Decision-Making on the Selection of Clean Energy Technology for Green Ships Based on the Rough Set and TOPSIS Method

Abstract

:1. Introduction

2. Clean Energy Technology Selection Method

2.1. Identification of Clean Energy Technology Alternatives

2.2. Determination of Target Attributes of Clean Energy Technology Program

2.3. RS Method to Determine Attribute Weights

2.4. TOPSIS Method to Determine Alternatives Ranking

3. Case Studies

3.1. Data Collection

3.2. Clean Energy Technology Choice Decision Results

3.2.1. Weight Calculation

3.2.2. Ranking of Clean Energy Technology Alternatives

4. Discussion

5. Conclusions

- (1)

- Under uncertain conditions, this paper constructed a clean energy technology selection model and established a clean energy technology evaluation index system for green ships, containing 12 indicators in four dimensions, including economic, technical, environment, and safety. The key indicators that affect the selection of clean energy technology solutions are extracted from the two types of ro-ro passenger ships and short-distance small ships in inland rivers. The assessment results show that technical maturity, volumetric energy density, technical application readiness, energy cost, investment cost, effect on CO2 reduction, and probability of risk occurrence are the key factors affecting the choice of clean energy technology options; the results are in line with reality. The paper provides a measure for the selection of clean energy technology solutions for different ship types in different waters.

- (2)

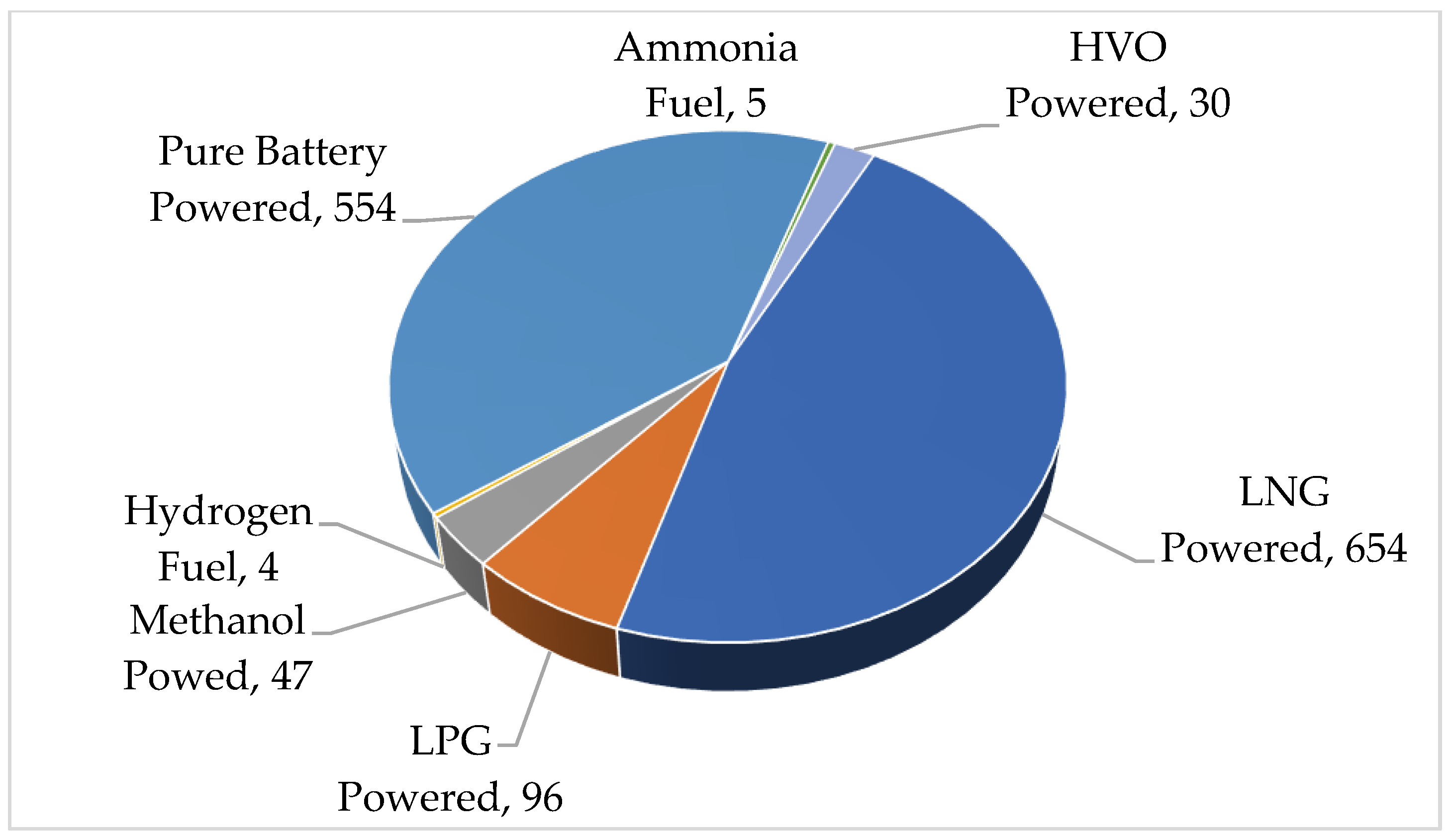

- Seven clean energy technology alternatives such as LNG power, LPG power, methanol power, pure battery power, hydrogen fuel cell, ammonia fuel cell, and biofuel power are considered for different ship types. It is found that LNG power technology is the best solution for the decarbonization transition of large coastal ro-ro passenger ships at this stage, and pure battery power technology is the best clean energy technology for small short-distance inland river ships. The results obtained are in line with reality.

- (3)

- The RS theory and TOPSIS method are combined to effectively determine the selection alternatives of clean energy technologies for green ships. This method converts the qualitative description of the applicability of existing clean energy technologies into a quantitative expression, which enhances the objectivity and scientificity of the evaluation results. The proposed method provides new insights in the field of clean energy technologies selection problems. Therefore, the proposed method is feasible and can be used to select the best clean energy technology option from multiple alternatives under uncertainty.

- (1)

- The application of clean energy technology for green ships is an emerging research field. Based on the limitation of data availability, the quantification of indicators in this paper has certain restrictions, and the current data comes from secondary information. Subsequently, with the expansion of the application scenario of green ship clean energy technology and the enrichment of relevant indicator data, it is intended to extract the relevant indicators and data of clean energy technology of different ship types in different waters, and apply them to the model to make the decision-making results more accurate.

- (2)

- Furthermore, the research methods proposed in this paper will be extended and applied to more ship types and different waters. Meanwhile, other multi-criteria selection decision-making methods will be explored and compared with the model results of existing research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Andreas, B.; Klaus, M. Standing up for the Paris Agreement: Do global climate targets influence individuals’ greenhouse gas emissions? Environ. Sci. Pol. 2019, 99, 72–79. [Google Scholar]

- Mersin, K. Review of Total Emission of Transit Ships in the Dardanelle. Therm. Sci. 2020, 24 (Suppl. S1), S391–S398. [Google Scholar] [CrossRef]

- IMO. Fourth IMO GHG Study 2020—Final Report; International Maritime Organization: London, UK, 2020. [Google Scholar]

- Paulauskas, V.; Filina-Dawidowicz, L.; Paulauskas, D. The Method to Decrease Emissions from Ships in Port Areas. Sustainability 2020, 12, 4374. [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, J.; Yan, X.; Shen, B.; Long, T. A review of multi-energy hybrid power system for ships. Renew. Sustain. Energy Rev. 2020, 132, 110081. [Google Scholar] [CrossRef]

- DNV GL (2020a). Maritime Forecast to 2050—Energy Transition Outlook 2020, DNV GL. Available online: https://eto.dnv.com/2020/Maritime/ (accessed on 16 April 2021).

- Akerman, P.; Cazzola, P.; Christiansen, E.S.; Van Heusden, R.; Kolomanska-van Iperen, J.; Christensen, J.; Crone, K.; Dawe, K.; De Smedt, G.; Keynes, A.; et al. Reaching Zero with Renewables; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2020. [Google Scholar]

- Li, Y. The future direction of green ships. China Ship Surv. 2013, 12, 70–74. [Google Scholar]

- Jeon, H.; Park, K.; Kim, J. Comparison and Verification of Reliability Assessment Techniques for Fuel Cell-Based Hybrid Power System for Ships. J. Mar. Sci. Eng. 2020, 8, 74. [Google Scholar] [CrossRef] [Green Version]

- Yan, X.P. Progress Review of New Energy Application in Ship. Ship Ocean. Eng. 2010, 39, 111–115, 120. [Google Scholar]

- Qin, Q.; Wang, Y.-z. Global new energy (clean) ship and related intelligent technology development. Ship Boat 2018, 29 (Suppl. S1), 29–41. [Google Scholar]

- Viktorelius, M. Adoption and use of energy-monitoring technology in ship officers’ communities of practice. Cogn. Technol. Work 2019, 22, 459–471. [Google Scholar] [CrossRef] [Green Version]

- DNV GL, 2019a. Alternative Fuels Narrative. Available online: https://globalmaritimehub.com/wp-content/uploads/2019/11/SEALNG_Alternative_fuels_narrative_V22.pdf (accessed on 7 April 2021).

- Xing, H.; Stuart, C.; Spence, S.; Chen, H. Alternative fuel options for low carbon maritime transportation: Pathways to 2050. J. Clean. Prod. 2021, 297, 126651. [Google Scholar] [CrossRef]

- Ren, J.; Lützen, M. Fuzzy multi-criteria decision-making method for technology selection for emissions reduction from shipping under uncertainties. Transp. Res. Part D Transp. Environ. 2015, 40, 43–60. [Google Scholar] [CrossRef]

- Ren, J.Z.; Lutzen, M. Selection of sustainable alternative energy source for shipping: Multi criteria decision-making under incomplete information. Renew. Sustain. Energy Rev. 2017, 74, 1003–1019. [Google Scholar] [CrossRef]

- Bui, K.Q.; Olcer, A.I.; Kitada, M.; Ballini, F. Selecting technological alternatives for regulatory compliance towards emissions reduction from shipping: An integrated fuzzy multi-criteria decision-making approach under vague environment. Proc. Inst. Mech. Eng. Part M-J. Eng. Marit. Environ. 2021, 235, 272–287. [Google Scholar] [CrossRef]

- Kim, A.R.; Seo, Y.J. The reduction of SOx emissions in the shipping industry: The case of Korean companies. Mar. Policy 2019, 100, 98–106. [Google Scholar] [CrossRef]

- Seddiek, I.S.; Elgohary, M.M. Eco-friendly selection of ship emissions reduction strategies with emphasis on SOx and NOx emissions. Int. J. Nav. Arch. Ocean Eng. 2014, 6, 737–748. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Zhang, D.; Caglayan, O.; Jenkinson, I.; Bonsall, S.; Wang, J.; Huang, M.; Yan, X. Selection of techniques for reducing shipping NOx and SOx emissions. Transp. Res. Part D Transp. Environ. 2012, 17, 478–486. [Google Scholar] [CrossRef]

- Haehl, C.; Spinler, S. Technology Choice under Emission Regulation Uncertainty in International Container Shipping. Eur. J. Oper. Res. 2019, 284, 383–396. [Google Scholar] [CrossRef]

- Sahin, B.; Yip, T.L. Shipping technology selection for dynamic capability based on improved Gaussian fuzzy AHP model. Ocean. Eng. 2017, 136, 233–242. [Google Scholar] [CrossRef]

- Inal, O.B.; Deniz, C. Assessment of fuel cell types for ships: Based on multi-criteria decision analysis. J. Clean. Prod. 2020, 265, 121734. [Google Scholar] [CrossRef]

- Gilbert, P.; Walsh, C.; Traut, M.; Kesieme, U.; Pazouki, K.; Murphy, A. Assessment of full life-cycle air emissions of alternative shipping fuels. J. Clean. Prod. 2018, 172, 855–866. [Google Scholar] [CrossRef]

- Perčić, M.; Vladimir, N.; Fan, A. Life-cycle cost assessment of alternative marine fuels to reduce the carbon footprint in short-sea shipping: A case study of Croatia. Appl. Energy 2020, 279, 115848. [Google Scholar] [CrossRef]

- Perčić, M.; Vladimir, N.; Fan, A. Techno-economic assessment of alternative marine fuels for inland shipping in Croatia. Renew. Sustain. Energy Rev. 2021, 148, 111363. [Google Scholar] [CrossRef]

- Fan, A.; Wang, J.; He, Y.; Perčić, M.; Vladimir, N.; Yang, L. Decarbonising inland ship power system: Alternative solution and assessment method. Energy 2021, 226, 120266. [Google Scholar] [CrossRef]

- Riberio, F.; Ferreira, P.; Araújo, M. Evaluating future scenarios for the power generation sector using a Multi-Criteria Decisions Analysis (MCDA) tool: The Portuguese case. Energy 2013, 52, 126–136. [Google Scholar] [CrossRef] [Green Version]

- Acciaro, M.; Hoffmann, P.N.; Eide, M.S. The energy efficiency gap in maritime transport. J. Shipp. Ocean. Eng. 2013, 3, 1. [Google Scholar]

- Rojon, I.; Dieperink, C. Blowin’in the wind? Drivers and barriers for the uptake of wind propulsion in international shipping. Energy Policy 2014, 67, 394–402. [Google Scholar] [CrossRef]

- IRENA. Renewablenenergy Options for Shipping—A Technology Brief; The International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2015. [Google Scholar]

- Andersson, K.; Brynolf, S.; Hansson, J.; Grahn, M. Criteria and Decision Support for a Sustainable Choice of Alternative Marine Fuels. Sustainability 2020, 12, 3623. [Google Scholar] [CrossRef]

- Ampah, J.D.; Yusuf, A.A.; Afrane, S.; Jin, C.; Liu, H. Reviewing two decades of cleaner alternative marine fuels: Towards IMO’s decarbonization of the maritime transport sector. J. Clean. Prod. 2021, 320, 128871. [Google Scholar] [CrossRef]

- ABS. Decarbonization of the Inland Water Sector in the United States. American Bureau of Shipping. September 2021. Available online: https://absinfo.eagle.org/acton/media/16130/decarbonization-of-the-inland-waterway-sector-in-the-united-states (accessed on 12 January 2022).

- ABS. Setting the Course to Low Carbon Shipping. American Bureau of Shipping. September 2021. Available online: https://absinfo.eagle.org/acton/media/16130/setting-the-course-to-low-carbon-shipping-outlook-i (accessed on 23 December 2021).

- Pawlak, Z. Rough set. Int. J. Inf. Comput. Sci. 1982, 11, 341–356. [Google Scholar] [CrossRef]

- Pattaraintakorn, P.; Cercone, N. Integrating rough set theory and medical applications. Appl. Math. Lett. 2008, 21, 400–403. [Google Scholar] [CrossRef] [Green Version]

- Hong, T.; Tseng, L.; Wang, S. Learning rules from incomplete training examples by rough sets. Expert Syst. Appl. 2002, 22, 285–293. [Google Scholar] [CrossRef]

- Wang, H.; Wang, S. Discovering patterns of missing data in survey databases: An application of rough sets. Expert Syst. Appl. 2009, 36, 6256–6260. [Google Scholar] [CrossRef]

- Lingras, P.J.; Yao, Y. Data mining using extensions of the rough set model. J. Am. Soc. Inf. Sci. 1998, 49, 415–422. [Google Scholar] [CrossRef]

- Pawlak, Z. Rough Sets: Theoretical Aspects of Reasoning about Data; Springer Science & Business Media: Berlin, Germany, 1991. [Google Scholar]

- Tzeng, G.H.; Huang, J.J. Multiple Attribute Decision Making: Methods and Applications; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

| Technologies | Technology Classification | Technology Name |

|---|---|---|

| Clean Energy Technologies | Alternative Fuels Technologies | Low-carbon fuel technologies: LNG fuel, LPG fuel, dual-fuel, methanol, HVO, etc. |

| Zero-carbon fuel technologies: hydrogen fuel, ammonia fuel, biofuel (bio-LNG, bio-methanol), etc. | ||

| Electric Power Technologies | Pure battery power technology, fuel cell technology, supercapacitor, hybrid power | |

| Renewable Energy | Solar energy technology, wind-assisted propulsion technology, bioenergy technology, hydro energy technology, wave energy technology | |

| Nuclear Energy Technology | Nuclear propulsion technology |

| Guideline Level | Indicator Level | Definition |

|---|---|---|

| Economic | Investment Cost (C1) [15,16] | The cost of retrofitting and new construction of clean energy propulsion systems and supporting infrastructure increases or decreases compared to fuel oil ships |

| Energy Cost (C2) [15,16] | The degree of increase or decrease in the fuel cost of clean energy ships compared to fuel oil ships | |

| Technical | Volumetric Energy density (C3) [13,14] | The energy contained in a unit volume, the higher the value, the smaller the required fuel tank volume, and the better the ship’s endurance |

| Technical Maturity (C4) [13,14] | The maturity level of energy application technologies and power systems | |

| Energy Availability (C5) [13,14] | The shipping industry belongs to the downstream end-use of the energy industry chain and depends on the supply capacity of the upstream energy industry | |

| Technical Application Readiness (C6) [13,14] | Specific requirements of the technology application, such as the difficulty of the technology in terms of vessel type, supporting infrastructure layout, and considering the maturity and availability of the technology and energy | |

| Environment | Effect on CO2 Reduction (C7) [15,16] | Reduction of CO2 emissions after fuel oil substitution |

| Effect on NOx Reduction (C8) [15,16] | Reduction of NOx emissions after fuel oil substitution | |

| Effect on SOx Reduction (C9) [15,16] | Reduction of SOx emissions after fuel oil substitution | |

| Effect on PM Reduction (C10) [15,16] | Reduction of PM missions after fuel oil substitution | |

| Safety | Probability of Risk Occurrence (C11) [14] | In the process of energy filling, storage, and supply, the probability of energy leakage depends on the characteristics of fuel, such as auto-ignition point and flashpoint. In this paper, the flammability and explosiveness of fuel represent the probability of risk occurrence. |

| The severity of Consequences (C12) [14] | In the event of energy leakage, the harm to the environment and the human body is characterized by the fuel toxicity in this paper. |

| Criteria | LNG Powered (T1) | LPG Powered (T2) | Methanol Powered (T3) | HVO Powered (T4) | Ammonia Fuel Cell (T5) | Hydrogen Fuel Cell (T6) | Pure Battery Powered (T7) |

|---|---|---|---|---|---|---|---|

| Investment Cost (C1) | 4 | 4 | 4 | 5 | 3 | 1 | V a |

| Energy Cost (C2) | 5 | 5 | 3 | 2 | 1 | 1 | V a |

| Volumetric Energy Density (C3) | 4 | 4 | 4 | 5 | 3 | 2 | 1 |

| Technical Maturity (C4) | 5 | 4 | 3 | 5 | 2 | 1 | 3 |

| Energy Availability (C5) | 4 | 4 | 3 | 1 | 2 | 1 | 2 |

| Technical Application Readiness (C6) | 5 | 3 | 4 | 3 | 2 | 1 | V |

| Effect on CO2 Reduction (C7) | 1 | 1 | 1 | 3 | 5 | 5 | 5 |

| Effect on NOx Reduction (C8) | 5 | 1 | 3 | 1 | 5 | 5 | 5 |

| Effect on SOx Reduction (C9) | 5 | 5 | 5 | 4 | 5 | 5 | 5 |

| Effect on PM Reduction (C10) | 5 | 5 | 5 | 3 | 5 | 5 | 5 |

| Probability of Risk Occurrence (C11) | 1 | 2 | 4 | 5 | 2 | 1 | 5 |

| Severity of Consequences (C12) | 5 | 5 | 3 | 5 | 1 | 5 | 5 |

| Ship Type Parameters | Length (m) | Breadth (m) | Depth (m) | Tonnage (t) | Design Speed (km/h) | Distance (km) |

|---|---|---|---|---|---|---|

| Inland River Ship (type 1) | 71.4 | 12.6 | 3.3 | 1165 | 14.8 | 250 |

| Coastal Ship (type 2) | 119.88 | 20.3 | 6 | 8965 | 13.8 | 33 |

| Criteria | T1 | T2 | T3 | T4 | T5 | T6 | T7 |

|---|---|---|---|---|---|---|---|

| Investment Cost (C1) | 4 | 4 | 4 | 5 | 3 | 1 | 5 (3) * |

| Energy Cost (C2) | 5 | 5 | 3 | 2 | 1 | 1 | 5 (3) |

| Volume Energy Density (C3) | 4 | 4 | 4 | 5 | 3 | 2 | 1 |

| Technical Maturity (C4) | 5 | 4 | 3 | 5 | 2 | 1 | 3 |

| Energy Availability (C5) | 4 | 4 | 3 | 1 | 2 | 1 | 2 |

| Technical Application Readiness (C6) | 5 | 3 | 4 | 3 | 2 | 1 | 5 (3) |

| Effect on CO2 Reduction (C7) | 1 | 1 | 1 | 3 | 5 | 5 | 5 |

| Effect on NOx Reduction (C8) | 5 | 1 | 3 | 1 | 5 | 5 | 5 |

| Effect on SOx Reduction (C9) | 5 | 5 | 5 | 4 | 5 | 5 | 5 |

| Effect on PM Reduction (C10) | 5 | 5 | 5 | 3 | 5 | 5 | 5 |

| Probability of Risk Occurrence (C11) | 1 | 2 | 4 | 5 | 2 | 1 | 5 |

| Severity of Consequences (C12) | 5 | 5 | 3 | 5 | 1 | 5 | 5 |

| Ship Type | Attributes | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C11 | C12 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Type 1 | Importance | 0.81 | 0.81 | 0.86 | 0.90 | 0.86 | 0.90 | 0.71 | 0.67 | 0.86 | 0.52 |

| Weights | 0.102 | 0.102 | 0.108 | 0.114 | 0.108 | 0.114 | 0.090 | 0.084 | 0.108 | 0.066 | |

| Type 2 | Importance | 0.81 | 0.86 | 0.86 | 0.90 | 0.86 | 0.86 | 0.71 | 0.67 | 0.86 | 0.52 |

| Weights | 0.102 | 0.108 | 0.108 | 0.114 | 0.108 | 0.108 | 0.090 | 0.084 | 0.108 | 0.066 |

| Ship Type | Ship Type 1 (Small Inland River Short-Distance Cargo Ship) | Ship Type 2 (Large Coastal Ro-Ro Passenger Ship) | ||||||

|---|---|---|---|---|---|---|---|---|

| Programs | sort | sort | ||||||

| LNG Powered T1 | 0.15 | 0.26 | 0.638 | 2 | 0.15 | 0.26 | 0.638 | 1 |

| LPG Powered T2 | 0.16 | 0.21 | 0.569 | 5 | 0.35 | 0.22 | 0.378 | 2 |

| Methanol Powered T3 | 0.14 | 0.20 | 0.584 | 4 | 0.44 | 0.19 | 0.308 | 5 |

| HVO Powered T4 | 0.15 | 0.24 | 0.612 | 3 | 0.45 | 0.24 | 0.347 | 3 |

| Ammonia Fuel Cell T5 | 0.21 | 0.15 | 0.427 | 6 | 0.42 | 0.15 | 0.267 | 7 |

| Hydrogen Fuel Cell T6 | 0.26 | 0.14 | 0.351 | 7 | 0.38 | 0.14 | 0.275 | 6 |

| Pure Battery Powered T7 | 0.13 | 0.26 | 0.664 | 1 | 0.45 | 0.21 | 0.317 | 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xuan, H.; Liu, Q.; Wang, L.; Yang, L. Decision-Making on the Selection of Clean Energy Technology for Green Ships Based on the Rough Set and TOPSIS Method. J. Mar. Sci. Eng. 2022, 10, 579. https://doi.org/10.3390/jmse10050579

Xuan H, Liu Q, Wang L, Yang L. Decision-Making on the Selection of Clean Energy Technology for Green Ships Based on the Rough Set and TOPSIS Method. Journal of Marine Science and Engineering. 2022; 10(5):579. https://doi.org/10.3390/jmse10050579

Chicago/Turabian StyleXuan, Huihui, Qing Liu, Lei Wang, and Liu Yang. 2022. "Decision-Making on the Selection of Clean Energy Technology for Green Ships Based on the Rough Set and TOPSIS Method" Journal of Marine Science and Engineering 10, no. 5: 579. https://doi.org/10.3390/jmse10050579

APA StyleXuan, H., Liu, Q., Wang, L., & Yang, L. (2022). Decision-Making on the Selection of Clean Energy Technology for Green Ships Based on the Rough Set and TOPSIS Method. Journal of Marine Science and Engineering, 10(5), 579. https://doi.org/10.3390/jmse10050579