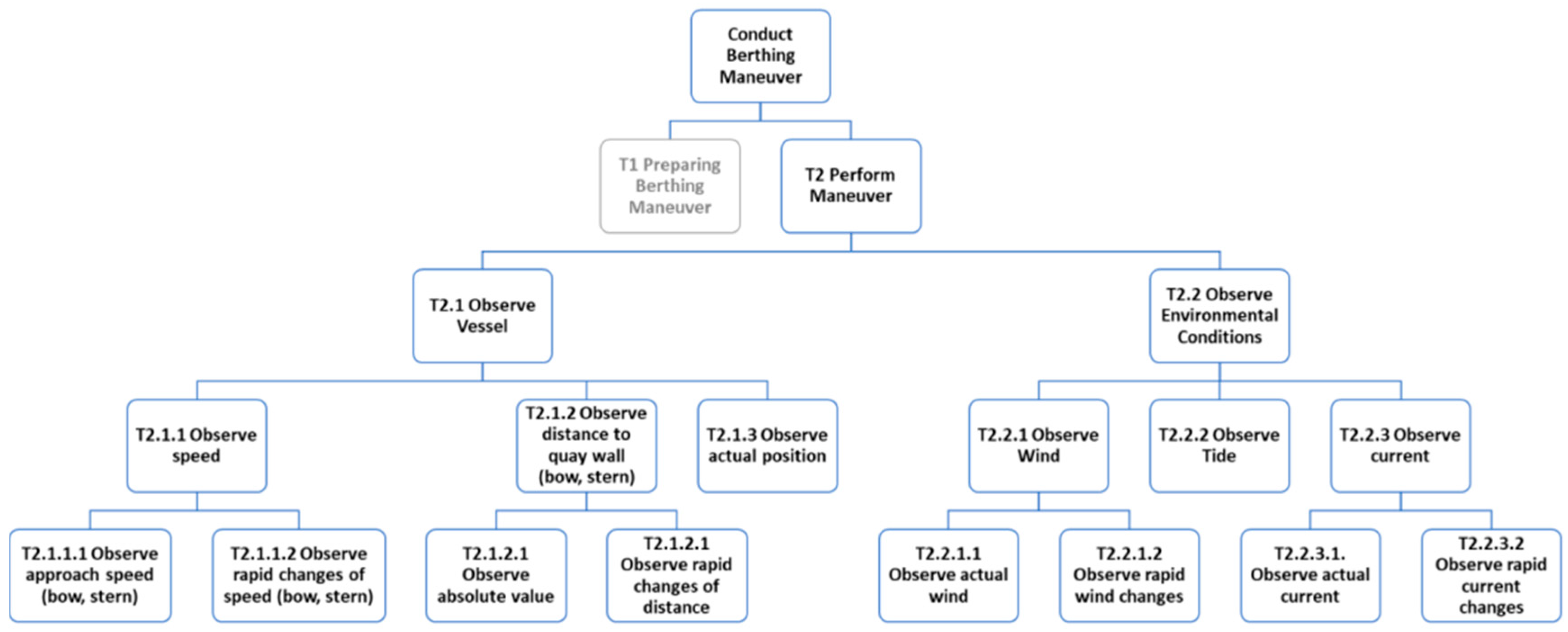

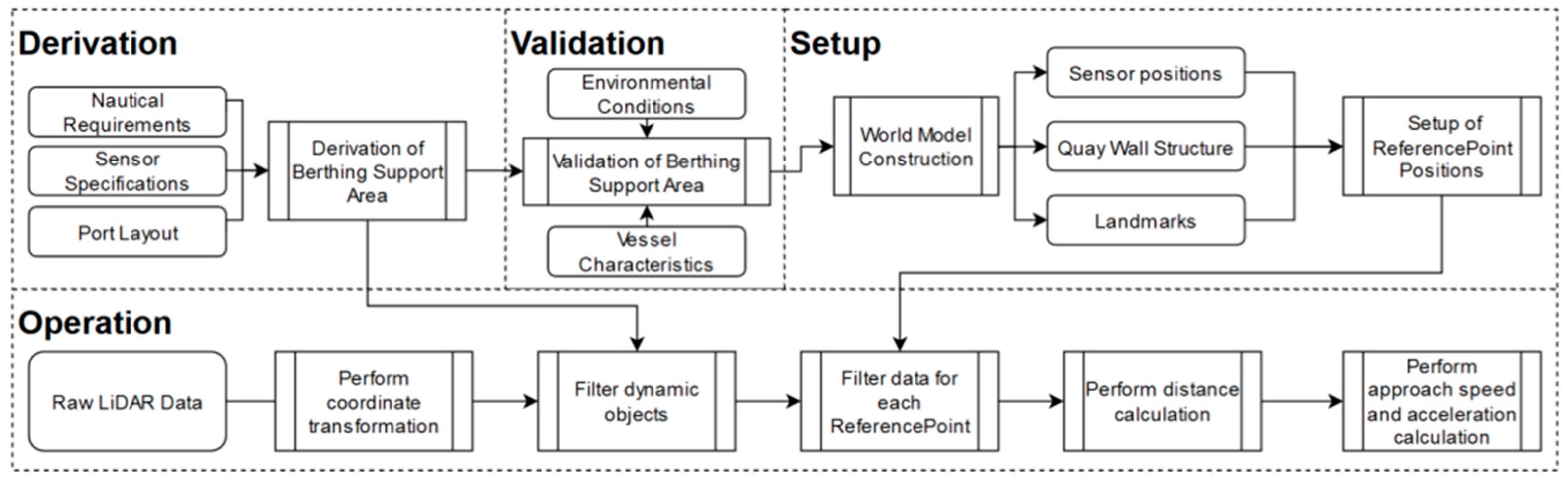

This section presents the evaluation of our BAS. Firstly, we describe the conducted test campaign and the defined scenarios. Secondly, we evaluate the precision, robustness, and stability of our system by using parallel sailing scenarios. Then we show how our system behaves in berthing scenarios in the port of Wilhelmshaven and compare our measurements with a DGPS sensor as a reference measurement. We will close with a discussion of the results and further improvements for our system.

6.1. Test Campaign Design

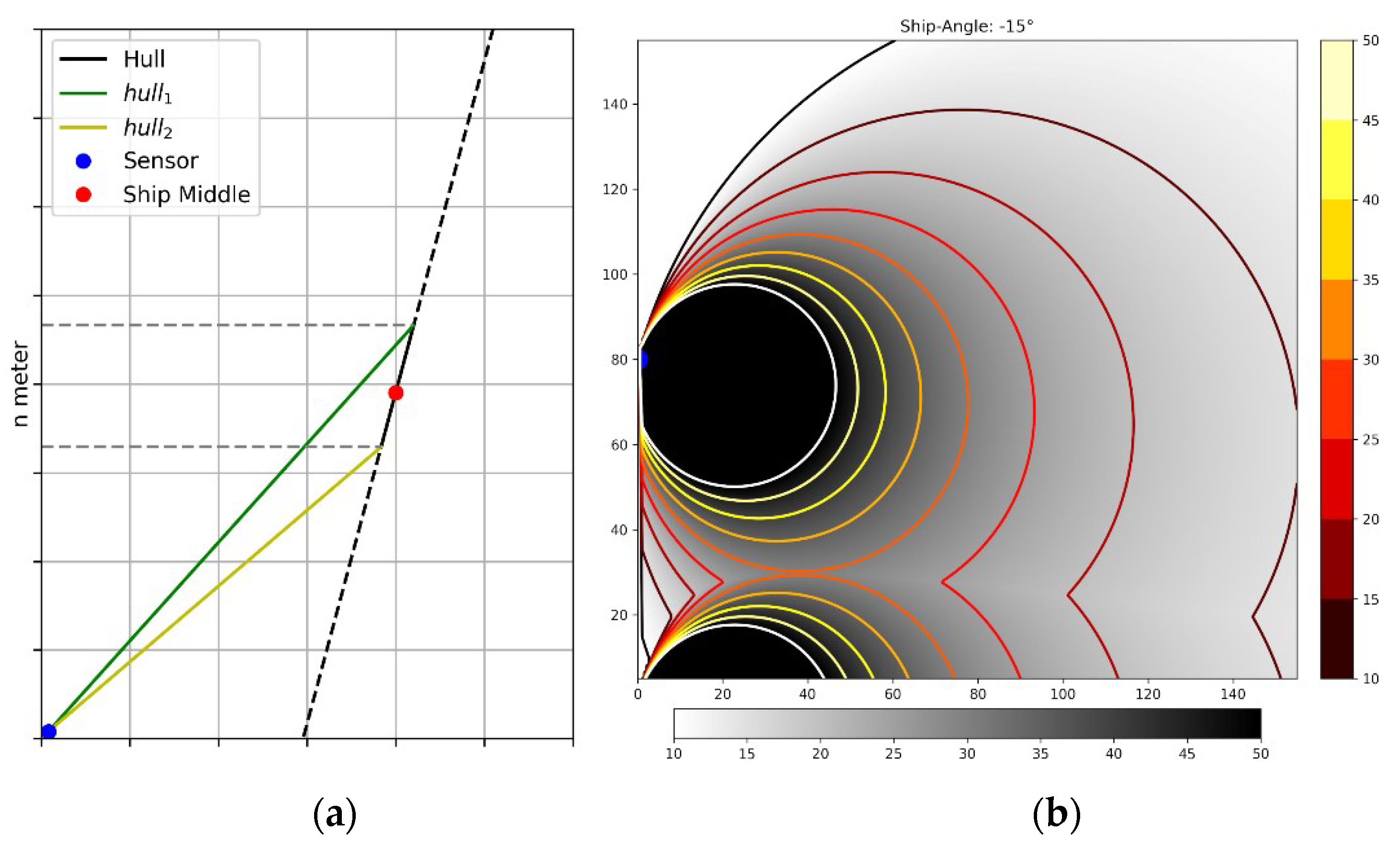

For the evaluation, we conducted a test campaign in Wilhelmshaven using the SmartKai prototype implementation and evaluated two types of maneuvers: parallel sailing along the quay and common regular berthing approaches as plotted by

Figure 11.

Because vessels over 200 m approach with berthing angles < 0.5 degrees but the ship available for the test campaign was much smaller, we decided to sail parallel tracks in four different distances to the quay: 20 m, 40 m, 60 m, and 150 m. We did not consider closer distances as the detection range of the LD-LRS 3611 sensors started above 5 m and chose 150 m as the maximum distance based on weighting the requirements of the pilots that stated 120 m as the berthing initiation range with the technical characteristics of the LiDAR Sensors (we expected the best detection results until this distance even for bad weather situations). All these tracks had a similar length of around 125 m, were sailed with nearly 3 kn, and the track times were each between 92 and 98 s. For the 20 m parallel track, the vessel slowed down and initiated a turn towards the end of the track to avoid a collision with the adjacent quay wall. To have comparable parallel tracks, the 20 m track was therefore cut, starting from the point that the berthing angle was >5 degrees.

Moreover, three different berthing maneuvers were performed (c.f.

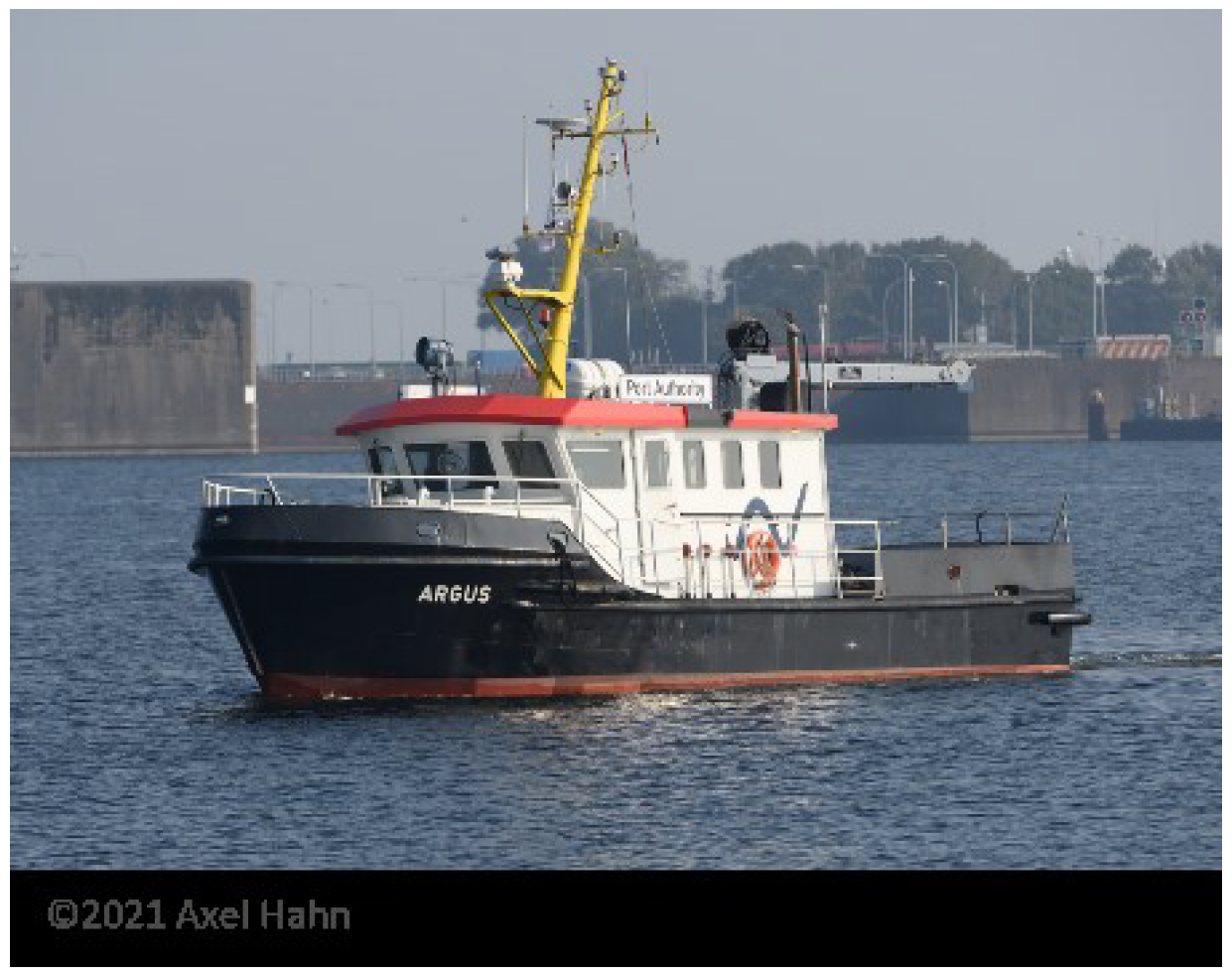

Figure 11b). For berthing, the ship started north of our berthing location heading towards the quay. The ship is approaching the location with a berthing angle of 15 degrees and an initial speed of four knots and continuously reducing it to one knot. A berthing angle of 15 degrees was the maximum of what was typically observed for smaller vessels without tug boat assistance [

16], such as the Argus ship. The shipmaster’s target was to berth between the two LiDAR sensors. This scenario was also varied with a start speed of six knots. Because our LiDAR sensors have a minimum range of 5 m, they were clipped up to this distance. The track lengths vary between 38 and 54 s due to the different starting positions and velocities.

The Argus ship master performed all maneuvers by navigating manually with the help of the onboard bridge systems (ECIDS, compass, and GPS). For the experiment, we installed an additional IMO approved (transmitting heading and satellite navigation device) DGPS sensor (JRC JLR-21) centrally on the ship, which enabled us to record the sailed maneuver tracks with more precision and keep it in sync with the LiDAR sensor measurements. In our configuration, the sensor provides a minimum accuracy of 6 m by specification, which is less accurate than the LiDAR sensor. But there were no buildings or other infrastructure on the quay wall that could affect the DGPS measurements. Good weather conditions were also present during the test campaign. Without clouds, rain, or other influencing factors for the DGPS signal, and therefore with very good satellite coverage, we assume the DGPS fixes to be much more accurate and precise than the corresponding minima stated in the sensor specifications.

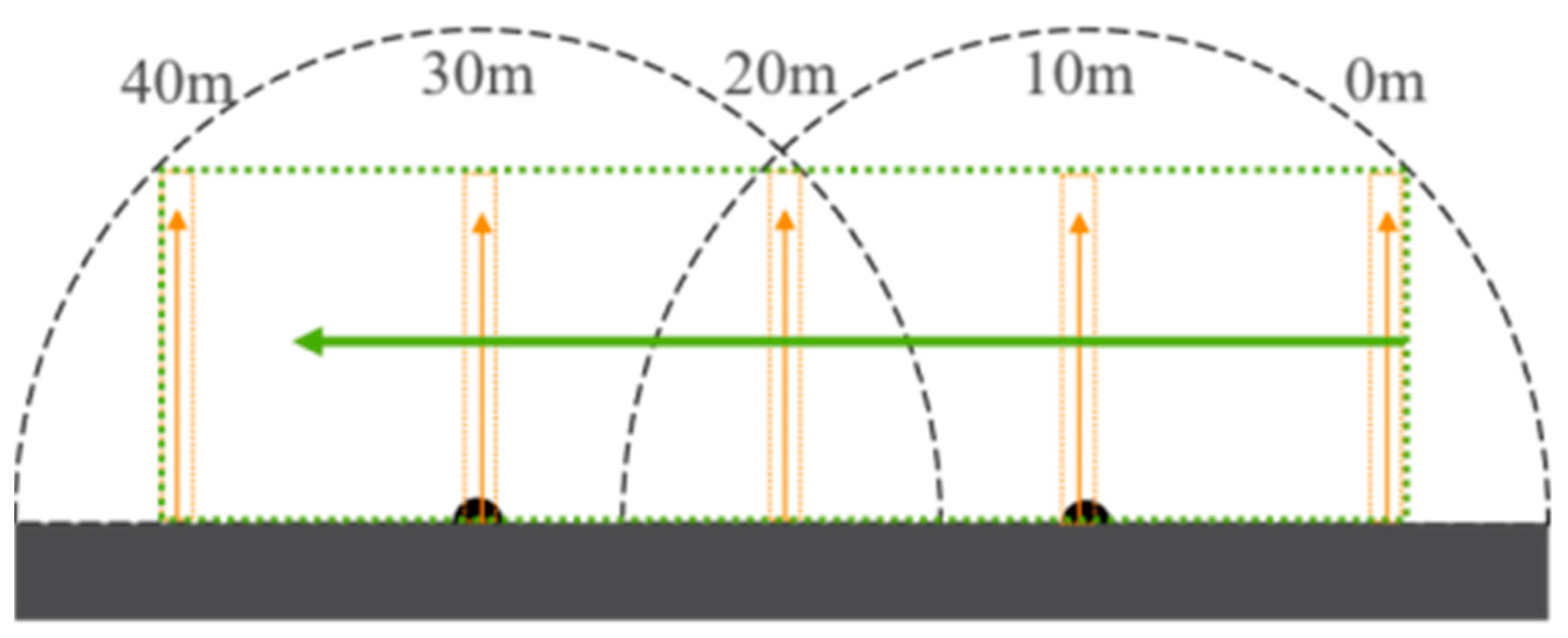

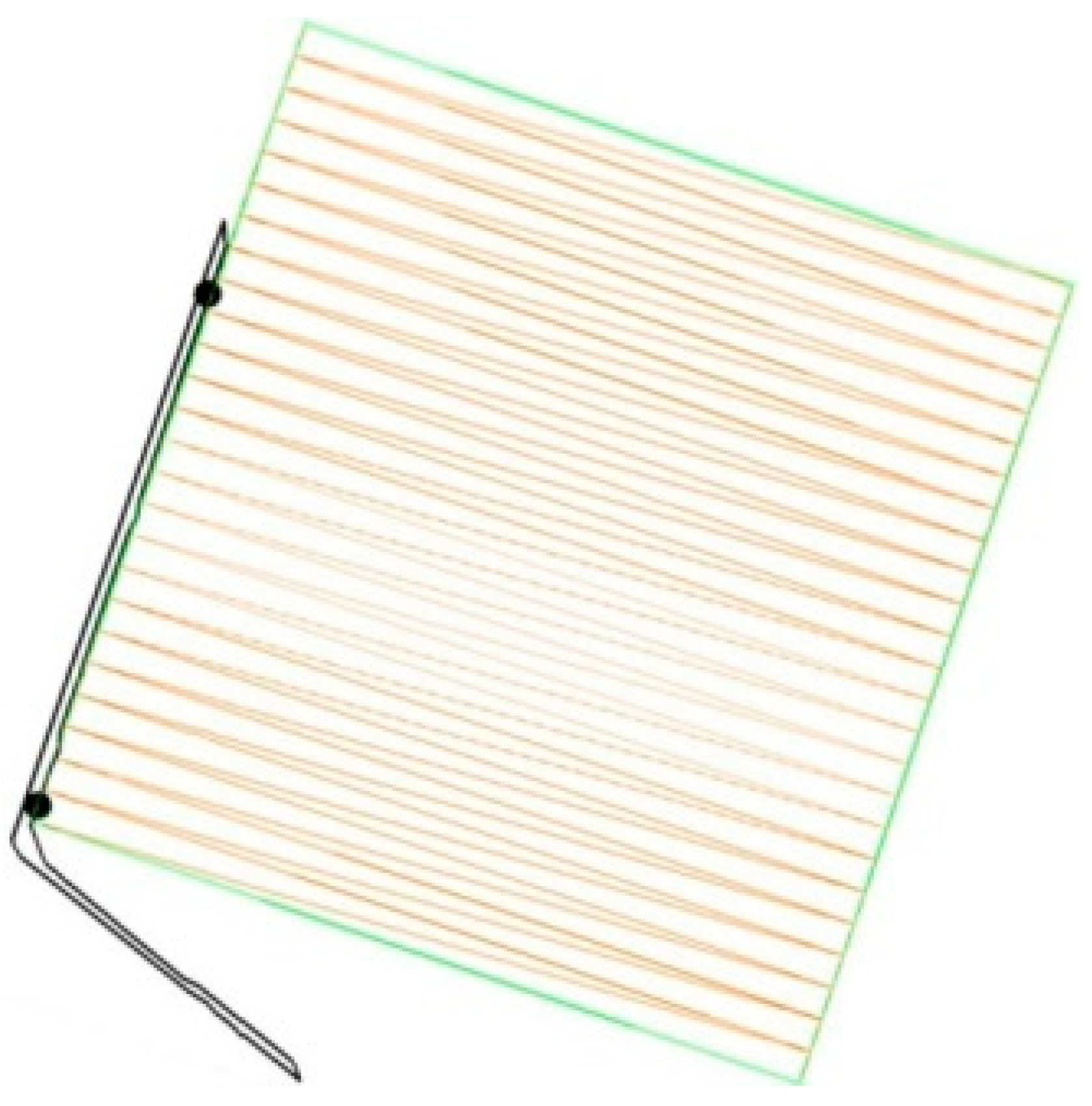

We defined Reference Points along the quay wall starting from the south-east sensor (c.f.

Figure 9) every 5 m to reflect the Argus ship size for a total of 120 m resulting with 24 Reference Points. An additional Reference Point was placed at meter mark 0 m to indicate where the ship needs to stop. We also aligned a vertical one to the southern quay to communicate forward speed and distance from there as well. The length of the vertical Reference Points was increased to 150 m to cover the 150 m maneuver track. The same applies to the width of our horizontal Reference Point.

The following

Section 6.2 covers the results of the parallel sailing maneuvers, whereas

Section 6.3 focuses on presenting the results of the berthing scenarios with higher berthing angles.

6.2. Parallel Sailing Results

For the parallel tracks a maximum variance by half the width of the ship can be expected. This is because when entering the area of a Reference Point, the bow of the ship is detected first, followed by a gradual inclusion of the outer hull of the ship. Therefore, for the ship used for this paper, the expected maximum variance is 2.4 m.

Figure 12 depicts the four parallel scenarios and for the three sensor combinations the 95% interval together with the expected maximum variance of 2.4 m for the measured distances for each Reference Point (

x-axis, numbered vertical Reference Points with 5 m spacing).

It can be seen that almost all measurements are within the expected variance, and also that with increasing distance the measurements fluctuate less. This can be explained by the higher point density especially at close ranges and the resulting better resolution of the bow. At higher distances, effects such as the lower point density and widening of the beam for better detection of the outer hull have to be considered.

Considering a Reference Point spacing of 5 m and a parallel sailing ship of 16 m length, on average 3.2 adjacent Reference Points are expected to communicate simultaneously a parallel sailing ship in 20 m, 40 m, 60 m, and 150 m.

Table 3 shows the mean and standard deviation divided according to the parallel runs. Here, the entry and exit times were removed so that the ship is completely inside the BSA.

For the first three scenarios with minor distances, the average is above the expected number of 3.2. In the 150 m scenario the ship sails outside the calculated BSA that requires at least three simultaneous measuring Reference Points. A significant reduction of the mean of measuring Reference Points for the 150 m scenario confirms the expectation. The standard deviation is around 0.5 for all scenarios. With increasing distance to the quay wall, the number of Reference Points that simultaneously detect a ship is reduced nearly linearly. Based on the calculations, we can also conclude that three reference points per ship length cannot be achieved in the 60 m scenario due to the standard deviation. In the initial sailing phase of the scenario, only the bow of the ship is detected. After the ship has passed the second sensor, the stern is also illuminated so that three Reference Points detect the ship. The illumination is therefore dependent on the relative positioning of the ship to the sensors. However, it is necessary to investigate why the average within the BSA is above the expected value of three.

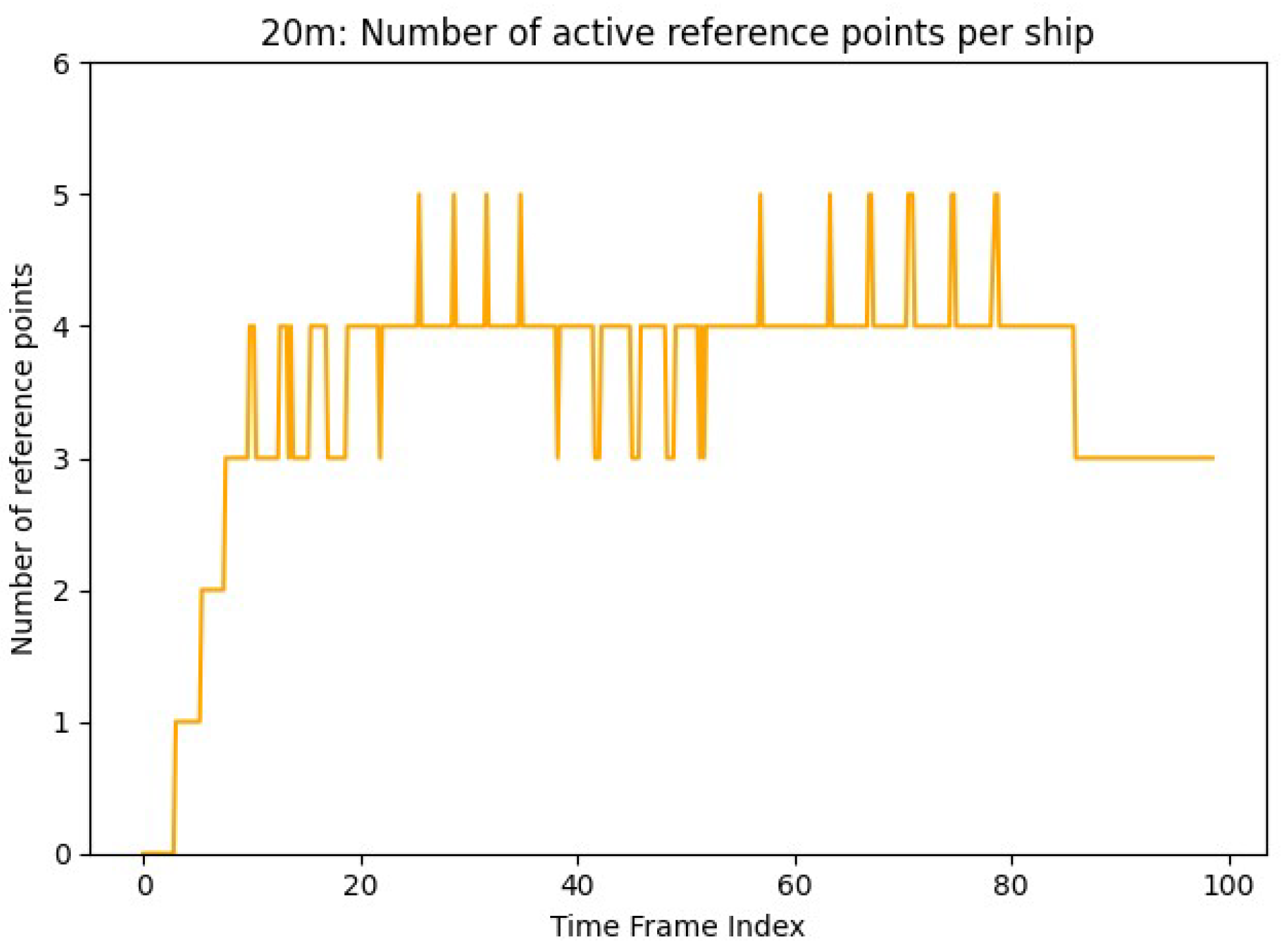

Figure 13 shows for each timestamp the number of Reference Points that simultaneously detect a ship for the 20 m scenario including the entry and exit times.

In the first few seconds the ship enters the BSA, the number increases. As soon as the ship has completely entered the BSA, at least three Reference Points are able to measure the ship (after 16 s). It is noticeable that in short time intervals the number of Reference Points which recognize a ship briefly sinks or rises (example: between 60 s and 80 s). In these moments the ship leaves one Reference Point and changes to the next one, so that the number changes. The fact that the number is above the expected value of three is therefore due to the fact that with a 16 m ship length divided by 5 m a surplus arises. If the ship is seen by three Reference Points, the bow and stern can be in the adjacent Reference Points so that it is seen by five.

In addition to the number of active Reference Points, we also measured how often these were turned on and off. One would expect a ship to enter and exit each vertical Reference Point just once. A higher toggling number is an indicator that point outliers may occur, which would result in causing false alarms. We therefore measured how often a Reference Point is triggered, which is listed by

Table 4.

For none of the scenarios the expected value of one activation per scenario was reached. For the 20 m and the 150 m scenario a Reference Point was activated three times. In the 20 m scenario this was caused by point outliers caused by the relatively tiny hull size of the ship. Due to the fact that 2D LiDAR sensors were used, movements of the ship on the

X or

Z axis result in suddenly seeing other parts than the hull such as objects on the ship’s deck. For the 150 m scenario, we realized that the point density of the ship is significantly lower than for the other scenarios. Due to the minimum number of points that must lie within a Reference Point in order to perform a distance measurement, measurements are discarded more often, and thus false alarms are produced more frequently. We therefore checked how often measurements were discarded. For this purpose, we collected the number of successful and unsuccessful measurements. Successful in this context means that there are at least five points per Reference Point measurement. Otherwise, measurements are not successful and were not considered.

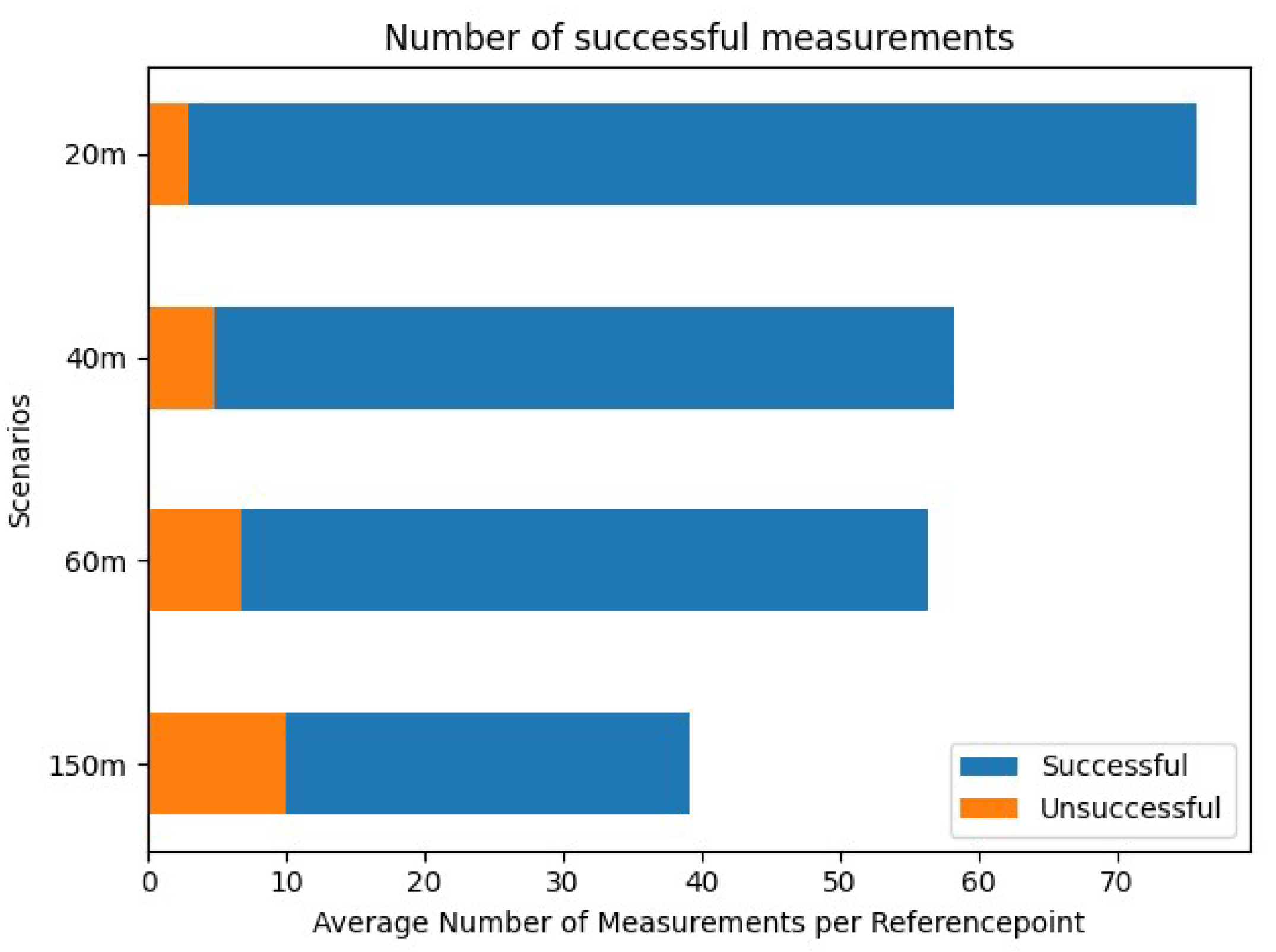

Figure 14 summarizes the number of successful and unsuccessful measurements for each scenario.

We recognized that with higher distance the point density decreases, and the number of unsuccessful measurements increases. Regarding the 150 m scenario, approximately 25% of our measurements were not considered because of the low point density. The still high amount of successful measurements indicates that the IMO positioning fix requirements of 1 Hz while berthing can be fulfilled with the 5 Hz sensor. To investigate this in more detail, we measured how many times per second a Reference Point takes a measurement. The factors that influence the calculation rate are the time synchronization of the LiDAR measurement and the failure rate due to too few points.

Figure 15 shows the calculated average Hz number for each scenario.

Due to the refresh rate of the sensor, the upper limit is 5 Hz, and our results are very close to this value. However, it is noticeable that there are a few outliers. The lowest value can be observed for the 150 m scenario (4.2 Hz).

6.3. Berthing Maneuvers Results

Scenarios 2.1–2.3 define the other extreme of berthing maneuvers with an angle of 15 degrees (which is in fact a typical berthing angle for small ships such as the one we used for our experiments). We evaluated the distance to Reference Point, speed, forward speed, and distance to meter mark 0 m. For these metrics, we examined the deviations from the DGPS. Because in general we expected the accuracy and precision of the DGPS to be much lower when compared to LiDAR, we focused a comparison of the measurement deviations to verify the stability of the Reference Point measurements.

We will start with the comparison of the measured distances on vertical (distance to the quay wall) and horizontal (distance ahead) level. It is expected that the variance of the measurements is low and thus a constant deviation between both measurement methods is achieved. Because several Reference Points were defined along the quay wall, but a DGPS sensor only determines a single position and speed, the measurements of the Reference Points are combined. Therefore, the shortest distance of all Reference Points is used as a reference value to compare it with the DGPS. Based on the determined positions of the GPS sensor, we calculated the vertical distance to the quay wall and the horizontal distance to enable the comparison.

Figure 16 shows the vertical (a) and horizontal (b) deviations between the Reference Point measurements and the DGPS.

In scenario 2.1, the variance of the measurements is small compared to other scenarios. However, with respect to the horizontal distance measurements, outliers are present. In the second scenario (2.2), the highest variance is present. Accordingly, the minimum and maximum values are also high. Due to the high range of values, there are also no outliers. In the third scenario, the variance is similar to that of scenario 2.1 (vertical and horizontal). However, outliers are also found here, especially below the minimum value. To first check for outliers in the first scenario, we first examine the horizontal distance measurements.

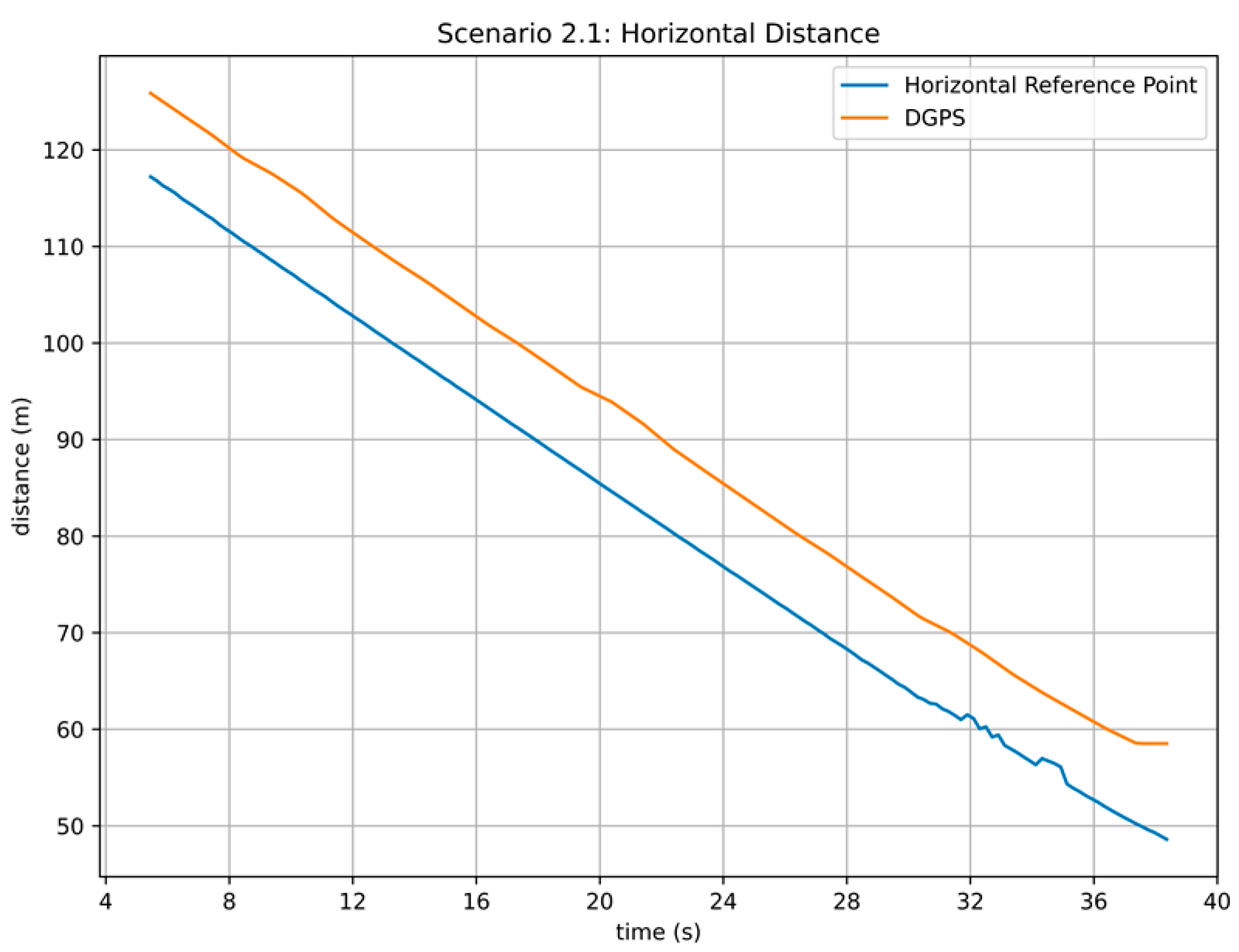

Figure 17 shows the horizontal distance measurements to the quay wall for scenario 2.1.

Up to second 32, the deviations between the measurement methods are relatively constant. From this point on, however, the horizontal Reference Point shows fluctuating distance measurements, which causes the outliers in

Figure 16b. Regardless of the scenario considered, these anomalies are also found in other scenarios (cf.

Figure 16 scenario 2.3), although we ascertained that the length of these phases is smaller.

The next step is to investigate the high variance in scenario 2.2. For this purpose,

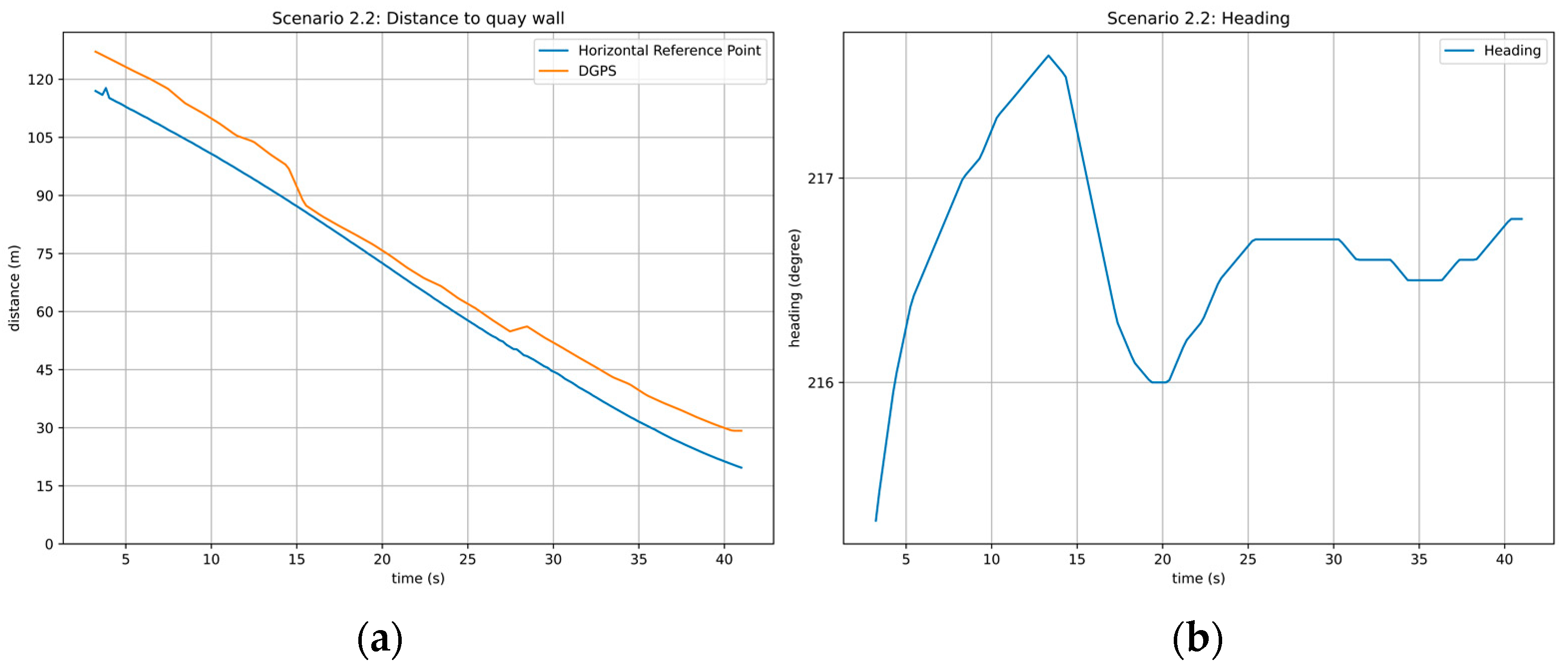

Figure 18 shows the horizontal distance to the quay wall (a) and the heading of the ship (b).

It is particularly striking that the deviations between the two measurement methods decrease between 15 s and 27 s. This increases the variance of the measurements, which is reflected in the

Figure 16b. However, the reason for this behavior is unknown. As can be seen from the right side of the figure, the ship did not change course. In the period under consideration, only a course change of <1° was made. We also checked the quality of the DGPS measurements. However, the number of satellites was constant at 8 and the Horizontal Dilution of precision (HDOP) was 1. Infrastructure at the mooring was not available, so the GPS measurements were not exposed to any influence. We therefore assume that this is an anomaly.

The next part is the comparison of measured speed between Reference Points and DGPS. For these we examine the average, standard deviation, mean error, and rooted mean squared error (RMSE) to be able to make a statement about the stability of the measurements. Due to deviations in the distance measurements (see

Figure 16), we have removed all speed values greater than 10 m/s, as this leads to disproportionate deviations. However, they will be analyzed in more detail in the following.

Table 5 shows the vertical velocity measurements (quay wall approach speed) of the respective scenarios.

The table shows that the measurements of the two methods are quite comparable. In all scenarios the absolute deviation is below 0.07 m/s (peak in Scenario 2.2). The highest deviation was recorded in scenario 2.2, in which the position anomalies on

Figure 18 cause varying velocity anomalies to be measured. However, the standard deviation of the Reference Points is consistently higher than that of the DGPS, so that the measurements vary more strongly. Due to the higher measurement rate of the LiDAR sensors (5 Hz) compared to the DGPS (1 Hz), more velocity measurements were recorded, which led to higher deviations.

Table 6 shows the measured forward velocities of the horizontal Reference Point and the DGPS.

Again, the absolute deviation to the DGPS is relatively small and is below 0.08 (peak again in scenario 2.2). Again, however, the standard deviation of the Reference Points is higher in scenario 2.1 and 2.3 than for the DGPS. Especially in scenario 2.3, the standard deviation is two times higher.

The highest speed deviation between both systems was recorded for scenario 2.3 (peak deviation). We also observed a high standard deviation for the Reference Points in this scenario, compared to DGPS. Because the velocity is calculated based on the measured distance, we further investigated in the distance measurements of scenario 2.3.

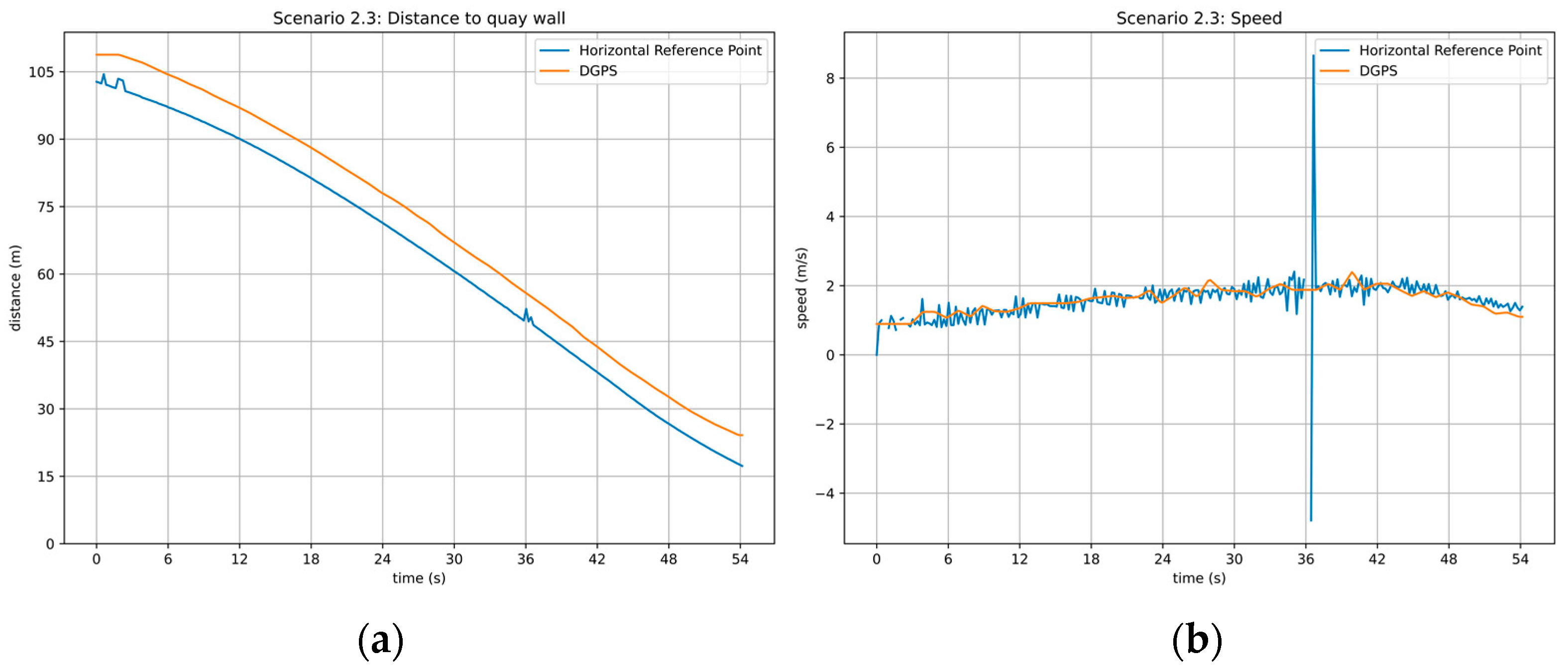

Figure 19 depicts the distance to meter mark 0 m and the resulting forward speed of the vessel.

We observed that the deviation in distance between the DGPS sensor and the horizontal Reference Point is relatively constant between 5 and 8 m apart (cf.

Figure 16b). However, between second 0 and 3 we measured jitter in the horizontal distance to meter mark 0 m. Because this generates incomparably high-speed measurements, they were removed. Velocity anomalies were also measured in the time range between 35 and 37. This results in speed deviations; thus, we calculated a maximum above ~8 m/s and a minimum below ~−4 m/s in forward speed. Due to the high update frequency of the LiDAR sensor (5 Hz) and distance change in a small time-window, the resulting forward speed is high. Compared to the DGPS, we can see that the reference points take varying velocity measurements, thus resulting in jitter. In comparison to the DGPS sensor, less frequent speed changes can be observed. High-speed deviations were also observed for the other scenarios. Therefore, to improve the stability of the measurements, a filter is required to smoothen the speed measurements for the nautical personnel.