Fleet Deployment Optimization for LNG Shipping Vessels Considering the Influence of Mixed Factors

Abstract

1. Introduction

2. Literature Review

3. Methods and Methodology

3.1. Modeling Assumptions

- The model planning period is one year and the annual operating time of each type of vessel is 345 days, during which the size of the fleet is stable and constant.

- The fleet has K types of ships operating H routes, the depreciable life of each type of LNG ship is 35 years, and the residual value at maturity is 10% of the vessel price.

- The fleet operates M ships, of which I ships are self-owned and J ships are on a time charter, with the same operating costs and cargo carrying capacity for the same type of ships.

- The same type of ship has the same loading and unloading efficiency, with the contract stipulating that the loading and unloading charges are borne by the carrier and that there are the same port charges at both the port of loading and the port of discharge.

- The carrier signs a COA charter contract with the cargo owner with fixed freight and a determined annual cargo volume, which allows for a certain degree of volume maneuvering margin.

- The model considers the losses caused by volatilization and the loss of time value of LNG in transit.

- The model supposes the navigational safety and costs arising from unforeseen conditions, such as bad weather, rescue in distress, reasonable detours, etc.

- All types of vessels are powered by LNG fuel without the use of fuel oil.

- The model assumes that the full-service speed when sailing in ballast is already known.

3.2. Mathematical Model and Parameters

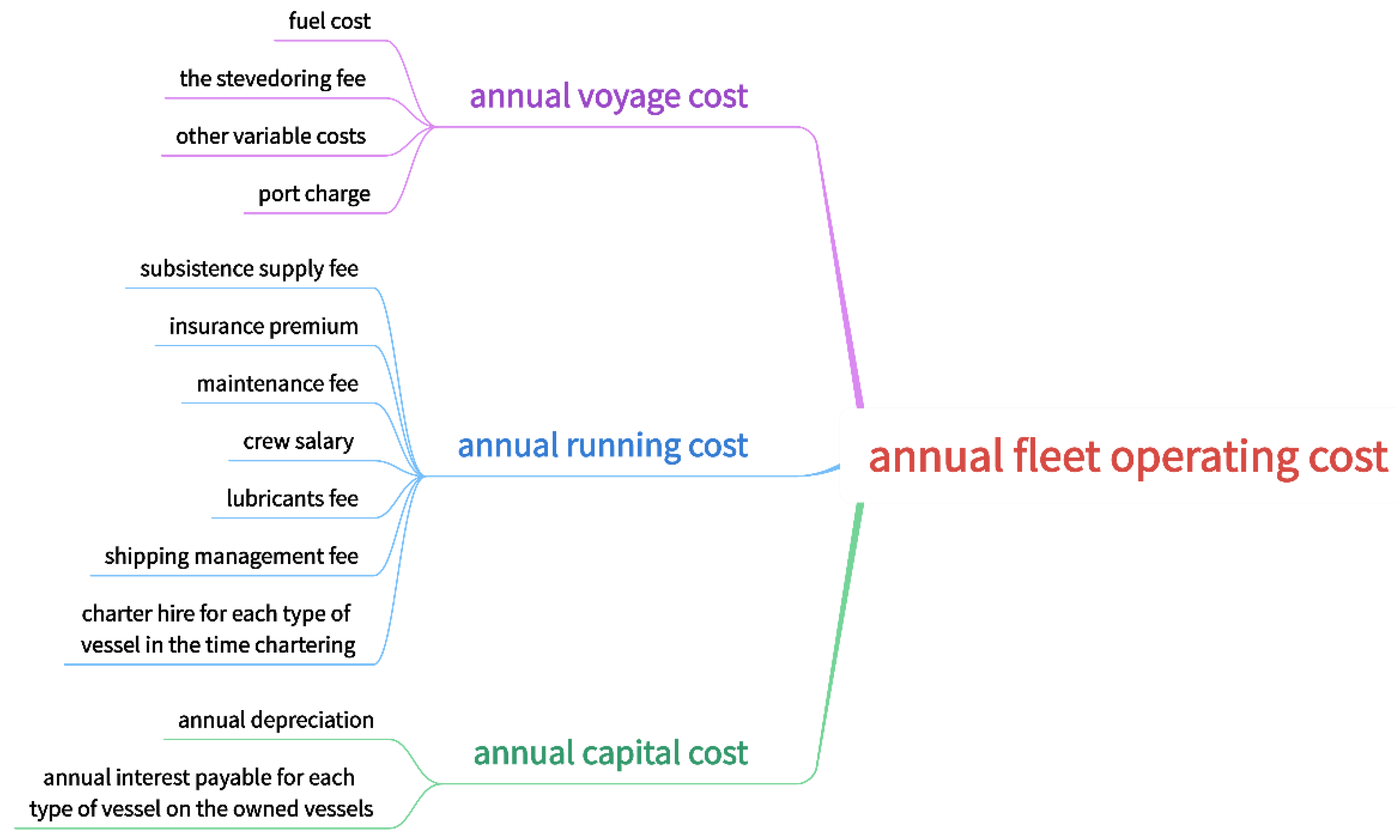

- The annual voyage cost is determined by constraints (2) and (3) and constraints (9)–(11), the voyage time is determined by constraint (4), the berthing time is determined by constraints (5)–(8), the annual running cost is determined by constraint (12), and the annual capital cost is determined by constraint (13).

- Constraint (16) is the cargo volume constraint, which shows that the annual total freight volume of each type of vessel on the corresponding route should meet the annual cargo demand of the route, considering the allowance for a certain amount of maneuver range.

- In the shipping frequency constraints, the minimum annual shipping frequency of the route is determined by constraints (14) and (15), and constraint (17) shows that the annual number of voyages of each type of ship on the corresponding route must meet the requirements of the annual minimum sailing frequency of the route.

- In the time constraint, it is indicated that the annual voyage time of the vessel type on the corresponding route shall be equal to the annual operating period of the vessel type assigned to the route by constraint (18).

- In the quantity constraints, constraint (19) is the sum of the number of type vessels assigned to each route. In constraint (20), it indicates the sum of the number of vessels assigned to each route.

- In the numerical constraints, constraint (21) indicates that the departure interval and departure times shall be positive integers, and constraint (22) shows that the service speed and loading efficiency of each type of ship are positive real numbers.

3.3. Numerical Experiments

4. Computational and Numerical Analyses

4.1. Data Preparation

- ①

- This study stipulates that 1 ton of VLSFO (Vessel Low Sulfur Fuel Oil) has a calorific value of 41.3 million BTU (British Thermal Unit), 1 ton of MGO (Marine Gasoline Oil) has a calorific value of 43.5 million BTU, 1 ton of LNG has a calorific value of 51.8 million BTU, and 1 ton of LNG = 2.27 LNG.

- ②

- Therefore: 1 ton of VLSFO = 1.81 LNG and 1 ton of MGO = 1.78 LNG. The LNG terminal handling efficiency is generally 11,000~12,000 m3/h; the precooling efficiency is 4 °C/min, which takes 1 h = 0.04 days; The equipment blowing and discharge residue and the interface disconnect operation take 5 h = 0.21 days.

4.2. Calculation of the Voyage Time and Cost

4.3. Results and Cost Comparison Analysis

4.4. Sensitivity Analysis

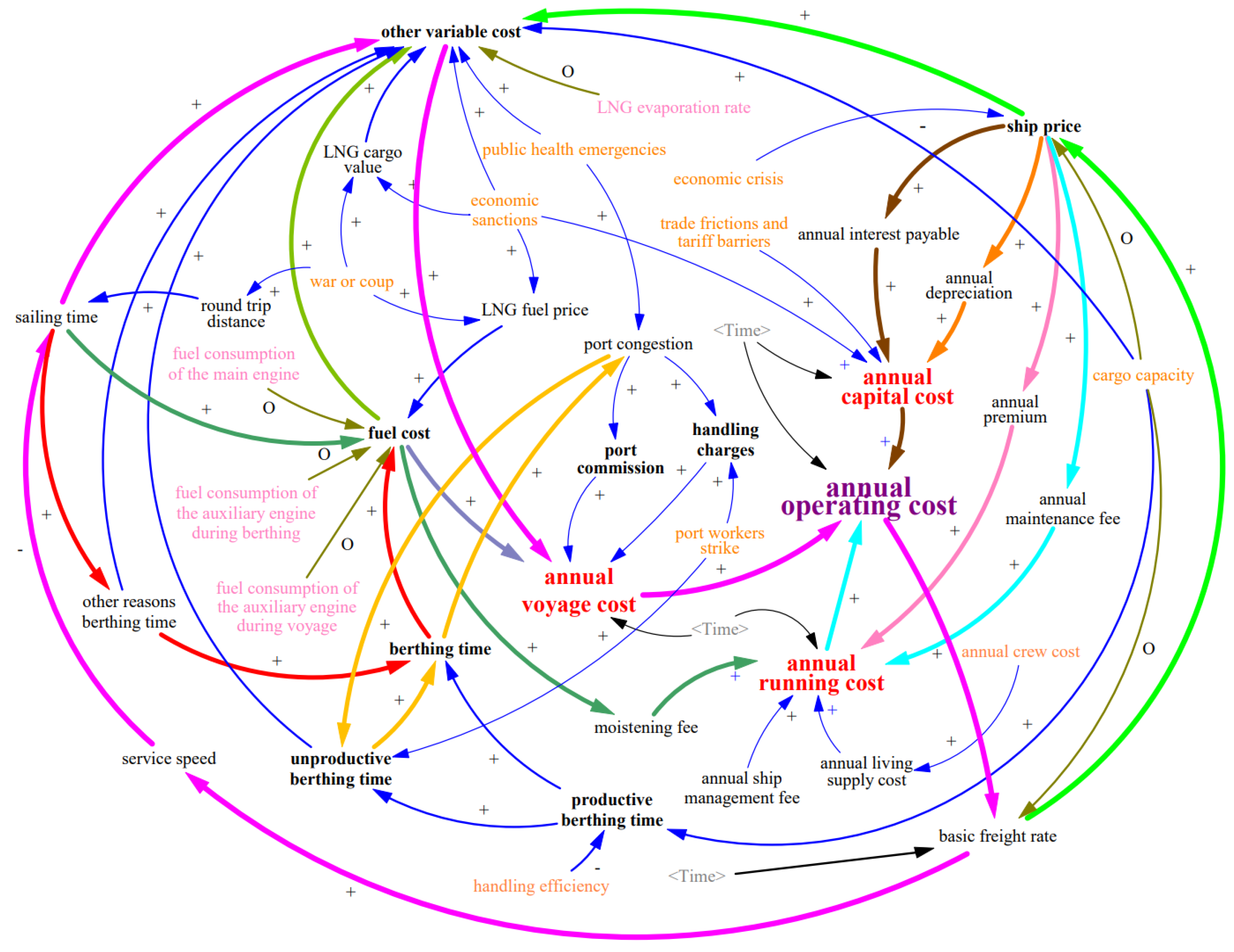

- As LNG itself is a high value-added and high-value cargo related to the nation’s livelihood, its in-transit inventory holding cost–namely, the time value of the cargo–has a great impact on the annual operating cost of the fleet, and the evaporation loss of LNG in transit is also unavoidable. Meanwhile, being a capital and technology intensive cutting-edge project with high technical content and investment cost, difficult construction, and long construction period, the construction of large LNG ships has been regarded as one of the most sophisticated projects in the shipbuilding industry, which makes its ship price high, causing the fleet to bear the high capital cost of its own ships every year. Furthermore, this has resulted in high vessel prices in the hundreds of millions of dollars, making it necessary for the fleet to incur high annual capital costs for owned vessels.

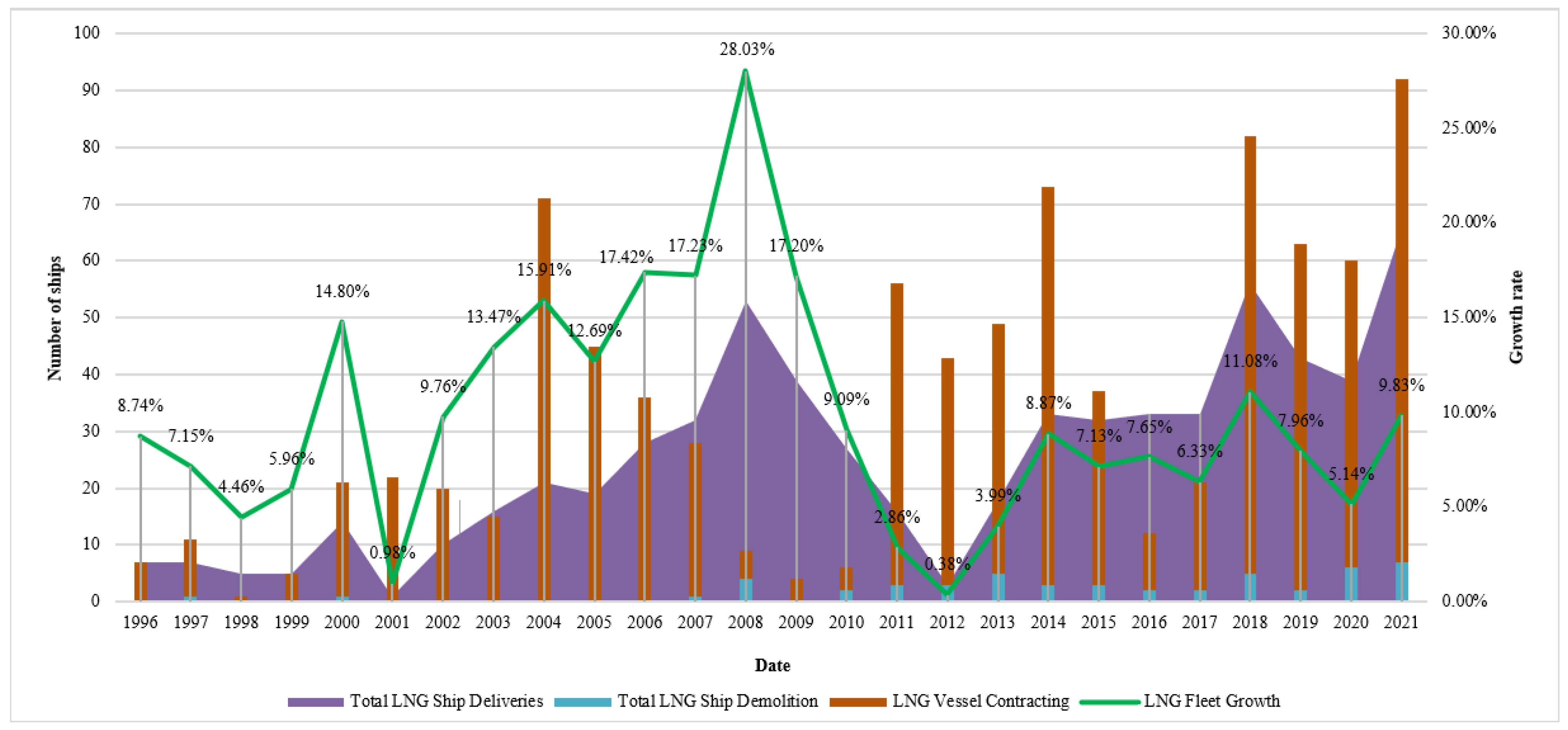

- In addition, the LNG shipping market is a high-yield, high-monopoly special transportation market. Based on the latest Clarkson research data, the supply of ships in the whole market is only around 660 ships so far, which–coupled with the large consumption and transportation demand–makes LNG ship charter hire rise; in addition, the term chartering ship cost is quite expensive. Furthermore, the increase in port charges, crew wages, and nonproductive berthing time will also have a significant impact on the annual operating costs of the fleet, and especially on the current global port congestion. Additionally, the new wave of epidemic impact caused by the new variant of the Delta coronavirus strain and the Omicron strain on crew protection, shift change, and mental health issues is worth the review and attention of shipping companies, regulatory authorities, and relevant international organizations.

4.5. Suggestions for Countermeasures

5. Conclusions and Further Research

- First, it analyzes the fleet deployment in LNG shipping under the influence of several mixed factors, proposing an optimization model based on the characteristics of LNG shipping and relevant data sources. Through a case study and cost-contrast analysis, the practicality and optimality of the model are verified.

- Second, the key factors that affect the annual operating cost of LNG shipping enterprises are identified through a sensitivity analysis, and their causes are analyzed one by one. LNG shipping companies can focus on these factors in fleet deployment and actual operation and adjust strategies in time to reduce total operating costs.

- Third, from the segments of fuel filling, port operation, transportation economy, and fleet cooperation, four corresponding reference suggestions are provided to all relevant parties to LNG shipping for these key factors in the sensitivity analysis.

- Ultimately, this study will be beneficial to promote the prosperity of transregional marine energy transport and further strengthen the energy security and development of port cities and their economic hinterland.

- For example, there is very little research literature on LNG route allocation. In the numerical experiments, some parameters and weights are determined by referring to research on liner shipping, Clarksons database, and some latest reports on LNG shipping industry.

- Meanwhile, the arithmetic validation link of this study is to carry out a limited number of integer optimization cases with the combination optimization of three types of vessels, 10 ships, and three fixed shipping routes, which means that the research results have a certain degree of deviation. However, in reality, LNG shipping enterprises generally only have a few types of ships, with several to over 10 LNG ships, such as CLNG and BP, while operating stable routes within a year influenced by transportation agreements and more fixed import/export countries. Therefore, the empirical case evidence of this study is reliable and realistic to some extent.

- With the increasing use of natural gas, a low carbon and clean energy, LNG shipping will become more prosperous and busier. Continuous expansion of the size of the LNG fleet will make the fleet operation more complex. In the near future, the system dynamics method may be used to provide LNG shipping enterprises with more scientific and adaptive decision-making reference.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, F.; Yu, H.; Li, H.; Peng, L.; Zhou, T. Safety or Efficiency? An ECSO Framework of Traffic Organization Optimization for LNG Carriers Entering and Leaving Port. Math. Probl. Eng. 2021, 2021, e8804219. [Google Scholar] [CrossRef]

- Ríos-Mercado, R.Z.; Borraz-Sánchez, C. Optimization Problems in Natural Gas Transportation Systems: A State-of-the-Art Review. Appl. Energy 2015, 147, 536–555. [Google Scholar] [CrossRef]

- Raj, R.; Ghandehariun, S.; Kumar, A.; Geng, J.; Linwei, M. A Techno-Economic Study of Shipping LNG to the Asia-Pacific from Western Canada by LNG Carrier. J. Nat. Gas Sci. Eng. 2016, 34, 979–992. [Google Scholar] [CrossRef]

- Yin, Y.W.; Lam, J.S.L. Bottlenecks of LNG Supply Chain in Energy Transition: A Case Study of China Using System Dynamics Simulation. Energy 2022, 250, 123803. [Google Scholar] [CrossRef]

- Engelen, S.; Dullaert, W. Designing a Decision Support Model for the LNG Market. Transp. Plan. Technol. 2010, 33, 719–731. [Google Scholar] [CrossRef]

- Yang, S.; Xu, D.; Cui, Y.; Ni, Y.; Duan, C. The Research about Storage and Transportation of Natural Gas Based on LNG Technology. Nat. Resour. 2015, 6, 306–311. [Google Scholar] [CrossRef][Green Version]

- Huemme, J.C.; Gabriel, S.A.; Chanpiwat, P.; Shu, T. An Analysis of the U.S.—China Trade War’s Impact on Global Natural Gas Markets and the U.S. Coast Guard’s LNG Inspection Workforce. J. Nat. Gas Sci. Eng. 2022, 97, 104198. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, Y.; Lv, Z. Research Status and Prospect of LNG Inland Waterway Transportation Safety in China. In Proceedings of the 6th International Conference on Transportation Information and Safety (ICTIS), Wuhan, China, 22–24 October 2021; pp. 318–322. [Google Scholar] [CrossRef]

- Zeng, W.; Zhang, X.; Li, N.; Wang, X.; Wang, X. China’s LNG Import Risk Assessment Based on the Perspective of Global Governance. Sci. Rep. 2022, 12, 15754. [Google Scholar] [CrossRef]

- Zahedi, B.; Norum, L.E. Modeling and Simulation of All-Electric Ships With Low-Voltage DC Hybrid Power Systems. IEEE Trans. Power Electron. 2013, 28, 4525–4537. [Google Scholar] [CrossRef]

- van Biert, L.; Godjevac, M.; Visser, K.; Aravind, P.V. A Review of Fuel Cell Systems for Maritime Applications. J. Power Sources 2016, 327, 345–364. [Google Scholar] [CrossRef]

- Hou, J.; Song, Z.Y.; Hofmann, H.; Sun, J. Adaptive Model Predictive Control for Hybrid Energy Storage Energy Management in All-Electric Ship Microgrids. Energy Convers. Manag. 2019, 198, 111929. [Google Scholar] [CrossRef]

- Haseltalab, A.; Botto, M.A.; Negenborn, R.R. Model Predictive DC Voltage Control for All-Electric Ships. Control Eng. Pract. 2019, 90, 133–147. [Google Scholar] [CrossRef]

- Burel, F.; Taccani, R.; Zuliani, N. Improving Sustainability of Maritime Transport through Utilization of Liquefied Natural Gas (LNG) for Propulsion. Energy 2013, 57, 412–420. [Google Scholar] [CrossRef]

- Schinas, O.; Butler, M. Feasibility and Commercial Considerations of LNG-Fueled Ships. Ocean Eng. 2016, 122, 84–96. [Google Scholar] [CrossRef]

- Baldi, F.; Moret, S.; Tammi, K.; Maréchal, F. The Role of Solid Oxide Fuel Cells in Future Ship Energy Systems. Energy 2020, 194, 116811. [Google Scholar] [CrossRef]

- Haseltalab, A.; Van Biert, L.; Sapra, H.; Mestemaker, B.; Negenborn, R.R. Component Sizing and Energy Management for SOFC-Based Ship Power Systems. Energy Convers. Manag. 2021, 245, 114625. [Google Scholar] [CrossRef]

- Ng, M. Revisiting a Class of Liner Fleet Deployment Models. Eur. J. Oper. Res. 2017, 257, 773–776. [Google Scholar] [CrossRef]

- Tan, Z.Y.; Li, H.L.; Wang, H.W.; Qian, Q.Y. Maritime Container Shipping Fleet Deployment Considering Demand Uncertainty. Asia-Pac. J. Oper. Res. 2021, 38, 2140026. [Google Scholar] [CrossRef]

- Gao, C.F.; Hu, Z.H. Speed Optimization for Container Ship Fleet Deployment Considering Fuel Consumption. Sustainability 2021, 13, 5242. [Google Scholar] [CrossRef]

- Wang, X.; Fagerholt, K.; Wallace, S.W. Planning for Charters: A Stochastic Maritime Fleet Composition and Deployment Problem. Omega 2018, 79, 54–66. [Google Scholar] [CrossRef]

- Zhen, L.; Hu, Y.; Wang, S.A.; Laporte, G.; Wu, Y.W. Fleet Deployment and Demand Fulfillment for Container Shipping Liners. Transp. Res. Part B Methodol. 2019, 120, 15–32. [Google Scholar] [CrossRef]

- Chen, J.H.; Ye, J.; Zhuang, C.L.; Qin, Q.D.; Shu, Y.Q. Liner Shipping Alliance Management: Overview and Future Research Directions. Ocean Coast. Manag. 2022, 219, 106039. [Google Scholar] [CrossRef]

- Pantuso, G.; Fagerholt, K.; Hvattum, L.M. A Survey on Maritime Fleet Size and Mix Problems. Eur. J. Oper. Res. 2014, 235, 341–349. [Google Scholar] [CrossRef]

- Wang, S.A. Fundamental Properties and Pseudo-Polynomial-Time Algorithm for Network Containership Sailing Speed Optimization. Eur. J. Oper. Res. 2016, 250, 46–55. [Google Scholar] [CrossRef]

- Kosmas, O.T.; Vlachos, D.S. Simulated Annealing for Optimal Ship Routing. Comput. Oper. Res. 2012, 39, 576–581. [Google Scholar] [CrossRef]

- Wang, C.X.; Chen, J.J. Strategies of Refueling, Sailing Speed and Ship Deployment of Containerships in the Low-Carbon Background. Comput. Ind. Eng. 2017, 114, 142–150. [Google Scholar] [CrossRef]

- Wang, S.; Zhuge, D.; Zhen, L.; Lee, C.-Y. Liner Shipping Service Planning Under Sulfur Emission Regulations. Transp. Sci. 2021, 55, 491–509. [Google Scholar] [CrossRef]

- Zhuge, D.; Wang, S.A.; Wang, D.Z.W. A Joint Liner Ship Path, Speed and Deployment Problem under Emission Reduction Measures. Transp. Res. Part B Methodol. 2021, 144, 155–173. [Google Scholar] [CrossRef]

- Tan, Z.J.; Zhang, M.; Shao, S.; Liang, J.P.; Sheng, D. Evasion Strategy for a Coastal Cargo Ship with Unpunctual Arrival Penalty under Sulfur Emission Regulation. Transp. Res. Part E Logist. Transp. Rev. 2022, 164, 102818. [Google Scholar] [CrossRef]

- Wang, C.X.; Yu, S.S.; Xu, L. Decisions on Sailing Frequency and Ship Type in Liner Shipping with the Consideration of Carbon Dioxide Emissions. Reg. Stud. Mar. Sci. 2022, 52, 102371. [Google Scholar] [CrossRef]

- Tan, Z.J.; Zeng, X.Y.; Shao, S.; Chen, J.H.; Wang, H. Scrubber Installation and Green Fuel for Inland River Ships with Non-Identical Streamflow. Transp. Res. Part E Logist. Transp. Rev. 2022, 161, 102677. [Google Scholar] [CrossRef]

- Msakni, M.K.; Haouari, M. Short-Term Planning of Liquefied Natural Gas Deliveries. Transp. Res. Part C Emerg. Technol. 2018, 90, 393–410. [Google Scholar] [CrossRef]

- Zhu, M.C.; Huang, L.W.; Huang, Z.Q.; Shi, F.; Xie, C. Hazard Analysis by Leakage and Diffusion in Liquefied Natural Gas Ships during Emergency Transfer Operations on Coastal Waters. Ocean Coast. Manag. 2022, 220, 106100. [Google Scholar] [CrossRef]

- Budiyanto, M.A.; Singgih, I.K.; Riadi, A.; Putra, G.L. Study on the LNG Distribution to Mobile Power Plants Using a Small-Scale LNG Carrier for the Case of the Sulawesi Region of Indonesia. Energy Rep. 2022, 8, 374–380. [Google Scholar] [CrossRef]

- Eriksen, U.; Kristiansen, J.; Fagerholt, K.; Pantuso, G. Planning a Maritime Supply Chain for Liquefied Natural Gas under Uncertainty. Marit. Transp. Res. 2022, 3, 100061. [Google Scholar] [CrossRef]

- Doymus, M.; Denktas Sakar, G.; Topaloglu Yildiz, S.; Acik, A. Small-Scale LNG Supply Chain Optimization for LNG Bunkering in Turkey. Comput. Chem. Eng. 2022, 162, 107789. [Google Scholar] [CrossRef]

- Niu, D.X.; Gao, C.N.; Xie, X.L.; Bao, T.T. A fleet deployment optimization model for LNG shipping. Nat. Gas Ind. 2015, 35, 101–104. [Google Scholar] [CrossRef]

- Wang, S.Y.; Notteboom, T. Shipowners’ Structure and Fleet Distribution in the Liquefied Natural Gas Shipping Market. Int. J. Shipp. Transp. Logist. 2014, 6, 488–512. [Google Scholar] [CrossRef]

- Bittante, A.; Pettersson, F.; Saxén, H. Optimization of a Small-Scale LNG Supply Chain. Energy 2018, 148, 79–89. [Google Scholar] [CrossRef]

- Koza, D.F.; Ropke, S.; Boleda Molas, A. The Liquefied Natural Gas Infrastructure and Tanker Fleet Sizing Problem. Transp. Res. Part E Logist. Transp. Rev. 2017, 99, 96–114. [Google Scholar] [CrossRef]

- Wang, N.; Yan, B.; Wu, N.; Zhao, W.J. Comments on “Case Studies of Shipping along Arctic Routes. Analysis and Profitability Perspectives for the Container Sector. Transp. Res. Part A Policy Pract. 2016, 94, 699–702. [Google Scholar] [CrossRef]

- Xing, Y.W.; Yang, H.L.; Ma, X.F. Optimization of containership sailing speed and fleet deployment for continental ocean liner based on freight rate differentiation strategy. Syst. Eng.—Theory Pract. 2018, 38, 3222–3234. [Google Scholar] [CrossRef]

- Quartieri, F. Are Vessel Sharing Agreements Pro-Competitive? Econ. Transp. 2017, 11–12, 33–48. [Google Scholar] [CrossRef]

- Chen, J.H.; Zhuang, C.L.; Yang, C.; Wan, Z.; Zeng, X.; Yao, J.Y. Fleet Co-Deployment for Liner Shipping Alliance: Vessel Pool Operation with Uncertain Demand. Ocean Coast. Manag. 2021, 214, 105923. [Google Scholar] [CrossRef]

| Ship Type with Subdivision Capacity | Daily Hire (USD/Day) | Annual Hire (USD/Year) | Ship Price (USD) |

|---|---|---|---|

| Type A LNG ship 145 K CBM | 49,163 | 17,944,496.84 | 130,000,000 |

| Type B LNG ship 174 K CBM | 91,084 | 33,245,508.84 | 170,000,000 |

| Type C LNG ship 220 K CBM | 102,305 | 37,341,481.95 | 220,000,000 |

| Ship Type | Ship Number | Fuel Price (USD/m3) | Cabin Capacity (104 m3) | Cargo Capacity (104 m3) | Service Speed (Knots) | Evaporation Rate (%/d) | Main Engine Consumption (m3/d) | Auxiliary Engine Consumption during Navigation (m3/d) | Auxiliary Engine Consumption during Berthing (m3/d) | Handling Efficiency (104 m3/d) |

|---|---|---|---|---|---|---|---|---|---|---|

| A | 3 | 150.29 | 14.72 | 13.25 | 20 | 0.135% | 325.80 | 14.24 | 23.14 | 26.40 |

| B | 4 | 150.29 | 17.40 | 15.66 | 19.5 | 0.142% | 289.60 | 18.69 | 27.06 | 27.60 |

| C | 3 | 150.29 | 21.62 | 19.46 | 19 | 0.145% | 262.45 | 21.36 | 30.97 | 28.80 |

| Line | Port of Discharge | Port of Loading | Round Trip Distance (Nautical Miles) | Annual Demand (104 m3) | Quantity Maneuver Range | Departure Interval (Days/Ship) | Annual Minimum Departure Frequency (Times/Year) | Cargo Value (USD/m3) |

|---|---|---|---|---|---|---|---|---|

| 1 | Shenzhen Dapeng LNG terminal, China | Withnell Bay, Australia | 5579.2 | 850 | 3% | 8.61 | 40 | 205.16 |

| 2 | Fujian Putian LNG terminal, China | Tangguh LNG terminal, Indonesia | 4041.4 | 800 | 4% | 9.25 | 37 | 205.16 |

| 3 | Shanghai Yangshan LNG terminal, China | Bintulu LNG terminal, Malaysia | 3652.8 | 900 | 5% | 8.31 | 42 | 205.16 |

| Vessel Type | Transportation Time | Route 1 | Route 2 | Route 3 |

|---|---|---|---|---|

| A | Sailing time | 13.95 | 10.10 | 9.13 |

| Berthing time | 3.28 | 2.89 | 2.79 | |

| Productive berthing | 1.25 | 1.25 | 1.25 | |

| Nonproductive berthing time | 0.63 | 0.63 | 0.63 | |

| Other reasons berthing time | 1.39 | 1.01 | 0.91 | |

| B | Sailing time | 14.31 | 10.36 | 9.37 |

| Berthing time | 3.51 | 3.11 | 3.01 | |

| Productive berthing | 1.38 | 1.38 | 1.38 | |

| Nonproductive berthing time | 0.69 | 0.69 | 0.69 | |

| Other reasons berthing time | 1.43 | 1.04 | 0.94 | |

| C | Sailing time | 14.68 | 10.64 | 9.61 |

| Berthing time | 3.87 | 3.47 | 3.36 | |

| Productive berthing | 1.60 | 1.60 | 1.60 | |

| Nonproductive berthing time | 0.80 | 0.80 | 0.80 | |

| Other reasons berthing time | 1.47 | 1.06 | 0.96 |

| Ship Type | Voyage Cost | Route | Capital Cost | Route | Running Cost | Route | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | ||||

| A | Fuel cost | 72.4 | 52.6 | 47.6 | Annual depreciation | 334.3 | 334.3 | 334.3 | Annual crew cost | 126.2 | 126.2 | 126.2 |

| Port commission | 16 | 16 | 16 | Annual premium | 260 | 260 | 260 | |||||

| Annual maintenance fee | 325 | 325 | 325 | |||||||||

| Handling charges | 14.7 | 14.7 | 14.7 | Annual interest payable | 520 | 520 | 520 | Moistening fee | 10.9 | 7.9 | 7.1 | |

| Other variable cost | 79 | 61.5 | 57.1 | Annual living supply cost | 25.2 | 25.2 | 25.2 | |||||

| Annual ship management fee | 50.5 | 50.5 | 50.5 | |||||||||

| Single voyage cost | 182.1 | 144.9 | 135.4 | Annual capital cost | 854.3 | 854.3 | 854.3 | Time charter annual hire | 1794.4 | 1794.4 | 1794.4 | |

| Annual running cost of self-owned ships | 797.8 | 794.8 | 794.1 | |||||||||

| B | Fuel cost | 74.3 | 54 | 48.9 | Annual depreciation | 437.1 | 437.1 | 437.1 | Annual crew cost | 128.2 | 128.2 | 128.2 |

| Port commission | 18 | 18 | 18 | Annual premium | 340 | 340 | 340 | |||||

| Annual maintenance hire | 425 | 425 | 425 | |||||||||

| Handling charges | 17.4 | 17.4 | 17.4 | Annual interest payable | 680 | 680 | 680 | Moistening fee | 11.1 | 8.1 | 7.3 | |

| Other variable cost | 100.4 | 78.3 | 72.8 | Annual living supply cost | 25.6 | 25.6 | 25.6 | |||||

| Annual ship management fee | 51.3 | 51.3 | 51.3 | |||||||||

| Single voyage cost | 210.1 | 167.8 | 157.1 | Annual capital cost | 1117.1 | 1117.1 | 1117.1 | Time charter annual hire | 3324.6 | 3324.6 | 3324.6 | |

| Annual running cost of self-owned ships | 981.2 | 978.2 | 977.4 | |||||||||

| C | Fuel cost | 76.4 | 55.6 | 50.3 | Annual depreciation | 565.7 | 565.7 | 565.7 | Annual crew cost | 130.2 | 130.2 | 130.2 |

| Port commission | 20 | 20 | 20 | Annual premium | 440 | 440 | 440 | |||||

| Annual maintenance fee | 550 | 550 | 550 | |||||||||

| Handling charges | 21.6 | 21.6 | 21.6 | Annual interest payable | 880 | 880 | 880 | Moistening fee | 11.5 | 8.3 | 7.5 | |

| Other variable cost | 130.3 | 101.9 | 94.7 | Annual living supply cost | 26 | 26 | 26 | |||||

| Annual ship management fee | 52.1 | 52.1 | 52.1 | |||||||||

| Single voyage cost | 248.3 | 199.1 | 186.6 | Annual capital cost | 1445.7 | 1445.7 | 1445.7 | Time charter annual hire | 3734.1 | 3734.1 | 3734.1 | |

| Annual running cost of self-owned ships | 1209.7 | 1206.6 | 1205.8 | |||||||||

| Vessel Type | Number of Ships Allocated to the Route | Route | Annual Voyages | Annual Cargo Volume of Completed Route (104 m3) | Vessel Type | Maximum Voyages | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Route 1 | Route 2 | Route 3 | Route 1 | Route 2 | Route 3 | |||||

| A | 0 | 2 | 1 | 1 | 44 | 852.35 | A | 20 | 27 | 29 |

| B | 1 | 1 | 2 | 2 | 41 | 801.02 | B | 24 | 26 | 28 |

| C | 1 | 1 | 1 | 3 | 46 | 900.72 | C | 23 | 24 | 27 |

| Type of Vessel | Number of Ships Allocated to the Route | Route | Annual Voyages | Annual Cargo Volume of Completed Route (104 m3) | ||

|---|---|---|---|---|---|---|

| Route 1 | Route 2 | Route 3 | ||||

| A | 1 | 1 | 1 | 1 | 43 | 842.36 |

| B | 2 | 1 | 1 | 2 | 42 | 807.23 |

| C | 1 | 1 | 1 | 3 | 47 | 898.31 |

| Serial Number | Variable Factors | Factor Change | Cost Variation | Cost Change | Sensitivity Coefficient |

|---|---|---|---|---|---|

| 1 | Ship price | 10% | 13,557,285.71 | 3.00% | 0.30 |

| 2 | Fuel price | 10% | 6,117,389.83 | 1.35% | 0.14 |

| 3 | Value of goods | 10% | 14,333,120.34 | 3.17% | 0.32 |

| 4 | Port Commission | 10% | 1,880,000.00 | 0.42% | 0.04 |

| 5 | Other variable costs | 10% | 10,377,366.84 | 2.30% | 0.23 |

| 6 | Annual crew cost | 10% | 1,230,528.00 | 0.27% | 0.03 |

| 7 | Time charter annual hire | 10% | 12,177,699.65 | 2.69% | 0.27 |

| 8 | Nonproductive berthing time | 10% | 492,256.37 | 0.11% | 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Wang, X.; Wang, H.; Cheng, S.; Liu, W. Fleet Deployment Optimization for LNG Shipping Vessels Considering the Influence of Mixed Factors. J. Mar. Sci. Eng. 2022, 10, 2034. https://doi.org/10.3390/jmse10122034

Zhao Z, Wang X, Wang H, Cheng S, Liu W. Fleet Deployment Optimization for LNG Shipping Vessels Considering the Influence of Mixed Factors. Journal of Marine Science and Engineering. 2022; 10(12):2034. https://doi.org/10.3390/jmse10122034

Chicago/Turabian StyleZhao, Zhongbin, Xifu Wang, Hao Wang, Suxin Cheng, and Wei Liu. 2022. "Fleet Deployment Optimization for LNG Shipping Vessels Considering the Influence of Mixed Factors" Journal of Marine Science and Engineering 10, no. 12: 2034. https://doi.org/10.3390/jmse10122034

APA StyleZhao, Z., Wang, X., Wang, H., Cheng, S., & Liu, W. (2022). Fleet Deployment Optimization for LNG Shipping Vessels Considering the Influence of Mixed Factors. Journal of Marine Science and Engineering, 10(12), 2034. https://doi.org/10.3390/jmse10122034