A Review of Durability Issues of Reinforced Concrete Structures Due to Coastal Soda Residue Soil in China

Abstract

:1. Introduction

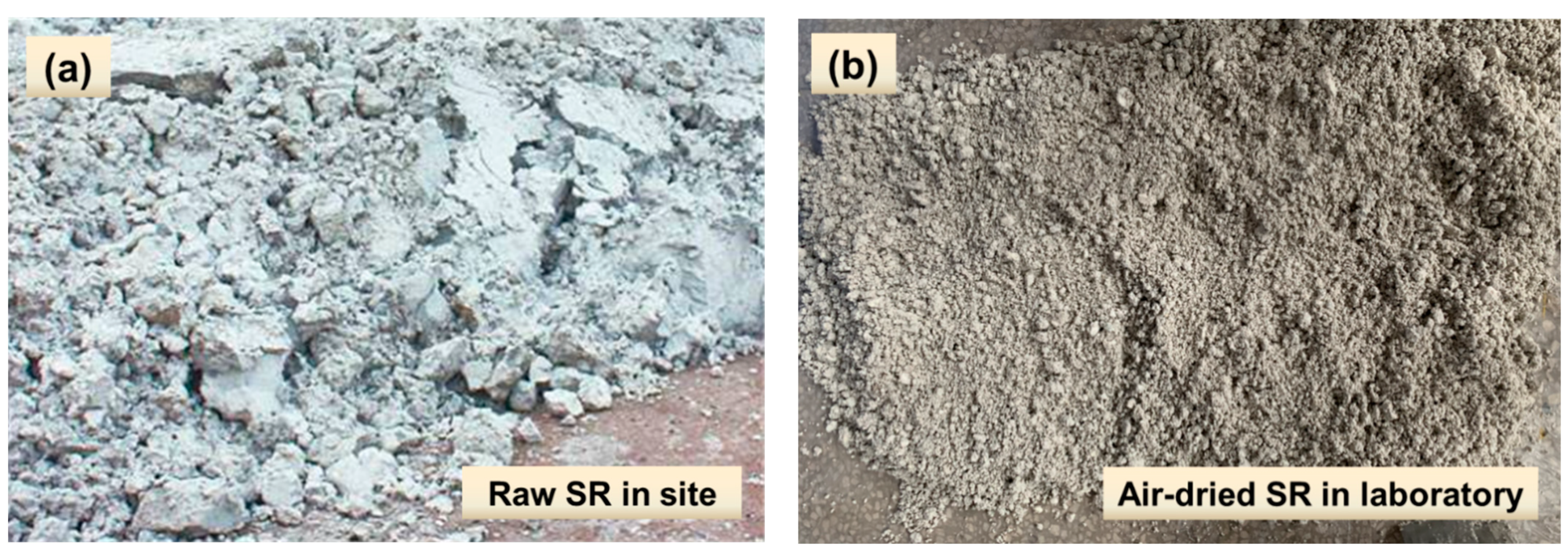

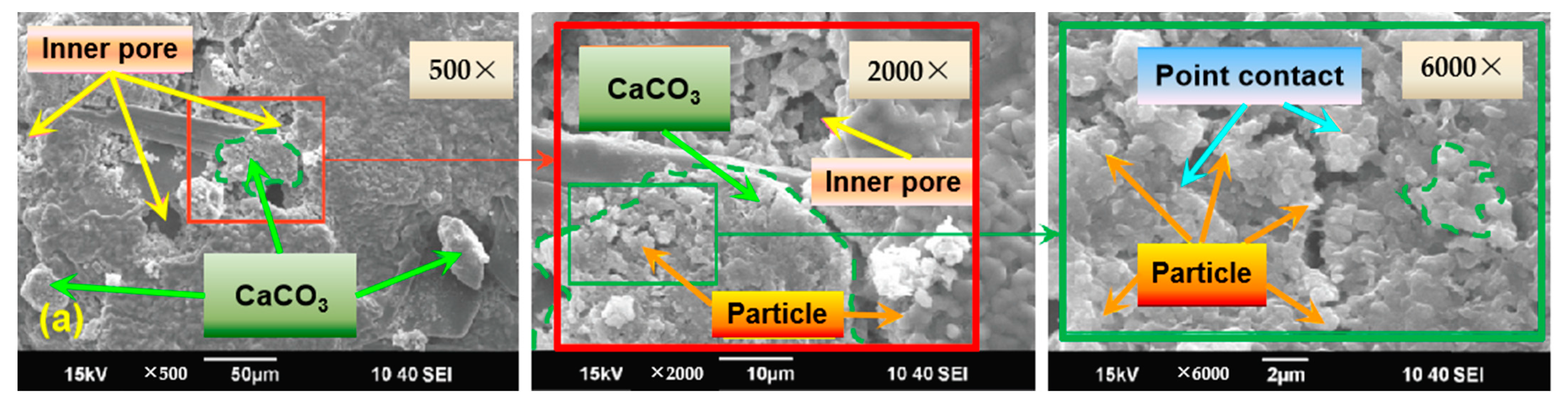

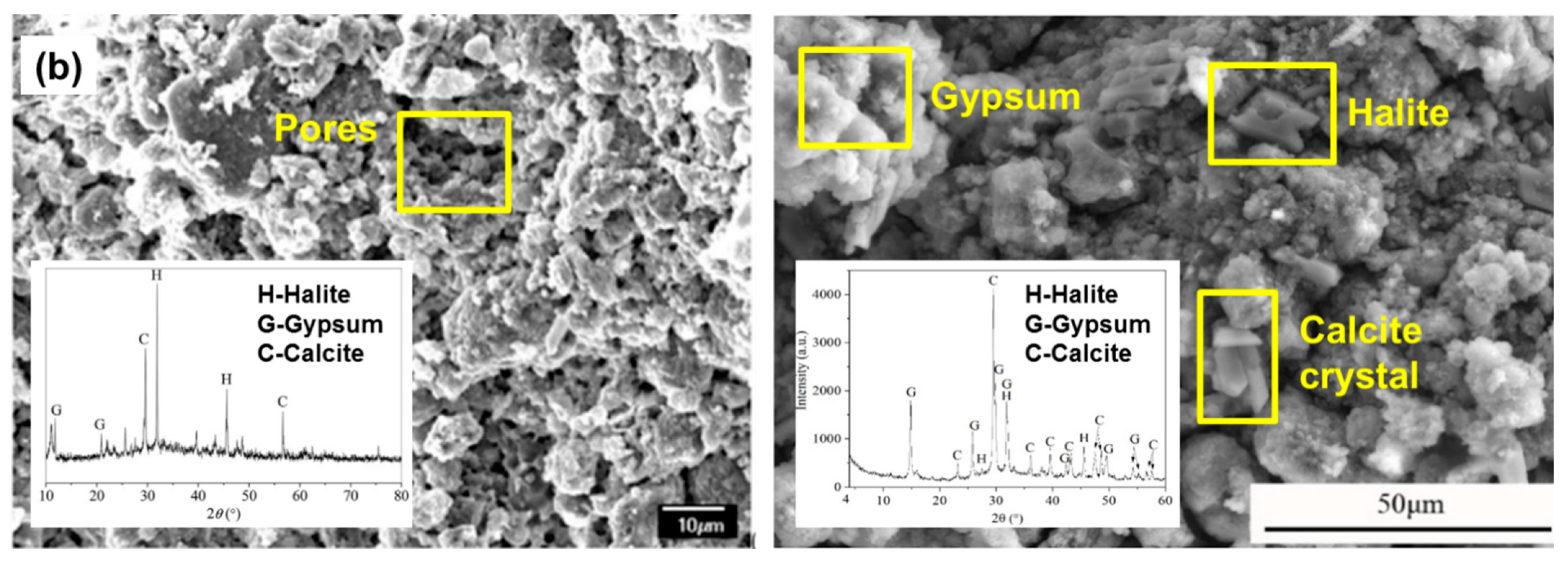

2. Material Properties of SRS

2.1. Using Soda Residue as Engineering Foundation Soil

2.2. Corrosive Property of SRS for RC Structure

2.3. Soil Type of SRS

3. Literature Review Exploring the Influence of Saline-Soil Corrosive Environments on RC Structure Durability

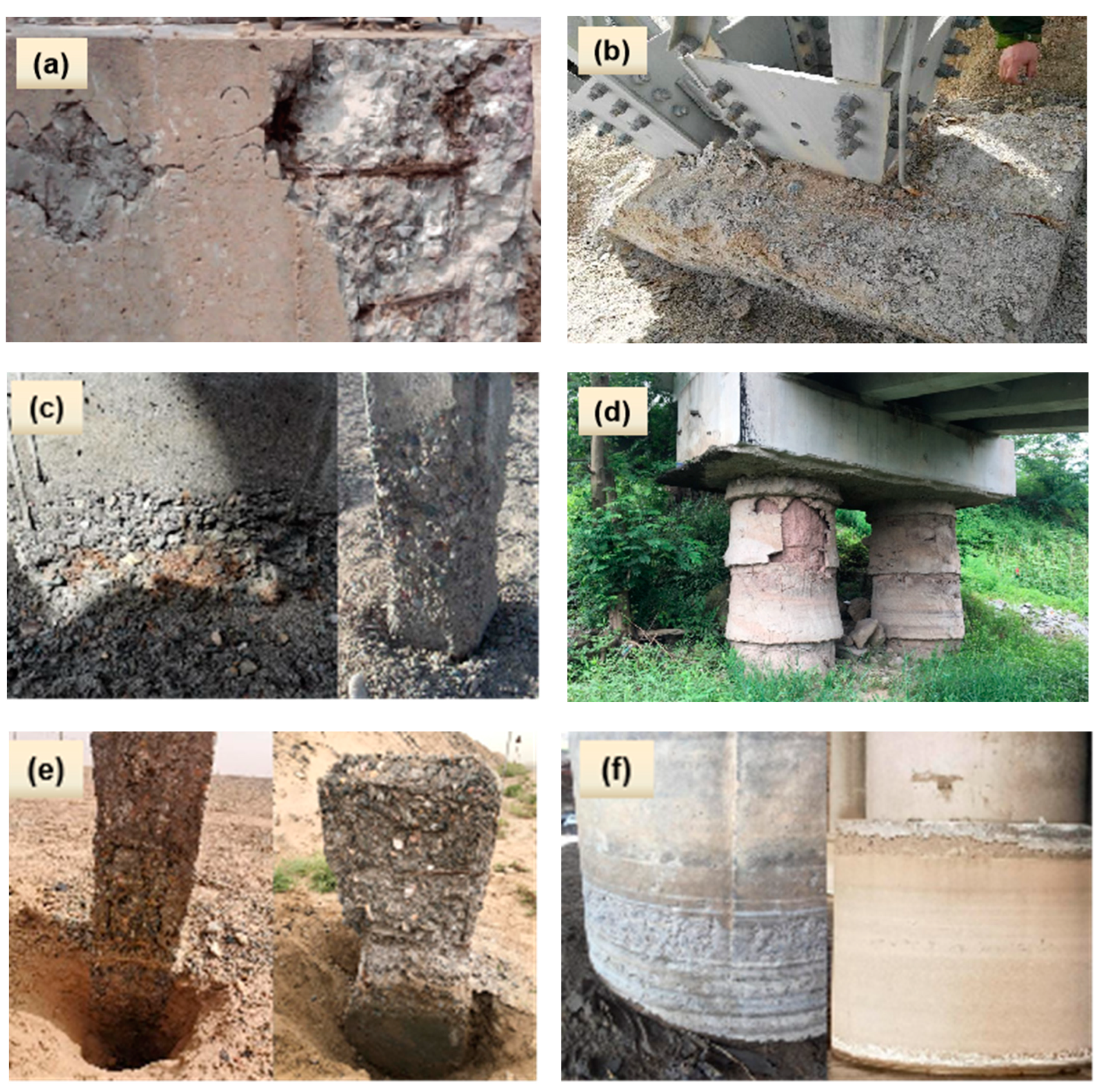

3.1. Deterioration of RC Structures in Saline Soil Corrosive Environments

3.2. Advances in the Durability of RC Structures in Saline-Soil Corrosive Environments

3.3. Measures to Improve the Durability of RC Structures in Saline Soil Environments

4. Results and Discussion of Durability Issues of RC Structures in Coastal SRS Environments

- (1)

- The transport mechanism and prediction model of corrosive ions dominated by Cl− in SRS and RC structures require in-depth investigation.

- (2)

- The deterioration mechanism of RC materials in coastal SRS environments needs to be further examined.

- (3)

- The long-term performance reduction process of RC components in coastal SRS corrosion environments requires elaboration.

- (4)

- A durability design theory for RC structures needs to be established, considering the effect of the intrusion of multiple corrosive ions into concrete.

- (5)

- Effective enhancement measures should be proposed to improve the durability of RC structures in coastal SRS corrosive environments.

5. Conclusions and Future Works

- (1)

- The soda residue used as an engineering foundation soil can be classified as coastal excessive-chlorine saline soil, based on its soil properties. The internal pore structure for SRS is well-developed and its moisture content is very high compared to that of general soil. The soluble Cl− content within the pore solution of SRS is almost 2–3 times higher than that of the marine environment. RC structures built on SRS are subjected to rapid invasion by high concentrations of Cl− ions, which induces accelerated rebar corrosion and shortens the durability service life of such structures.

- (2)

- According to our review of the advances in the durability of RC structures in saline soil environments in China, the importance and urgency of durability issues are further demonstrated. A number of useful methods, technical approaches, significant achievements and improvement measures reported in the literature can help us to provide vital support for further exploration of the durability of RC structures in coastal SRS environments.

- (3)

- In view of the threat to RC structures caused by coastal SRS in China, the durability of such structures should be urgently investigated. Investigations can be divided into three aspects, namely, materials, components and structures, covering the transport mechanisms and prediction models of corrosive ions dominated by Cl− in RC, the deterioration mechanisms of RC materials, long-term performance evaluations of RC components, durability design theory for RC structures considering the effect of the intrusion of multiple corrosive ions into concrete, and enhancement measures which are needed to improve the durability of such structures. These are clear research directions for the development of a basic theory of RC structure durability in coastal SRS environments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, H.H.; Xu, B.; Liu, Q.; Gu, J.F. Study on Failure Performance of the Thin-Walled Steel-Reinforced Concrete Pier under Low Cyclic Loading. Buildings 2022, 12, 1412. [Google Scholar] [CrossRef]

- Skokandić, D.; Vlašić, A.; Kušter Marić, M.; Srbić, M.; Mandić Ivanković, A. Seismic Assessment and Retrofitting of Existing Road Bridges: State of the Art Review. Materials 2022, 15, 2523. [Google Scholar] [CrossRef]

- Wang, B.X.; Liu, J.Q.; Wang, Q. Experimental Study on the Permeation and Migration Rules of Pressurized Water in Textile-Reinforced Concrete (TRC). Materials 2021, 14, 6512. [Google Scholar] [CrossRef]

- Oktavianus, Y.; Sofi, M.; Lumantarna, E.; Kusuma, G.; Duffield, C. Long-Term Performance of Trestle Bridges: Case Study of an Indonesian Marine Port Structure. J. Mar. Sci. Eng. 2020, 8, 358. [Google Scholar] [CrossRef]

- Lecieux, Y.; Rozière, E.; Gaillard, V.; Lupi, C.; Leduc, D.; Priou, J.; Guyard, R.; Chevreuil, M.; Schoefs, F. Monitoring of a Reinforced Concrete Wharf Using Structural Health Monitoring System and Material Testing. J. Mar. Sci. Eng. 2019, 7, 84. [Google Scholar] [CrossRef] [Green Version]

- Yao, M.B.; Li, J.P. Effect of the degradation of concrete friction piles exposed to external sulfate attack on the pile bearing capacity. Ocean Eng. 2019, 173, 599–607. [Google Scholar] [CrossRef]

- Liang, Y.Q.; Wang, L.C. Prediction of corrosion-induced cracking of concrete cover: A critical review for thick-walled cylinder models. Ocean Eng. 2020, 213, 107688. [Google Scholar] [CrossRef]

- Shao, W.; Nie, Y.H.; Shi, D.D.; Xu, Y.Z. Probabilistic analysis of the behaviour of laterally loaded piles in chloride environments. Ocean Eng. 2020, 217, 107872. [Google Scholar] [CrossRef]

- Zeng, B.; Yang, Y.; Gong, F.; Maekawa, K. Corrosion Crack Morphology and Creep Analysis of Members Based on Meso-Scale Corrosion Penetration. Materials 2022, 15, 7338. [Google Scholar] [CrossRef]

- Zhang, S.H.; Tian, B.; Chen, B.F.; Lu, X.C.; Xiong, B.B.; Shuang, N. The Influence of Freeze–Thaw Cycles and Corrosion on Reinforced Concrete and the Relationship between the Evolutions of the Microstructure and Mechanical Properties. Materials 2022, 15, 6215. [Google Scholar] [CrossRef]

- Wang, J.; Yuan, Y.Y.; Xu, Q.; Qin, H.T. Prediction of Corrosion-Induced Longitudinal Cracking Time of Concrete Cover Surface of Reinforced Concrete Structures under Load. Materials 2022, 15, 7395. [Google Scholar] [CrossRef]

- Ahmed, E.S.J.; Ganesh, G.M. A Comprehensive Overview on Corrosion in RCC and Its Prevention Using Various Green Corrosion Inhibitors. Buildings 2022, 12, 1682. [Google Scholar] [CrossRef]

- Syll, A.S.; Kanakubo, T. Impact of Corrosion on the Bond Strength between Concrete and Rebar: A Systematic Review. Materials 2022, 15, 7016. [Google Scholar] [CrossRef]

- Renne, N.; Kara De Maeijer, P.; Craeye, B.; Buyle, M.; Audenaert, A. Sustainable Assessment of Concrete Repairs through Life Cycle Assessment (LCA) and Life Cycle Cost Analysis (LCCA). Infrastructures 2022, 7, 128. [Google Scholar] [CrossRef]

- Lajevardi, S.M.S.; Moghadas Nejad, F.; Ravanshadnia, M. Experimental Study on a Reinforced Concrete Element to Extract the Durability Index with the Automated Visualization. Appl. Sci. 2022, 12, 9609. [Google Scholar] [CrossRef]

- Ju, X.L.; Wu, L.J.; Lin, C.; Yang, X.; Yang, C. Prediction of chloride concentration with elevation in concrete exposed to cyclic drying-wetting conditions in marine environments. Constr. Build. Mater. 2021, 278, 122370. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Wu, L.J.; Wang, Y.C.; Li, Q.M.; Xiao, Z. Prediction model of long-term chloride diffusion into plain concrete considering the effect of the heterogeneity of materials exposed to marine tidal zone. Constr. Build. Mater. 2018, 159, 297–315. [Google Scholar] [CrossRef]

- Ju, X.L.; Wu, L.J.; Liu, M.W.; Jiang, H.; Zhang, W.X. Modelling of Chloride Concentration Profiles in Concrete by the Consideration of Concrete Material Factors under Marine Tidal Environment. J. Mar. Sci. Eng. 2022, 10, 917. [Google Scholar] [CrossRef]

- Ju, X.L.; Wu, L.J.; Liu, M.W.; Guan, L.; Ma, Y.F. Determination of Chloride Diffusion Coefficient of Interfacial Transition Zone in Coastal Concrete Structures Based on the Experimental and Numerical Methods. In Proceedings of the Fourteenth ISOPE Pacific/Asia Offshore Mechanics Symposium, Dalian, China, 22 November 2020. [Google Scholar]

- Wang, Y.; Gong, X.; Wu, L. Prediction model of chloride diffusion in concrete considering the coupling effects of coarse aggregate and steel reinforcement exposed to marine tidal environment. Constr. Build. Mater. 2019, 216, 40–57. [Google Scholar] [CrossRef] [Green Version]

- Morales, C.N.; Claure, G.; Emparanza, A.R.; Nanni, A. Durability of GFRP reinforcing bars in seawater concrete. Constr. Build. Mater. 2021, 270, 121492. [Google Scholar] [CrossRef]

- Cui, Z.; Alipour, A. Concrete cover cracking and service life prediction of reinforced concrete structures in corrosive environments. Constr. Build. Mater. 2018, 159, 652–671. [Google Scholar] [CrossRef]

- Safehian, M.; Ramezanianpour, A.A. Assessment of service life models for determination of chloride penetration into silica fume concrete in the severe marine environmental condition. Constr. Build. Mater. 2013, 48, 287–294. [Google Scholar] [CrossRef]

- Lliso-Ferrando, J.; Gasch, I.; Martínez-Ibernón, A.; Valcuende, M. Effect of macrocell currents on rebar corrosion in reinforced concrete structures exposed to a marine environment. Ocean Eng. 2022, 257, 111680. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, L.; Wang, Y.; Liu, C.; Li, Q. Effects of coarse aggregates on chloride diffusion coefficients of concrete and interfacial transition zone under experimental drying-wetting cycles. Constr. Build. Mater. 2018, 185, 230–245. [Google Scholar] [CrossRef]

- Wu, L.; Ju, X.; Liu, M.; Guan, L.; Ma, Y.; Li, M. Influences of multiple factors on the chloride diffusivity of the interfacial transition zone in concrete composites. Compos. Part B Eng. 2020, 199, 108236. [Google Scholar] [CrossRef]

- Wu, L.; Wang, Y.; Wang, Y.; Ju, X.; Li, Q. Modelling of two-dimensional chloride diffusion concentrations considering the heterogeneity of concrete materials. Constr. Build. Mater. 2020, 243, 118213. [Google Scholar] [CrossRef]

- Wu, L.J.; Ju, X.L.; Ma, Y.F.; Guan, L. Prediction Model of Chloride Diffusion in Concrete Considering the Blocking Effects of Rebar. J. Build. Mater. 2021, 24, 296–303+332. [Google Scholar] [CrossRef]

- Ju, X.L.; Wu, L.J.; Liu, M.W.; Zhang, H.; Li, T.T. Service Life Prediction for Reinforced Concrete Wharf Considering the InfluenceChloride Erosion Dimension. Mater. Rep. 2021, 35, 24075–24080+24087. [Google Scholar] [CrossRef]

- Li, D.; Li, L.; Li, P.; Xing, F. Analytical modelling of chloride ingress in surface-treated concrete. Ocean Eng. 2022, 250, 111091. [Google Scholar] [CrossRef]

- Bansal, T.; Talakokula, V.; Rama Jyosyula, S.K.; Vicente, R.; Ascensão, G. Embedded Piezo-Sensor-Based Automatic Performance Monitoring of Chloride-Induced Corrosion in Alkali-Activated Concrete. Sustainability 2022, 14, 12917. [Google Scholar] [CrossRef]

- Kim, Y.S.; Lee, B.G.; Jung, J.S.; Lee, K.S. Seismic Performance Evaluation of Corrosion-Damaged Reinforced Concrete Columns Controlled by Shear Based on Experiment and FEA. Materials 2022, 15, 6361. [Google Scholar] [CrossRef] [PubMed]

- Xi, Y.N.; Gao, Y.; Li, W.W.; Lei, D. A Numerical Study on the Electrochemical Treatment of Chloride-Contaminated Reinforced Concrete. Modelling 2022, 3, 374–384. [Google Scholar] [CrossRef]

- Otieno, M.; Beushausen, H.; Alexander, M. Chloride-induced corrosion of steel in cracked concrete—Part II: Corrosion rate prediction models. Cem. Concr. Res. 2016, 79, 386–394. [Google Scholar] [CrossRef]

- Otieno, M.; Beushausen, H.; Alexander, M. Chloride-induced corrosion of steel in cracked concrete—Part I: Experimental studies under accelerated and natural marine environments. Cem. Concr. Res. 2016, 79, 373–385. [Google Scholar] [CrossRef]

- Zhao, X.H.; Liu, C.Y.; Wang, L.; Zuo, L.M.; Zhu, Q.; Ma, W. Physical and mechanical properties and micro characteristics of fly ash-based geopolymers incorporating soda residue. Cem. Concr. Compos. 2019, 98, 125–136. [Google Scholar] [CrossRef]

- Erabi, M.; Goshadrou, A. Bioconversion of Glycyrrhiza glabra residue to ethanol by sodium carbonate pretreatment and separate hydrolysis and fermentation using Mucor hiemalis. Ind. Crops. Prod. 2020, 152, 112537. [Google Scholar] [CrossRef]

- Liu, R.Z.; Li, J.L.; Wang, Y.W.; Liu, D.W. Flotation separation of pyrite from arsenopyrite using sodium carbonate and sodium humate as depressants. Colloids Surf. A Physicochem. Eng. Asp. 2020, 595, 124669. [Google Scholar] [CrossRef]

- Wang, X.; Xiang, Y.; Li, X. Environmental risk for application of ammonia-soda white mud in soils in China. J. Integr. Agric. 2020, 19, 601–611. [Google Scholar] [CrossRef]

- Uçal, G.O.; Mahyar, M.; Tokyay, M. Hydration of alinite cement produced from soda waste sludge. Constr. Build. Mater. 2018, 164, 178–184. [Google Scholar] [CrossRef]

- Zha, F.; Pan, D.; Xu, L.; Kang, B.; Yang, C.; Chu, C. Investigations on engineering properties of solidified/stabilized Pb-contaminated soil based on alkaline residue. Adv. Civ. Eng. 2018, 2018, 8595419. [Google Scholar] [CrossRef]

- Jiang, Q.; Ismail, J.; Zaïri, F.; Qu, Z.; Naït-Abdelaziz, M.; Azari, Z.; Liu, X.D. Damage interaction and angle effects on the erosion behavior of soda-lime-silica glass. Int. J. Damage Mech. 2019, 28, 118–133. [Google Scholar] [CrossRef]

- Zhao, X.H.; Liu, C.Y.; Zuo, L.M.; Zhu, Q.; Ma, W.; Liu, Y.C. Preparation and characterization of press-formed fly ash cement incorporating soda residue. Mater. Lett. 2020, 259, 126852. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, C.; Zuo, L.; Wang, L.; Zhu, Q.; Liu, Y.; Zhou, B. Synthesis and characterization of fly ash geopolymer paste for goaf backfill: Reuse of soda residue. J. Clean. Prod. 2020, 260, 121045. [Google Scholar] [CrossRef]

- Chen, T. Experimental Study on Mechanical Properties and Long-Term Deformation of Soda Residue Soil under Complex Stress Conditions. Master’s thesis, Tianjin University, Tianjin, China, 2019. [Google Scholar] [CrossRef]

- Ma, J.X.; Yan, N.; Zhang, M.Y.; Liu, J.W.; Bai, X.Y.; Wang, Y.H. Mechanical Characteristics of Soda Residue Soil Incorporating Different Admixture: Reuse of Soda Residue. Sustainability 2020, 12, 5852. [Google Scholar] [CrossRef]

- Yuan, X.; Zhang, H.; Liu, X.; Xiong, F. Influence of alkaline residue site on carst groundwater. Adm. Tech. Environ. Monit. 2010, 22, 36–39. [Google Scholar] [CrossRef]

- Gomes, H.I.; Mayes, W.M.; Rogerson, M.; Stewart, D.I.; Burke, I.T. Alkaline residues and the environment: A review of impacts, management practices and opportunities. J. Clean. Prod. 2016, 112, 3571–3582. [Google Scholar] [CrossRef] [Green Version]

- He, J.; Wang, X.; Su, Y.; Li, Z.; Shi, X. Shear strength of stabilized clay treated with soda residue and ground granulated blast furnace slag. J. Mater. Civ. Eng. 2019, 31, 06018029. [Google Scholar] [CrossRef]

- He, J.; Li, Z.-X.; Wang, X.-Q.; Shi, X.-K. Durability of soft soil treated with soda residue and ground granulated blast furnace slag in a soaking environment. J. Mater. Civ. Eng. 2020, 32, 06019018. [Google Scholar] [CrossRef]

- Zięba, J.; Rzepka, P.; Olek, B.S. Strength and Compressibility of Ammonia-Soda Residue from the Solvay Sodium Plant. Appl. Sci. 2021, 11, 11305. [Google Scholar] [CrossRef]

- Li, H.; Zhu, S.; Yin, W.; Zhu, Z.; Zhang, K.; Bai, X.; Liu, D.; Tang, Y. Study on Strength Test and Application of Lime Soil in Pavement Base Modified by Soda Residue. Adv. Civ. Eng. 2022, 2022, 4887647. [Google Scholar] [CrossRef]

- Lin, Y.; Xu, D.; Zhao, X. Effect of Soda Residue Addition and Its Chemical Composition on Physical Properties and Hydration Products of Soda Residue-Activated Slag Cementitious Materials. Materials 2020, 13, 1789. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Zhao, X.; Zhou, B.; Lin, Y.; Gao, H. Performance Optimization and Characterization of Soda Residue-Fly Ash Geopolymer Paste for Goaf Backfill: Beta-Hemihydrate Gypsum Alternative to Sodium Silicate. Materials 2020, 13, 5604. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Liang, Y.; Jiang, L.; Zhang, C.; Wang, Q. Characteristics of ammonia-soda residue and its reuse in magnesium oxychloride cement pastes. Constr. Build. Mater. 2021, 300, 123981. [Google Scholar] [CrossRef]

- Ding, W.; Ma, X.; Leng, F.; Wang, Y. Evaluation and applied measures of base concrete in saline area of Ge’ermu. Concrete 2005, 7, 78–83. [Google Scholar] [CrossRef]

- Tian, G.F.; Leng, F.G.; Zhang, R.Y.; Ma, X.X. Experiment study of corrosion regularity and mechanism of concrete in alkaline soil. Equip. Environ. Eng. 2007, 5, 10–14+22. [Google Scholar] [CrossRef]

- Leng, F.; Ma, X.; Ding, W.; Wang, J.; Zhou, Y.; Ji, X. Durability analysis of RC piles exposed naturally in coastal saline soil environment for 17 years. Build. Struct. 2011, 41, 148–151+144. [Google Scholar] [CrossRef]

- GB 50021-2001(2009); Code for Investigation of Geotechincal Engineering. Available online: https://www.chinesestandard.net/PDF.aspx/GB50021-2001 (accessed on 1 October 2022).

- Ma, X. The classification of main soil corrosion to concrete materials in our country. Build. Sci. 2003, 6, 56–57. [Google Scholar] [CrossRef]

- Guo, J. Research on Service Performance of Buried Concrete Components in Qinghai Saline Soil Area. Master’s thesis, Qinghai University, Xining, China, 2021. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, W.; Zhang, W.; Li, B.; Yang, X.; Hu, P. The Current Situation and Prospect of the Corrosion of reinforced Concrete in Saline Soils. Sci. Technol. Eng. 2020, 20, 883–891. [Google Scholar] [CrossRef]

- Luo, B.F.; Ding, S.X.; Pan, J.Y.; Fang, J.; Wang, Y.; Li, Z.; Chen, F.; Xu, H.; Wang, Q.; Xi, Y.; et al. Guide for Highway Design and Construction in Saline Soil Areas, 1st ed.; China Communications Press: Beijing, China, 2006. [Google Scholar]

- Zhuang, Y.; Dai, Y. Corrosion damages to the reinforced concrete box foundation of the steam-turbine houes at the dagang plant in tianjin. Hydro-Sci. Eng. 1990, 4, 439–444. [Google Scholar] [CrossRef]

- Zhao, J.D. Study on the Corrosion Resistance of Partially-Exposed Concrete in Saline Soil Areas. Master’s thesis, Chang’an University, Xian, China, 2013. [Google Scholar] [CrossRef]

- Cao, J.; Wang, C.; Zhang, X.X.; Wang, H.Y.; Qi, Z.L. Corrosion degradation test of basalt fiber concrete under salt-wet cycle. Energy Conserv. Technol. 2021, 39, 475–481. [Google Scholar] [CrossRef]

- Yang, Y.; Chadha, M.; Hu, Z.; Vega, M.A.; Parno, M.D.; Todd, M.D. A probabilistic optimal sensor design approach for structural health monitoring using risk-weighted f-divergence. Mech. Syst. Signal Process. 2021, 161, 107920. [Google Scholar] [CrossRef]

- Yuan, Z.L. Experimental Study on Degradation Mechanism of Polypropylene Fiber Concrete under the Action of Compound Salt Erosion. Master’s thesis, Tarim University, Alar, China, 2021. [Google Scholar] [CrossRef]

- Yang, L.L. The Research on Evaluation of Steel Corrosion and Technology of Anti-Corrosion for Reinforced Concrete. Master’s thesis, Lanzhou University of Technology, Lanzhou, China, 2019. [Google Scholar]

- Li, J.; Li, L.; Chen, H.; Shao, W.; Yue, Z. Advances in concrete pile durability in corrosive environment. J. Harbin Inst. Technol. 2017, 49, 1–15. [Google Scholar] [CrossRef]

- Li, S.Y. Study on Durability of Concrete in Saline Soil: A Case Study in Hetao Area of Inner Mongolia. Master’s thesis, Inner Mongolia University, Hohhot, China, 2018. [Google Scholar] [CrossRef]

- Lin, D.Y.; Yi, B.; Chen, Y.X.; Zhang, J.X.; Hong, Y.C. Research development of the corrosion of reinforced concrete in saline soil environment. Mater. Rep. 2014, 28, 137–141. [Google Scholar]

- Man, D.L.; Yin, H.; Cao, M.Q. Research progress of concrete durability in saline soil environment. Bull. Chin. Ceram. Soc. 2016, 35, 3575–3580+3606. [Google Scholar] [CrossRef]

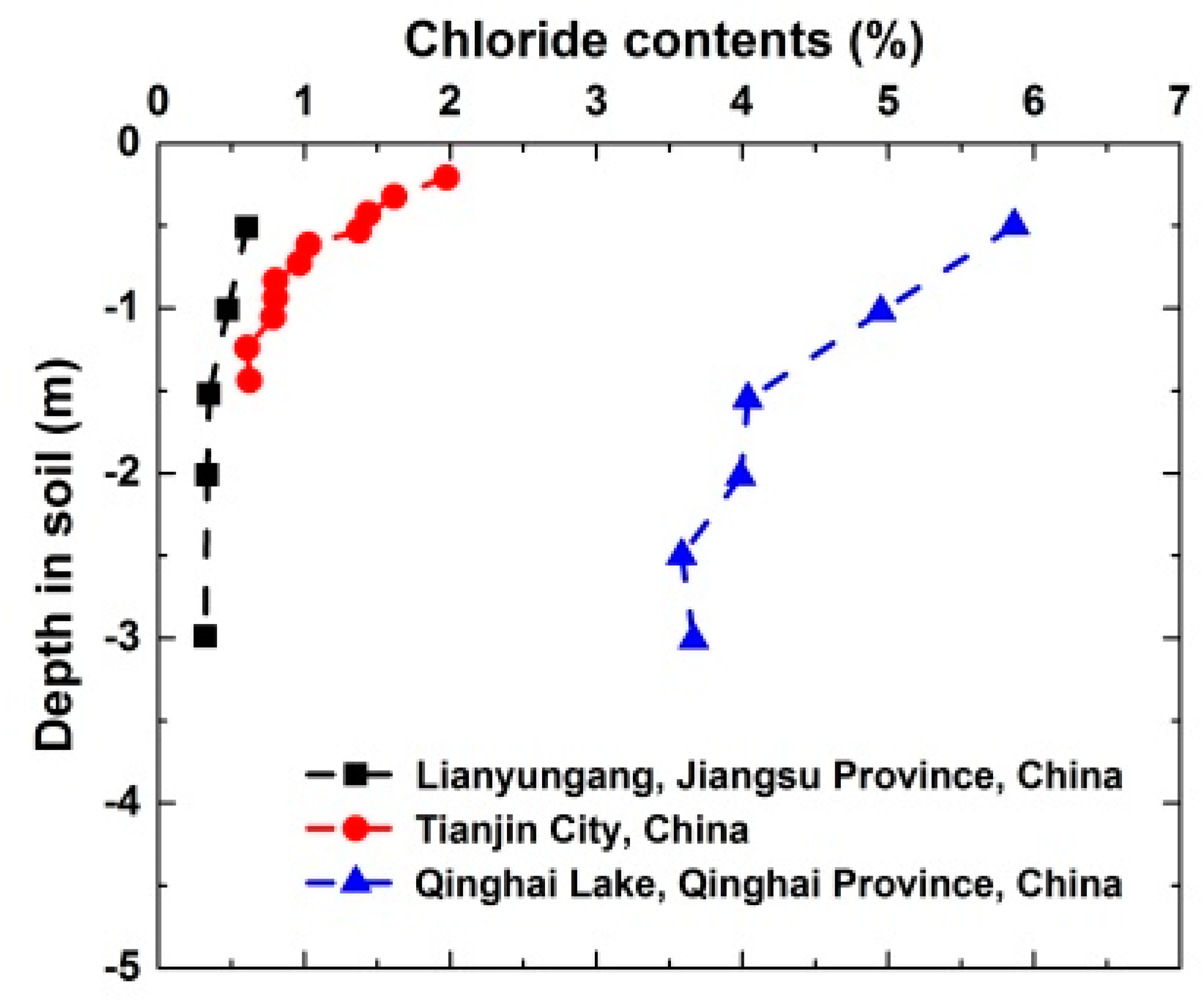

- Qiao, D.; Xia, W.; Zhao, Y.; Zhou, X.; Xu, Y. Durability of concrete in saline soil in Lianyungang. Chin. J. Geotech. Eng. 2010, 32 (S2), 611–614. [Google Scholar]

- Zhang, H.L.; Zhu, Y.F.; Han, J.C. Study of the durability of partially-exposed concretein chloride saline soil areas of Qinghai Province. J. Hefei Univ. Technol. 2015, 38, 804–809. [Google Scholar] [CrossRef]

- Sun, B. Experimental Research on the Durability and Life Prediction of the Ordinary Concrete Field Exposure in Tianshui. Master’s thesis, Lanzhou University of Technology, Lanzhou, China, 2014. [Google Scholar] [CrossRef]

- Qiao, H.; Lu, C.; Li, Y.; Guan, L. Experiment on durability damage assessment of concrete field exposed in saline soil area of ningxia. J. Archit. Civ. Eng. 2016, 33, 44–52. [Google Scholar] [CrossRef]

- Qiao, H.X.; Zhu, B.R.; Chen, D.S. Experimental Study of the Deterioration Mechanism of Concrete in Xining Saline Soil Area. J. Basic Sci. Eng. 2017, 25, 805–815. [Google Scholar] [CrossRef]

- Qiao, H.; Gong, W.; Cheng, Q.; Dong, J.; Chen, G.; Hua, L. Durability of magnesium cement reinforced concrete in saline soil area. J. China Coal. Soc. 2015, 40 (S2), 346–352. [Google Scholar] [CrossRef]

- Qiao, H.X.; Ma, H.W.; Wang, J.L.; Lu, C.G. Optimum mix ratio of magnesium cement concrete based on nondestructive testing method under different environment. Bull. Chin. Ceram. Soc. 2017, 36, 1258–1265. [Google Scholar] [CrossRef]

- Qiao, H.; Wang, P.; Li, Y.; Guo, X.; Gong, W. Corrosion prediction of coated steel in magnesium cement concrete based on wiener degradation. J. Southwest Jiaotong Univ. 2019, 54, 1252–1257. [Google Scholar] [CrossRef]

- Qiao, H.; Yang, Z.; Wang, P.; Wen, S. Corrosion life investigation of coated steel bars in magnesium cement concrete under salt solution environment using wiener process. J. Build. Mater. 2021, 24, 986–993. [Google Scholar] [CrossRef]

- Qiao, H.X.; Fu, Y.; Lu, C.G.; Guo, F. Research on durability of concrete accelerated test based on wiener degradation. Bull. Chin. Ceram. Soc. 2020, 39, 3496–3502. [Google Scholar] [CrossRef]

- Yan, C.; Ll, J.; Zhang, J.; Liu, S. Chloride diffusion in concrete in a west chlorine saline soil medium. J. Funct. Mater. 2016, 47, 2060–2066. [Google Scholar] [CrossRef]

- Jing, L.; Yan, C.; Liu, S.; Zhang, J. Corrosion probability analysis of reinforcement in concrete protective layer in chlorinated soil area. Highway 2016, 61, 187–190. [Google Scholar]

- Jing, L.; Yan, C.; Liu, S.; Zhang, J.; Duan, L. BP neural network to predict service life of concrete structures in the chlorine saline soil environment. Concrete 2016, 10, 8–10+15. [Google Scholar] [CrossRef]

- Jing, L.; Yan, C.W.; Liu, S.G.; Zhang, J.; Duan, L.J. Service life prediction of concrete structures in chlorine saline soil region based on monte carlo method. Corros. Prot. 2016, 37, 743–747+752. [Google Scholar] [CrossRef]

- Wu, Q.; Li, B.C.; Yin, R.R.; Shi, T.Y.; Yu, C.J. Study on the deterioration process of directional corrosion of concrete in sulfate and chloride solution. J. Jiangsu Univ. Sci. Technol. Nat. Sci. Ed. 2017, 31, 865–870. [Google Scholar] [CrossRef]

- Gao, Z.; Li, S.; Chen, Z.; Xu, Y. Coupling model of chloride ion migration from saline soil to concrete. J. Yangtze River Sci. Res. Inst. 2017, 34, 131–134+140. [Google Scholar] [CrossRef]

- Liao, M.K.; Liu, E.L.; Fu, L.; Yang, S.J.; You, Z.M. Experimental study on salt ion corrosion of concrete in saline soil environments. Concrete 2019, 1, 81–85+89. [Google Scholar] [CrossRef]

- Wang, J.B.; Zhang, K.F.; Hou, Z.Y.; Niu, D.T. Ion diffusion in shotcrete lining under compound salt corrosion environment saline soil in Northwest China. China Civ. Eng. J. 2020, 53, 21–35. [Google Scholar] [CrossRef]

- Wang, C.P.; Zhang, J.S. Field exposure test of reinforced concrete short columns in saline soil area based on three-parameter weibull function. J. Water Resour. Archit. Eng. 2021, 19, 118–123. [Google Scholar] [CrossRef]

- Meng, X.; Feng, Q.; Zhang, Y.; Qiao, H.; Xie, X. Analysis of corrosion-induced deterioration behavior and competing failure of reinforced concrete in saline soil environment. Mater. Rep. 2022, 14, 1–24. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, W.X.; Bai, Y.; Ning, F.W. Influence of compressive strength on durability of bored pile concrete in saline soil region. Water Resour. Power 2016, 34, 165–168. [Google Scholar]

- Wang, C.; Ge, G.H.; Hou, J.G.; Li, L.; Wan, R.X. Study of durability of concrete structures and its influencing factors in south region of Xinjiang. Eng. J. Wuhan Univ. 2017, 50, 447–453. [Google Scholar] [CrossRef]

- Da, X.T. The technical control of concrete anti-corrosion construction of bridge structures in saline soil area is discussed. Qinghai Transp. Sci. Technol. 2018, 1, 113–114. [Google Scholar] [CrossRef]

- Cao, Y.; Zeng, L.; Wang, X.; Liu, S. Effect of mineral admixture on the corrosion resistance of concrete in saline soil area of northwest china. J. Yangtze River Sci. Res. Inst. 2019, 36, 170–174. [Google Scholar] [CrossRef]

- Wei, P.; Bian, L.D.; Wang, X.M.; Zhu, M.W.; Yuan, J. Research on enhancing the resistance to saline soil corrosion of concrete based on the composition and content of cementitious materials. In Proceedings of the Civil Engineering New Materials, New Technology and Engineering Application Exchange Conference, Beijing, China, 17 May 2019. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, X.; Wei, P.; Zhu, M. Effect of mineral admixture on the resistance to saline soil erosion of concrete under condition of insufficient moist curing. Bull. Chin. Ceram. Soc. 2019, 38, 2829–2834+2841. [Google Scholar] [CrossRef]

- Yang, D. Application of concrete mix design technology for corrosion resistance and rust resistance in hexi saline soil area of gansu province. Eng. Des. 2019, 4, 170–173. [Google Scholar] [CrossRef]

- Guan, G.J.; Li, S.B. Research on the distribution and corrosivity of the saline soil in the western margin of Tarim balsin based on 750 kV ultra-high voltage transmission line project. Eng. J. Wuhan Univ. 2021, 54, 243–246. [Google Scholar]

- Lu, Y.; Xia, X.; Jing, W.D.; Wang, K. Research on crack resistance of mineral admixture concrete under large temperature difference and saline soil environment. China Concr. Cem. Prod. 2022, 5, 7–11. [Google Scholar] [CrossRef]

- Ma, Y.X.; Nie, S.F.; Guo, J.Q. Experimental research on mechanical properties of fly ash concrete in sulfate saline soil area. J. Changsha Univ. Sci. Technol. Nat. Sci. 2022, 19, 64–72. [Google Scholar]

- Liao, M.; Liang, G.; Fu, L.; Zeng, N.; Zhou, Y. Discussion on damaged mechanism at air position of concrete pole in saline soil area of xinjiang. Cem. Technol. 2022, 3, 93–97. [Google Scholar] [CrossRef]

| Measurements | Moisture Content (%) | pH Value | Cl− (%, mg/kg) | SO42− (%, mg/kg) | Mg2+ (%, mg/kg) |

|---|---|---|---|---|---|

| Maximum value | 160 | 11.28 | 88,233.08 | 2012.16 | 10.06 |

| Minimum value | 149 | 7.720 | 79,178.37 | 1730.45 | 7.240 |

| Average value | 155 | 9.500 | 83,565.37 | 1883.39 | 8.610 |

| Type of Saline Soil | Chlorine Saline Soil | Chlorite Saline Soil | Sulfite Saline Soil | Sulfate Saline Soil |

|---|---|---|---|---|

| mC-S | >2.0 | 1.0~2.0 | 0.3~1.0 | <0.3 |

| Type of Saline Soil | Average Salt Content of Saline Soil Layer (%, as a Percentage of Soil Mass) | |||

|---|---|---|---|---|

| Chlorine Saline Soil | Chlorite Saline Soil | Sulfite Saline Soil | Sulfate Saline Soil | |

| Weak saline soil | 0.3~1.5 | 0.3~1.0 | 0.3~0.8 | 0.3~0.5 |

| Middle saline soil | 1.5~5.0 | 1.0~4.0 | 0.8~2.0 | 0.5~1.5 |

| Strong saline soil | 5.0~8.0 | 4.0~7.0 | 2.0~5.0 | 1.5~4.0 |

| Exceed saline soil | >8.0 | >7.0 | >5.0 | >4.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, L.; Xiang, Z.; Jiang, H.; Liu, M.; Ju, X.; Zhang, W. A Review of Durability Issues of Reinforced Concrete Structures Due to Coastal Soda Residue Soil in China. J. Mar. Sci. Eng. 2022, 10, 1740. https://doi.org/10.3390/jmse10111740

Wu L, Xiang Z, Jiang H, Liu M, Ju X, Zhang W. A Review of Durability Issues of Reinforced Concrete Structures Due to Coastal Soda Residue Soil in China. Journal of Marine Science and Engineering. 2022; 10(11):1740. https://doi.org/10.3390/jmse10111740

Chicago/Turabian StyleWu, Linjian, Zhouyu Xiang, Han Jiang, Mingwei Liu, Xueli Ju, and Wenxiao Zhang. 2022. "A Review of Durability Issues of Reinforced Concrete Structures Due to Coastal Soda Residue Soil in China" Journal of Marine Science and Engineering 10, no. 11: 1740. https://doi.org/10.3390/jmse10111740

APA StyleWu, L., Xiang, Z., Jiang, H., Liu, M., Ju, X., & Zhang, W. (2022). A Review of Durability Issues of Reinforced Concrete Structures Due to Coastal Soda Residue Soil in China. Journal of Marine Science and Engineering, 10(11), 1740. https://doi.org/10.3390/jmse10111740