Fire Risk Assessment in Engine Rooms Considering the Fire-Induced Domino Effects

Abstract

1. Introduction

- (1)

- Ship engine room fire evolution characteristics are studied based on the domino effect of fire;

- (2)

- The uncertainties of shipboard personnel, automatic detection systems, sprinkler systems after the fire are addressed;

- (3)

- Employing matrix calculations and Monte Carlo simulation methods, the synergistic effects of multiple escalation vectors from different units are considered;

- (4)

- The fire size probability of occurrence is calculated, and vital time nodes and key equipment in the fire spread process are identified;

- (5)

- According to the proposed engine room fire risk assessment model, the foundation is laid for developing multi-compartment and ship-wide fire risk assessments.

2. Problem Description

3. Methodology

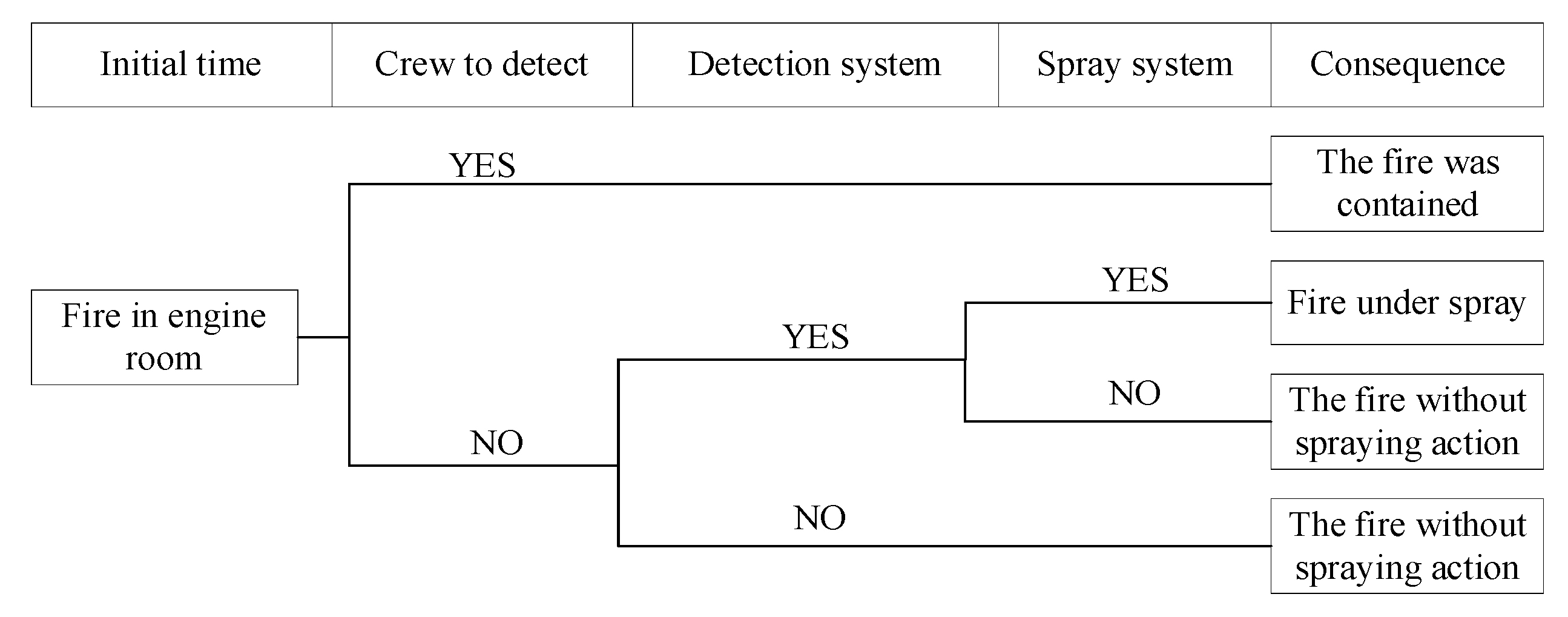

3.1. Determination of the Fire Accident Scene

3.2. Collecting Basic Information

3.3. Parameter Settings

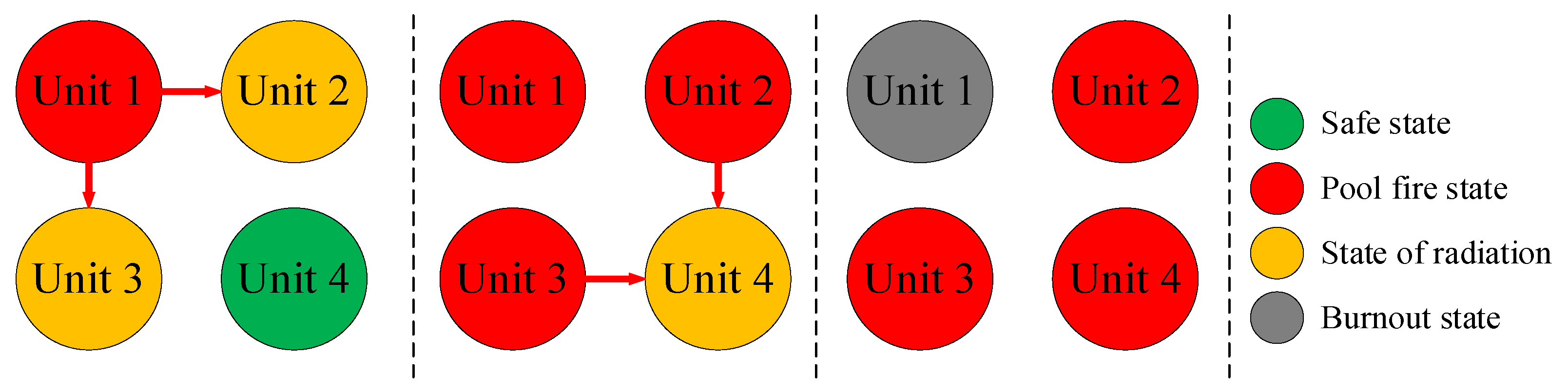

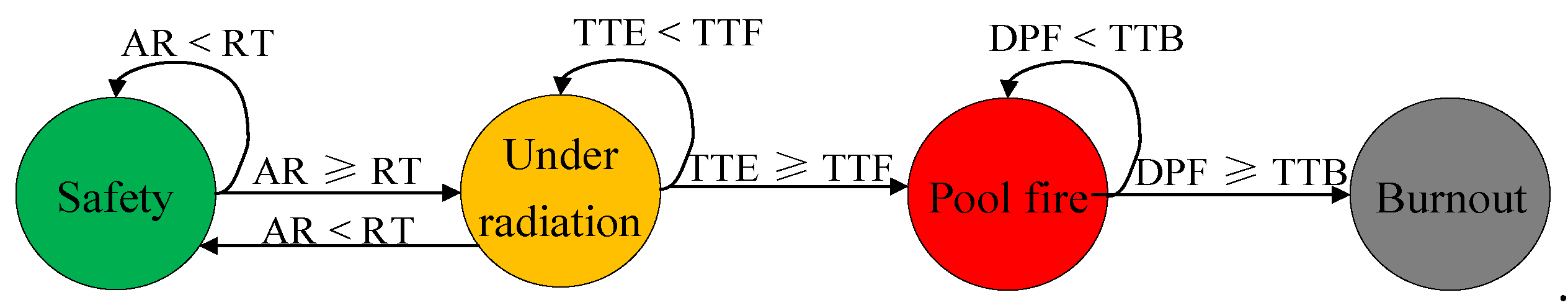

3.4. Status Analysis of Each Unit

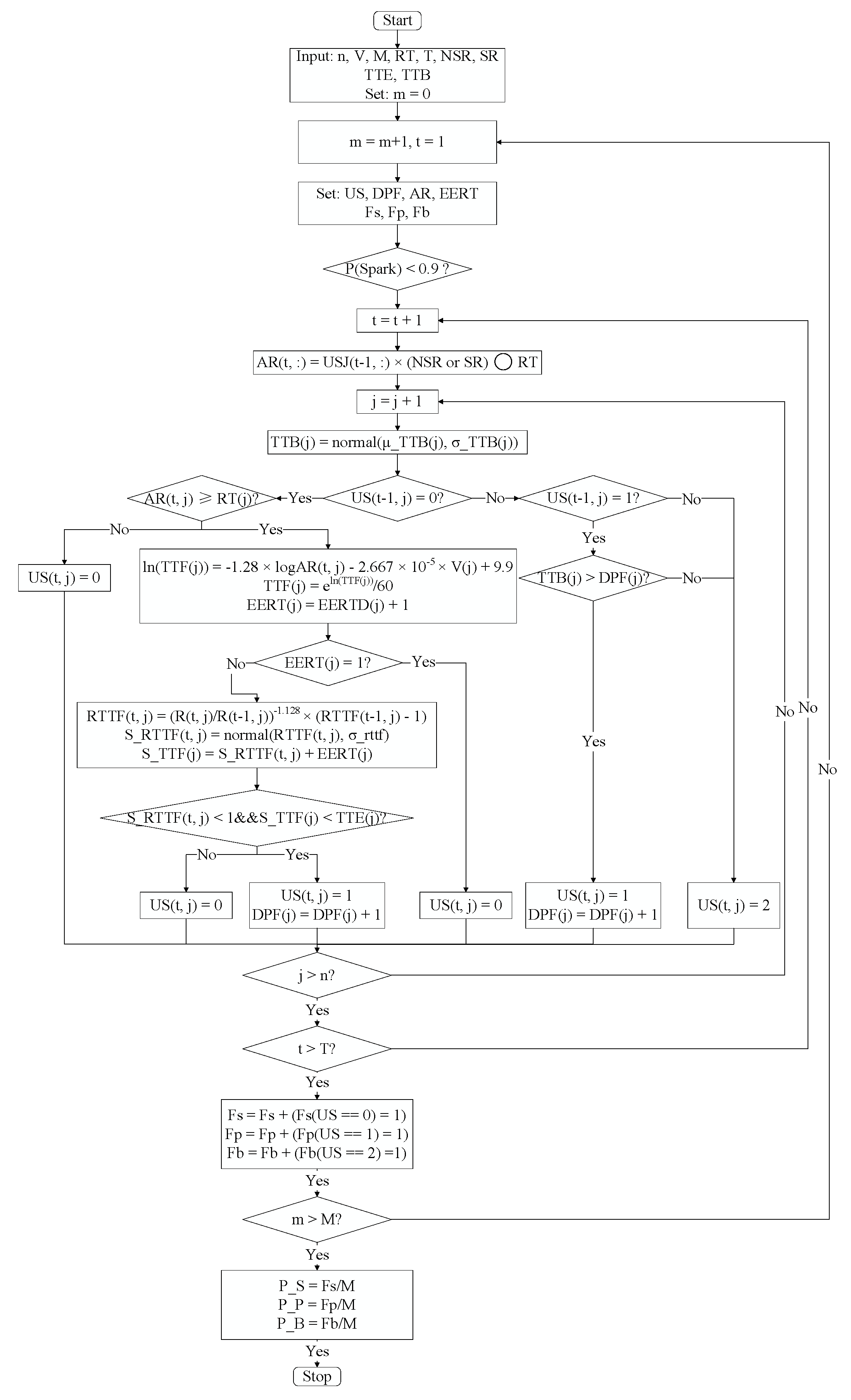

3.5. Dynamic Domino Probability Calculation

4. Case Analysis

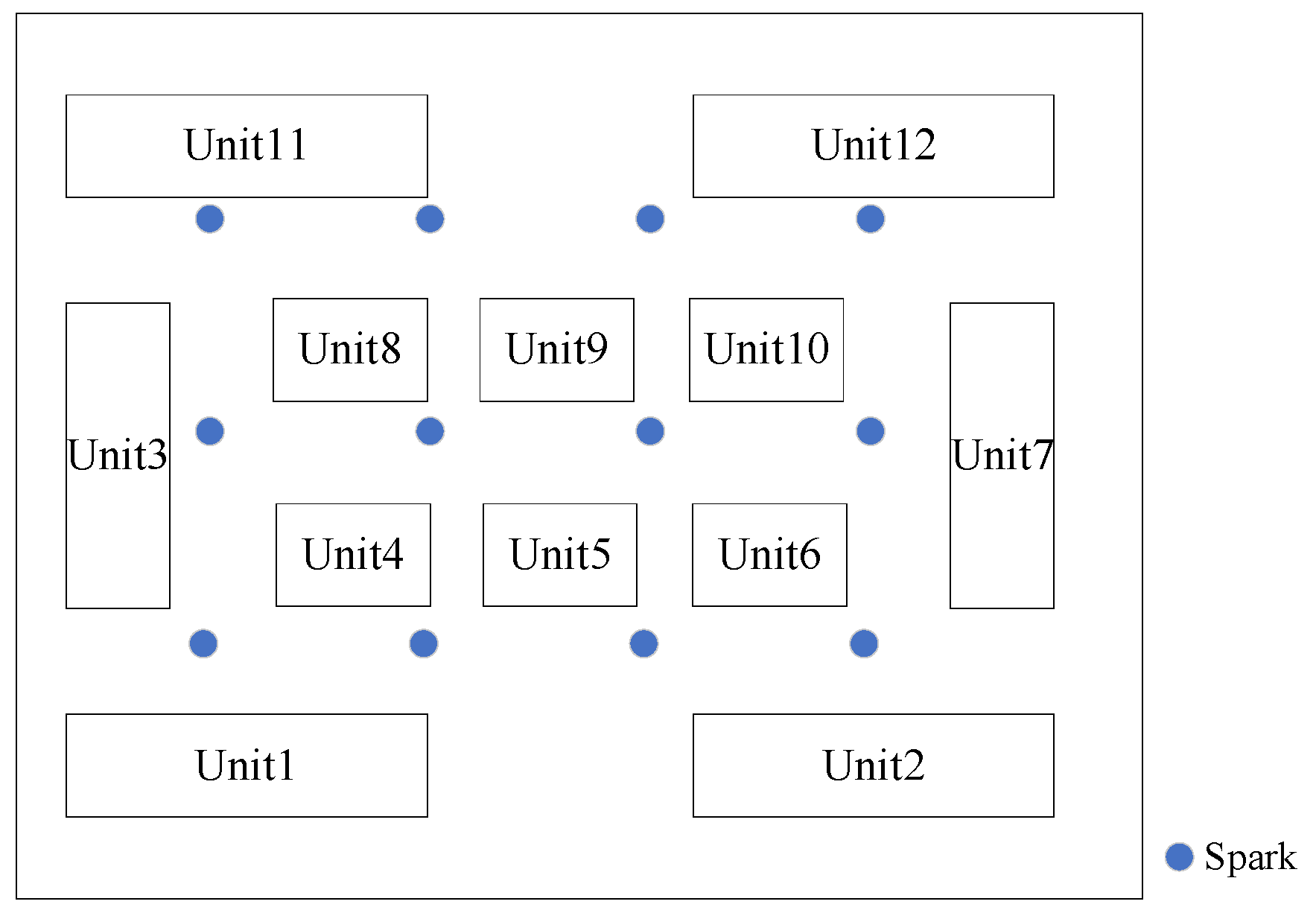

4.1. Domino Effect Model of Ship Engine Room Fire Risk Assessment

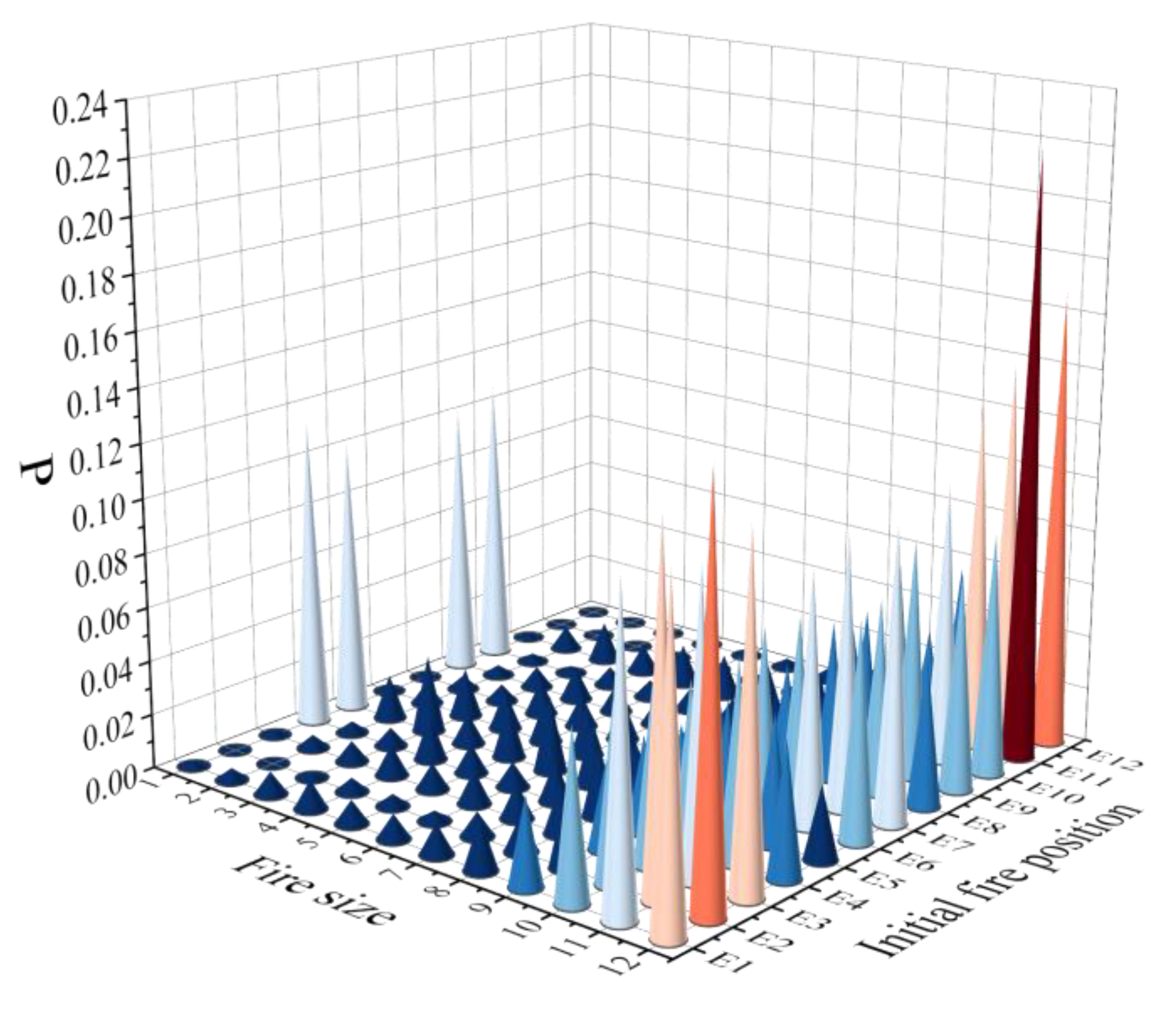

4.2. Fire Risk Assessment of a Ship Engine Room Based on Dynamic Analysis of the Domino Effect

4.3. Analysis of Key Equipment in the Engine Room Fire

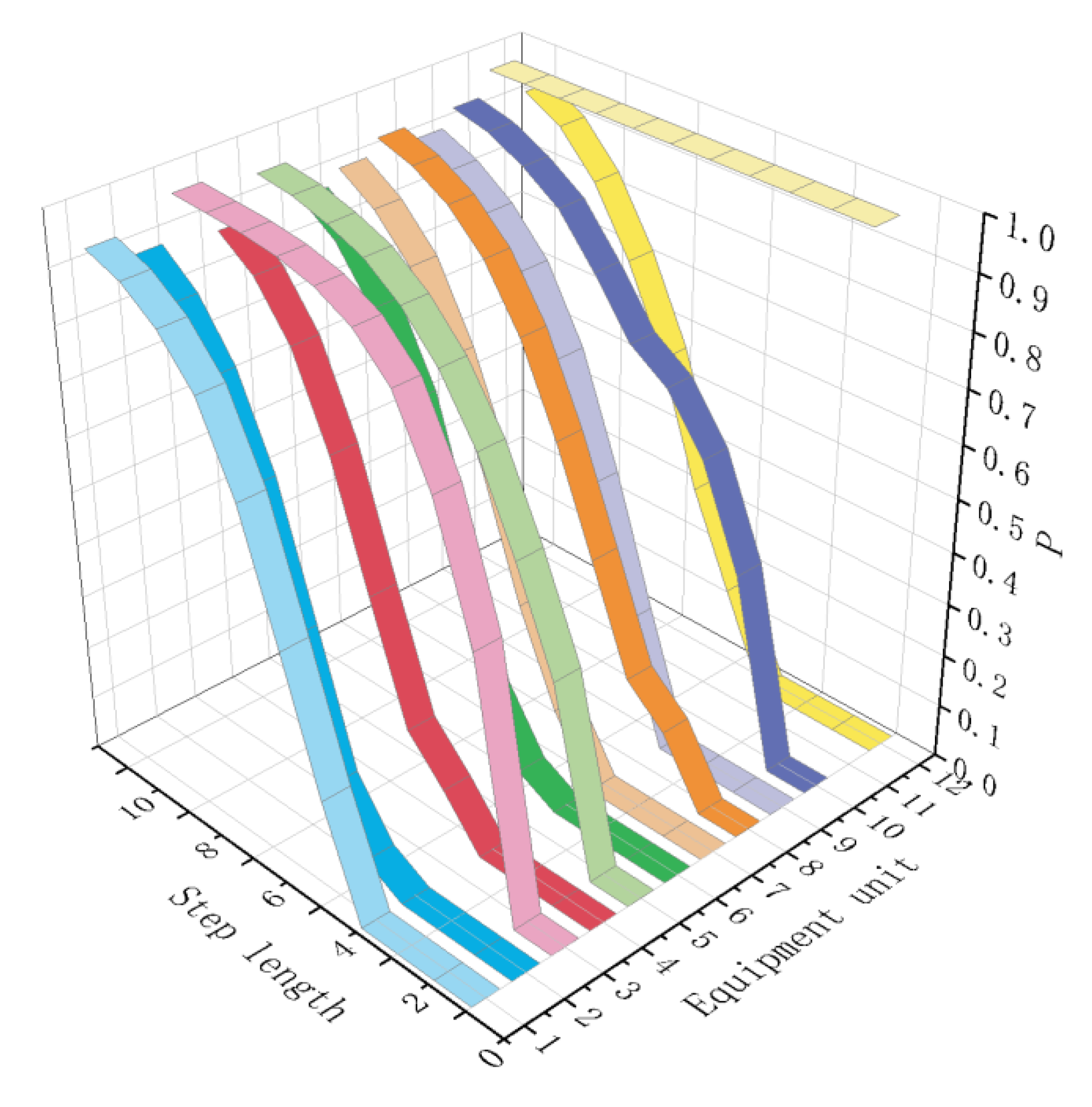

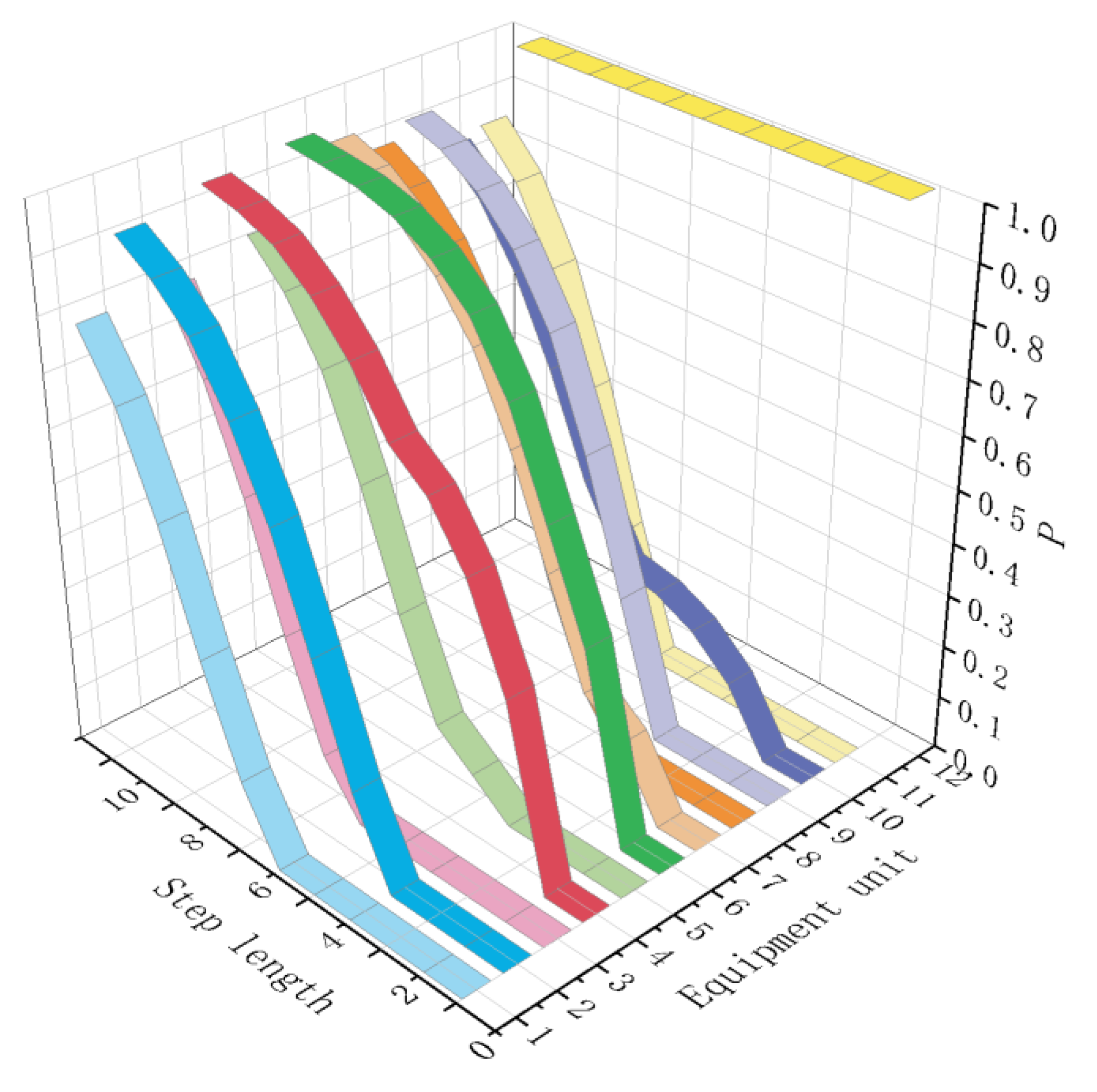

4.4. Analysis of Key Equipment in the Fire Spread Path

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yazir, D. Application of IF-TOPSIS method on fixed fire fighting systems for cargo hold fires on the dry/bulk cargo ships. Ocean. Eng. 2022, 260, 1–12. [Google Scholar] [CrossRef]

- Deng, J.; Liu, S.; Xie, C.; Liu, K. Risk Coupling Characteristics of Maritime Accidents in Chinese Inland and Coastal Waters Based on N-K Model. J. Mar. Sci. Eng. 2022, 10, 4. [Google Scholar] [CrossRef]

- Allianz. Safety and Shipping Report 2021; Allianz: Shanghai, China, 2021. [Google Scholar]

- International Maritime Organization (IMO). Global Integrated Shipping Information System (GISIS); International Maritime Organization: London, UK, 2019. [Google Scholar]

- Ji, J.; Ma, Z.; He, J.; Xu, Y.; Liu, Z. Research on Risk Evaluation and Dynamic Escape Path Planning Algorithm Based on Real-Time Spread of Ship Comprehensive Fire. J. Mar. Sci. Eng. 2020, 8, 602. [Google Scholar] [CrossRef]

- Su, S.C.; Wang, L. Three dimensional reconstruction of the fire in a ship engine room with multilayer structures. Ocean. Eng. 2013, 70, 201–207. [Google Scholar] [CrossRef]

- Ahn, Y.-J.; Yu, Y.-U.; Kim, J.-K. Accident Cause Factor of Fires and Explosions in Tankers Using Fault Tree Analysis. J. Mar. Sci. Eng. 2021, 9, 844. [Google Scholar] [CrossRef]

- Zhang, J.Q.; Lu, S.X.; Li, Q.; Yuen, R.; Yuan, M.; Li, C.H. Impacts of elevation on pool fire behavior in a closed compartment: A study based upon a distinct stratification phenomenon. J. Fire Sci. 2013, 31, 178–193. [Google Scholar] [CrossRef]

- He, Q.; Ezekoye, O.A.; Li, C.; Lu, S. Ventilation limited extinction of fires in ceiling vented compartments. Int. J. Heat Mass Transf. 2015, 91, 570–583. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, Y.L.; Chen, X.; Li, C.; Lu, S. Effect of pressure on the heat transfer and flame characteristics of small-scale ethanol pool fires. Fire Saf. J. 2018, 99, 27–37. [Google Scholar] [CrossRef]

- Wang, J.H.; Jiao, Y.; Shi, L. An experimental and non-dimensional study on the vertical temperature distribution of a sealed ship engine room fire. Ocean. Eng. 2018, 165, 22–33. [Google Scholar] [CrossRef]

- Liu, W.; Wang, L.; Su, S.C.; Wu, Z.Z.; Guo, Y.S.; Du, K.D. Study of the flame flow and combustion characteristics of pool fires around a bluff body in the ship engine room. Case Stud. Therm. Eng. 2021, 28, 101514. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, Z.; Li, Y.; Zhu, L.; Yuan, C. An Improved Failure Risk Assessment Method for Bilge System of the Large Luxury Cruise Ship under Fire Accident Conditions. J. Mar. Sci. Eng. 2021, 9, 957. [Google Scholar] [CrossRef]

- Guan, Y.; Zhao, J.; Shi, T.; Zhu, P. Fault tree analysis of fire and explosion accidents for dual fuel (diesel/natural gas) ship engine rooms. J. Mar. Sci. Appl. 2016, 15, 331–335. [Google Scholar] [CrossRef]

- Sarıalioğlu, S.; Uğurlu, O.; Aydin, M. A hybrid model for human-factor analysis of engine-room fires on ships: HFACS-PV&FFTA. Ocean. Eng. 2020, 217, 107992. [Google Scholar]

- Jia, J.; Lu, S.X. A mission-oriented risk assessment methodology for naval vessel fire caused by non-contact explosions using Bayesian Networks. Procedia Eng. 2013, 62, 573–580. [Google Scholar] [CrossRef]

- Ahn, S.I.; Kurt, R.E. Application of a CREAM based framework to assess human reliability in emergency response to engine room fires on ships. Ocean. Eng. 2020, 216, 108078. [Google Scholar] [CrossRef]

- Spyrou, K.J.; Koromila, I.A. A risk model of passenger ship fire safety and its application. Reliab. Eng. Syst. Saf. 2020, 200, 106937. [Google Scholar] [CrossRef]

- Li, H.; Soares, C. Assessment of failure rates and reliability of floating offshore wind turbines. Reliab. Eng. Syst. Saf. 2022, 228, 108777. [Google Scholar] [CrossRef]

- Reniers, G.; Cozzani, V. Domino Effects in the Process Industries, Modeling, Prevention and Managing; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Zarei, E.; Gholamizadeh, K.; Khan, F.; Khakzad, N. A dynamic domino effect risk analysis model for rail transport of hazardous material. J. Loss Prev. Process Ind. 2022, 74, 104666. [Google Scholar] [CrossRef]

- Huang, K.X.; Chen, G.H.; Khan, F.; Yang, Y.F. Dynamic analysis for fire-induced domino effects in chemical process industries. Process Saf. Environ. Prot. 2021, 148, 686–697. [Google Scholar] [CrossRef]

- Li, M.; Jiang, X.; Carroll, J.; Negenborn, R.R. A multi-objective maintenance strategy optimization framework for offshore wind farms considering uncertainty. Appl. Energy 2022, 321, 119284. [Google Scholar] [CrossRef]

- ClassNK. Guidelines for the Prevention of Human Error Aboard Ships; ClassNK: Tokyo, Japan, 2010. [Google Scholar]

- Li, Y.L.; Wang, Y.H.; Lu, S.X. Ignition of the leaked diesel on a heated horizontal surface. Fire Saf. J. 2010, 45, 58–68. [Google Scholar] [CrossRef]

- Panama Maritime Authority (PMA). Ocean Star Pacific-Marine Casualty; Panama Maritime Authority: Panama City, Panama, 2011. [Google Scholar]

- Dai, X.; Gamba, A.; Liu, C.; Anderson, J.; Charlier, M.; Rush, D.; Welch, S. An engineering CFD model for fire spread on wood cribs for travelling fires. Adv. Eng. Softw. 2022, 173, 103213. [Google Scholar] [CrossRef]

- Huang, K.; Chen, G.; Yang, Y.; Chen, P. An innovative quantitative analysis methodology for Natech events triggered by earthquakes in chemical tank farms. Saf. Sci. 2020, 128, 104744. [Google Scholar] [CrossRef]

- Chen, C.; Reniers, G.; Zhang, L. An innovative methodology for quickly modeling the spatial-temporal evolution of domino accidents triggered by fire. J. Loss Prev. Process Ind. 2018, 54, 312–324. [Google Scholar] [CrossRef]

- Zhou, J.; Reniers, G. A matrix-based modeling and analysis approach for fire-induced domino effects. Process Saf. Environ. Prot. 2018, 116, 347–353. [Google Scholar] [CrossRef]

- Cozzani, V.; Gubinelli, G.; Antonioni, G.; Spadoni, G.; Zanelli, S. The assessment of risk caused by domino effect in quantitative area risk analysis. J. Hazard. Mater. 2005, 127, 14–30. [Google Scholar] [CrossRef]

- Landucci, G.; Gubinelli, G.; Antonioni, G.; Cozzani, V. The assessment of the damage probability of storage tanks in domino events triggered by fire. Accid. Anal. Prev. 2009, 41, 1206–1215. [Google Scholar] [CrossRef]

- Khakzad, N. Application of dynamic Bayesian network to risk analysis of domino effects in chemical infrastructures. Reliab. Eng. Syst. Saf. 2015, 138, 263–272. [Google Scholar] [CrossRef]

- Bukowski, R.W.; Budnick, E.; Schemel, C. Estimates of the operational reliability of fire protection systems. In Proceedings of the 3rd International Conference on Fire Research and Engineering, Chicago, IL, USA, 4–8 October 2022; CRC Press: Boca Raton, FL, USA, 1999; pp. 87–98. [Google Scholar]

- Wang, J.H.; Zhang, R.Q.; Wang, Y.C.; Shi, L.; Zhang, S.G.; Li, C.C.; Zhang, Y.; Zhang, Q.J. Smoke filling and entrainment behaviors of fire in a sealed ship engine room. Ocean. Eng. 2022, 245, 110521. [Google Scholar] [CrossRef]

| Detection Measures | Probability of Reliability | |

|---|---|---|

| a | Detection by crew | 0.59 [34] |

| b | Smoke detector | 0.778 [34] |

| c | Automatic water sprinkler system | 0.96 [34] |

| Code | Length(m) × Width(m) × Height(m) | Substance | Equipment Size (m3) |

|---|---|---|---|

| E1 | 7.0 × 2.0 × 2.0 | Diesel | 28 |

| E2 | 7.0 × 2.0 × 2.0 | Diesel | 28 |

| E3 | 6.0 × 2.0 × 2.0 | Diesel | 24 |

| E4 | 3.0 × 2.0 × 2.0 | Diesel | 12 |

| E5 | 3.0 × 2.0 × 2.0 | Diesel | 12 |

| E6 | 3.0 × 2.0 × 2.0 | Diesel | 12 |

| E7 | 6.0 × 2.0 × 2.0 | Diesel | 24 |

| E8 | 3.0 × 2.0 × 2.0 | Diesel | 12 |

| E9 | 3.0 × 2.0 × 2.0 | Diesel | 12 |

| E10 | 3.0 × 2.0 × 2.0 | Diesel | 12 |

| E11 | 7.0 × 2.0 × 2.0 | Diesel | 28 |

| E12 | 7.0 × 2.0 × 2.0 | Diesel | 28 |

| E1 | E2 | E3 | E4 | E5 | E6 | E7 | E8 | E9 | E10 | E11 | E12 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E1 | 88.4 | 6.7 | 59.5 | 63.0 | 15.9 | 8.2 | 4.9 | 15.5 | 13.8 | 8.9 | 15.4 | 6.0 |

| E2 | 7.4 | 94.7 | 5.9 | 8.8 | 16.2 | 82.4 | 65.2 | 8.7 | 12.8 | 18.8 | 6.0 | 17.7 |

| E3 | 22.4 | 6.9 | 83.2 | 25.7 | 11.6 | 7.7 | 6.2 | 63.8 | 22.5 | 9.1 | 27.0 | 7.4 |

| E4 | 7.8 | 6.4 | 13.7 | 103.6 | 11.2 | 5.4 | 4.5 | 23.4 | 8.1 | 5.3 | 6.5 | 5.2 |

| E5 | 7.5 | 7.9 | 5.3 | 10.7 | 76.9 | 14.1 | 7.3 | 8.1 | 16.8 | 6.8 | 5.5 | 5.5 |

| E6 | 6.2 | 7.5 | 4.8 | 5.7 | 8.6 | 91.6 | 18.8 | 5.4 | 7.3 | 31.6 | 6.1 | 6.2 |

| E7 | 6.5 | 21.7 | 6.0 | 7.2 | 10.6 | 30.1 | 93.1 | 10.1 | 19.2 | 64.1 | 7.9 | 24.4 |

| E8 | 7.3 | 4.7 | 15.3 | 13.9 | 7.1 | 4.7 | 4.2 | 148.4 | 10.2 | 5.2 | 7.1 | 5.5 |

| E9 | 5.9 | 5.2 | 5.5 | 7.8 | 11.6 | 7.3 | 5.7 | 10.7 | 80.8 | 9.3 | 7.1 | 7.6 |

| E10 | 5.5 | 8.4 | 4.7 | 5.7 | 7.7 | 40.7 | 12.1 | 5.7 | 9.7 | 96.6 | 5.6 | 8.8 |

| E11 | 17.3 | 6.6 | 52.5 | 16.4 | 13.2 | 6.9 | 5.1 | 68.8 | 12.6 | 6.1 | 87.3 | 6.6 |

| E12 | 7.9 | 20.4 | 6.0 | 9.6 | 13.8 | 15.5 | 62.8 | 10.6 | 16.3 | 51.1 | 6.3 | 96.8 |

| E1 | E2 | E3 | E4 | E5 | E6 | E7 | E8 | E9 | E10 | E11 | E12 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E1 | 35.9 | 4.8 | 8.7 | 5.0 | 24.6 | 4.8 | 23.0 | 8.0 | 5.8 | 8.5 | 7.5 | 5.8 |

| E2 | 5.5 | 36.5 | 5.2 | 9.3 | 4.5 | 26.8 | 6.1 | 6.9 | 28.8 | 6.4 | 6.8 | 9.2 |

| E3 | 10.2 | 5.4 | 11.2 | 5.9 | 38.6 | 5.5 | 13.8 | 7.5 | 5.2 | 20.3 | 9.5 | 6.5 |

| E4 | 7.0 | 5.8 | 5.5 | 4.3 | 13.1 | 4.2 | 78.3 | 10.5 | 4.6 | 9.5 | 5.6 | 4.3 |

| E5 | 7.4 | 7.0 | 4.4 | 4.3 | 4.5 | 5.7 | 8.4 | 56.9 | 9.3 | 5.5 | 8.8 | 5.4 |

| E6 | 5.8 | 7.1 | 4.7 | 5.8 | 4.2 | 14.4 | 4.5 | 6.7 | 64.2 | 4.5 | 5.2 | 23.9 |

| E7 | 5.2 | 9.6 | 5.9 | 14.9 | 5.1 | 44.9 | 5.1 | 6.5 | 10.8 | 5.7 | 8.5 | 20.2 |

| E8 | 6.3 | 4.5 | 6.0 | 4.7 | 11.1 | 3.9 | 14.1 | 6.0 | 4.1 | 79.7 | 9.7 | 4.6 |

| E9 | 5.5 | 4.5 | 5.8 | 5.4 | 4.9 | 5.2 | 7.4 | 9.9 | 5.8 | 8.7 | 56.7 | 7.4 |

| E10 | 5.0 | 7.3 | 4.9 | 6.2 | 4.2 | 11.4 | 4.4 | 5.9 | 20.9 | 4.3 | 7.1 | 72.8 |

| E11 | 9.9 | 5.0 | 41.4 | 4.8 | 29.0 | 4.2 | 9.7 | 6.5 | 5.5 | 27.7 | 8.6 | 4.8 |

| E12 | 5.6 | 11.9 | 5.2 | 54.3 | 5.0 | 28.2 | 6.5 | 8.0 | 13.1 | 6.7 | 11.5 | 28.1 |

| Fire Size | E1 | E2 | E3 | E4 | E5 | E6 | E7 | E8 | E9 | E10 | E11 | E12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.002 | 0.000 | 0.002 | 0.115 | 0.103 | 0.002 | 0.001 | 0.103 | 0.108 | 0.001 | 0.000 | 0.000 |

| 2 | 0.005 | 0.000 | 0.005 | 0.005 | 0.017 | 0.009 | 0.005 | 0.004 | 0.003 | 0.009 | 0.000 | 0.000 |

| 3 | 0.009 | 0.002 | 0.008 | 0.007 | 0.029 | 0.019 | 0.007 | 0.008 | 0.003 | 0.015 | 0.000 | 0.001 |

| 4 | 0.011 | 0.005 | 0.012 | 0.017 | 0.012 | 0.015 | 0.014 | 0.013 | 0.007 | 0.011 | 0.001 | 0.002 |

| 5 | 0.009 | 0.005 | 0.010 | 0.011 | 0.020 | 0.017 | 0.012 | 0.011 | 0.007 | 0.015 | 0.000 | 0.002 |

| 6 | 0.009 | 0.004 | 0.013 | 0.010 | 0.028 | 0.019 | 0.016 | 0.010 | 0.009 | 0.016 | 0.000 | 0.004 |

| 7 | 0.012 | 0.009 | 0.013 | 0.016 | 0.024 | 0.016 | 0.017 | 0.014 | 0.009 | 0.020 | 0.001 | 0.004 |

| 8 | 0.019 | 0.014 | 0.019 | 0.026 | 0.021 | 0.024 | 0.026 | 0.025 | 0.015 | 0.022 | 0.003 | 0.010 |

| 9 | 0.033 | 0.028 | 0.032 | 0.035 | 0.033 | 0.041 | 0.037 | 0.038 | 0.029 | 0.040 | 0.009 | 0.022 |

| 10 | 0.062 | 0.064 | 0.065 | 0.060 | 0.047 | 0.068 | 0.066 | 0.059 | 0.057 | 0.070 | 0.039 | 0.058 |

| 11 | 0.117 | 0.131 | 0.111 | 0.073 | 0.048 | 0.093 | 0.100 | 0.072 | 0.088 | 0.103 | 0.130 | 0.139 |

| 12 | 0.123 | 0.152 | 0.127 | 0.050 | 0.027 | 0.080 | 0.108 | 0.054 | 0.080 | 0.089 | 0.224 | 0.169 |

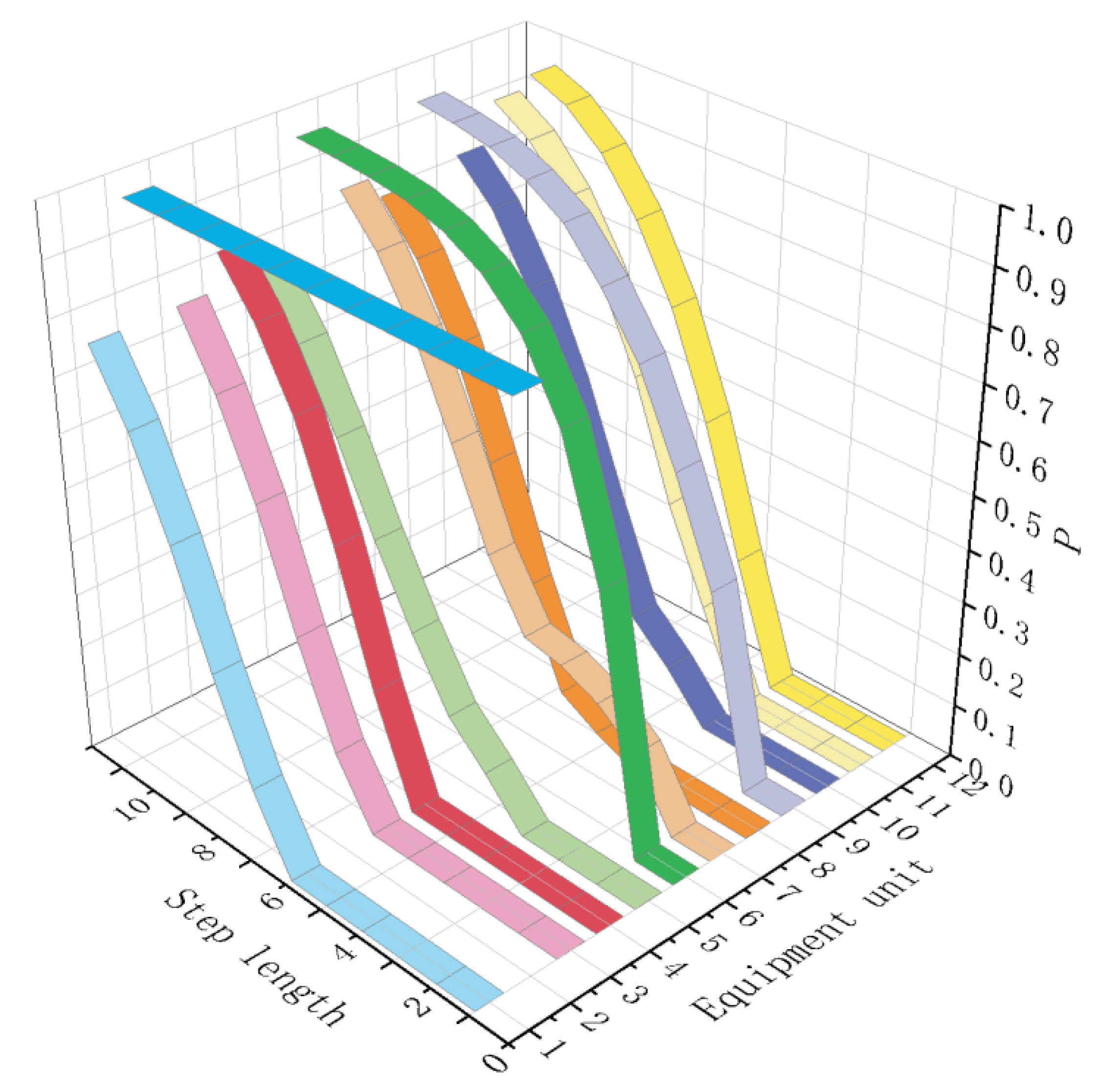

| Step Length | E1 | E2 | E3 | E4 | E5 | E6 | E7 | E8 | E9 | E10 | E11 | E12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1.000 | 0.000 |

| 1 min | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1.000 | 0.000 |

| 2 min | 0.000 | 0.000 | 0.477 | 0.000 | 0.341 | 0.000 | 0.000 | 0.118 | 0.000 | 0.346 | 1.000 | 0.000 |

| 3 min | 0.000 | 0.000 | 0.710 | 0.000 | 0.522 | 0.000 | 0.000 | 0.182 | 0.000 | 0.529 | 1.000 | 0.000 |

| 4 min | 0.198 | 0.038 | 0.854 | 0.087 | 0.680 | 0.037 | 0.118 | 0.373 | 0.217 | 0.628 | 1.000 | 0.163 |

| 5 min | 0.433 | 0.138 | 0.922 | 0.161 | 0.790 | 0.147 | 0.285 | 0.561 | 0.447 | 0.676 | 1.000 | 0.331 |

| 6 min | 0.658 | 0.376 | 0.957 | 0.377 | 0.865 | 0.399 | 0.500 | 0.717 | 0.646 | 0.774 | 1.000 | 0.552 |

| 7 min | 0.806 | 0.611 | 0.975 | 0.602 | 0.916 | 0.631 | 0.679 | 0.826 | 0.775 | 0.859 | 1.000 | 0.707 |

| 8 min | 0.885 | 0.768 | 0.985 | 0.762 | 0.944 | 0.766 | 0.812 | 0.893 | 0.850 | 0.906 | 1.000 | 0.825 |

| 9 min | 0.933 | 0.863 | 0.989 | 0.854 | 0.963 | 0.857 | 0.884 | 0.933 | 0.899 | 0.941 | 1.000 | 0.899 |

| 10 min | 0.957 | 0.916 | 0.993 | 0.902 | 0.973 | 0.903 | 0.928 | 0.955 | 0.928 | 0.957 | 1.000 | 0.937 |

| Step Length | E1 | E2 | E3 | E4 | E5 | E6 | E7 | E8 | E9 | E10 | E11 | E12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1.000 |

| 1 min | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1.000 |

| 2 min | 0.000 | 0.000 | 0.000 | 0.332 | 0.000 | 0.345 | 0.121 | 0.000 | 0.000 | 0.115 | 0.000 | 1.000 |

| 3 min | 0.000 | 0.000 | 0.000 | 0.514 | 0.000 | 0.533 | 0.178 | 0.000 | 0.000 | 0.181 | 0.000 | 1.000 |

| 4 min | 0.000 | 0.154 | 0.000 | 0.621 | 0.057 | 0.715 | 0.368 | 0.100 | 0.242 | 0.216 | 0.000 | 1.000 |

| 5 min | 0.000 | 0.363 | 0.000 | 0.677 | 0.112 | 0.833 | 0.562 | 0.280 | 0.483 | 0.231 | 0.000 | 1.000 |

| 6 min | 0.127 | 0.562 | 0.092 | 0.784 | 0.287 | 0.898 | 0.714 | 0.504 | 0.677 | 0.363 | 0.221 | 1.000 |

| 7 min | 0.317 | 0.713 | 0.283 | 0.864 | 0.495 | 0.940 | 0.808 | 0.684 | 0.797 | 0.545 | 0.471 | 1.000 |

| 8 min | 0.531 | 0.825 | 0.506 | 0.921 | 0.671 | 0.962 | 0.875 | 0.798 | 0.871 | 0.695 | 0.672 | 1.000 |

| 9 min | 0.703 | 0.891 | 0.686 | 0.949 | 0.779 | 0.972 | 0.927 | 0.872 | 0.918 | 0.802 | 0.805 | 1.000 |

| 10 min | 0.814 | 0.937 | 0.812 | 0.966 | 0.849 | 0.980 | 0.953 | 0.913 | 0.943 | 0.866 | 0.882 | 1.000 |

| Step Length | E1 | E2 | E3 | E4 | E5 | E6 | E7 | E8 | E9 | E10 | E11 | E12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.000 | 1.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| 1 min | 0.000 | 1.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| 2 min | 0.000 | 1.000 | 0.000 | 0.000 | 0.000 | 0.466 | 0.118 | 0.000 | 0.349 | 0.000 | 0.000 | 0.000 |

| 3 min | 0.000 | 1.000 | 0.000 | 0.000 | 0.000 | 0.712 | 0.175 | 0.000 | 0.533 | 0.000 | 0.000 | 0.000 |

| 4 min | 0.000 | 1.000 | 0.000 | 0.000 | 0.079 | 0.839 | 0.207 | 0.030 | 0.692 | 0.080 | 0.164 | 0.219 |

| 5 min | 0.000 | 1.000 | 0.000 | 0.000 | 0.146 | 0.908 | 0.221 | 0.070 | 0.796 | 0.144 | 0.330 | 0.453 |

| 6 min | 0.131 | 1.000 | 0.115 | 0.192 | 0.267 | 0.948 | 0.339 | 0.240 | 0.877 | 0.323 | 0.539 | 0.638 |

| 7 min | 0.307 | 1.000 | 0.296 | 0.429 | 0.404 | 0.971 | 0.514 | 0.442 | 0.922 | 0.515 | 0.692 | 0.768 |

| 8 min | 0.503 | 1.000 | 0.505 | 0.629 | 0.557 | 0.982 | 0.678 | 0.627 | 0.951 | 0.670 | 0.807 | 0.862 |

| 9 min | 0.668 | 1.000 | 0.666 | 0.760 | 0.692 | 0.988 | 0.796 | 0.754 | 0.966 | 0.787 | 0.884 | 0.921 |

| 10 min | 0.786 | 1.000 | 0.788 | 0.852 | 0.793 | 0.993 | 0.875 | 0.836 | 0.976 | 0.856 | 0.928 | 0.949 |

| Initial Ignition Location | 2 min | 4 min | 6 min |

|---|---|---|---|

| E11 | E3, E5, E8, E10 | E1, E2, E4, E6, E7, E9, E12 | |

| E12 | E4, E6, E7, E10 | E2, E5, E8, E9 | E1, E3, E11 |

| E2 | E6, E7, E9 | E5, E8, E10, E11, E12 | E1, E3, E4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Li, C.; Zhao, N.; Chen, B.-Q.; Ren, H.; Kang, J. Fire Risk Assessment in Engine Rooms Considering the Fire-Induced Domino Effects. J. Mar. Sci. Eng. 2022, 10, 1685. https://doi.org/10.3390/jmse10111685

Zhang H, Li C, Zhao N, Chen B-Q, Ren H, Kang J. Fire Risk Assessment in Engine Rooms Considering the Fire-Induced Domino Effects. Journal of Marine Science and Engineering. 2022; 10(11):1685. https://doi.org/10.3390/jmse10111685

Chicago/Turabian StyleZhang, Houyao, Chenfeng Li, Nan Zhao, Bai-Qiao Chen, Huilong Ren, and Jichuan Kang. 2022. "Fire Risk Assessment in Engine Rooms Considering the Fire-Induced Domino Effects" Journal of Marine Science and Engineering 10, no. 11: 1685. https://doi.org/10.3390/jmse10111685

APA StyleZhang, H., Li, C., Zhao, N., Chen, B.-Q., Ren, H., & Kang, J. (2022). Fire Risk Assessment in Engine Rooms Considering the Fire-Induced Domino Effects. Journal of Marine Science and Engineering, 10(11), 1685. https://doi.org/10.3390/jmse10111685