Full-Field Deformation-Aided Compressive Failure Evaluation of Seawater Concrete Using Digital Image Correlation Technique

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Component Design of the Seawater Concrete

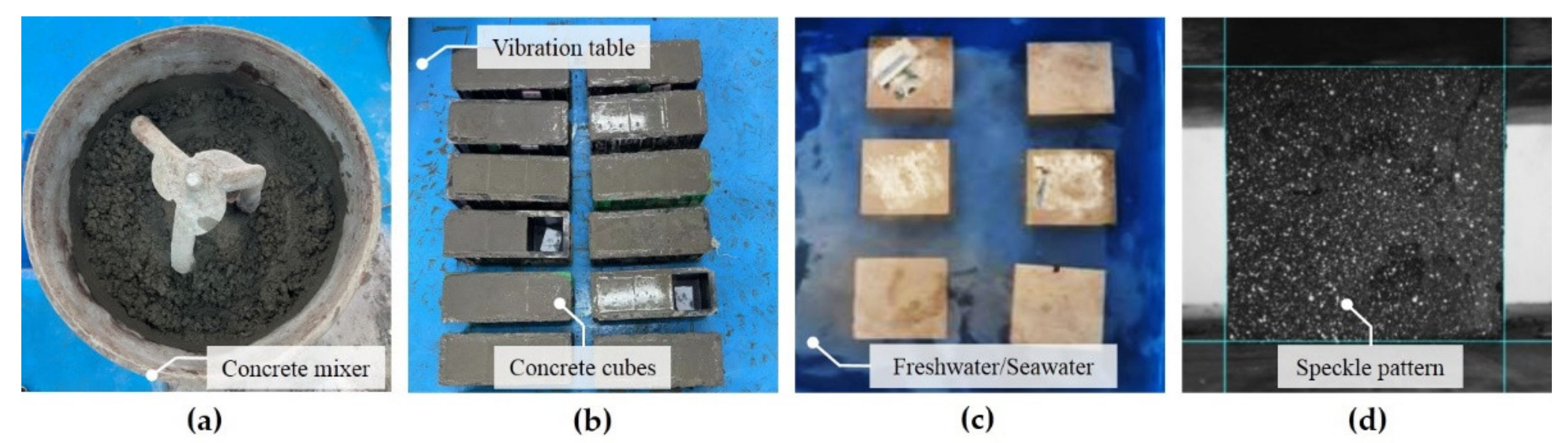

2.2. Preparation of the Specimen

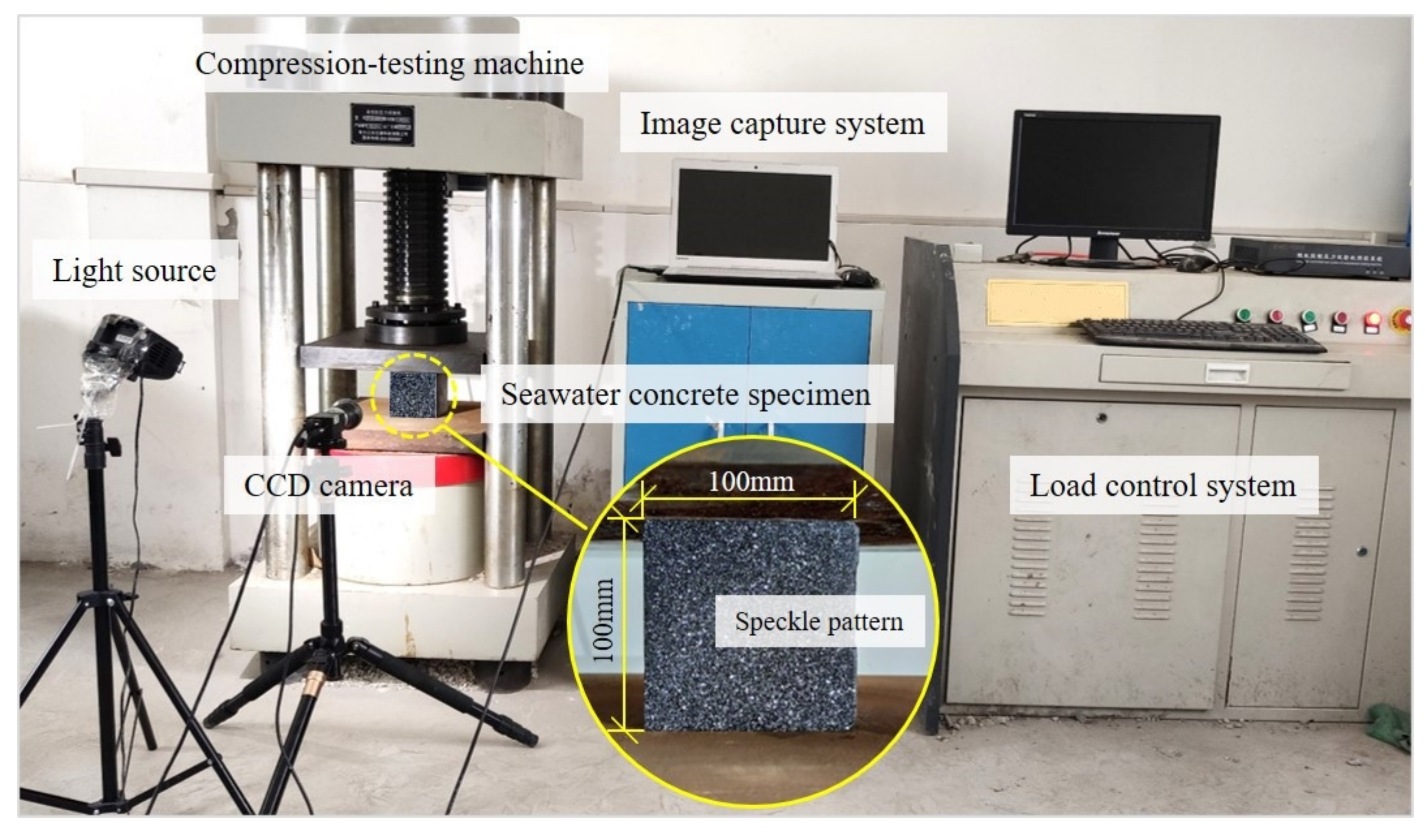

2.3. Uniaxial Compression Test and Digital Speckle Image Capturing

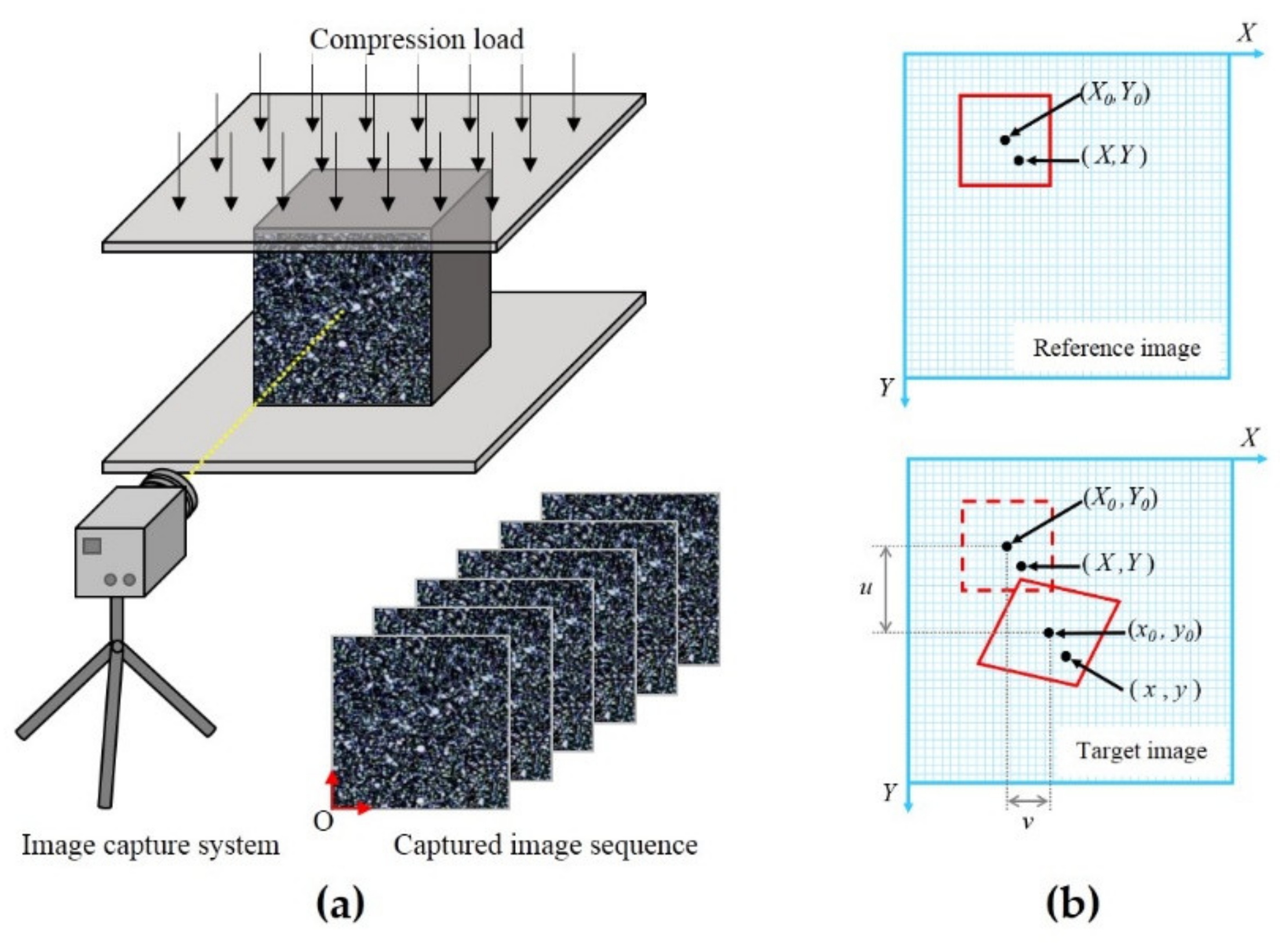

2.4. Digital Image Correlation Algorithm

3. Full-Field Deformation Measurement

3.1. Compressive Displacement Measurement of OPC-Based Concrete

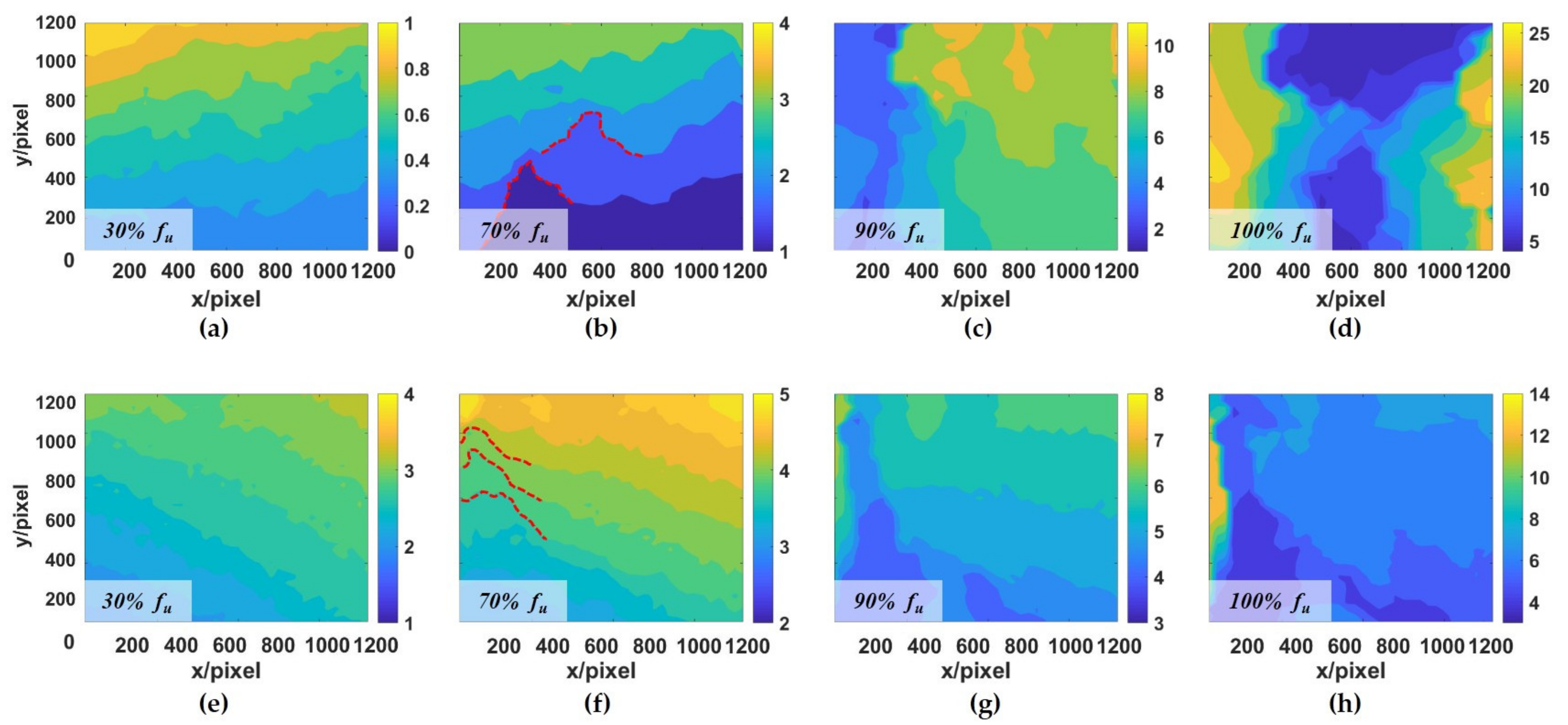

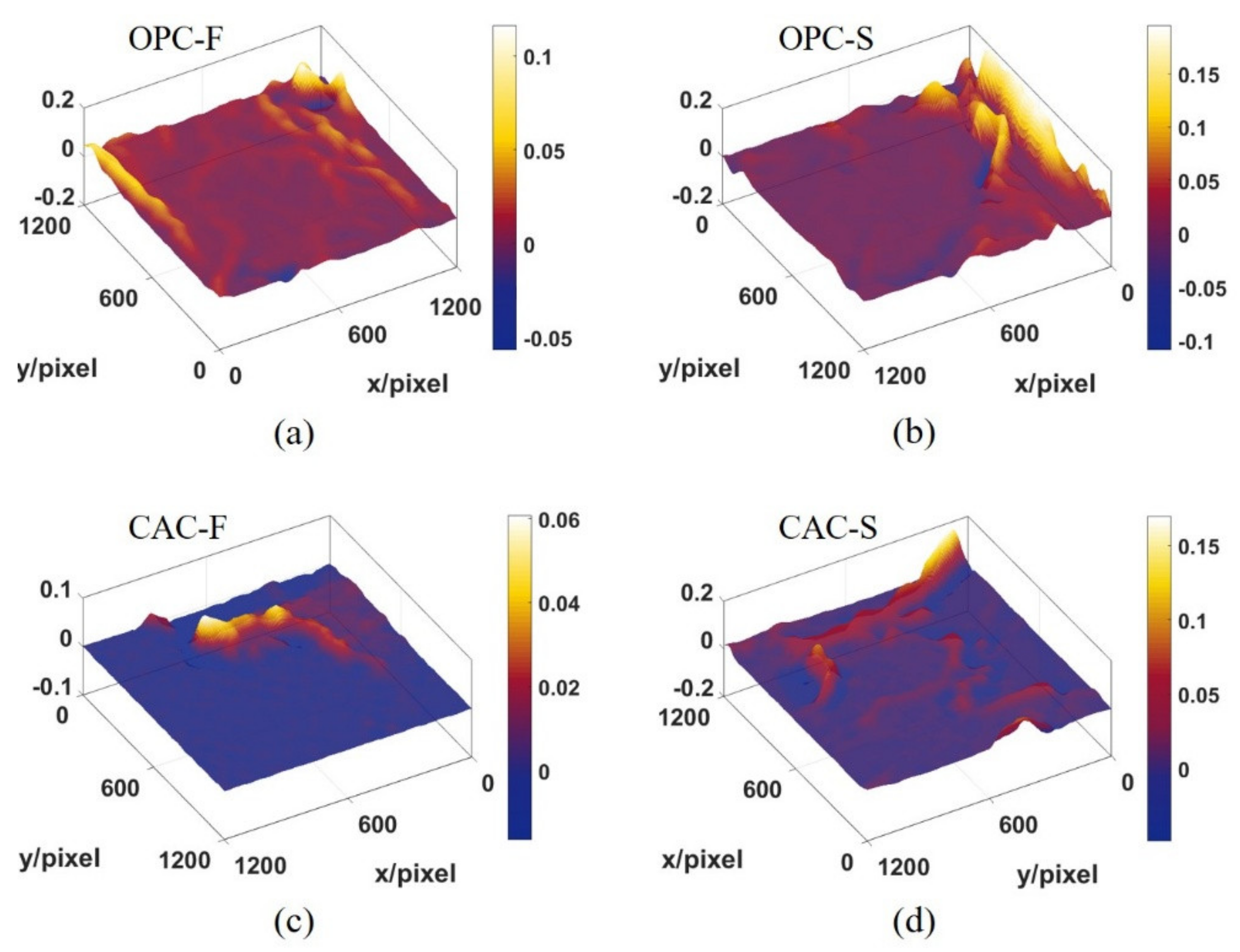

3.2. Strain Field Analysis of OPC-Based Concrete

4. Failure Behavior Evaluation

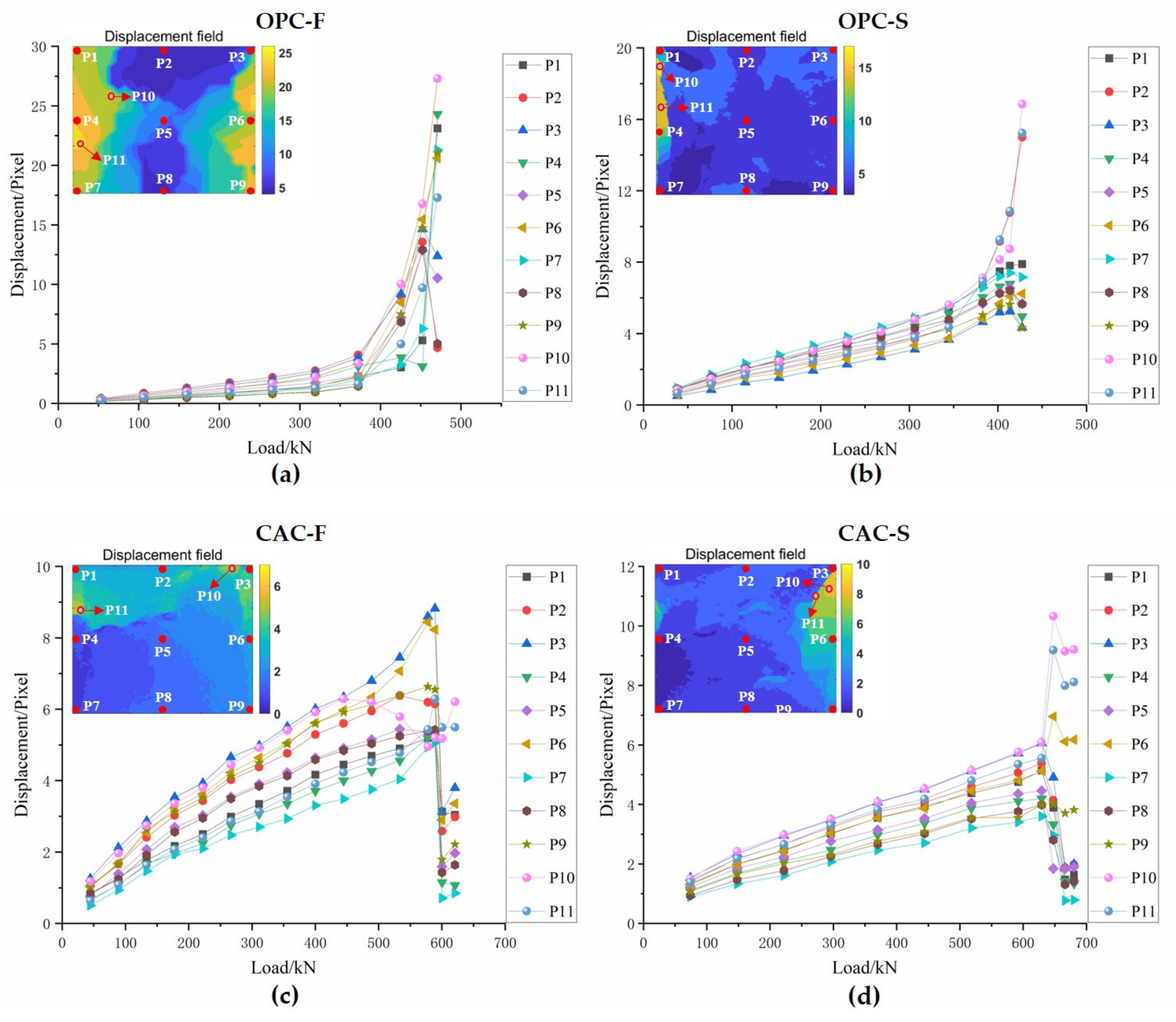

4.1. Compressive Deformation Analysis

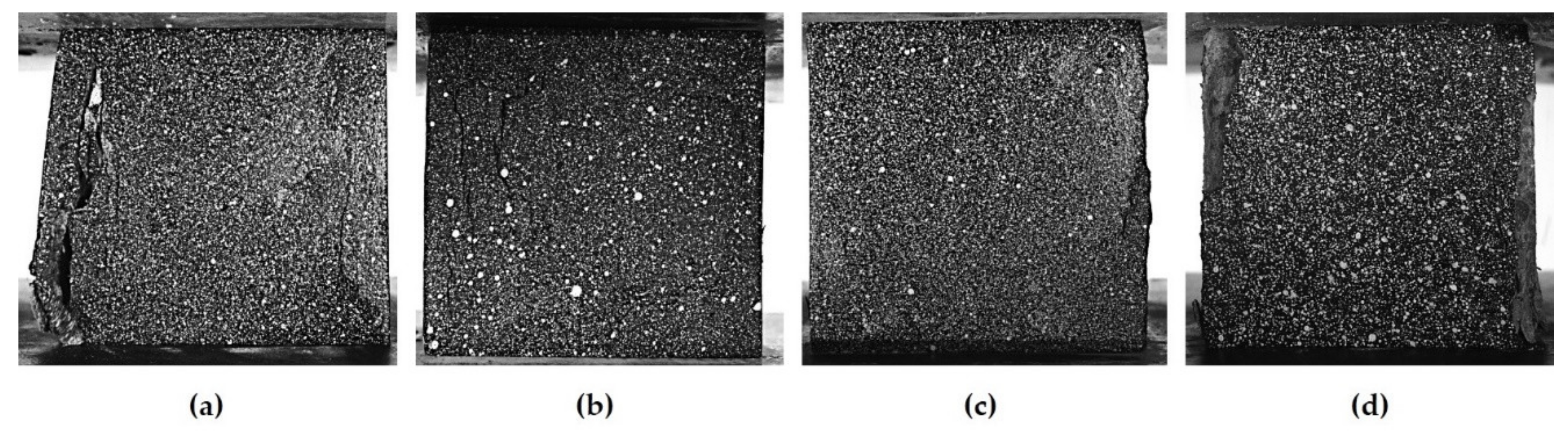

4.2. Crack Propagation Analysis

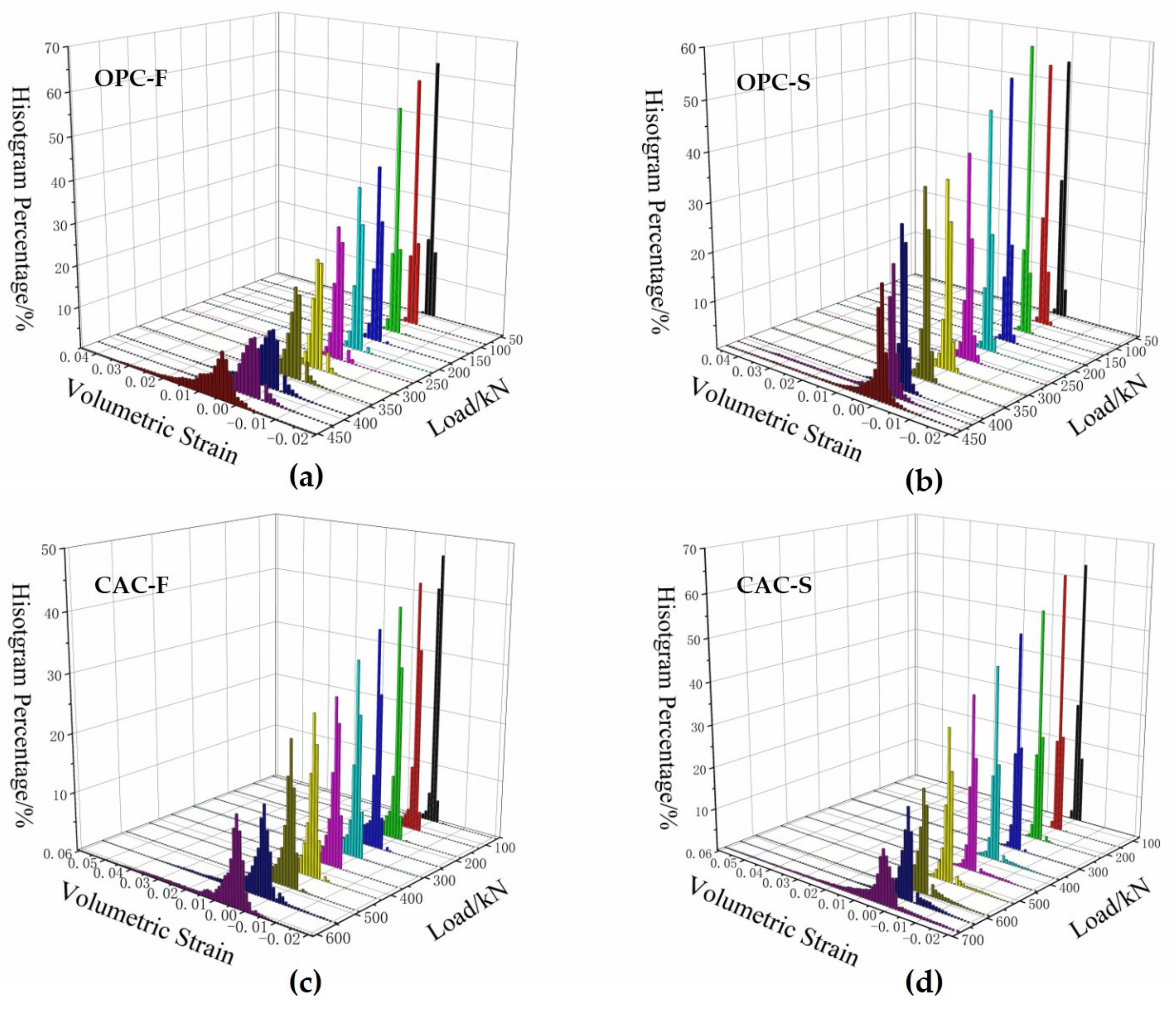

4.3. Volumetric Strain Histogram Evaluation

5. Conclusions

- (1)

- The DIC technique could be employed to obtain displacement fields of seawater concretes during the whole compressive loading process, by which the failure behavior of the samples at different loading stages could be recorded. The peak-shape region observed in the displacement field indicated the initiation of the cracks, and the displacement gradients could be used to predict the failure of concrete. The cyclo-hoop effect was observed in the displacement field of OPC-F but not found in OPC-S.

- (2)

- The spatial distribution of strains on the cube concrete indicated the deformation characteristics of OPC-based concretes. It was revealed that the OPC-S concrete experienced biaxial and shear deformation under uniaxial compressive load whereas the OPC-F concrete mainly experienced latitudinal tensile deformation. The OPC-S concrete presented higher compressive strength in comparison with the OPC-F concrete.

- (3)

- Displacement-loading curves were plotted based on the displacement data of selected points all over the concrete surface of OPC- and CAC-based concretes, indicating that the failure of the OPC-based concrete was ductile but the CAC-based concrete was brittle.

- (4)

- The volumetric strain fields of seawater concretes could be constructed based on the DIC strain data, by which the spatial distribution and scales of compressive-load-induced cracks could be clearly exhibited. It was demonstrated that cracks generated in OPC-S were larger and distributed more concentrated in a local region compared with OPC-F. On the contrary, cracks in CAC-S were adversely widely-spread in comparison with CAC-F.

- (5)

- The volumetric strain histogram percentage was introduced to quantitatively evaluate the failure behavior of four groups of seawater concrete. The distribution and percentage of volumetric strain histogram revealed that the volume change of OPC-F was much larger and had a wide distribution whereas the OPC-S presented smaller expansion. Comparatively, failure of the CAC-F concrete behaved local fracture while a larger area in CAC-S concrete expanded under the uniaxial compressive load.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ebead, U.; Lau, D.; Lollini, F.; Nanni, A.; Suraneni, P.; Yu, T. A review of recent advances in the science and technology of seawater-mixed concrete. Cem. Concr. Res. 2022, 152, 106666. [Google Scholar] [CrossRef]

- Khatibmasjedi, M.; Ramanathan, S.; Suraneni, P.; Nanni, A. Compressive strength development of seawater-mixed concrete subject to different curing regimes. ACI Mater. J. 2020, 117, 3–12. [Google Scholar] [CrossRef]

- Chen, M.; Geng, J.; Xiong, H.; Shang, T.; Xue, C.; Abbas, M. Effect of curing on mechanical properties of cement-stabilized coral sand in marine environment. Adv. Mater. Sci. Eng. 2020, 2020, 4678376. [Google Scholar] [CrossRef]

- Hossain, K.M.A. Pumice based blended cement concretes exposed to marine environment: Effects of mix composition and curing conditions. Cem. Concr. Compos. 2008, 30, 97–105. [Google Scholar] [CrossRef]

- Camba, C.; Mier, J.L.; Carral, L.; Lamas, M.I.; Alvarez, J.C.; Diaz-Diaz, A.M.; Tarrio-Saavedra, J. Erosive degradation study of concrete augmented by mussel shells for marine construction. J. Mar. Sci. Eng. 2021, 9, 1087. [Google Scholar] [CrossRef]

- Shao, W.; Shi, D. Numerical simulation of degradation behavior of concrete piles in sulfate saline soils. KSCE J. Civ. Eng. 2022, 26, 183–192. [Google Scholar] [CrossRef]

- Takahiro, N.; Nobuaki, O.; Hiroki, O.; Zoulkanel, M.G.; Tomohiro, N. Some considerations for applicability of seawater as mixing water in concrete. J. Mater. Civ. Eng. 2015, 27, B4014004. [Google Scholar]

- Dimri, A.; Varshney, J.K.; Verma, V.K.; Gupta, S. A review on strength of concrete in seawater. Int. J. Eng. Res. Technol. 2015, 4, 844–847. [Google Scholar]

- Guo, M.; Hu, B.; Xing, F.; Zhou, X.; Sun, M.; Sui, L.; Zhou, Y. Characterization of the mechanical properties of eco-friendly concrete made with untreated sea sand and seawater based on statistical analysis. Constr. Build. Mater. 2020, 234, 117339. [Google Scholar] [CrossRef]

- Chen, Z.; Mo, L.; Song, C.; Zhang, Y. Investigation on compression properties of seawater-sea sand concrete. Adv. Concr. Constr. 2021, 12, 93–103. [Google Scholar]

- Yang, S.; Xu, J.; Zang, C.; Li, R.; Yang, Q.; Sun, S. Mechanical properties of alkali-activated slag concrete mixed by seawater and sea sand. Constr. Build. Mater. 2019, 196, 395–410. [Google Scholar] [CrossRef]

- Xiao, J.; Huang, Y.; Yang, J.; Zhang, C. Mechanical properties of confined recycled aggregate concrete under axial compression. Constr. Build. Mater. 2012, 26, 591–603. [Google Scholar] [CrossRef]

- Shan, B.; Xu, C.; Lai, D.; Xiao, Y.; Li, T. Experimental research on compressive behavior of seawater and sea sand concrete-filled RPC tubes. Eng. Struct. 2020, 222, 111117. [Google Scholar] [CrossRef]

- Huang, Y.; He, X.; Wang, Q.; Sun, Y. Mechanical properties of sea sand recycled aggregate concrete under axial compression. Constr. Build. Mater. 2018, 175, 55–63. [Google Scholar] [CrossRef]

- Da, B.; Yu, H.; Ma, H.; Wu, Z. Research on compression behavior of coral aggregate reinforced concrete columns under large eccentric compression loading. Ocean Eng. 2018, 155, 251–260. [Google Scholar] [CrossRef]

- Li, P.; Li, W.; Sun, Z.; Shen, L.; Sheng, D. Development of sustainable concrete incorporating seawater: A critical review on cement hydration, microstructure and mechanical strength. Cem. Concr. Compos. 2021, 121, 104100. [Google Scholar] [CrossRef]

- Ann, K.Y.; Cho, C.G. Corrosion resistance of calcium aluminate cement concrete exposed to a chloride environment. Materials 2014, 7, 887–898. [Google Scholar] [CrossRef] [Green Version]

- Li, G.; Zhang, A.; Song, Z.; Shi, C.; Wang, Y.; Zhang, J. Study on the resistance to seawater corrosion of the cementitious systems containing ordinary Portland cement or/and calcium aluminate cement. Constr. Build. Mater. 2017, 157, 852–859. [Google Scholar] [CrossRef]

- GB/T 50107-2010; Standard for Evaluation of Concrete Compressive Strength. National Standards Committee: Beijing, China, 2010.

- Mohammed, T.U.; Hamada, H.; Yamaji, T. Performance of seawater-mixed concrete in the tidal environment. Cem. Concr. Res. 2004, 34, 593–601. [Google Scholar] [CrossRef]

- Katano, K.T.N.; Ishizeki, Y.; Iriya, K. Properties and application of concrete made with sea water and un-washed sea sand. In Proceedings of the Third International Conference on Sustainable Construction Materials and Technologies, Kyoto, Japan, 19–21 August 2013. [Google Scholar]

- Jiang, Y.D.; Jin, Z.; Zhao, T.; Chen, Y.; Chen, F. Strain field of reinforced concrete under accelerated corrosion by digital image correlation technique. J. Adv. Concr. Technol. 2017, 15, 290–299. [Google Scholar] [CrossRef] [Green Version]

- Gencturk, B.; Hossain, K.; Kapadia, A.; Labib, E.; Mo, Y.L. Use of digital image correlation technique in full-scale testing of prestressed concrete structures. Measurement 2014, 47, 505–515. [Google Scholar] [CrossRef]

- Yuan, Y.; Huang, J.; Peng, X.; Xiong, C.; Fang, J.; Yuan, F. Accurate displacement measurement via a self-adaptive digital image correlation method based on a weighted ZNSSD criterion. Opt. Laser. Eng. 2014, 52, 75–85. [Google Scholar] [CrossRef]

- Perez, V.Q.; Prieto, D.C.; Zapata, L.E. Mechanical characterization of self-compacting steel fiber reinforced concrete using digital image correlation. Eng. Fract. Mech. 2021, 246, 107618. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhan, Q.; Xiong, C.; Huang, J. Digital image correlation based on a fast convolution strategy. Opt. Laser. Eng. 2017, 97, 52–61. [Google Scholar] [CrossRef]

- Li, S.; Chen, X.; Feng, L.; Zhang, X.; Fan, X.; Lu, J. Experimental study on concrete fracture process zone using digital image correlation technique. J. Test. Eval. 2021, 49, 896–914. [Google Scholar] [CrossRef]

- Sharafisafa, M.; Aliabadian, Z.; Shen, L. Crack initiation and failure of block-in-matrix rocks under Brazilian test using digital image correlation. Theor. Appl. Fract. Mec. 2020, 109, 102743. [Google Scholar] [CrossRef]

- Gehri, N.; Mata-Falcon, J.; Kaufmann, W. Automated crack detection and measurement based on digital image correlation. Constr. Build. Mater. 2020, 256, 119383. [Google Scholar] [CrossRef]

- Dzaye, E.D.; Tsangouri, E.; De Schutter, G.; Aggelis, D.G. Full-Field Settlement measurement at fresh cementitious material by digital image correlation. J. Adv. Concr. Technol. 2019, 17, 168–176. [Google Scholar] [CrossRef]

- Yu, X.; Sun, L.; Yang, F. Study on mechanical properties of confined concrete based on digital image correlation technology. Rev. Rom. Mater. 2018, 48, 53–57. [Google Scholar]

- Boulekbache, B.; Hamrat, M.; Chemrouk, M.; Amziane, S. Failure mechanism of fibre reinforced concrete under splitting test using digital image correlation. Mater. Struct. 2015, 48, 2713–2726. [Google Scholar] [CrossRef]

- Shah, S.G.; Kishen, J.M.C. Fracture Properties of concrete-concrete interfaces using digital image correlation. Exp. Mech. 2011, 51, 303–313. [Google Scholar] [CrossRef]

- Xie, Z.; Zhou, H.; Lu, L.; Chen, Z. An investigation into fracture behavior of geopolymer concrete with digital image correlation technique. Constr. Build. Mater. 2017, 155, 371–380. [Google Scholar] [CrossRef]

- GB 50010-2010; Code for Design of Concrete Structures. National Standards Committee: Beijing, China, 2015.

- GB/T176-2017; Methods for Chemical Analysis of Cement. National Standards Committee: Beijing, China, 2017.

- Wang, X. Volume change of heterogeneous quasi-brittle materials in uniaxial compression. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 2006, 21, 162. [Google Scholar]

| Mix Ingredients | Mix Proportion (kg/m3) |

|---|---|

| Cement (OPC/CAC) | 525 |

| Coarse aggregate (gravel) | 1130 |

| Fine aggregate (sand) | 484 |

| Mixing water (seawater) | 220 |

| Water reducer | 1 |

| Cement | Components | Specific Surface Area/(m2/kg) | Density/(kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | K2O | S2O3 | |||

| OPC (%) | 55.27 | 23.85 | 7.52 | 3.00 | 2.32 | 0.37 | 0.59 | 1.06 | 430 | 6300 |

| CAC (%) | 32.07 | 7.84 | 52.01 | 2.82 | 1.11 | 0.28 | 0.29 | 0.40 | 350 | 6100 |

| Seawater Concrete Sample | Peak Load (kN) | Coefficient of Variation | S/F (%) |

|---|---|---|---|

| OPC-F | 411.2 ± 45.2 | 0.0163 | 1.0058 |

| OPC-S | 413.6 ± 37.3 | 0.0148 | |

| CAC-F | 589.1 ± 57.2 | 0.0128 | 1.0681 |

| CAC-S | 629.2 ± 81.6 | 0.0144 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Y.; Wang, L.; Wu, Z.; Mou, W.; Feng, X.; Liu, J.; Wang, X.; Yang, X. Full-Field Deformation-Aided Compressive Failure Evaluation of Seawater Concrete Using Digital Image Correlation Technique. J. Mar. Sci. Eng. 2022, 10, 518. https://doi.org/10.3390/jmse10040518

Yuan Y, Wang L, Wu Z, Mou W, Feng X, Liu J, Wang X, Yang X. Full-Field Deformation-Aided Compressive Failure Evaluation of Seawater Concrete Using Digital Image Correlation Technique. Journal of Marine Science and Engineering. 2022; 10(4):518. https://doi.org/10.3390/jmse10040518

Chicago/Turabian StyleYuan, Yuan, Lixin Wang, Zhirui Wu, Wensong Mou, Xiaotian Feng, Jinzhe Liu, Xiaohui Wang, and Xiao Yang. 2022. "Full-Field Deformation-Aided Compressive Failure Evaluation of Seawater Concrete Using Digital Image Correlation Technique" Journal of Marine Science and Engineering 10, no. 4: 518. https://doi.org/10.3390/jmse10040518

APA StyleYuan, Y., Wang, L., Wu, Z., Mou, W., Feng, X., Liu, J., Wang, X., & Yang, X. (2022). Full-Field Deformation-Aided Compressive Failure Evaluation of Seawater Concrete Using Digital Image Correlation Technique. Journal of Marine Science and Engineering, 10(4), 518. https://doi.org/10.3390/jmse10040518