table 11. Although the maximum values predicted by the LSTM neural network are smaller than those calculated by AQWA, and the minimum values predicted by the LSTM neural network are larger than those calculated by AQWA, the average values of the two results are closer than the result of the single working condition. This is because, with the increase of training data, the LSTM neural network can better learn the change characteristics of mooring line tension. It can be found that the long short-term memory neural network model is reliable to predict the mooring tension.

Table 11.

Result statistics of case2.

5.2.2. Test Sets Prediction

The environmental conditions of the test set are consistent with Table 5. The combination form is given in Table 12. The direction is determined with the angle relative to the bow by anticlockwise. The AD7 and AD10 have the same wind wave and current directions. The AD32 and AD35 have a wind and wave angle of 30 degrees, and a current and wave angle of 60 degrees.

Table 12.

Test set environment combination form.

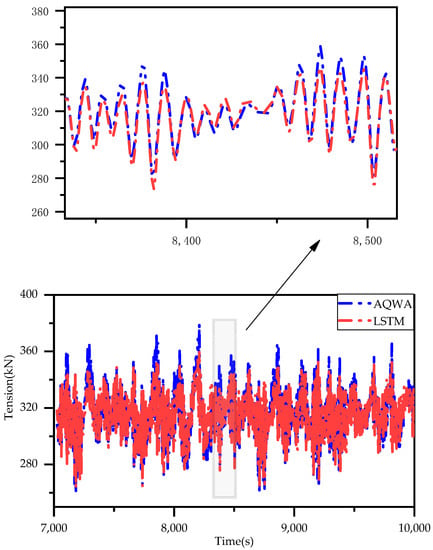

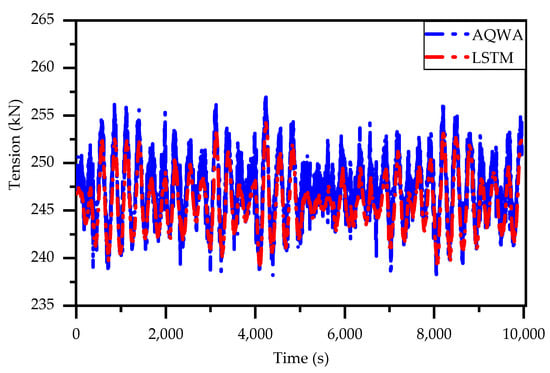

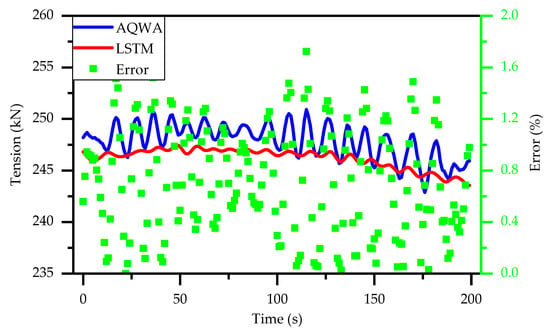

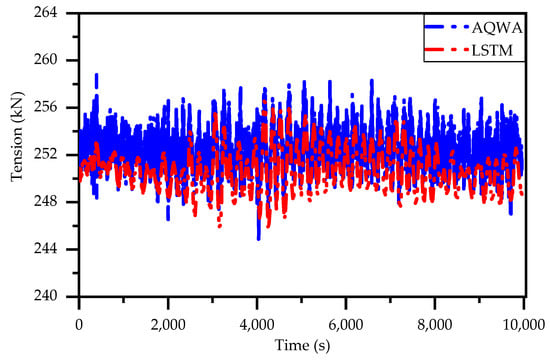

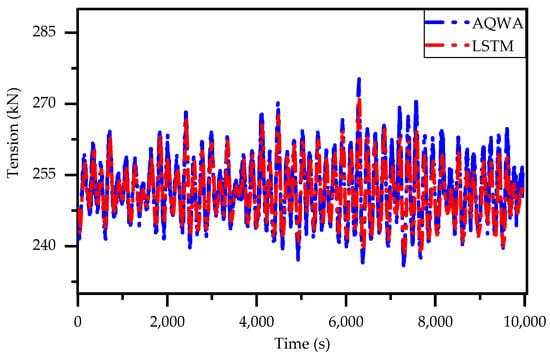

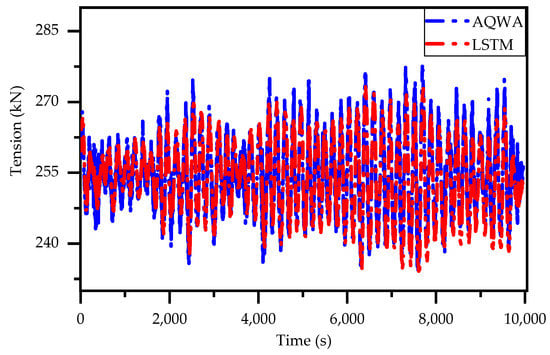

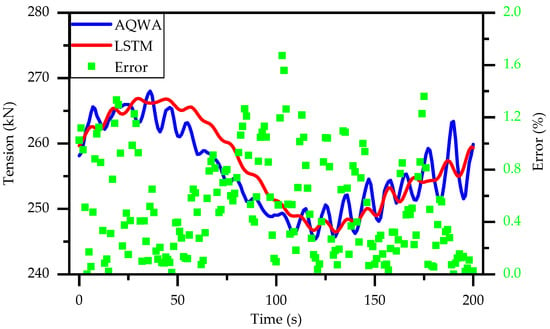

The LSTM model trained in Case 2 predicted the mooring tensions of the mooring system in four working conditions of the test set. Take out the test set, AD10 Mooring Line 8, AD35 Mooring Line 4, AD32 Mooring Line 3, AD7 Mooring Line 7 prediction results, and AQWA results to draw the time history curve, and draw the error distribution map for the first 200 s and statistics on the results of 4 test sets. These are shown in Figure 6, Figure 7, Figure 8, Figure 9, Figure 10, Figure 11, Figure 12 and Figure 13 and Table 13, Table 14, Table 15 and Table 16.

Figure 6.

Time history curve comparison of AD10 Mooring Line 8.

Figure 7.

Error analysis of AD10 Mooring Line 8.

Figure 8.

Time history curve comparison of AD7 Mooring Line 7.

Figure 9.

Error analysis of AD7 Mooring Line 7.

Figure 10.

Time history curve comparison of AD35 Mooring Line 4.

Figure 11.

Error analysis of AD35 Mooring Line 4.

Figure 12.

Time history curve comparison of AD32 Mooring Line 3.

Figure 13.

Error analysis of AD32 Mooring Line 3.

Table 13.

Result statistics of AD10.

Table 14.

Result statistics of AD7.

Table 15.

Result statistics of AD35.

Table 16.

Result statistics of AD32.

In Figure 6 and Figure 8, we showed a comparison chart of the mooring line tension calculated by LSTM and the results of the AQWA calculation; the blue curve represents the AQWA calculated value, and the red curve represents the LSTM predicted value. The prediction results of the AD10 and AD7 test sets are in good agreement with the AQWA calculation results in the low-frequency variation trend. As shown in Figure 7 and Figure 9, the value predicted by LSTM is slightly smaller than the value calculated by AQWA, the two curves vary identically in wave frequency, and the error is kept within 1.8%. As exhibited in Table 13 and Table 14, the maximum values of the result predicted by LSTM neural network are smaller than those calculated by AQWA, the minimum values of the result predicted by LSTM neural network are larger than those calculated by AQWA, and the average values and the standard deviation are very close. In general, the LSTM model built and trained here has high accuracy in predicting the tension of the mooring line and has the same trend in both low frequency and wave frequency when the wind, wave, and current come from the same direction.

In Figure 10 and Figure 12, we showed a comparison chart of mooring line tension calculated by LSTM and the results of the AQWA calculation; the blue curve shows the AQWA calculated value, and the red curve shows the LSTM predicted value. The prediction results of AD35 and AD32 test sets are in good agreement with the AQWA calculation results in the low-frequency variation trend. As shown in Figure 11 and Figure 13, the value predicted by LSTM is close to the value calculated by AQWA, and the error is kept within 1.8%, but the trend of wave frequency variation of the two curves is not very consistent. This could be because the wind, wave, and current are not in the same direction. As exhibited in Table 15 and Table 16, the maximum values of the result predicted by the LSTM neural network are smaller than those calculated by AQWA, the minimum values of the result predicted by the LSTM neural network are larger than those calculated by AQWA, and the average values and the standard deviation are very close. The standard deviations of the AD35 and AD32 are larger than those of the AD10 and AD7 due to the different directions of the wind, wave, and current. In general, the LSTM model built and trained here has high accuracy in predicting the tension of the mooring line and has the same trend in low frequency when wind, wave, and current come from a different direction. Compared with the prediction performance of wind, wave, and current in the same direction, the LSTM neural network model has poor prediction performance in wave frequency variation trend.

6. Conclusions

This paper studied the short-term prediction of the mooring tension of the FPSO inner turret single-point mooring system and used the commercial software AQWA to model and calculate the three-dimensional hull and mooring system. In this way, a data set of hull motion and mooring force was obtained, and then an LSTM neural network was built to train and predict the data set. Using the ship’s 5-DOF data calculated by the AQWA software in the time domain as input data, we obtained the predicted results of the tension and bowing of the nine mooring lines. The following conclusions are obtained through the research of this paper:

- (1)

- The LSTM model built here performs well in predicting the mooring tension.

- (2)

- In the prediction of mooring line tension under multiple combinations of wind, wave, and current, the predicted value does not deviate much from the true value, and the prediction result is relatively satisfactory, so the LSTM neural network model can learn the low-frequency trend regardless of whether the wind, wave, and current are in the same direction.

- (3)

- Here, the research on the prediction of the mooring line tension of the inner turret FPSO can realize the comparative analysis of the real-time measurement data and numerical calculation data at sea to a certain extent and provide a new calculation method for the calculation of the dynamic mooring line tension.

Author Contributions

Conceptualization, G.M.; methodology, J.Y.; software, C.J.; writing—original draft preparation, review and editing, P.L., C.J.; supervision, L.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant Nos. 51979050, 51739001, and 51979062).

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Minnebo, J.; Aalberts, P.; Duggal, A. Mooring System Monitoring using DGPS. In Proceedings of the 33rd ASME International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014. [Google Scholar]

- Correa, F.N.; Jacovazzo, B.M.; Alves de Lima, M.H., Jr.; Jacob, B.P. A reduced integration method for the coupled analysis of floating production systems. Ocean Eng. 2015, 104, 422–436. [Google Scholar] [CrossRef]

- Queau, L.M.; Kimiaei, M.; Randolph, M.F. Artificial neural network development for stress analysis of steel catenary risers: Sensitivity study and approximation of static stress range. Appl. Ocean Res. 2014, 48, 148–161. [Google Scholar] [CrossRef]

- Kim, Y. Finite memory quadratic Volterra model for the response prediction of a slender marine structure under a Morison load. J. Fluids Struct. 2015, 56, 75–88. [Google Scholar] [CrossRef]

- Mak, B.; Duz, B. Ship as a Wave Buoy: Using Simulated Data to Train Neural Networks for Real Time Estimation of Relative Wave Direction. In Proceedings of the 38th ASME International Conference on Ocean, Offshore and Arctic Engineering (OMAE 2019), Glasgow, UK, 9–14 June 2019. [Google Scholar]

- Chaves, V.; Sagrilo, L.V.S.; da Silva, V.R.M. Optimization of Flexible Pipes Dynamic Analysis using Artificial Neural Networks. In Proceedings of the 35th ASME International Conference on Ocean, Offshore and Arctic Engineering, Busan, Korea, 18–24 June 2016. [Google Scholar]

- Guo, X.; Zhang, X.; Tian, X.; Li, X.; Lu, W. Predicting heave and surge motions of a semi-submersible with neural networks. Appl. Ocean Res. 2021, 112, 102708. [Google Scholar] [CrossRef]

- Lin, Z.; Liu, X. Assessment of Wind Turbine Aero-Hydro-Servo-Elastic Modelling on the Effects of Mooring Line Tension via Deep Learning. Energies 2020, 13, 2264. [Google Scholar] [CrossRef]

- Li, C.B.; Choung, J. Fatigue damage analysis for a floating offshore wind turbine mooring line using the artificial neural network approach. Ships Offshore Struct. 2016, 12, S288–S295. [Google Scholar] [CrossRef]

- Janas, K.; Milne, I.A.; Whelan, J.R. Application of a convolutional neural network for mooring failure identification. Ocean Eng. 2021, 232, 109119. [Google Scholar] [CrossRef]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.-S.; Lee, J.-B.; Roh, M.-I.; Han, K.-M.; Lee, G.-H. Prediction of Ocean Weather Based on Denoising AutoEncoder and Convolutional LSTM. J. Mar. Sci. Eng. 2020, 8, 805. [Google Scholar] [CrossRef]

- Karevan, Z.; Suykens, J.A.K. Transductive LSTM for time-series prediction: An application to weather forecasting. Neural Netw. 2020, 125, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhang, T.; Han, G.; Gou, Y. TD-LSTM: Temporal Dependence-Based LSTM Networks for Marine Temperature Prediction. Sensors 2018, 18, 3797. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nelson, D.M.Q.; Pereira, A.C.M.; de Oliveira, R.A. Stock Market’s Price Movement Prediction with LSTM Neural Networks. In Proceedings of the International Joint Conference on Neural Networks (IJCNN), Anchorage, AK, USA, 14–19 May 2017; pp. 1419–1426. [Google Scholar]

- Duan, S.; Ma, Q.; Huang, L.; Ma, X. A LSTM deep learning model for deterministic ship motions estimation using wave-excitation inputs. In Proceedings of the 29th International Ocean and Polar Engineering Conference (ISOPE 2019), Honolulu, HI, USA, 16–21 June 2019; International Society of Offshore and Polar Engineers: Mountain View, CA, USA, 2019; pp. 959–965. [Google Scholar]

- Liu, Y.; Duan, W.; Huang, L.; Duan, S.; Ma, X. The input vector space optimization for LSTM deep learning model in real-time prediction of ship motions. Ocean Eng. 2020, 213, 107681. [Google Scholar] [CrossRef]

- Gumley, J.M.; Marcollo, H.; Wales, S.; Potts, A.E.; Carra, C.J. Application of Machine Learning Techniques as a Means of Mooring Integrity Monitoring. In Proceedings of the 38th ASME International Conference on Ocean, Offshore and Arctic Engineering (OMAE 2019), Glasgow, UK, 9–14 June 2019. [Google Scholar]

- Chung, M.; Kim, S.; Lee, K.; Shin, D. Detection of damaged mooring line based on deep neural networks. Ocean Eng. 2020, 209, 107522. [Google Scholar] [CrossRef]

- Sidarta, D.E.; Kyoung, J.; O’Sullivan, J.; Lambrakos, K.F. Prediction of Offshore Platform Mooring Line Tensions using Artificial Neural Network. In Proceedings of the 36th ASME International Conference on Ocean, Offshore and Arctic Engineering, Trondheim, Norway, 25–30 June 2017. [Google Scholar]

- Sidarta, D.E.; O’Sullivan, J.; Lim, H.J. Damage Detection of Offshore Platform Mooring Line Using Artificial Neural Network. In Proceedings of the 37th ASME International Conference on Ocean, Offshore and Arctic Engineering, Madrid, Spain, 17–22 June 2018. [Google Scholar]

- Guarize, R.; Matos, N.A.F.; Sagrilo, L.V.S.; Lima, E.C.P. Neural networks in the dynamic response analysis of slender marine structures. Appl. Ocean Res. 2007, 29, 191–198. [Google Scholar] [CrossRef]

- Saad, A.M.; Schopp, F.; Barreira, R.A.; Santos, I.H.F.; Tannuri, E.A.; Gomi, E.S.; Reali Costa, A.H. Using Neural Network Approaches to Detect Mooring Line Failure. IEEE Access 2021, 9, 27678–27695. [Google Scholar] [CrossRef]

- Qiao, D.; Li, P.; Ma, G.; Qi, X.; Yan, J.; Ning, D.; Li, B. Realtime prediction of dynamic mooring lines responses with LSTM neural network model. Ocean Eng. 2021, 219, 108368. [Google Scholar] [CrossRef]

- Qiao, D.; Li, B.; Yan, J.; Qin, Y.; Liang, H.; Ning, D. Transient Responses Evaluation of FPSO with Different Failure Scenarios of Mooring Lines. J. Mar. Sci. Eng. 2021, 9, 103. [Google Scholar] [CrossRef]

- American Petroleum Institute. Design and Analysis of Stationkeeping Systems for Floating Structures; American Petroleum Institute: Washington, DC, USA, 2005; pp. 60–64. [Google Scholar]

- Hall, M.; Goupee, A. Validation of a lumped-mass mooring line model with DeepCwind semisubmersible model test data. Ocean Eng. 2015, 104, 590–603. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Qiao, D.; Yan, J.; Tang, G.; Li, B.; Ning, D. A new approach to predict dynamic mooring tension using LSTM neural network based on responses of floating structure. Ocean Eng. 2022, 249, 110905. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).